Modification and Application of Söhne, McKyes, and Perumpral Models for Predicting Draught Forces in a Duckfoot Tool

Abstract

1. Introduction

1.1. Development of Predictive Models

1.2. Wide Tools and Challenges in Duckfoot Modelling

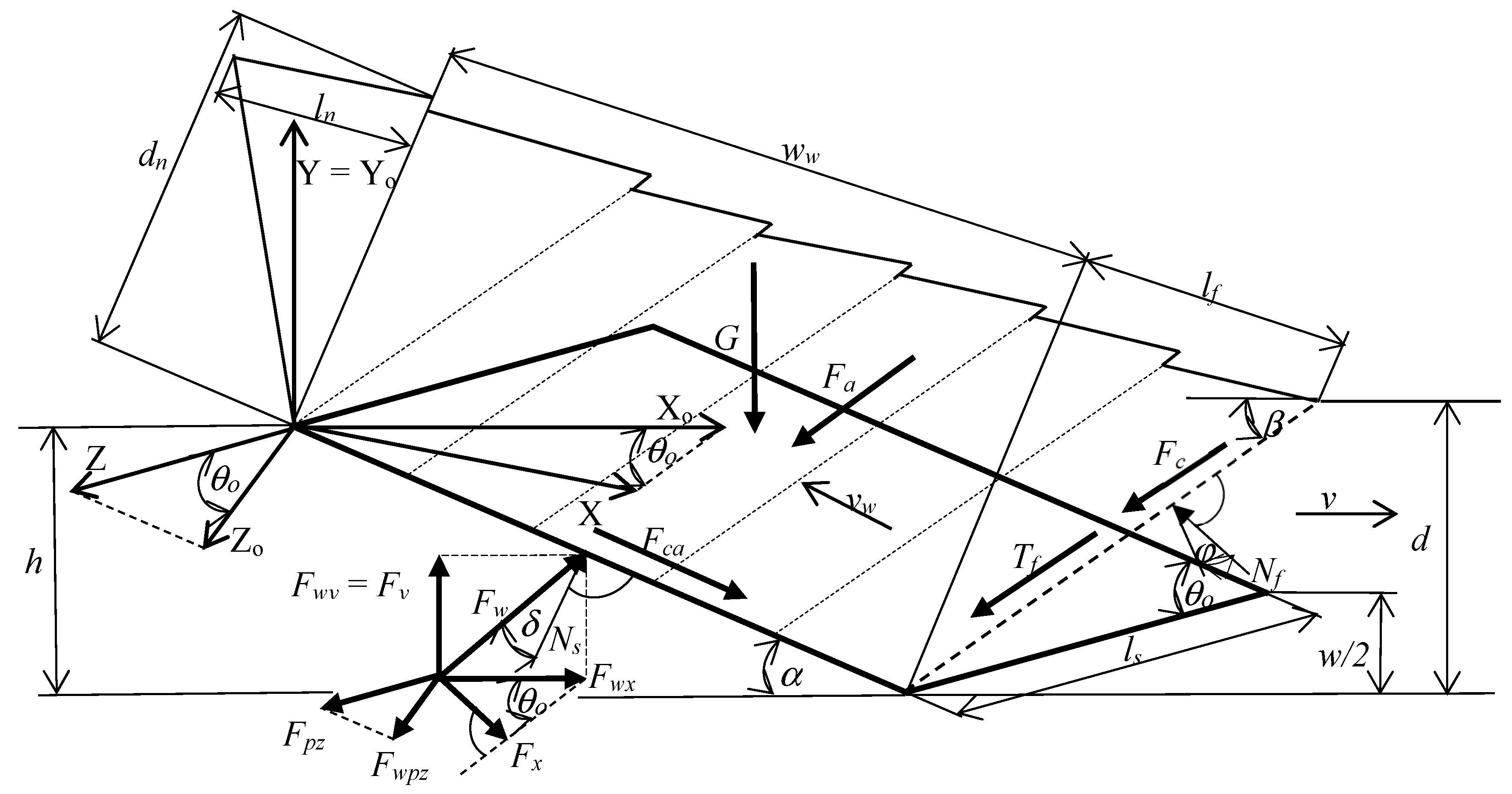

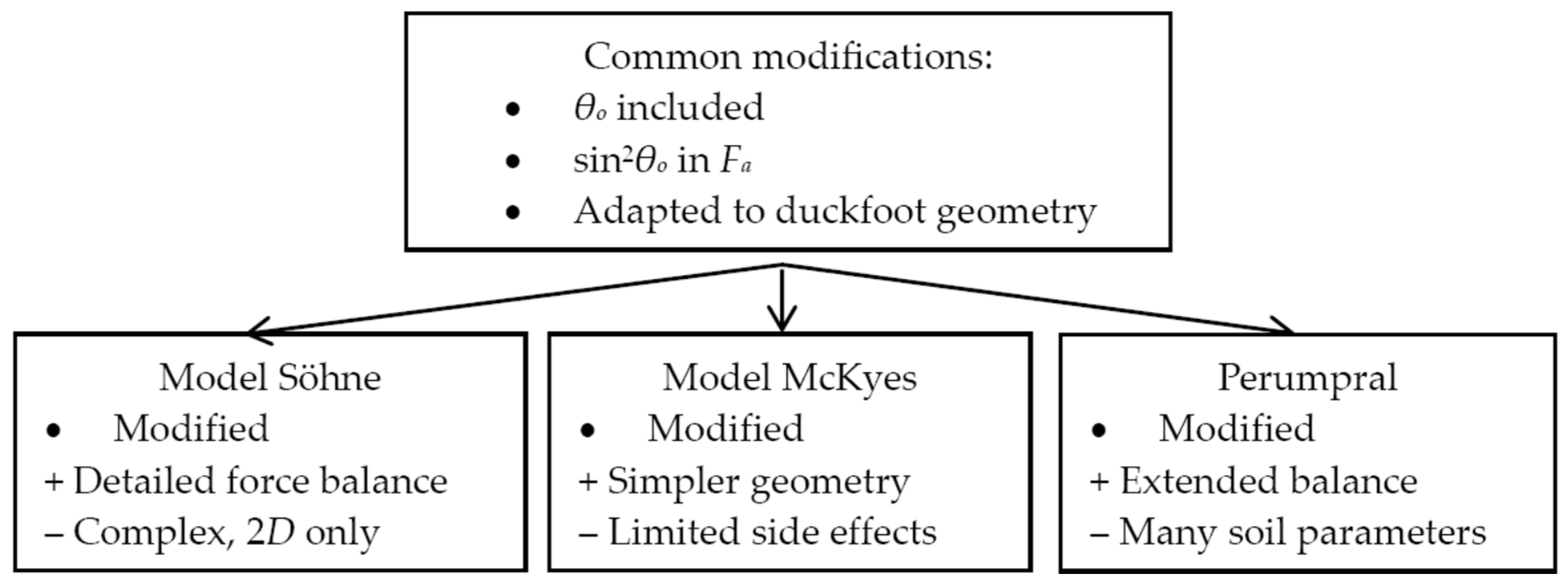

2. Theoretical Model of Duckfoot Work in Soil

2.1. General Data and Assumptions

2.2. Model 1 Söhne

2.3. Model 2 McKyes

2.4. Model 3 Perumpral

3. Materials and Methods

3.1. Soil Properties

3.2. Test Objects

3.3. Soil Bin with Measuring Equipment

3.4. Measurement Procedure

3.5. Statistical Analysis

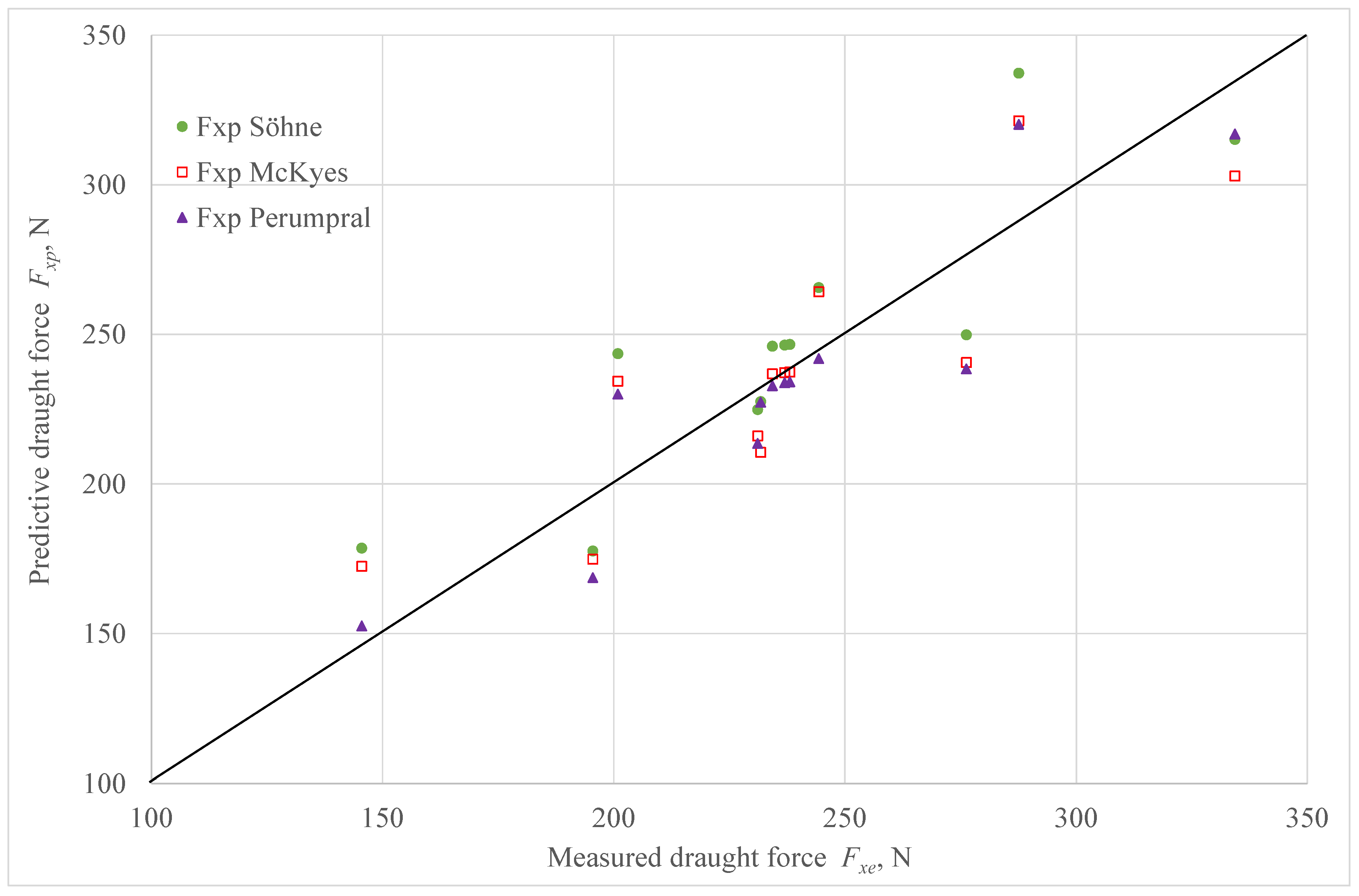

4. Research Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Af, Aw | area of the soil pile, shear, and on the tool wing, respectively, m2 |

| c | soil cohesion, kPa |

| ca | adhesion of the soil to the surface of the tool, kPa |

| d | depth of tool work, m |

| dn | the apparent height of the soil pile, after its accumulation on the wing of the tool, m |

| E′ | specific energy needed to deform the soil, J·m−3 |

| F | net force of the tool’s pressure on the soil, N |

| F1 | specific force of the tool pressure on the soil overworking width, N·m−1 |

| Fa | inertia force of the soil pile, N |

| Fc | cohesion force on the soil shear surface, N |

| Fca | adhesion force at the contact surface of the soil pile with the tool wing, N |

| ffc | soil flowability, flow index (dimensionless quantity), |

| Fw, Fwx, Fwy | draught pressure forces of the tool wing on the soil in the XoYoZo system; total, horizontal, and vertical, respectively, N |

| Fx | draught force, horizontal component of the tool’s pressure force on the soil in the XYZ system, N |

| Fxei, Fxpi | ith draught experimental and predictive value from the draught force model, respectively, N |

| Fy | vertical component of the tool’s pressure force on the soil in the XYZ coordinate system, N |

| G | weight of the soil pile, N |

| g | acceleration of gravity, m·s−2 |

| h | tool wing elevation, m |

| k, ka, k′ | empirical coefficients |

| lf, ln | edge length of the soil pile of the leading and fall of the soil from the duckfoot wing, respectively, m |

| ls | tool blade length, m |

| N | number of observations |

| Nf | normal component of the soil reaction to the soil pile, N |

| Ns | normal component of soil–tool interaction, N |

| Nγ, Nc, Nca, Nq, Na | dimensionless coefficients, related to soil pile weight, soil cohesion, soil–tool adhesion, external pressure on the soil surface, and soil pile inertia, respectively |

| q | external pressure exerted on the soil surface, N·m−2, kPa |

| r | range of soil pile cracking, m |

| Tf | soil–soil pile frictional force, N |

| v | speed of tool movement, m·s−1 |

| vw | speed of movement of the soil pile on the surface of the tool wing, m·s−1 |

| w | tool width, m |

| ww | width of the tool wing, m |

| XoYoZo, XYZ | coordinates of the Cartesian system, in the direction perpendicular to the tool blade and in the direction of tool movement, respectively |

| Z | auxiliary variable |

| α | angle of position (inclination) of the tool wing, ° |

| β | soil shear angle, ° |

| γ | volumetric weight of the soil, N·m−3 |

| δ | angle of external friction soil–steel, ° |

| δg, δr | global and relative error, respectively, % |

| θo | lateral angle of application of the tool wing (2θo—angle of the nose), ° |

| μf, μs | coefficient of friction, the internal soil, and the external soil–steel, respectively |

| φ | angle of internal friction of the soil, ° |

| Tine’s markings | |

| S | spring tine with a stiffness of 5.3 kN·m−1 |

| VCO | Vibro Crop spring tine with a stiffness of 8.3 kN·m−1 |

References

- Kushwaha, R.L.; Zhang, Z.X. Evaluation of factors and current approaches related to computerized design of tillage tools: A review. J. Terramech. 1998, 35, 69–86. [Google Scholar] [CrossRef]

- Shmulevich, I.; Asaf, Z.; Rubinstein, D. Interaction between soil and a wide cutting blade using the discrete element method. Soil Tillage Res. 2007, 97, 37–50. [Google Scholar] [CrossRef]

- Hu, H.; Hu, X.; Gong, X. ScienceDirect Predicting the strut forces of the steel supporting structure of deep excavation considering various factors by machine learning methods. Undergr. Space 2024, 18, 114–129. [Google Scholar] [CrossRef]

- Söhne, W. Einige Grundlagen für eine landtechnische Bodenmechanik (Fundamentals of agricultural soil mechanics). Grundl. Landtech. 1956, 7, 11–27. [Google Scholar]

- McKyes, E. Soil Cutting and Tillage; Elsevier: Amsterdam, The Netherlands, 1985. [Google Scholar]

- Swick, W.C.; Perumpral, J.V. A model for predicting soil-tool interaction. J. Terramech. 1988, 25, 43–56. [Google Scholar] [CrossRef]

- Bernacki, H. Agricultural Machines, Theory and Construction; State Agricultural and Forest: Warsaw, Poland, 1981. [Google Scholar]

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley and Sons, Inc.: New York, NY, USA; London, UK, 1959. [Google Scholar]

- Sokołowski, W.W. Statics of Loose Media; PSP: Warsaw, Poland, 1958. (In Polish) [Google Scholar]

- Osman, M.S. The mechanics of soil cutting blades. Trans. ASAE 1964, 9, 318–328. [Google Scholar]

- Reece, A.R. The fundamental equation of mechanics. In Proceedings of the Institution of Mechanical Engineers, Conference Proceedings; Sage: Newcastle Upon Tyne, UK, 1964; Volume 179, pp. 16–22. [Google Scholar]

- Hettiaratchi, D.R.P.; Reece, A.R. The calculation of passive soil resistance. Géotechnique 1974, 24, 289–310. [Google Scholar] [CrossRef]

- Wheeler, P.N.; Godwin, R.J. Soil dynamics of single and multiple tines at speeds up to 20 km/h. J. Agric. Eng. Res. 1996, 63, 243–249. [Google Scholar] [CrossRef]

- Glancey, J.L.; Upadhyaya, S.K.; Chancellor, W.J.; Rumsey, J.W. Prediction of agricultural implement draft using an instrumented analog tillage tool. Soil Tillage Res. 1996, 37, 47–65. [Google Scholar] [CrossRef]

- Fielke, J.M.; Riley, T.W. The universal earthmoving equation applied to chisel plough wings. J. Terramech. 1991, 28, 11–19. [Google Scholar] [CrossRef]

- Hettiaratchi, D.R.P.; O’Callaghan, J.R. Mechanical behaviour of agricultural soils. J. Agric. Eng. Res. 1980, 25, 239–259. [Google Scholar] [CrossRef]

- Singh, G.; Singh, D. Optimum energy model for tillage. Soil Tillage Res. 1986, 6, 235–245. [Google Scholar] [CrossRef]

- Lisowski, A.; Lauryn, D.; Nowakowski, T.; Klonowski, J.; Świętochowski, A.; Sypuła, M.; Chlebowski, J.; Kamiński, J.; Kostyra, K. Impact of tine stiffness and operational parameters on soil disturbance profiles: Moisture content, speed, depth, width, and cross-sectional analysis of furrows by duckfoot tools. Int. Agrophys. 2025, 39, 287–299. [Google Scholar] [CrossRef]

- Lisowski, A.; Lauryn, D.; Nowakowski, T.; Klonowski, J.; Świętochowski, A.; Sypuła, M.; Chlebowski, J.; Kamiński, J.; Kostyra, K.; Dąbrowska, M.; et al. Empirical Models for Estimating Draught and Vertical Reaction Forces of a Duckfoot Tool in Compacted Soil: Effects of Moisture Content, Depth, Width, and Speed. Appl. Sci. 2025, 15, 3573. [Google Scholar] [CrossRef]

- Rowe, R.J.; Barnes, K.K. Influence of Speed on Elements of Draft of a Tillage Tool. Trans. ASAE 1961, 4, 0055–0057. [Google Scholar] [CrossRef]

- Onwualu, A.P.; Watts, K.C. Draught and vertical forces obtained from dynamic soil cutting by plane tillage tools. Soil Tillage Res. 1998, 48, 239–253. [Google Scholar] [CrossRef]

- McKyes, E.; Ali, O.S. The cutting of soil by narrow blades. J. Terramech. 1977, 14, 43–58. [Google Scholar] [CrossRef]

- ASAE S313.3; Soil Cone Penetrometer. American Society of Agricultural and Biological Engineers: Saint Joseph, MI, USA, 2006.

- ISO 11465; Soil Quality—Determination of Dry Matter and Water Content on a Mass Basis—Gravimetric Method. International Organization for Standardization: Geneva, Switzerland, 2004.

- Schulze, D. Flow properties of powders and bulk solids. In Powders and Bulk Solids: Behavior, Characterization, Storage and Flow; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; pp. 57–100. ISBN 1600325910. [Google Scholar]

- Stasiak, M.; Opaliński, I.; Molenda, M. Bulk and microscopic properties of bulk plant and industrial materials. Part 1, Comparison of mechanical properties. Chem. Ind. 2008, 87, 199–202. [Google Scholar]

- EN 1991-1-1; Eurocode 1 Part 4: Basis of Design and Actions on Structures. Actions in Silos and Tanks; European Committee for Standardization: Amsterdam, The Netherlands, 2006.

- Lisowski, A.; Klonowski, J.; Green, O.; Świętochowski, A.; Sypuła, M.; Strużyk, A.; Nowakowski, T.; Chlebowski, J.; Kamiński, J.; Kostyra, K.; et al. Duckfoot tools connected with flexible and stiff tines: Three components of resistances and soil disturbance. Soil Tillage Res. 2016, 158, 76–90. [Google Scholar] [CrossRef]

- Godwin, R.J.; O’Dogherty, M.J.; Saunders, C.; Balafoutis, A.T. A force prediction model for mouldboard ploughs incorporating the effects of soil characteristic properties, plough geometric factors and ploughing speed. Biosyst. Eng. 2007, 97, 117–129. [Google Scholar] [CrossRef]

- de Melo Ferreira, S.R.; Fucale, S.; de Oliveira, J.T.R.; de Sá, W.B.; de Andrade Moura, S.F. Evaluation of the Friction Angle of Soil-Wall in Contact with Different Materials and Surface Roughness. Electron. J. Geotech. Eng. 2016, 21, 4655–4672. [Google Scholar]

- Manuwa, S.I. Performance evaluation of tillage tines operating under different depths in a sandy clay loam soil. Soil Tillage Res. 2009, 103, 399–405. [Google Scholar] [CrossRef]

| Feature | Söhne | McKyes | Perumpral | ||||||

|---|---|---|---|---|---|---|---|---|---|

| φ, ° | d, ° | b, ° | φ, ° | d, ° | b, ° | φ, ° | d, ° | b, ° | |

| All data | 30.00 | 20.00 | 35.00 | 40.00 | 24.38 | 39.64 | 40.00 | 28.77 | 45.00 |

| MC = 10% | 30.00 | 20.32 | 33.66 | 40.00 | 29.05 | 40.00 | 37.03 | 29.42 | 45.00 |

| MC = 14% | 30.00 | 20.00 | 35.00 | 40.00 | 20.79 | 40.00 | 40.00 | 27.84 | 45.00 |

| Model | Söhne | ||||

|---|---|---|---|---|---|

| Feature | Fxe, N | Fxp, N | RMSE, N | δr, % | δg, % |

| All data | 238.04 | 246.57 | 64.37 | −11.58 | 24.95 |

| MC = 10% | 231.78 | 227.48 | 46.76 | −3.94 | 18.78 |

| MC = 14% | 244.30 | 265.66 | 78.12 | −19.22 | 29.29 |

| Duckfoot = A105 | 195.45 | 177.56 | 57.59 | −4.54 | 26.81 |

| Duckfoot = B135 | 231.13 | 224.86 | 52.83 | −4.77 | 21.30 |

| Duckfoot = C200 | 287.56 | 337.29 | 79.53 | −25.44 | 26.21 |

| d = 0.03 m | 145.50 | 178.55 | 56.92 | −33.23 | 36.64 |

| d = 0.05 m | 234.31 | 246.01 | 53.13 | −6.01 | 22.06 |

| d = 0.07 m | 334.33 | 315.15 | 79.80 | 4.49 | 23.28 |

| v = 0.84 m·s−1 | 200.89 | 243.53 | 65.39 | −27.94 | 30.45 |

| v = 1.67 m·s−1 | 236.97 | 246.36 | 55.67 | −10.46 | 21.85 |

| v = 2.31 m·s−1 | 276.27 | 249.82 | 71.11 | 3.65 | 23.88 |

| Model | McKyes | ||||

| All data | 238.04 | 237.38 | 64.39 | −7.68 | 24.96 |

| MC = 10% | 231.78 | 210.52 | 50.61 | 3.31 | 20.32 |

| MC = 14% | 244.30 | 264.24 | 75.70 | −18.66 | 28.39 |

| Duckfoot = A105 | 195.45 | 174.78 | 58.53 | −2.49 | 27.25 |

| Duckfoot = B135 | 231.13 | 216.0 | 57.4 | −0.78 | 23.15 |

| Duckfoot = C200 | 287.56 | 321.35 | 75.62 | −19.76 | 24.93 |

| d = 0.03 m | 145.50 | 172.44 | 55.08 | −29.09 | 35.45 |

| d = 0.05 m | 234.31 | 236.77 | 52.96 | −2.20 | 21.99 |

| d = 0.07 m | 334.33 | 302.92 | 81.24 | 8.26 | 23.70 |

| v = 0.84 m·s−1 | 200.89 | 234.35 | 59.99 | −23.49 | 27.93 |

| v = 1.67 m·s−1 | 236.97 | 237.17 | 54.98 | −6.51 | 21.58 |

| v = 2.31 m·s−1 | 276.27 | 240.61 | 76.27 | 6.97 | 25.61 |

| Model | Perumpral | ||||

| All data | 238.04 | 234.11 | 58.41 | −3.38 | 22.64 |

| MC = 10% | 231.78 | 227.29 | 45.13 | −2.00 | 18.12 |

| MC = 14% | 244.30 | 241.91 | 68.73 | −5.70 | 25.77 |

| Duckfoot = A105 | 195.45 | 168.68 | 56.54 | 3.44 | 26.32 |

| Duckfoot = B135 | 231.13 | 213.46 | 49.28 | 2.93 | 19.87 |

| Duckfoot = C200 | 287.56 | 320.20 | 67.89 | −16.52 | 22.38 |

| d = 0.03 m | 145.50 | 152.57 | 42.43 | −13.75 | 27.31 |

| d = 0.05 m | 234.31 | 232.83 | 47.06 | −0.28 | 19.54 |

| d = 0.07 m | 334.33 | 316.94 | 78.86 | 3.89 | 23.00 |

| v = 0.84 m·s−1 | 200.89 | 230.03 | 53.81 | −18.00 | 25.06 |

| v = 1.67 m·s−1 | 236.97 | 233.83 | 49.56 | −2.38 | 19.46 |

| v = 2.31 m·s−1 | 276.27 | 238.48 | 69.87 | 10.23 | 23.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świętochowski, A.; Lisowski, A.; Lauryn, D.; Nowakowski, T.; Klonowski, J.; Sypuła, M.; Chlebowski, J.; Dąbrowska, M. Modification and Application of Söhne, McKyes, and Perumpral Models for Predicting Draught Forces in a Duckfoot Tool. Appl. Sci. 2025, 15, 12306. https://doi.org/10.3390/app152212306

Świętochowski A, Lisowski A, Lauryn D, Nowakowski T, Klonowski J, Sypuła M, Chlebowski J, Dąbrowska M. Modification and Application of Söhne, McKyes, and Perumpral Models for Predicting Draught Forces in a Duckfoot Tool. Applied Sciences. 2025; 15(22):12306. https://doi.org/10.3390/app152212306

Chicago/Turabian StyleŚwiętochowski, Adam, Aleksander Lisowski, Daniel Lauryn, Tomasz Nowakowski, Jacek Klonowski, Michał Sypuła, Jarosław Chlebowski, and Magdalena Dąbrowska. 2025. "Modification and Application of Söhne, McKyes, and Perumpral Models for Predicting Draught Forces in a Duckfoot Tool" Applied Sciences 15, no. 22: 12306. https://doi.org/10.3390/app152212306

APA StyleŚwiętochowski, A., Lisowski, A., Lauryn, D., Nowakowski, T., Klonowski, J., Sypuła, M., Chlebowski, J., & Dąbrowska, M. (2025). Modification and Application of Söhne, McKyes, and Perumpral Models for Predicting Draught Forces in a Duckfoot Tool. Applied Sciences, 15(22), 12306. https://doi.org/10.3390/app152212306