Development of Wheat Bread Fortified with Sea Buckthorn (Hippophae rhamnoides L.) Pomace: Nutritional Enhancement, Technological Properties, and Consumer Acceptance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bread-Making Procedure

2.3. Farinograph Properties of Dough

2.4. Evaluation of Bread Quality Characteristics

2.5. Evaluation of Color Parameters of Bread Crumbs

2.6. Texture Profile Analysis (TPA) of Bread

2.7. Sensory Evaluation of Bread

2.8. Chemical Composition of Raw Materials and Bread

2.9. Statistical Analysis

3. Results and Discussion

3.1. Farinograph Properties of Dough

3.2. Chemical Composition of Raw Materials and Bread

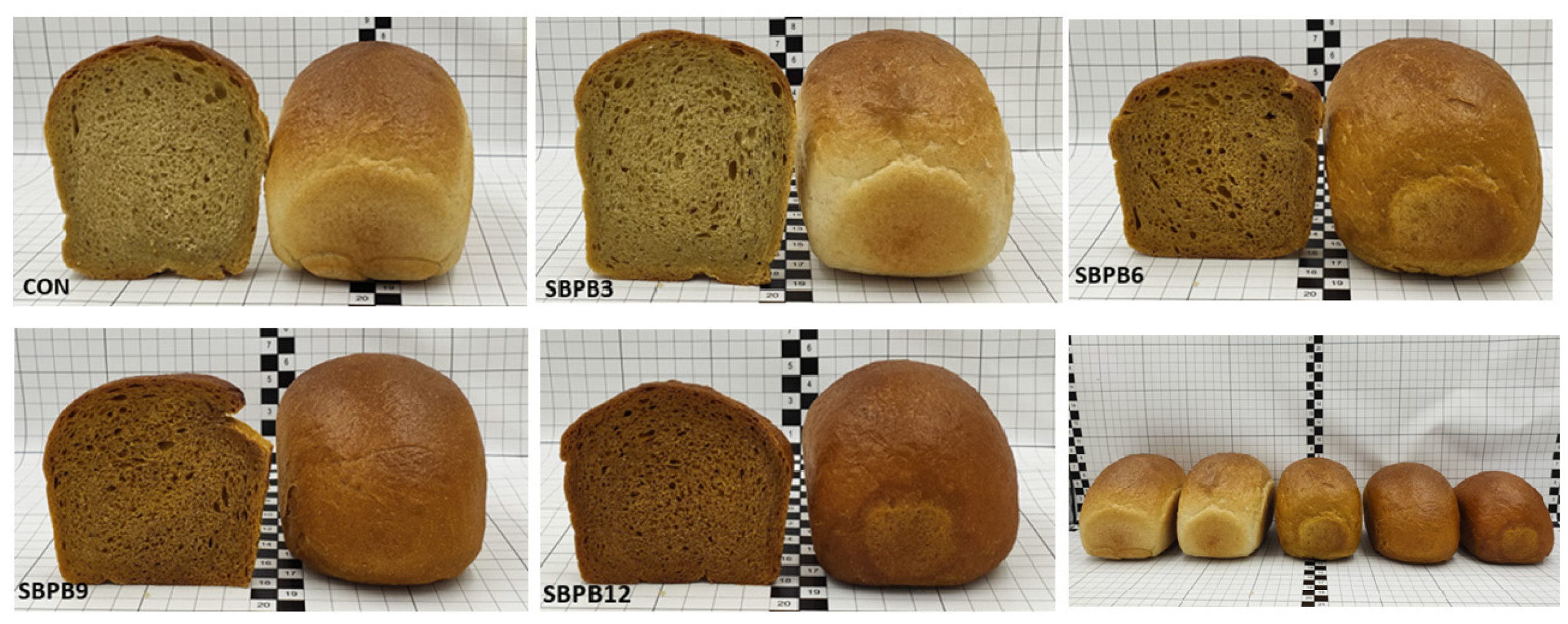

3.3. Evaluation of Bread Quality Characteristics

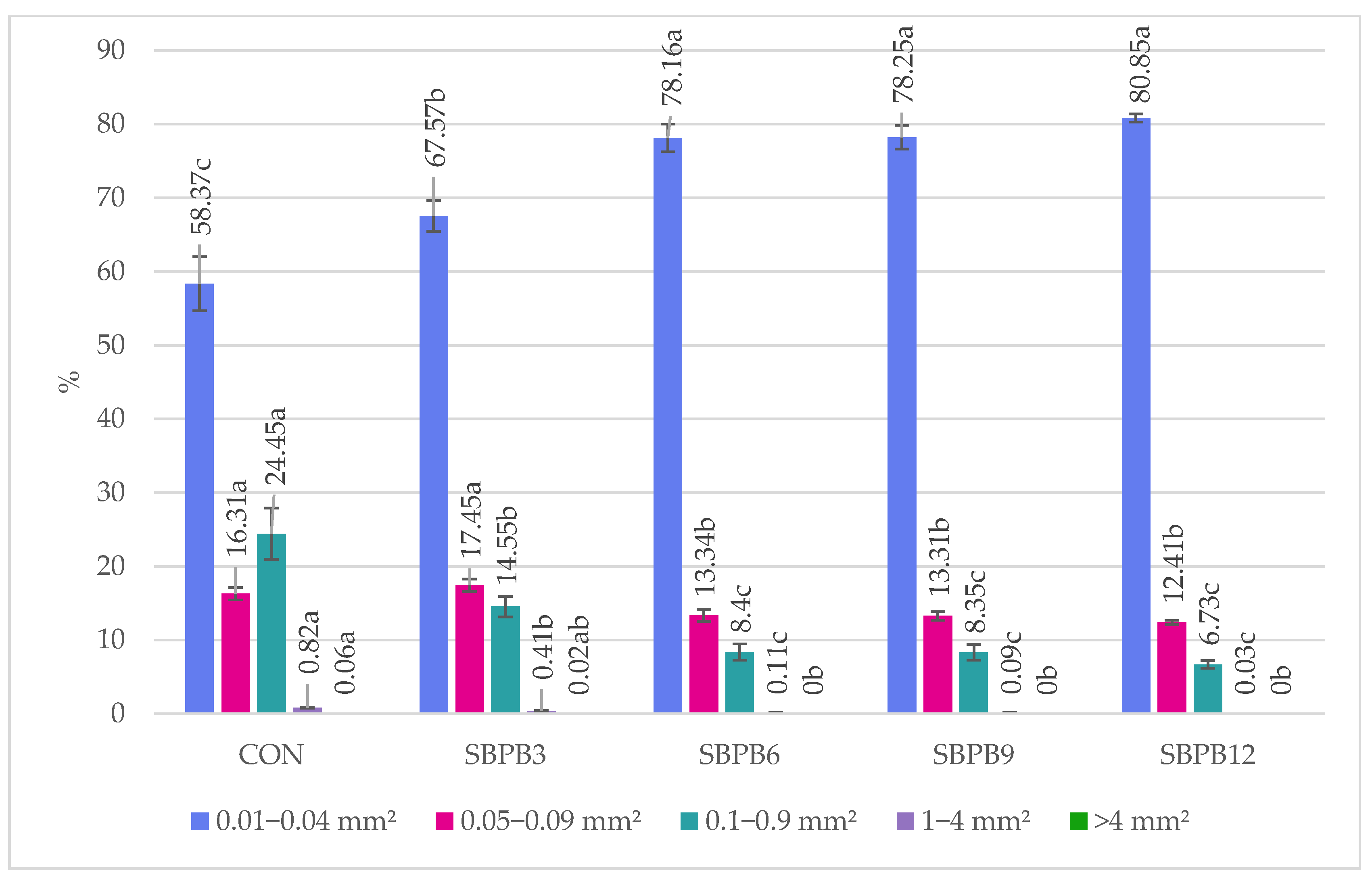

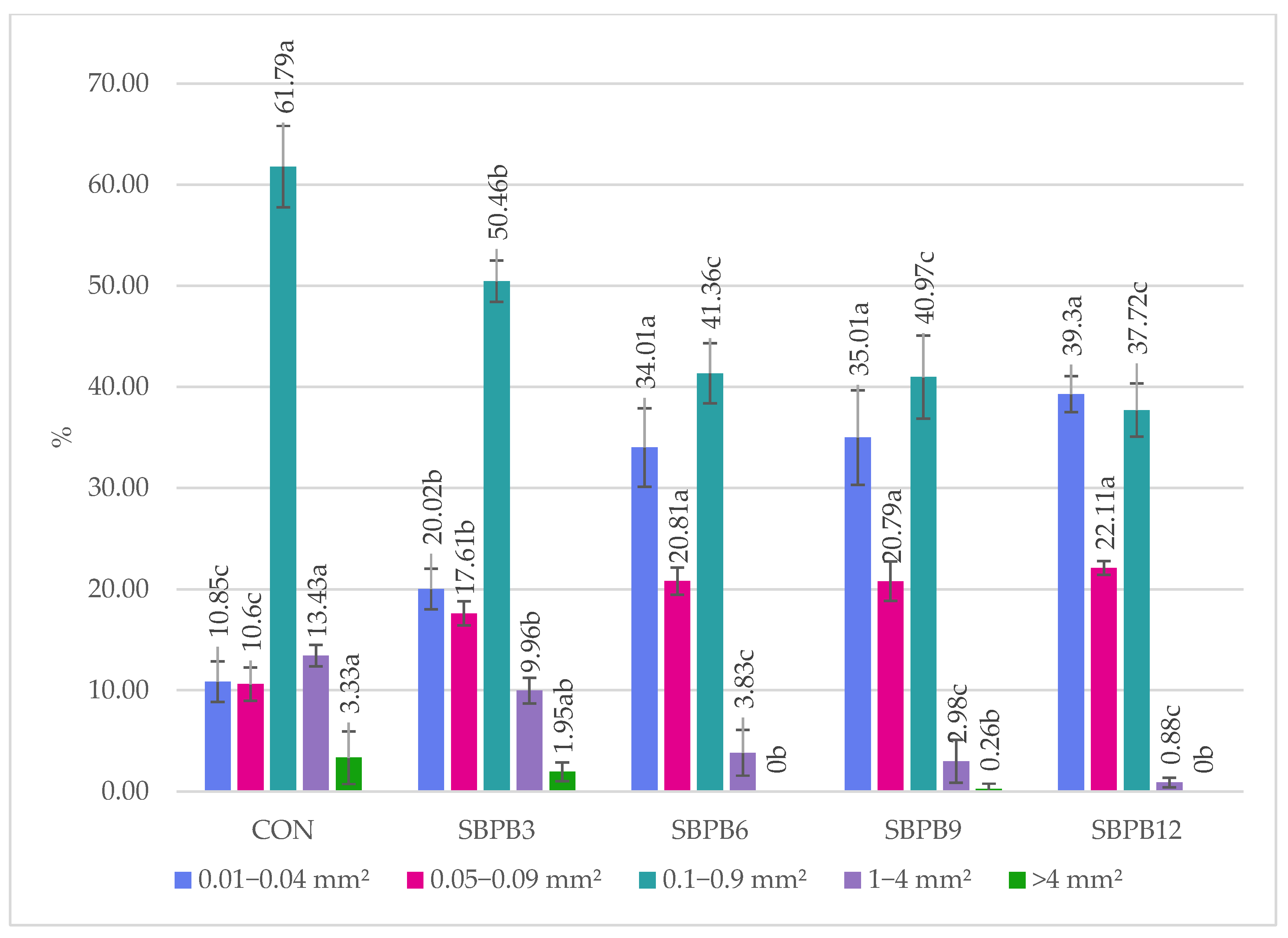

3.4. Texture Profile Analysis (TPA) of Bread

3.5. Evaluation of Color Parameters of Bread Crumbs

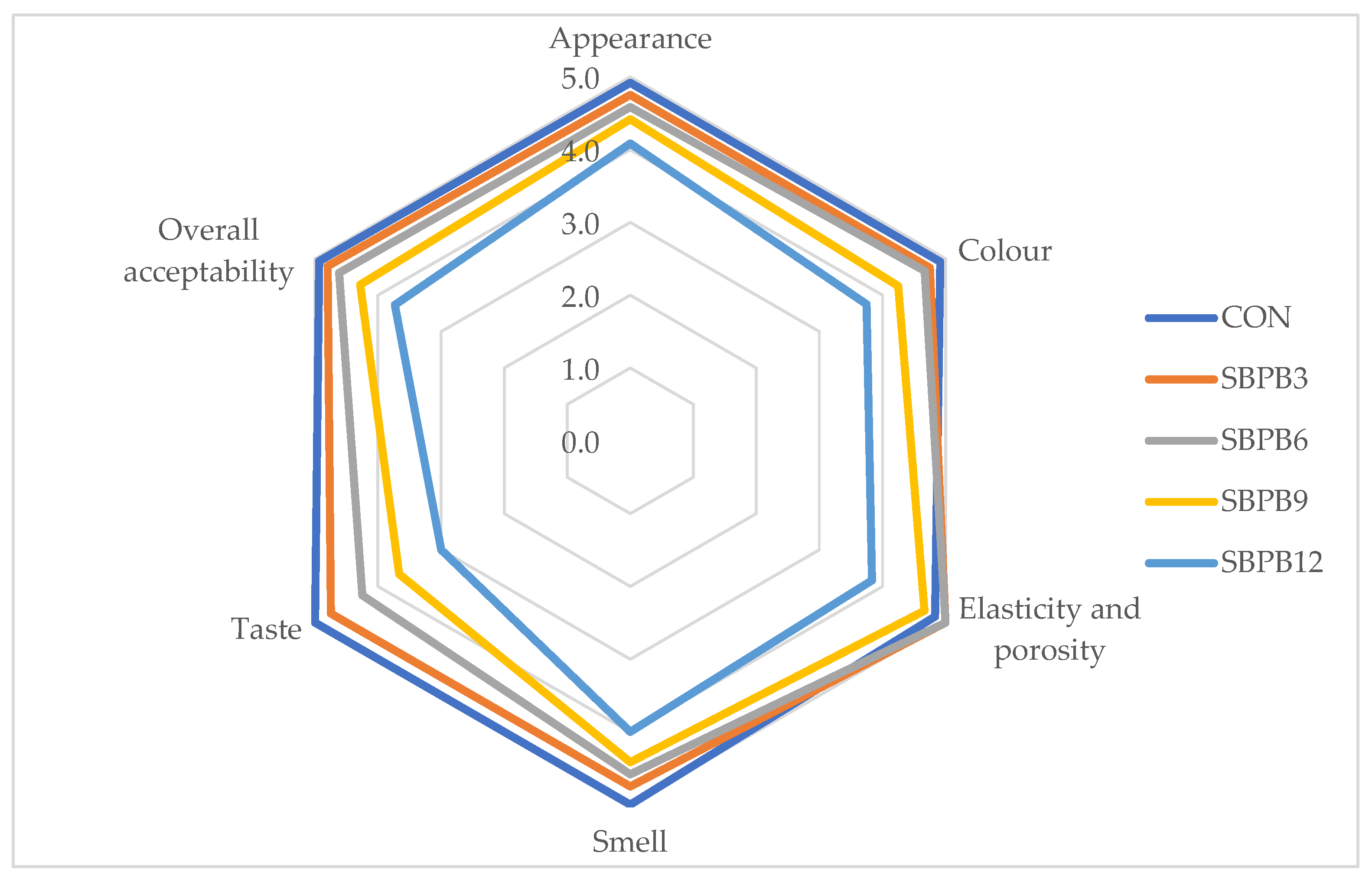

3.6. Sensory Evaluation of Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mollakhalili-Meybodi, N.; Ehrampoush, M.H.; Hajimohammadi, B.; Mosaddeg, M.H. Formulation optimization of functional wheat bread with low glycemic index from technological and nutritional perspective. Food Sci. Nutr. 2023, 11, 284–294. [Google Scholar] [CrossRef]

- Almeida, E.L.; Chang, Y.K.; Steel, C.J. Dietary fibre sources in bread: Influence on technological quality. LWT-Food Sci. Technol. 2013, 50, 545–553. [Google Scholar] [CrossRef]

- FMCG Gurus. Clean Label: Redefining the Bakery Sector. Food Business Insights. 2020. Available online: https://eu-assets.contentstack.com/v3/assets/blt7a82e963f79cc4ec/blt02da71327172fae1/64b54ea9221d77b423491c9d/FBI-DM-CleanLabelBakery-0620.pdf (accessed on 28 April 2025).

- Trigo, J.P.; Alexandre, E.M.C.; Saraiva, J.A.; Pintado, M.E. High value-added compounds from fruit and vegetable by-products—Characterization, bioactivities, and application in the development of novel food products. Crit. Rev. Food Sci. Nutr. 2019, 60, 1388–1416. [Google Scholar] [CrossRef]

- Jimenez-Moreno, N.; Esparza, I.; Bimbela, F.; Gandia, L.M.; Ancin-Azpilicueta, C. Valorization of selected fruit and vegetable wastes as bioactive compounds: Opportunities and challenges. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2061–2108. [Google Scholar] [CrossRef]

- Ancuța, P.; Sonia, A. Oil press-cakes and meals valorization through circular economy approaches: A review. Appl. Sci. 2020, 10, 7432. [Google Scholar] [CrossRef]

- Faustino, M.; Veiga, M.; Sousa, P.; Costa, E.M.; Silva, S.; Pintado, M. Agro-Food Byproducts as a New Source of Natural Food Additives. Molecules 2019, 24, 1056. [Google Scholar] [CrossRef] [PubMed]

- Fernández-López, J.; Lucas-González, R.; Viuda-Martos, M.; Sayas-Barberá, E.; Pérez-Alvarez, J.A. Chia oil extraction coproduct as a potential new ingredient for the food industry: Chemical, physicochemical, techno-functional and antioxidant properties. Plant Foods Hum. Nutr. 2018, 73, 130–136. [Google Scholar] [CrossRef]

- Prakash, K.; Naik, S.N.; Vadivel, D.; Hariprasad, P.; Gandhi, D.; Saravanadevi, S. Utilization of defatted sesame cake in enhancing the nutritional and functional characteristics of biscuits. J. Food Process. Preserv. 2018, 42, e13751. [Google Scholar] [CrossRef]

- Zarzycki, P.; Wirkijowska, A.; Nawrocka, A.; Kozłowicz, K.; Krajewska, M.; Kłosok, K.; Krawęcka, A. Effect of Moldavian Dragonhead Seed Residue on the Baking Properties of Wheat Flour and Bread Quality. LWT 2022, 155, 112967. [Google Scholar] [CrossRef]

- Suryakumar, G.; Gupta, A. Medicinal and therapeutic potential of Sea buckthorn (Hippophae rhamnoides L.). J. Ethnopharmacol. 2011, 138, 268–278. [Google Scholar] [CrossRef]

- Nour, V.; Panaite, T.D.; Corbu, A.R.; Ropota, M.; Turcu, R.P. Nutritional and Bioactive Compounds in Dried Sea-Buckthorn Pomace. Erwerbs-Obstbau 2021, 63, 91–98. [Google Scholar] [CrossRef]

- Mihalcea, L.; Turturică, M.; Cucolea, E.I.; Dănilă, G.-M.; Dumitrașcu, L.; Coman, G.; Constantin, O.E.; Grigore-Gurgu, L.; Stănciuc, N. CO2 Supercritical Fluid Extraction of Oleoresins from Sea Buckthorn Pomace: Evidence of Advanced Bioactive Profile and Selected Functionality. Antioxidants 2021, 10, 1681. [Google Scholar] [CrossRef]

- Zarzycki, P.; Wirkijowska, A.; Teterycz, D.; Łysakowska, P. Innovations in Wheat Bread: Using Food Industry By-Products for Better Quality and Nutrition. Appl. Sci. 2024, 14, 3976. [Google Scholar] [CrossRef]

- Stanciu, I.; Ungureanu, E.L.; Popa, E.E.; Geicu-Cristea, M.; Draghici, M.; Mitelut, A.C.; Mustatea, G.; Popa, M.E. The Experimental Development of Bread with Enriched Nutritional Properties Using Organic Sea Buckthorn Pomace. Appl. Sci. 2023, 13, 6513. [Google Scholar] [CrossRef]

- American Association of Cereal Chemists (AACC). AACC Approved Methods of Analysis, 11th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2010. [Google Scholar]

- Wirkijowska, A.; Teterycz, D.; Zarzycki, P. The Impact of Nut-Based Plant Beverages on Wheat Bread Quality: A Study of Almond, Hazelnut, and Walnut Beverages. Appl. Sci. 2025, 15, 8821. [Google Scholar] [CrossRef]

- Felisiak, K.; Przybylska, S.; Tokarczyk, G.; Tabaszewska, M.; Słupski, J.; Wydurska, J. Effect of Chickpea (Cicer arietinum L.) Flour Incorporation on Quality, Antioxidant Properties, and Bioactive Compounds of Shortbread Cookies. Foods 2024, 13, 2356. [Google Scholar] [CrossRef]

- ISO 8586:2012; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- Lukas, B.F.; Morais, M.G.; Santos, T.D.; Costa, J.A.V. Spirulina for Snack Enrichment: Nutritional, Physical and Sensory Evaluations. LWT 2018, 90, 270–276. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists International (AOAC). AOAC Official Methods, 20th ed.; Association of Official Analytical Chemists International: Rockville, MD, USA, 2016. [Google Scholar]

- Zhou, J.; Liu, J.; Tang, X. Effects of whey and soy protein addition on bread rheological property of wheat flour. J. Texture Stud. 2018, 49, 38–46. [Google Scholar] [CrossRef]

- Bchir, B.; Rabetafika, H.N.; Paquot, M.; Blecker, C. Effect of Pear, Apple and Date Fibres from Cooked Fruit By-products on Dough Performance and Bread Quality. Food Bioprocess Technol. 2014, 7, 1114–1127. [Google Scholar] [CrossRef]

- Azadfar, E.; Rad, A.H.; Sharifi, A.; Armin, M. Effect of olive pomace fiber on the baking properties of wheat flour and flat bread (Barbari Bread) quality. J. Food Process. Preserv. 2023, 1, 1405758. [Google Scholar] [CrossRef]

- Tolve, R.; Simonato, B.; Rainero, G.; Bianchi, F.; Rizzi, C.; Cervini, M.; Giuberti, G. Wheat Bread Fortification by Grape Pomace Powder: Nutritional, Technological, Antioxidant, and Sensory Properties. Foods 2021, 10, 75. [Google Scholar] [CrossRef]

- Usman, M.; Ahmed, S.; Mehmood, A.; Bilal, M.; Patil, P.J.; Akram, K.; Farooq, U. Effect of apple pomace on nutrition, rheology of dough and cookies quality. J. Food Sci. Technol. 2020, 57, 3244–3251. [Google Scholar] [CrossRef]

- Roozegar, M.H.; Shahedi, M.; Keramet, J.; Hamdami, N.; Roshanak, S. Effect of Coated and Uncoated Ground Flaxseed Addition on Rheological, Physical and Sensory Properties of Taftoon Bread. J. Food Sci. Technol. 2015, 52, 5102–5110. [Google Scholar] [CrossRef] [PubMed]

- Codină, G.G.; Istrate, A.M.; Gontariu, I.; Mironeasa, S. Rheological Properties of Wheat–Flaxseed Composite Flours Assessed by Mixolab and Their Relation to Quality Features. Foods 2019, 8, 333. [Google Scholar] [CrossRef] [PubMed]

- Koneva, S.I.; Zakharova, A.S.; Meleshkina, L.E.; Egorova, E.Y.; Mashkova, I.A. Technological Properties of Dough from a Mix of Rye and Wheat Flour with Processed Sea Buckthorn. Food Process. Tech. Technol. 2023, 53, 247–258. [Google Scholar] [CrossRef]

- Mironeasa, S.; Mironeasa, C. Dough bread from refined wheat flour partially replaced by grape peels: Optimizing the rheological properties. J. Food Process Eng. 2019, 42, e13207. [Google Scholar] [CrossRef]

- Kohajdová, Z.; Karovičová, J.; Magala, M.; Kuchtová, V. Effect of apple pomace powder addition on farinographic properties of wheat dough and biscuits quality. Chem. Pap. 2014, 68, 1059–1065. [Google Scholar] [CrossRef]

- Wirkijowska, A.; Zarzycki, P.; Sobota, A.; Nawrocka, A.; Blicharz-Kania, A.; Andrejko, D. The possibility of using by-products from the flaxseed industry for functional bread production. LWT 2020, 118, 108860. [Google Scholar] [CrossRef]

- Dahdah, P.; Cabizza, R.; Farbo, M.G.; Fadda, C.; Mara, A.; Hassoun, G.; Piga, A. Improving the Rheological Properties of Dough Obtained by Partial Substitution of Wheat Flour with Freeze-Dried Olive Pomace. Foods 2024, 13, 478. [Google Scholar] [CrossRef]

- Kaminskytė, G.; Jagelavičiūtė, J.; Bašinskienė, L.; Syrpas, M.; Čižeikienė, D. Effect of Modification Methods on Composition and Technological Properties of Sea Buckthorn (Hippophae rhamnoides L.) Pomace. Appl. Sci. 2025, 15, 8722. [Google Scholar] [CrossRef]

- Xiao, Q.; Yang, L.; Guo, J.; Zhang, X.; Huang, Y.; Fu, Q. Preparation, Structural Characterization, and Hypoglycemic Activity of Dietary Fiber from Sea Buckthorn Pomace. Foods 2024, 13, 3665. [Google Scholar] [CrossRef]

- Wang, L.; Yan, M.; Jiang, Q.; Wang, B.; Luo, D.; Yue, C.; Guo, J.; Qiu, J.; Wang, H.; Wu, W.; et al. Effect of buckwheat bran protein enzymatic hydrolysates on the rheological, textural and structural properties of non-fermented wheat dough. Food Chem. X 2025, 27, 102501. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, T.; Zhao, J.; AL-Ansi, W.; Fan, M.; Wafaa, K.A.; Qian, H.; Li, Y.; Wang, L. Effects of sea buckthorn residue protein hydrolysate on the quality of frozen pre-baked bread: Water state and gluten structures. Food Hydrocoll. 2025, 167, 111404. [Google Scholar] [CrossRef]

- Sudha, M.L.; Rajeswari, G.; Venkateswara Rao, G. Effect of wheat and oat brans on the dough rheological and quality characteristics of instant vermicelli. J. Texture Stud. 2012, 43, 195–202. [Google Scholar] [CrossRef]

- Rocha-Parra, A.F.; Belorio, M.; Ribotta, P.D.; Ferrero, C.; Gómez, M. Effect of the particle size of pear pomace on the quality of enriched layer and sponge cakes. Int. J. Food Sci. Technol. 2019, 54, 1265–1275. [Google Scholar] [CrossRef]

- Hussain, S.; Sharma, M.; Bhat, R. Valorisation of Sea Buckthorn Pomace by Optimization of Ultrasonic-Assisted Extraction of Soluble Dietary Fibre Using Response Surface Methodology. Foods 2021, 10, 1330. [Google Scholar] [CrossRef] [PubMed]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Parol-Nadłonek, N.; Kalisz, S.; Krajewska, A.; Stępniewska, S. Wheat Bread Enriched with Black Chokeberry (Aronia melanocarpa L.) Pomace: Physicochemical Properties and Sensory Evaluation. Appl. Sci. 2023, 13, 6936. [Google Scholar] [CrossRef]

- Pecyna, A.; Krzywicka, M.; Blicharz-Kania, A.; Buczaj, A.; Kobus, Z.; Zdybel, B.; Domin, M.; Siłuch, D. Impact of incorporating two types of dried raspberry pomace into gluten-free bread on its nutritional and antioxidant characteristics. Appl. Sci. 2024, 14, 1561. [Google Scholar] [CrossRef]

- Schleißinger, M.; Meyer, A.L.; Afsar, N.; Nagy, Á.G.; Dieker, V.; Schmitt, J.J. Research Article Impact of Dietary Fibers on Moisture and Crumb Firmness of Brown Bread. Adv. J. Food Sci. Technol. 2013, 5, 1281–1284. [Google Scholar] [CrossRef]

- Sardabi, F.; Azizi, M.H.; Gavlighi, H.A.; Rashidinejad, A. The effect of Moringa peregrina seed husk on the in vitro starch digestibility, microstructure, and quality of white wheat bread. LWT 2021, 136, 110332. [Google Scholar] [CrossRef]

- Ghendov-Mosanu, A.; Cristea, E.; Patras, A.; Sturza, R.; Padureanu, S.; Deseatnicova, O.; Turculet, N.; Boestean, O.; Niculaua, M. Potential Application of Hippophae rhamnoides in Wheat Bread Production. Molecules 2020, 25, 1272. [Google Scholar] [CrossRef] [PubMed]

- Nilova, L.; Malyutenkova, S. The possibility of using powdered sea-buckthorn in the development of bakery products with antioxidant properties. Agron. Res. 2018, 16, 1444–1456. [Google Scholar] [CrossRef]

- Wiedemair, V.; Gruber, K.; Knöpfle, N.; Bach, K.E. Technological Changes in Wheat-Based Breads Enriched with Hemp Seed Press Cakes and Hemp Seed Grit. Molecules 2022, 27, 1840. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, X.; Zhou, S. Effect of flaxseed marc flour on high-yield wheat bread production: Comparison in baking, staling, antioxidant and digestion properties. LWT 2022, 169, 113979. [Google Scholar] [CrossRef]

- Almoumen, A.; Mohamed, H.; Sobti, B.; Ayyash, M.; Kamleh, R.; Al-Marzouqi, A.H.; Kamal-Eldin, A. Quality of bread rolls fortified with date fruit pomace: Structure, proximate composition, staling, and sensory evaluation. NFS J. 2025, 38, 100214. [Google Scholar] [CrossRef]

- Wang, C.C.; Yang, Z.; Xing, J.J.; Guo, X.N.; Zhu, K.X. Effects and underlying mechanisms of insoluble dietary fiber and ferulic acid on the crumb structure of steamed bread. Food Hydrocoll. 2022, 125, 107448. [Google Scholar] [CrossRef]

- Zhou, Y.; Dhital, S.; Zhao, C.; Ye, F.; Chen, J.; Zhao, G. Dietary fiber-gluten protein interaction in wheat flour dough: Analysis, consequences and proposed mechanisms. Food Hydrocoll. 2021, 111, 106203. [Google Scholar] [CrossRef]

| Sample | WA [%] | DDT [min] | ST [min] | DS [FU] | FQN |

|---|---|---|---|---|---|

| CON | 59.9 ± 1.2 d | 6.0 ± 0.1 b | 12.3 ± 0.4 a | 45.3 ± 1.2 d | 137.1 ± 3.2 a |

| SBPB3 | 61.6 ± 1.1 dc | 6.5 ± 0.1 b | 10.3 ± 0.3 b | 52.2 ± 1.7 c | 126.2 ± 4.7 a |

| SBPB6 | 64.5 ± 2.1 cb | 7.6 ± 0.3 a | 6.2 ± 0.1 c | 62.2 ± 1.7 b | 109.9 ± 3.7 b |

| SBPB9 | 66.5 ± 1.5 ba | 7.4 ± 0.3 a | 5.5 ± 0.2 d | 70.4 ± 2.6 a | 103.8 ± 4.9 b |

| SBPB12 | 68.9 ± 1.8 a | 7.5 ± 0.4 a | 5.9 ± 0.2 dc | 66.5 ± 2.7 ba | 108.0 ± 5.9 b |

| Sample | Raw Materials and Bread Compositions [% d.b.] | |||||||

|---|---|---|---|---|---|---|---|---|

| Ash | Protein | Fat | TDF | IDF | SDF | CHO | Energy [kcal/100 g] | |

| Raw materials | ||||||||

| WF | 0.72 ± 0.02 b | 13.3 ± 0.4 b | 0.49 ± 0.02 b | 5.38 ± 0.14 b | 2.45 ± 0.07 b | 2.97 ± 0.07 b | 80.1 ± 0.6 a | 340.3 ± 0.2 a |

| SBP | 1.89 ± 0.06 a | 24.2 ± 0.7 a | 14.8 ± 0.6 a | 55.8 ± 1.4 a | 44.5 ± 1.0 a | 11.3 ± 0.3 a | 3.3 ± 2.8 b | 319.8 ± 0.4 b |

| Bread | ||||||||

| CON | 2.29 ± 0.05 b | 13.5 ± 0.4 b | 0.51 ± 0.02 e | 5.4 ± 0.2 e | 2.4 ± 0.1 e | 2.99 ± 0.07 c | 78.2 ± 0.6 a | 229.6 ± 0.3 e |

| SBPB3 | 2.33 ± 0.06 b | 13.6 ± 0.3 b | 1.05 ± 0.02 d | 7.2 ± 0.2 d | 3.8 ± 0.1 d | 3.43 ± 0.12 b | 75.8 ± 0.5 b | 223.7 ± 0.3 d |

| SBPB6 | 2.38 ± 0.07 ba | 14.2 ± 0.4 b | 1.26 ± 0.04 c | 8.5 ± 0.2 c | 5.0 ± 0.1 c | 3.47 ± 0.13 b | 73.7 ± 0.8 c | 222.3 ± 0.3 c |

| SBPB9 | 2.45 ± 0.06 ba | 16.4 ± 0.4 a | 1.78 ± 0.05 b | 10.4 ± 0.3 b | 6.6 ± 0.1 b | 3.85 ± 0.13 a | 69.0 ± 0.8 d | 219.2 ± 0.3 b |

| SBPB12 | 2.51 ± 0.06 a | 16.8 ± 0.4 a | 2.13 ± 0.06 a | 11.6 ± 0.4 a | 7.4 ± 0.2 a | 4.11 ± 0.13 a | 67.0 ± 0.8 e | 216.8 ± 0.4 a |

| Sample | Bread Yield [%] | Baking Loss [%] | Specific Volume [cm3 g−1] | Crumb Moisture After 24 h [%] | Crumb Moisture After 72 h [%] |

|---|---|---|---|---|---|

| CON | 136.3 ± 0.2 e | 10.8 ± 0.1 a | 3.45 ± 0.08 a | 40.0 ± 0.9 b | 38.5 ± 0.9 b |

| SBPB3 | 140.5 ± 0.5 d | 10.6 ± 0.3 ba | 3.49 ± 0.11 a | 41.4 ± 0.1 a | 40.0 ± 0.1 ab |

| SBPB6 | 147.1 ± 1.4 c | 10.4 ± 0.5 ba | 2.86 ± 0.06 b | 41.5 ± 0.2 a | 40.0 ± 0.3 ab |

| SBPB9 | 152.5 ± 1.0 b | 10.2 ± 0.2 ba | 2.69 ± 0.10 cb | 42.0 ± 0.3 a | 40.8 ± 0.4 a |

| SBPB12 | 157.3 ± 0.7 a | 9.9 ± 0.5 b | 2.42 ± 0.12 c | 42.6 ± 0.5 a | 41.1 ± 0.7 a |

| Sample | Hardness [N] | Cohesiveness [-] | Chewiness [N] | Springiness [-] | ||||

|---|---|---|---|---|---|---|---|---|

| 24 h | 72 h | 24 h | 72 h | 24 h | 72 h | 24 h | 72 h | |

| CON | 3.8 ± 0.3 dB | 7.1 ± 0.8 eA | 0.66 ± 0.04 aA | 0.46 ± 0.06 aB | 2.5 ± 0.2 dA | 3.0 ± 0.3 cA | 0.97 ± 0.02 aA | 0.94 ± 0.02 aA |

| SBPB3 | 6.8 ± 0.5 cB | 10.7 ± 1.9 dA | 0.58 ± 0.04 bA | 0.44 ± 0.04 aB | 3.5 ± 0.4 cA | 4.2 ± 1.2 bcA | 0.89 ± 0.05 bA | 0.88 ± 0.05 baA |

| SBPB6 | 8.4 ± 0.5 bB | 14.5 ± 0.7 cA | 0.58 ± 0.04 bA | 0.36 ± 0.01 bB | 4.3 ± 0.6 bA | 4.4 ± 0.4 bA | 0.88 ± 0.08 bA | 0.84 ± 0.05 cbA |

| SBPB9 | 8.8 ± 0.8 bB | 17.2 ± 1.1 bA | 0.58 ± 0.02 bA | 0.35 ± 0.03 bB | 4.4 ± 0.4 bA | 5.0 ± 0.4 bA | 0.88 ± 0.03 bA | 0.83 ± 0.06 cbA |

| SBPB12 | 12.4 ± 0.7 aB | 25.8 ± 2.1 aA | 0.54 ± 0.03 bA | 0.34 ± 0.02 bB | 5.7 ± 0.5 aA | 6.7 ± 1.0 aA | 0.85 ± 0.03 bA | 0.77 ± 0.05 cB |

| Sample | L* | a* | b* | ∆E* | WI | BI | YI |

|---|---|---|---|---|---|---|---|

| Raw materials | |||||||

| WF | 87.3 ± 0.2 | 0.8 ± 0.1 | 11.1 ± 0.1 | - | 83.1 ± 0.3 | 14.0 ± 0.3 | 18.2 ± 0.3 |

| SBP | 46.4 ± 0.0 | 23.6 ± 0.4 | 43.7 ± 0.1 | - | 26.9 ± 0.2 | 218 ± 1.8 | 134.5 ± 0.5 |

| Bread | |||||||

| CON | 62.4 ± 2.9 a | 0.7 ± 0.2 ba | 11.6 ± 1.2 ba | - | 60.6 ± 2.5 a | 20.8 ± 1.7 cb | 26.4 ± 1.9 cb |

| SBPB3 | 61.4 ± 2.9 a | 0.5 ± 0.3 b | 11.1 ± 1.0 b | 2.8 ± 1.4 b | 59.8 ± 2.8 a | 20.1 ± 2.7 cb | 25.9 ± 2.9 cb |

| SBPB6 | 59.5 ± 3.0 a | 0.4 ± 0.1 b | 9.8 ± 0.7 c | 3.8 ± 2.6 ba | 58.3 ± 2.9 a | 18.1 ± 1.5 c | 23.5 ± 1.8 c |

| SBPB9 | 54.1 ± 2.1 b | 0.4 ± 0.5 b | 10.5 ± 0.8 bc | 8.4 ± 2.1 a | 52.8 ± 2.2 b | 21.9 ± 3.2 b | 27.9 ± 2.9 b |

| SBPB12 | 53.5 ± 2.5 b | 0.9 ± 0.4 a | 12.4 ± 0.9 a | 9.0 ± 2.5 a | 51.8 ± 2.6 b | 27.3 ± 3.3 a | 33.3 ± 3.4 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wirkijowska, A.; Zarzycki, P.; Terpiłowski, K. Development of Wheat Bread Fortified with Sea Buckthorn (Hippophae rhamnoides L.) Pomace: Nutritional Enhancement, Technological Properties, and Consumer Acceptance. Appl. Sci. 2025, 15, 12319. https://doi.org/10.3390/app152212319

Wirkijowska A, Zarzycki P, Terpiłowski K. Development of Wheat Bread Fortified with Sea Buckthorn (Hippophae rhamnoides L.) Pomace: Nutritional Enhancement, Technological Properties, and Consumer Acceptance. Applied Sciences. 2025; 15(22):12319. https://doi.org/10.3390/app152212319

Chicago/Turabian StyleWirkijowska, Anna, Piotr Zarzycki, and Konrad Terpiłowski. 2025. "Development of Wheat Bread Fortified with Sea Buckthorn (Hippophae rhamnoides L.) Pomace: Nutritional Enhancement, Technological Properties, and Consumer Acceptance" Applied Sciences 15, no. 22: 12319. https://doi.org/10.3390/app152212319

APA StyleWirkijowska, A., Zarzycki, P., & Terpiłowski, K. (2025). Development of Wheat Bread Fortified with Sea Buckthorn (Hippophae rhamnoides L.) Pomace: Nutritional Enhancement, Technological Properties, and Consumer Acceptance. Applied Sciences, 15(22), 12319. https://doi.org/10.3390/app152212319