Numerical Simulation of Clay Layer Permeability Failure Under Loose Strata: Effects of Mining-Induced Fracture Width

Abstract

1. Introduction

2. Methodology

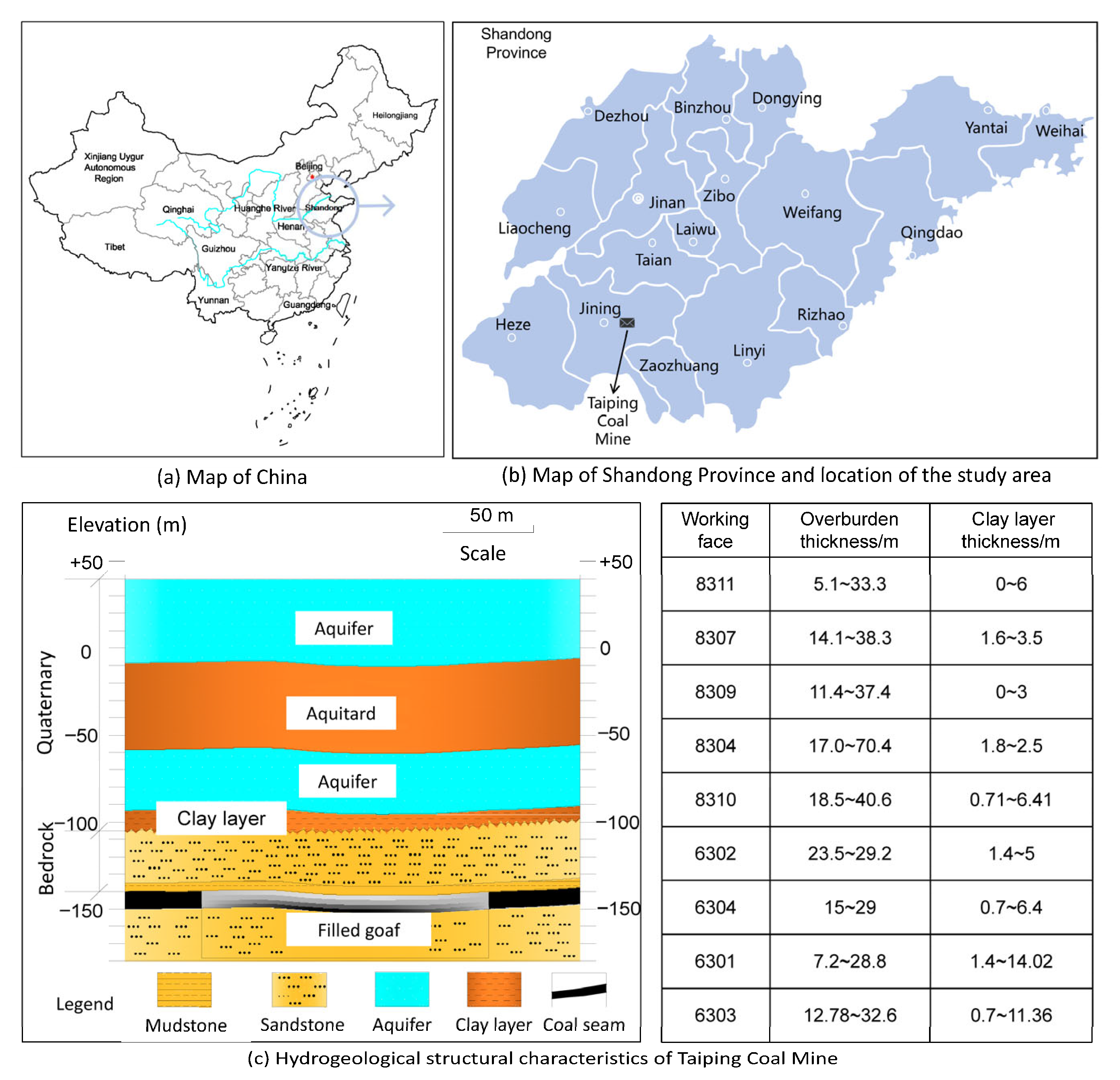

2.1. Study Area

2.2. Characteristics of the Method

2.3. Basic Assumptions of the Model

- (1)

- Assumptions about particles

- (2)

- Assumptions for walls

- (3)

- Assumptions on the contact model

- (4)

- Contact constitutive model

2.4. Multi-Physics Coupling

3. Results and Discussion

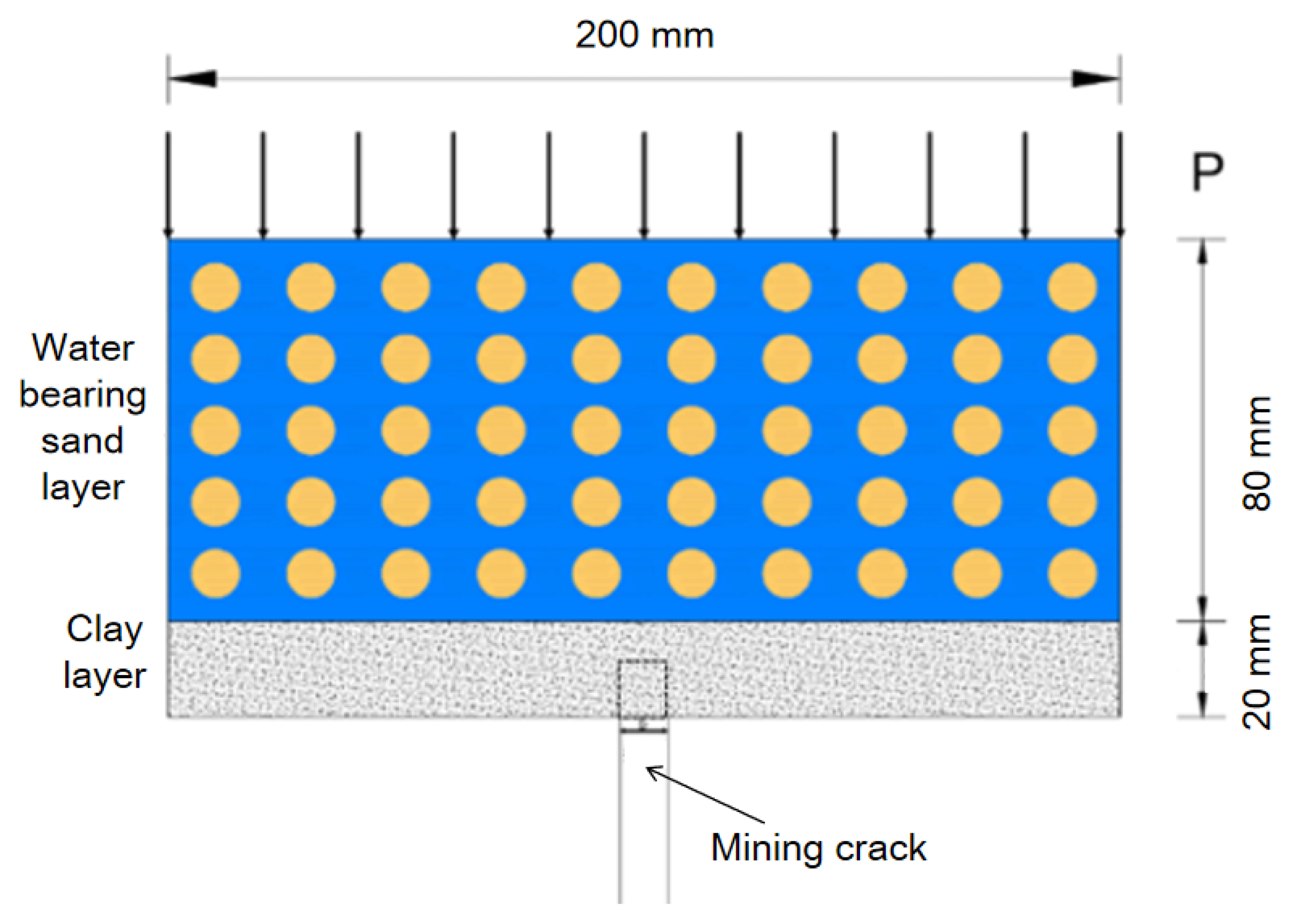

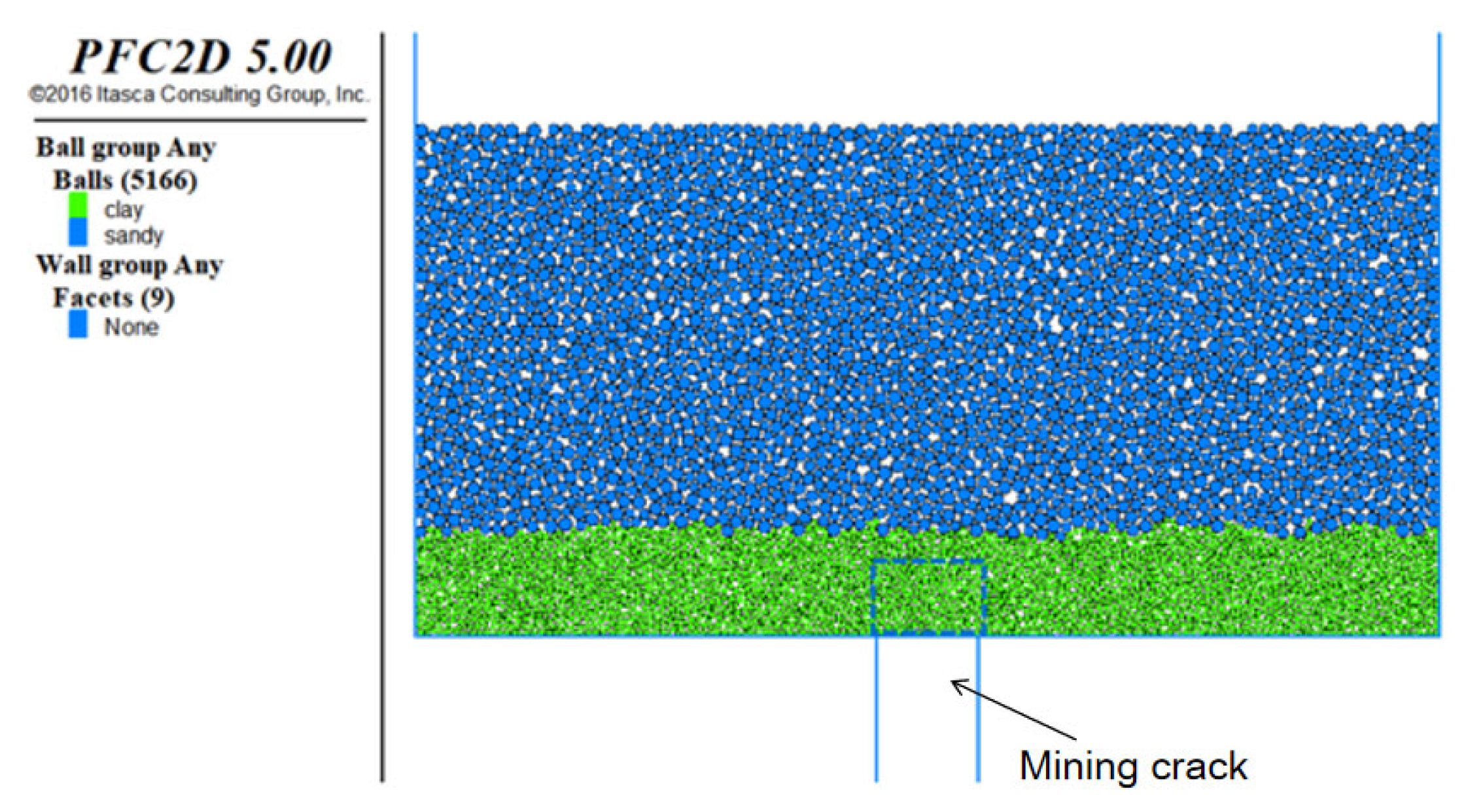

3.1. Establishment and Monitoring of the Model

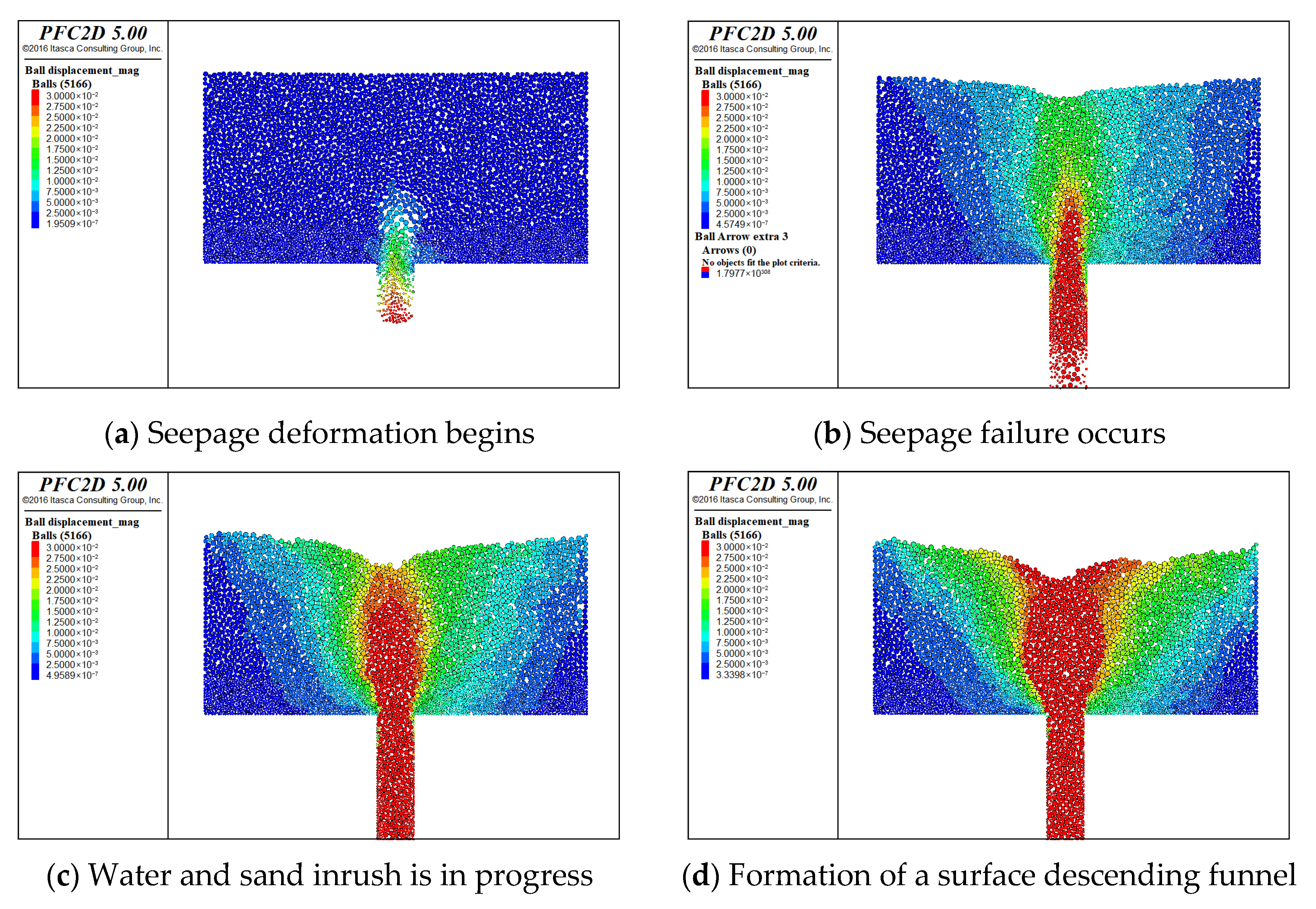

3.2. Infiltration Damage Simulation Result Analysis

- (1)

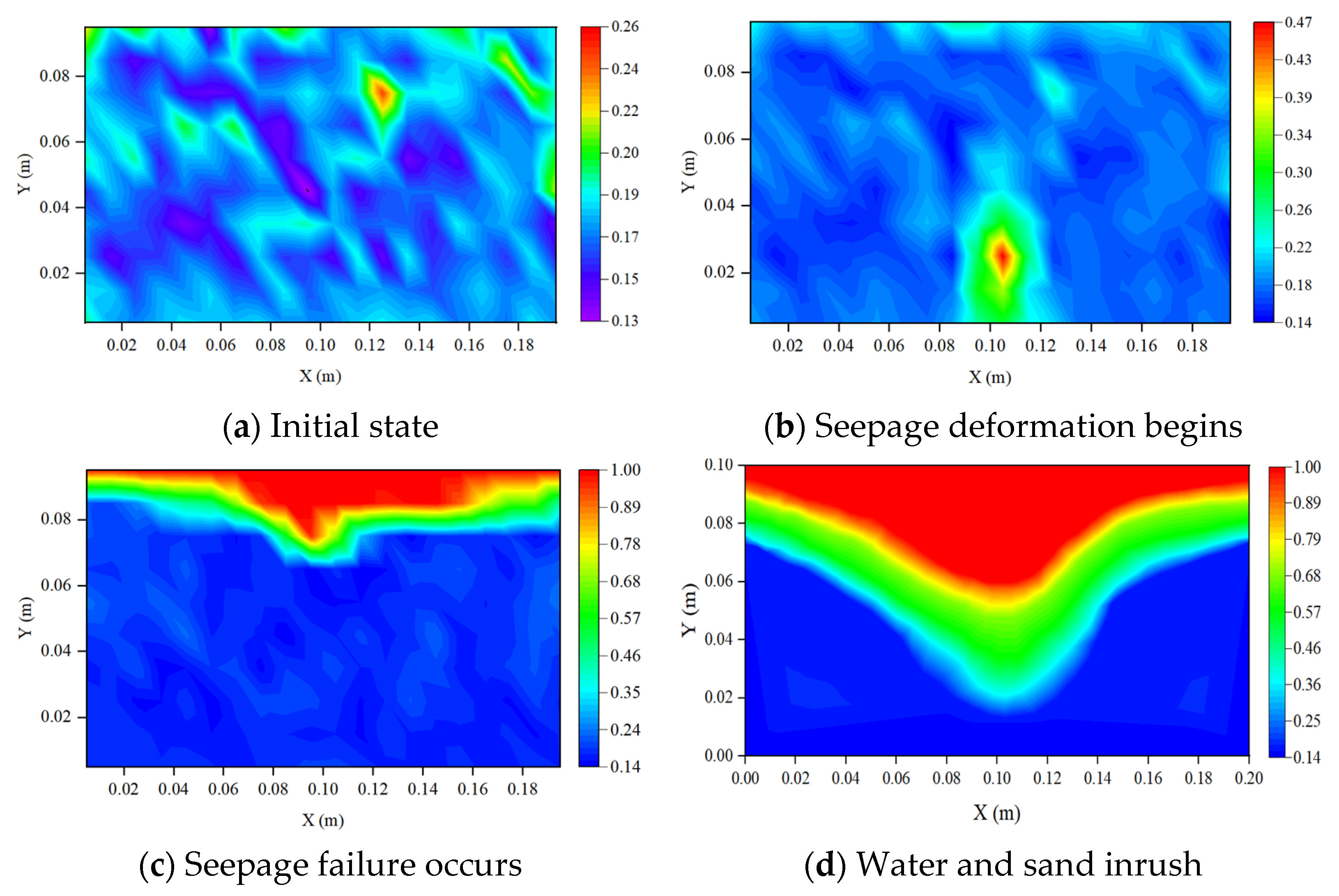

- Analysis of porosity variation

- (2)

- Analysis of the variation in the number of contacts between clay and sand particles

- (3)

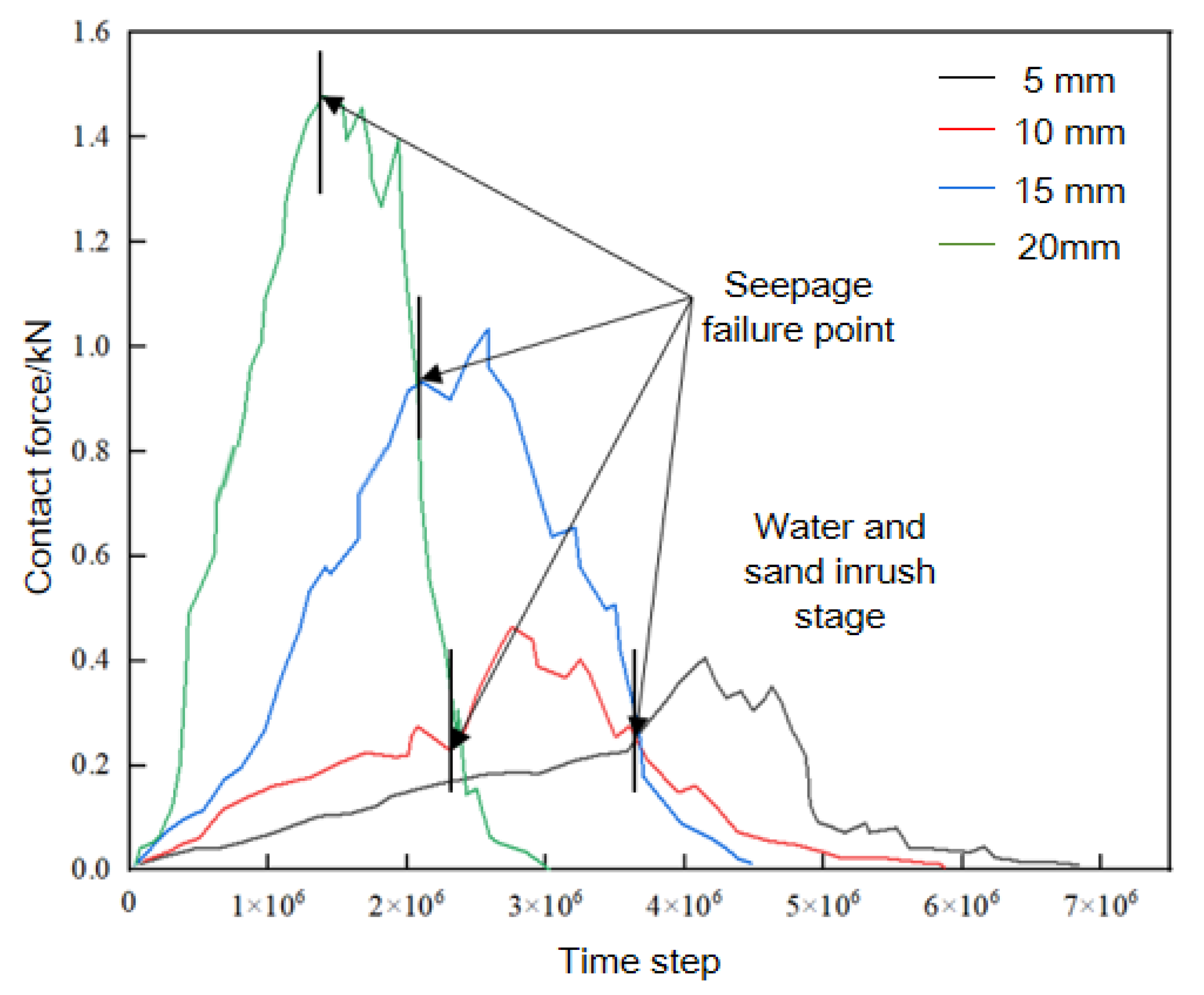

- Analysis of the variation in contact forces between clay and sand particles on both sides of the fissure

4. Conclusions and Future Work

- (1)

- Based on the porosity distribution analysis using the 20 mm fissure model’s numerical results, it was revealed that clay particles at the base fissure mouth initiated movement first, accompanied by a progressive increase in local porosity. As the seepage-induced failure progresses, continuous migration of clay particles through the fracture aperture is observed, accompanied by initiation of mobilization for upper sand layer particles due to the loss of underlying particles. Systematic monitoring reveals progressive increases in porosity within both upper and lateral model regions, with quantitative documentation of upward propagation dynamics. Following the initiation of water and sand inrush, continuous centripetal migration of sand particles towards the central axis leads to gradual depletion of particle concentration at the sand layer’s upper surface and lateral margins. This dual-phase process results in progressive porosity expansion within the collapsing zone, accompanied by downward propagation that ultimately develops into pit-like morphological structures. As the sand inrush phenomenon gradually ceases, the pit morphology on both sides of the model expands upward through continuous particle loss mechanisms.

- (2)

- By monitoring the total contact numbers between clay and sand particles in the model and analyzing their variation patterns over time steps, it is observed that the contact number variation curve exhibits a linear decreasing trend. The results indicate that with increasing joint width, both the rate of contact number reduction and water and sand inrush velocity accelerate, while the duration of failure initiation shortens correspondingly.

- (3)

- Based on the analysis of contact force variation curves between clay and sand particles and fracture mouth over time steps, the entire seepage failure process reveals two distinct developmental stages. Phase I corresponds to clay permeation-induced deformation stage, during which the contact forces at both sides of the fracture mouth exhibit a gradual increasing trend that remains below the clay layer’s anti-seepage failure capacity, thereby preventing water and sand inrush occurrence. Phase II corresponds to water and sand inrush stage. When the clay layer completely loses its anti-seepage failure capacity, the entire clay mass erupts through the fracture mouth, initiating active water and sand inrush. At this critical stage, the contact forces between particles at both sides of the fracture mouth exhibit rapid increase while maintaining continuous fluctuations. Analysis of the curves reveals that larger fracture widths correspond to increased contact forces, while the durations of seepage failure and water and sand inrush processes decrease accordingly.

- (4)

- Future work will prioritize developing 3D models and conducting field validation to improve the practical application of these findings in mine water inrush disaster prevention. Such works will be crucial for translating the quantitative relationships between fracture width and seepage failure dynamics into reliable early-warning systems and operational guidelines for mining safety.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keawsawasvong, S.; Likitlersuang, S. Undrained stability of active trapdoors in two-layered clays. Undergr. Space 2021, 6, 446–454. [Google Scholar] [CrossRef]

- Alagha, A.S.N.; Chapman, D.N. Numerical modelling of tunnel face stability in homogeneous and layered soft ground. Tunn. Undergr. Space Technol. 2019, 94, 103096. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.K. Water barrier pillar design for safety in underground coal mines: A review. Mine Water Environ. 2025, 44, 203–225. [Google Scholar] [CrossRef]

- Liu, J.; Sui, W. Evolution and quantitative characterization of stress and displacement of surrounding rock structure due to the multiple layers backfill mining under loose aquifers. Water 2024, 16, 2574. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Yang, B.; Yuan, S. Assessing water and sand inrushes hazard reductions due to backfill mining by combining GIS and entropy methods. Mine Water Environ. 2021, 40, 956–969. [Google Scholar] [CrossRef]

- Xie, K. China’s energy development for 2035: Strategic thinking and suggestions. Strateg. Study CAE 2022, 24, 1–7, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Qian, M.; Xu, J.; Wang, J. Further on the sustainable mining of coal. J. China Coal Soc. 2018, 43, 1–13, (In Chinese with English Abstract). [Google Scholar]

- Liu, F.; Guo, L.; Zhang, J.; Wang, L. Synergistic mode of digitalization-intelligentization-greeniation of the coal industry and it’s path of building new coal productivity. J. China Coal Soc. 2024, 49, 1–15, (In Chinese with English Abstract). [Google Scholar]

- Lin, G.; Dong, D.; Li, X.; Fan, P. Accounting for mine water in coal mining activities and its spatial characteristics in China. Mine Water Environ. 2020, 39, 150–156. [Google Scholar] [CrossRef]

- Sun, W.; Li, W.; Wu, Q.; Zhao, S.; Liu, W.; Wang, C. Unraveling the spatio-temporal pattern of mine water accidents in China. Mine Water Environ. 2025, 44, 226–238. [Google Scholar] [CrossRef]

- Yuan, S.; Han, G. Combined drilling methods to install grout curtains in a deep underground mine: A case study in Southwest China. Mine Water Environ. 2020, 39, 902–909. [Google Scholar] [CrossRef]

- Yuan, S.; Han, G.; Liu, D.; Zhang, A. Multicriteria risk assessment of water inrush in underground mines with large-scale curtain grouting: A mine disaster risk reduction strategy. Geomat. Nat. Hazards Risk 2024, 15, 2409200. [Google Scholar] [CrossRef]

- Xia, R.; Wang, H.; Hu, T.; Yuan, S.; Huang, B.; Wang, J.; Ren, Z. A risk assessment of water inrush in deep mining in metal mines based on the coupling methods of the Analytic Hierarchy Process and Entropy Weight method: A case study of the Huize lead-Zinc Mine in Northeastern Yunnan, China. Water 2025, 17, 643. [Google Scholar] [CrossRef]

- Liang, Y.; Yuan, S.; Ma, S.; Han, G.; Shi, J. Migration of water and sand inrush through the mining-induced caving zone: Insights from model test and numerical analysis. Water 2024, 16, 2527. [Google Scholar] [CrossRef]

- Cai, G.; Sui, W.; Wu, S.; Wang, J.; Chen, J. On-site monitoring for the stability evaluation of a highway tunnel above goaves of multi-layer coal seams. Appl. Sci. 2021, 11, 7383. [Google Scholar] [CrossRef]

- Tong, L.; Liu, L.; Yu, Q. Highway construction across heavily mined ground and steep topography in southern China. Bull. Eng. Geol. Environ. 2014, 73, 43–60. [Google Scholar] [CrossRef]

- Li, Q.; Sui, W. Risk evaluation of mine-water inrush based on principal component logistic regression analysis and an improved analytic hierarchy process. Hydrogeol. J. 2021, 29, 1299–1311. [Google Scholar] [CrossRef]

- Sui, W.; Zhang, D.; Cui, Z.C.; Wu, Z.; Zhao, Q. Environmental implications of mitigating overburden failure and subsidences using paste-like backfill mining: A case study. Int. J. Min. Reclam. Environ. 2015, 29, 521–543. [Google Scholar] [CrossRef]

- Yang, B.; Sui, W.; Liu, J. Application of GIS-based decision-making model to evaluate safety of underground mining under Neogene aquifers. Int. J. Oil Gas Coal Technol. 2019, 22, 40–63. [Google Scholar] [CrossRef]

- Yang, B.; Yuan, S.; Liang, Y.; Liu, J. Investigation of overburden failure characteristics due to combined mining: Case study, Henan Province, China. Environ. Earth Sci. 2021, 80, 143. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, W.; LaMoreaux, W. Water inrush conceptual site models for coal mines of China. Environ. Earth Sci. 2018, 77, 746. [Google Scholar] [CrossRef]

- Liu, R.; Zhi, G.; Yang, S.; Xu, X. Investigation on mining-induced floor water inrush from column and its control based on microseismic monitoring. Adv. Civ. Eng. 2023, 2023, 3754079. [Google Scholar] [CrossRef]

- Wu, J.; Xu, S.; Zhou, R.; Qin, Y. Scenario analysis of mine water inrush hazard using Bayesian networks. Saf. Sci. 2016, 89, 231–239. [Google Scholar] [CrossRef]

- Sui, W. Evaluation method of resistance to seepage failure due to mining near unconsolidated aquifers I: Critical hydraulic gradient. Coal Geol. Explor. 2023, 51, 175–186, (In Chinese with English Abstract). [Google Scholar]

- Sui, W.; Liang, Y.; Zhang, X.; Jain, R.; Zhu, T. An experimental investigation on the speed of sand flow through a fixed porous bed. Sci. Rep. 2017, 7, 54. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, L.; Shi, Y.; Hou, X.; Zhang, M.; Ou, Q.; Wu, M.; Huang, P. Layered damage evolution mechanism of an underground waterproof grouting curtain wall under hydrodynamic-hydrochemical coupling. Constr. Build. Mater. 2025, 458, 139725. [Google Scholar] [CrossRef]

- Sui, W.; Hang, Y.; Ma, L.; Wu, Z.; Zhou, Y.; Long, G.; Wei, L. Interactions of overburden failure zones due to multiple-seam mining using longwall caving. Bull. Eng. Geol. Environ. 2015, 74, 1019–1035. [Google Scholar] [CrossRef]

- Hang, Y.; Sui, W.; Yuan, S. Experimental investigation of the seepage failure between bulkheads and surrounding rocks in deep underground mines. Bull. Eng. Geol. Environ. 2022, 81, 362. [Google Scholar] [CrossRef]

- Ji, Y.; Yu, L.; Wei, Z.; Ding, J.; Dong, D. Research progress on identification of mine water inrush sources: A visual analysis perspective. Mine Water Environ. 2025, 44, 3–15. [Google Scholar] [CrossRef]

- Du, Z.; Wu, Q.; Zhao, Y.; Zhang, X.; Yao, Y. A multi-constraint and multi-objective optimization layout method for a mine water inrush monitoring network. Sci. Rep. 2023, 13, 11817. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.; Li, Q.; Wu, J.; Zhong, W.; Huang, Z. Water–rock two-phase flow model for water inrush and instability of fault rocks during mine tunnelling. Int. J. Coal Sci. Technol. 2023, 10, 77. [Google Scholar] [CrossRef]

- Hang, Y.; Jin, L.; Yang, B.; Li, N.; Yuan, S.; Gao, Z.; Sun, L.; Zheng, S.; Hu, M. Evaluation of water retention capacity of bulkheads in underground coal mines. Adv. Civ. Eng. 2021, 2021, 6612498. [Google Scholar] [CrossRef]

- Zhao, Z.; Gu, J. Risk evaluation of mine-water inrush based on comprehensive weight method. Geotech. Geol. Eng. 2023, 41, 189–203. [Google Scholar] [CrossRef]

- Lu, C.; Li, P.; Xu, J.; Chai, J. Knowledge map analysis of coal mine water disaster prevention and control in China from 2000 to 2023. Earth Sci. Inform. 2024, 17, 2791–2799. [Google Scholar] [CrossRef]

- Dong, G.; Sui, W.; Li, Y.; Yao, J.; Guo, H.; Fu, W. Evaluation method of anti-seepage failure due to mining near unconsolidated layers Ⅱ: Hydraulic gradient analytical method. J. Eng. Geol. 2023, 31, 1486–1493, (In Chinese with English Abstract). [Google Scholar]

- Sui, W. Catastrophic mechanism and its prevention and control of seepage deformation and failure of mining rock mass Ⅲ: A review of water retention bulkhead. Coal Sci. Technol. 2023, 51, 36–43, (In Chinese with English Abstract). [Google Scholar]

| Materials | Radius /mm | Density /kg·m−3 | Coefficient of Friction | Stiffness Ratio | Dynamic Viscosity Coefficient/Pa·s |

|---|---|---|---|---|---|

| Sand | 1.0~1.5 | 2600 | 0.4 | 1.5 | / |

| Water | / | / | / | / | 0.001 |

| Radius /mm | Density /kg·m−3 | Coefficient of Friction | Stiffness Ratio | Contact Modulus/MPa | Parallel Bond Modulus/MPa | Parallel Bonding Stiffness Ratio | Parallel Bonding Tangential Strength/MPa | Parallel Bonding Normal Strength/MPa |

|---|---|---|---|---|---|---|---|---|

| 0.5~0.8 | 2700 | 0.5 | 2.0 | 8.0 | 8.0 | 2.0 | 0.4 | 0.4 |

| Test Number | Sand Particle Size/mm | Mining Crack Width/mm |

|---|---|---|

| 1 | 0.25~0.5 | 5 |

| 2 | 0.25~0.5 | 10 |

| 3 | 0.25~0.5 | 15 |

| 4 | 0.25~0.5 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hang, Y.; Li, J.; Yuan, S.; Zhang, D.; Wei, C. Numerical Simulation of Clay Layer Permeability Failure Under Loose Strata: Effects of Mining-Induced Fracture Width. Appl. Sci. 2025, 15, 12318. https://doi.org/10.3390/app152212318

Hang Y, Li J, Yuan S, Zhang D, Wei C. Numerical Simulation of Clay Layer Permeability Failure Under Loose Strata: Effects of Mining-Induced Fracture Width. Applied Sciences. 2025; 15(22):12318. https://doi.org/10.3390/app152212318

Chicago/Turabian StyleHang, Yuan, Jinwei Li, Shichong Yuan, Dengkui Zhang, and Chuanyong Wei. 2025. "Numerical Simulation of Clay Layer Permeability Failure Under Loose Strata: Effects of Mining-Induced Fracture Width" Applied Sciences 15, no. 22: 12318. https://doi.org/10.3390/app152212318

APA StyleHang, Y., Li, J., Yuan, S., Zhang, D., & Wei, C. (2025). Numerical Simulation of Clay Layer Permeability Failure Under Loose Strata: Effects of Mining-Induced Fracture Width. Applied Sciences, 15(22), 12318. https://doi.org/10.3390/app152212318