Research on the Short-Term Compressive Creep Behavior of the Bamboo Scrimber Based on Different Zener Models

Abstract

1. Introduction

2. Materials and Methods

2.1. The Test Material

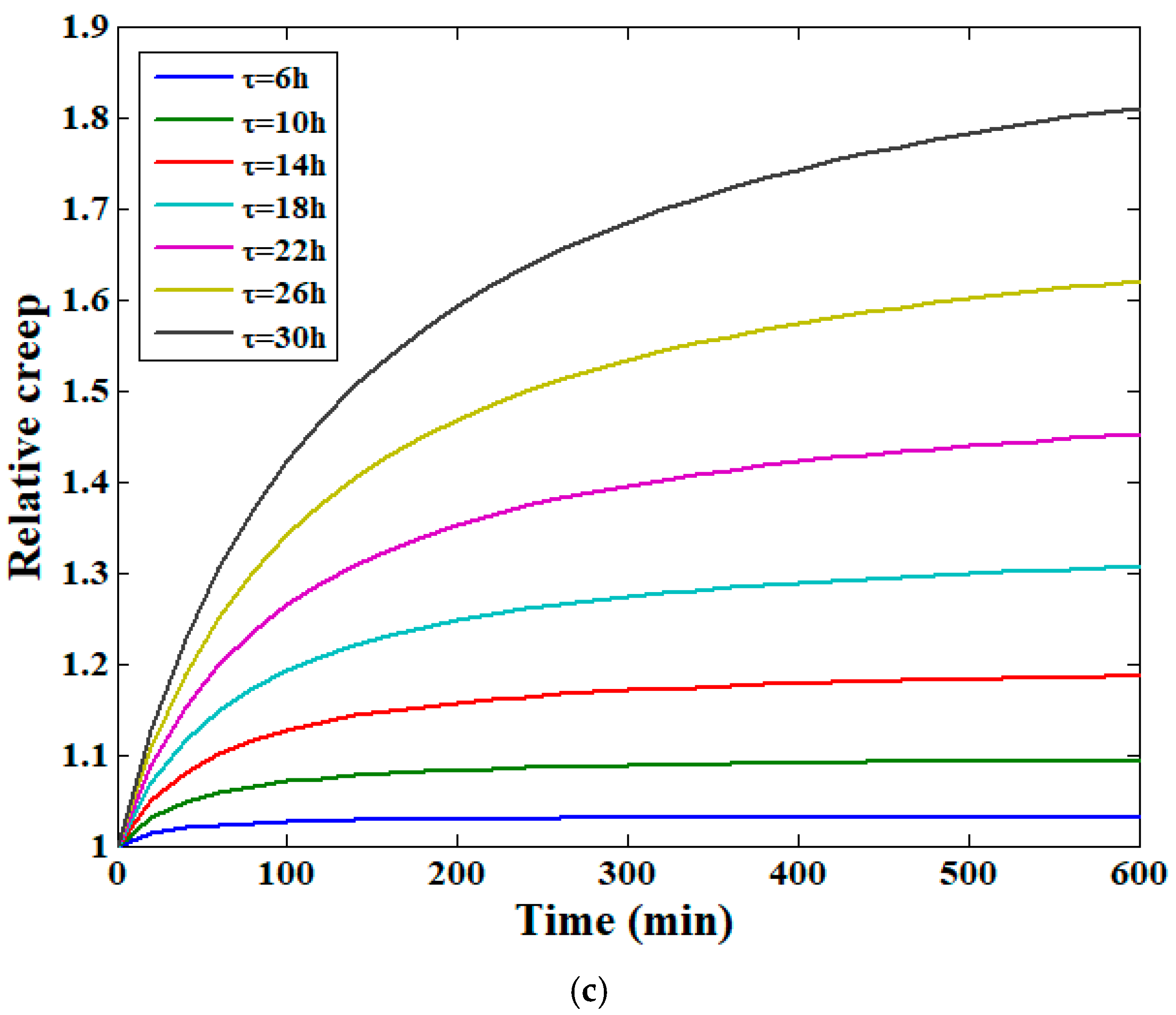

2.2. The Experiment Method

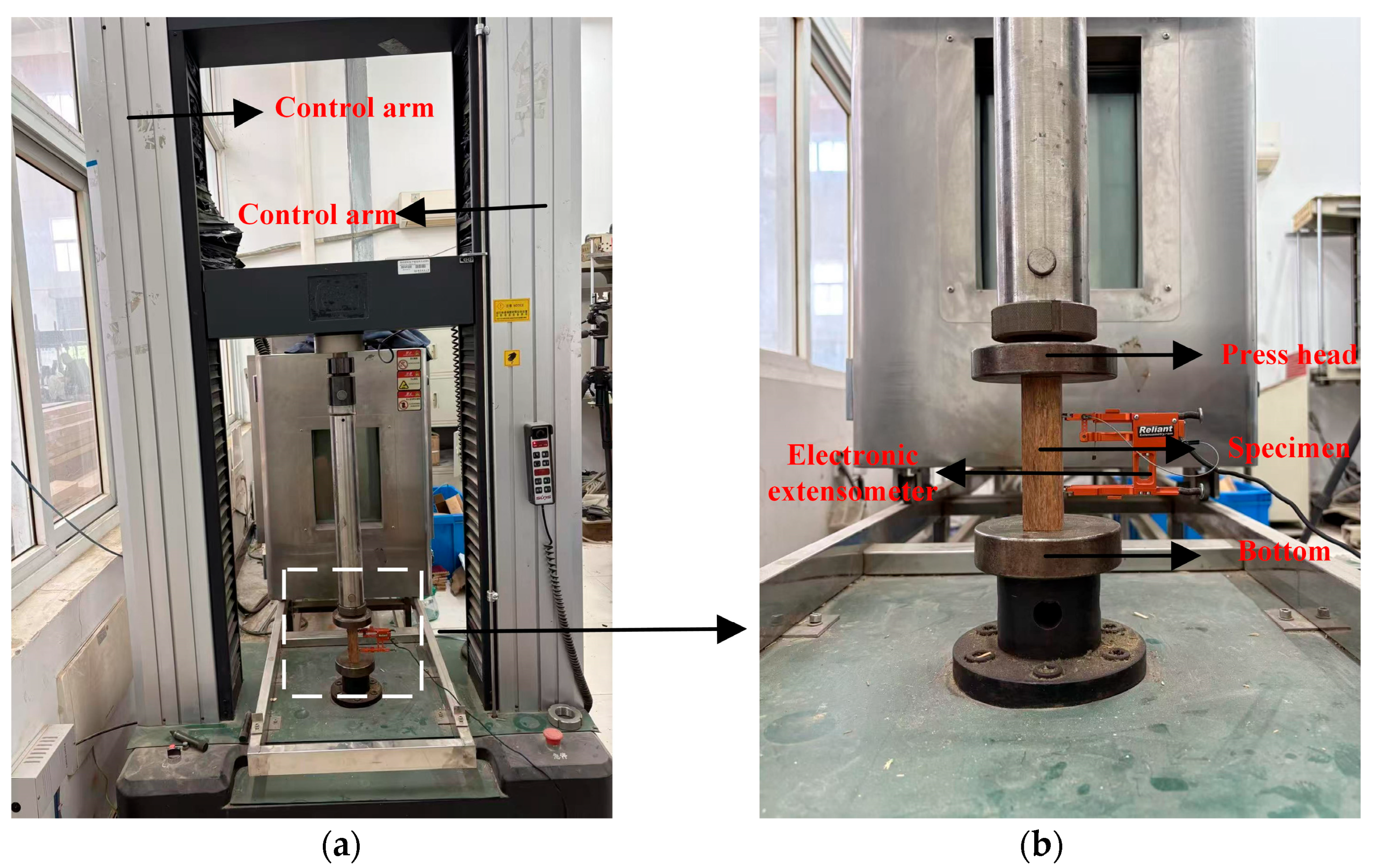

2.3. The MD-Defined Zener Model

3. Results

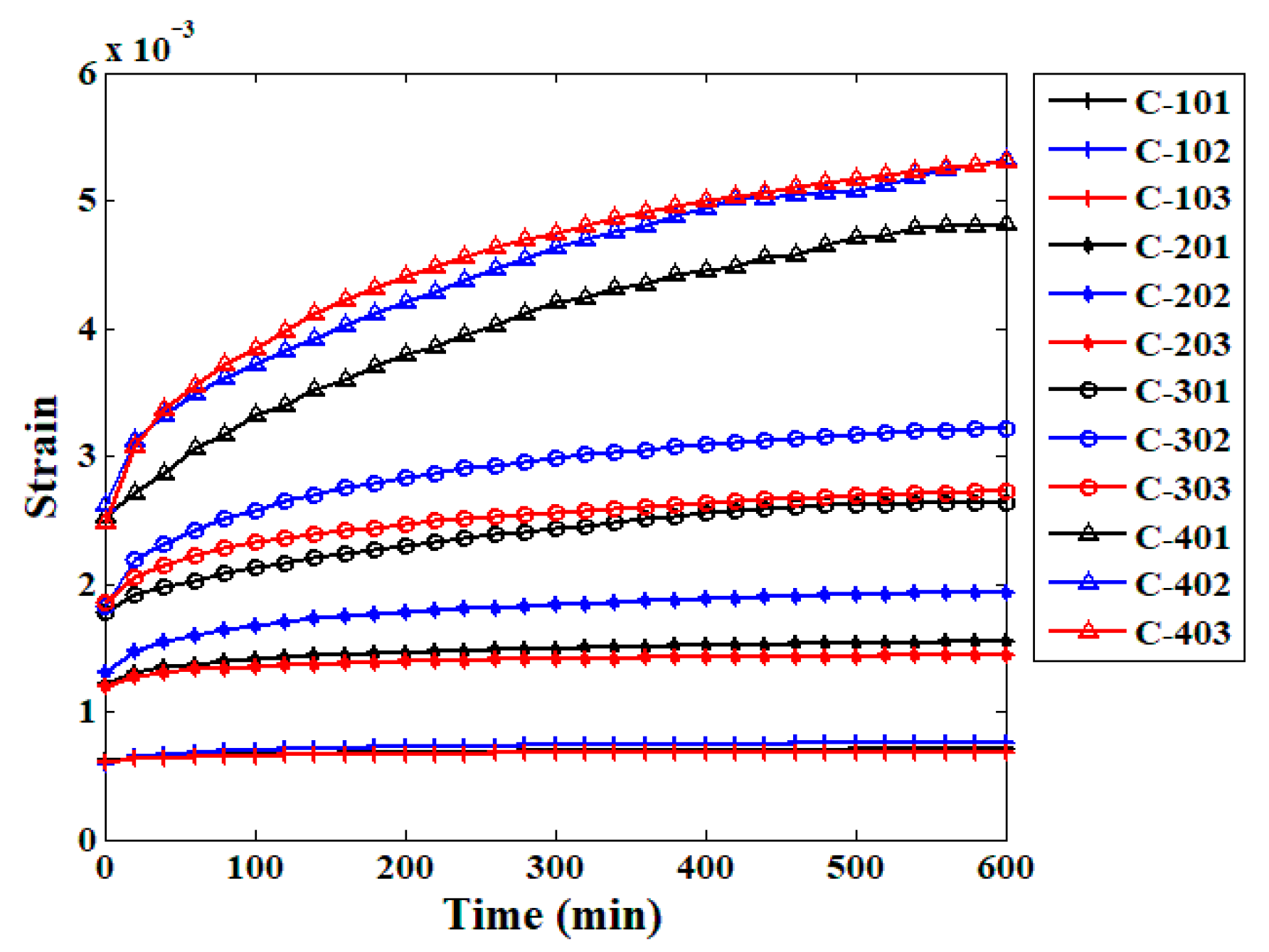

3.1. The Creep Test Results

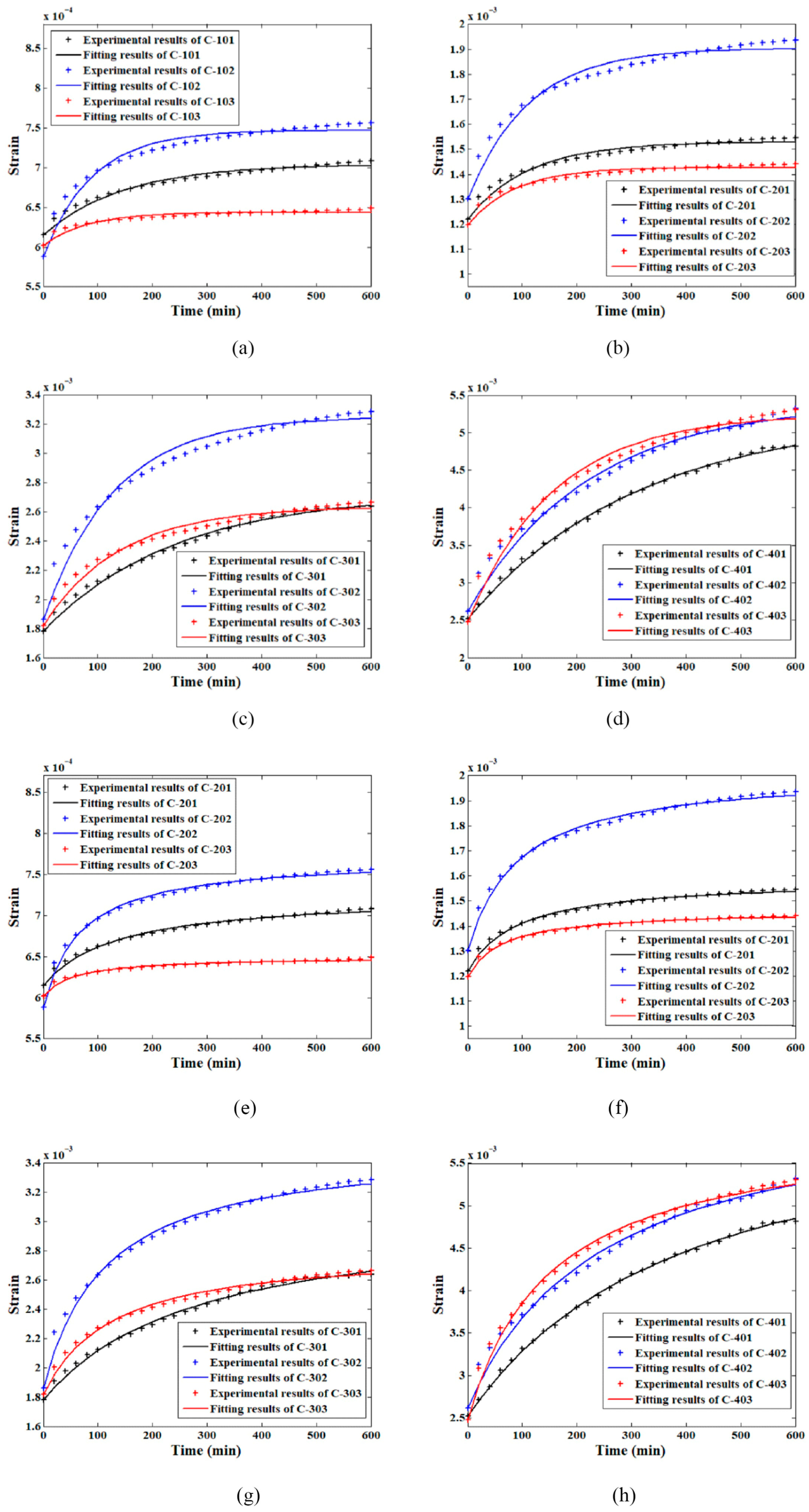

3.2. The Model Validation Results

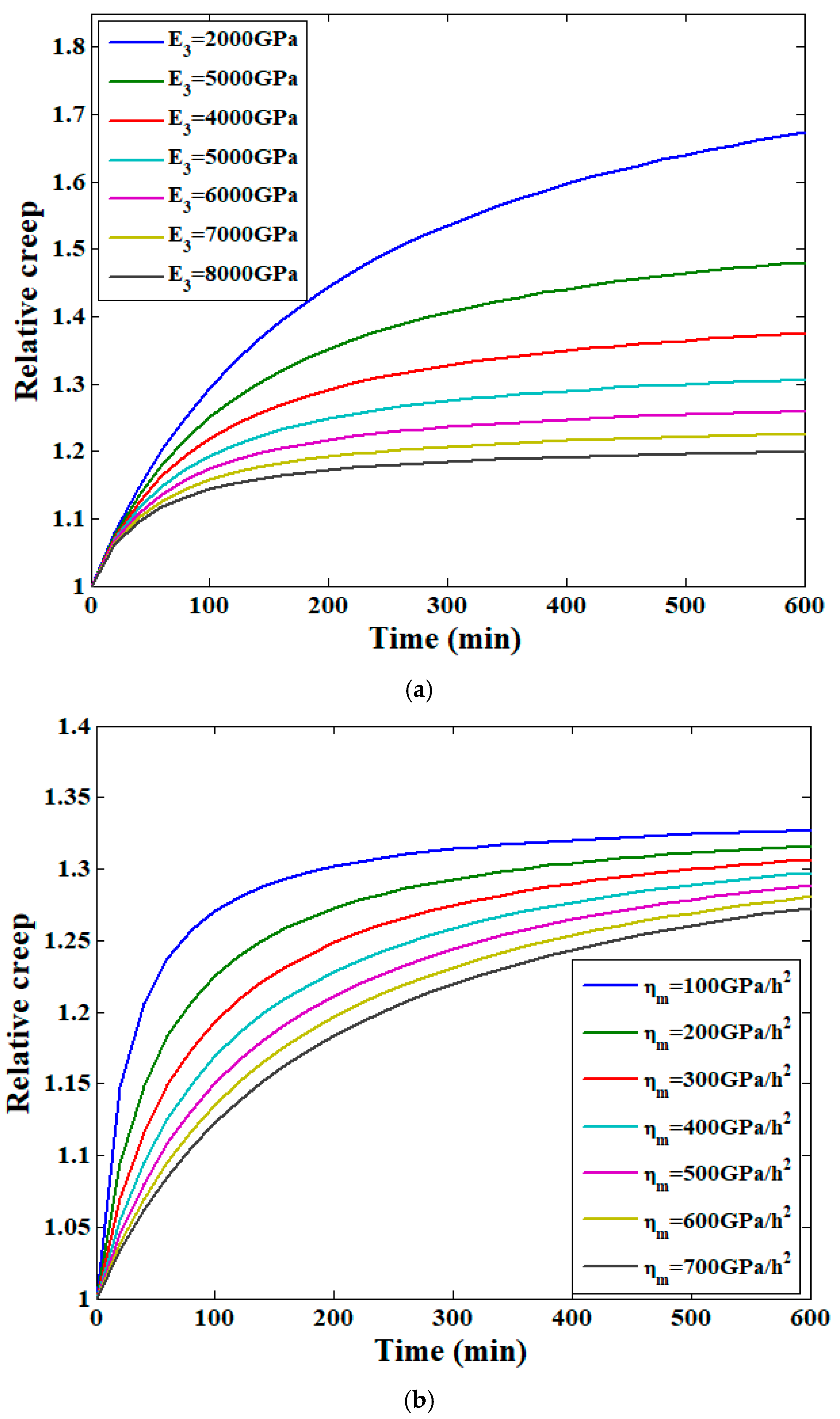

3.3. Model Parameter Analysis Results

3.4. Discussion

4. Conclusions

- (1)

- Obvious creep behavior can be observed when the static compressive load is applied on the specimen for hours, and the stress level has a significant effect on the growth rate of compressive creep strain. The larger the stress level acted on the material, the later the change point of the creep strain curve appeared.

- (2)

- The original Zener model might introduce some errors in the bamboo scrimber compressive creep strain evolution process, especially for the compressive creep at a relatively low stress level. In this paper, the memory content of the definition of a Zener model for creep-type behavior can be used to accurately simulate the evolution curves for the compositional creep strain of the bamboo scrimber under various levels of stress, indicating its merit for adoption of the model in practice.

- (3)

- As for the main parameters in the proposed Zener model, the influence of the duration time on the speed of the creep strain growth is positive and the most significant. Both the viscosity coefficient and elastic modulus have a differential detrimental impact on creep strain growth speed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, H.; Qiu, Z.; Wu, G.; Wei, D.; Lorenzo, R.; Yuan, C.; Zhang, H. Compression behaviors of parallel bamboo strand lumber under static loading. J. Renew. Mater. 2019, 7, 583–600. [Google Scholar] [CrossRef]

- Tan, C.; Li, H.; Wei, D.; Lorenzo, R.; Yuan, C. Mechanical performance of parallel bamboo strand lumber columns under axial compression: Experimental and numerical investigation. Constr. Build. Mater. 2020, 231, 117168. [Google Scholar] [CrossRef]

- Shangguan, W.; Gong, Y.; Zhao, R.; Ren, H. Effects of heat treatment on the pproperties of bamboo scrimber. J. Wood Sci. 2016, 62, 383–391. [Google Scholar] [CrossRef]

- Huang, D.; Sheng, B.; Shen, Y.; Chui, Y.H. An analytical solution for doublecantilever beam based on elastic-plastic bilinear cohesive law: Analysis for mode I fracture of fibrous composites. Eng. Fract. Mech. 2018, 193, 66–76. [Google Scholar] [CrossRef]

- Huang, D.; Bian, Y.; Zhou, A.; Sheng, B. Experimental study on stress–strain relationships and failure mechanisms of parallel strand bamboo made from phyllostachys. Constr. Build. Mater. 2015, 77, 130–138. [Google Scholar] [CrossRef]

- Li, H.; Zhang, H.; Qiu, Z.; Su, J.; Wei, D.; Lorenzo, R.; Yuan, C.; Liu, H.; Zhou, C. Mechanical properties and stress strain relationship models for bamboo scrimber. J. Renew. Mater. 2020, 8, 13–27. [Google Scholar] [CrossRef]

- Li, H.; Yang, D.; Chen, B.; Mohrmann, S.; Lorenzo, B.; Zhou, K.; Shen, F. Experimental and numerical study on the flexural performance of reinforced laminated bamboo lumber beams with prestressed GFRP bars. Sustain. Struct. 2025, 5, 000070. [Google Scholar] [CrossRef]

- Li, H.; Zhou, W.; Jian, B.; Shen, X.; Lorenzo, R.; Ashraf, M. Experimental evaluation on the axial crushing performance of BFRP-bamboo winding composite hollow components. Sustain. Struct. 2024, 4, 000053. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, Z.; Sun, Z.; Yan, Y.; Cai, Z.; Zhang, X. Impact performance of two bamboo-based laminated composites. Eur. J. Wood Wood Prod. 2017, 75, 711–718. [Google Scholar] [CrossRef]

- Cui, Z.; Tang, S.; Xu, M.; Huang, D.; Zhang, Z. Experimental and theoretical study on mechanical performance of dowel joints with inserted steel plates constructed of laminated bamboo lumber. J. Build. Eng. 2022, 61, 105320. [Google Scholar] [CrossRef]

- Cui, Z.; Huang, D.; Huang, Z.; Zhuang, M.L.; Xu, M. Experimental investigation and calculation method for the bearing capability of bolt steel-to-laminated bamboo connections under the coupling of bending moment and shear force. J. Build. Eng. 2022, 59, 105126. [Google Scholar] [CrossRef]

- Chen, G.; Yu, Y.; Li, X.; He, B. Mechanical behavior of laminated bamboo lumber for structural application: An experimental investigation. Eur. Wood Wood Prod. 2020, 78, 53–63. [Google Scholar] [CrossRef]

- Ma, X.; Li, H.; Zehui, J.; Fei, B. Flexural fatigue behavior of bamboo-based products. Holzforsch. Int. J. Biol. Chem. Phys. Technol. Wood 2020, 74, 1053–1060. [Google Scholar] [CrossRef]

- Zhao, K.; Wei, Y.; Chen, S.; Hang, C.; Zhao, K. Experimental investigation of the long-term behavior of reconstituted bamboo beams with various loading levels. J. Build. Eng. 2020, 36, 102107. [Google Scholar] [CrossRef]

- Wei, Y.; Zhao, K.; Hang, C.; Chen, S.; Ding, M. Experimental Study on the Creep Behavior of Recombinant Bamboo. J. Renew. Mater. 2020, 8, 251–273. [Google Scholar] [CrossRef]

- Chen, S.; Wei, Y.; Zhao, K.; Hang, C.; Zhao, K. Creep performance and prediction model of bamboo scrimber under compression. Acta Mater. Compos. Sin. 2021, 38, 944–952. [Google Scholar]

- Ma, X.; Luo, Z.; Ji, C.H.; Cai, L.; Fei, B. Flexural creep behaviors of bamboo subjected to different gradient variation directions and relative humidity. Ind. Crops Prod. 2022, 179, 114679. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, D.; Sheng, B.; Wang, W. Prediction of the long-term flexural behavior of glued laminated bamboo using accelerated creep test. Wood Sci. Technol. 2023, 57, 1139–1155. [Google Scholar] [CrossRef]

- Luo, X.; Wang, X.; Ren, H.; Zhang, S.; Zhong, Y. Long-term mechanical properties of bamboo scrimber. Constr. Build. Mater. 2022, 338, 127659. [Google Scholar] [CrossRef]

- Zahed, M.; Dimitri, R.; Tornabene, F.; Ashrafi, H. Modeling and analysis of time-dependent creep and relaxation behavior of polymeric materials using fractional derivative three-component standard viscoelastic models and nanoindentation experimental data. Arch. Civ. Mech. Eng. 2025, 25, 111. [Google Scholar] [CrossRef]

- ASTMD 143-94; Standard Test Methods for Small Clear Specimens of Timber. ASTM International: West Conshohocken, PA, USA, 2023.

- GB T1041-2008; Plastics—Determination of Compressive Properties. National Standard of the People’s Republic of China: Beijing, China. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT1041-2008 (accessed on 30 November 2025).

- ASTMD D2990-17; Standard Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics. ASTM International: West Conshohocken, PA, USA, 2017.

- Liu, Y.; Jia, W.; Su, X.; Ma, H.; Xiao, Z. Assessing the Creep Performance of Full-scale Bamboo Scrimber Columns. Bioresources 2021, 16, 3691–3705. [Google Scholar] [CrossRef]

- Wen, T.; Zhou, Z.; Zhang, Y.; Xu, X. Advances and Challenges in the Battery Thermal Management Systems of Electric Vehicles. Materials 2025, 18, 4718. [Google Scholar] [CrossRef]

- Zhao, K.; Wei, Y.; Wang, Z.; Jin, H.; Li, H. Study on Short-Term Compressive Creep Properties of Reconstituted Bamboo Considering Temperature Effects. Acta Mater. Compos. Sin. 2025, 44, 1–12. [Google Scholar]

- Sun, S.; Miao, Z.; Gong, X. Prediction of the compressive creep strain of the recombinant bamboo based on a variable-order fractional derivative defined Maxwell model. Structures 2025, 80, 109950. [Google Scholar] [CrossRef]

- Wang, J.L.; Li, H.F. Surpassing the fractional derivative: Concept of the memory-dependent derivative. Comput. Math. Appl. 2011, 62, 1562–1567. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, D.; Wang, Z.; Cong, Y.; Wang, X. Constructing a three-dimensional creep model for rocks and soils based on memory-dependent derivatives: A theoretical and experimental study. Comput. Geotech. 2023, 159, 105366. [Google Scholar] [CrossRef]

| Specimen Number | Stress Level/% | Stress/MPa |

|---|---|---|

| C-101, C-102, C-103 | 10 | 7.85 |

| C-201, C-202, C-203 | 20 | 15.7 |

| C-301, C-302, C-303 | 30 | 23.55 |

| C-401, C-402, C-403 | 40 | 31.4 |

| Specimen Number | Value | Mean Value |

|---|---|---|

| C-101 | 0.9785 | 0.9584 |

| C-102 | 0.9655 | |

| C-103 | 0.9312 | |

| C-201 | 0.9718 | 0.9695 |

| C-202 | 0.9716 | |

| C-203 | 0.9651 | |

| C-301 | 0.9942 | 0.9831 |

| C-302 | 0.9772 | |

| C-303 | 0.9779 | |

| C-401 | 0.9986 | 0.9906 |

| C-402 | 0.9876 | |

| C-403 | 0.9855 |

| Specimen Number | Value | Mean Value |

|---|---|---|

| C-101 | 0.9916 | 0.9919 |

| C-102 | 0.9926 | |

| C-103 | 0.9917 | |

| C-201 | 0.9921 | 0.9924 |

| C-202 | 0.9924 | |

| C-203 | 0.9926 | |

| C-301 | 0.9956 | 0.9937 |

| C-302 | 0.9911 | |

| C-303 | 0.9945 | |

| C-401 | 0.9991 | 0.9948 |

| C-402 | 0.9941 | |

| C-403 | 0.9911 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Sun, S.; Gong, X.; Fu, J. Research on the Short-Term Compressive Creep Behavior of the Bamboo Scrimber Based on Different Zener Models. Appl. Sci. 2025, 15, 12745. https://doi.org/10.3390/app152312745

Wang S, Sun S, Gong X, Fu J. Research on the Short-Term Compressive Creep Behavior of the Bamboo Scrimber Based on Different Zener Models. Applied Sciences. 2025; 15(23):12745. https://doi.org/10.3390/app152312745

Chicago/Turabian StyleWang, Shuqin, Songsong Sun, Xiaolin Gong, and Jiahong Fu. 2025. "Research on the Short-Term Compressive Creep Behavior of the Bamboo Scrimber Based on Different Zener Models" Applied Sciences 15, no. 23: 12745. https://doi.org/10.3390/app152312745

APA StyleWang, S., Sun, S., Gong, X., & Fu, J. (2025). Research on the Short-Term Compressive Creep Behavior of the Bamboo Scrimber Based on Different Zener Models. Applied Sciences, 15(23), 12745. https://doi.org/10.3390/app152312745