1. Introduction

The efficient extraction of thin coal seams represents a significant aspect of global coal mining, holding considerable potential for unlocking additional energy resources. In China, where such seams are abundantly distributed, their mining has become increasingly economically viable due to recent advancements in equipment and technology. A critical method for safely recovering these resources is upward mining, where a lower, thicker seam is extracted first to precondition the overlying strata, thereby facilitating the subsequent mining of an upper, thinner seam. However, the success of this method hinges on accurately assessing the mining-induced damage in the interburden, specifically the development height of the water-conducting fracture zone (WCFZ). Accurate detection of the WCFZ height is the cornerstone for evaluating water inrush risks and ensuring the safety of upward mining operations [

1,

2].

This is particularly challenging under high-intensity mining conditions, prevalent in western China, characterized by advancing speeds exceeding 5 m/d and mining heights greater than 3.5 m. In geological settings featuring thick unconsolidated layers, thin bedrock, and shallow burial depths, overburden failure often manifests as discontinuous deformation, where the “caving zone and fracture zone” connect directly to the surface. This behavior challenges the predictive capacity of the traditional “vertical three zones” theory [

3,

4].

Substantial research efforts have been directed at detecting and characterizing the WCFZ. Previous studies [

5,

6,

7] reported that the measured fracture–mining ratio under high-intensity mining significantly exceeds empirical formula predictions, with errors attributed to factors like lithology and bedrock thickness. A variety of detection methodologies have been employed, including monitoring drilling fluid leakage [

8], borehole television imaging [

9], and water injection tests [

10]. Numerically, Zhang et al. [

11] simulated the three-stage evolution of fractures, while previous studies [

12,

13,

14] combined physical simulation with fractal theory to quantify fracture network complexity. The complexity increases in close-distance seam groups, where studies [

15,

16] observed that repeated mining leads to secondary fracture development and a significant increase in WCFZ height, forming complex shapes like “double trapezoid” or “M-shaped” zones. Recent studies continue to refine our understanding through similar physical simulations [

17] and advanced modeling techniques [

18,

19].

Despite these advancements, several critical research gaps remain. A primary limitation of existing methods is their inadequacy in capturing the temporal evolution of overburden failure. The asynchrony between fracture initiation and strata compaction in high-intensity mining means that surface cracks often lag behind the advance of the working face, making static observations insufficient. Furthermore, field detection methods present a trade-off: surface drilling is accurate but costly, while geophysical prospecting is efficient but suffers from interpretive non-uniqueness [

20].

Yujialiang Coal Mine exemplifies this practical challenge. The mine contains four minable seams, including the 1.3 m thick 4-4 coal seam, which was initially deemed uneconomical to mine. Following the prior extraction of the underlying 5-2 coal seam, the 4-4 seam now presents an upward mining scenario. Therefore, there is an urgent need to precisely determine the WCFZ height after the 5-2 seam extraction and to analyze its impact on the upward mining of the 4-4 seam.

Aiming to address these gaps, this paper takes Yujialiang Coal Mine as a case study. We integrate multi-source field detection data with numerical simulation analysis to systematically investigate the temporal evolution and spatial distribution of the overburden failure height. The ultimate objective is to construct a reliable prediction model for overburden failure height under high-intensity mining conditions, thereby providing a theoretical foundation for the safe design of upward mining operations.

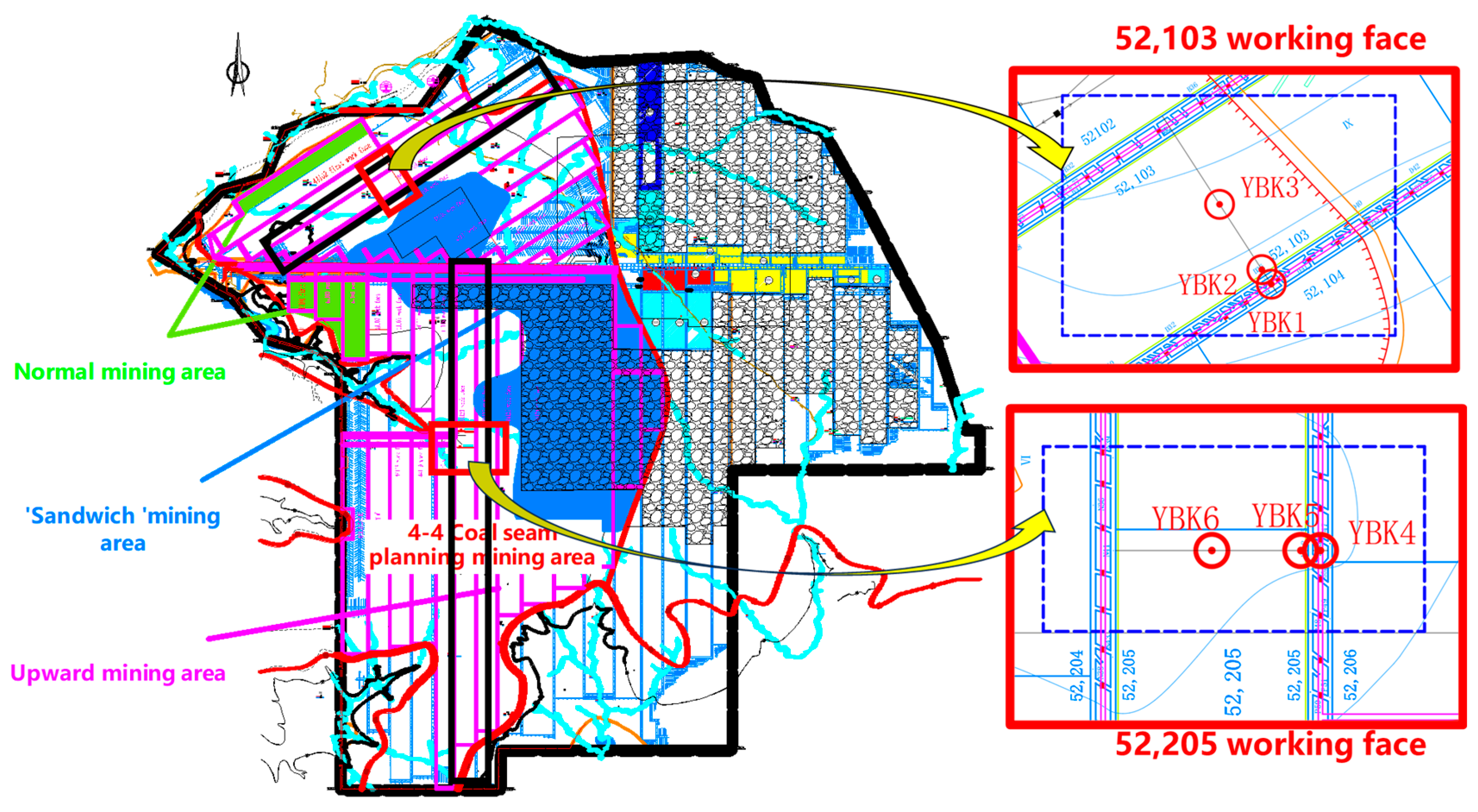

2. Mine Overview

The 4-4 coal seam of Yujialiang Coal Mine is located in the middle of the second member of the Yan’an Formation. The thickness of the coal seam gradually decreases from west to east, and the planned mining area of the 4-4 coal seam is situated in the western part of the mine field, with complex mining conditions, including three types: upward mining, “sandwich” mining, and normal mining. Among them, the edge of the western mining area in the planned mining area is a normal mining area, the central and partial eastern areas are “sandwich” mining areas, and the rest are upward mining areas, corresponding to the first panel and the second panel of the 5-2 coal seam, as shown in

Figure 1.

The 5-2 coal seam is located at the top of the first member of the Yan’an Formation and is mineable throughout the entire area. The vertical distance from the 5-2 coal seam to the 4-4 coal seam above is 25.15–46.69 m, with an average of 39.45 m; the average burial depth of the coal seam is 119.83 m. The thickness of the coal seam ranges from 0.83 m to 5.18 m, with an average of 3.93 m, belonging to a thick coal seam with a variation coefficient of 23%, indicating little change in thickness. The coal seam is thicker in the southwest of the area and relatively thinner in the northeast and generally thickens from east to west. It usually contains no partings but sometimes has a 0.12–0.33 m thick parting in the lower part. The coal seam structure is simple-to-relatively simple, and the coal type is non-caking coal. An erosion thinning zone is found in the eastern part of the mine field, which has been fully mined out at present.

The roof of the 5-2 coal seam is mainly composed of medium-grained sandstone in the northern part and coarse-grained sandstone in the southern part, followed by siltstone and fine-grained sandstone. Expressed by the sandstone content within 10 m of the roof, the higher the sandstone content (including coarse-grained sandstone, medium-grained sandstone, and fine-grained sandstone) in the rock layers within 10 m of the roof, the more stable the roof. The sandstone content in most parts of the mine field is greater than 90%, and it is only 50% in the northern and southern edges. The floor of the coal seam is mainly siltstone, and small patches of mudstone and fine-grained sandstone are developed in some areas of the northern and central parts. A comprehensive columnar section of the mine is shown in

Figure 2.

According to the

building, water, railway, and main roadway coal pillar setting and coal mining regulations [

21] and the mechanical properties of interlayer rock mass, for a gently inclined coal seam, when the coal seam roof overburden is a hard, medium hard, weak, or extremely weak rock layer or its interbedded, the height of the caving zone and the fractured zone can be determined by referring to the following method.

For hard rock strata with a uniaxial compressive strength of 40 MPa to 80 MPa, the calculation formula of the caving zone is as follows:

The calculation formula of the water-conducting fracture zone is:

In the formula,

Hm is the height of the caving zone;

HL is the height of the water-conducting fracture zone; ∑

M is the cumulative mining height; the mining height of each layer is 1–3 m; and the total mining height is less than 15 m.

From the preliminary mine geological survey data, the roof of the 5-2 coal seam in Yujialiang Coal Mine is dominated by siltstone and medium-grained sandstone. The measured compressive strength of the 5-2 coal roof strata is 45.463–62.179 MPa, with an average of 55.9 MPa, indicating that the roof strata are hard overburden. The average thickness of the coal mining seam is 4.13 m, and the design mining height is 4.1 m. The influence of errors is not considered in the calculation. According to Equations (1) and (2), the height of the caving zone is 14.16–19.16 m, and the height of the fracture zone is 50.35–70.75 m.

3. Surface Drilling Test

3.1. Drill Hole Design

To investigate the development characteristics of the “two zones” (i.e., the caving zone and fracture zone) in the overlying rock of the 5-2 coal goaf, the reserve state of the 4-4 coal seam, and the physical and mechanical characteristics of the surrounding rock, surface drilling exploration work was carried out, including drilling coring analysis, logging, sample testing and analysis, downhole television imaging, and other tests. Targeting the mineable area of the 4-4 coal seam and combined with the surface conditions, six detection drill holes were arranged in the surface area corresponding to the planned mining area of the 4-4 coal seam. The opening positions and layout of the exploration drill holes are shown in

Figure 1, and the specific layout plan is as follows:

(1) The corresponding area is Panel 1 of the 5-2 coal seam. The borehole numbers are YBK1, YBK2, and YBK3, respectively. The hole-opening positions are arranged 2430 m away from the northeast end of the 52,103 working face, and the three boreholes are aligned on the axis perpendicular to the working face. Among them, borehole YBK1 is arranged on the roadway coal pillar between the return airway of the 52,104 working face and the haulage airway of the 52,103 working face; borehole YBK2 is arranged in the goaf of the 52,103 fully mechanized mining face, 15 m away from the coal pillar of the 52,103 working face haulage airway; and borehole YBK3 is arranged in the middle of the goaf of the 52,103 fully mechanized mining face.

(2) The corresponding area is Panel 2 of the 5-2 coal seam. The borehole numbers are YBK4, YBK5, and YBK6, respectively. The hole-opening positions are arranged 2160 m away from the northern end of the 52,205 working face, and the three boreholes are aligned on the axis perpendicular to the working face. Among them, borehole YBK4 is arranged on the roadway coal pillar between the haulage airway of the 52,205 working face and the return airway of the 52,206 working face; borehole YBK5 is arranged in the goaf of the 52,205 fully mechanized mining face, 15 m away from the coal pillar of the 52,205 working face haulage airway; and borehole YBK6 is arranged in the middle of the goaf of the 52,205 fully mechanized mining face.

According to the statistical results of previous boreholes in Yujialiang Coal Mine, the average interval between the 4-4 coal seam and the 5-2 coal seam is 39.45 m. To expose the location of the caving zone and ensure adequate penetration into the fractured rock mass for accurate identification of the “two zones”, the design principle for the final hole horizon is as follows: the final hole horizon of boreholes YBK5 and YBK6 is 20 m below the floor of the 4-4 coal seam to ensure that the borehole traverses the potential caving zone developed below the 4-4 seam. The final hole horizon of the other boreholes (YBK1, YBK2, YBK3, YBK4) is 10 m below the floor of the 5-2 coal seam, which is sufficient to assess the immediate overburden failure characteristics above the mined-out seam and the condition of the interburden rock. The borehole result parameters are shown in

Table 1.

3.2. Surrounding Rock Strength Analysis

Based on the Protodyakonov coefficient of borehole cores, the overburden of the 5-2 coal seam is rated as medium–hard-to-hard rock after mining. This classification is based on the Protodyakonov coefficient rock classification method specified in the

Mining Engineering Design Manual [

22]. According to the surrounding rock strength of boreholes at different positions, the order from highest to lowest is as follows: the middle part of the remaining coal pillar in the 5-2 coal seam, the position 15 m away from the edge of the coal pillar, and the middle part of the goaf in the 5-2 coal seam. Details are shown in

Table 2.

Compared with the surrounding rock strength of boreholes at the coal pillar, the following are observed:

(1) Within the 0–50 m overlying range of the 4-4 coal seam, the strength decreases by 12.26–15.98% at the position 15 m away from the edge of the coal pillar and by 20.7% in the middle part of the goaf;

(2) Within the 0–20 m underlying range of the 4-4 coal seam, the strength decreases by 7.25% at the position 15 m away from the edge of the coal pillar and by 25.49% in the middle part of the goaf.

It can be seen that, affected by the mining of the 5-2 coal seam, the overall strength of the overlying surrounding rock has decreased.

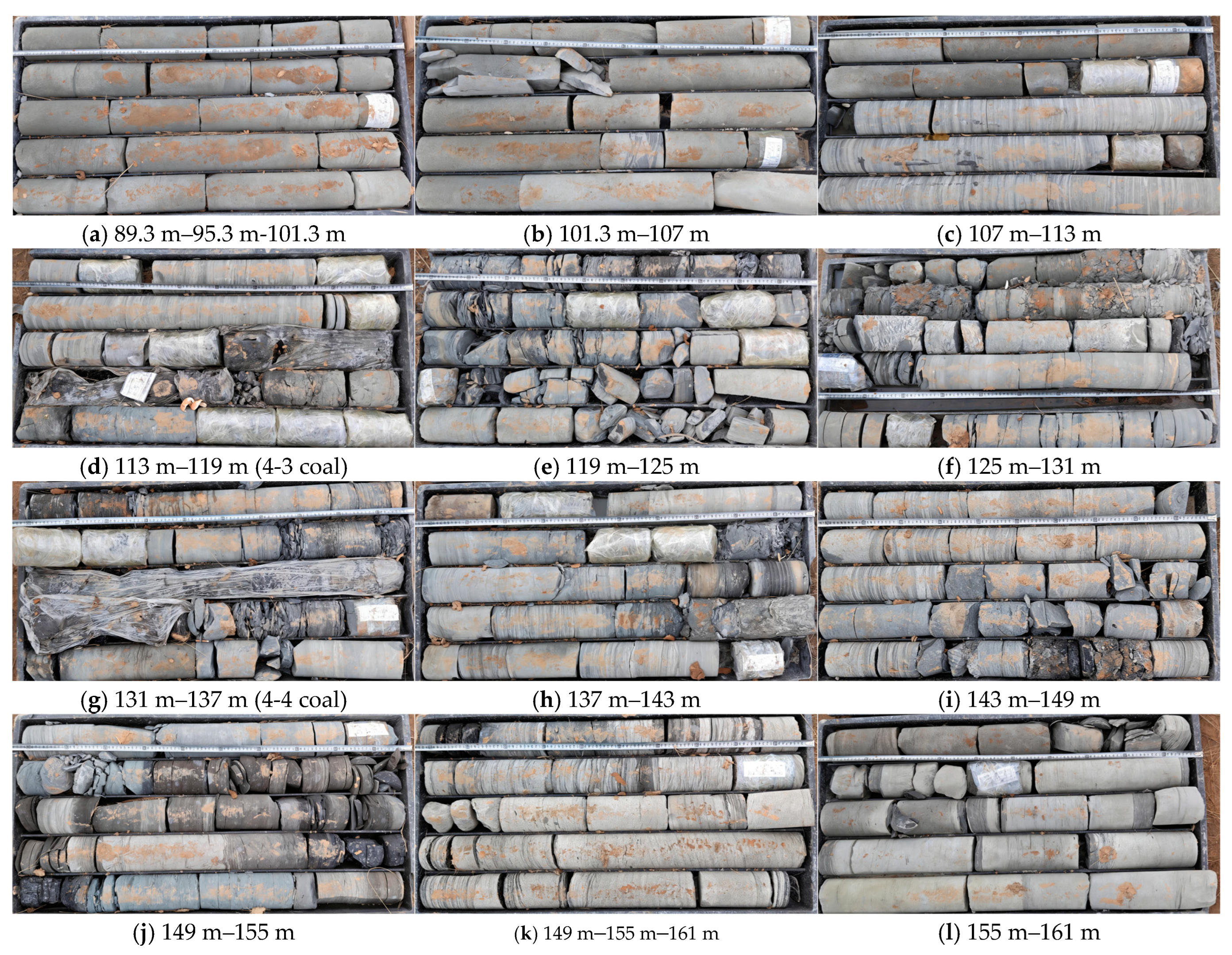

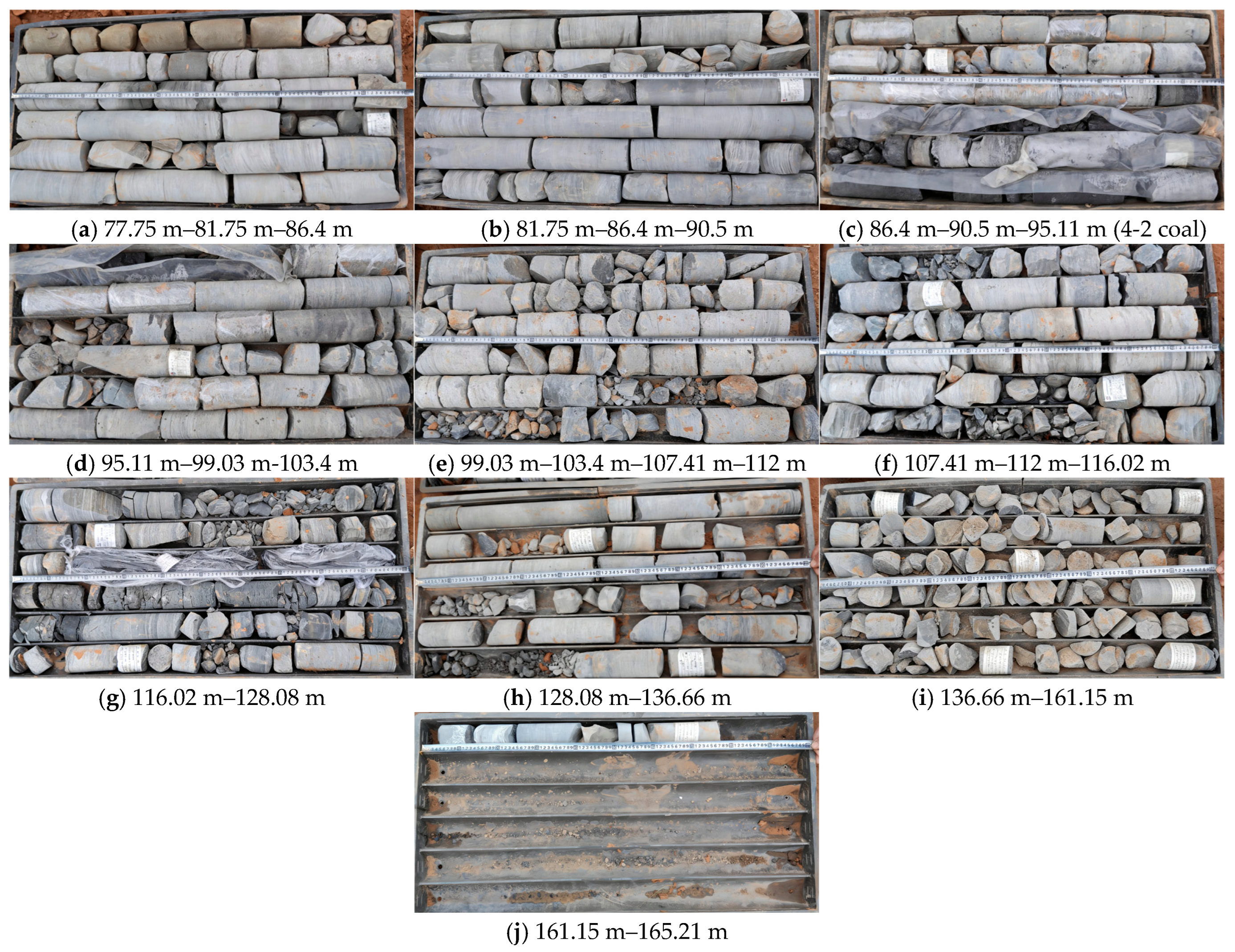

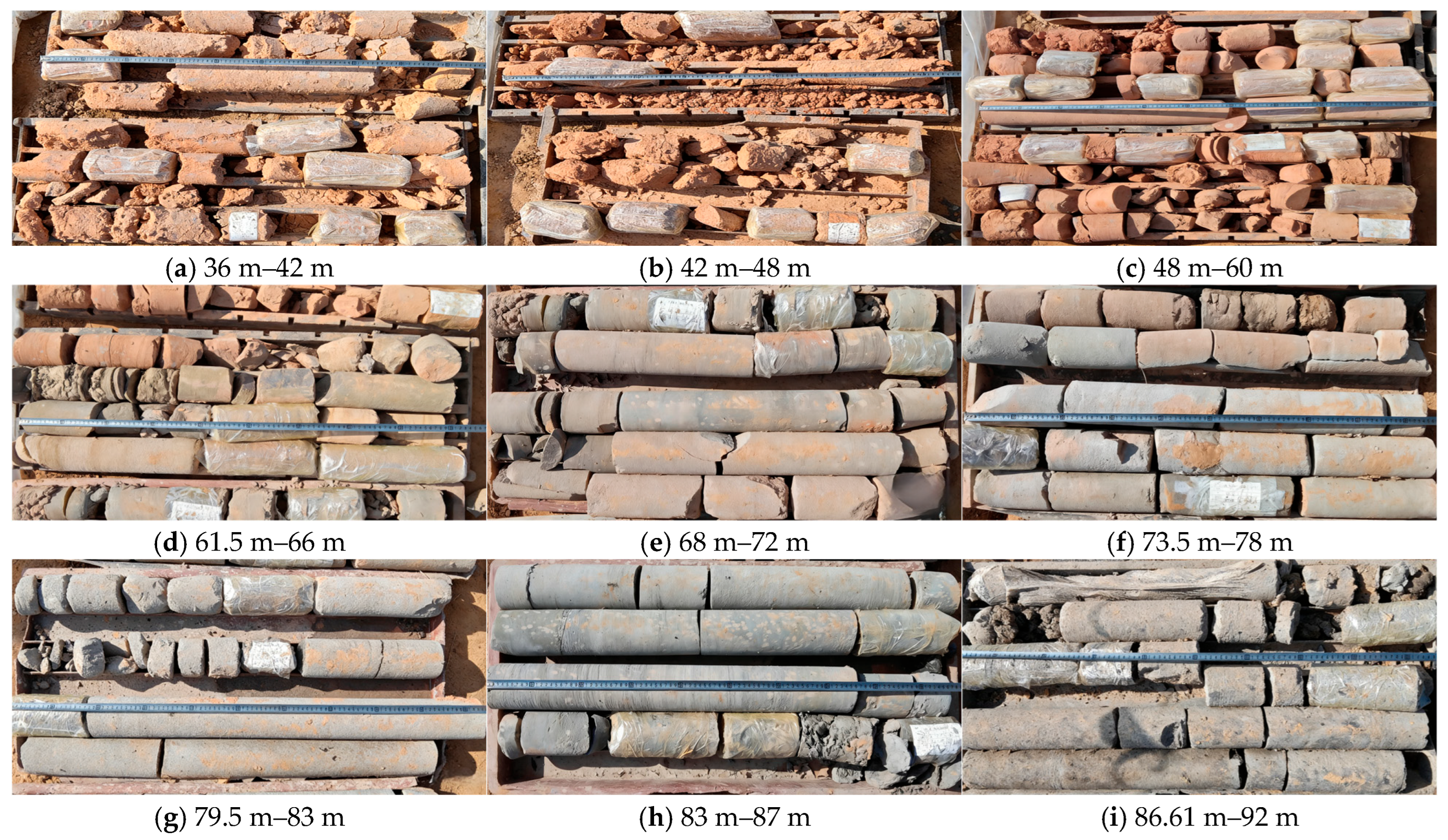

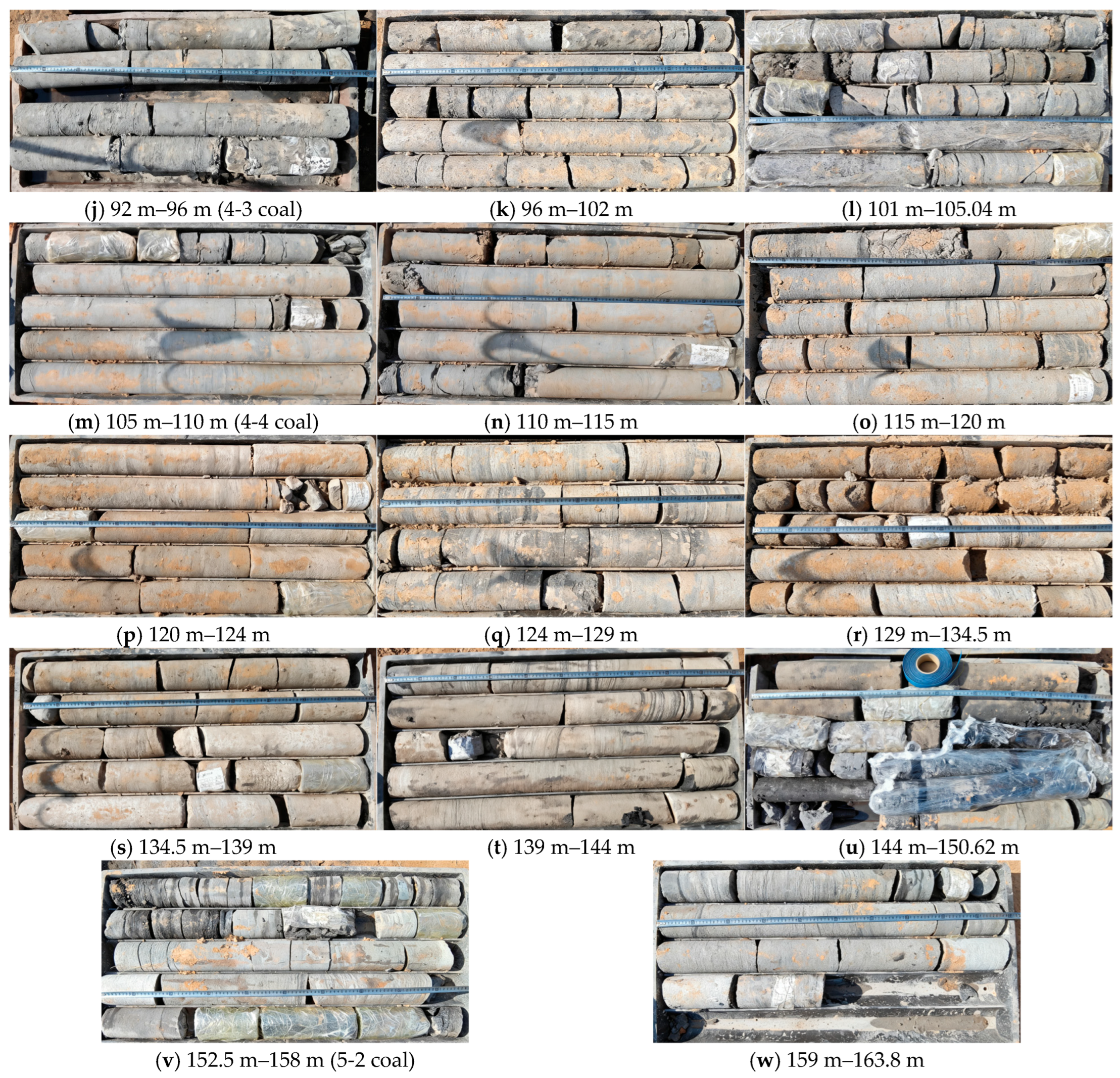

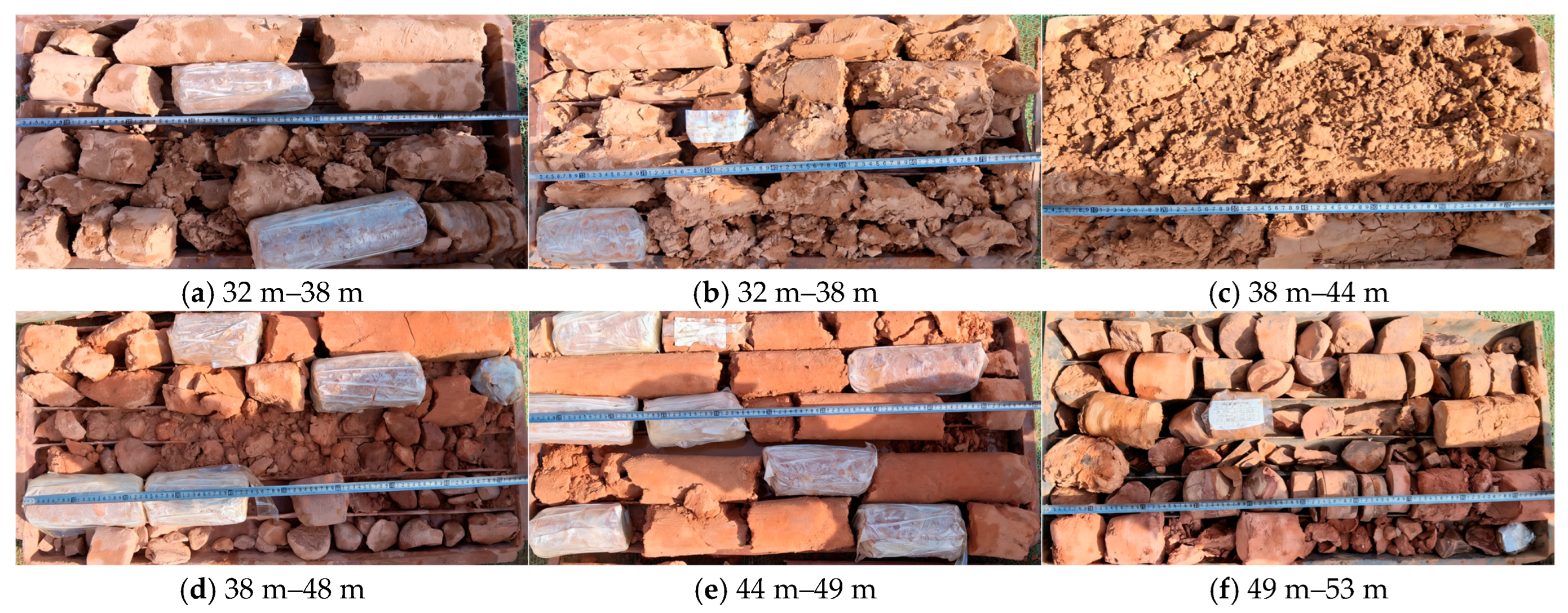

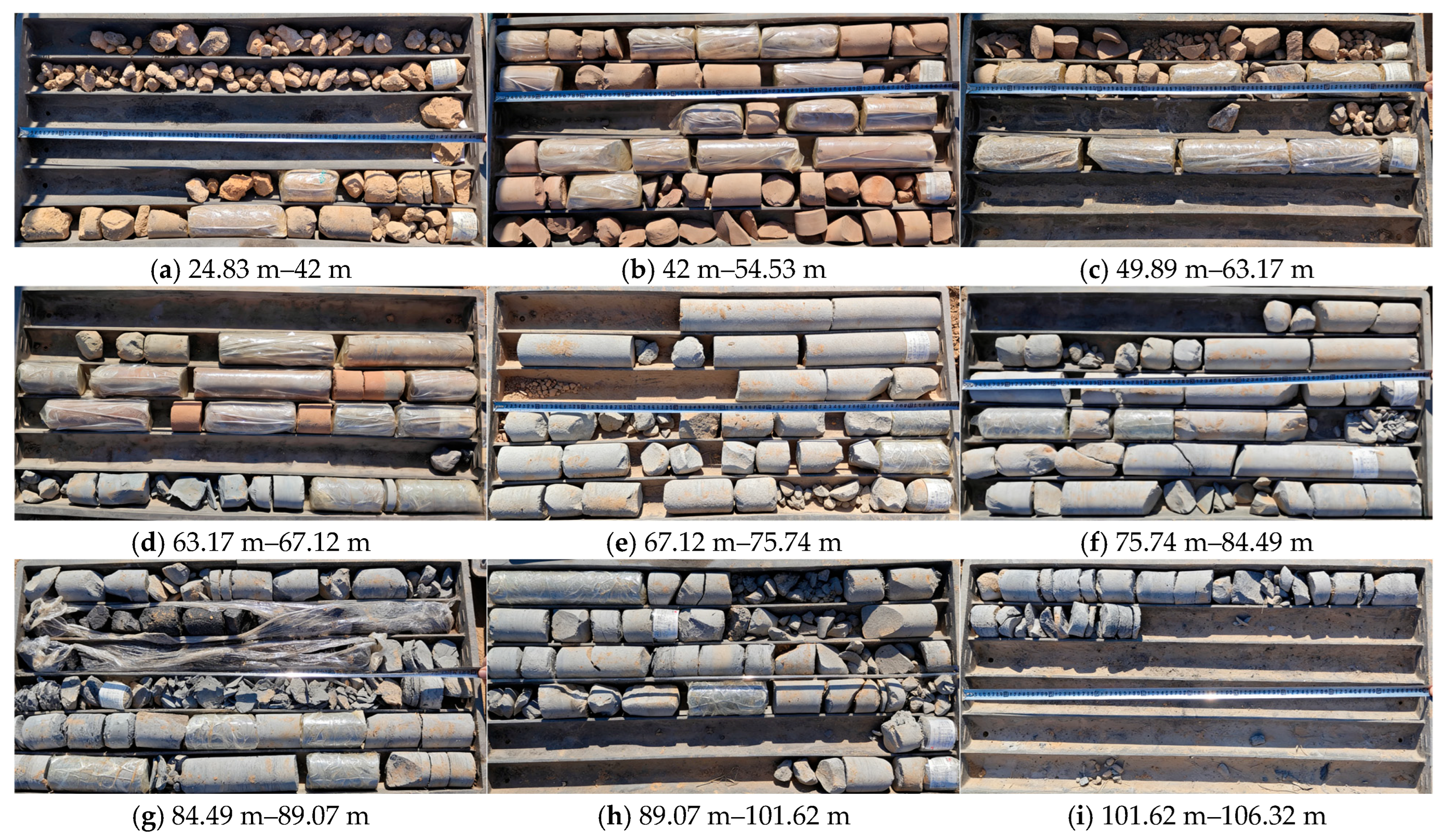

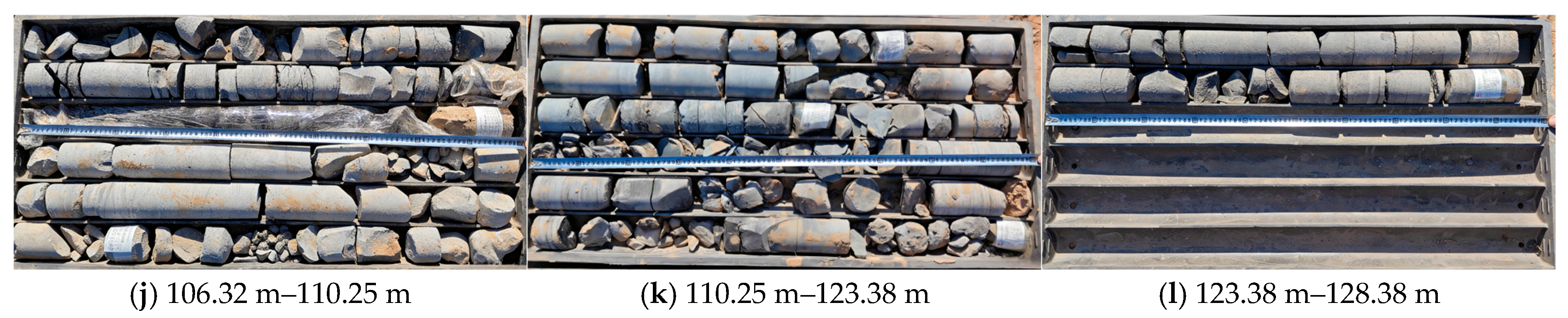

3.3. Coal-Rock Integrity Analysis

To evaluate the roof integrity of the upward mining face in the 4-4 coal seam, the Rock Quality Designation method was adopted. Rock Quality Designation (RQD) refers to the ratio of the cumulative length of columnar cores with a length of 10 cm or more to the footage of each drilling round. The discrimination indicators are as follows: excellent (very few cracks) (>90%), good (few cracks) (90–75%), fair (moderately fractured) (75–50%), poor (many cracks) (50–25%), and very poor (highly fractured) (25–0%). The integrity of cores was evaluated based on RQD values. Details of core sampling results of each borehole, statistical results of RQD values, and the correspondence between RQD values of boreholes in the upper and lower rock layers of the 4-4 coal seam and borehole columns are shown in

Table 3.

Through the analysis of the integrity of the overlying rock layers after the mining of the 5-2 coal seam, the following results were obtained:

(1) Analysis by horizontal position ranks core integrity (descending order) as follows: 5-2 coal pillar (fair–excellent) > 15 m from pillar edge (fair–poor) > goaf center (poor–very poor).

(2) Analysis by vertical horizon indicates superior integrity in the 10 m zone above the 4-4 coal seam compared to the 20 m zone below it.

(3) Focusing on the 10 m above the 4-4 coal seam, integrity is ranked as follows: 5-2 coal pillar (fair) > 15 m from pillar edge (fair–poor) > goaf center (poor–very poor).

(4) For the 20 m below the 4-4 coal seam, integrity is ranked as follows: 5-2 coal pillar (fair–excellent) > 15 m from pillar edge (poor) > goaf center (very poor).

3.4. Borehole Television Result Analysis

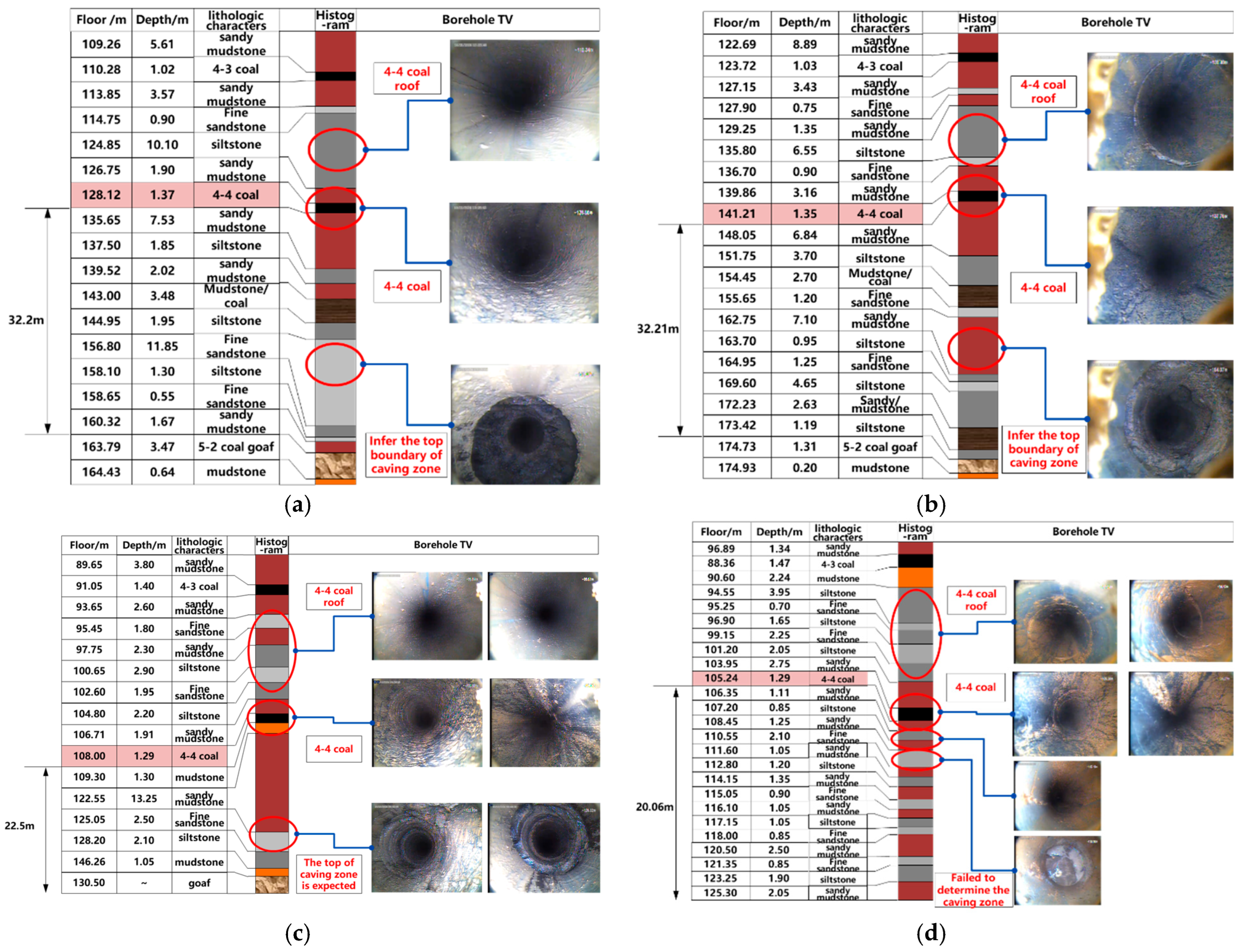

Borehole television detection, which employs a downhole camera to visually document the borehole wall, provides direct insight into fracture development. The following describes the progression of fractures from the collar to the bottom of the borehole, as revealed by the actual rock conditions: transverse fractures → longitudinal fractures→ transverse–longitudinal intersecting fractures. This rule is used to determine the height of the top boundary of the water-conducting fracture zone, and the location of rock fragmentation and collapse is taken as the top boundary of the caving zone. Since the rock layer above the coal pillar is less affected by mining activities and mining-induced fractures are not well-developed, only the borehole camera survey results corresponding to the middle part of the 5-2 coal seam goaf (YBK3, YBK6) and the position 15 m away from the coal pillar (YBK2, YBK5) at the end of the goaf are analyzed to study the overlying rock structure of the goaf and the development height of the “two zones”. The analysis results of the borehole camera surveys for each exploration borehole are shown in

Figure 3.

Through the analysis of the camera survey results of boreholes YBK2, YBK3, YBK5, and YBK6 and the judgment of the range of the two zones after mining the 5-2 coal seam, the following conclusions can be drawn:

Borehole YBK2: The water-conducting fracture zone begins at 40.99 m and the caving zone at approximately 146.88 m. After mining of the 5-2 coal seam, the caving zone extends from 0 m to 13.44 m, overlain by a fracture zone from 13.44 m to 119.33 m. The 4-4 coal seam is located within the fracture zone, 18.76 m above the caving zone.

Borehole YBK3: The water-conducting fracture zone begins at 43.50 m and the caving zone at approximately 164.10 m. After mining, the caving zone extends from 0 m to 9.32 m, overlain by a fracture zone from 9.32 m to 129.92 m. The 4-4 coal seam lies within the fracture zone, 22.88 m above the caving zone.

Borehole YBK5: The water-conducting fracture zone begins at 32.31 m and the caving zone at approximately 123.99 m. After mining, the caving zone extends from 0 m to 21.16 m, overlain by a fracture zone from 21.16 m to 116.25 m. The 4-4 coal seam is situated within the fracture zone, 15.99 m above the caving zone.

Borehole YBK6: The water-conducting fracture zone begins at 37.23 m. No evidence of a caving zone was observed to a depth of 110.55 m (5.31 m below the 4-4 coal seam floor). The camera survey was terminated due to water accumulation. In general, the boreholes reveal differences in the overlying rock fracture and caving characteristics after the mining of the 5-2 coal seam, and the 4-4 coal seam is consistently located within the fracture zone.

3.5. Well Log Curve Result Analysis

To analyze the development degree of coal-rock fractures, geophysical logging was conducted on the boreholes. The principle of density logging is as follows: Gamma rays with an energy of 0.661 MeV are emitted from the source → the rays irradiate the formation and cause the Compton effect → scattered rays reach the detector → the count rate N (pulse value) is recorded. Different formation bulk densities (ρb) result in different scattering and absorption capacities for gamma photons, leading to different count rates recorded by the instrument. Specifically, as ρ decreases, N increases. According to the logging principle, when the detector (with long and short source distances) passes through fracture-developed intervals, the N value increases significantly. The following is a detailed analysis of the density logging results of each borehole.

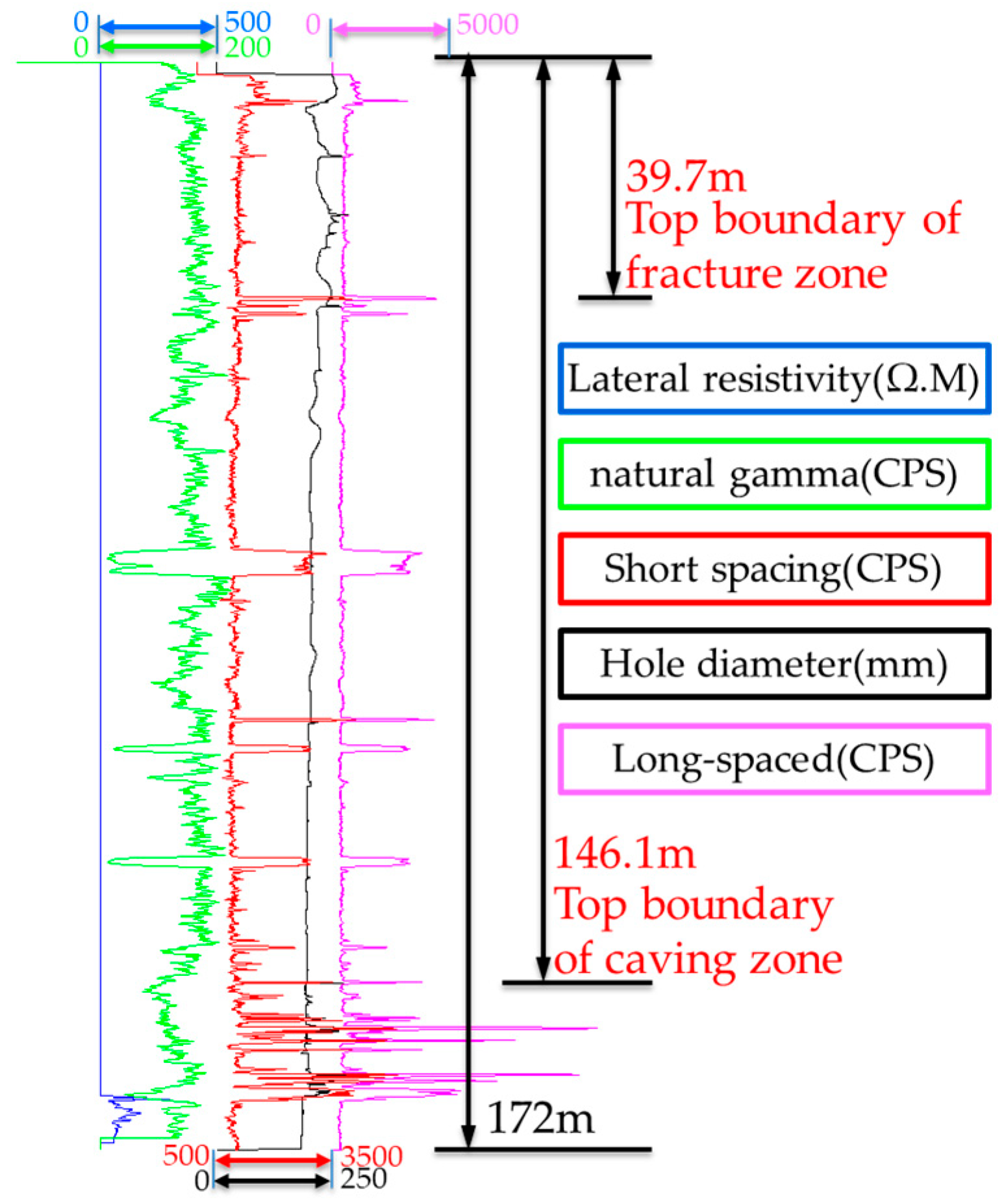

Analysis of the logging density curve of borehole YBK2 shows that at borehole depths of 39.70 m and 146.10 m, the long- and short-source distance pulse values of borehole YBK2 exhibit dense and large anomalies, and the borehole diameter varies significantly (see

Figure 4). This phenomenon is caused by the collapse and fragmentation of the borehole wall, developed fractures, increased borehole diameter, and expanded cross-sectional area, which lead to an increase in the long- and short-source distance values. It can be concluded that the top boundary of the fracture zone of this borehole is at a depth of 39.70 m, and the top boundary of the caving zone is at a depth of 146.10 m. Judging from the logging curve, after the mining of the 5-2 coal seam at the location of borehole YBK2, the range of the overlying rock caving zone is 0–14.22 m, the range of the fracture zone is 14.22–116.82 m, and the 4-4 coal seam is located within the fracture zone formed after the mining of the 5-2 coal seam, 17.98 m above the caving zone.

Observation of the logging density curve of borehole YBK3 reveals that at borehole depths of 51.80 m and 163.70 m, the long- and short-source distance pulse values of borehole YBK3 also exhibit dense and large anomalies, with a significant variation in borehole diameter (see

Figure 5). This phenomenon is caused by the collapse and fragmentation of the borehole wall, developed fractures, an increase in borehole diameter, and an expanded cross-sectional area—all of which lead to higher values of long and short source distances. It can be concluded that the top boundary of the fracture zone of this borehole is at a depth of 51.80 m, and the top boundary of the caving zone is at a depth of 163.70 m. Judging from the logging curve, after the mining of the 5-2 coal seam at the location of borehole YBK3, the range of the overlying rock caving zone is 0–21.56 m, the range of the fracture zone is 21.56–121.62 m, and the 4-4 coal seam is located within the fracture zone formed after the mining of the 5-2 coal seam, 22.48 m above the caving zone.

After a comprehensive comparison of a variety of two-zone height calculation and detection methods in shallow buried depth and high-intensity mining, it is found that the error of the caving zone is small, but there is a large error between the empirical formula calculation results of the water-conducting fracture zone and the actual detection results.

4. Numerical Simulation Study on Rock Movement Law After Mining of 5-2 Coal Seam

4.1. Establishment of Numerical Model

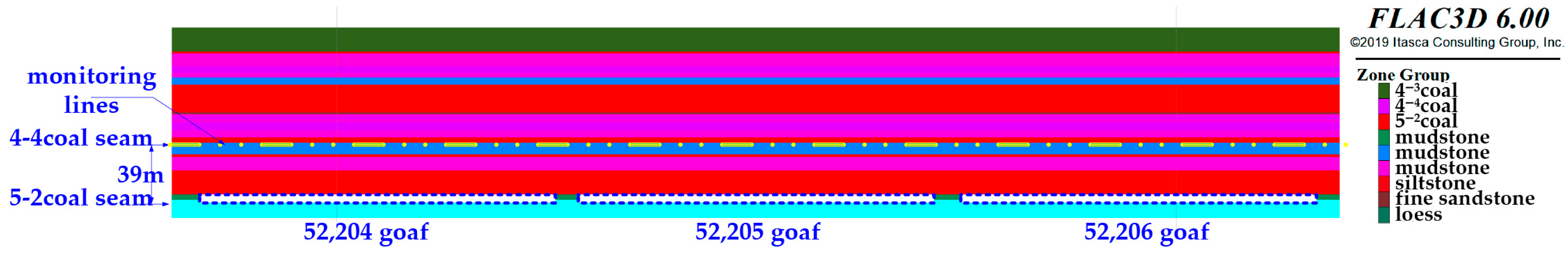

A numerical simulation model was established based on the rock occurrence characteristics and the physical and mechanical properties of each rock layer in Yujialiang Coal Mine, as shown in

Figure 6. The model is divided into 21 layers with a size of 832 m × 100 m × 132 m (X × Y × Z). The number of division units is 10,982,400, and the number of nodes is 11,357,955. The Mohr–Coulomb model was adopted for this model. The 21 layers consist of five different rock materials. The parameter values of each rock material used in the model are shown in

Table 4, which are the mean values of the corresponding rock properties from tests of cores of the six boreholes, as given in

Appendix A.2. The boundary constraints are as follows: horizontal displacement constraints for the four side boundaries, vertical displacement constraints for the lower boundary, and a vertical load applied to the upper boundary of the model, and the load magnitude is equal to the self-weight of the overlying rock above the model.

The selection of the 3D numerical analysis method (FLAC3D) in this study is based on the actual geological conditions of Yujialiang Coal Mine and the research objectives, and this cannot be replaced by 2D analysis. The specific reasons are as follows:

First, in terms of the mechanical response of the overlying rock, the mining of the 5-2 coal seam will cause the overlying rock to produce three-dimensional stress and displacement. The 2D plane strain model assumes that there is no strain in the direction perpendicular to the cross-section, which will ignore the stress transfer and deformation coordination between adjacent working faces in the strike direction. For example, the 52,103 and 52,104 working faces in Panel 1 of the 5-2 coal seam are adjacent in the strike direction. The mining disturbance of both working faces overlaps in the overlying rock, resulting in a more complex stress environment in the overlying 4-4 coal seam. The 3D model can simulate the stress superposition effect caused by the mining of multiple adjacent working faces, while the 2D model can only simulate the stress state of a single working face in the dip direction, which cannot reflect the actual stress distribution of the 4-4 coal seam.

Second, regarding the research on the feasibility of upward mining, the core of this study is to determine the reasonable layout position of the 4-4 coal seam roadway. The 2D model can only analyze the stability of the roadway in a single cross-section but cannot evaluate the spatial variation in the roadway stability along the strike direction. The 3D model can simulate the settlement deformation and stress distribution of the 4-4 coal seam floor in the entire research area (including the coal pillar area, the area 15 m from the coal pillar edge, and the goaf middle area) and obtain the continuous variation law of the settlement change rate and stress concentration degree along the strike and dip directions. For example, the simulation results show that the settlement change rate of the 4-4 coal seam floor in the 0–40 m area from the coal pillar edge is significantly higher than that in the goaf middle area, which provides a more comprehensive basis for determining the optimal roadway layout position. If a 2D model is used, it is impossible to obtain such spatial continuous variation information, and the proposed roadway layout scheme may lack overall rationality.

According to the production sequence, the 52,204, 52,205, and 52,206 working faces are excavated, respectively. The width of the working face is 240 m, the width of the coal pillar is 30 m, and the height of the coal seam is the height of the working face. The excavation is carried out step by step, with a 50 m distance for each step.

To study the movement and deformation of the 4-4 coal seam after the mining of the 5-2 coal seam, measuring points were arranged on the floor of the 4-4 coal seam. These points were used to monitor the displacement and stress distribution of the 4-4 coal seam. The layout of the measuring points is shown in

Figure 7.

4.2. Simulation Study on the Law of Overlying Rock Movement and Deformation

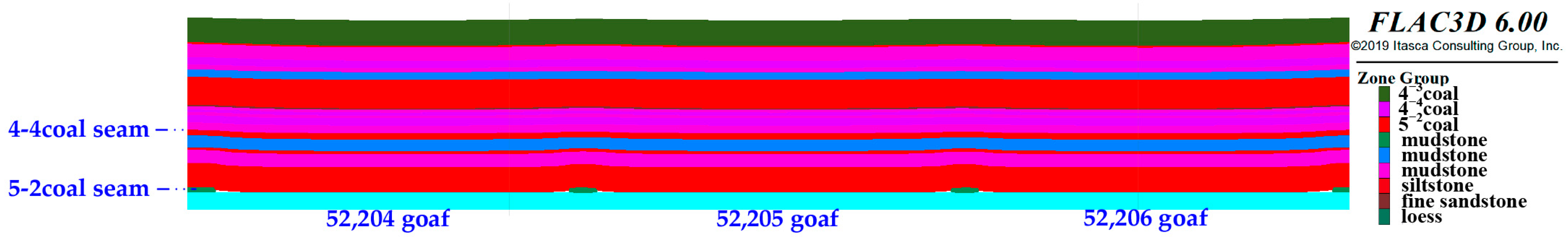

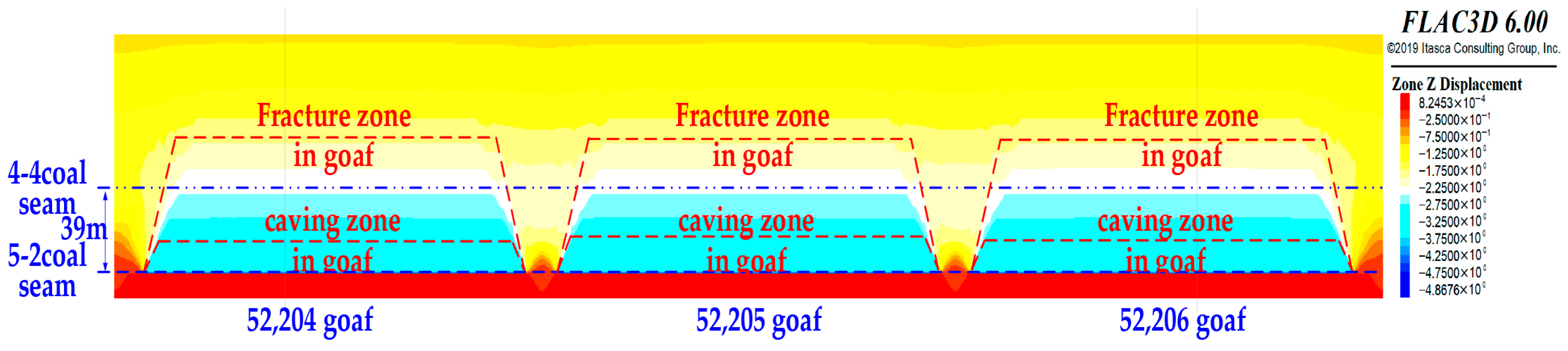

The movement and deformation of the overlying rock layers after the excavation of the 5-2 coal seam working faces are shown in

Figure 8. Taking the excavation of the 52,204, 52,205, and 52,206 working faces in the 5-2 coal seam as examples, three overlapping caving influence zones are mainly formed after the working face excavation.

The law of overlying rock movement and deformation in the affected area is analyzed through the measuring points arranged in the 4-4 coal seam.The vertical displacement contour map and vertical displacement curve of its overlying rock layers after the mining of the 5-2 coal seam are shown in

Figure 9 and

Figure 10, respectively.

After the mining of the 5-2 coal seam, the overlying rock layers above the goaf collapsed, as shown in

Figure 9. After the excavation of the working face, there is a gradient change in vertical displacement above the goaf. The height of the caving zone is determined based on the extent of deformation, and the caving angle is calculated from the geometry of the caving arch. From the simulated vertical displacement contour map of the overlying rock layers after the excavation of the 5-2 coal seam, it can be concluded that the caving angles on both sides of the goaf in the overlying rock layers are 58.02°, 61.82°, 63.38°, 61.44°, 59.65°, and 59.38°, respectively, with an average caving angle of 60.20°. The development heights of the caving zone are approximately 11.93 m, 11.99 m, and 11.94 m, respectively, with an average development height of the caving zone of 11.95 m.

According to the results of borehole TV, the average height of the caving zone is about 0–14.64 m. The logging results show that the average height of the caving zone is about 0–17.89 m. This is basically consistent with the numerical simulation results, indicating that the numerical model has reference significance.

To quantitatively evaluate the accuracy of the numerical model, the Mean Absolute Error (MAE) and Root Mean Square Error (RMSE) between the simulated and field-measured heights of the caving zone and fracture zone were calculated for boreholes YBK2, YBK3, YBK5, and YBK6. The results are summarized in

Table 5.

The error analysis indicates that the numerical model provides a reasonable prediction of the overburden failure height, with the simulated caving zone heights showing closer agreement to field data than the fracture zone heights. The discrepancies, particularly for YBK5, may be attributed to local geological heterogeneity and the simplification of the constitutive model. Overall, the model demonstrates sufficient predictive capability to support the feasibility analysis and engineering recommendations presented in this study.

4.3. Settlement Trend of 4-4 Coal Seam Floor

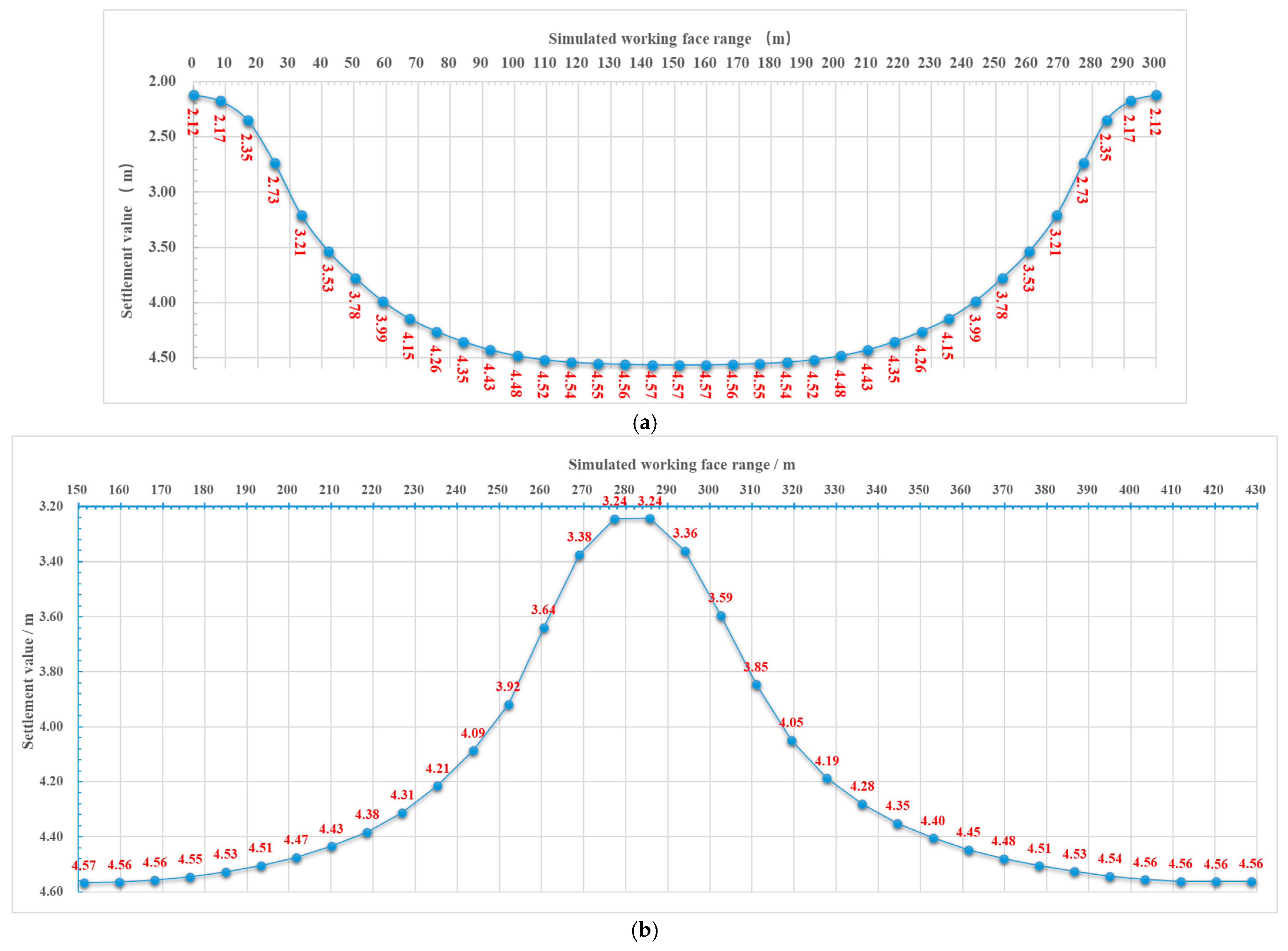

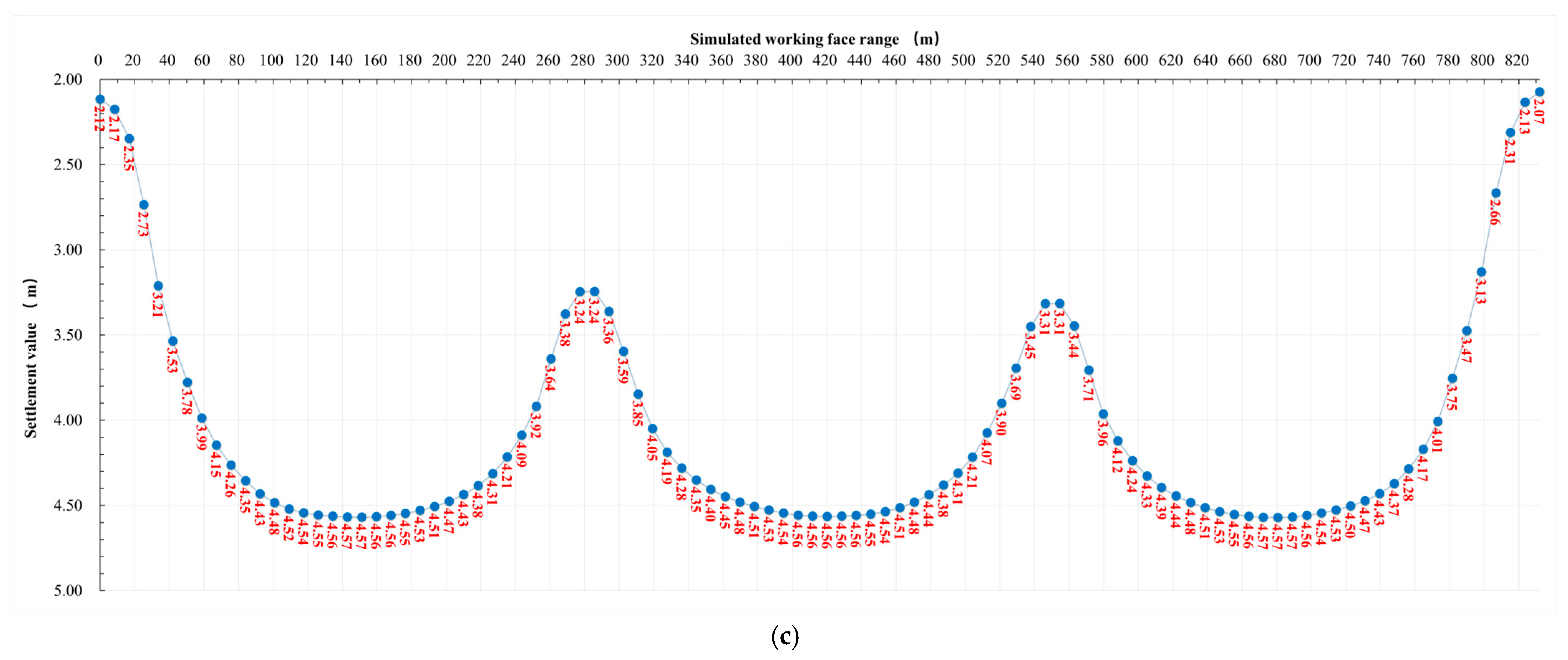

As shown in

Figure 10, after the excavation of the 5-2 coal seam working face, the overlying rock layers collapsed, causing subsidence deformation at the location of the 4-4 coal seam. Based on the monitoring results of the displacement survey lines arranged in the 4-4 coal seam, the settlement curves of the 4-4 coal seam at various positions were plotted, and the analysis results are as follows:

(1) After the excavation of the 5-2 coal seam working face, the maximum subsidence position of the 4-4 coal seam floor is located in the middle of the goaf of the underlying 5-2 coal seam, with a maximum subsidence amount of 4.57 m.

(2) For the 4-4 coal seam overlying the remaining coal pillar of the 5-2 coal seam, affected by the mining disturbance of the 5-2 coal seam goaf, the maximum subsidence amount at the center of the coal pillar (x = 292 m in

Figure 10a) after mining of the first working face (52,204) is 2.17 m; after mining of all three working faces (52,204, 52,205, 52,206), the maximum subsidence amount is 3.31 m.

(3) The maximum elevation difference between the 4-4 coal seam overlying the remaining coal pillar of the 5-2 coal seam and the coal seam overlying the middle of the 5-2 coal seam goaf is 2.4 m after mining of the first working face (52,204) and 1.33 m after mining of all three working faces (52,204, 52,205, 52,206).

(4) Under single-seam mining conditions, the settlement curve of the 4-4 coal seam floor extends across the region from the center of the 5-2 coal pillar to the centers of the two adjacent goafs. After mining of the first working face (52,204) conditions, the maximum subsidence difference in the 4-4 coal seam floor corresponding to the range of 0–10 m from the middle of the remaining coal pillar to the edge of the coal pillar in the 5-2 coal seam is 0.18 m; within the range of 0–15 m from the edge of the 5-2 coal seam coal pillar to the goaf, the maximum subsidence difference in the corresponding overlying 4-4 coal seam floor is 0.86 m; within the range of 15 m from the edge of the 5-2 coal seam coal pillar to the middle of the goaf, the maximum subsidence difference in the corresponding overlying 4-4 coal seam floor is 1.31 m.

(5) Under after mining of all three working face (52,204, 52,205, 52,206) conditions, the settlement curve of the 4-4 coal seam floor extends across the region from the center of the 5-2 coal pillar to the centers of the two adjacent goafs, as shown in

Figure 10b. Within the range of 0–10 m from the middle of the remaining coal pillar to the edge of the coal pillar in the 5-2 coal seam, the maximum subsidence difference in the corresponding overlying 4-4 coal seam floor is 0.14 m; within the range of 0–15 m from the edge of the 5-2 coal seam coal pillar to the goaf, the maximum subsidence difference in the corresponding overlying 4-4 coal seam floor is 0.54 m; within the range of 15 m from the edge of the 5-2 coal seam coal pillar to the middle of the goaf, the maximum subsidence difference in the corresponding overlying 4-4 coal seam floor is 0.65 m.

(6) From the above analysis, it can be concluded that compared with after mining of the first working face (52,204), after mining of all three working faces (52,204, 52,205, 52,206), the subsidence amount of the overlying 4-4 coal seam floor corresponding to the remaining coal pillar and the area 0–15 m from the edge of the coal pillar both increased. The increase rate at the coal pillar is approximately 52.53%, and the increase rate at the area 0–15 m from the edge of the coal pillar is approximately 43.82%.

4.4. Settlement Change Rate of 4-4 Coal Seam Floor

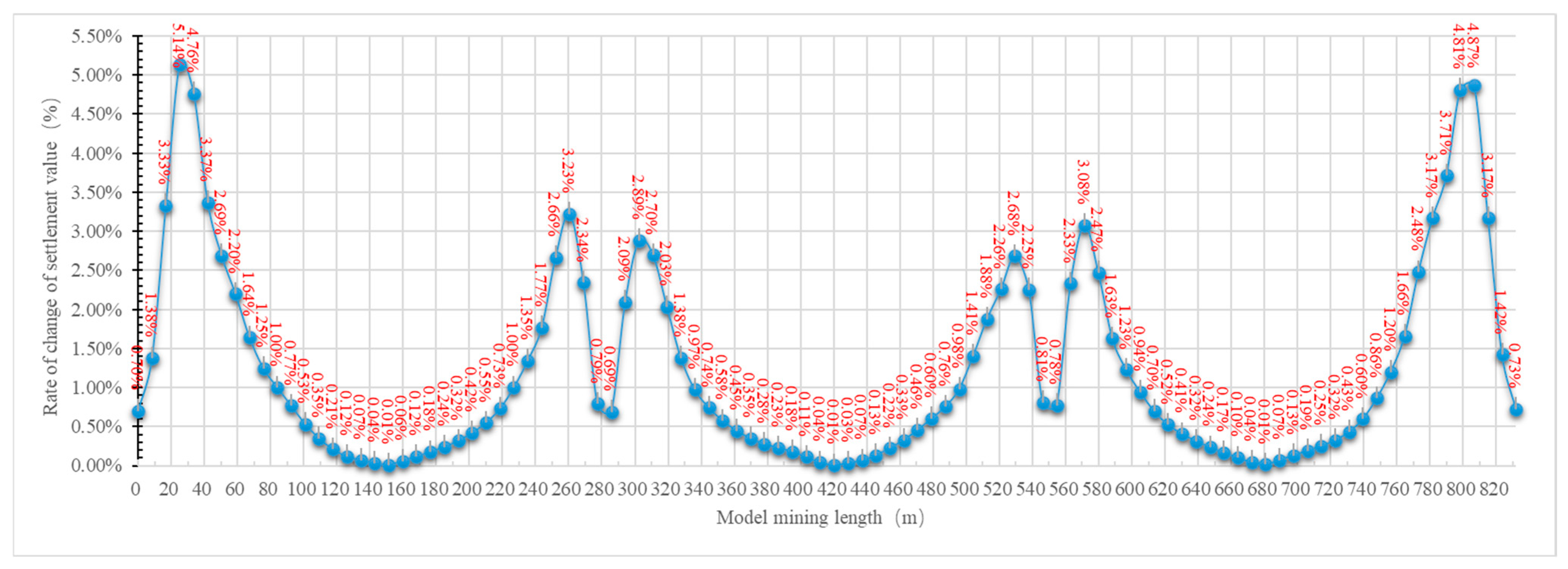

We calculated the first derivative of the vertical displacement curve for the 4-4 coal seam (

Figure 10) to quantify the settlement change rate (slope, dw/dx) across its floor after the mining of the 5-2 coal seam. This yielded the per-meter settlement curve of the 4-4 coal seam floor at each position, as shown in

Figure 11. The analysis results are as follows:

(1) Following the mining of the 5-2 coal seam, the highest settlement change rates in the 4-4 coal seam floor were primarily concentrated within a zone extending from the coal pillar edge. Specifically, the following were observed:

After mining of the first working face (52,204), the zone of highest differential settlement extended 40 m from the pillar edge, with an average gradient of 0.027 m/m.

After mining of all three working faces (52,204, 52,205, 52,206), this zone was reduced to 35 m, with a lower average gradient of 0.022 m/m.

(2) For the per-meter settlement displacement change rate of the 4-4 coal seam floor overlying the remaining coal pillar of the 5-2 coal seam, after mining of the first working face (52,204), the average per-meter settlement change is 0.018 m/m; after mining of all three working faces (52,204, 52,205, 52,206), the average per-meter settlement change is 0.0074 m/m.

(3) The average per-meter settlement change in the 4-4 coal seam floor overlying the goaf of the 5-2 coal seam is 0.003 m/m.

(4) By counting the per-meter settlement of the 4-4 coal seam floor, the overall change trend is as follows: per-meter settlement change rate in the 0–40 m area from the coal pillar edge > per-meter settlement change rate in the coal pillar area > per-meter settlement change rate in the middle of the goaf. That is, the continuity of the 4-4 coal seam floor is in the following order: middle of the goaf > coal pillar area > 0–40 m area from the coal pillar edge. Considering the coal-rock mass continuity (per-meter settlement), it is recommended that the mining roadway be arranged in the middle of the 5-2 coal seam goaf.

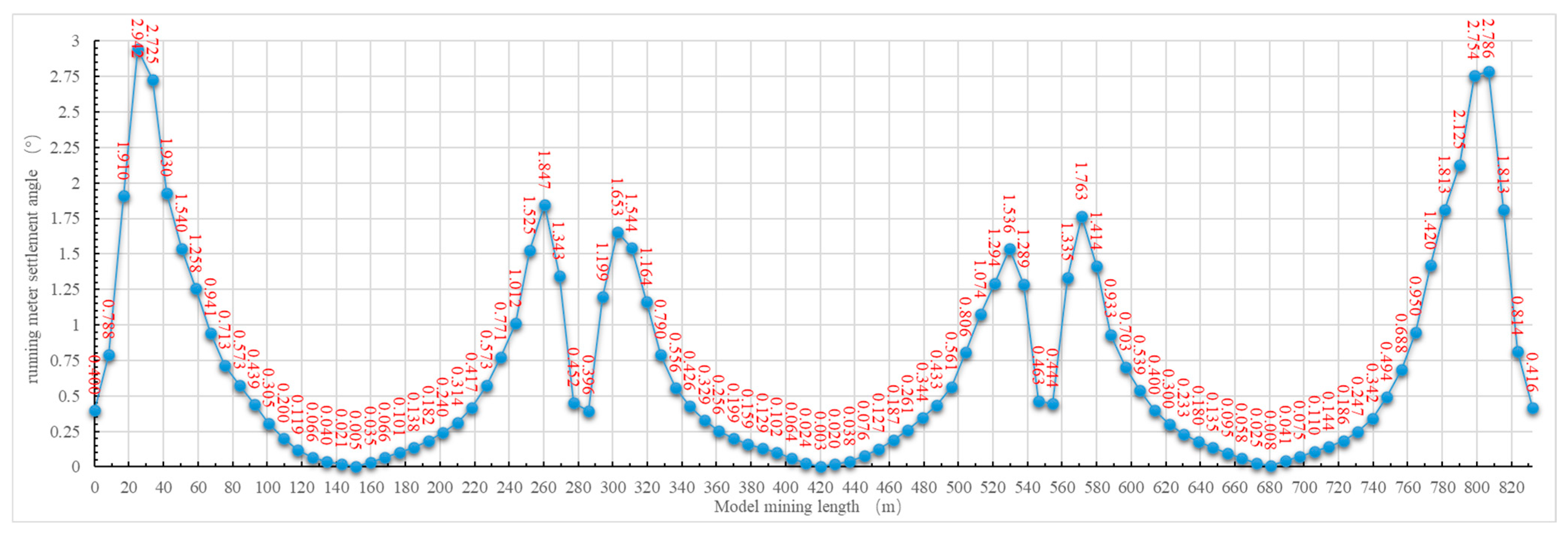

The settlement slope angle (

θ) at any point on the 4-4 coal seam floor was derived from the arctangent of the slope (the first derivative, dw/dx) of its subsidence displacement curve. As shown in

Figure 12, the calculated angles were plotted, leading to the following analysis:

(1) After the mining of the 5-2 coal seam, the overall settlement slope angle of the corresponding 4-4 coal seam floor was analyzed. According to the per-meter settlement angle change curve at any position of the 4-4 coal seam floor, after mining of the first working face (52,204) in the 5-2 coal seam, the position with the maximum angle change in the overlying 4-4 coal seam floor is 15.21 m from the center of the coal pillar, with a maximum settlement slope angle of 2.94°; after mining of all three working faces (52,204, 52,205, 52,206), the position with the maximum angle change in the overlying 4-4 coal seam floor is 22.04 m from the center of the coal pillar, with a maximum settlement slope angle of 1.653°.

(2) For the area from the center to the edge of the coal pillar in the 5-2 coal seam, the per-meter angular change in the overlying 4-4 coal seam floor shows specific values. After mining of the first working face (52,204), the values range from 0.788° to 1.910°, averaging 1.349°. After mining of all three working faces (52,204, 52,205, 52,206), the values decrease significantly to a range of 0.396–0.463°, with an average of 0.430°.

(3) For the settlement slope angle of the 4-4 coal seam floor corresponding to the area from the edge of the remaining coal pillar to the middle of the goaf in the 5-2 coal seam, a settlement slope angle of 1° is used as the boundary:

After mining of the first working face (52,204), in the area from the edge of the remaining coal pillar to the middle of the goaf (0–47 m) in the 5-2 coal seam, the settlement slope angle of the overlying 4-4 coal seam floor ranges from 1° to 2.942°, with an average of 2.078°;

After mining of the first working face (52,204), in the area from 47 m from the edge of the remaining coal pillar to the middle of the goaf in the 5-2 coal seam, the settlement slope angle of the overlying 4-4 coal seam floor ranges from 0.004° to 1°, with an average of 0.311°;

After mining of all three working faces (52,204, 52,205, 52,206), in the area from the edge of the remaining coal pillar to the middle of the goaf (0–30.25 m) in the 5-2 coal seam, the settlement slope angle of the overlying 4-4 coal seam floor ranges from 1° to 1.847°, with an average of 1.378°;

After mining of all three working faces (52,204, 52,205, 52,206), in the area from 30.25 m from the edge of the remaining coal pillar to the middle of the goaf in the 5-2 coal seam, the settlement slope angle of the overlying 4-4 coal seam floor ranges from 0.0029° to 1°, with an average of 0.262°.

(4) By counting the per-meter settlement angle change in the 4-4 coal seam floor, the overall change trend is as follows: settlement slope angle in the 0–47 m area from the coal pillar edge > settlement slope angle in the coal pillar area > settlement slope angle in the middle of the goaf. That is, the continuity of the 4-4 coal seam floor is in the following order: middle of the goaf > coal pillar area > 0–40 m area from the coal pillar edge. Considering the coal-rock mass continuity (per-meter settlement angle), it is recommended that the mining roadway be arranged in the middle of the 5-2 coal seam goaf.

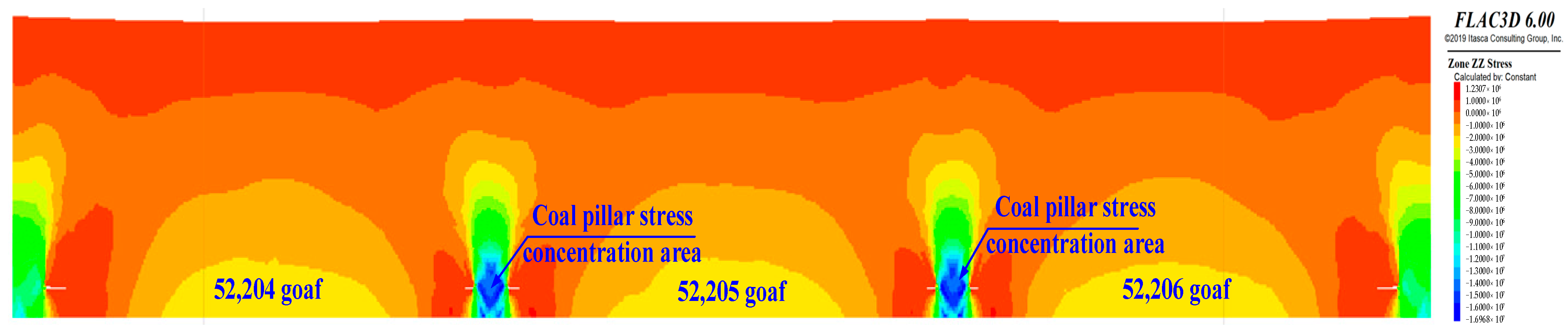

4.5. Variation Law of Stress Field in 4-4 Coal Seam

The stress contour maps of the 4-4 coal seam above the goaf and corresponding to the coal pillar in the 5-2 coal seam are shown in

Figure 13. It can be seen from the diagram that (52,204, 52,205, 52,206), there is a significant stress concentration phenomenon in the coal pillars. The peak stress is significantly greater than after mining of the first working face (52,204). Based on the stress contour maps, the vertical stress curve of the 4-4 coal seam was plotted and is shown in

Figure 14, and the analysis results are as follows:

(1) After the mining of the 5-2 coal seam, the maximum vertical stress of the corresponding overlying 4-4 coal seam is located above the remaining coal pillar of the 5-2 coal seam. After mining of the first working face (52,204), the maximum vertical stress at the floor of the overlying 4-4 coal seam at this position is 3.86 MPa, with a stress concentration factor of 0.56; after mining of all three working faces (52,204, 52,205, 52,206), the maximum vertical stress at the floor of the overlying 4-4 coal seam at this position is 4.10 MPa, with a stress concentration factor of 1.24. The maximum stress value after mining of all three working faces (52,204, 52,205, 52,206) is greater than that after mining of the first working face (52,204).

(2) The vertical stress in the area of the 4-4 coal seam overlying the goaf of the 5-2 coal seam ranges from 0.78 MPa to 1.76 MPa, all lower than the in situ stress (3.3 MPa), and the stress concentration factor ranges from 0.23 to 0.53.

(3) Overall, after the mining of the 5-2 coal seam, the overall vertical stress trend at the floor of the 4-4 coal seam overlying the remaining coal pillar and goaf is as follows: maximum stress value at the remaining coal pillar (4.10 MPa) > maximum stress value at the goaf (1.76 MPa). From the perspective of the stress environment, the overall stress environment at the goaf is better than that at the coal pillar.

(4) By counting the stress concentration degree at the floor of the 4-4 coal seam overlying the remaining coal pillar and goaf of the 5-2 coal seam, although the maximum stress concentration factor at the remaining coal pillar of the 5-2 coal seam (1.24) is greater than that at the goaf (0.53), the maximum stress at the coal pillar is only 0.80 MPa higher than the in situ stress, with a small stress increase.

(5) From the above analysis, it can be concluded that after the mining of the 5-2 coal seam, the overall vertical stress at the floor of the 4-4 coal seam overlying the remaining coal pillar and goaf has little impact on the roadway layout of the 4-4 coal seam. From the stress perspective, the mining gateway of the working face can be arranged in the overlying 4-4 coal seam corresponding to the goaf of the 5-2 coal seam.

5. Discussion

This study systematically investigates the overburden failure law and the feasibility of upward mining of the 4-4 coal seam after mining of the 5-2 coal seam in Yujialiang Coal Mine using multi-source field detection and numerical simulation. The results are discussed in the context of previous studies, practical engineering implications, and limitations to provide a comprehensive understanding of the research findings.

This study has several limitations that need to be addressed in future research. First, the field detection was limited to six boreholes, which may not fully reflect the spatial heterogeneity of overburden failure in the entire mining area. Increasing the number of boreholes in the eastern erosion thinning zone of the mine field can improve the representativeness of the results. Second, the numerical simulation does not consider the time-dependent deformation of the rock mass (e.g., creep), which may underestimate the long-term settlement of the 4-4 coal seam floor. Introducing a creep model (e.g., Burgers model) in subsequent simulations can better predict the long-term stability of upward mining.

Future research can also focus on two aspects: (1) the evolution law of overburden fractures under the combined action of upward mining of the 4-4 coal seam and residual mining disturbance of the 5-2 coal seam to clarify the interaction mechanism between the two mining processes; (2) the optimization of support parameters for the 4-4 coal seam roadway, combining in situ monitoring (e.g., borehole stress gauge) and numerical simulation to propose a support scheme suitable for fractured rock mass; (3) the Mohr–Coulomb (M-C) model is a significant simplification for simulating rock mass behavior, especially in the goaf where fractured rock undergoes large strains and bulking. However, the M-C model may not fully capture the complex, strain-softening behavior of the caved and fractured zones.

Based on the integrated multi-criteria analysis of the stress environment (

Section 4.5), settlement continuity (

Section 4.3 and

Section 4.4), and rock mass integrity (

Section 3.3), a comprehensive evaluation for the optimal layout of the 4-4 coal seam roadway can be conducted. Although the rock quality (RQD) is poorest in the middle of the goaf, this area benefits from a favorable low-stress environment (0.78–1.76 MPa) and minimal settlement gradients (per-meter settlement change rate of 0.003 m/m). In contrast, the area above the coal pillars, while having better rock integrity, is subjected to significant stress concentration (up to 4.10 MPa) and higher settlement change rates. The zone 0–40 m from the pillar edge exhibits the most severe differential settlement and angular deformation, making it the least favorable. Therefore, the middle of the 5-2 coal seam goaf is recommended as the optimal location for the 4-4 coal seam gateway. If layout over the pillar area is unavoidable, enhanced support measures must be implemented to counteract the higher stress levels.

In conclusion, the research results provide a basis for the upward mining design of the 4-4 coal seam in Yujialiang Coal Mine and have important reference value for similar shallow-buried, thin-bedrock coal mines. The results can guide subsequent research and engineering practice, promoting the safe and efficient development of coal resources.

6. Conclusions

Through analysis, the movement law of the overlying rock layers after the mining of the 5-2 coal seam and the influence characteristics on the 4-4 coal seam were obtained. The specific conclusions are as follows:

(1) This study drilled six boreholes in the goafs of Panels 1 and 2 of the 5-2 coal seam to determine the development height of the overlying “two zones” (caving zone and fracture zone) and the condition of the 4-4 coal seam. Boreholes YBK1 and YBK4 were drilled in the coal pillars within the goaf; boreholes YBK2 and YBK5 were arranged at the position 15 m away from the remaining coal pillars in the goaf; boreholes YBK3 and YBK6 were arranged in the middle of the goaf.

(2) After the mining disturbance of the 5-2 coal seam, the overall strength of the 4-4 coal seam and its surrounding rock has decreased. The strength reduction rate for the 4-4 coal seam and the underlying rock strata (0–20 m depth) is 7.25% at 15 m from the goaf’s pillar edge and 25.49% at the goaf center, relative to the strata overlying the coal pillars.

(3) Comprehensive analysis shows that after the mining of the 5-2 coal seam, the development height of the fractured zone in the goaf ranges from 116.25 m to 129.92 m, and the height of the caving zone ranges from 9.32 m to 21.56 m. The 4-4 coal seam is located in the fractured zone after the mining of the 5-2 coal seam and 15.99 m to 22.88 m above the caving zone.

(4) The stress distribution characteristics of the 4-4 coal seam are affected by the mining of the 5-2 coal seam. Within the goaf range of the 5-2 coal seam, the 4-4 coal seam is in a pressure-relief zone, while above the remaining coal pillars of the 5-2 coal seam, the stress of the 4-4 coal seam increases. According to the numerical simulation results, after the mining of the 5-2 coal seam, the maximum vertical stress at the floor of the overlying 4-4 coal seam corresponding to the remaining coal pillars is 4.10 MPa, and the maximum vertical stress at the floor of the overlying 4-4 coal seam corresponding to the goaf is the smallest at 1.76 MPa. From the perspective of stress environment, the overall stress environment at the goaf is better than that at the coal pillar.

(5) A comprehensive evaluation, considering stress distribution, settlement gradient, and rock integrity, conclusively identifies the middle of the 5-2 coal seam goaf as the optimal and recommended location for laying out the 4-4 coal seam mining gateway. This positioning ensures a lower stress environment and superior deformation continuity, which are critical for long-term roadway stability.