A Review of Challenges and Future Perspectives for High-Speed Material Extrusion Technology

Abstract

1. Introduction

1.1. Application Fields of Additive Manufacturing Technologies

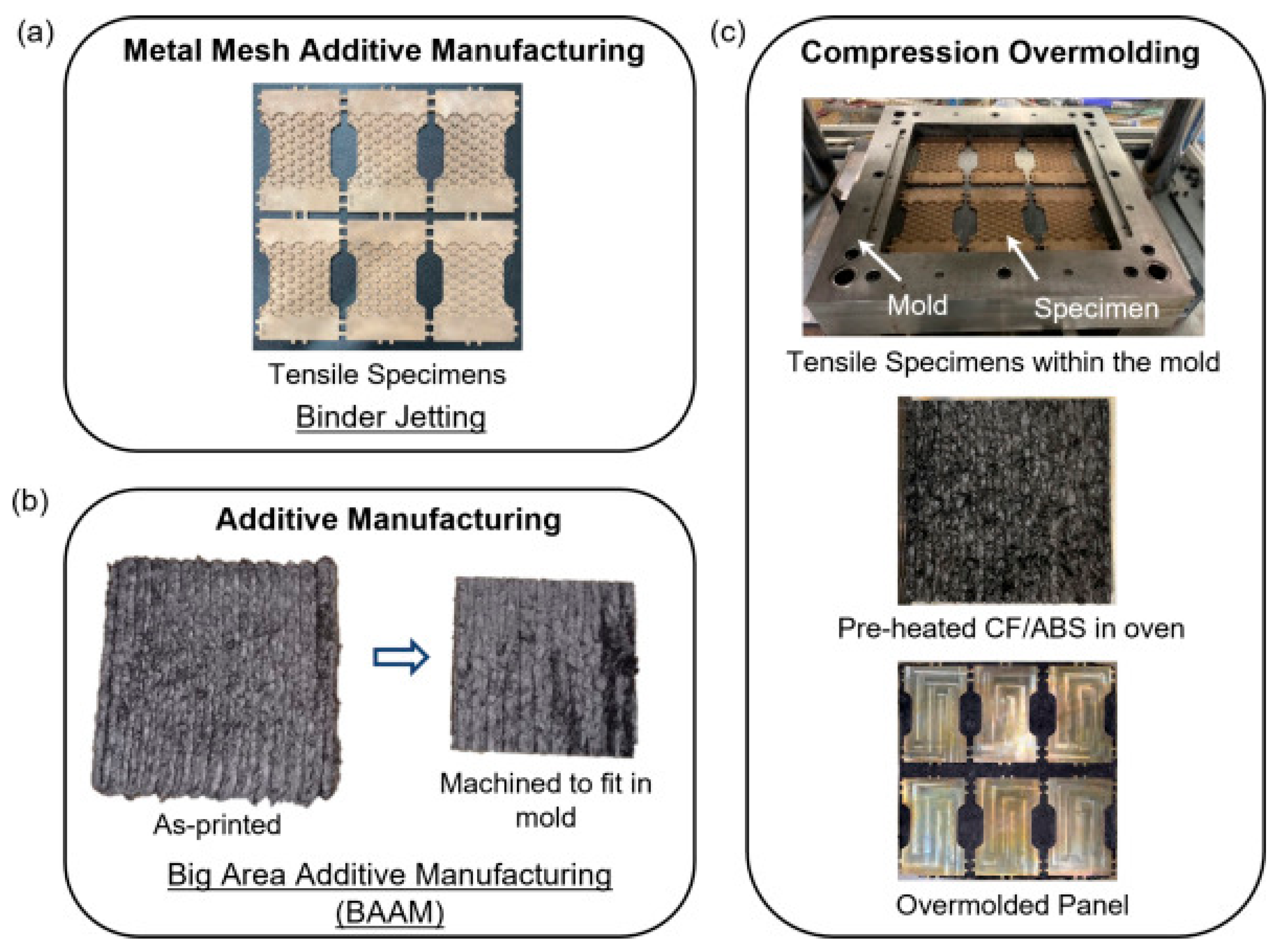

1.1.1. Automotive Field

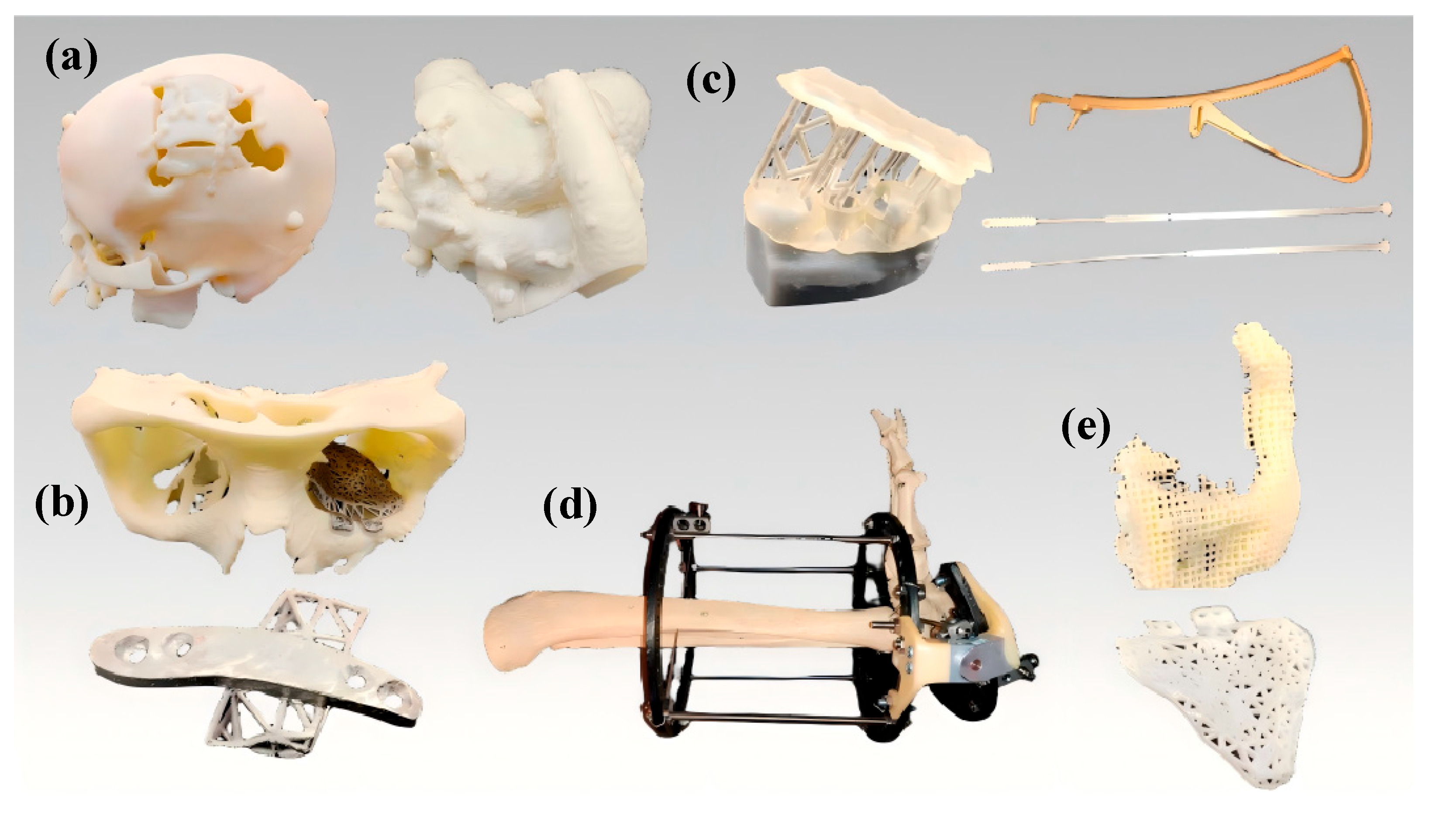

1.1.2. Medical Field

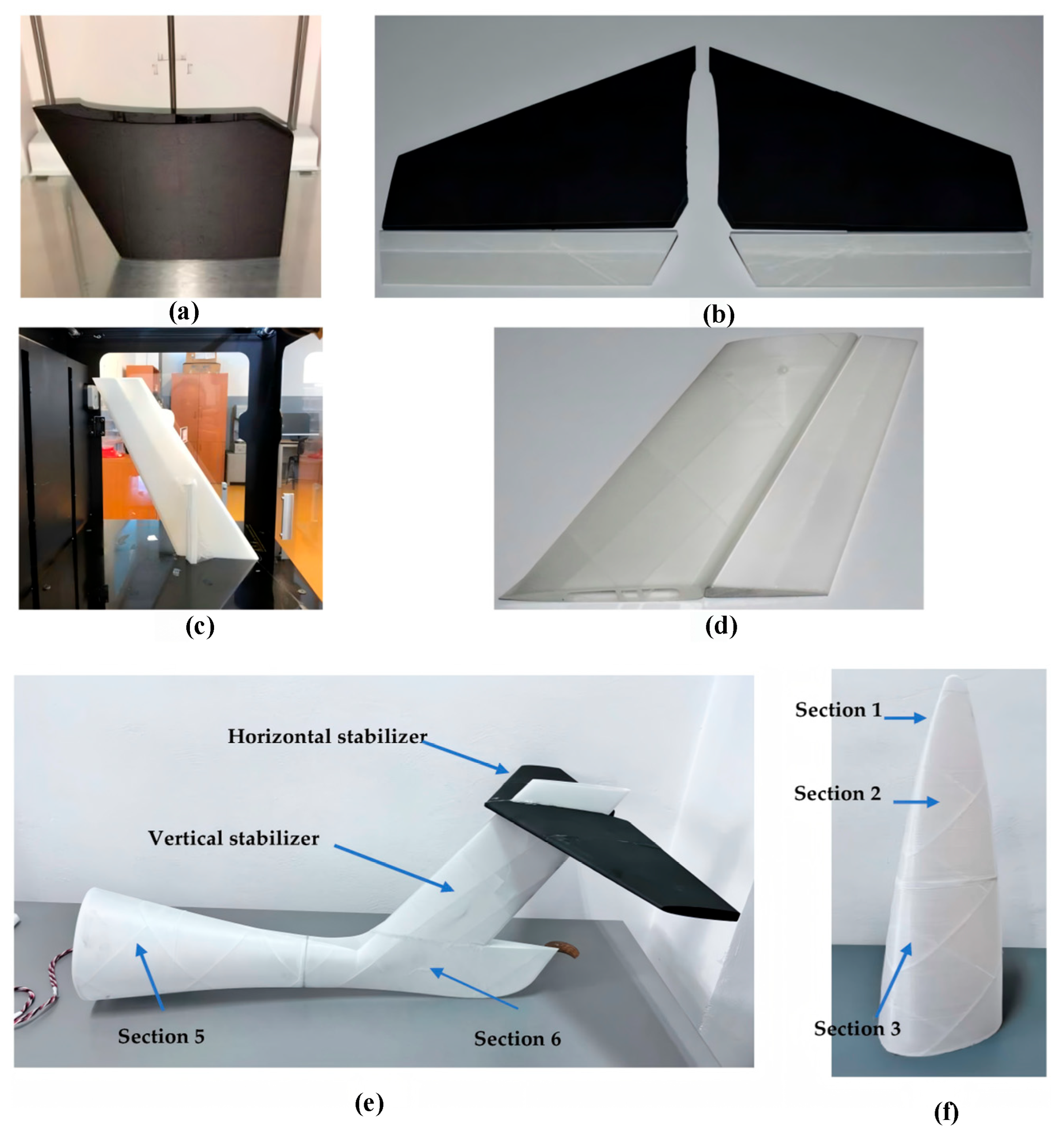

1.1.3. Aerospace Field

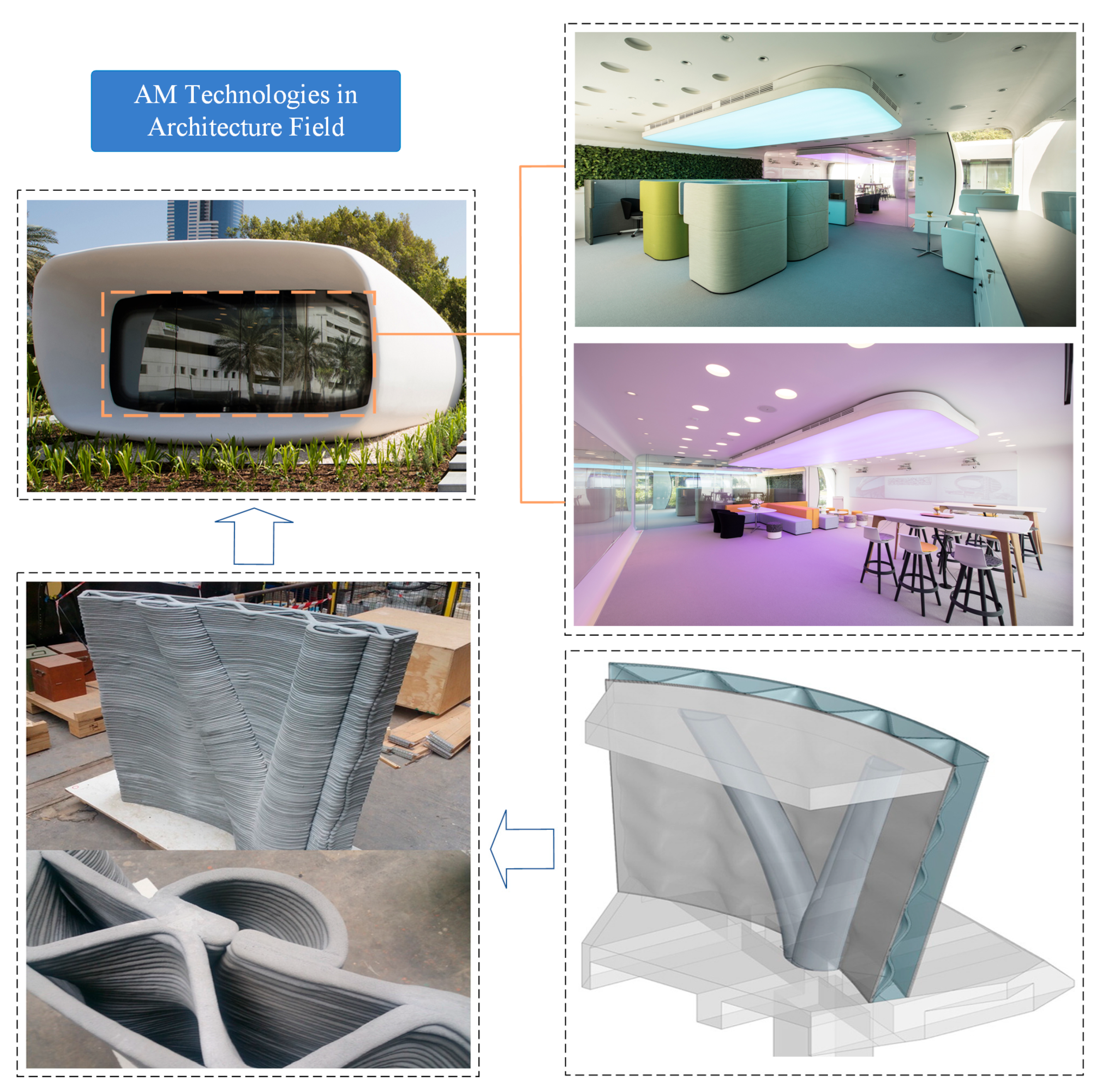

1.1.4. Architecture Field

1.2. Additive Manufacturing Processes and Classification

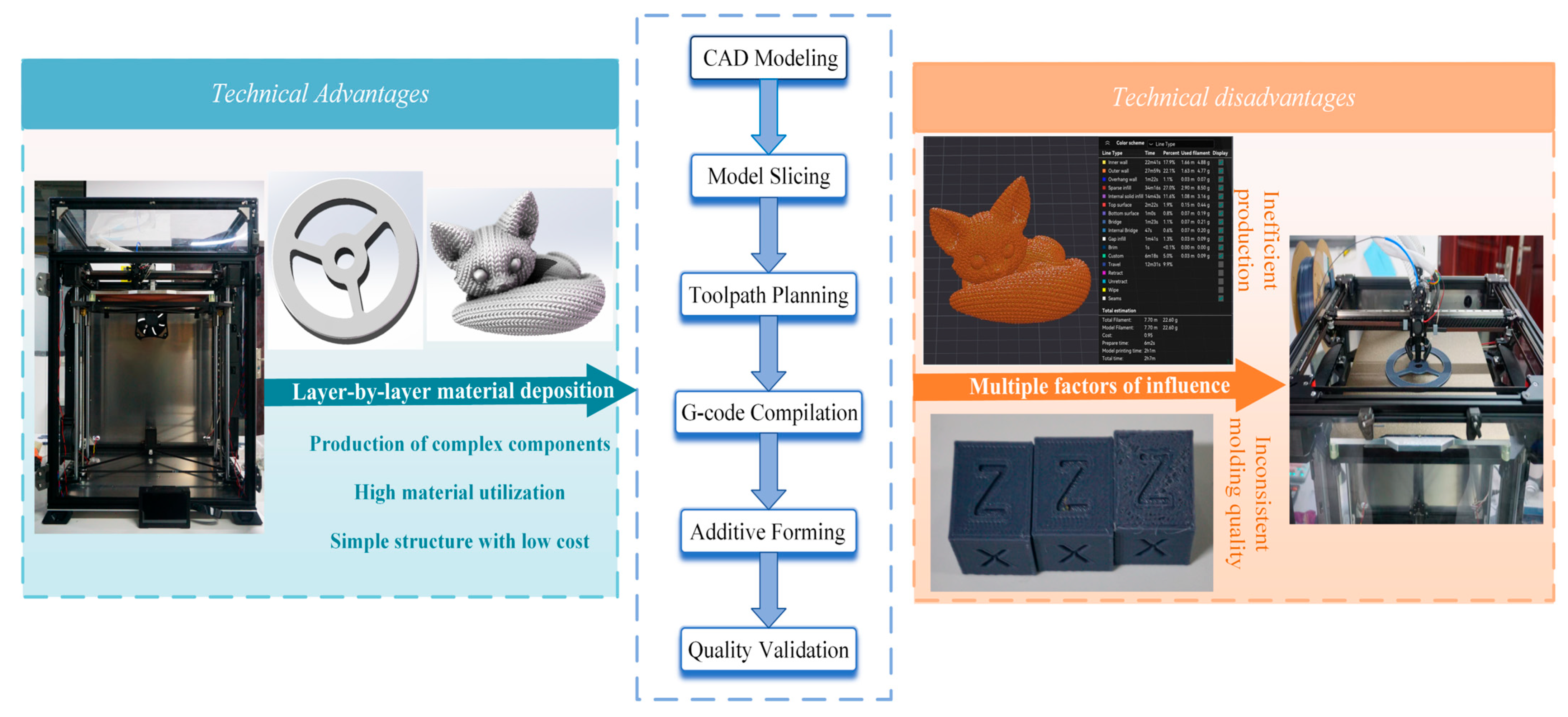

1.3. Fused Filament Fabrication (FFF) Technology

2. High-Speed Material Extrusion Technology

2.1. Common Structure of ME Printer

- (1)

- For general purpose high-speed and high-quality printing, the Core XY box-type architecture is preferred.

- (2)

- For maximum acceleration performance, either Delta or Core XY designs are suitable.

- (3)

- For large-diameter rotational parts, the polar-coordinate system offers distinct advantages.

- (4)

- The gantry bed-slinger remains a cost-effective choice for educational use and small prototype fabrication.

2.2. Materials and Applications

2.2.1. Common Pure Resin Materials

2.2.2. High-Performance Composite Materials

2.2.3. Optimized High-Speed Materials

| Material | Manufacturer | Recommended Nozzle Temperature (°C) | Recommended Speed (mm/s) | Volumetric Flow Rate |

|---|---|---|---|---|

| PolySonic PLA [81] | Polymaker | High-speed: 210–230; Regular: 190–210 | High-speed: 100–300; Regular: 50–100 | - |

| Ultrafuse PLA PRO1 [82] | BASF Forward AM | 200–220 | 40–300 | 22 mm3/s |

| PLA Basic [83] | Bambu Lab | 190–230 | 250–300 | - |

| Hyper Speed PLA [84] | Raise3D | 200–230 | 60-300 | - |

| ePLA-HS [85] | eSUN | 190–230 | 50–350 | - |

3. Technical Challenges in High-Speed ME Technology

- (1)

- Insufficient material flow, caused by limited hot-end throughput and inadequate melt residence time;

- (2)

- Vibration issues arising from the platform, extrusion system, and motion transmission under high acceleration and deceleration;

- (3)

- Thermal management imbalance, resulting from inefficient cooling and temperature control of the build environment.

3.1. Melt Flow Issues

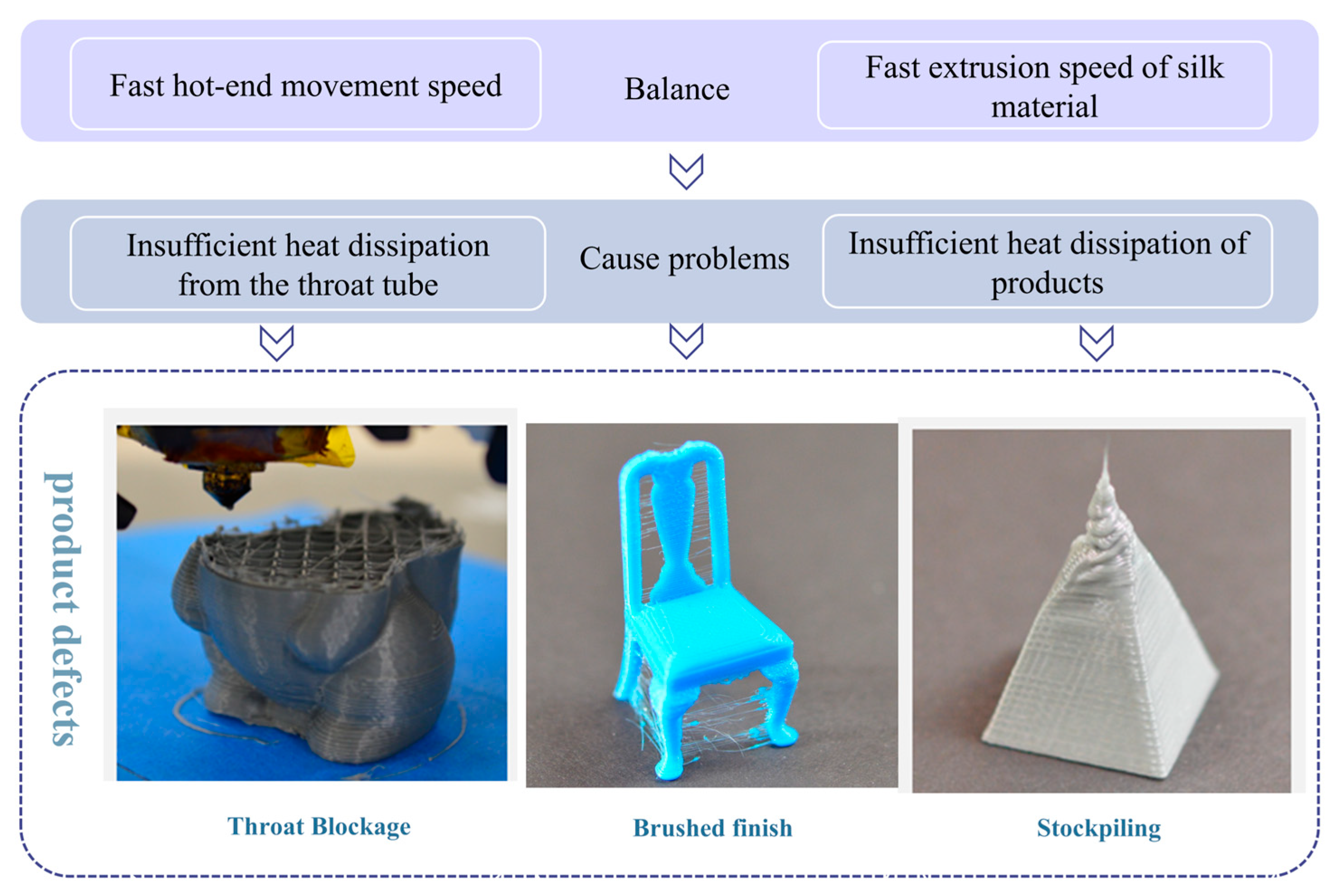

3.2. Thermal End and Ambient Temperature Control Issues During High-Speed Printing

- (1)

- Overheating of the heat break region—insufficient heat dissipation causes premature softening and wall adhesion of the filament, eventually leading to nozzle clogging;

- (2)

- Inadequate cooling of printed parts—slow melt solidification may result in stringing during non-print moves or material accumulation on small-area features such as pyramid tips;

- (3)

- Uneven hot-end temperature under excessive feed rates, which produces unstable extrusion flow.

3.3. Vibration Issues During High-Speed Printing

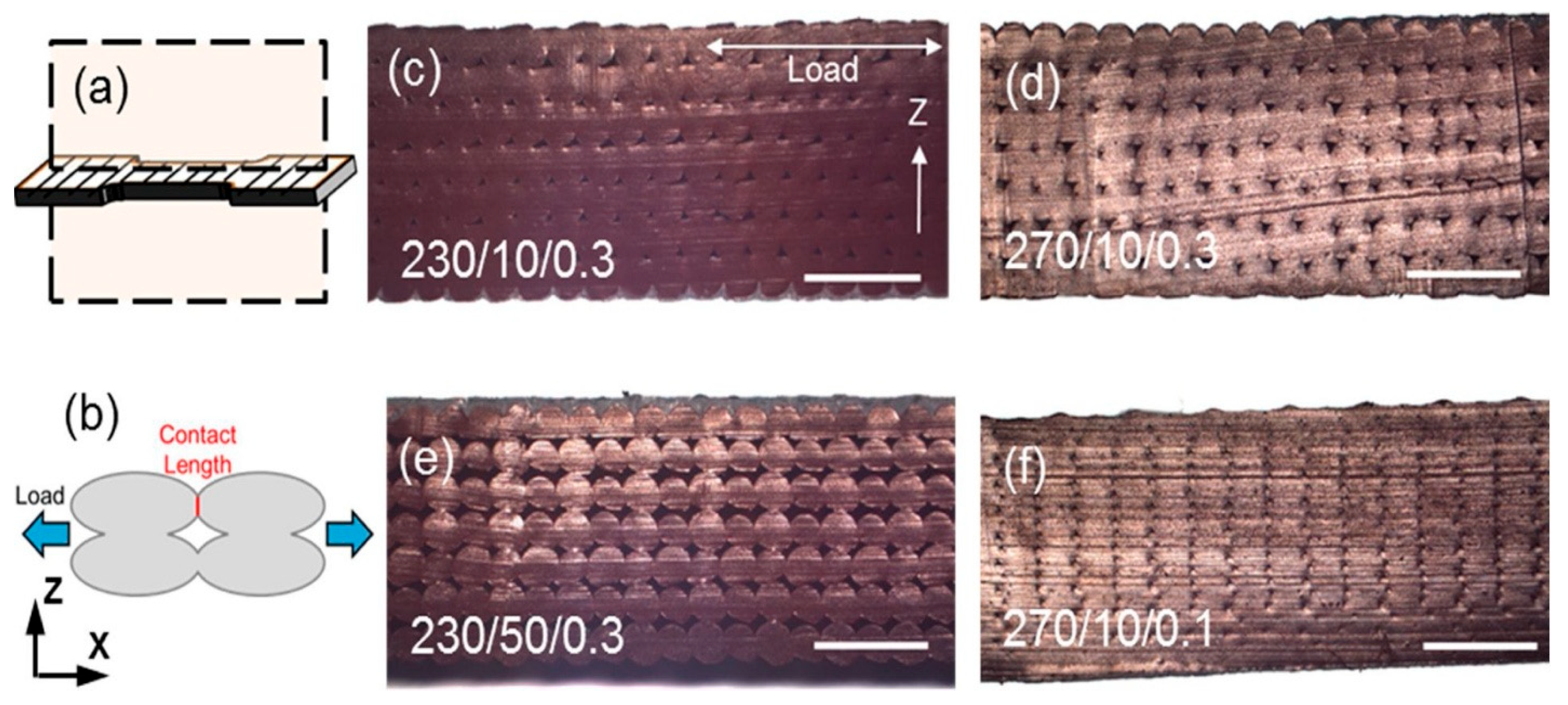

3.4. Interlayer Resolution and Mechanical Strength in Speed Limitation Issues

4. Optimization Method of High-Speed ME Technology

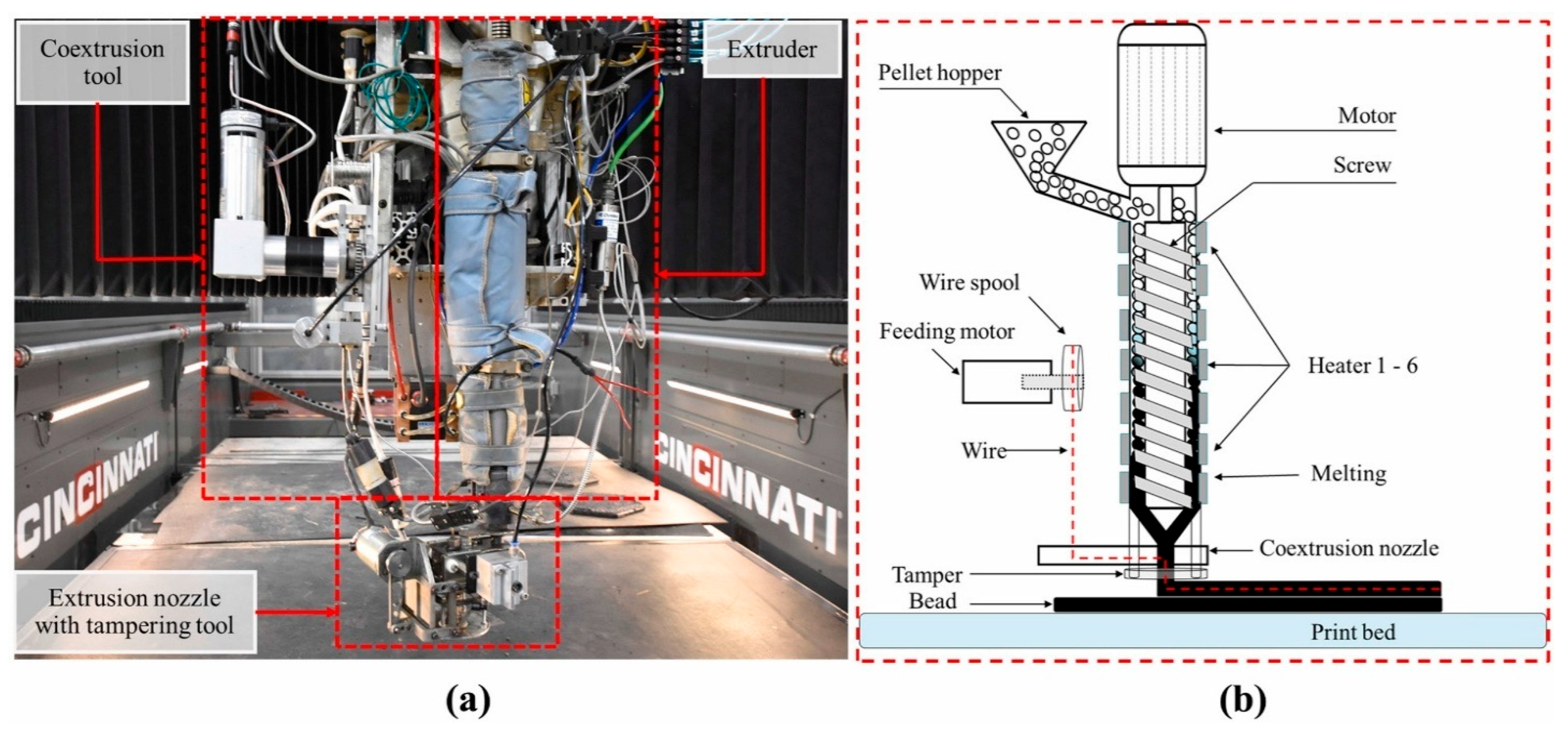

4.1. High-Speed Traffic Boosting and Control

4.2. Thermal Management Optimization Requirements and Strategies

4.3. Vibration Effects and Control Strategies

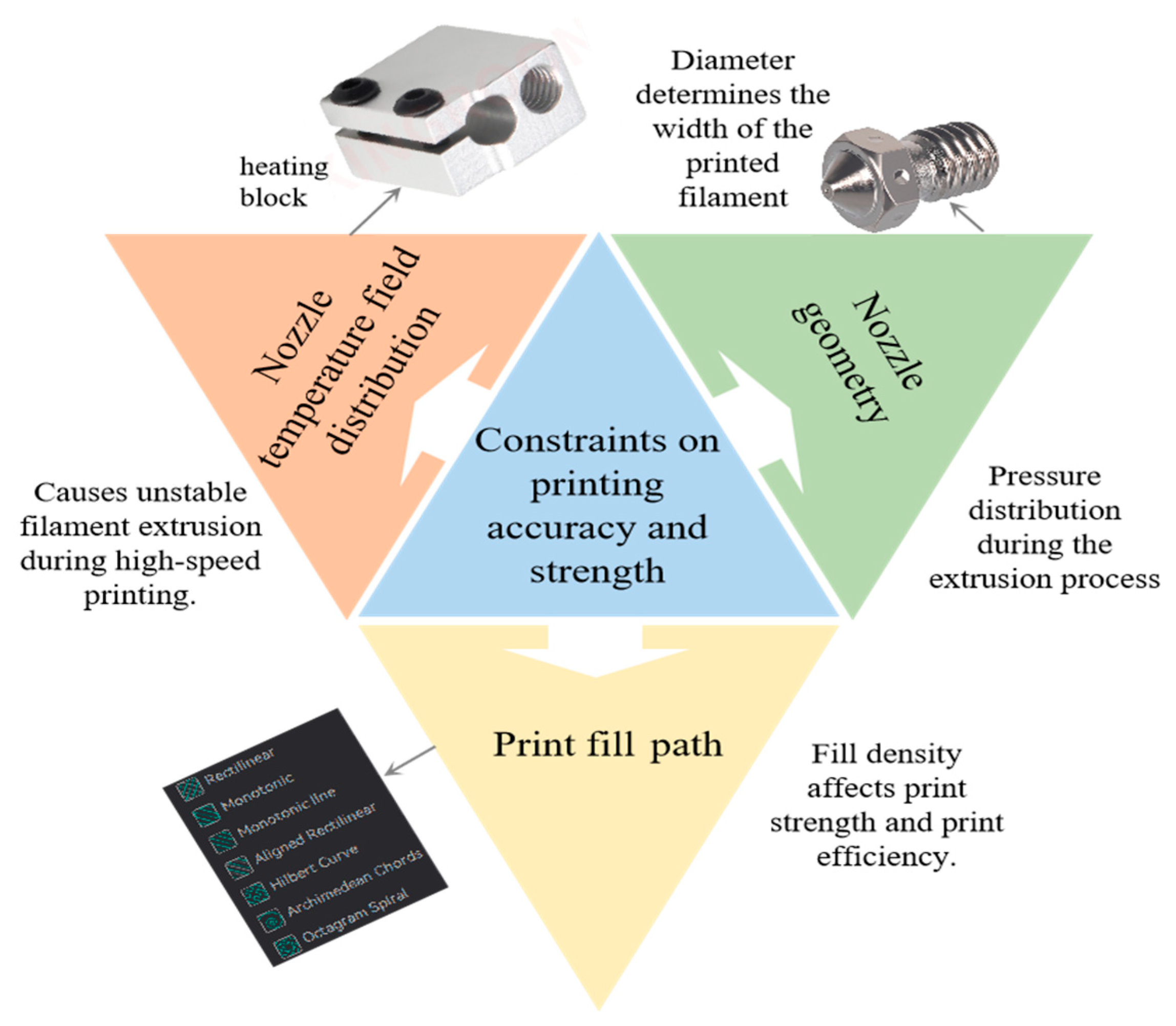

4.4. Interlayer Resolution and Mechanical Properties Under High-Speed Conditions

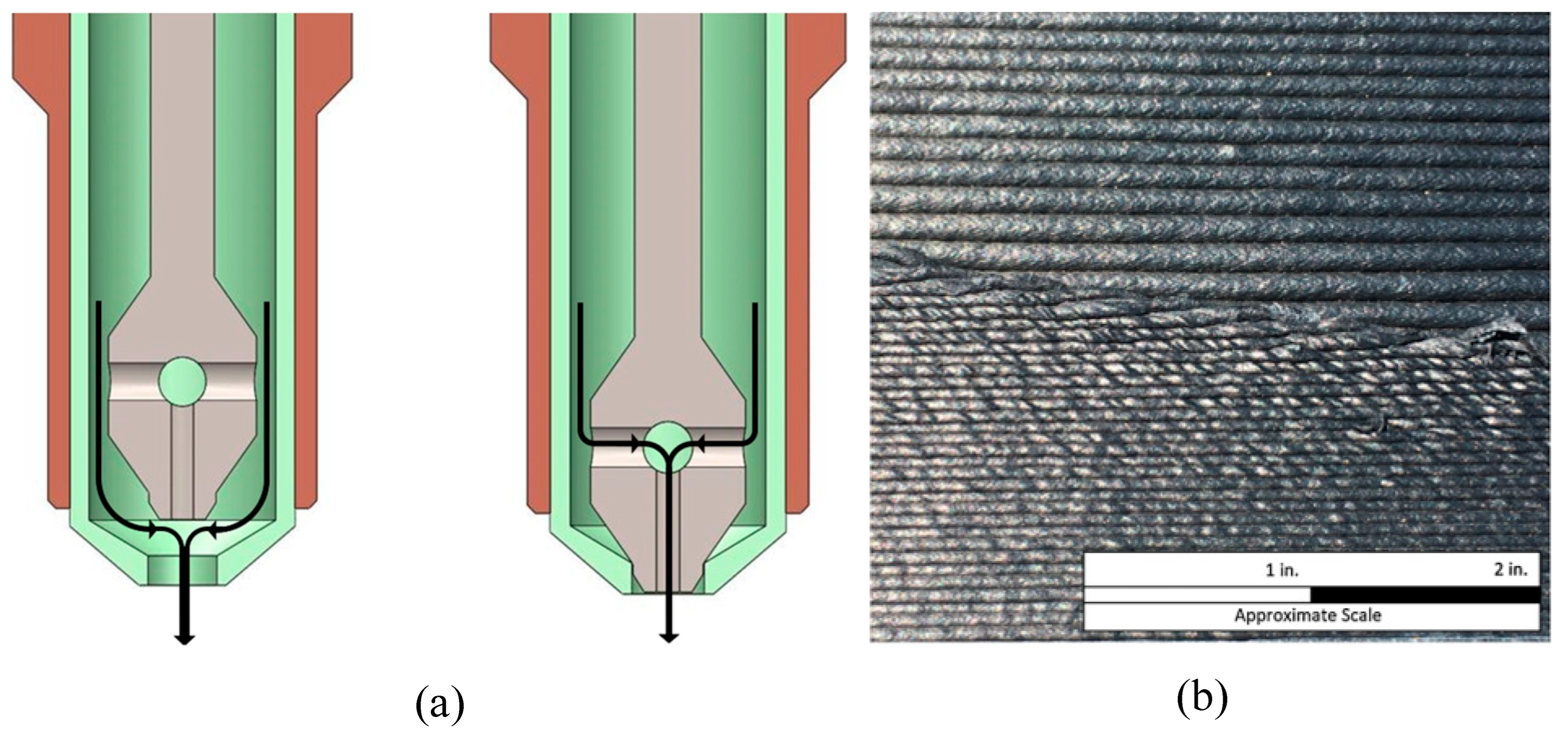

- (1)

- Optimizing nozzle geometry to reduce the total pressure drop and mitigate backflow effects while keeping the nozzle diameter constant;

- (2)

- Using variable-diameter nozzles, which enable rapid deposition with a larger orifice, followed by fine surface finishing using a smaller one, thereby achieving high surface quality and productivity without significantly increasing the total print time.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile Butadiene Styrene |

| AM | Additive Manufacturing |

| ASTM | American Society for Testing and Materials |

| BAAM | Big Area Additive Manufacturing |

| BJT | Binder Jetting |

| CFRP | Carbon Fiber Reinforced Polymer |

| CLIP | Continuous Liquid Interface Production |

| DED | Directed Energy Deposition |

| FFF | Fused Filament Fabrication |

| LQT | Linear Quadratic Tracking |

| MJT | Material Jetting |

| MEX | Material Extrusion |

| PA | Polyamide |

| PBF | Powder Bed Fusion |

| PC | Polycarbonate |

| PEKK | Polyetherketoneketone |

| PEEK | Polyether Ether Ketone |

| PETG | Polyethylene Terephthalate Glycol |

| PLA | Polylactic Acid |

| PP-MA | Polypropylene Grafted with Maleic Anhydride |

| PPS | Polyphenylene Sulfide |

| SHL | Sheet Lamination |

| SWIFT | Sacrificial Writing into Functional Tissue |

| TPU | Thermoplastic Polyurethane |

| UAV | Unmanned Aerial Vehicle |

| ULTEM9085 | High-performance Polyetherimide Thermoplastic |

| VPP | Vat Photopolymerization Process |

References

- Bourhis, F.L.; Kerbrat, O.; Hascoet, J.-Y.; Mognol, P. Sustainable Manufacturing: Evaluation and Modeling of Environmental Impacts in Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2013, 69, 1927–1939. [Google Scholar] [CrossRef]

- Popov, V.V.; Grilli, M.L.; Koptyug, A.; Jaworska, L.; Katz-Demyanetz, A.; Klobčar, D.; Balos, S.; Postolnyi, B.O.; Goel, S. Powder Bed Fusion Additive Manufacturing Using Critical Raw Materials: A Review. Materials 2021, 14, 909. [Google Scholar] [CrossRef]

- Mitra, S.; Rodríguez De Castro, A.; El Mansori, M. On the Rapid Manufacturing Process of Functional 3D Printed Sand Molds. J. Manuf. Process. 2019, 42, 202–212. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Ayatollahi, M.R.; Reinicke, T. Effects of Post-Processing Techniques on the Mechanical Characterization of Additively Manufactured Parts. J. Manuf. Process. 2023, 107, 98–114. [Google Scholar] [CrossRef]

- Rosli, N.A.; Alkahari, M.R.; Abdollah, M.F.B.; Maidin, S.; Ramli, F.R.; Herawan, S.G. Review on Effect of Heat Input for Wire Arc Additive Manufacturing Process. J. Mater. Res. Technol. 2021, 11, 2127–2145. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Pokkalla, D.K.; Garg, N.; Paramanathan, M.; Kumar, V.; Rencheck, M.L.; Nandwana, P.; Kunc, V.; Hassen, A.A.; Kim, S. Design Optimization of Lightweight Automotive Seatback through Additive Manufacturing Compression Overmolding of Metal Polymer Composites. Compos. Struct. 2024, 349–350, 118504. [Google Scholar] [CrossRef]

- Garmabi, M.M.; Shahi, P.; Tjong, J.; Sain, M. 3D Printing of Polyphenylene Sulfide for Functional Lightweight Automotive Component Manufacturing through Enhancing Interlayer Bonding. Addit. Manuf. 2022, 56, 102780. [Google Scholar] [CrossRef]

- Andreozzi, M.; Bianchi, I.; Mancia, T.; Simoncini, M. Investigation on the Mechanical and Environmental Behaviour of 3D-Printed Molds for Manufacturing of CFRP Components. Int. J. Adv. Manuf. Technol. 2024, 135, 4785–4802. [Google Scholar] [CrossRef]

- Fedulov, B.; Fedorenko, A.; Khaziev, A.; Antonov, F. Optimization of Parts Manufactured Using Continuous Fiber Three-Dimensional Printing Technology. Compos. Part B Eng. 2021, 227, 109406. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef] [PubMed]

- Amaya-Rivas, J.L.; Perero, B.S.; Helguero, C.G.; Hurel, J.L.; Peralta, J.M.; Flores, F.A.; Alvarado, J.D. Future Trends of Additive Manufacturing in Medical Applications: An Overview. Heliyon 2024, 10, e26641. [Google Scholar] [CrossRef]

- Germaini, M.-M.; Belhabib, S.; Guessasma, S.; Deterre, R.; Corre, P.; Weiss, P. Additive Manufacturing of Biomaterials for Bone Tissue Engineering—A Critical Review of the State of the Art and New Concepts. Prog. Mater. Sci. 2022, 130, 100963. [Google Scholar] [CrossRef]

- Culmone, C.; Smit, G.; Breedveld, P. Additive Manufacturing of Medical Instruments: A State-of-the-Art Review. Addit. Manuf. 2019, 27, 461–473. [Google Scholar] [CrossRef]

- Fortin, M.-A.; Zekraoui, S.; Lescot, T.; Akbari Taemeh, M. Radiopaque Filaments for Fused Filament Fabrication (Fff) 3D Printing; Elsevier: Amsterdam, The Netherlands, 2025. [Google Scholar]

- Niu, C.; Luan, C.; Shen, H.; Song, X.; Fu, J.; Zhang, L.; Sun, Y.; Xu, G.; Ruan, Z. Tunable Soft–Stiff Hybridized Fiber-Reinforced Thermoplastic Composites Using Controllable Multimaterial Additive Manufacturing Technology. Addit. Manuf. 2022, 55, 102836. [Google Scholar] [CrossRef]

- Wang, J.; Shao, C.; Wang, Y.; Sun, L.; Zhao, Y. Microfluidics for Medical Additive Manufacturing. Engineering 2020, 6, 1244–1257. [Google Scholar] [CrossRef]

- Skylar-Scott, M.A.; Uzel, S.G.M.; Nam, L.L.; Ahrens, J.H.; Truby, R.L.; Damaraju, S.; Lewis, J.A. Biomanufacturing of Organ-Specific Tissues with High Cellular Density and Embedded Vascular Channels. Sci. Adv. 2019, 5, eaaw2459. [Google Scholar] [CrossRef]

- Zaharia, S.-M.; Pascariu, I.S.; Chicos, L.-A.; Buican, G.R.; Pop, M.A.; Lancea, C.; Stamate, V.M. Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions. Drones 2023, 7, 602. [Google Scholar] [CrossRef]

- Huang, Y.; He, S.; Tian, X.; Li, W.; Mei, Z.; Liu, P.; Kong, W.; Lei, L.; Wang, P.; Li, J.; et al. Multiscale Topology Optimization and 3D Printing of Continuous Carbon Fiber Reinforced Composites Lattice Structure. Compos. Part B Eng. 2025, 304, 112691. [Google Scholar] [CrossRef]

- Huang, Y.; Tian, X.; Li, W.; He, S.; Zhao, P.; Hu, H.; Jia, Q.; Luo, M. 3D Printing of Topologically Optimized Wing Spar with Continuous Carbon Fiber Reinforced Composites. Compos. Part B Eng. 2024, 272, 111166. [Google Scholar] [CrossRef]

- Kobenko, S.; Dejus, D.; Jātnieks, J.; Pazars, D.; Glaskova-Kuzmina, T. Structural Integrity of the Aircraft Interior Spare Parts Produced by Additive Manufacturing. Polymers 2022, 14, 1538. [Google Scholar] [CrossRef]

- Rinaldi, M.; Cecchini, F.; Pigliaru, L.; Ghidini, T.; Lumaca, F.; Nanni, F. Additive Manufacturing of Polyether Ether Ketone (PEEK) for Space Applications: A Nanosat Polymeric Structure. Polymers 2020, 13, 11. [Google Scholar] [CrossRef]

- Gosselin, C.; Duballet, R.; Roux, P.; Gaudillière, N.; Dirrenberger, J.; Morel, P. Large-Scale 3D Printing of Ultra-High Performance Concrete—A New Processing Route for Architects and Builders. Mater. Des. 2016, 100, 102–109. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Delgado Camacho, D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of Additive Manufacturing in the Construction Industry—A Forward-Looking Review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A Review of Various Materials for Additive Manufacturing: Recent Trends and Processing Issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Kim, J.; Pinhata-Baptista, O.; Ayres, A.; Da Silva, R.; Lima, J.; Urbano, G.; No-Cortes, J.; Vasques, M.; Cortes, A. Accuracy Comparison among 3D-Printing Technologies to Produce Dental Models. Appl. Sci. 2022, 12, 8425. [Google Scholar] [CrossRef]

- Bezek, L.B.; Williams, C.B. Process-Structure-Property Effects of Ultraviolet Curing in Multi-Material Jetting Additive Manufacturing. Addit. Manuf. 2023, 73, 103640. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder Jet 3D Printing—Process Parameters, Materials, Properties, Modeling, and Challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Sun, X.; Mazur, M.; Cheng, C.-T. A Review of Void Reduction Strategies in Material Extrusion-Based Additive Manufacturing. Addit. Manuf. 2023, 67, 103463. [Google Scholar] [CrossRef]

- Ahn, D.; Kweon, J.-H.; Choi, J.; Lee, S. Quantification of Surface Roughness of Parts Processed by Laminated Object Manufacturing. J. Mater. Process. Technol. 2012, 212, 339–346. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Z.; Zhao, J.; Jiang, F. Effect of Ultrasonic Amplitude on Interfacial Characteristics and Mechanical Properties of Ti/Al Laminated Metal Composites Fabricated by Ultrasonic Additive Manufacturing. Addit. Manuf. 2023, 74, 103725. [Google Scholar] [CrossRef]

- Wei, C.; Li, L. Recent Progress and Scientific Challenges in Multi-Material Additive Manufacturing via Laser-Based Powder Bed Fusion. Virtual Phys. Prototyp. 2021, 16, 347–371. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Alvarez Rosales, M.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass Rolling of Ti-6Al-4V Wire + Arc Additively Manufactured Features for Microstructural Refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Khanna, N.; Zadafiya, K.; Patel, T.; Kaynak, Y.; Rahman Rashid, R.A.; Vafadar, A. Review on Machining of Additively Manufactured Nickel and Titanium Alloys. J. Mater. Res. Technol. 2021, 15, 3192–3221. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and Performance of 3D Printed Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Frunzaverde, D.; Cojocaru, V.; Bacescu, N.; Ciubotariu, C.-R.; Miclosina, C.-O.; Turiac, R.R.; Marginean, G. The Influence of the Layer Height and the Filament Color on the Dimensional Accuracy and the Tensile Strength of FDM-Printed PLA Specimens. Polymers 2023, 15, 2377. [Google Scholar] [CrossRef]

- Singhal, I.; Tyagi, B.; Raj, A.; Jain, A.; Kapoor, S.; Sahai, A.; Sharma, R.S. Analysis of Multiple Print-Head Displacement Mechanisms in 3D Space for Material Extrusion Machine. 3D Print. Addit. Manuf. 2024, 11, 1787–1798. [Google Scholar] [CrossRef]

- Lhndo GitHub—Lhndo/LH-Stinger: Fast, Precise, Cartesian, FDM 3D Printer. Available online: https://github.com/lhndo/LH-Stinger/tree/main/CAD/Printer (accessed on 15 October 2025).

- WillemBoshoff GitHub. WillemBoshoff/circa-3D-Printer: The circa 3D Printer Is an Open Source Polar 3D Printer Designed by and for Artists, Designers and Engineers. Available online: https://github.com/WillemBoshoff/Circa-3D-Printer (accessed on 10 November 2025).

- Thingiverse.com. TriNS Delta 3D Printer by Enesyucepur. Available online: https://www.thingiverse.com/thing:6188388 (accessed on 15 October 2025).

- VzBoT. Available online: https://github.com/VzBoT3D (accessed on 15 October 2025).

- Raj, A.; Tyagi, B.; Kapoor, A.; Parashar, A.; Satsangi, A.; Sahai, A.; Sharma, R.S. Optimization of Cartesian and Polar 3D Printer Structures Using Finite Element Analysis: A Comparative Study on Material Selection and Design Enhancement. Proc. Indian Natl. Sci. Acad. 2025, 91, 804–820. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, W.; Aiyiti, W.; Kasimu, A.; Jia, R. Investigation of Influence of Printing Modes on the Quality of 6-PSS FDM 3D Printed Thin-Walled Parts. Results Eng. 2023, 17, 100926. [Google Scholar] [CrossRef]

- Ali, M.H.; Kurokawa, S.; Shehab, E.; Mukhtarkhanov, M. Development of a Large-Scale Multi-Extrusion FDM Printer, and Its Challenges. Int. J. Lightweight Mater. Manuf. 2023, 6, 198–213. [Google Scholar] [CrossRef]

- Seno Flores, J.D.; De Assis Augusto, T.; Lopes Vieira Cunha, D.A.; Gonçalves Beatrice, C.A.; Henrique Backes, E.; Costa, L.C. Sustainable Polymer Reclamation: Recycling Poly(Ethylene Terephthalate) Glycol (PETG) for 3D Printing Applications. J. Mater. Sci. Mater. Eng. 2024, 19, 16. [Google Scholar] [CrossRef]

- Kumar, G.S.P.; Keshavamurthy, R.; Panigrahi, S.P.; Thomas, S.; Hebbar, G.S.; Prasad, C.D.; Aden, A.A. Enhanced Mechanical Properties of CNT/Graphene Reinforced PLA-Based Composites Fabricated via Fused Deposition Modelling. Results Eng. 2025, 25, 104472. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact Damage Resistance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Shahdan, D.; Rosli, N.A.; Chen, R.S.; Ahmad, S.; Gan, S. Strategies for Strengthening Toughened Poly(Lactic Acid) Blend via Natural Reinforcement with Enhanced Biodegradability: A Review. Int. J. Biol. Macromol. 2023, 251, 126214. [Google Scholar] [CrossRef]

- Fekete, I.; Ronkay, F.; Lendvai, L. Highly Toughened Blends of Poly(Lactic Acid) (PLA) and Natural Rubber (NR) for FDM-Based 3D Printing Applications: The Effect of Composition and Infill Pattern. Polym. Test. 2021, 99, 107205. [Google Scholar] [CrossRef]

- Dev, S.; Srivastava, R. Experimental Investigation and Optimization of FDM Process Parameters for Material and Mechanical Strength. Mater. Today Proc. 2020, 26, 1995–1999. [Google Scholar] [CrossRef]

- Hibbert, K.; Warner, G.; Brown, C.; Ajide, O.; Owolabi, G.; Azimi, A. The Effects of Build Parameters and Strain Rate on the Mechanical Properties of FDM 3D-Printed Acrylonitrile Butadiene Styrene. Open J. Org. Polym. Mater. 2019, 9, 1–27. [Google Scholar] [CrossRef]

- Srinivasan, R.; Prathap, P.; Raj, A.; Aswinth Kannan, S.; Deepak, V. Influence of Fused Deposition Modeling Process Parameters on the Mechanical Properties of PETG Parts. Mater. Today Proc. 2020, 27, 1877–1883. [Google Scholar] [CrossRef]

- Bates, S.R.G.; Farrow, I.R.; Trask, R.S. 3D Printed Polyurethane Honeycombs for Repeated Tailored Energy Absorption. Mater. Des. 2016, 112, 172–183. [Google Scholar] [CrossRef]

- Su, K.-H.; Su, C.-Y.; Shih, W.-L.; Lee, F.-T. Improvement of the Thermal Conductivity and Mechanical Properties of 3D-Printed Polyurethane Composites by Incorporating Hydroxylated Boron Nitride Functional Fillers. Materials 2022, 16, 356. [Google Scholar] [CrossRef]

- Li, Y.; Gancheva, T.; Estakhrianhaghighi, E.; Favis, B.D.; Akbarzadeh, A. Material Extrusion of Quaternary Co-Continuous Biopolymers: A Strategy for Realizing Lightweight Cellular Solids with High Impact Toughness. Addit. Manuf. 2023, 77, 103805. [Google Scholar] [CrossRef]

- Tikhani, F.; Gurbin, A.; Hubert, P. Unveiling the Impact of Short Fibre Reinforcement and Extrusion Properties on Microstructure of 3D Printed Polycarbonate Composites. Addit. Manuf. 2024, 93, 104423. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Ye, W.; Wang, Y.; Wang, S.; Zhang, S. Effects of Extrusion Speed and Printing Speed on the 3D Printing Stability of Extruded PEEK Filament. J. Manuf. Process. 2019, 37, 266–273. [Google Scholar] [CrossRef]

- Dua, R.; Rashad, Z.; Spears, J.; Dunn, G.; Maxwell, M. Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers 2021, 13, 4046. [Google Scholar] [CrossRef] [PubMed]

- Rodzeń, K.; Sharma, P.K.; McIlhagger, A.; Mokhtari, M.; Dave, F.; Tormey, D.; Sherlock, R.; Meenan, B.J.; Boyd, A. The Direct 3D Printing of Functional PEEK/Hydroxyapatite Composites via a Fused Filament Fabrication Approach. Polymers 2021, 13, 545. [Google Scholar] [CrossRef]

- Rezaeian, P.; Ayatollahi, M.R.; Nabavi-Kivi, A.; Razavi, N. Effect of Printing Speed on Tensile and Fracture Behavior of ABS Specimens Produced by Fused Deposition Modeling. Eng. Fract. Mech. 2022, 266, 108393. [Google Scholar] [CrossRef]

- Aliheidari, N.; Tripuraneni, R.; Ameli, A.; Nadimpalli, S. Fracture Resistance Measurement of Fused Deposition Modeling 3D Printed Polymers. Polym. Test. 2017, 60, 94–101. [Google Scholar] [CrossRef]

- Subbarao, C.V.; Srinivasa Reddy, Y.; Inturi, V.; Indra Reddy, M. Dynamic Mechanical Analysis of 3D Printed PETG Material. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1057, p. 12031. [Google Scholar] [CrossRef]

- Lv, Y.; Dejus, D.; Kobenko, S.; Singamneni, S.; Glaskova-Kuzmina, T. Evaluation of the Fire-Retardancy of ULTEM 9085 Polymer Composites Processed by Fused Deposition Modelling. Mater. Sci. 2022, 28, 353–359. [Google Scholar] [CrossRef]

- Hernandez, K.M.; O’Brien, S.; Bischoff, A.; Parmigiani, J.; Roach, D.J. Influence of 3D Printing Parameters on ULTEM 9085 Mechanical Properties Using Experimentation and Machine Learning. npj Adv. Manuf. 2025, 2, 41. [Google Scholar] [CrossRef]

- Alqurashi, H.; Khurshid, Z.; Syed, A.U.Y.; Rashid Habib, S.; Rokaya, D.; Zafar, M.S. Polyetherketoneketone (PEKK): An Emerging Biomaterial for Oral Implants and Dental Prostheses. J. Adv. Res. 2021, 28, 87–95. [Google Scholar] [CrossRef]

- Doyle, L.; García-Molleja, J.; Fernández-Blázquez, J.P.; González, C. Unraveling the Print–Structure–Property Relationships in the FFF of PEEK: A Critical Assessment of Print Parameters. Polymers 2025, 17, 1444. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.; Ullah, A.; Samreen, A.; Qasim, M.; Nawaz, K.; Ahmad, W.; Alnaser, A.; Kannan, A.M.; Egilmez, M. Hydrogen Production, Storage, Transportation and Utilization for Energy Sector: A Current Status Review. J. Energy Storage 2024, 101, 113733. [Google Scholar] [CrossRef]

- Vatandaş, B.B.; Gümrük, R. Additive Manufacturing and Mechanical Performance of Short Fiber Reinforced PEEK (Polyether Ether Ketone) Thermoplastic Composites in a Vacuum Environment. Int. J. Adv. Manuf. Technol. 2024, 134, 1677–1698. [Google Scholar] [CrossRef]

- Guo, P.; Wu, J.; An, X.; Zhou, Z.; Yang, D.; Zhang, H. On the Mitigation of the Fiber Breakage in Material Extrusion Based Additive Manufacturing of Carbon Fiber Reinforced Polymer Composites. Addit. Manuf. 2025, 109, 104896. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, W.; Ding, X. Multi-Axis Additive Manufacturing Process for Continuous Fibre Reinforced Composite Parts. Procedia CIRP 2019, 85, 114–120. [Google Scholar] [CrossRef]

- Liu, G.; Huang, W.; Wang, Y.; Ren, H.; Zhang, G.; Zhou, L.; Xiong, Y. Stress Field-Aware Infill Toolpath Generation for Additive Manufacturing of Continuous Fiber Reinforced Polymer Composites. Mater. Des. 2024, 239, 112756. [Google Scholar] [CrossRef]

- Ray, B.; Oskolkov, B.; Liu, C.; Leblanc, Z.; Tian, W. FFF-Based Metal and Ceramic Additive Manufacturing: Production Scale-up from a Stream of Variation Analysis Perspective. Manuf. Lett. 2023, 35, 811–821. [Google Scholar] [CrossRef]

- Rubiano Buitrago, J.D.; Gil Plazas, A.F.; Boyacá Mendivelso, L.A.; Herrera Quintero, L.K. Fused Filament Fabrication of WC-10Co Hardmetals: A Study on Binder Formulations and Printing Variables. J. Manuf. Mater. Process. 2024, 8, 118. [Google Scholar] [CrossRef]

- Yi, Z.; Shen, T.; Xiong, H.; Kang, X.; Zhang, L.; Zhou, K. Strong and Densified 3D Metal-Ceramic Composite with Strengthened Layer Structure by Material Extrusion Additive Manufacturing. Addit. Manuf. 2024, 84, 104136. [Google Scholar] [CrossRef]

- Kantaros, A.; Katsantoni, M.; Ganetsos, T.; Petrescu, N. The Evolution of Thermoplastic Raw Materials in High-Speed FFF/FDM 3D Printing Era: Challenges and Opportunities. Materials 2025, 18, 1220. [Google Scholar] [CrossRef]

- Kruzliak, J.; Morovic, L.; Martinkovic, M.; Sugarova, J. Effect of Selected Parameters on Fdm-High-Speed 3D Printed Specimen Properties. MM Sci. J. 2025, 2025, 8619. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Slemenik Perše, L.; Nanni, F. Advancements in Metal Additive Manufacturing: A Comprehensive Review of Material Extrusion with Highly Filled Polymers. J. Manuf. Mater. Process. 2024, 8, 14. [Google Scholar] [CrossRef]

- PolySonicTM PLA. Available online: https://polymaker.com/product/polysonic-pla/ (accessed on 4 November 2025).

- Ultrafuse® PLA PRO1. Available online: https://forward-am.com/material-portfolio/ultrafuse-filaments-for-fused-filaments-fabrication-fff/engineering-filaments/ultrafuse-pla-pro1/ (accessed on 4 November 2025).

- PLA Basic. Available online: https://us.store.bambulab.com/products/pla-basic-filament (accessed on 4 November 2025).

- eSUN PLA-HS 1.75 mm 3D Filament 1KG. Available online: https://esun3dstore.com/products/epla-hs (accessed on 4 November 2025).

- Hyper Speed PLA Filament—Versatile and User-Friendly. Available online: https://www.raise3d.com/materials/hyper-speed-pla/ (accessed on 4 November 2025).

- Go, J.; Schiffres, S.N.; Stevens, A.G.; Hart, A.J. Rate Limits of Additive Manufacturing by Fused Filament Fabrication and Guidelines for High-Throughput System Design. Addit. Manuf. 2017, 16, 1–11. [Google Scholar] [CrossRef]

- Abbott, A.C.; Tandon, G.P.; Bradford, R.L.; Koerner, H.; Baur, J.W. Process-Structure-Property Effects on ABS Bond Strength in Fused Filament Fabrication. Addit. Manuf. 2018, 19, 29–38. [Google Scholar] [CrossRef]

- Riddick, J.C.; Haile, M.A.; Wahlde, R.V.; Cole, D.P.; Bamiduro, O.; Johnson, T.E. Fractographic Analysis of Tensile Failure of Acrylonitrile-Butadiene-Styrene Fabricated by Fused Deposition Modeling. Addit. Manuf. 2016, 11, 49–59. [Google Scholar] [CrossRef]

- Shanmugam, V.; Babu, K.; Kannan, G.; Mensah, R.A.; Samantaray, S.K.; Das, O. The Thermal Properties of FDM Printed Polymeric Materials: A Review. Polym. Degrad. Stab. 2024, 228, 110902. [Google Scholar] [CrossRef]

- Zavrakli, E.; Parnell, A.; Dickson, A.; Dey, S. Data-Driven Linear Quadratic Tracking Based Temperature Control of a Big Area Additive Manufacturing System. J. Intell. Manuf. 2025, 36, 4549–4565. [Google Scholar] [CrossRef]

- Gong, C.; Chen, S.; Han, Y.; Lu, J.; Tang, S.; Fan, H.; Wang, R.; Xiang, Z.; Wang, H.; Xia, Y.; et al. Exploring the Impact of Printing Speed and Ambient Temperature on Support-Free Rod Extrusion. Mater. Today Commun. 2025, 43, 111615. [Google Scholar] [CrossRef]

- Ramos-Grez, J.; Sen, M.; Ramos-Cahis, M. Theoretical Study of the Interactions between Vibrations of Large Numbers of FDM 3D Printers. Prog. Addit. Manuf. 2024, 9, 135–149. [Google Scholar] [CrossRef]

- Jensen, N.J.; Parker, G.G.; Blough, J.R. Base Vibration Effects on Additive Manufactured Part Quality. Exp. Tech. 2024, 48, 159–170. [Google Scholar] [CrossRef]

- Huo, X.; Zhang, B.; Han, Q.; Huang, Y.; Yin, J. Numerical Simulation and Printability Analysis of Fused Deposition Modeling with Dual-Temperature Control. Bio-Des. Manuf. 2023, 6, 174–188. [Google Scholar] [CrossRef]

- Heller, B.P.; Smith, D.E.; Jack, D.A. Effects of Extrudate Swell and Nozzle Geometry on Fiber Orientation in Fused Filament Fabrication Nozzle Flow. Addit. Manuf. 2016, 12, 252–264. [Google Scholar] [CrossRef]

- Sajjad, R.; Butt, S.U.; Saeed, H.A.; Anwar, M.T.; Rasheed, T. Impact of Multiple Infill Strategy on the Structural Strength of Single Build FDM Printed Parts. J. Manuf. Process. 2023, 89, 105–110. [Google Scholar] [CrossRef]

- ELDeeb, I.S.; Esmael, E.; Ebied, S.; Diab, M.R.; Dekis, M.; Petrov, M.A.; Zayed, A.A.; Egiza, M. Optimization of Nozzle Diameter and Printing Speed for Enhanced Tensile Performance of FFF 3D-Printed ABS and PLA. J. Manuf. Mater. Process. 2025, 9, 221. [Google Scholar] [CrossRef]

- Le, L.; Rabsatt, M.A.; Eisazadeh, H.; Torabizadeh, M. Reducing Print Time While Minimizing Loss in Mechanical Properties in Consumer FDM Parts. Int. J. Lightweight Mater. Manuf. 2022, 5, 197–212. [Google Scholar] [CrossRef]

- Xu, X.; Ren, H.; Chen, S.; Luo, X.; Zhao, F.; Xiong, Y. Review on Melt Flow Simulations for Thermoplastics and Their Fiber Reinforced Composites in Fused Deposition Modeling. J. Manuf. Process. 2023, 92, 272–286. [Google Scholar] [CrossRef]

- Zhang, J.; Vasiliauskaite, E.; De Kuyper, A.; De Schryver, C.; Vogeler, F.; Desplentere, F.; Ferraris, E. Temperature Analyses in Fused Filament Fabrication: From Filament Entering the Hot-End to the Printed Parts. 3D Print. Addit. Manuf. 2022, 9, 132–142. [Google Scholar] [CrossRef]

- Serdeczny, M.P.; Comminal, R.; Pedersen, D.B.; Spangenberg, J. Experimental and Analytical Study of the Polymer Melt Flow through the Hot-End in Material Extrusion Additive Manufacturing. Addit. Manuf. 2020, 32, 100997. [Google Scholar] [CrossRef]

- Owens, J.T.; Das, A.; Bortner, M.J. Accelerating Heat Transfer Modeling in Material Extrusion Additive Manufacturing: From Desktop to Big Area. Addit. Manuf. 2022, 55, 102853. [Google Scholar] [CrossRef]

- Billah, K.M.M.; Heineman, J.; Mhatre, P.; Roschli, A.; Post, B.; Kumar, V.; Kim, S.; Haye, G.; Jackson, J.; Skelton, Z.; et al. Large-Scale Additive Manufacturing of Self-Heating Molds. Addit. Manuf. 2021, 47, 102282. [Google Scholar] [CrossRef]

- Liu, X.; Chi, B.; Jiao, Z.; Tan, J.; Liu, F.; Yang, W. A Large-Scale Double-Stage-Screw 3D Printer for Fused Deposition of Plastic Pellets. J. Appl. Polym. Sci. 2017, 134, 45147. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef]

- Caltanissetta, F.; Dreifus, G.; Hart, A.J.; Colosimo, B.M. In-Situ Monitoring of Material Extrusion Processes via Thermal Videoimaging with Application to Big Area Additive Manufacturing (BAAM). Addit. Manuf. 2022, 58, 102995. [Google Scholar] [CrossRef]

- Long, K. FDM 3D Printer Temperature Control System Based on PID Control. Appl. Comput. Eng. 2023, 28, 72–79. [Google Scholar] [CrossRef]

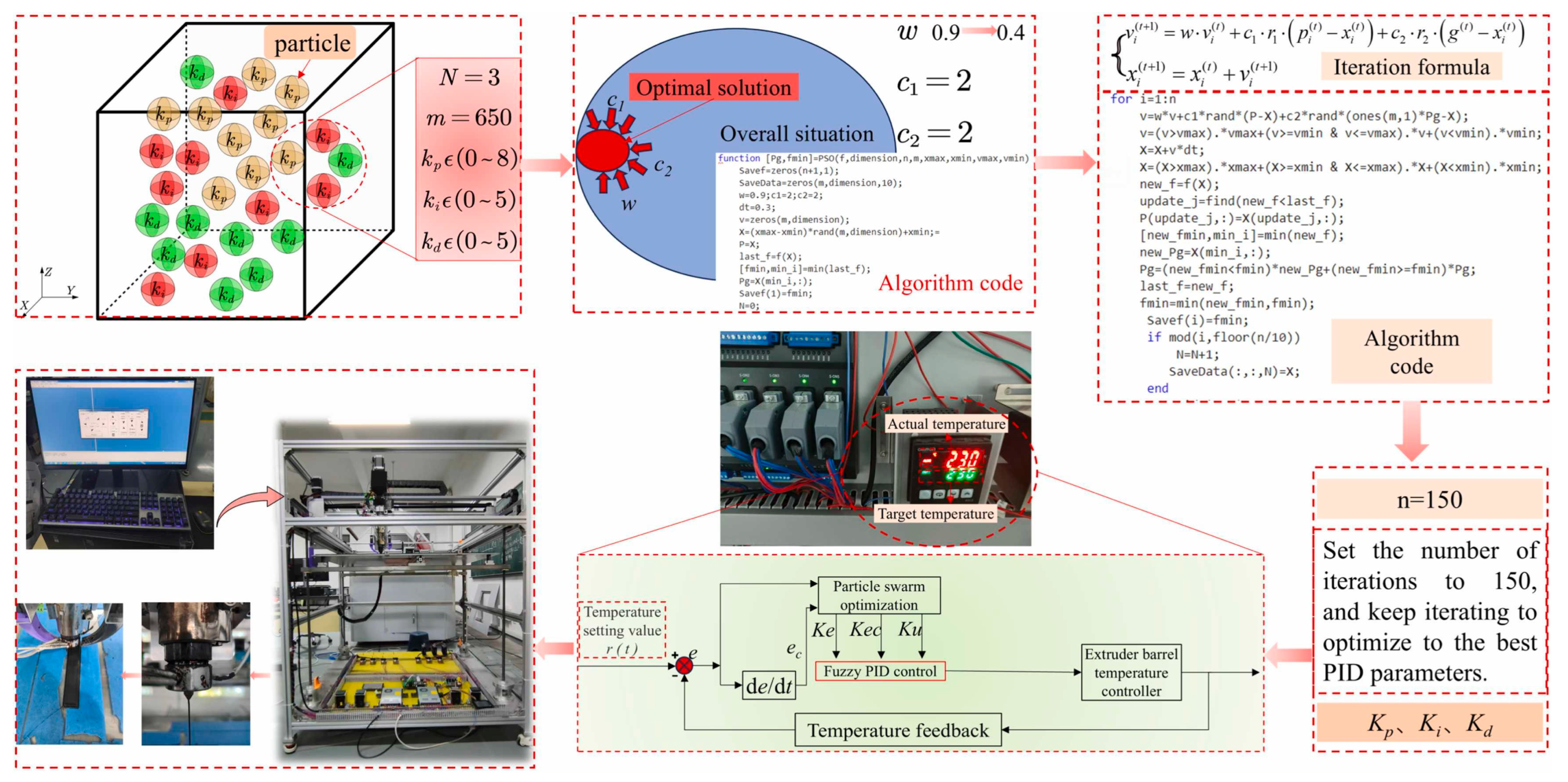

- Liu, B.; Qian, B.; Liang, Y.; Dai, P.; Li, R.; Wei, Q. Fast and Accurate Auto-Disturbances-Rejection Temperature Control System Based on Particle Swarm Optimized Fuzzy Control: Applied for Particle Three-Dimensional (3D) Printing Prosthetic Orthotic Plate. Addit. Manuf. 2025, 101, 104704. [Google Scholar] [CrossRef]

- Samy, A.A.; Golbang, A.; Harkin-Jones, E.; Archer, E.; Tormey, D.; McIlhagger, A. Finite Element Analysis of Residual Stress and Warpage in a 3D Printed Semi-Crystalline Polymer: Effect of Ambient Temperature and Nozzle Speed. J. Manuf. Process. 2021, 70, 389–399. [Google Scholar] [CrossRef]

- Choi, Y.-H.; Kim, C.-M.; Jeong, H.-S.; Youn, J.-H. Influence of Bed Temperature on Heat Shrinkage Shape Error in FDM Additive Manufacturing of the ABS-Engineering Plastic. World J. Eng. Technol. 2016, 4, 186–192. [Google Scholar] [CrossRef]

- Santos, E.C.; Munõz, S.N.M. Control of Temperature Distribution of a Thermal Bed Divided into Resistive Elements for FDM 3D Printers. Int. J. Adv. Manuf. Technol. 2025, 136, 3607–3620. [Google Scholar] [CrossRef]

- Cano-Vicent, A.; Tambuwala, M.M.; Hassan, S.S.; Barh, D.; Aljabali, A.A.A.; Birkett, M.; Arjunan, A.; Serrano-Aroca, Á. Fused Deposition Modelling: Current Status, Methodology, Applications and Future Prospects. Addit. Manuf. 2021, 47, 102378. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Wang, S.; Li, P. Study and Design of FDM 3D Printer Based on Magnetic Refrigeration. China Plast. Ind. 2017, 45, 47–52. [Google Scholar] [CrossRef]

- Kam, M.; Saruhan, H.; İPekçi, A. Investigation the Effect of 3D Printer System Vibrations on Surface Roughness of the Printed Products. Düzce Üniversitesi Bilim Teknol. Derg. 2019, 7, 147–157. [Google Scholar] [CrossRef]

- Chan, T.-C.; Medarametla, S.V.; Behera, R. Analyzing Positional Accuracy and Structural Efficiency in Additive Manufacturing Systems with Moving Elements. Results Eng. 2024, 23, 102344. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Z.; Qin, S.; Han, S. Optimization of Vibration Characteristics of Fused Deposition Modeling Color 3D Printer Based on Modal and Power Spectrum Method. Appl. Sci. 2019, 9, 4154. [Google Scholar] [CrossRef]

- Edoimioya, N.; Chou, C.-H.; Okwudire, C.E. Vibration Compensation of Delta 3D Printer with Position-Varying Dynamics Using Filtered B-Splines. Int. J. Adv. Manuf. Technol. 2023, 125, 2851–2868. [Google Scholar] [CrossRef]

- Kopets, E.; Karimov, A.; Scalera, L.; Butusov, D. Estimating Natural Frequencies of Cartesian 3D Printer Based on Kinematic Scheme. Appl. Sci. 2022, 12, 4514. [Google Scholar] [CrossRef]

- Alhadar, F.; Kessentini, A.; Jamhour, H.; Hadeeyah, A.; Wali, M. Mechanical Properties Investigations of PLA Products Made by FDM under Controlled Vibration. J. Mech. Sci. Technol. 2025, 39, 4009–4016. [Google Scholar] [CrossRef]

- Mishra, R.; Powers, W.B.; Kate, K. Comparative Study of Vibration Signatures of FDM 3D Printers. Prog. Addit. Manuf. 2023, 8, 205–209. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Extrusion-Based Additive Manufacturing Technologies: State of the Art and Future Perspectives. J. Manuf. Process. 2022, 83, 607–636. [Google Scholar] [CrossRef]

- Osswald, T.A.; Puentes, J.; Kattinger, J. Fused Filament Fabrication Melting Model. Addit. Manuf. 2018, 22, 51–59. [Google Scholar] [CrossRef]

- De Vries, S.; Schuller, T.; Galindo-Rosales, F.J.; Fanzio, P. Pressure Drop Non-Linearities in Material Extrusion Additive Manufacturing: A Novel Approach for Pressure Monitoring and Numerical Modeling. Addit. Manuf. 2024, 80, 103966. [Google Scholar] [CrossRef]

- Schuller, T.; Jalaal, M.; Fanzio, P.; Galindo-Rosales, F.J. Optimal Shape Design of Printing Nozzles for Extrusion-Based Additive Manufacturing. Addit. Manuf. 2024, 84, 104130. [Google Scholar] [CrossRef]

- Chesser, P.; Post, B.; Roschli, A.; Carnal, C.; Lind, R.; Borish, M.; Love, L. Extrusion Control for High Quality Printing on Big Area Additive Manufacturing (BAAM) Systems. Addit. Manuf. 2019, 28, 445–455. [Google Scholar] [CrossRef]

- Lubombo, C.; Huneault, M.A. Effect of Infill Patterns on the Mechanical Performance of Lightweight 3D-Printed Cellular PLA Parts. Mater. Today Commun. 2018, 17, 214–228. [Google Scholar] [CrossRef]

- Qamar Tanveer, M.; Mishra, G.; Mishra, S.; Sharma, R. Effect of Infill Pattern and Infill Density on Mechanical Behaviour of FDM 3D Printed Parts—A Current Review. Mater. Today Proc. 2022, 62, 100–108. [Google Scholar] [CrossRef]

- Kaur, M.; Yun, T.G.; Han, S.M.; Thomas, E.L.; Kim, W.S. 3D Printed Stretching-Dominated Micro-Trusses. Mater. Des. 2017, 134, 272–280. [Google Scholar] [CrossRef]

- Li, Y.; Shi, C.; Wang, X.; Yuan, S.; Zhu, J.; Zhang, W. A Mapping-Based Graded Infill Structure Design Method and Continuous Printing Path Planning. Addit. Manuf. 2025, 98, 104639. [Google Scholar] [CrossRef]

- Liu, T.; Yuan, S.; Wang, Y.; Xiong, Y.; Zhu, J.; Lu, L.; Tang, Y. Stress-Driven Infill Mapping for 3D-Printed Continuous Fiber Composite with Tunable Infill Density and Morphology. Addit. Manuf. 2023, 62, 103374. [Google Scholar] [CrossRef]

- Quan, Z.; Liu, C.; Li, J.; Qin, X.; Yu, J. Fiber Bundle Deposition Model and Variable Speed Printing Strategy for In-Situ Impregnation 3D Printing of Continuous Fiber Reinforced Thermoplastic Composites. Compos. Sci. Technol. 2024, 255, 110723. [Google Scholar] [CrossRef]

- Kim, S.; Andreu, A.; Kim, I.; Kim, J.-H.; Lee, J.; Yoon, Y.-J. Continuously Varied Infill Pattern (ConVIP): Improvement of Mechanical Properties and Printing Speed of Fused Filament Fabrication (FFF) 3D Printing. J. Mater. Res. Technol. 2022, 18, 1055–1069. [Google Scholar] [CrossRef]

| Main Category | Sub-Category | Characteristics | Applicable Fields |

|---|---|---|---|

| Vat Photopolymerization (VPP) [29] | Stereolithography (SLA) Digital Light Processing (DLP) Continuous Liquid Interface Production (CLIP) | High precision and smooth surface but limited to photopolymer resins and high equipment costs. | Precision prototypes, dental models, jewelry design, and biomedical scaffolds. |

| Material Jetting (MJT) [30] | PolyJet | Supports multi-material/multi-color with superior surface quality but has high material costs and weak mechanical properties. | Full-color prototypes, medical models, multi-material composite parts combining soft and rigid regions, and educational models. |

| Binder Jetting (BJT) [31] | Metal Binder Jetting | Capable of printing large-scale parts, but low part strength. | Sand casting molds, architectural structures, and lightweight metal components. |

| Material Extrusion (MEX) [32] | Fused Filament Fabrication (FFF) Fused Granulate Fabrication (FGF) Direct Ink Writing (DIW) Big Area Additive Manufacturing (BAAM) | Low cost and material accessibility, but lower precision and anisotropic mechanical properties. | Educational tools, prosthetics, and customized consumer products. |

| Sheet Lamination (SHL) [33,34] | Laminated Object Manufacturing (LOM Ultrasonic Additive Manufacturing (UAM) | Suitable for low-cost large-scale parts but has weak interlayer bonding and rough surface. | Metal laminated parts (electronic packaging), large-scale models, and functionally graded materials. |

| Powder Bed Fusion (PBF) [35] | PBF-LB/P (Laser Beam, Polymers) PBF-LB/M (Laser Beam, Metals) PBF-EB/M (Electron Beam, Metals) | Enables fabrication of high-density, geometrically complex metal parts; requires expensive equipment; relatively low powder utilization. | Aerospace components (turbine blades), biomedical implants (titanium alloys), high-temperature alloys, and lightweight structures. |

| Directed Energy Deposition (DED) [36] | DED-LB/M (Laser Beam) DED-EB/M (Electron Beam) DED-Arc (Arc Energy/Wire Feed) | Suitable for high-speed repair of large parts but requires post-processing due to rough surface and low precision. | Large metal part repairs (turbine blades), aerospace structural components, weapon manufacturing, and functionally graded material coatings. |

| Architecture | Main Advantages | Main Limitations | Key Considerations for High-Speed Printing |

|---|---|---|---|

| Gantry | Simple calibration; low cost; and easy to manufacture | Large bed mass; vibrations likely during high-speed reciprocating motion | Reduce heated-bed mass; reinforce frame rigidity |

| Polar | Simple mechanism; high precision for rotational and axisymmetric parts | Limited precision for fine geometric details due to rotational kinematics | Use lightweight rotating platforms; optimize airflow and structural balance |

| Delta | Lightweight moving mass; independent actuation; and high space utilization | Kinematic coupling and dynamic vibration depend on position; calibration complexity | Increase system stiffness; apply vibration compensation techniques |

| Core XY | Stable frame; reduced printing-force bias and torsional effects; and well-suited for high-speed operation | Complex belt routing may cause diagonal motion errors if misaligned | Minimize printhead mass; ensure precise and symmetric belt configuration |

| Material | Performance Characteristics | Application Fields |

|---|---|---|

| PLA (Polylactic Acid) | Excellent biodegradability, non-toxic, and low shrinkage rate; poor heat resistance, high brittleness, and low toughness. | Educational models, handicrafts, medical applications (e.g., dental molds), and eco-friendly packaging materials [51,52]. |

| ABS (Acrylonitrile Butadiene Styrene) | High strength (tensile strength ≥ 30 MPa), impact resistance, and moderate heat resistance; requires high-temperature printing and enclosed chamber. | Automotive component prototypes, electronic product housings, tool handles, and drones [53,54]. |

| PETG (Polyethylene Terephthalate Glycol) | High transparency, impact resistance, and chemical corrosion resistance. | Food packaging containers, industrial protective covers, and consumer electronics housings [55]. |

| TPU (Thermoplastic Polyurethane) | The material exhibits softness with high elasticity and excellent wear resistance yet presents high-forming difficulty during printing. | Flexible seals, wearable device components, and shock-absorbing structures [56,57]. |

| PA (Polyamide) | Superior wear resistance, impact resistance, high strength, and high toughness. | Drone propellers, mechanical gears, and high-performance industrial components [58]. |

| PC (Polycarbonate) | High-temperature resistance, impact resistance; requires enclosed printing environment. | Automotive lamp covers, optical lenses, and protective equipment [59]. |

| PEEK (Polyether Ether Ketone) | Ultra-high strength, extreme heat resistance, and biocompatibility; requires specialized high-temperature printers. | Orthopedic implants, aerospace engine components, and high-stress industrial parts [60,61,62]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, Q.; Fu, B.; Zhong, F. A Review of Challenges and Future Perspectives for High-Speed Material Extrusion Technology. Appl. Sci. 2025, 15, 12176. https://doi.org/10.3390/app152212176

Tao Q, Fu B, Zhong F. A Review of Challenges and Future Perspectives for High-Speed Material Extrusion Technology. Applied Sciences. 2025; 15(22):12176. https://doi.org/10.3390/app152212176

Chicago/Turabian StyleTao, Qi, Boao Fu, and Fei Zhong. 2025. "A Review of Challenges and Future Perspectives for High-Speed Material Extrusion Technology" Applied Sciences 15, no. 22: 12176. https://doi.org/10.3390/app152212176

APA StyleTao, Q., Fu, B., & Zhong, F. (2025). A Review of Challenges and Future Perspectives for High-Speed Material Extrusion Technology. Applied Sciences, 15(22), 12176. https://doi.org/10.3390/app152212176