Enhancing Gluten-Free Muffins with Cornelian Cherry (Cornus mas L.) and Carob–Taro–Rice Flour Blend: A Functional and Bioactive Approach

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Muffin Formulation

2.2. Proximate Composition Analysis

2.3. Baking Loss and Muffin Height

2.4. Total Phenolic Content and Antioxidant Activity Analysis

2.5. Color Measurements

2.6. Texture Analysis

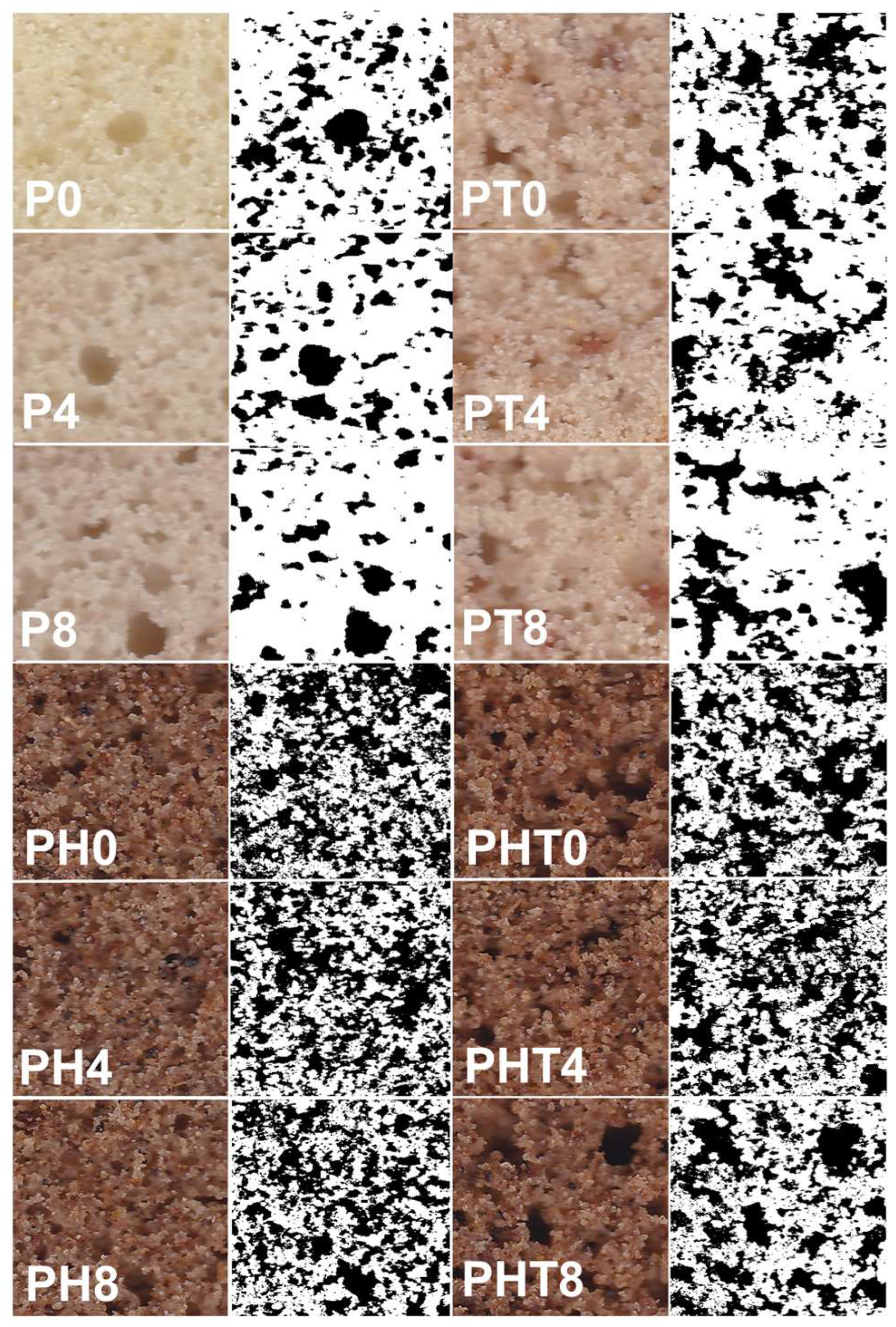

2.7. Image Processing

2.8. Sensory Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition, Total Phenolic Content and Antioxidant Activity

3.2. Color Analysis

3.3. Texture, Baking Loss and Height Results

3.4. Image Processing Results

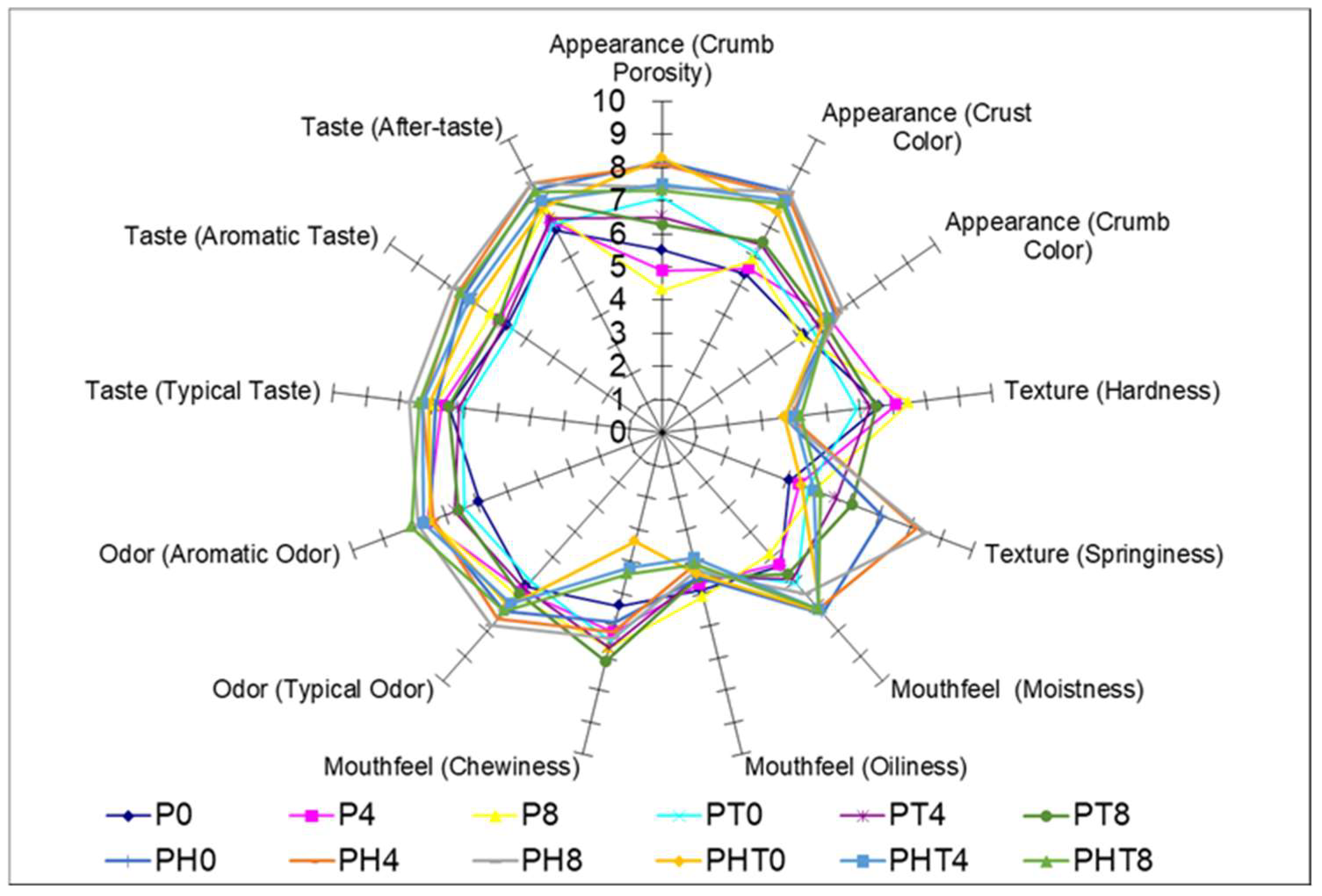

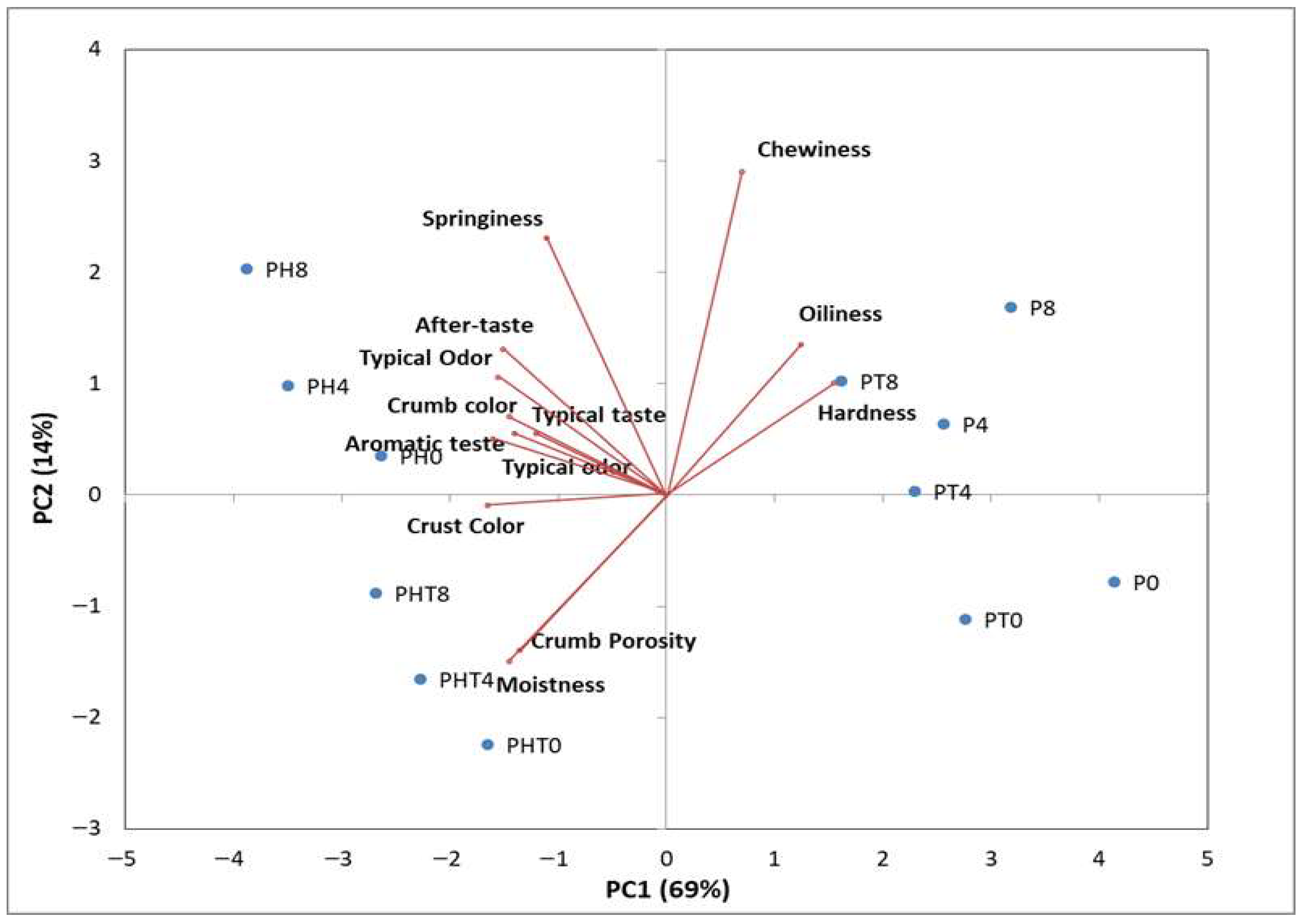

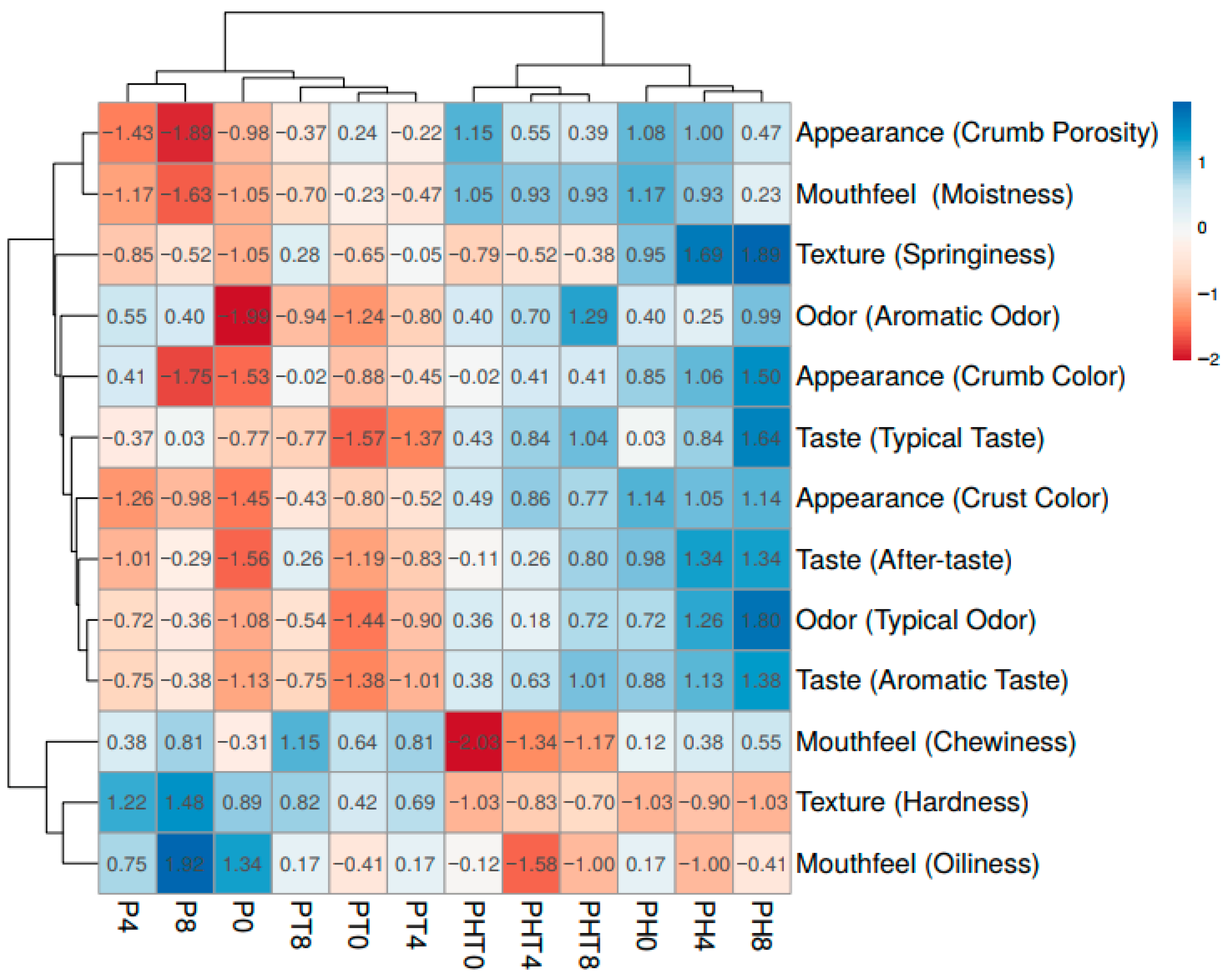

3.5. Sensory Analysis Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gasparre, N.; Rosell, C.M. Wheat Gluten: A Functional Protein Still Challenging to Replace in Gluten-Free Cereal-Based Foods. Cereal Chem. 2023, 100, 243–255. [Google Scholar] [CrossRef]

- Joye, I. Gluten as a Unique Protein Building Cereal Product Structure, Is There an Alternative? J. Am. Oil Chem. Soc. 2022, 99, 155. [Google Scholar]

- Aguiar, E.V.; Centeno, A.C.L.; Santos, F.G.; Capriles, V.D. Whole Grain Pearl Millet-Based Gluten-Free Bread: A Novel Alternative with Nutrition and Sensory Appeal. Appl. Food Res. 2024, 4, 100520. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E. A Systematic Review of Gluten-Free Dough and Bread: Dough Rheology, Bread Characteristics, and Improvement Strategies. Appl. Sci. 2020, 10, 6559. [Google Scholar] [CrossRef]

- Rosell, C.M.; Marco, C. Rice. In Gluten-Free Cereal Products and Beverages; Arendt, E.K., Dal Bello, F., Eds.; Academic Press: Cambridge, MA, USA, 2008; pp. 81–111. [Google Scholar]

- Chiş, M.S.; Păucean, A.; Man, S.M.; Bonta, V.; Pop, A.; Stan, L.; Beldean, B.V.; Pop, C.R.; Mureşan, V.; Muste, S. Effect of Rice Flour Fermentation with Lactobacillus spicheri DSM 15429 on the Nutritional Features of Gluten-Free Muffins. Foods 2020, 9, 822. [Google Scholar] [CrossRef]

- Paixã, A.; Cardoso, J.; Loução, A.; Embaló, D.; Costa, C.; Pereira, A.M.A.F.; Filemone, L.L.; Simões, C.; Morais, J. Obtention of Taro Flour (Colocasia esculenta L.) and Its Potential in Bread Making. Int. J. Food Sci. Agric. 2021, 5, 393–398. [Google Scholar] [CrossRef]

- Boahemaa, L.V.; Dzandu, B.; Amissah, J.G.N.; Akonor, P.T.; Saalia, K.W. Physico-Chemical and Functional Characterization of Flour and Starch of Taro (Colocasia esculenta) for Food Applications. Food Human. 2024, 2, 100245. [Google Scholar] [CrossRef]

- Arici, M.; Yildirim, R.M.; Özülkü, G.; Yaşar, B.; Toker, O.S. Physicochemical and Nutritional Properties of Taro (Colocasia esculenta L. Schott) Flour as Affected by Drying Temperature and Air Velocity. LWT-Food Sci. Technol. 2016, 74, 434–440. [Google Scholar] [CrossRef]

- Papageorgiou, M.; Paraskevopoulou, A.; Pantazi, F.; Skendi, A. Cake Perception, Texture and Aroma Profile as Affected by Wheat Flour and Cocoa Replacement with Carob Flour. Foods 2020, 9, 1586. [Google Scholar] [CrossRef]

- Sęczyk, Ł.; Świeca, M.; Gawlik-Dziki, U. Effect of Carob (Ceratonia siliqua L.) Flour on the Antioxidant Potential, Nutritional Quality, and Sensory Characteristics of Fortified Durum Wheat Pasta. Food Chem. 2016, 194, 637–642. [Google Scholar] [CrossRef]

- Czerwinska, M.E.; Melzig, M.F. Cornus mas and Cornus officinalis Analogies and Differences of Two Medicinal Plants Traditionally Used. Front. Pharmacol. 2018, 9, 894. [Google Scholar] [CrossRef]

- Haghani, S.; Hadidi, M.; Pouramin, S.; Adinepour, F.; Hasiri, Z.; Moreno, A.; Munekata, P.E.S.; Lorenzo, J.M. Application of Cornelian Cherry (Cornus mas L.) Peel in Probiotic Ice Cream: Functionality and Viability During Storage. Antioxidants 2021, 10, 1777. [Google Scholar] [CrossRef]

- Aurori, M.; Niculae, M.; Hanganu, D.; Pall, E.; Cenariu, M.; Vodnar, D.C.; Bunea, A.; Fiţ, N.; Andrei, S. Phytochemical Profile, Antioxidant, Antimicrobial and Cytoprotective Effects of Cornelian Cherry (Cornus mas L.) Fruit Extracts. Pharmaceuticals 2023, 16, 420. [Google Scholar] [CrossRef]

- Tural, S.; Koca, I. Physico-Chemical and Antioxidant Properties of Cornelian Cherry Fruits (Cornus mas L.) Grown in Turkey. Sci. Hortic. 2008, 116, 362–366. [Google Scholar] [CrossRef]

- Celik, S.; Bakirci, I.; Şat, I.G. Physicochemical and Organoleptic Properties of Yogurt with Cornelian Cherry Paste. Int. J. Food Prop. 2006, 9, 401–408. [Google Scholar] [CrossRef]

- Salejda, A.M.; Kucharska, A.Z.; Krasnowska, G. Effect of Cornelian Cherry (Cornus mas L.) Juice on Selected Quality Properties of Beef Burgers. J. Food Qual. 2018, 2018, 1563651. [Google Scholar] [CrossRef]

- Kavak, D.D.; Akpunar, E.B. Quality Characteristics of Turkish Delight (Lokum) as Influenced by Different Concentrations of Cornelian Cherry Pulp. J. Food Process. Preserv. 2018, 42, e13656. [Google Scholar] [CrossRef]

- Ateş, G.; Elmacı, Y. Coffee Silverskin as Fat Replacer in Cake Formulations and Its Effect on Physical, Chemical and Sensory Attributes of Cakes. LWT-Food Sci. Technol. 2018, 90, 519–525. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of AOAC International, 18th ed.; AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Sung, W.C.; Chai, P.S. Effect of Flaxseed Flour and Xanthan Gum on Gluten-Free Cake Properties. J. Food Nutr. Res. 2017, 5, 717–728. [Google Scholar] [CrossRef]

- Kumar, V.; Sharma, H.K. Process Optimization for Extraction of Bioactive Compounds from Taro (Colocasia esculenta), Using RSM and ANFIS Modeling. J. Food Meas. Charact. 2017, 11, 704–718. [Google Scholar] [CrossRef]

- Tsykhanovska, I.; Stabnikova, O.; Riabchykov, M.; Shevchenko, M.; Stabnikov, V. Effect of Partial Replacement of Wheat Flour by Flour from Extruded Sunflower Seed Kernels on Muffins Quality. Plant Food. Hum. Nutr. 2024, 79, 769–778. [Google Scholar] [CrossRef]

- Grasso, S.; Liu, S.; Methven, L. Quality of Muffins Enriched with Upcycled Defatted Sunflower Seed Flour. LWT-Food Sci. Technol. 2020, 119, 108893. [Google Scholar] [CrossRef]

- Rodríguez-García, J.; Salvador, A.; Hernando, I. Replacing Fat and Sugar with Inulin in Cakes: Bubble Size Distribution, Physical and Sensory Properties. Food Bioprocess Technol. 2014, 7, 964–974. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; Salvador, A.; Muguerza, B.; Moulay, L.; Fiszman, S.M. Cocoa Fibre and Its Application as a Fat Replacer in Chocolate Muffins. LWT-Food Sci. Technol. 2011, 44, 729–736. [Google Scholar] [CrossRef]

- Metsalu, T.; Vilo, J. ClustVis: A Web Tool for Visualizing Clustering of Multivariate Data Using Principal Component Analysis and Heatmap. Nucleic Acids Res. 2015, 43, W566–W570. [Google Scholar] [CrossRef]

- Červenka, L.; Frühbauerová, M.; Velichová, H. Functional Properties of Muffin as Affected by Substituting Wheat Flour with Carob Powder. Potravinarstvo Slovak J. Food Sci. 2019, 13, 212–217. [Google Scholar] [CrossRef]

- Bianchi, F.; Cervini, M.; Giuberti, G.; Rocchetti, G.; Lucini, L.; Simonato, B. Distilled grape pomace as a functional ingredient in vegan muffins: Effect on physicochemical, nutritional, rheological and sensory aspects. Int. J. Food Sci. Technol. 2022, 57, 4847–4858. [Google Scholar] [CrossRef]

- Mureșan, A.E.; Man, S.M.; Socaci, S.A.; Pușcaș, A.; Tanislav, A.E.; Păll, E.; Mureșan, V.; Cerbu, C.G. Functionality of Muffins Fortified with Apple Pomace: Nutritional, Textural, and Sensory Aspects. Appl. Sci. 2024, 14, 6439. [Google Scholar] [CrossRef]

- Talens, C.; Álvarez-Sabatel, S.; Rios, Y.; Rodríguez, R. Effect of a new microwave-dried orange fibre ingredient vs. a commercial citrus fibre on texture and sensory properties of gluten-free muffins. Innov. Food Sci. Emerg. Technol. 2017, 44, 83–88. [Google Scholar] [CrossRef]

- Kasapoglu, M.Z.; Acar, I. Utilization of safflower seed by-product protein for gluten-free muffin production: A physicochemical and rheological perspective. LWT-Food Sci. Technol. 2025, 223, 117720. [Google Scholar] [CrossRef]

- Yousif, A.K.; Alghzawi, H.M. Processing and Characterization of Carob Powder. Food Chem. 2000, 69, 283–287. [Google Scholar] [CrossRef]

- Ghobadi, M.; Fazeli, F.; Mohammadi, H.; Zoghi, A.; Khorshidian, N.; Mohammadi, M. Physicochemical, Textural and Sensorial Characteristics of Oily Cake Enriched with Cornelian Cherry (Cornus mas L.) Extract and Peanut Flour: A Valorized Food. Appl. Food Res. 2025, 5, 101443. [Google Scholar] [CrossRef]

- Moldovan, B.; David, L. Influence of Different Sweeteners on the Stability of Anthocyanins from Cornelian Cherry Juice. Foods 2020, 9, 1266. [Google Scholar] [CrossRef]

- Sharma, P.; Gujral, H.S. Cookie Making Behavior of Wheat-Barley Flour Blends and Effects on Antioxidative Properties. LWT-Food Sci. Technol. 2014, 55, 301–307. [Google Scholar] [CrossRef]

- Loganathan, R.; Ahmad Tarmizi, A.H.; Vethakkan, S.R.; Teng, K.T. Thermal Stability and Sensory Acceptance of Cupcakes Containing Red Palm Olein. J. Oleo Sci. 2020, 69, 671–676. [Google Scholar] [CrossRef]

- Hasmadi, M.; Ronie, M.E. Factors Affecting the Properties of Rice Flour: A Review. Food Res. 2022, 6, 1–12. [Google Scholar] [CrossRef]

- Kaushal, P.; Kumar, V.; Sharma, H.K. Utilization of Taro (Colocasia esculenta): A Review. J. Food Sci. Technol. 2015, 52, 27–40. [Google Scholar] [CrossRef]

- Tess, M.; Bhaduri, S.; Ghatak, R.; Navder, K.P. Physical, Textural and Sensory Characteristics of Gluten Free Muffins Prepared with Teff Flour (Eragrostis tef (zucc) trotter). J. Food Process. Technol. 2015, 6, 490. [Google Scholar]

- Salehi, F. Effect of Common and New Gums on the Quality, Physical, and Textural Properties of Bakery Products: A Review. J. Texture Stud. 2020, 51, 361–370. [Google Scholar] [CrossRef]

- Hosseininejad, S.; Larrea, V.; Moraga, G.; Hernando, I. Evaluation of the Bioactive Compounds, and Physicochemical and Sensory Properties of Gluten-Free Muffins Enriched with Persimmon ‘Rojo Brillante’ Flour. Foods 2022, 11, 3357. [Google Scholar] [CrossRef] [PubMed]

- Pawłowska, K.; Kuligowski, M.; Jasińska-Kuligowska, I.; Kidoń, M.; Siger, A.; Rudzińska, M.; Nowak, J. Effect of Replacing Cocoa Powder by Carob Powder in the Muffins on Sensory and Physicochemical Properties. Plant Foods Hum. Nutr. 2018, 73, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Ainiwan, D.; Liu, Y.; Dong, X.; Fan, H.; Sun, T.; Huang, P.; Zhang, S.; Wang, D.; Liu, T.; et al. Adsorption and Controlled Release Performances of Flavor Compounds by Rice Bran Insoluble Dietary Fiber Improved Through Steam Explosion Method. Curr. Res. Food Sci. 2023, 7, 100550. [Google Scholar] [CrossRef] [PubMed]

| Sample | Moisture | Fat | Protein | Ash | Fiber | CHO | TPC | AA |

|---|---|---|---|---|---|---|---|---|

| P0 | 23.28 ± 0.63 bc | 14.79 ± 0.27 abcde | 5.77 ± 0.14 d | 1.35 ± 0.04 a | 1.19 ± 0.10 a | 53.63 ± 1.1 ef | 0.22 ± 0.01 a | 47.71 ± 0.29 a |

| P4 | 23.30 ± 0.09 bc | 14.53 ± 0.14 abc | 5.51 ± 0.13 bc | 1.36 ± 0.01 a | 1.14 ± 0.14 a | 54.16 ± 0.05 f | 0.25 ± 0.01 a | 54.25 ± 0.59 b |

| R8 | 23.56 ± 0.62 c | 14.38 ± 0.2 a | 5.59 ± 0.06 cd | 1.39 ± 0.09 a | 1.11 ± 0.15 a | 53.98 ± 0.3 f | 0.25 ± 0.02 a | 59.38 ± 0.18 d |

| PT0 | 21.66 ± 0.41 a | 15.04 ± 0.12 def | 5.49 ± 0.03 bc | 1.88 ± 0.03 b | 3.23 ± 0.02 b | 52.70 ± 0.61 ef | 0.60 ± 0.01 b | 56.58 ± 0.62 c |

| PT4 | 22.23 ± 0.26 ab | 14.57 ± 0.1 2abcd | 5.34 ± 0.07 b | 1.83 ± 0.01 b | 3.17 ± 0.03 b | 52.86 ± 0.03 ef | 0.61 ± 0.02 b | 59.05 ± 0.23 d |

| PT8 | 23.13 ± 0.44 bc | 14.49 ± 0.38 ab | 5.31 ± 0.16 b | 1.91 ± 0.01 b | 3.10 ± 0.05 b | 52.06 ± 0.07 e | 0.76 ± 0.06 c | 60.47 ± 0.21 e |

| PH0 | 21.75 ± 0.38 a | 15.41 ± 0.13 f | 5.65 ± 0.02 cd | 2.06 ± 0.05 c | 7.69 ± 0.05 c | 47.43 ± 0.16 d | 1.63 ± 0.04 d | 66.57 ± 0.46 f |

| PH4 | 22.43 ± 0.86 abc | 15.20 ± 0.25 ef | 5.67 ± 0.11 cd | 2.19 ± 0.07 cd | 7.79 ± 0.02 c | 46.72 ± 0.81 cd | 1.66 ± 0.08 d | 69.47 ± 0.75 g |

| PH8 | 23.20 ± 0.88 bc | 15.15 ± 0.11 ef | 5.59 ± 0.15 cd | 2.24 ± 0.06 d | 7.81 ± 0.03 c | 46.01 ± 1.22 bcd | 2.09 ± 0.03 f | 71.14 ± 0.4 h |

| PHT0 | 22.21 ± 0.63 ab | 15.24 ± 0.11 def | 4.92 ± 0.09 a | 2.62 ± 0.1 e | 9.37 ± 0.12 d | 45.65 ± 1.05 abc | 2.04 ± 0.03 f | 69.46 ± 0.38 g |

| PHT4 | 23.24 ± 0.26 bc | 14.93 ± 0.13 bcdef | 4.80 ± 0.08 a | 2.76 ± 0.12 f | 9.44 ± 0.1 d | 44.82 ± 0.7 ab | 1.88 ± 0.03 e | 72.16 ± 0.56 ı |

| PHT8 | 23.64 ± 0.07 c | 15.00 ± 0.33 cdef | 4.82 ± 0.07 a | 2.80 ± 0.07 f | 9.38 ± 0.1 d | 44.36 ± 0.64 a | 2.24 ± 0.21 g | 70.35 ± 0.15 gh |

| Crumb | Crust | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample | L* | a* | b* | ΔE* | L* | A* | B* | ΔE* |

| P0 | 68.12 ± 0.26 h | 2.60 ± 0.04 a | 23.18 ± 0.37 g | 4.34 ± 0.02 d | 53.55 ± 0.28 f | 21.57 ± 0.15 g | 33.04 ± 0.17 i | 5.75 ± 0.03 e |

| P4 | 66.41 ± 0.17 g | 4.67 ± 0.13 b | 17.37 ± 0.29 b | 4.34 ± 0.05 d | 53.29 ± 0.30 f | 20.44 ± 0.36 f | 31.51 ± 0.16 h | 5.97 ± 0.03 f |

| P8 | 64.62 ± 0.40 f | 5.83 ± 0.12 c | 15.79 ± 0.18 a | 4.59 ± 0.05 e | 49.06 ± 0.72 e | 19.89 ± 0.21 de | 29.60 ± 0.26 g | 5.77 ± 0.08 e |

| PT0 | 36.59 ± 0.17 c | 11.75 ± 0.23 e | 18.28 ± 0.39 c | 3.06 ± 0.18 a | 37.35 ± 0.69 b | 15.57 ± 0.17 b | 19.48 ± 0.32 a | 3.90 ± 0.11 a |

| PT4 | 36.36 ± 0.40 c | 11.79 ± 0.33 e | 18.61 ± 0.30 cd | 3.37 ± 0.19 b | 37.25 ± 0.77 b | 15.56 ± 0.24 b | 20.06 ± 0.14 b | 4.18 ± 0.09 b |

| PT8 | 36.04 ± 0.39 c | 11.93 ± 0.33 e | 18.49 ± 0.35 cd | 3.31 ± 0.12 b | 37.32 ± 0.60 b | 14.98 ± 0.23 a | 19.75 ± 0.40 ab | 4.07 ± 0.10 ab |

| PH0 | 61.23 ± 0.38 e | 8.25 ± 0.35 d | 20.24 ± 0.31 f | 4.33 ± 0.06 d | 48.97 ± 0.55 e | 20.22 ± 0.08 ef | 28.37 ± 0.06 e | 5.16 ± 0.05 d |

| PH4 | 60.76 ± 0.18 e | 8.70 ± 0.31 d | 20.06 ± 0.35 f | 4.54 ± 0.02 e | 47.05 ± 0.62 d | 19.49 ± 0.16 d | 27.27 ± 0.20 e | 4.99 ± 0.10 cd |

| PH8 | 59.51 ± 0.47 d | 8.23 ± 0.43 d | 19.76 ± 0.32 f | 4.48 ± 0.09 de | 45.30 ± 0.67 c | 18.70 ± 0.39 c | 27.19 ± 0.01 f | 4.87 ± 0.11 c |

| PHT0 | 34.72 ± 0.43 b | 13.05 ± 0.11 f | 18.96 ± 0.15 de | 3.80 ± 0.09 c | 33.11 ± 0.70 a | 15.00 ± 0.29 a | 22.06 ± 0.23 d | 4.23 ± 0.18 b |

| PHT4 | 34.38 ± 0.26 ab | 13.08 ± 0.32 f | 18.99 ± 0.16 de | 3.81 ± 0.11 c | 33.44 ± 0.34 a | 14.96 ± 0.26 a | 21.32 ± 0.17 c | 4.22 ± 0.08 b |

| PHT8 | 34.11 ± 0.37 a | 13.08 ± 0.21 f | 19.14 ± 0.06 e | 3.81 ± 0.03 c | 32.60 ± 0.60 a | 15.20 ± 0.23 ab | 21.15 ± 0.41 c | 4.14 ± 0.16 b |

| Sample | Hardness | Springiness | Cohesiveness | Chewiness | Resilience | Height (mm) | Baking Lossc (%) |

|---|---|---|---|---|---|---|---|

| P0 | 1.83 ± 0.34 g | 0.95 ± 0.06 ab | 0.68 ± 0.02 a | 1.19 ± 0.84 cd | 0.44 ± 0.04 bc | 40.4 ± 0.42 bc | 18.04 ± 0.52 e |

| P4 | 1.95 ± 0.07 h | 1.00 ± 0.00 ab | 0.77 ± 0.02 bc | 1.50 ± 0.52 ef | 0.48 ± 0.01 bcd | 39.6 ± 0.65 a | 18.87 ± 0.45 f |

| P8 | 2.09 ± 0.36 i | 1.07 ± 0.11 ab | 0.83 ± 0.03 cd | 1.87 ± 2.85 gh | 0.52 ± 0.02 cd | 39.9 ± 0.65 ab | 18.64 ± 0.50 f |

| PT0 | 1.67 ± 0.07 f | 0.99 ± 0.01 ab | 0.80 ± 0.07 bcd | 1.34 ± 1.12 de | 0.34 ± 0.05 a | 42.0 ± 0.61 de | 15.33 ± 0.37 c |

| PT4 | 1.71 ± 0.27 f | 1.09 ± 0.08 b | 0.86 ± 0.04 cd | 1.60 ± 2.23 efg | 0.40 ± 0.03 ab | 41.7 ± 0.27 d | 16.84 ± 0.41 d |

| PT8 | 1.80 ± 0.23 g | 1.17 ± 0.02 c | 0.88 ± 0.01 d | 2.48 ± 0.26 i | 0.42 ± 0.02 ab | 41.6 ± 0.55 d | 16.48 ± 0.47 d |

| PH0 | 0.76 ± 0.11 a | 1.66 ± 0.14 c | 0.82 ± 0.04 cd | 1.03 ± 1.60 bc | 0.46 ± 0.04 bcd | 43.1 ± 0.22 f | 14.19 ± 0.31 a |

| PH4 | 0.83 ± 0.18 b | 2.46 ± 0.08 d | 0.83 ± 0.03 cd | 1.70 ± 0.40 fg | 0.48 ± 0.02 bcd | 42.6 ± 0.42 ef | 14.76 ± 0.44 b |

| PH8 | 0.90 ± 0.11 c | 2.59 ± 0.11 d | 0.87 ± 0.02 d | 2.03 ± 1.54 C | 0.53 ± 0.02 d | 42.7 ± 0.45 f | 15.05 ± 0.36 bc |

| PHT0 | 0.87 ± 0.25 bc | 0.90 ± 0.01 a | 0.73 ± 0.05 a | 0.57 ± 0.11 a | 0.43 ± 0.07 b | 41.9 ± 0.65 d | 16.83 ± 0.42 d |

| PHT4 | 1.01 ± 0.23 d | 0.99 ± 0.00 ab | 0.82 ± 0.04 cd | 0.82 ± 0.60 ab | 0.47 ± 0.02 bcd | 40.7 ± 0.45 c | 15.51 ± 0.41 c |

| PHT8 | 1.19 ± 0.14 e | 1.01 ± 0.03 ab | 0.85 ± 0.01 cd | 1.02 ± 0.06 bc | 0.47 ± 0.02 bcd | 40.9 ± 0.42 c | 15.48 ± 0.37 c |

| Sample | Total Air Cell Area | Average Air Cell Size | Air Cell Area (%) | Circularity |

|---|---|---|---|---|

| P0 | 38.98 ± 0.136 b | 0.18 ± 0.001 b | 24.17 ± 0.085 b | 0.74 ± 0.002 a |

| P4 | 36.47 ± 0.107 b | 0.23 ± 0.001 c | 22.61 ± 0.066 b | 0.72 ± 0.001 a |

| P8 | 26.50 ± 0.141 a | 0.25 ± 0.003 c | 16.43 ± 0.087 a | 0.76 ± 0.001 b |

| PT0 | 48.39 ± 0.612 d | 0.22 ± 0.002 bc | 30.00 ± 0.380 d | 0.81 ± 0.010 d |

| PT4 | 44.52 ± 1.240 c | 0.18 ± 0.006 b | 27.60 ± 0.769 c | 0.79 ± 0.001 cd |

| PT8 | 43.61 ± 1.484 c | 0.31 ± 0.045 d | 27.04 ± 0.920 c | 0.78 ± 0.011 bc |

| PH0 | 82.10 ± 0.375 g | 0.12 ± 0.025 a | 50.90 ± 0.232 g | 0.87 ± 0.012 e |

| PH4 | 81.51 ± 1.790 g | 0.18 ± 0.014 b | 50.54 ± 1.110 g | 0.87 ± 0.016 e |

| PH8 | 77.88 ± 0.675 f | 0.18 ± 0.019 b | 48.28 ± 0.418 f | 0.86 ± 0.010 e |

| PHT0 | 82.56 ± 3.258 g | 0.18 ± 0.033 b | 50.78 ± 1.441 g | 0.86 ± 0.013 e |

| PHT4 | 78.42 ± 1.139 f | 0.11 ± 0.021 a | 48.62 ± 0.706 f | 0.87 ± 0.011 e |

| PHT8 | 72.87 ± 1.662 e | 0.12 ± 0.001 a | 45.18 ± 1.031 e | 0.85 ± 0.001 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kavak, D.D.; Akdeniz, B.; Yılmaz, B.A. Enhancing Gluten-Free Muffins with Cornelian Cherry (Cornus mas L.) and Carob–Taro–Rice Flour Blend: A Functional and Bioactive Approach. Appl. Sci. 2025, 15, 12362. https://doi.org/10.3390/app152312362

Kavak DD, Akdeniz B, Yılmaz BA. Enhancing Gluten-Free Muffins with Cornelian Cherry (Cornus mas L.) and Carob–Taro–Rice Flour Blend: A Functional and Bioactive Approach. Applied Sciences. 2025; 15(23):12362. https://doi.org/10.3390/app152312362

Chicago/Turabian StyleKavak, Dilek Demirbuker, Bilge Akdeniz, and Betül Aslan Yılmaz. 2025. "Enhancing Gluten-Free Muffins with Cornelian Cherry (Cornus mas L.) and Carob–Taro–Rice Flour Blend: A Functional and Bioactive Approach" Applied Sciences 15, no. 23: 12362. https://doi.org/10.3390/app152312362

APA StyleKavak, D. D., Akdeniz, B., & Yılmaz, B. A. (2025). Enhancing Gluten-Free Muffins with Cornelian Cherry (Cornus mas L.) and Carob–Taro–Rice Flour Blend: A Functional and Bioactive Approach. Applied Sciences, 15(23), 12362. https://doi.org/10.3390/app152312362