Machinability of Sintered Metallic Materials in Additive Manufacturing

Abstract

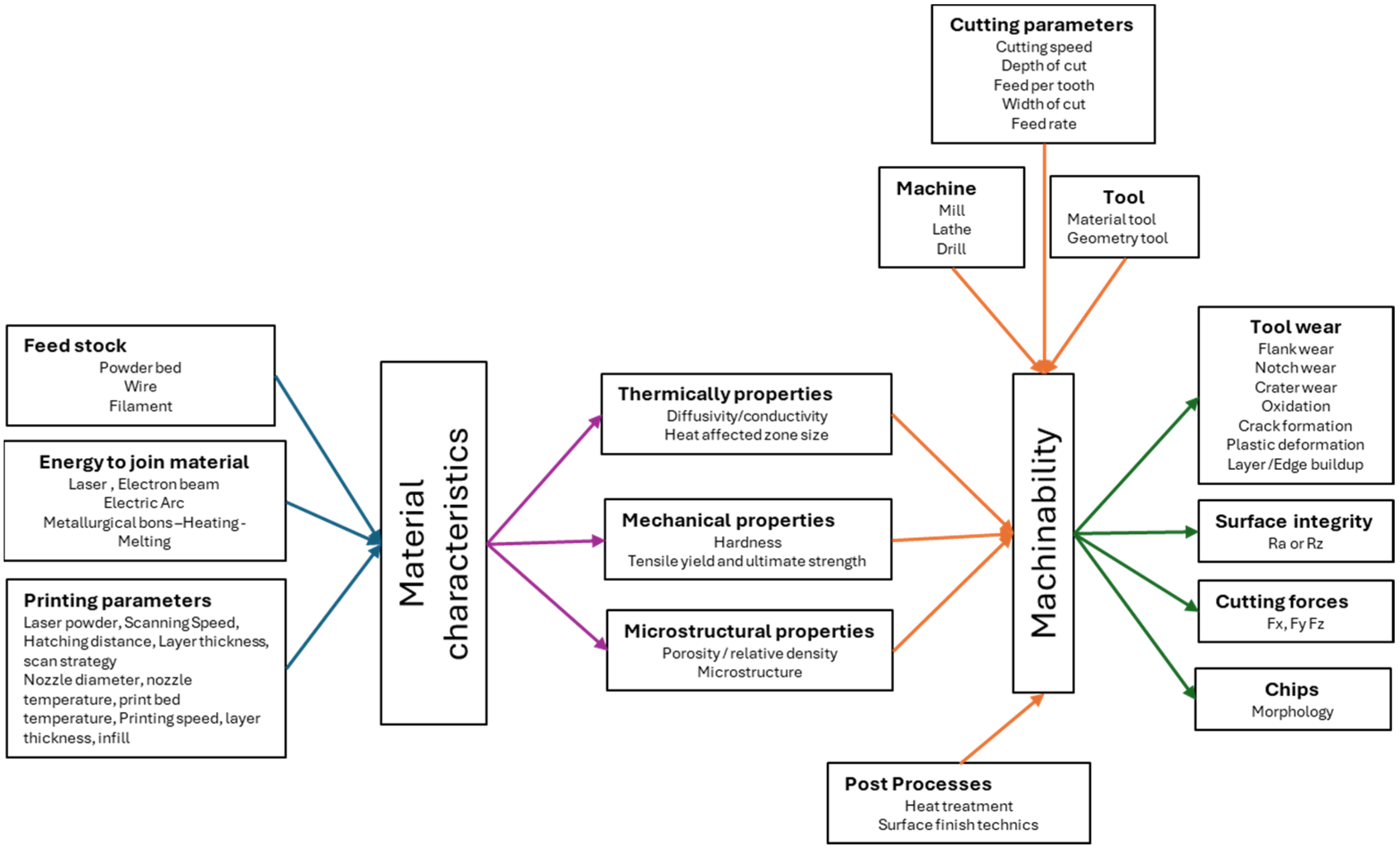

1. Introduction

2. Additive Manufacturing Technologies Based on Sintering

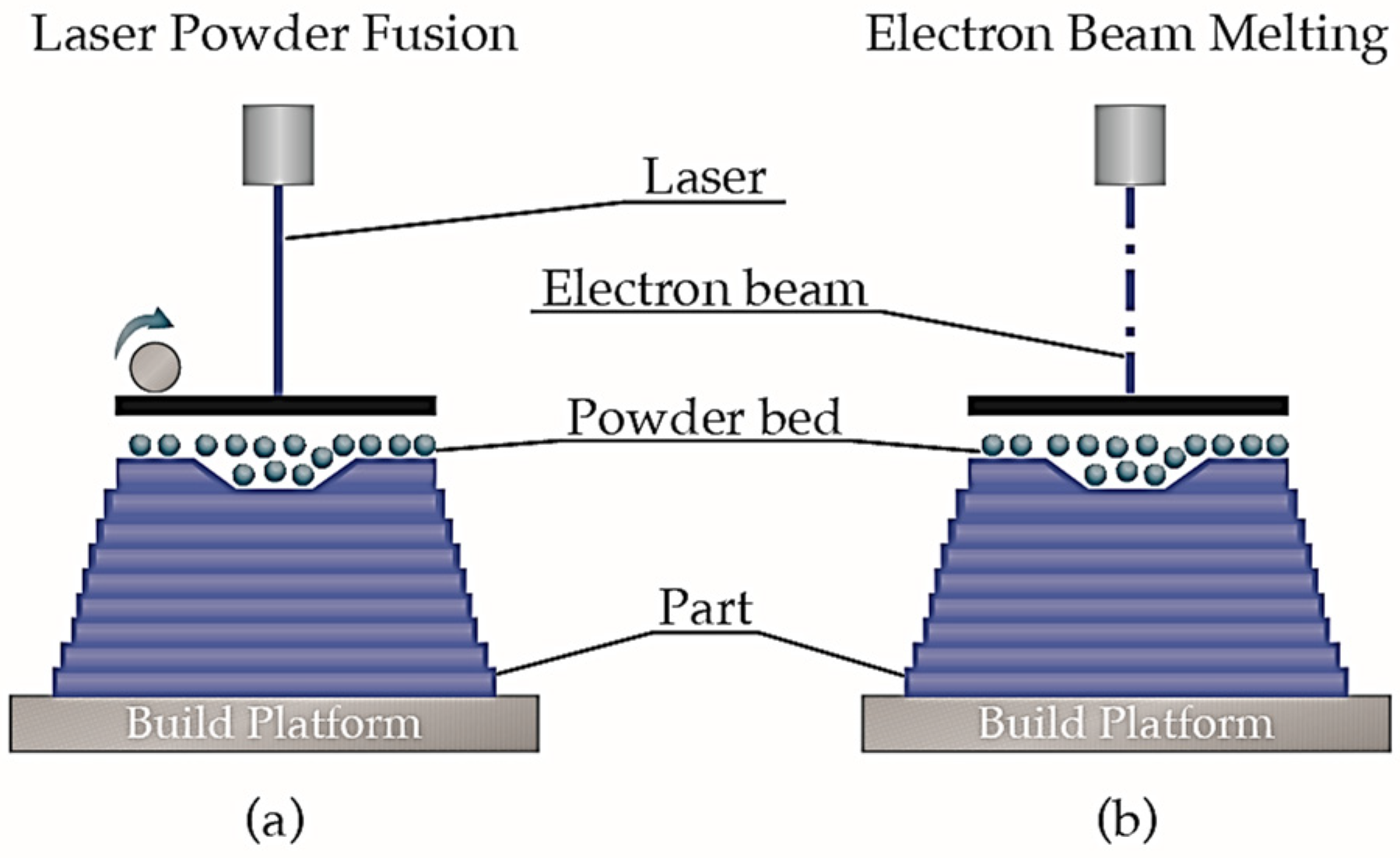

2.1. Powder Bed Fusion (PBF)

2.2. Direct Energy Deposition (DED)

2.3. Binder Jetting (BJT)

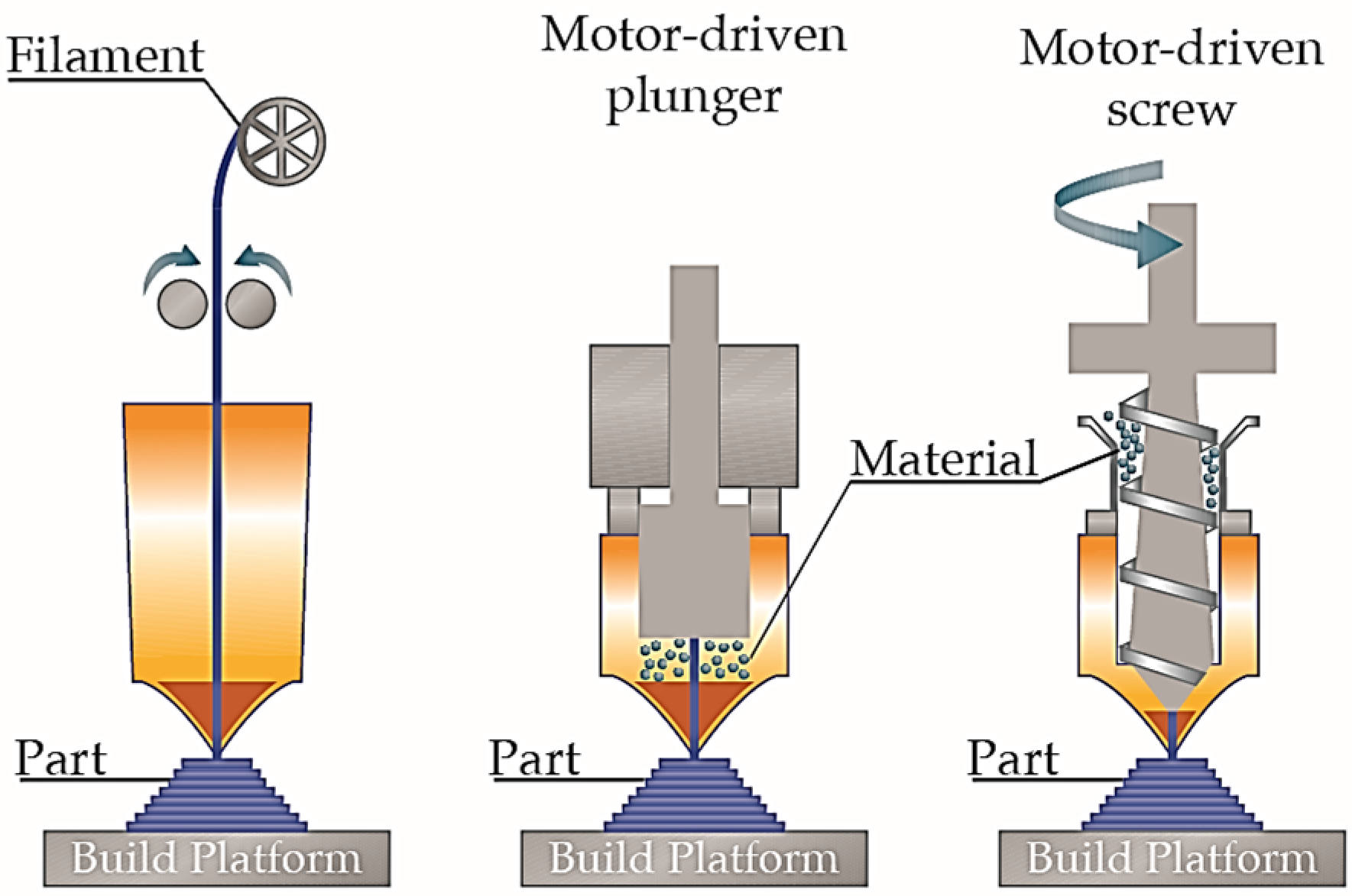

2.4. Material Extrusion (MEX)

2.5. Advantages and Disadvantages

3. Properties of Sintered AM Metallic Materials Affecting Machinability

- Microstructural properties, which include grain size, microstructure, and porosity/relative density.

- Mechanical properties, which analyze hardness, residual stress, and strength.

- Thermal properties, which examine conductivity, thermal expansion, and melting point.

3.1. Microstructural Properties

3.2. Mechanical Properties

3.3. Thermal Properties

3.4. Field Assisted Additive Technologies

4. Machinability of Sintered AM Metallic Materials

4.1. Turning Processes

4.2. Milling

4.3. Drilling

5. Post-Processing Strategies for Improving Machinability, Treat Thermic

6. Summary and Future Perspectives and Research Opportunities

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MAM | metal additive manufacturing |

| AM | additive manufacturing |

| BJT | binder jetting technology |

| DED | direct energy deposition |

| MEX | material extrusion |

| PBF | powder bed fusion |

| SM | sheet metal |

| VAT | vat photopolymerization |

| VED | volumetric energy density |

| FFF | filament-fused fabrication |

| BDM | bound metal deposition |

| MEXM | material extrusion metal |

| BASCA | beta annealed, solution treated, and aged |

| STA | solution treated and aged |

| DA | direct aging |

References

- Booysen, T.W.J.; Jamiru, T.; Adegbola, T.A. Classification of Metal Additive Manufacturing Technologies. RD J. 2023, 39, 35–43. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing-General Principles-Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2021.

- Singh, D.D.; Mahender, T.; Reddy, A.R. Powder bed fusion process: A brief review. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; pp. 350–355. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.; Wang, P.; Nai, M.; Loh, N.; Liu, E.; Tor, S. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Tuncer, N.; Bose, A. Solid-State Metal Additive Manufacturing: A Review. JOM J. Miner. Met. Mater. Soc. 2020, 72, 3090–3111. [Google Scholar] [CrossRef]

- Sames, W.; List, F.; Pannala, S.; Dehoff, R.; Babu, S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Ladani, L.; Sadeghilaridjani, M. Review of powder bed fusion additive manufacturing for metals. Metals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Sateesh, N.H.; Kumar, G.C.M.; Prasad, K.; SC, K.; Vinod, A.R. Microstructure and Mechanical Characterization of Laser Sintered Inconel-625 Superalloy. Procedia Mater. Sci. 2014, 5, 772–779. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufactured Inconel 718 superalloy parts: High-temperature oxidation property and its mechanisms. Opt. Laser Technol. 2014, 62, 161–171. [Google Scholar] [CrossRef]

- Akib, Y.M.; Marzbanrad, E.; Ahmed, F.; Li, J. A Numerical Study on the Powder Flowability, Spreadability, Packing Fraction in Powder Bed Additive Manufacturing. In Volume 1: Additive Manufacturing; Biomanufacturing; Life Cycle Engineering; Manufacturing Equipment and Automation; Nano/Micro/Meso Manufacturing; American Society of Mechanical Engineers: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Milaat, F.A.; Witherell, P.; Hardwick, M.; Yeung, H.; Ferrero, V.; Monnier, L.; Brown, M. STEP-NC Process Planning for Powder Bed Fusion Additive Manufacturing. J. Comput. Inf. Sci. Eng. 2022, 22, 060904. [Google Scholar] [CrossRef]

- Yao, L.; Ramesh, A.; Xiao, Z.; Chen, Y.; Zhuang, Q. Multimetal Research in Powder Bed Fusion: A Review. Materials 2023, 16, 4287. [Google Scholar] [CrossRef] [PubMed]

- Vats, P.; Kumar, A.; Gajrani, K.K. Novel insights into conventional machining of metal additive manufactured components: A comprehensive review. Mach. Sci. Technol. 2024, 28, 866–959. [Google Scholar] [CrossRef]

- Zhao, C.; Fezzaa, K.; Cunningham, R.; Wen, H.; De Carlo Chen, L.; Rollett, A.; Sun, T. Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci. Rep. 2017, 7, 3602. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Kostavelis, I.; Tzetzis, D.; Tzovaras, D. Impact of metal additive manufacturing parameters on the powder bed fusion and direct energy deposition processes: A comprehensive review. Prog. Addit. Manuf. 2021, 6, 349–365. [Google Scholar] [CrossRef]

- Li, S.H.; Kumar, P.; Chandra, S.; Ramamurty, U. Directed energy deposition of metals: Processing, microstructures, and mechanical properties. Int. Mater. Rev. 2023, 68, 605–647. [Google Scholar] [CrossRef]

- Sachs, E.; Cima, M.; Williams, P.; Brancazio, D.; Cornie, J. Three Dimensional Printing: Rapid Tooling and Prototypes Directly from a CAD Model. J. Eng. Ind. 1992, 114, 481–488. [Google Scholar] [CrossRef]

- Padmakumar, M. Additive Manufacturing of Tungsten Carbide Hardmetal Parts by Selective Laser Melting (SLM), Selective Laser Sintering (SLS) and Binder Jet 3D Printing (BJ3DP) Techniques. Lasers Manuf. Mater. Process. 2020, 7, 338–371. [Google Scholar] [CrossRef]

- Singh, J.; Singh, R.P.; Pandey, P.M. Additive Manufacturing Techniques. In Handbook of Post-Processing in Additive Manufacturing; CRC Press: New York, NY, USA, 2023; pp. 1–34. [Google Scholar] [CrossRef]

- Zafar, M.; Sajjad, R.; Anwar, M.; Mustafa, M.; Husnain, N.; Aqeel, A.; Khan, M. A Review on Metal Additive Manufacturing-Types, Applications and Future Trends. Recent. Prog. Mater. 2025, 7, 006. [Google Scholar] [CrossRef]

- Zhu, B.; Li, R.; Yuan, T.; Li, W.; Cai, D.; Kang, N. Metal binder jetting additive manufacturing: An overview of the process, materials and reinforcement methods. J. Alloys Compd. 2025, 1037, 182196. [Google Scholar] [CrossRef]

- Jasik, K.; Śnieżek, L.; Kluczyński, J. Additive Manufacturing of Metals Using the MEX Method: Process Characteristics and Performance Properties—A Review. Materials 2025, 18, 2744. [Google Scholar] [CrossRef]

- Locatelli, G.; Quarto, M.; D’Urso, G.; Giardini, C. Geometric Benchmarking of Metal Material Extrusion Technology: A Preliminary Study. Appl. Sci. 2024, 14, 6229. [Google Scholar] [CrossRef]

- Capasso, I.; Andreacola, F.R.; Brando, G. Additive Manufacturing of Metal Materials for Construction Engineering: An Overview on Technologies and Applications. Metals 2024, 14, 1033. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Pellegrini, A.; Guerra, M.G.; Lavecchia, F. 3D Printing of parts using metal extrusion: An overview of shaping debinding and sintering technology. Adv. Technol. Mater. 2022, 47, 25–32. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Perše, L.S.; Nanni, F. Advancements in Metal Additive Manufacturing: A Comprehensive Review of Material Extrusion with Highly Filled Polymers. J. Manuf. Mater. Process. 2024, 8, 14. [Google Scholar] [CrossRef]

- Cañadilla, A.; Rodríguez, G.; Romero, A.; Caminero, M.A.; Dura, O.J. Sustainable production of copper components using concentrated solar energy in material extrusion additive manufacturing (MEX-CSE). Sustain. Mater. Technol. 2024, 39, e00799. [Google Scholar] [CrossRef]

- Cañadilla, A.; Romero, A.; Rodríguez, G.P.; Caminero, M.; Dura, Ó.J. Mechanical, Electrical, and Thermal Characterization of Pure Copper Parts Manufactured via Material Extrusion Additive Manufacturing. Materials 2022, 15, 4644. [Google Scholar] [CrossRef]

- Muñiz-Lerma, J.A.; Nommeots-Nomm, A.; Waters, K.E.; Brochu, M. A comprehensive approach to powder feedstock characterization for powder bed fusion additive manufacturing: A case study on AlSi7Mg. Materials 2018, 11, 2386. [Google Scholar] [CrossRef]

- Lores, A.; Azurmendi, N.; Agote, I.; Zuza, E. A review on recent developments in binder jetting metal additive manufacturing: Materials and process characteristics. Powder Met. 2019, 62, 267–296. [Google Scholar] [CrossRef]

- Dwivedi, A.; Khurana, M.K.; Bala, Y.G. Effect of parameters on quality of IN718 parts using laser additive manufacturing. Mater. Sci. Technol. 2024, 40, 633–648. [Google Scholar] [CrossRef]

- Yildiz, R.A.; Popa, A.-A.; Malekan, M. On the Effect of Small Laser Spot Size on the Mechanical Behaviour of 316 L Stainless Steel Fabricated by L-PBF Additive Manufacturing. Mater. Today Commun. 2024, 38, 108168. [Google Scholar] [CrossRef]

- Alazhari, M. Optimization of Process Parameters in Metal Additive Manufacturing for Enhanced Mechanical Properties and Surface Finish. Int. J. Multidiscip. Res. 2025, 7, 1–8. [Google Scholar] [CrossRef]

- Shoukr, D.; Morocos, P.; Sundermann, T.; Yates, C.; Jain, J.; Arroyave, R.; Karaman, I.; Elwany, A. Influence of layer thickness on the printability of nickel alloy 718:A systematic process optimization framework. Addit. Manuf. 2023, 73, 103646. [Google Scholar] [CrossRef]

- Brudler, S.; Medvedev, A.; Pandelidi, C.; Piegert, S.; Illston, T.; Qian, M.; Brandt, M. Systematic Investigation of Performance and Productivity in Laser Powder Bed Fusion of Ti6Al4V up to 300 µm Layer Thickness. J. Mater. Process. Technol. 2024, 330, 118450. [Google Scholar] [CrossRef]

- Gallego, D.A.; Oliveira, H.R.; da Cunha, T.V.; Pacheco, J.T.; Kovalenko, O.P.; Volpato, N. Impact of Laser Power and Scanning Speed on Single-Walled Support Structures in Powder Bed Fusion of AISI 316L. J. Manuf. Mater. Process. 2025, 9, 254. [Google Scholar] [CrossRef]

- Paraschiv, A.; Matache, G.; Condruz, M.R.; Frigioescu, T.F.; Pambaguian, L. Laser Powder Bed Fusion Process Parameters’ Optimization for Fabrication of Dense IN 625. Materials 2022, 15, 5777. [Google Scholar] [CrossRef] [PubMed]

- Pitrmuc, Z.; Šimota, J.; Beránek, L.; Mikeš, O.; Andronov, V.; Sommer, J.; Holešovský, F. Mechanical and Microstructural Anisotropy of Laser Powder Bed Fusion 316L Stainless Steel. Materials 2022, 15, 551. [Google Scholar] [CrossRef]

- Shin, S.; Kwon, S.-M.; Kim, C.; Lee, J.; Hwang, J.; KIm, H. Optimization of Direct Energy Deposition of 304L Stainless Steel through Laser Process Parameters. J. Weld. Join. 2021, 39, 182–188. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Madapana, D.; Manna, I. 3-D Printing by Laser-Assisted Direct Energy Deposition (LDED): The Present Status. Trans. Indian. Natl. Acad. Eng. 2021, 6, 933–953. [Google Scholar] [CrossRef]

- Jung, J.; Jo, M.C.; Lee, K.; Park, L. Influence of Powder Feed Density on Mechanical Properties and Microstructure in L-DED Additive Manufactured STS316L. Korean J. Met. Mater. 2024, 63, 11–22. [Google Scholar] [CrossRef]

- Chen, Y.; Qiu, J.-R.; Chang, W.; Hwang, Y.-K.; Hwang, S. Process Optimization and Mechanical Properties Analysis of Inconel 718/Stainless Steel 316L Multi-material via Direct Energy Deposition. Sci. Rep. 2024, 14, 28927. [Google Scholar] [CrossRef]

- Xu, K.H.; Li, B.; Jiang, C. Adjusting microstructure and improving mechanical property of additive manufacturing 316L based on process optimization. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2023, 870, 144824. [Google Scholar] [CrossRef]

- Miyanaji, H.; Rahman, K.M.; Da, M.; Williams, C.B. Effect of fine powder particles on quality of binder jetting parts. Addit. Manuf. 2020, 36, 101587. [Google Scholar] [CrossRef]

- Huang, N.; Cook, O.J.; Argüelles, A.P.; Beese, A.M. Review of Process–Structure–Property Relationships in Metals Fabricated Using Binder Jet Additive Manufacturing. Met. Microstruct. Anal. 2023, 12, 883–905. [Google Scholar] [CrossRef]

- Shanthappa, P.; Malgave, S.; Nagaraja, A.; Acharya, K. Optimization of stainless-steel powder and printing parameters to enhance the densification and productivity in binder jet additive manufacturing process. Funtai Oyobi Fummatsu Yakin/J. Jpn. Soc. Powder Powder Metall. 2025, 72, S335–S340. [Google Scholar] [CrossRef]

- Zago, M.; Segata, G.; Perina, M.; Molinari, A. Binder jet 3D printing of 316L stainless steel: A Taguchi analysis of the dependence of density and mechanical properties on the printing parameters. J. Mater. Res. Technol. 2025, 34, 337–347. [Google Scholar] [CrossRef]

- Wang, C.; Mai, W.; Shi, Q.; Liu, Z.; Pan, Q.; Peng, J. Effect of Printing Parameters on Mechanical Properties and Dimensional Accuracy of 316L Stainless Steel Fabricated by Fused Filament Fabrication. J. Mater. Eng. Perform. 2024, 33, 11781–11793. [Google Scholar] [CrossRef]

- Fazzini, F.; Boschetto, A.; Bottini, L.; Diez, A.C.; Cini, A. Correlation between Metal Fused Filament Fabrication parameters and material properties of sintered 17-4 PH. Procedia Struct. Integr. 2023, 49, 59–66. [Google Scholar] [CrossRef]

- Godec, D.; Cano, S.; Holzer, C.; Gonzalez-Gutierrez, J. Optimization of the 3D printing parameters for tensile properties of specimens produced by fused filament fabrication of 17-4PH stainless steel. Materials 2020, 13, 774. [Google Scholar] [CrossRef]

- Huang, N.; Cook, O.J.; Smithson, R.L.W.; Kube, C.M.; Argüelles, A.P.; Beese, A.M. Use of ultrasound to identify microstructure-property relationships in 316 stainless steel fabricated with binder jet additive manufacturing. Addit. Manuf. 2022, 51, 102591. [Google Scholar] [CrossRef]

- Drazan, T.; Joska, Z.; Kluczyński, J.; Płatek, P.; Dobrocky, D.; Krchova, M. Analysis of the effect of changing printing parameters on the properties of additively manufactured Ultrafuse 316L steel samples. Arch. Civ. Mech. Eng. 2025, 25, 204. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Paul, B.K.; Pasebani, S. Microstructure-property relationship in binder jet produced and vacuum sintered 316 L. Addit. Manuf. 2022, 53, 102720. [Google Scholar] [CrossRef]

- Ibrahim, B.; Lopez, L.; Kulkarni, S.; Jobes, D.; Forgiarini, M.; Barber, J.; Gordon, J. Increasing strength properties in sinter-based additive manufacturing of SS316L via metal material jetting of sub-micron powders. Addit. Manuf. 2024, 89, 104268. [Google Scholar] [CrossRef]

- Xu, M.; Guo, H.; Wang, Y.; Hou, Y.; Dong, Z.; Zhang, L. Mechanical properties and microstructural characteristics of 316L stainless steel fabricated by laser powder bed fusion and binder jetting. J. Mater. Res. Technol. 2023, 24, 4427–4439. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Nanni, F. A simple route for additive manufacturing of 316L stainless steel via Fused Filament Fabrication. J. Manuf. Process. 2021, 67, 141–150. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Nurhudan, A.I.; Supriadi, S.; Whulanza, Y.; Saragih, A.S. Additive manufacturing of metallic based on extrusion process: A review. J. Manuf. Process. 2021, 66, 228–237. [Google Scholar] [CrossRef]

- Kathiresan, M.; Karthikeyan, M.; Immanuel, R.J. A short review on SLM-processed Ti6Al4V composites. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2023, 238, 3054–3069. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, J.; Zhang, B.; An, K.; Wang, Y.; Liu, D.; Lu, W.; Zhu, L.; Liu, C. Recent advance in laser powder bed fusion of Ti–6Al–4V alloys: Microstructure, mechanical properties and machinability. Virtual Phys. Prototyp. 2025, 20, e2446952. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Gokce, A.; Atre, S.V.; Kate, K.H. Additive manufacturing of Ti-6Al-4V alloy by metal fused filament fabrication (MF3): Producing parts comparable to that of metal injection molding. Progress. Addit. Manuf. 2021, 6, 593–606. [Google Scholar] [CrossRef]

- Simchi, A.; Petzoldt, F.; Hartwig, T.; Hein, S.B.; Barthel, B.; Reineke, L. Microstructural development during additive manufacturing of biomedical grade Ti-6Al-4V alloy by three-dimensional binder jetting: Material aspects and mechanical properties. Int. J. Adv. Manuf. Technol. 2023, 127, 1541–1558. [Google Scholar] [CrossRef]

- Barbagallo, R.; Di Bella, S.; Mirone, G.; La Rosa, G. Study of the Electron Beam Melting Process Parameters’ Influence on the Tensile Behavior of 3D Printed Ti6Al4V ELI Alloy in Static and Dynamic Conditions. Materials 2022, 15, 4217. [Google Scholar] [CrossRef] [PubMed]

- Thompson, Y.; Zissel, K.; Förner, A.; Gonzalez Gutierrez, J.; Kukla, C.; Neumeier, S.; Felfer, P. Metal fused filament fabrication of the nickel-base superalloy IN 718. J. Mater. Sci. 2022, 57, 9541–9555. [Google Scholar] [CrossRef]

- Kubášová, K.; Drátovská, V.; Losertová, M.; Salvetr, P.; Kopelent, M.; Kořínek, F.; Havlas, V.; Džugan, J.; Daniel, M. A Review on Additive Manufacturing Methods for NiTi Shape Memory Alloy Production. Materials 2024, 17, 1248. [Google Scholar] [CrossRef]

- Meng, G.; Gong, Y.; Zhang, J.; Ren, Q.; Zhao, J. Microstructure effect on the machinability behavior of additive and conventionally manufactured Inconel 718 alloys. J. Mater. Process. Technol. 2024, 324, 118228. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A review of the as-built SLM Ti-6Al-4V mechanical properties towards achieving fatigue resistant designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef]

- Dong, H.; Liu, F.; Ye, L.; Ouyang, X.; Wang, Q.; Wang, L.; Huang, L.; Tan, L.; Jin, X.; Liu, Y. Process optimization and mechanical property investigation of Inconel 718 manufactured by selective electron beam melting. Mater. Sci. Addit. Manuf. 2022, 1, 23. [Google Scholar] [CrossRef]

- Zimmermann, M.; Müller, D.; Kirsch, B.; Greco, S.; Aurich, J.C. Analysis of the machinability when milling AlSi10Mg additively manufactured via laser-based powder bed fusion. Int. J. Adv. Manuf. Technol. 2020, 112, 989–1005. [Google Scholar] [CrossRef]

- Ross, N.S.; Srinivasan, N.; Ananth, M.B.J.; AlFaify, A.Y.; Anwar, S.; Gupta, M.K. Performance assessment of different cooling conditions in improving the machining and tribological characteristics of additively manufactured AlSi10Mg alloy. Tribol. Int. 2023, 186, 108631. [Google Scholar] [CrossRef]

- Zhao, L.; Song, L.; Santos Macías, J.; Zhu, Y.; Huang, M.; Simar, A.; Li, Z. Review on the correlation between microstructure and mechanical performance for laser powder bed fusion AlSi10Mg. Addit. Manuf. 2022, 56, 102914. [Google Scholar] [CrossRef]

- de L, G.; Reis, L.; de Oliveira, R.; Massi, M.; Gonçalves, R.L.; Couto, A.A. The Influence of Manufacturing Parameters and Heat Treatments on the Properties of AlSi10Mg Alloy Produced Using L-PBF. Metals 2025, 15, 941. [Google Scholar] [CrossRef]

- Qi, S.; Li, L.; Sun, J.; Yang, B.; Song, B.; Zhang, H.; Gu, D. Effect of Powder Spreading Parameters on Laser Absorption Behavior and Processability of High-Strength Aluminum Alloy Fabricated by Laser Powder Bed Fusion. Adv. Eng. Mater. 2024, 26, 2401588. [Google Scholar] [CrossRef]

- Klanjšček, U.; Kalin, M. Analysis of the Topographical, Microstructural and Mechanical Surface Properties of Powder Bed Fusion Melted AlSi10Mg for a Broad Range of Process Parameters. J. Manuf. Mater. Process. 2025, 9, 200. [Google Scholar] [CrossRef]

- Hosseini, F.; Asad, A.; Yakout, M. Microstructure Characterization and Mechanical Properties of Al6061 Alloy Fabricated by Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2024, 8, 288. [Google Scholar] [CrossRef]

- Hakami, A.; Ojo, S.A.; Abere, D.V.; Uzuh, F.D.; Robert, R.A. Advancements in metal additive manufacturing: Opportunities, limitations, impact on properties, and potential solutions: A review. Progress. Addit. Manuf. 2025, 10, 4447–4495. [Google Scholar] [CrossRef]

- Skrodzka, M.; Cieślak, A.; Szymczyk-Ziółkowska, P.; Łabowska, M.B.; Ducka, M.; Detyna, J. Comparison of Different Metal Additive Manufacturing Techniques for Biomedical Application. In Metal Additive Manufacturing: Principles, Techniques and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2025; pp. 297–331. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.; Lee, J.; Zhang, J. Additive Manufacturing of Metallic Materials: A Review. J. Mater. Eng. Perform. 2017, 27, 1–13. [Google Scholar] [CrossRef]

- Sharma, S.; Meena, A. Microstructure Induced Shear Instability Criterion During High-Speed Machining of Ti–6Al–4V. J. Manuf. Sci. Eng.-Trans. Asme 2020, 143, 061001. [Google Scholar] [CrossRef]

- Malakizadi, A.; Mallipeddi, D.; Dadbakhsh, S.; M’Saoubi, R.; Krajnik, P. Post-processing of additively manufactured metallic alloys–A review. Int. J. Mach. Tools Manuf. 2022, 179, 103908. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Al-Rubaie, K.S.; Melotti, S.; Rabelo, A.; Paiva, J.M.; Elbestawi, M.A.; Veldhuis, S.C. Machinability of SLM-produced Ti6Al4V titanium alloy parts. J. Manuf. Process. 2020, 57, 768–786. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Sievers, D.E.; Liang, S.Y. Effect of Time Spacing and Hatch Spacing on Thermal Material Properties and Melt Pool Geometry in Additive Manufacturing of S316L. In International Manufacturing Science and Engineering Conference; American Society of Mechanical Engineers: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Yang, P.; Johnson, K.; Carroll, J.; Buckner, J.; Blea-Kirby, M.; Groves, C.; Coker, E. Thermophysical properties of additively manufactured Ti-5553 alloy. Addit. Manuf. 2023, 76, 103769. [Google Scholar] [CrossRef]

- Morfini, L.; Gurrado, N.; Spina, R. Effect of process parameters on the thermal properties of material extruded AM parts. In Materials Research Proceedings; Association of American Publishers: Washington, DC, USA, 2023; pp. 225–231. [Google Scholar] [CrossRef]

- Ron, T.; Shirizly, A.; Aghion, E. Additive Manufacturing Technologies of High Entropy Alloys (HEA): Review and Prospects. Materials 2023, 16, 2454. [Google Scholar] [CrossRef]

- Ramazani, H.; Kami, A. Metal FDM, a new extrusion-based additive manufacturing technology for manufacturing of metallic parts: A review. Prog. Addit. Manuf. 2022, 7, 609–626. [Google Scholar] [CrossRef]

- Tosto, C.; Tirillò, J.; Sarasini, F.; Sergi, C.; Cicala, G. Fused Deposition Modeling Parameter Optimization for Cost-Effective Metal Part Printing. Polymers 2022, 14, 3264. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Gutiérrez, A.R.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J. Effects of fused filament fabrication parameters on the manufacturing of 316L stainless-steel components: Geometric and mechanical properties. Rapid Prototyp. J. 2022, 28, 2004–2026. [Google Scholar] [CrossRef]

- Kumar, A.; Boparai, K.S.; Chohan, J.S.; Singh, R. Investigations and predictions for mechanical and surface properties of FFF prints using DOE, ML and FEA. Adv. Mater. Process. Technol. 2024, 10, 1767–1783. [Google Scholar] [CrossRef]

- Aruanno, B.; Paoli, A.; Razionale, A.V.; Tamburrino, F. Effect of printing parameters on extrusion-based additive manufacturing using highly filled CuSn12 filament. Int. J. Adv. Manuf. Technol. 2023, 128, 1101–1114. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.; et al. The microstructure, mechanical properties and corrosion resistance of 316 L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Saboori, A.; Piscopo, G.; Lai, M.; Salmi, A.; Biamino, S. An investigation on the effect of deposition pattern on the microstructure, mechanical properties and residual stress of 316L produced by Directed Energy Deposition. Mater. Sci. Eng. A 2020, 780, 139179. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by ‘selective laser melting’, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.; Liu, E.; Tor, S.B. Process parameter optimization and mechanical properties for additively manufactured stainless steel 316L parts by selective electron beam melting. Mater. Des. 2018, 147, 157–166. [Google Scholar] [CrossRef]

- Kas, M.; Muslim, T.; Yilmaz, O.; Karagoz, T.; Turedi, E.; Gumus, S.; Bayram, A. Directed energy deposition of PH 13–8 Mo stainless steel: Microstructure and mechanical property analysis. Int. J. Adv. Manuf. Technol. 2024, 132, 701–715. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Pasebani, S. A review on binder jet additive manufacturing of 316L stainless steel. J. Manuf. Mater. Process. 2019, 3, 82. [Google Scholar] [CrossRef]

- Wang, D.; Lv, J.; Wei, X.; Lu, D.; Chen, C. Study on Surface Roughness Improvement of Selective Laser Melted Ti6Al4V Alloy. Crystals 2023, 13, 306. [Google Scholar] [CrossRef]

- Alegre, J.M.; Díaz, A.; García, R.; Peral, L.B.; Lorenzo-Bañuelos, M.; Cuesta, I.I. Mechanical and Fatigue Properties of Ti-6Al-4V Alloy Fabricated Using Binder Jetting Process and Subjected to Hot Isostatic Pressing. Materials 2024, 17, 3825. [Google Scholar] [CrossRef] [PubMed]

- Braun, D.; Ganor, Y.; Samuha, S.; Guttmann, G.; Chonin, M.; Frage, N.; Hayun, S.; Tiferet, E. A Design of Experiment Approach for Development of Electron Beam Powder Bed Fusion Process Parameters and Improvement of Ti-6Al-4V As-Built Properties. J. Manuf. Mater. Process. 2022, 6, 90. [Google Scholar] [CrossRef]

- Mostafaei, A.; Stevens, E.L.; Hughes, E.T.; Biery, S.D.; Hilla, C.; Chmielus, M. Powder bed binder jet printed alloy 625: Densification, microstructure and mechanical properties. Mater. Des. 2016, 108, 126–135. [Google Scholar] [CrossRef]

- Mostafaei, A.; Toman, J.; Stevens, E.L.; Hughes, E.T.; Krimer, Y.L.; Chmielus, M. Microstructural evolution and mechanical properties of differently heat-treated binder jet printed samples from gas- and water-atomized alloy 625 powders. Acta Mater. 2017, 124, 280–289. [Google Scholar] [CrossRef]

- Strondl, A.; Palm, M.; Gnauk, J.; Frommeyer, G. Microstructure and mechanical properties of nickel based superalloy IN718 produced by rapid prototyping with electron beam melting (EBM). Mater. Sci. Technol. 2011, 27, 876–883. [Google Scholar] [CrossRef]

- Ortmann, R.; Kretzer, N.; Grimm, D.-I.T.; Jan Sehrt, D.-I.T. Powder bed fusion of AlSi10Mg using an electron beam-Processability, microstructure and mechanical properties. RTe J. 2024. [Google Scholar] [CrossRef]

- Volosevich, D.; Shabunina, Z.; Yurchenko, N.; Mendagaliev, R.; Slatenko, E.; Klimov, G.; Klimova-Korsmik, O.; Eremeev, A. Investigation of the Heat Treatment Regimes on the Structure and Microhardness of Laser Direct Energy Dep; osition Aluminum Alloy AlSi10Mg. Metals 2025, 15, 92. [Google Scholar] [CrossRef]

- Soni, H.; Limbasiya, N.; Jain, A.; Gill, S.S.; Sahlot, P. Investigation of mechanical and surface properties of additively manufactured AlSi10Mg part produced through direct metal laser sintering. Mater. Today Proc. 2022, 62, 7204–7209. [Google Scholar] [CrossRef]

- Tan, C.; Li, R.; Su, J.; Du, D.; Du, Y.; Attard, B.; Chew, Y.; Zhang, H.; Lavernia, E.J.; Fautrelle, Y.; et al. Review on field assisted metal additive manufacturing. Int. J. Mach. Tools Manuf. 2023, 189, 104032. [Google Scholar] [CrossRef]

- Kumar, S.; Kishor, B. Ultrasound Added Additive Manufacturing for Metals and Composites: Process and Control. In Additive and Subtractive Manufacturing of Composites; Rangappa, S.M., Gupta, M.K., Siengchin, S., Song, Q., Eds.; Springer: Singapore, 2021; pp. 53–72. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, D.; Wan, M. A review of strengthening mechanisms and applications of the multifield-coupled manufacturing process. J. Mater. Process. Technol. 2023, 320, 118128. [Google Scholar] [CrossRef]

- Li, X.; Wang, W.; Wu, Y.; Zhou, D.; Kang, H.; Guo, E.; Li, J.; Chen, Z. Ultrasonic field-assisted metal additive manufacturing (U-FAAM): Mechanisms, research and future directions. Ultrason. Sonochem. 2024, 111, 107070. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Brandt, M.; StJohn, D.H.; Qian, M. Grain refinement of stainless steel in ultrasound-assisted additive manufacturing. Addit. Manuf. 2021, 37, 101632. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Dun, Y.; Ning, J.; Wang, S.; Xue, P.; Xu, P.; Yu, M.; Yan, B.; Xin, B. In-situ monitoring of the melt pool dynamics in ultrasound-assisted metal 3D printing using machine learning. Virtual Phys. Prototyp. 2023, 18, 2251453. [Google Scholar] [CrossRef]

- Liao, Z.; Schoop, J.; Saelzer, J.; Bergmann, B.; Priarone, P.; Splettstößer, A.; Bedekar, V.; Zanger, F.; Kaynak, Y. Review of current best-practices in machinability evaluation and understanding for improving machining performance. CIRP J. Manuf. Sci. Technol. 2024, 50, 151–184. [Google Scholar] [CrossRef]

- Li, G.; Chandra, S.; Rashid, R.A.R.; Palanisamy, S.; Ding, S. Machinability of additively manufactured titanium alloys: A comprehensive review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Silva, T.; Amaral, A.; Couto, A.; Coelho, J.; Reis, A.; Rosa, P.; de Jesus, A. Comparison of the machinability of the 316L and 18Ni300 additively manufactured steels based on turning tests. Proc. Inst. Mech. Eng. Part. L J. Mater. Des. Appl. 2021, 235, 2207–2226. [Google Scholar] [CrossRef]

- Miroslav, P.; Pavlĺna, T.; Jana, H.; Pavel, Š.; Boivie, K. A Study of Selective Laser Melting Technology on the Ultra-High Strength Tool Steel Use—Quality, Mechanical Properties and Fatigue. In Applied Mechanics, Behavior of Materials, and Engineering Systems; Boukharouba, T., Pluvinage, G., Azouaoui, K., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 67–86. [Google Scholar]

- Cozzolino, E.; Franchitti, S.; Borrelli, R.; Astarita, A. Comparison of specific cutting energy in dry and wet post-process turning of Ti6Al4V EBM parts. In Materials Research Proceedings; Association of American Publishers: Washington, DC, USA, 2023; pp. 95–102. [Google Scholar] [CrossRef]

- Festas, A.J.; Ramos, A.; Davim, J.P. Machining of a functional hip prosthesis cone in TI-6AL-4V ELI titanium alloy produced by electron beam melting. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 182. [Google Scholar] [CrossRef]

- Raval, J.; Kazi, A.; Randolph, O.; Guo, X.; Zvanut, R.; Lee, C.; Tai, B. Machinability comparison of additively manufactured and traditionally wrought Ti-6Al-4V alloys using single-point cutting. J. Manuf. Process. 2023, 94, 539–549. [Google Scholar] [CrossRef]

- Tripathi, V.; Armstrong, A.; Gong, X.; Manogharan, G.; Simpson, T.; De Meter, E. Milling of Inconel 718 block supports fabricated using laser powder bed fusion. J. Manuf. Process. 2018, 34, 740–749. [Google Scholar] [CrossRef]

- Hojati, F.; Daneshi, A.; Soltani, B.; Azarhoushang, B.; Biermann, D. Study on machinability of additively manufactured and conventional titanium alloys in micro-milling process. Precis. Eng. 2020, 62, 1–9. [Google Scholar] [CrossRef]

- Duro, M.; Silva, T.; Marques, M.J.; Batista, A.; Rosa, P.; de Jesus, A. Influence of post-processing milling conditions on the machinability and residual stresses evolution of LPBF 18Ni300 maraging steel. Int. J. Adv. Manuf. Technol. 2023, 127, 2287–2297. [Google Scholar] [CrossRef]

- Jeyamohan, R.; Dhayanithi, S.; Krishnaswamy, H.; Astarita, A.; Narayanan, A. A comprehensive investigation on the effect of processing conditions on the dry drilling performance of electron beam melting–manufactured Ti6Al4V. Int. J. Adv. Manuf. Technol. 2024, 132, 2427–2441. [Google Scholar] [CrossRef]

- Dang, J.; Cai, X.; Yu, D.; An, Q.; Ming, W.; Chen, M. Effect of material microstructure on tool wear behavior during machining additively manufactured Ti6Al4V. Arch. Civ. Mech. Eng. 2020, 20, 4. [Google Scholar] [CrossRef]

- Utayeva, N.N. Surface characteristics improvement methods for metal additively manufactured parts: A review. Adv. Mater. Process. Technol. 2022, 8, 4524–4563. [Google Scholar] [CrossRef]

- Diniță, A.; Neacșa, A.; Portoacă, A.I.; Tănase, M.; Ilinca, C.N.; Ramadan, I.N. Additive Manufacturing Post-Processing Treatments, a Review with Emphasis on Mechanical Characteristics. Materials 2023, 16, 4610. [Google Scholar] [CrossRef]

- Dinesh, S.; Sahu, J. A Comprehensive Review on Laser Powder Bed Fusion Process of SS316L Mechanical Properties and Post-Processing. Met. Mater. Int. 2025, 1–33. [Google Scholar] [CrossRef]

- Oyelola, O.; Jackson-Crisp, A.; Crawforth, P.; Pieris, D.; Smith, R.; M’Saoubi, R.; Clare, A. Machining of directed energy deposited Ti6Al4V using adaptive control. J. Manuf. Process. 2020, 54, 240–250. [Google Scholar] [CrossRef]

- Denkena, B.; Hufenbach, J.; Bergmann, B.; Kühn, U.; Kaban, V.; Schenzel, J.; Worpenberg, S.; Kunz, C. Impact of microstructure and heat treatment on chip formation of Ti-5553 processed by laser powder bed fusion. Prod. Eng. 2025, 19, 1163–1175. [Google Scholar] [CrossRef]

- Amith, V.K.; Baloor, S.S.; Polishetty, A.; Bolar, G.; Govindhan, A.N. Heat treatment and its effect on machining induced surface roughness of cast and additive manufactured AlSi10Mg. Sci. Rep. 2025, 15, 26433. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Kim, K.-H.; Jeong, J.; Jeon, H.; Jung, I.D. Advancing intelligent additive manufacturing: Machine learning approaches for process optimization and quality control. Deleted J. 2025, 2, 25130010. [Google Scholar] [CrossRef]

- Gunasegaram, D.; Barnard, A.; Matthews, M.; Jared, B.; Andreaco, A.; Bartsch, K.; Bartsch, K. Machine learning-assisted in-situ adaptive strategies for the control of defects and anomalies in metal additive manufacturing. Addit. Manuf. 2024, 81, 104013. [Google Scholar] [CrossRef]

- Rao, Y.; Vempati, S.R.; Chinni, H.B.; Gamini, S. Intelligent Additive Manufacturing is Unleashing the Power of 3D Printing with Machine Learning. Recent Pat. Mech. Eng. 2025, 19, 1–16. [Google Scholar] [CrossRef]

- Chen, Y.; Karkaria, V.; Tsai, Y.; Rolark, F.; Quispe, D.; Gao, R.; Cao, J.; Chen, W. Real-Time Decision-Making for Digital Twin in Additive Manufacturing with Model Predictive Control using Time-Series Deep Neural Networks. J. Manuf. Syst. 2025, 80, 412–424. [Google Scholar] [CrossRef]

- Hu, C.; Yang, H.-C.; Lu, Y.; Yang, C.-W.; Kao, Y.; Cheng, F. A Distributed AM Architecture with Digital Twin for L-PBF Cluster. In Proceedings of the 2024 IEEE 20th International Conference on Automation Science and Engineering (CASE), Bari, Italy, 28 August–1 September 2024; pp. 698–704. [Google Scholar] [CrossRef]

- Amor, S.B.; Elloumi, N.; Eltaief, A.; Louhichi, B.; Alrasheedi, N.H.; Seibi, A. Digital Twin Implementation in Additive Manufacturing: A Comprehensive Review. Processes 2024, 12, 1062. [Google Scholar] [CrossRef]

- Fan, H.; Liu, C.; Bian, S.; Ma, C.; Huang, J.; Liu, X.; Doyle, M.; Lu, T.; Chow, E.; Chen, L.i.; et al. New Era Towards Autonomous Additive Manufacturing: A Review of Recent Trends and Future Perspectives. Int. J. Extrem. Manuf. 2025, 7, 032006. [Google Scholar] [CrossRef]

- Phua, A.; Delaney, G.W.; Cook, P.S.; Davies, C.H.J. Intelligent Digital Twins can Accelerate Scientific Discovery and Control Complex Multi-Physics Processes. Addit. Manuf. 2024, 87, 104214. [Google Scholar]

- Li, Y.; Mojumder, S.; Lu, Y.; Amin, A.; Guo, J.; Xie, X.; Chen, W.; Wagner, G.; Cao, J.; Liu, W. Statistical Parameterized Physics-Based Machine Learning Digital Twin Models for Laser Powder Bed Fusion Process. arXiv 2023, arXiv:2311.07821. [Google Scholar] [CrossRef]

- Liu, N.; Li, X.; Rajanna, M.; Reutzel, E.; Sawyer, B.; Rao, P.; Lua, J.; Phan, N.; Phan, N. Deep Neural Operator Enabled Digital Twin Modeling for Additive Manufacturing. arXiv 2024, arXiv:2405.09572. [Google Scholar] [CrossRef]

| Material | PBF | LDED | BJT | MEX | References | |

|---|---|---|---|---|---|---|

| SLM | EBM | |||||

| SS316L | P = 90 to 400 W PT = 150 °C SG: Ar 550–600 L/min BO: 45° or 90° SR: 45° ot 67° HP: rectangular or hexagonal h: reducer v: moderated d: 30 to 50 µm ED = 50–125 J/mm3 SpS: smaller or higher | BC: 15 mA PT: 800 to 850 °C VP: He for 10−3 to 10−2 BO: Vertical or horizontal ScSt: 90° h: 0.1 mm v: 2800 to 4350 mm/s d: 50 to 70 µm ED: 64.28 J/mm3 BSS: smaller | P = 400 W PT = 300 °C SG = Ar + 3%Ni; 5–25 L/min BO: 0° or 90° FR: 10 g/min DP: Offset, Raster ND: 0.02 to 0.40 mm ID: 15% v: 960 to 1200 mm/min | BS: 85 to 65% d: 25–100 µm DT: 20 to 15 s RTS: 7 mm/s PT: 45 to 55 °C PS: 150 mm/s Cured 55 °C Sintered: Tem: 1380 to 1950 °C Time: 2 to 6 h Atm: Vaccum/Ar or H2 | B: TPE, O, LDPE, POM, PW NT: 220 to 290 °C ND: 0.3 to 0.8 mm PT: 60 to 100 °C d: 0.1 to 0.25 mm PS: 15 to 80 mm/s Lw: ±10–20% ID 100% Raster angle 0–90° Debindig Cycloehexane Ni Temp: 70 to 500 °C Time: 90 min Heating rate: 5 °C/min Sintered H2, Ar Tem: 1380 °C Time: 180 min Heating rate: 5 °C/min | [14,32,53,54,55,56,57,58,59,60] |

| Ti6Al4V | P = 150–400 W PT = 220–500 °C SG: BO: 45° SR: HP: Chessboard, stripe pattern h: 50 to 100 µm v: 800 to 1200 mm/s d: 30 to 50 µm ED: SpS: 45 to 100 | BC: 25 to 30 mA PT: 730 °C VP: 10−3 mbar BO: horizontal ScSt: h: 0.1 mm v: d: 50 µm ED: BSS: | P: 70 to 400 W PT: SG d: 20 to 50 µm FR DP ND ID v: 70 to 1800 mm/s | B: Organic and inorganic BS: 40 to 80% d: 30 to 90 µm DS: RTS PT: 40 to 60 °C Cured Oven at 180 °C for 4 h Heating rate 3 °C/min up to 550 °C held for 60 min Sintered: Tem: 1000 to 1360 °C Time: 60 and 40 min Heating rate: 5 °C/min Cooling rate: 10 °C/min | B: PVA, PP-PE, TPE, PO NT: 240 °C ND: 400 µm PT: 65 °C D: 150 µm PS: 10 mm/s Lw: ID: 100% Debinding Acetone, water Heating rate 1 °C/min four holds 250° for 3 h 330 °C for 3 h 440 °C for h and 550 °C for 4 h Sintered Partial vacuum of 150 millitons at 1250 °C or 1340 °C for 4 h Ar Heating rate 3 °C/min | [27,60,61,62,63,64,65] |

| Inconel 718, Inconel NiTi | P = 40 to 1000 W PT= SG: BO: 67° SR: HP: h: 60 to 120 µm v: 50 to 1400 mm/S d: 30 to 1000 µm LT: ED: SpS: | BC: 7.5 to 27.5 mA PT: 900 °C VP: BO: 90° ScSt: h: v: 2000 to 8000 mm/s d: 50 µm LT: ED: SpS: 50 µm | P: 500 to 1000 W PT SG d: 250 to 1000 µm h: 500 to 220 µm FR DP ND ID v: 10.16 to 16.67 mm/s | BS: LT: DS: RTS PT: Sintered: Tem: 1270 °C Time: 10 h Atm: | B: TPE, PO, PD, LDPE, SA, PA, PW NT: 210 to 280 °C ND: 0.6 mm PT: 20 °C d: 0.1 mm PS: 10 mm/s Lw: 0.75 mm Debinding | [66,67,68,69,70] |

| Al Alloys | P = 300–400 W PT = 35–200 °C SG: BO: 67° SR: HP: h: 60–190 µm v: 600–1300 mm/s d: 30 to 70 µm ED: 42.18 to 80.58 j/mm3 SpS: | BC: 3.33 to 8.33 mA PT: VP: BO: 90, 45, and 0° ScSt: h: 100 µm v: 500–1500 mm/s d: 100 µm ED: SpS: 100 µm | P: 370 W PT SG d: 30 µm FR DP ND ID v: 1300 mm/s | BS: d: DS: RTS PT: Sintered: Tem: °C Time: hr Atm: | NT: ND: PT: d: PS: Lw: | [71,72,73,74,75,76,77] |

| Material | Mechanical Characteristics | |||||

|---|---|---|---|---|---|---|

| PBF | DED | BJ | MEX | References | ||

| SLM | EBM | |||||

| SS316L | MG: has an austenite microstructure Ra: H: 197 to 270 HV Ts: 555 to 738 MPa Ys: 541 to 718 MPa %e: 20 to 47 | MG: columnar grain, intergranular dendrites, discontinuous precipitates, and precipitates are rich in Cr and Mo Ra: - H: - Ts: 436 to 651.7 MPa Ys: 315.17 to 395.8 MPa %e: 9.6 to 30.6 | MG: columnar dendrites that grew epitaxially from the substrate, primary austenite cells contain intercellular ferrite and martensite Ra: H: 272 to 289 HV; 295 to 428 PH13-8Mo Ts: 469 to 703 MPa 1129 to 1148 MPa PH13-8Mo Ys: 479 to 649 MPa 641 to 787 MPa PH13-8Mo %e: 17 to 33; 5.17 to 7.28 PH13-8Mo | MG: Sintering introduces a higher level of delta-ferrite phase, and leaves some ferrite residues after cooling Ra: - H; 66 HRB Ts: 437 to 640 MPa Ys: 191 to 312 MPa %e: 5.3 to 73 | MG: extrusión Poros, Interlayer gap Ra: - H: 60 HRB Ts: 719 to 761 MPa Ys: 548 to 590 MPa %e: 168 to 6.62 | [51,53,55,56,57,63,94,95,96,97,98,99] |

| Ti6Al4V | MG: bimodal (α + β), lamellar (α + β), Equiaxed (globular) primary α with β along the grain boundaries, acicular α’ Ra: 2.65 to 5.10 µm H: 364 HV Ts: 1260 MPa Ys: 925 to 1160 MPa %e: 1.7 to 9.66 | MG: V-rich β phase and Al-rich α phase, β length and width, and α thickness Ra: 1.62 to 3.49 µm H: 371 to 385 HV Ts: 792 to 1269 MPa Ys: 630 to 1195 MPa %e: 2.7 to 17 | MG: - Ra: - H: - Ts: 884 to 1190 MPa Ys: 892 to 1020 MPa %e: 4 to 23 | MG: - Ra: - H: - Ts: 912 to 957 MPa Ys: 869 to 790 MPa %e: 6 to 9.4 | MG: α + β phases, presence of intergranular β lamella (prior β). Presence of spherical, isolated pores. Ra: - H: - Ts: 875 MPa Ys; 745 MPa %e: 17% | [4,17,62,64,69,100,101,102] |

| Inconel | MG: orderly distribution of grains in bands, with many fine equiaxed grains surrounding the coarser grains Ra: - H: 313–302 HV Ts: 1010 to 1417 Mpa Ys: 737 to 1222 MPa %e 15.9 to 20.6 | MG: γ matrix with FCC Al crystal structure with round fcc MX precipitates (Nb, Ti) (C, N), B1 type crystal structure and platelike orthorhombic δ phase precipitates, Ni3 (Nb, Ti) Ra: - H: 410 to 500 HV Ts: 929 to 1270 MPa Yp: 744 to 954 MPa %e: 5.5 to 34 | MG: large number of coarse columnar grains, texture along the build Ra: - H: 195–201 HV Ts: 687 to 1436 MPa Ys: 325 to 1170 MPa %e | MG: - Ra: - H: - Ts: 612 to 718 MPa Ys: 327 to 394 MPa %e: 29 to 40 | MG: - Ra: - H: 350 HV Ts: 1247 MPa Ys: %e, 6.6 | [4,17,66,68,70,103,104,105] |

| Al alloys AlSi10Mg | MG: - Ra: 2.3 to 8.2 µm H: 106 HV to 127 HV Ts: 267 to 1387 MPa Ys: 169 to 1186 MPa %e: 1 to 17.4 | MG: dendritic solidification behavior of near-eutectic AlSi10Mg alloy. Finer distribution of Si precipitates and low dendritic arm spacing Ra H: 14 to 36 HV Ts: 113 to 152 MPa Ys: - %e: 22 to 27.5 | MG: eutectic type with α Al cells surrounded by a eutectic Si network Ra: 6 µm H: 58 to 102 HV Ts: 237 to 377 MPa Ys: 187 to 140 MPa %e: 5.27 to 7.9 | MG: - Ra: - H: - Ts: 320 to 330 MPa Ys: 276 to 240 MPa %e: 8.2 to 9.5 | MG: - Ra: - H: - Ts: - Ys: - %e: - | [4,76,106,107,108] |

| EBM Ti6Al4V | EBM Ti-6Al-4V ELI | DML Ti64 | |

|---|---|---|---|

| Machining | FEL-660HG lathe | Turning center with 22 kW spindle power maximum rotation of 4000 rpm, | EMCO (Hallein, Austria) CT60 CNC Lathe |

| Tool | Sandvik CNMG 12 04 08-SM H13A | SECO Tools carbide insert CNMG120408-MF4 TS2000 TiAlN/Tin coating, tool holder: PCLNL2020K2 6° rake angle, 95° cutting edge angle 0.8 mm of corner radius and a chip breaker on both sides | DCGT070201LF coating grade of KCU10: multilayer PVD coating noise radius 0.1 mm 95° major cutting edge angle 30° relief angle 10° rake angle |

| Enviromental | Dry and lubricant oil Siroil Emulg | Dry | |

| Cutting speed | - | 60 m/min | 90 and 120 m/min |

| Spindel speed | 300 rev/min | - | - |

| Feed rate | 0.28 mm/tol | 0.1 and 0.2 mm/rev | 0.05 mm/rev |

| Depth per cut | 0.8 mm | 0.15 mm | 0.25 mm |

| MRR | 10.5 mm3/s | - | - |

| Reference | [119] | [120] | [121] |

| LPBF Inconel | EBM Ti6Al4V | LBPF 18Ni300 | |

|---|---|---|---|

| Machining | Mill Haas VF0 Three-axis vertical machining center. | High-precision five-axis CNC machining center (KERN Pyramid Nano) | Mill |

| Tool | Kennametal Model No. HPFT250S6075 TiAlN-coated carbide end mill Six-flute Diameter of 6.35 mm (0.25 in.) Helix angle of 45°. | Three-flute micro-end milling tool WN 3142 R-N PVD coating TiAlN 1.8 mm diameter | XPET 060204 PDER-LP carbide insert solution AlTiN coated through Physical Vapor Deposition (PVD) 4 slot 0.4 tool radius and a positive rake angle |

| Enviromental | Dry | Wet Oil as a coolant and lubricant | Dry |

| Cutting speed | 24.4 m/min | Variable 35, 60, 80 m/min | 80, 200, 300 m/min |

| Spindel speed | - | - | - |

| Feed rate | 0.0254 mm/th | Variable 1.5, 2.5, 5, 10, 15, 20, 25, 50 µm/th | 0.05, 0.1, 0.2 mm/tooth |

| Depth per cut | 1.016 mm | 1 mm | 0.2, 0.4, 0.6 mm |

| Radial immersion | 50% | - | - |

| Width of cut | - | 0.3 mm | - |

| Strategy | - | Down milling | - |

| Observations | - | Samples were polished and etched prior to micro-milling. | - |

| Reference | [122] | [123] | [124] |

| EBM Ti6Al4V | DMLS Ti6Al4V | |

|---|---|---|

| Machining | CNC high-speed machining center (Model K-mill 8). | CNC vertical machining center (HURCO VMX42) |

| Tool | drill bits | Cemented carbide drill made of tungsten carbide (WC-Co) with a single layer of TiAlN coating |

| Feed rate | Varing 40 to 200 mm/min | 0.06, 0.09, 0.12, 0.15 |

| Spindel speed | Varing 3000, 3500, 4000 4500 and 5000 rpm | 500, 800, 1200, 1500 |

| Environmental machining | Dry | Dry |

| Drill depth | 12 mm | |

| Reference | [125] | [126] |

| Material/Technique | Heat Treatment/Surface Finish | Results | References |

|---|---|---|---|

| L-PBF AlSi10Mg | Direct Aging (DA) 150 °C and 170 °C for different times | 195 HV for DA 6 h Fine cell microstructure—precipitation of Si nanoparticles Improve mechanical properties DA 170 °C for 6 h increases tensile strength to 430 MPa compared to the as-built condition | [74] |

| L-PBF Ti5553 | BASCA (Beta annealed, solution treated, and aged) STA (solution treated and aged) | BASCA: increase fatigue strength and toughness α-phase precipitates in the form of plates within the β-phase matrix STA: enhance strength α-globular/plates and β matrix Tool life decreases due to increased mechanical properties such as hardness and toughness. | [131] |

| DMLS AlSi10Mg | T6 | Reduce the surface roughness, refine the microstructure, increase micro hardness (78.7 HV), and increase ductility. Cutting force 16.9–67.1% reduction relative to untreated AM parts | [132] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esquivel, A.; Marcelino, S.; Veiga, F.; Olvera-Trejo, D. Machinability of Sintered Metallic Materials in Additive Manufacturing. Appl. Sci. 2025, 15, 12455. https://doi.org/10.3390/app152312455

Esquivel A, Marcelino S, Veiga F, Olvera-Trejo D. Machinability of Sintered Metallic Materials in Additive Manufacturing. Applied Sciences. 2025; 15(23):12455. https://doi.org/10.3390/app152312455

Chicago/Turabian StyleEsquivel, Ana, Sara Marcelino, Fernando Veiga, and Daniel Olvera-Trejo. 2025. "Machinability of Sintered Metallic Materials in Additive Manufacturing" Applied Sciences 15, no. 23: 12455. https://doi.org/10.3390/app152312455

APA StyleEsquivel, A., Marcelino, S., Veiga, F., & Olvera-Trejo, D. (2025). Machinability of Sintered Metallic Materials in Additive Manufacturing. Applied Sciences, 15(23), 12455. https://doi.org/10.3390/app152312455