The Effect of Heat Treatment on the Abrasive Wear Resistance of Boron-Alloyed Armor Steel Welded Joints

Abstract

1. Introduction

2. Materials and Methods

- Double normalization: 900 °C, 2 × 30 min, air cooling;

- Quenching: 930 °C, 20 min, water;

- Tempering: 100 °C, 5 h, air cooling.

- kb—relative abrasion resistance coefficient;

- Zw—weight loss of reference samples in [g];

- Zb—weight loss of the tested material in [g];

- Nw—number of roller revolutions during testing of the reference sample;

- Nb—number of roller revolutions during testing of the sample;

- ρw, ρb—density of the reference sample material and the tested material [g/cm3].

3. Results

3.1. Metallographic Analysis

3.2. Abrasive Wear Resistance Tests

4. Discussion

5. Conclusions

- The welded joint in the as-welded condition is characterized by a dendritic microstructure dominated by Widmanstätten ferrite, acicular ferrite, and allotriomorphic ferrite, with bainite and pearlite occurring only locally. The hardness of the weld metal ranges from 210 to 240 HV, corresponding to approximately 45% of the base material hardness (503 HV), which results in the lowest abrasive wear resistance (kb = 0.98 ± 0.01).

- In the normalized condition, the microstructure is refined and consists mainly of bainite and tempered martensite with carbide precipitates along the prior austenite grain boundaries. The hardness of the weld metal is approximately 217 HV, and that of the base material is about 410 HV. Despite the lower hardness compared to the as-welded state, the abrasive wear resistance increased (kb = 1.00 ± 0.02 for the weld metal and 1.10 ± 0.02 for the base material), which can be attributed to the microstructural homogenization achieved through normalization.

- After the application of comprehensive post-weld heat treatment, a uniform martensitic microstructure was obtained throughout all zones of the joint, with fresh martensite observed in the weld metal. The hardness of the weld metal increased to 370–390 HV, while the base material retained its original hardness of 503 HV. The abrasive wear resistance coefficient reached kb = 1.08 ± 0.01, representing an improvement of approximately 55% compared to the as-welded state.

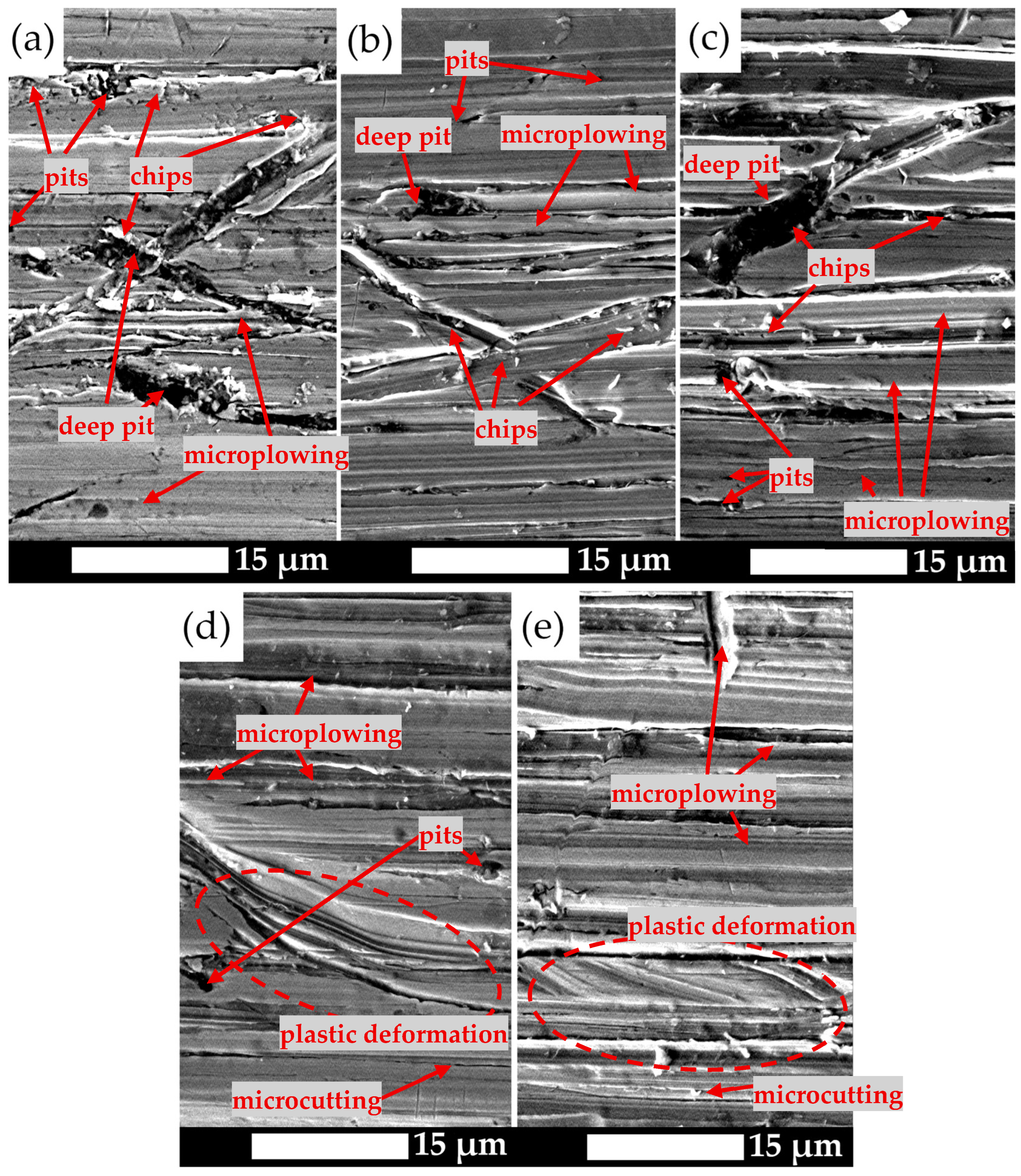

- Surface examinations after abrasive wear testing revealed that, in the as-welded and normalized states, deep grooves, pits, and local material detachments predominated. Following the post-weld heat treatment, the surface was characterized by shallow, parallel scratches and traces of plastic deformation, indicating a shift in the dominant wear mechanisms towards microscratching and microplowing.

- The roughness parameter analysis confirmed a distinct differentiation of surface topography depending on the applied heat treatment condition. The highest values of all evaluated parameters were recorded for the as-welded joint, resulting from the presence of deep cavities and pits caused by the intensive penetration of abrasive particles. The application of post-weld heat treatment led to a clear surface smoothing effect, as reflected by the reduction in the ratio of depth-related parameters. Among the analyzed parameters, Ra and Rq demonstrated the strongest correlation with abrasive wear resistance, indicating their high prognostic relevance.

- Depth-related parameters, particularly their mutual relationship, can serve as sensitive indicators of the prevailing wear micromechanisms and the tribological response of materials. The analysis of the Rv/Rp ratio revealed that in the normalized state, wear processes are dominated by the formation of deep pits (Rv/Rp > 1), while after the post-weld heat treatment, their occurrence is significantly reduced, with wear mechanisms shifting towards microplowing and microscratching (Rv/Rp < 1).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Frydman, S.; Konat, Ł.; Pękalski, G. Structure and Hardness Changes in Welded Joints of Hardox Steels. Arch. Civ. Mech. Eng. 2008, 8, 15–27. [Google Scholar] [CrossRef]

- Baskutis, S.; Baskutiene, J.; Dragašius, E.; Kavaliauskiene, L.; Keršiene, N.; Kusyi, Y.; Stupnytskyy, V. Influence of Additives on the Mechanical Characteristics of Hardox 450 Steel Welds. Materials 2023, 16, 5593. [Google Scholar] [CrossRef] [PubMed]

- Konat, Ł.; Zemlik, M.; Jasiński, R.; Grygier, D. Austenite Grain Growth Analysis in a Welded Joint of High-Strength Martensitic Abrasion-Resistant Steel Hardox 450. Materials 2021, 14, 2850. [Google Scholar] [CrossRef]

- Białobrzeska, B.; Konat, Ł.; Jasiński, R. The Influence of Austenite Grain Size on the Mechanical Properties of Low-Alloy Steel with Boron. Metals 2017, 7, 26. [Google Scholar] [CrossRef]

- Zuo, Z.; Haowei, M.; Yarigarravesh, M.; Assari, A.H.; Tayyebi, M.; Tayebi, M.; Hamawandi, B. Microstructure, Fractography, and Mechanical Properties of Hardox 500 Steel TIG-Welded Joints Using Different Filler Weld Wires. Materials 2022, 15, 8196. [Google Scholar] [CrossRef]

- Teker, T.; Gencdogan, D. Heat Affected Zone and Weld Metal Analysis of HARDOX 450 and Ferritic Stainless Steel Double Sided TIG-Joints. Mater. Test. 2021, 63, 923–928. [Google Scholar] [CrossRef]

- Gupta, A.; Sharma, V.; Kumar, P.; Thakur, A. Investigating the Effect of Ferritic Filler Materials on the Mechanical and Metallurgical Properties of Hardox 400 Steel Welded Joints. Mater. Today Proc. 2021, 39, 1640–1646. [Google Scholar] [CrossRef]

- Prochenka, P.; Janiszewski, J.; Kucewicz, M. Crash Response of Laser-Welded Energy Absorbers Made of Docol 1000DP and Docol 1200M Steels. Materials 2021, 14, 2808. [Google Scholar] [CrossRef] [PubMed]

- Turichin, G.; Kuznetsov, M.; Klimova-Korsmik, O.; Sklyar, M.; Zhitenev, A.; Kurakin, A.; Pozdnyakov, A. Laser-Arc Hybrid Welding of Ultra-High Strength Steels: Influence of Weld Metal Composition on Microstructure and Mechanical Properties. Procedia CIRP 2018, 74, 752–756. [Google Scholar] [CrossRef]

- Konat, Ł. Structural Aspects of Execution and Thermal Treatment of Welded Joints of Hardox Extreme Steel. Metals 2019, 9, 915. [Google Scholar] [CrossRef]

- Konat, Ł. Technological, Microstructural and Strength Aspects of Welding and Post-Weld Heat Treatment of Martensitic, Wear-Resistant Hardox 600 Steel. Materials 2021, 14, 4541. [Google Scholar] [CrossRef]

- Valtonen, K.; Keltamäki, K.; Kuokkala, V.-T. High-Stress Abrasion of Wear Resistant Steels in the Cutting Edges of Loader Buckets. Tribol. Int. 2018, 119, 707–720. [Google Scholar] [CrossRef]

- Barnes, N.; Joseph, T.; Mendez, P.F. Issues Associated with Welding and Surfacing of Large Mobile Mining Equipment for Use in Oil Sands Applications. Sci. Technol. Weld. Join. 2015, 20, 483–493. [Google Scholar] [CrossRef]

- Gáspár, M. Effect of Welding Heat Input on Simulated HAZ Areas in S960QL High Strength Steel. Metals 2019, 9, 1226. [Google Scholar] [CrossRef]

- Lee, H.W.; Yoo, K.J.; Tran, M.T.; Moon, I.Y.; Oh, Y.-S.; Kang, S.-H.; Kim, D.-K. Effect of Quenching-Tempering Post-Weld Heat Treatment on the Microstructure and Mechanical Properties of Laser-Arc Hybrid-Welded Boron Steel. Materials 2019, 12, 2862. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Peer, A.; Abke, T.; Kimchi, M.; Zhang, W. Subcritical Heat Affected Zone Softening in Hot-Stamped Boron Steel during Resistance Spot Welding. Mater. Des. 2018, 155, 170–184. [Google Scholar] [CrossRef]

- Bramowicz, M.; Kulesza, S.; Lewalski, P.; Szatkowski, J. Structural Studies of Welds in Wear-Resistant Steels. Acta Phys. Pol. A 2016, 130, 963–965. [Google Scholar] [CrossRef]

- Krawczyk, R.; Słania, J.; Golański, G.; Zieliński, A. Evaluation of the Properties and Microstructure of Thick-Walled Welded Joint of Wear Resistant Materials. Materials 2022, 15, 7009. [Google Scholar] [CrossRef] [PubMed]

- Uzunali, U.Y.; Cuvalcı, H.; Atmaca, B.; Demir, S.; Özkaya, S. Mechanical Properties of Quenched and Tempered Steel Welds. Mater. Test. 2022, 64, 1662–1674. [Google Scholar] [CrossRef]

- Silva, A.P.; Węgrzyn, T.; Szymczak, T.; Szczucka-Lasota, B.; Łazarz, B. Hardox 450 Weld in Microstructural and Mechanical Approaches after Welding at Micro-Jet Cooling. Materials 2022, 15, 7118. [Google Scholar] [CrossRef]

- Valtonen, K.; Ojala, N.; Haiko, O.; Kuokkala, V.-T. Comparison of Various High-Stress Wear Conditions and Wear Performance of Martensitic Steels. Wear 2019, 426–427, 3–13. [Google Scholar] [CrossRef]

- Mondal, J.; Das, K.; Das, S. An Investigation of Mechanical Property and Sliding Wear Behaviour of 400 HV Grade Martensitic Steels. Wear 2020, 458–459, 203436. [Google Scholar] [CrossRef]

- Jankauskas, V.; Žunda, A.; Katinas, A.; Tučkutė, S. Wear Study of Bulk Cargo Vehicle Body Materials Used to Transport Dolomite. Coatings 2025, 15, 227. [Google Scholar] [CrossRef]

- Katinas, E.; Jankauskas, V.; Kazak, N.; Michailov, V. Improving Abrasive Wear Resistance for Steel Hardox 400 by Electro-Spark Deposition. J. Frict. Wear 2019, 40, 100–106. [Google Scholar] [CrossRef]

- Haiko, O.; Javaheri, V.; Valtonen, K.; Kaijalainen, A.; Hannula, J.; Kömi, J. Effect of Prior Austenite Grain Size on the Abrasive Wear Resistance of Ultra-High Strength Martensitic Steels. Wear 2020, 454–455, 203336. [Google Scholar] [CrossRef]

- Mukhamedov, A.A. Strength and Wear Resistance in Relation to the Austenite Grain Size and Fine Structure of the Steel. Met. Sci. Heat Treat. 1968, 10, 526–528. [Google Scholar] [CrossRef]

- Rojacz, H.; Katsich, C.; Kirchgaßner, M.; Kirchmayer, R.; Badisch, E. Impact-Abrasive Wear of Martensitic Steels and Complex Iron-Based Hardfacing Alloys. Wear 2022, 492–493, 204183. [Google Scholar] [CrossRef]

- Ratia, V.; Rojacz, H.; Terva, J.; Valtonen, K.; Badisch, E.; Kuokkala, V.-T. Effect of Multiple Impacts on the Deformation of Wear-Resistant Steels. Tribol. Lett. 2015, 57, 15. [Google Scholar] [CrossRef]

- Lindroos, M.; Valtonen, K.; Kemppainen, A.; Laukkanen, A.; Holmberg, K.; Kuokkala, V.-T. Wear Behavior and Work Hardening of High Strength Steels in High Stress Abrasion. Wear 2015, 322–323, 32–40. [Google Scholar] [CrossRef]

- Sundström, A.; Rendón, J.; Olsson, M. Wear Behaviour of Some Low Alloyed Steels under Combined Impact/Abrasion Conditions. Wear 2001, 250, 744–754. [Google Scholar] [CrossRef]

- Gahr, K.-H.Z. Wear by Hard Particles. Tribol. Int. 1998, 31, 587–596. [Google Scholar] [CrossRef]

- Jafari, A.; Dehghani, K.; Bahaaddini, K.; Abbasi Hataie, R. Experimental Comparison of Abrasive and Erosive Wear Characteristics of Four Wear-Resistant Steels. Wear 2018, 416–417, 14–26. [Google Scholar] [CrossRef]

- Ojala, N.; Valtonen, K.; Heino, V.; Kallio, M.; Aaltonen, J.; Siitonen, P.; Kuokkala, V.-T. Effects of Composition and Microstructure on the Abrasive Wear Performance of Quenched Wear-Resistant Steels. Wear 2014, 317, 225–232. [Google Scholar] [CrossRef]

- SSAB. High-Strength Steel Sheet, Plate, Coil, Tube, Profile; SSAB: Stockholm, Sweden, 2021. [Google Scholar]

- Tarasiuk, W.; Napiórkowski, J.; Ligier, K. Impact of Slip Speed on the Wear Intensity of 38GSA and Hardox 500 Steels. Q. Tribol. 2018, 280, 121–125. [Google Scholar] [CrossRef]

- Tarasiuk, W.; Napiórkowski, J.; Ligier, K.; Krupicz, B. Comparison of the Wear Resistance of Hardox 500 Steel and 20MnCr5. Q. Tribol. 2017, 273, 165–170. [Google Scholar] [CrossRef]

- EN 1011-2:2001; Welding—Recommendations for Welding of Metallic Materials—Part 2: Arc Welding of Ferritic Steels. European Committee for Standardization: Brussels, Belgium, 2001.

- EN ISO 16834-A:2025; Welding Consumables—Wire Electrodes, Wires, Rods and Deposits for Gas-Shielded Arc Welding of High-Strength Steels—Classification (System Based on Yield Strength + 47 J Impact Energy. ISO: Geneva, Switzerland, 2025.

- ESAB. Welding Consumables; ESAB: North Bethesda, MD, USA, 2012. [Google Scholar]

- EN ISO 6508-1:2016; Metallic Materials—Rockwell Hardness Test—Part 1: Test Method. ISO: Geneva, Switzerland, 2016.

- EN ISO 18265:2014; Metallic Materials—Conversion of Hardness Values. ISO: Geneva, Switzerland, 2014.

- ASTM E407-07(2015)e1; Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2023.

- GOST 23.208-79; Metallic Materials—Methods for Testing Wear Resistance Under Abrasive Conditions. Russian Technical Standard: Moscow, Russia, 1979.

- ISO 8486-2:1998; Abrasive Grains—Testing—Part 2: Determination of Bulk Density. ISO: Geneva, Switzerland, 1998.

- Hebda, M.; Wachal, M. Tribology; Scientific and Technical Publishing House: Warsaw, Poland, 1999. [Google Scholar]

- Zemlik, M.; Konat, Ł.; Białobrzeska, B.; Stachowicz, M.; Hanszke, J. The Influence of Grain Size on the Abrasive Wear Resistance of Hardox 500 Steel. Appl. Sci. 2024, 14, 11490. [Google Scholar] [CrossRef]

- Zemlik, M.; Konat, Ł.; Lemecha, M.; Ligier, K.; Napiórkowski, J. Tribological and Mechanical Aspects of the Welding and Post-Weld Heat Treatment of High Strength, Wear-Resistant Martensitic Boron Steel. J. Tribol. 2026, 148, 110271. [Google Scholar] [CrossRef]

- Krishnan, S.N.; Toppo, V.; Basak, A.; Ray, K.K. Wear Behaviour of a Steel Weld-Joint. Wear 2006, 260, 1285–1294. [Google Scholar] [CrossRef]

- Ligier, K.; Bramowicz, M.; Kulesza, S.; Lemecha, M.; Pszczółkowski, B. Use of the Ball-Cratering Method to Assess the Wear Resistance of a Welded Joint of XAR400 Steel. Materials 2023, 16, 4523. [Google Scholar] [CrossRef]

- Ligier, K.; Napiórkowski, J.; Lemecha, M. Assessment of Changes in Abrasive Wear Resistance of a Welded Joint of Low-Alloy Martensitic Steel Using Microabrasion Test. Materials 2024, 17, 2101. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Wang, Y.; Chen, Z.; Liu, H.; Wang, X. Study on Microstructure and Sliding Wear Behavior of Similar and Dissimilar Welded Joints Produced by Laser-Arc Hybrid Welding of Wear-Resistant Steels. Wear 2025, 562–563, 205643. [Google Scholar] [CrossRef]

- Roshanghias, A.; Barzegari, M.; Kokabi, A.H.; Mirazizi, M. The Effects of Functionally Graded Material Structure on Wear Resistance and Toughness of Repaired Weldments. Mater. Des. 2011, 32, 892–899. [Google Scholar] [CrossRef]

- Jiang, W.J.; Liu, C.; He, C.G.; Guo, J.; Wang, W.J.; Liu, Q.Y. Investigation on Impact Wear and Damage Mechanism of Railway Rail Weld Joint and Rail Materials. Wear 2017, 376–377, 1938–1946. [Google Scholar] [CrossRef]

| C | Mn | Cr | Ni | Mo | V | Cu | CEV | CET | # |

|---|---|---|---|---|---|---|---|---|---|

| Selected Chemical Element [wt.%] | [%] | [mm] | |||||||

| 0.29 | 0.86 | 0.49 | 1.03 | 0.37 | 0.0230 | 0.23 | 0.69 | 0.47 | 6.0 |

| CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15; CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40 | |||||||||

| Si | P | S | Al | Ti | Nb | Co | B | # |

|---|---|---|---|---|---|---|---|---|

| Selected Chemical Element [wt.%] | [mm] | |||||||

| 0.23 | 0.007 | - | 0.044 | 0.002 | - | 0.008 | 0.008 | 6.0 |

| Filler Material | C | Mn | Si | Cr | Ni | Mo | Rp0.2 | Rm | A | KV−40 |

|---|---|---|---|---|---|---|---|---|---|---|

| Chemical Composition [% wt.] | [MPa] | [%] | [J] | |||||||

| OK AristoRod™ 89 | 0.10 | 1.90 | 0.80 | 0.30 | 2.10 | 0.65 | 920 | 960 | 18 | 55 |

| C | Mn | Cr | Ni | Mo | V | Cu | CEV | CET | |

|---|---|---|---|---|---|---|---|---|---|

| Selected Chemical Element [wt.%] | [%] | ||||||||

| 0.12 | 0.83 | 0.36 | 2.02 | 0.56 | 0.007 | 0.088 | 0.59 | 0.33 | |

| CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Cu + Ni)/15; CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40 | |||||||||

| Si | P | S | Al | Ti | Nb | Co | B |

|---|---|---|---|---|---|---|---|

| Selected Chemical Element [wt.%] | |||||||

| 0.420 | 0.008 | 0.002 | 0.003 | 0.005 | - | 0.002 | 0.0014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zemlik, M.; Białobrzeska, B.; Stachowicz, M.; Konat, Ł. The Effect of Heat Treatment on the Abrasive Wear Resistance of Boron-Alloyed Armor Steel Welded Joints. Appl. Sci. 2025, 15, 12860. https://doi.org/10.3390/app152412860

Zemlik M, Białobrzeska B, Stachowicz M, Konat Ł. The Effect of Heat Treatment on the Abrasive Wear Resistance of Boron-Alloyed Armor Steel Welded Joints. Applied Sciences. 2025; 15(24):12860. https://doi.org/10.3390/app152412860

Chicago/Turabian StyleZemlik, Martyna, Beata Białobrzeska, Mateusz Stachowicz, and Łukasz Konat. 2025. "The Effect of Heat Treatment on the Abrasive Wear Resistance of Boron-Alloyed Armor Steel Welded Joints" Applied Sciences 15, no. 24: 12860. https://doi.org/10.3390/app152412860

APA StyleZemlik, M., Białobrzeska, B., Stachowicz, M., & Konat, Ł. (2025). The Effect of Heat Treatment on the Abrasive Wear Resistance of Boron-Alloyed Armor Steel Welded Joints. Applied Sciences, 15(24), 12860. https://doi.org/10.3390/app152412860