A Pumpkin Seed Oil and Orange Peel Flour Gelled Emulsion as a Novel Fat Replacer in English Breakfast Sausages: Effects on Composition, Quality, and Sensory Acceptance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Gelled Emulsion Elaboration

2.3. Elaboration of English Breakfast Sausages

2.4. Chemical Composition

2.5. Fatty Acid Composition, Health Indices, and Nutritional Parameters

2.6. Physico-Chemical Analysis

2.7. Cooking Loss

2.8. Texture Analysis

2.9. Lipid Oxidation

2.10. Sensory Assessment

2.11. Statistical Analysis

3. Results and Discussion

3.1. Proximal Composition of English Breakfast Sausages

3.2. Lipid Profile and Nutritional Indices of English Breakfast Sausages

3.3. Physico-Chemical Properties of English Breakfast Sausages

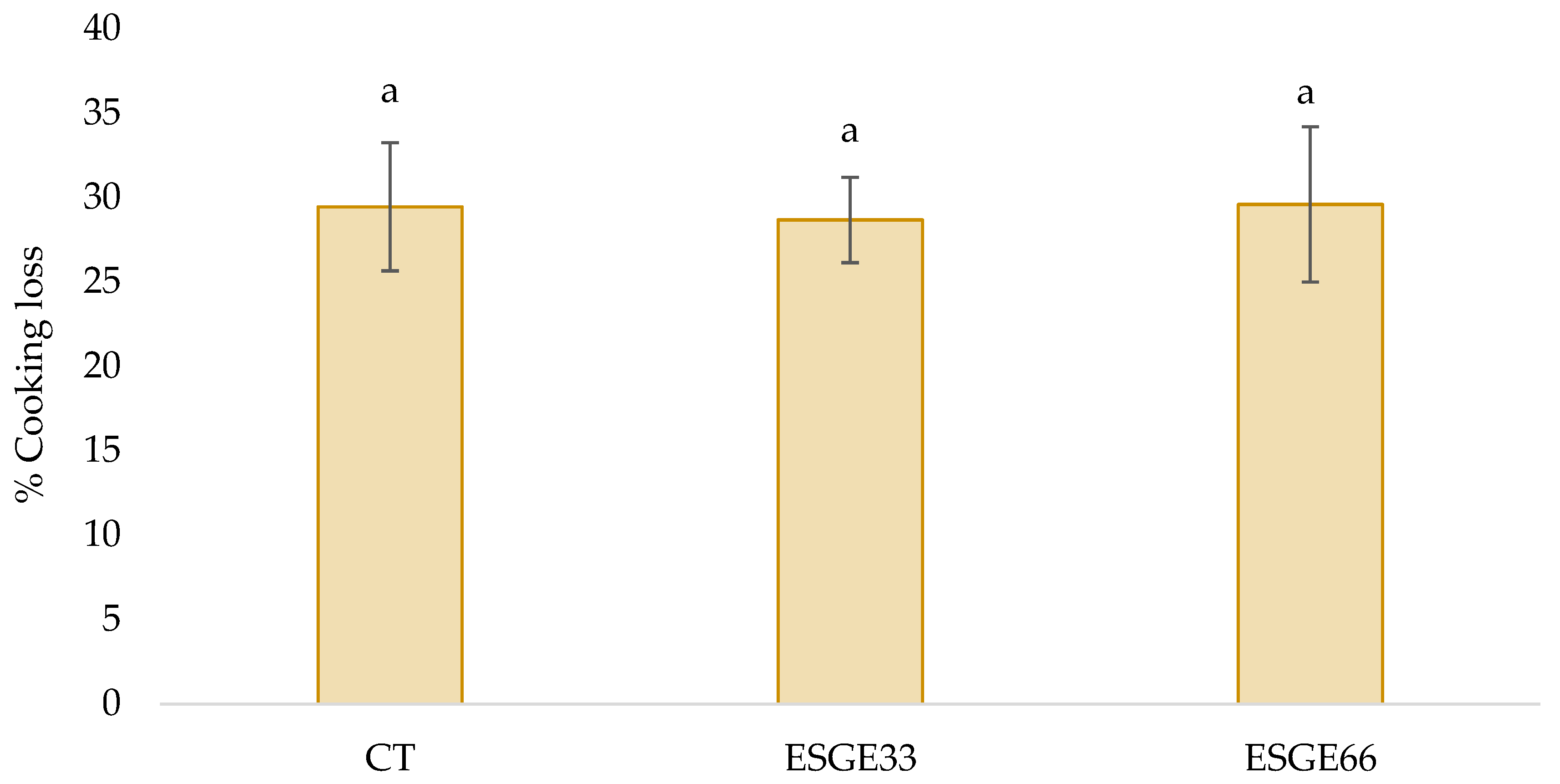

3.4. Cooking Loss of English Breakfast Sausages

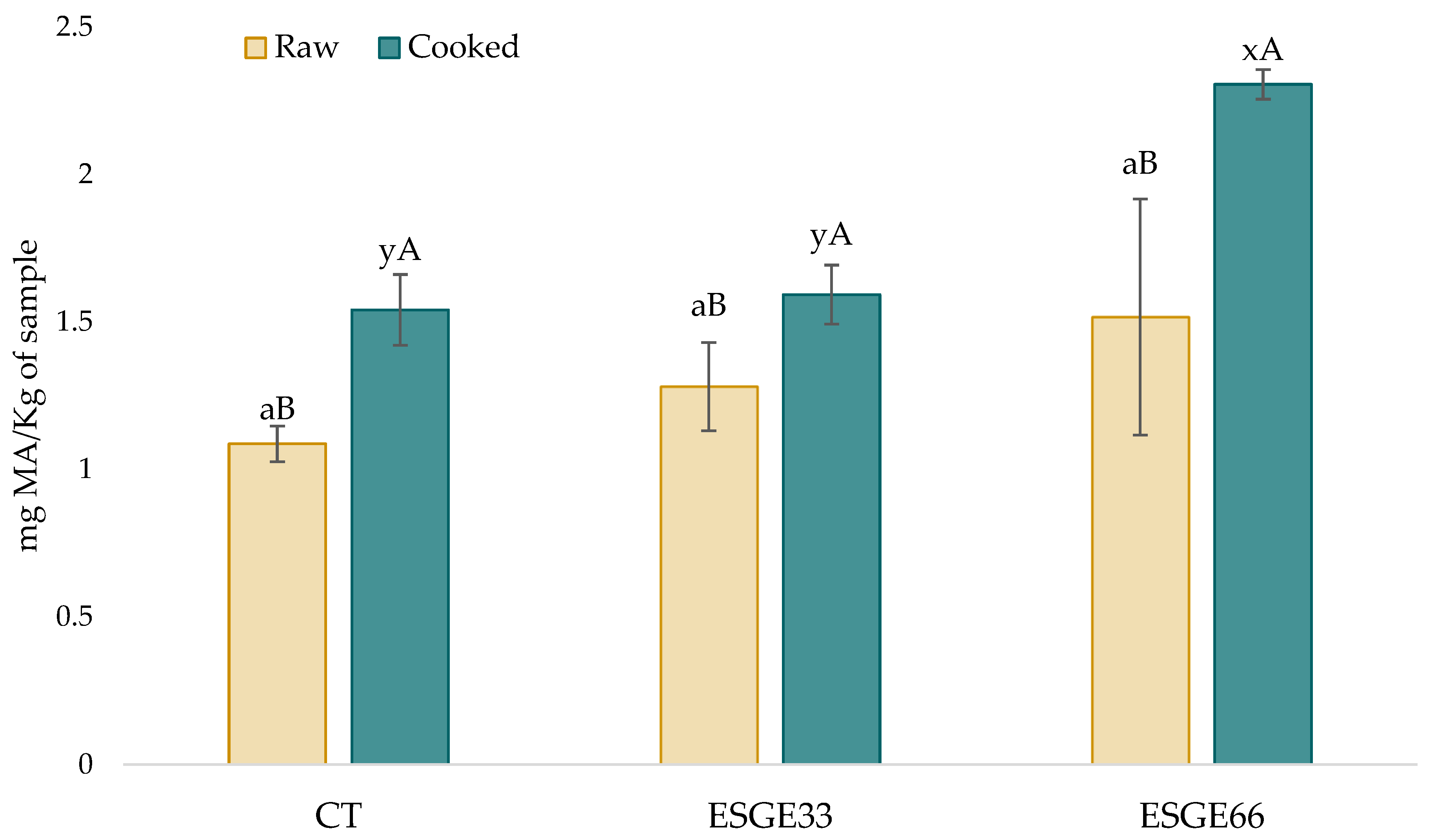

3.5. Lipid Oxidation of English Breakfast Sausages

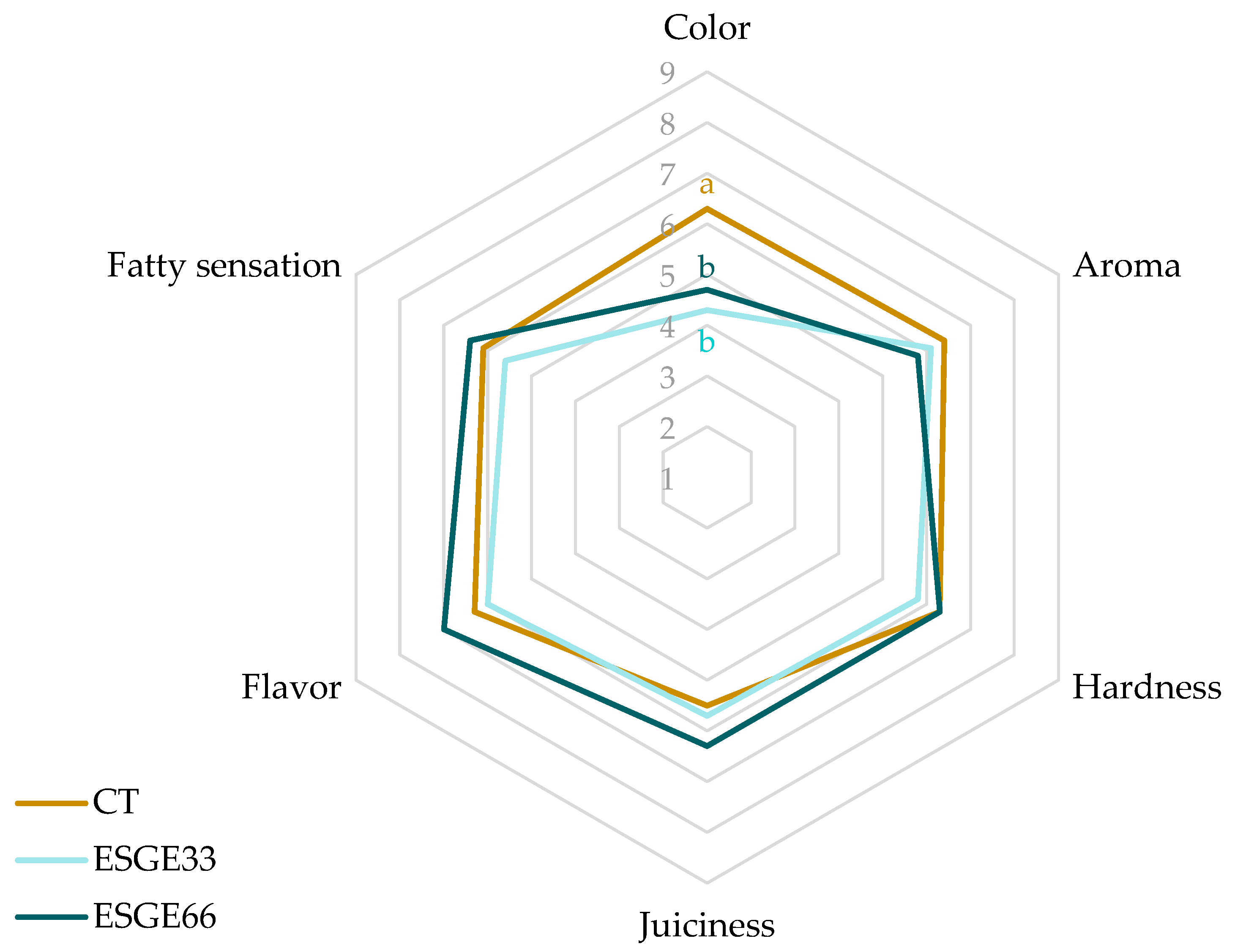

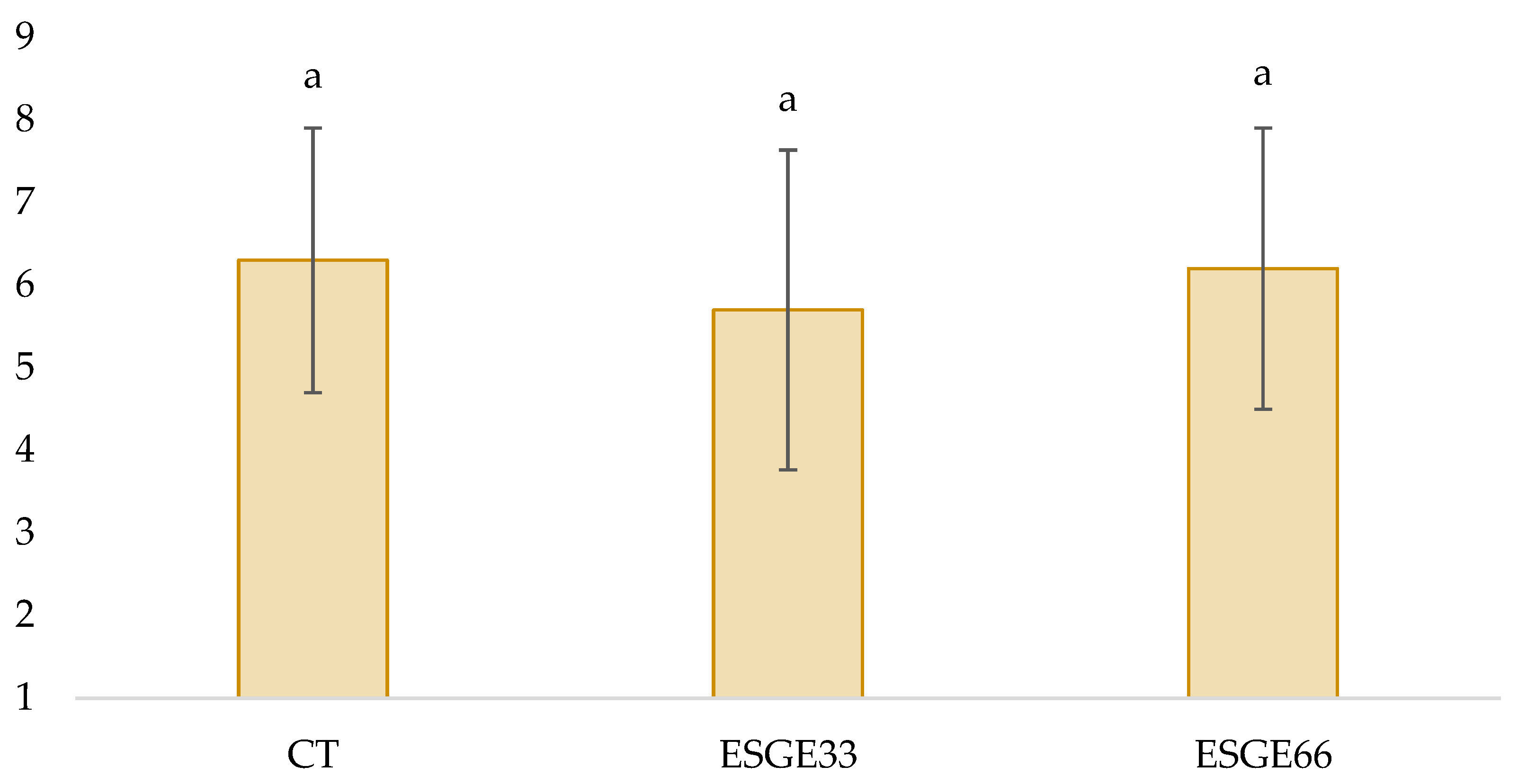

3.6. Sensorial Analysis of English Breakfast Sausages

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vasilopoulou, D.; Markey, O.; Kliem, K.E.; Fagan, C.C.; Grandison, A.S.; Humphries, D.J.; Todd, S.; Jackson, K.G.; Givens, D.I.; Lovegrove, J.A. Reformulation Initiative for Partial Replacement of Saturated with Unsaturated Fats in Dairy Foods Attenuates the Increase in LDL Cholesterol and Improves Flow-Mediated Dilatation Compared with Conventional Dairy: The Randomized, Controlled Replacement of Saturated Fat in Dairy on Total Cholesterol (RESET) Study. Am. J. Clin. Nutr. 2020, 111, 739–748. [Google Scholar]

- Mensink, R.P.; Zock, P.L.; Kester, A.D.; Katan, M.B. Effects of Dietary Fatty Acids and Carbohydrates on the Ratio of Serum Total to HDL Cholesterol and on Serum Lipids and Apolipoproteins: A Meta-Analysis of 60 Controlled Trials. Am. J. Clin. Nutr. 2003, 77, 1146–1155. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Y.; Huang, K.; Li, S.; Cao, H.; Guan, X. Application of Fat Replacers in Low-Fat Starch-Based Foods: Type, Formulation and Action Mechanism on Food Quality. Int. J. Biol. Macromol. 2025, 309, 142855. [Google Scholar] [CrossRef]

- Jia-Wei, K.; Fu, M.; Asyrul-Izhar, A.B.; Suryaningsih, L.; Utama, D.T.; Alirezalu, K.; Ismail-Fitry, M.R. The Role of Plant Oils/Lipids as Innovative Fat Replacers in Various Food Products: A Review. Appl. Food Res. 2025, 5, 101010. [Google Scholar] [CrossRef]

- AESAN (Spanish Food Safety and Nutrition Agency). Results of the Final Assessment of Compliance with the Agreements of the Collaboration Plan for the Improvement of Food and Beverage Composition and Other Measures 2020. Study of the Composition of Food and Beverages in the Manufacturing and Distribution Sectors and Analysis of Menu Offerings and Food Products in Catering and Vending Establishments in 2021; Ministry of Consumer Affairs: Madid, Spain, 2022; Available online: https://www.aesan.gob.es/AECOSAN/docs/documentos/nutricion/EN_DOSSIER_PLAN_2020.pdf (accessed on 19 September 2025).

- WHO (World Health Organization). Obesity and Overweight. 2025. Available online: https://www.who.int/news-room/fact-sheets/detail/obesity-and-overweight (accessed on 20 September 2025).

- Eurostat. Overweight and Obesity—BMI Statistics. Statistics Explained. 2024. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Overweight_and_obesity_-_BMI_statistics (accessed on 20 September 2025).

- Parmar, V.; Sharma, R.; Sharma, S.; Singh, B. Recent Advances in Fabrication of Food Grade Oleogels: Structuring Methods, Functional Properties and Technical Feasibility in Food Products. J. Food Mesur. Charact. 2022, 16, 4687–4702. [Google Scholar] [CrossRef]

- Martínez-Martí, J.; Sanz, T.; Hernando, I.; Quiles, A. Emulsion Gels Structured with Clementine Pomace: A Clean-Label Strategy for Fat Reduction. Food Hydrocoll. 2025, 167, 111471. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, L.; Zhang, Y.; Li, H.; Zhao, D.; Cao, J.; Liu, X. Application of Emulsion Gels as Fat Substitutes in Meat Products. Foods 2022, 11, 1950. [Google Scholar] [CrossRef] [PubMed]

- Sanli, I.; Ozkan, G.; Şahin-Yeşilçubuk, N. Green Extractions of Bioactive Compounds from Citrus Peels and Their Applications in the Food Industry. Food Res. Int. 2025, 212, 116352. [Google Scholar] [CrossRef]

- Revathi, V.; Bora, S.; Afzia, N.; Ghosh, T. Orange peel composition, biopolymer extraction, and applications in paper and packaging sector: A review. Sustain. Chem. Pharm. 2025, 43, 101908. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Fernández-López, J.; Ferreira, I.; Leite, A.; Vasconcelos, L.; Domínguez, R.; Pérez-Álvarez, J.Á.; Teixeira, A.; Viuda-Martos, M. Alheiras with Animal Fat Replacement: Application of a Gelled Emulsion Based on Hemp Oil (Cannabis sativa L.) and Buckwheat. Eur. Food Res. Technol. 2023, 249, 2273–2285. [Google Scholar] [CrossRef]

- Zhou, L.; Ali, I.; Goh, B.H.; Fu, J.Y.; Manickam, S.; Tang, S.Y.; Shen, Q. Enhancing Meat Emulsion Gels with Soy Protein Fibril and Red Palm Oil Pickering Emulsions: The Role of Emulsification Techniques in Chicken Fat Substitution. LWT 2025, 216, 117348. [Google Scholar] [CrossRef]

- Hegab, D.Y.; El-Sharkawy, N.I.; Moustafa, G.G.; Abd-Elhakim, Y.M.; Said, E.N.; Metwally, M.M.M.; Saber, T.M. Pumpkin Seeds Oil Rescues Colchicine-Induced Neurotoxicity in Rats via Modifying Oxidative Stress, DNA Damage, and Immunoexpression of BDNF and GFAP. Tissue Cell 2025, 94, 102792. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, J.; Guo, J. A Sustainable Approach in Pumpkin Seed Oil Processing Line: Recent Advances in Pumpkin Seed Oil and Oil Processing by-Products. Food Chem. X 2025, 26, 102259. [Google Scholar] [CrossRef]

- Zaki, A.H.; Saleh Gazwi, H.S.; Hamed, M.M.; Galal, S.M.; Almehmadi, A.M.; Almuraee, A.A.; Alqurashi, A.F.; Yassien, E.E. The Synergistic Potential of Orange Peel Extract: A Comprehensive Investigation into Its Phenolic Composition, Antioxidant, Antimicrobial, and Functional Fortification Properties in Yogurt. Food Chem. X 2024, 22, 101458. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists AOAC. Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Gaithersburgs, MD, USA, 2010. [Google Scholar]

- Folch, J.; Lees, M.; Stanley, G.H.S. A Simple Method for The Isolation and Purification of Total Lipides from Animal Tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Pellegrini, M.; Lucas-Gonzalez, R.; Sayas-Barberá, E.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Bioaccessibility of Phenolic Compounds and Antioxidant Capacity of Chia (Salvia hispanica L.) Seeds. Plant Foods Hum. Nutr. 2018, 73, 47–53. [Google Scholar] [CrossRef]

- Chen, J.; Liu, H. Nutritional Indices for Assessing Fatty Acids: A Mini-Review. Int. J. Mol. Sci. 2020, 21, 5695. [Google Scholar] [CrossRef] [PubMed]

- Claus, J.R. Methods for the Objective Measurement of Meat Product Texture. Meat Conf. Proc. 1995, 48, 96–101. [Google Scholar]

- Rosmini, M.R.; Perlo, F.; Pérez-Alvarez, J.A.; Pagán-Moreno, M.J.; Gago-Gago, A.; López-Santoveña, F.; Aranda-Catalá, V. TBA Test by an Extractive Method Applied to ‘Paté’. Meat Sci. 1996, 42, 103–110. [Google Scholar] [CrossRef]

- Han, M.; Bertram, H.C. Designing Healthier Comminuted Meat Products: Effect of Dietary Fibers on Water Distribution and Texture of a Fat-Reduced Meat Model System. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef]

- Zhuang, X.; Wang, L.; Jiang, X.; Chen, Y.; Zhou, G. Insight into the Mechanism of Myofibrillar Protein Gel Influenced by Konjac Glucomannan: Moisture Stability and Phase Separation Behavior. Food Chem. 2021, 339, 127941. [Google Scholar] [CrossRef]

- Ma, F.; Wang, W.-Y.; Wang, W.; Cai, K.-Z.; Shang, Y.-F.; Chen, C.-G.; Xu, B.-C. Effects of Water-Immersion Cooling Temperatures on the Moisture Retention of Sodium-Reduced Pork Sausages. J. Food Sci. Technol. 2020, 57, 2516–2523. [Google Scholar] [CrossRef]

- Song, Y.; Huang, F.; Li, X.; Han, D.; Zhang, C. Effects of Different Wet Heating Methods on the Water Distribution, Microstructure and Protein Denaturation of Pork Steaks. Int. J. Food Sci. Technol. 2021, 56, 4627–4638. [Google Scholar] [CrossRef]

- Zampouni, K.; Filippou, A.; Papadimitriou, K.; Katsanidis, E. Evaluation of bigel systems as potential substitutes to partially replace pork backfat in semi-dry sausages. Meat Sci. 2024, 208, 109392. [Google Scholar] [CrossRef] [PubMed]

- Badar, I.H.; Li, Y.; Liu, H.; Chen, Q.; Liu, Q.; Kong, B. Effect of vegetable oil hydrogel emulsion as a fat substitute on the physicochemical properties, fatty acid profile, and color stability of modified atmospheric packaged buffalo burgers. Meat Sci. 2023, 199, 109143. [Google Scholar] [CrossRef]

- Botella-Martinez, C.; Lucas-González, R.; Lorenzo, J.M.; Santos, E.M.; Rosmini, M.; Sepúlveda, N.; Teixeira, A.; Sayas-Barberá, E.; Pérez-Alvarez, J.A.; Fernandez-Lopez, J.; et al. Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers. Foods 2021, 10, 2706. [Google Scholar] [CrossRef]

- Thangavelu, K.P.; Tiwari, B.; Kerry, J.P.; Álvarez, C. A Comparative Study on the Effect of Ultrasound-Treated Apple Pomace and Coffee Silverskin Powders as Phosphate Replacers in Irish Breakfast Sausage Formulations. Foods 2022, 11, 2763. [Google Scholar] [CrossRef]

- Lee, C.-W.; Kim, T.-K.; Hwang, K.-E.; Kim, H.-W.; Kim, Y.-B.; Kim, C.-J.; Choi, Y.-S. Combined Effects of Wheat Sprout and Isolated Soy Protein on Quality Properties of Breakfast Sausage. Korean J. Food Sci. Anim. Resour. 2017, 37, 52–61. [Google Scholar] [CrossRef]

- Morin, L.A.; Temelli, F.; McMullen, L. Interactions between Meat Proteins and Barley (Hordeum Spp.) β-Glucan within a Reduced-Fat Breakfast Sausage System. Meat Sci. 2004, 68, 419–430. [Google Scholar] [CrossRef] [PubMed]

- Youssef, M.K.; Barbut, S. Physicochemical Effects of the Lipid Phase and Protein Level on Meat Emulsion Stability, Texture, and Microstructure. J. Food Sci. 2010, 75, 108–114. [Google Scholar] [CrossRef] [PubMed]

- Serdaroğlu, M.; Nacak, B.; Karabıyıkoğlu, M. Effects of Beef Fat Replacement with Gelled Emulsion Prepared with Olive Oil on Quality Parameters of Chicken Patties. Korean J. Food Sci. Anim. Resour. 2017, 37, 376–384. [Google Scholar] [CrossRef] [PubMed]

- Jimenez-Colmenero, F.; Salcedo-Sandoval, L.; Bou, R.; Cofrades, S.; Herrero, A.M.; Ruiz-Capillas, C. Novel Applications of Oil-Structuring Methods as a Strategy to Improve the Fat Content of Meat Products. Trends Food Sci. Tech. 2015, 44, 177–188. [Google Scholar] [CrossRef]

- Cîrstea, N.; Nour, V.; Boruzi, A.I. Effects of Pork Backfat Replacement with Emulsion Gels Formulated with a Mixture of Olive, Chia and Algae Oils on the Quality Attributes of Pork Patties. Foods 2023, 12, 519. [Google Scholar] [CrossRef]

- de Brito Sodré, L.W.; Rodrigues da Silva, L.; Marques da Silva, N.; Rech de Marins, A.; Ferreira de Campos, T.A.; Matiucci, M.A.; Baumgartner, M.; Santos Serpa, F.; de Souza Nunes, G.C.; Dariva, C.; et al. Impact of açaí oil and guar gum-based emulsion gel on goat burger quality: Technological, sensory, and fatty acid profile. Meat Sci. 2025, 225, 109823. [Google Scholar] [CrossRef]

- Heck, R.T.; Saldaña, E.; Lorenzo, J.M.; Correa, L.P.; Fagundes, M.B.; Cichoski, A.J.; de Menezes, C.R.; Wagner, R.; Campagnol, P.C.B. Hydrogelled Emulsion from Chia and Linseed Oils: A Promising Strategy to Produce Low-Fat Burgers with a Healthier Lipid Profile. Meat Sci. 2019, 156, 174–182. [Google Scholar] [CrossRef]

- Barros, J.C.; Munekata, P.E.S.; de Carvalho, F.A.L.; Domínguez, R.; Trindade, M.A.; Pateiro, M.; Lorenzo, J.M. Healthy Beef Burgers: Effect of Animal Fat Replacement by Algal and Wheat Germ Oil Emulsions. Meat Sci. 2021, 173, 108396. [Google Scholar] [CrossRef] [PubMed]

- Attia, Y.A.; Al Sagan, A.A.; Hussein, E.O.S.; Olal, M.J.; Ebeid, T.A.; Alhotan, R.A.; Qaid, M.M.; Bovera, F.; Shehta, H.A.; Tufarelli, V. Antioxidant Status, Lipid Metabolism, Egg Fatty Acids, and Nutritional Index of White-Egg Laying Hens Fed Flaxseed Cake. J. Poult. Sci. 2024, 61, 2024010. [Google Scholar] [CrossRef] [PubMed]

- Stamenić, T.; Todorović, V.; Petričević, M.; Keškić, T.; Cekić, B.; Stojiljković, N.; Stanišić, N. Linseed, Walnut, and Algal Oil Emulsion Gels as Fat Replacers in Chicken Frankfurters: Effects on Composition, Lipid Profile and Sensory Quality. Foods 2025, 14, 2677. [Google Scholar] [CrossRef]

- Idyryshev, B.; Nurgazezova, A.; Assirzhanova, Z.; Utegenova, A.; Amirkhanov, S.; Jumazhanova, M.; Baikadamova, A.; Dautova, A.; Spanova, A.; Serikova, A. Nutritional and Technological Benefits of Pine Nut Oil Emulsion Gel in Processed Meat Products. Foods 2025, 14, 2553. [Google Scholar] [CrossRef]

- Pietrasik, Z.; Soladoye, O.P. Use of Native Pea Starches as an Alternative to Modified Corn Starch in Low-Fat Bologna. Meat Sci. 2021, 171, 108283. [Google Scholar] [CrossRef]

- Martínez, J.A.; Melgosa, M.; Pérez, M.M.; Hita, E.; Negueruela, A.I. Note. Visual and Instrumental Color Evaluation in Red Wines. FST Int. 2001, 7, 439–444. [Google Scholar]

- Freire, M.; Cofrades, S.; Pérez-Jiménez, J.; Gómez-Estaca, J.; Jiménez-Colmenero, F.; Bou, R. Emulsion Gels Containing N-3 Fatty Acids and Condensed Tannins Designed as Functional Fat Replacers. Food Res. Int. 2018, 113, 465–473. [Google Scholar] [CrossRef]

- Martínez, E.; Pardo, J.E.; Álvarez-Ortí, M.; Rabadán, A.; Pardo-Giménez, A.; Alvarruiz, A. Substitution of Pork Fat by Emulsified Seed Oils in Fresh Deer Sausage (‘Chorizo’) and Its Impact on the Physical, Nutritional, and Sensory Properties. Foods 2023, 12, 828. [Google Scholar] [CrossRef] [PubMed]

- Badar, I.H.; Wang, Z.; Zhou, Y.; Guo, X.; Jaspal, M.H.; Kong, B.; Liu, H. Effect of flaxseed-derived diglyceride-based high internal phase Pickering emulsion on the quality characteristics of reformulated beef burgers. Meat Sci. 2024, 212, 109474. [Google Scholar] [CrossRef] [PubMed]

- Borela, V.L.; de Alencar, E.R.; Mendonça, M.A.; Han, H.; Raposo, A.; Ariza-Montes, A.; Araya-Castillo, L.; Zandonadi, R.P. Influence of Different Cooking Methods on Fillet Steak Physicochemical Characteristics. Int. J. Environ. Res. Public Health 2022, 19, 606. [Google Scholar] [CrossRef]

- Panagiotopoulou, E.; Moschakis, T.; Katsanidis, E. Sunflower Oil Organogels and Organogel-in-Water Emulsions (Part II): Implementation in Frankfurter Sausages. LWT 2016, 73, 351–356. [Google Scholar] [CrossRef]

- de Araujo, C.D.L.; da Costa, G.F.; de Oliveira, F.L.N.; Azerêdo, G.A. Elaboração de Salsichas de Frango Com Redução de Gordura e Adição de Inulina. Braz. J. Food Technol. 2021, 24, e2019334. [Google Scholar] [CrossRef]

- Choe, J.; Kim, H.-Y. Quality Characteristics of Reduced Fat Emulsion-Type Chicken Sausages Using Chicken Skin and Wheat Fiber Mixture as Fat Replacer. Poult. Sci. 2019, 98, 2662–2669. [Google Scholar] [CrossRef]

- Lima, D.M.; Rangel, A.; Urbano, S.; Mitzi, G.; Moreno, G.M. Lipid Oxidation and Lamb Meat Quality. Acta Vet. Bras. 2013, 7, 14–28. [Google Scholar]

- Niglio, S.; Razola-Díaz, M.C.; Waegeman, H.; Verardo, V. Food grade pilot scale strategy for non-thermal extraction and recovery of phenolic compounds from orange peels. LWT-Food Sci. Technol. 2024, 205, 116538. [Google Scholar] [CrossRef]

- Alonso-Vázquez, P.; Isola, A.; Sánchez-Arévalo, C.M.; Cuartas-Uribe, B.; Vincent-Vela, M.C.; Álvarez-Blanco, S. Concentration of phenolic compounds from an orange peel waste extract using a combination of ultrafiltration and forward osmosis. Separ. Purif. Technol. 2025, 360, 131228. [Google Scholar] [CrossRef]

- Ganiyu, O.; Olunbamigbe, O.O.; Ogunsuyi, O.B.; Aro, O.P.; Oyeleye, I.S.; Ademosun, A.O. Evaluating the nutrient composition and antioxidant properties of orange (Citrus sinensis) peels through Penicillium camemberti-based solid-substrate fermentation. Discov. Food 2024, 4, 114. [Google Scholar] [CrossRef]

- Heck, R.T.; Freitas Ferreira, D.; Bittencourt Fagundes, M.; Alves Dos Santos, B.; Cichoski, A.J.; Saldaña, E.; Lorenzo, J.M.; Ragagnin de Menezes, C.; Wagner, R.; Smanioto Barin, J.; et al. Jabuticaba peel extract obtained by microwave hydrodiffusion and gravity extraction: A green strategy to improve the oxidative and sensory stability of beef burgers produced with healthier oils. Meat Sci. 2020, 170, 108230. [Google Scholar] [CrossRef]

- Cîrstea, N.; Nour, V.; Corbu, A.R.; Muntean, C.; Codină, G.G. Reformulation of Bologna Sausage by Total Pork Backfat Replacement with an Emulsion Gel Based on Olive, Walnut, and Chia Oils, and Stabilized with Chitosan. Foods 2023, 12, 3455. [Google Scholar] [CrossRef]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Bohrer, B.; Munekata, P.E.S.; Pateiro, M.; Lorenzo, J.M. Recent Discoveries in the Field of Lipid Bio-Based Ingredients for Meat Processing. Molecules 2021, 26, 190. [Google Scholar] [CrossRef] [PubMed]

- Moghtadaei, M.; Soltanizadeh, N.; Goli, S.A.H.; Sharifimehr, S. Physicochemical Properties of Beef Burger after Partial Incorporation of Ethylcellulose Oleogel Instead of Animal Fat. J. Food Sci. Technol. 2021, 58, 4775–4784. [Google Scholar] [CrossRef] [PubMed]

- Alejandre, M.; Ansorena, D.; Calvo, M.I.; Cavero, R.Y.; Astiasarán, I. Influence of a Gel Emulsion Containing Microalgal Oil and a Blackthorn (Prunus spinosa L.) Branch Extract on the Antioxidant Capacity and Acceptability of Reduced-Fat Beef Patties. Meat Sci. 2019, 148, 219–222. [Google Scholar] [CrossRef]

| CT | ESGE33 | ESGE66 | |

|---|---|---|---|

| Pork meat | 588.00 | 588.00 | 588.00 |

| Pork backfat | 205.00 | 136.70 | 68.30 |

| PS-GE | 0 | 68.30 | 136.70 |

| Ice | 134.50 | 134.50 | 134.50 |

| Breadcrumbs | 57.50 | 57.50 | 57.50 |

| Tripolyphosphate | 0.50 | 0.50 | 0.5 |

| Salt | 7.16 | 7.16 | 7.16 |

| Yeast extract | 1.35 | 1.35 | 1.35 |

| White pepper | 1.04 | 1.04 | 1.04 |

| Mace | 0.94 | 0.94 | 0.94 |

| Nutmeg | 0.85 | 0.85 | 0.85 |

| Dill | 0.75 | 0.75 | 0.75 |

| Oregano | 0.75 | 0.75 | 0.75 |

| Potassium metabisulphite | 0.63 | 0.63 | 0.63 |

| Sweet paprika | 0.47 | 0.47 | 0.47 |

| Ginger | 0.38 | 0.38 | 0.38 |

| Sodium ascorbate | 0.19 | 0.19 | 0.19 |

| RAW | COOKED | |||||

|---|---|---|---|---|---|---|

| Sample | CT | ESGE33 | ESGE66 | CT | ESGE33 | ESGE66 |

| Fat | 13.44 ± 1.04 aA | 13.99 ± 1.47 aA | 12.49 ± 0.99 aA | 10.80 ± 1.00 xB | 8.78 ± 0.50 xyB | 6.87 ± 0.87 yB |

| Protein | 16.91 ± 0.14 aB | 16.08 ± 1.76 aB | 17.09 ± 1.02 aB | 26.60 ± 0.16 xA | 22.78 ± 0.74 yA | 23.17 ± 0.28 yA |

| Ash | 1.11 ± 0.58 aB | 0.79 ± 0.18 aB | 0.75 ± 0.11 aB | 2.04 ± 0.07 xA | 2.09 ± 0.09 xA | 2.22 ± 0.08 xA |

| Moisture | 64.36 ± 0.66 bA | 64.68 ± 0.28 bA | 66.73 ± 0.69 aA | 54.78 ± 0.19 xB | 55.83 ± 0.12 xB | 54.93 ± 1.13 xB |

| RAW | COOKED | |||||

|---|---|---|---|---|---|---|

| Fatty Acid | CT | ESGE33 | ESGE66 | CT | ESGE33 | ESGE66 |

| C16:0 | 23.33 ± 0.33 aA | 19.32 ± 0.95 bA | 16.44 ± 0.26 cB | 22.43 ± 0.89 xA | 20.78 ± 0.29 xyA | 18.96 ± 0.05 yA |

| C16:1 | 2.38 ± 0.13 aA | 1.58 ± 0.21 bB | 0.97 ± 0.07 aB | 2.30 ± 0.15 xA | 1.89 ± 0.04 xyA | 1.54 ± 0.00 yA |

| C18:0 | 12.23 ± 0.13 aA | 9.81 ± 0.98 bA | 7.91 ± 0.35 cB | 11.66 ± 0.33 xA | 10.31 ± 0.06 yA | 9.35 ± 0.01 zA |

| C18:1 | 45.56 ± 0.03 aA | 40.50 ± 1.73 bA | 36.75 ± 1.62 cB | 45.95 ± 0.50 xA | 42.64 ± 0.56 yA | 41.56 ± 0.20 zA |

| C18:2 (n6,9) | 11.07 ± 0.36 cA | 24.62 ± 2.80 bA | 34.95 ± 1.82 aA | 12.66 ± 1.37 zA | 19.96 ± 0.11 yA | 24.58 ± 0.04 xB |

| ∑SFA | 38.15 ± 0.31 aA | 30.97 ± 1.50 bB | 25.68 ± 0.49 cB | 36.13 ± 0.95 xB | 34.66 ± 0.31 yA | 31.31 ± 0.04 zA |

| ∑UFA | 61.85 ± 0.31 cB | 68.84 ± 1.31 bA | 74.30 ± 0.51 aA | 63.70 ± 0.76 zA | 65.34 ± 0.31 yB | 68.68 ± 0.05 xB |

| ∑MUFA | 48.74 ± 0.25 aA | 42.98 ± 1.28 bA | 38.34 ± 1.10 cB | 49.19 ± 0.64 xA | 43.94 ± 0.35 yA | 42.67 ± 0.20 zA |

| ∑PUFA | 12.74 ± 0.37 cB | 25.97 ± 2.77 bA | 36.04 ± 1.75 aA | 14.32 ± 1.29 zA | 21.46 ± 0.09 yB | 26.06 ± 0.11 xB |

| ∑n-3 | 0.64 ± 0.02 aA | 0.54 ± 0.01 bA | 0.44 ± 0.01 cA | 0.62 ± 0.02 xA | 0.58 ± 0.00 yB | 0.60 ± 0.05 xyB |

| ∑n-6 | 11.07 ± 0.36 cA | 24.62 ± 2.80 bA | 34.95 ± 1.82 aA | 12.66 ± 1.37 zA | 19.96 ± 0.11 yB | 24.58 ± 0.04 xB |

| Health indices | ||||||

| ∑n-3/∑n-6 | 0.06 ± 0.01 aA | 0.02 ± 0.00 bA | 0.01 ± 0.00 cB | 0.05 ± 0.01 xA | 0.03 ± 0.00 yB | 0.02 ± 0.00 zA |

| ∑PUFA/∑SFA | 0.33 ± 0.09 cA | 0.83 ± 0.10 bA | 1.40 ± 0.05 aaA | 0.39 ± 0.09 zB | 0.62 ± 0.03 yB | 0.83 ± 0.07 xB |

| AI | 0.49 ± 0.01 aA | 0.35 ± 0.02 bB | 0.26 ± 0.01 cB | 0.45 ± 0.02 xB | 0.40 ± 0.01 yA | 0.34 ± 0.00 zA |

| TI | 1.17 ± 0.02 aA | 0.85 ± 0.06 bB | 0.66 ± 0.02 cB | 1.09 ± 0.04 xB | 0.96 ± 0.01 yA | 0.83 ± 0.00 zA |

| h/H | 2.33 ± 0.04 cB | 3.26 ± 0.20 bA | 4.25 ± 0.09 aA | 2.52 ± 0.11 zA | 2.91 ± 0.04 yB | 3.38 ± 0.01 xB |

| CT | ESGE33 | ESGE66 | |

|---|---|---|---|

| pH | 5.50 ± 0.04 a | 5.40 ± 0.06 a | 5.41 ± 0.04 a |

| Aw | 0.964 ± 0.023 a | 0.975 ± 0.003 a | 0.973 ± 0.003 a |

| External color | |||

| L* | 56.32 ± 5.38 a | 49.83 ± 3.93 b | 51.79 ± 3.93 b |

| a* | 4.14 ± 0.94 a | 3.55 ± 1.28 ab | 3.11 ± 1.12 b |

| b* | 14.97 ± 3.72 a | 12.18 ± 2.48 b | 11.01 ± 1.93 b |

| C* | 11.62 ± 2.03 b | 12.61 ± 2.52 b | 15.56 ± 3.74 a |

| h* | 72.17 ± 5.48 b | 75.66 ± 4.78 a | 74.20 ± 2.90 ab |

| ∆E* | - | 7.14 ± 1.59 a | 6.15 ± 0.98 a |

| Internal color | |||

| L* | 47.72 ± 2.99 b | 54.72 ± 4.59 a | 51.61 ± 5.59 ab |

| a* | 3.83 ± 1.03 a | 2.86 ± 1.24 a | 2.78 ± 1.13 a |

| b* | 12.78 ± 2.02 a | 16.07 ± 4.32 a | 15.67 ± 4.26 a |

| C* | 13.35 ± 2.16 a | 16.37 ± 4.28 a | 15.67 ± 4.26 a |

| h* | 73.50 ± 3.21 b | 79.39 ± 4.75 a | 78.63 ± 5.04 a |

| ∆E* | - | 7.56 ± 2.03 a | 4.49 ± 0.74 b |

| Sample | CT | ESGE33 | ESGE66 |

|---|---|---|---|

| Hardness (N) | 65.94 ± 4.76 a | 49.64 ± 11.22 b | 43.38 ± 5.56 b |

| Springiness | 0.25 ± 0.01 a | 0.24 ± 0.04 a | 0.28 ± 0.14 a |

| Cohesiveness | 0.35 ± 0.07 a | 0.28 ± 0.08 ab | 0.20 ± 0.02 b |

| Chewiness | 5.91 ± 0.69 a | 3.04 ± 1.30 b | 2.58 ± 0.53 b |

| Resilience | 0.12 ± 0.03 a | 0.09 ± 0.02 b | 0.06 ± 0.01 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Botella-Martínez, C.; López-Córdoba, A.; Lucas-González, R.; Fernández-López, J.; Pérez-Álvarez, J.Á.; Viuda-Martos, M. A Pumpkin Seed Oil and Orange Peel Flour Gelled Emulsion as a Novel Fat Replacer in English Breakfast Sausages: Effects on Composition, Quality, and Sensory Acceptance. Appl. Sci. 2025, 15, 12488. https://doi.org/10.3390/app152312488

Botella-Martínez C, López-Córdoba A, Lucas-González R, Fernández-López J, Pérez-Álvarez JÁ, Viuda-Martos M. A Pumpkin Seed Oil and Orange Peel Flour Gelled Emulsion as a Novel Fat Replacer in English Breakfast Sausages: Effects on Composition, Quality, and Sensory Acceptance. Applied Sciences. 2025; 15(23):12488. https://doi.org/10.3390/app152312488

Chicago/Turabian StyleBotella-Martínez, Carmen, Alejandro López-Córdoba, Raquel Lucas-González, Juana Fernández-López, José Ángel Pérez-Álvarez, and Manuel Viuda-Martos. 2025. "A Pumpkin Seed Oil and Orange Peel Flour Gelled Emulsion as a Novel Fat Replacer in English Breakfast Sausages: Effects on Composition, Quality, and Sensory Acceptance" Applied Sciences 15, no. 23: 12488. https://doi.org/10.3390/app152312488

APA StyleBotella-Martínez, C., López-Córdoba, A., Lucas-González, R., Fernández-López, J., Pérez-Álvarez, J. Á., & Viuda-Martos, M. (2025). A Pumpkin Seed Oil and Orange Peel Flour Gelled Emulsion as a Novel Fat Replacer in English Breakfast Sausages: Effects on Composition, Quality, and Sensory Acceptance. Applied Sciences, 15(23), 12488. https://doi.org/10.3390/app152312488