Overburden Behavior and Coal Wall Spalling Characteristics Under Large-Mining-Height Conditions

Abstract

1. Introduction

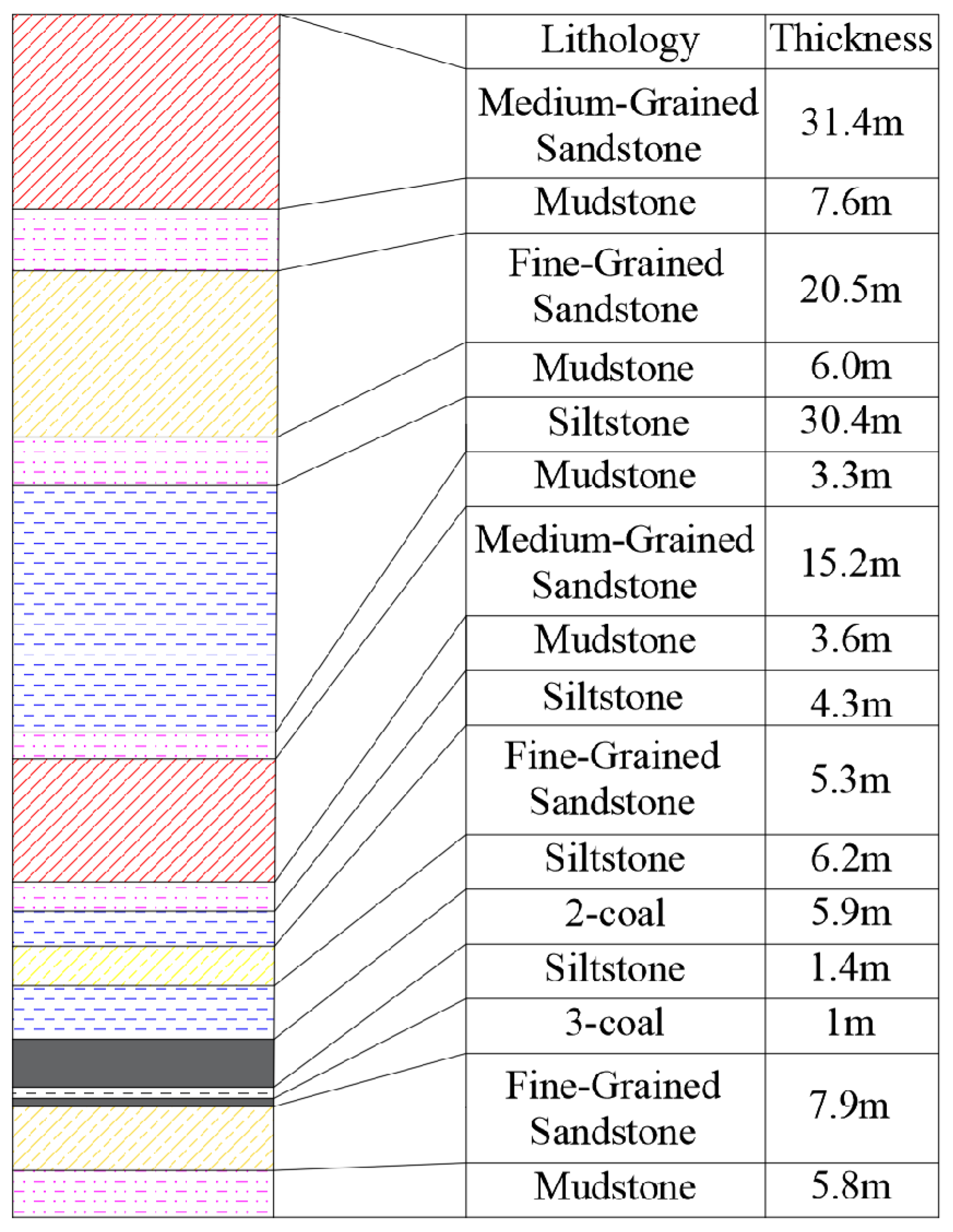

2. Engineering Background

3. Study on the Movement Law of Overlying Strata in a Large-Mining-Height Face Based on Physical Similarity Modeling

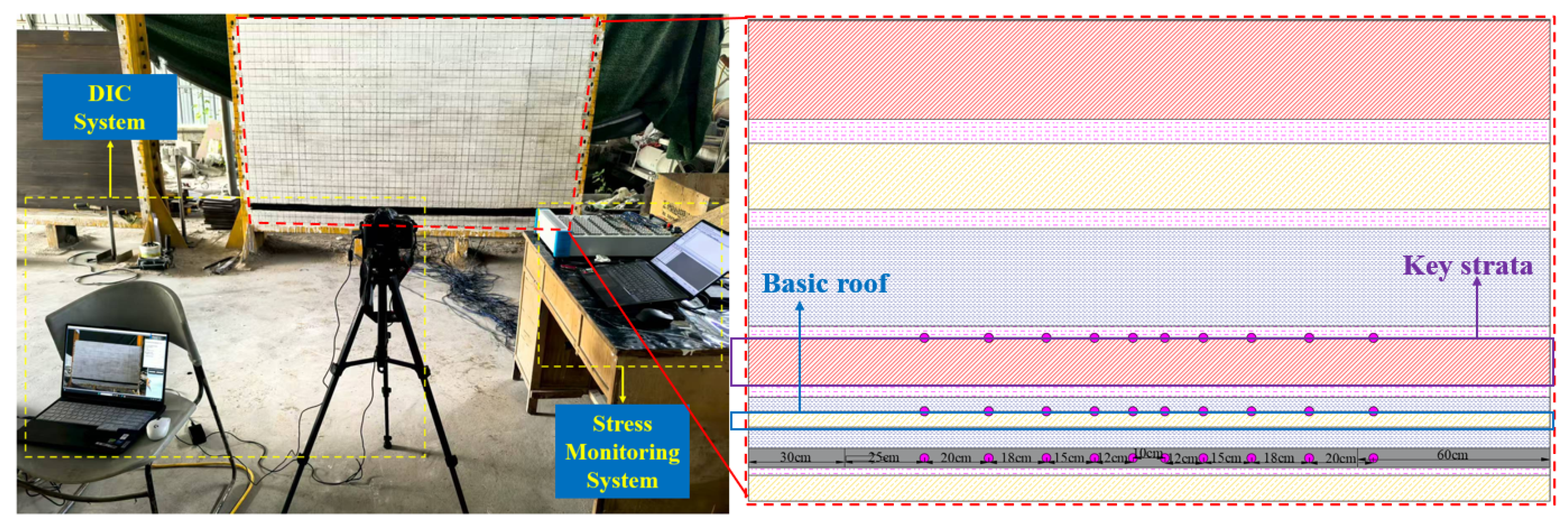

3.1. Experimental Design of Similarity Model for Overburden Movement in Large-Mining-Height Working Face

3.1.1. Similarity Model Experimental Design

3.1.2. Similarity Test Procedure

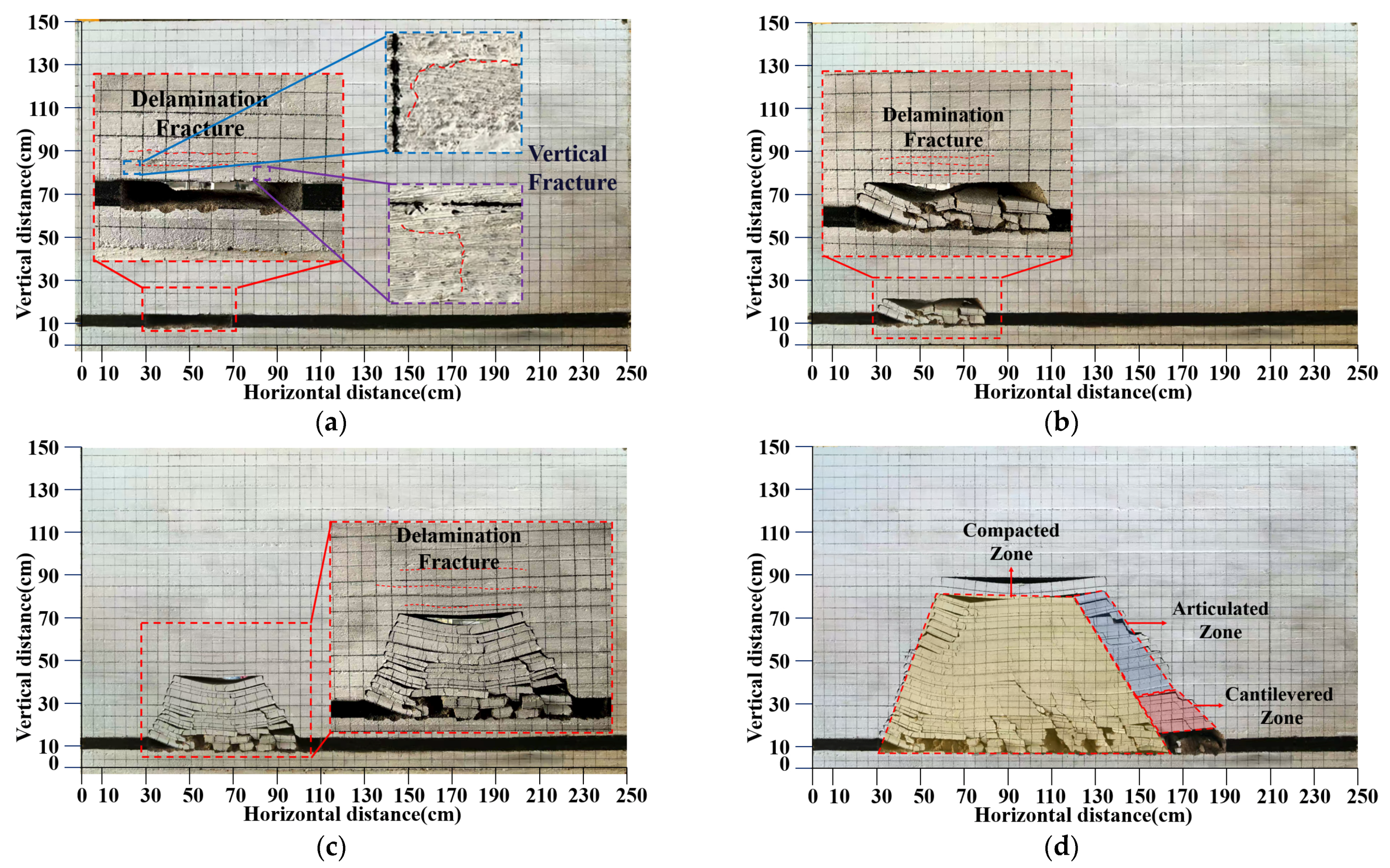

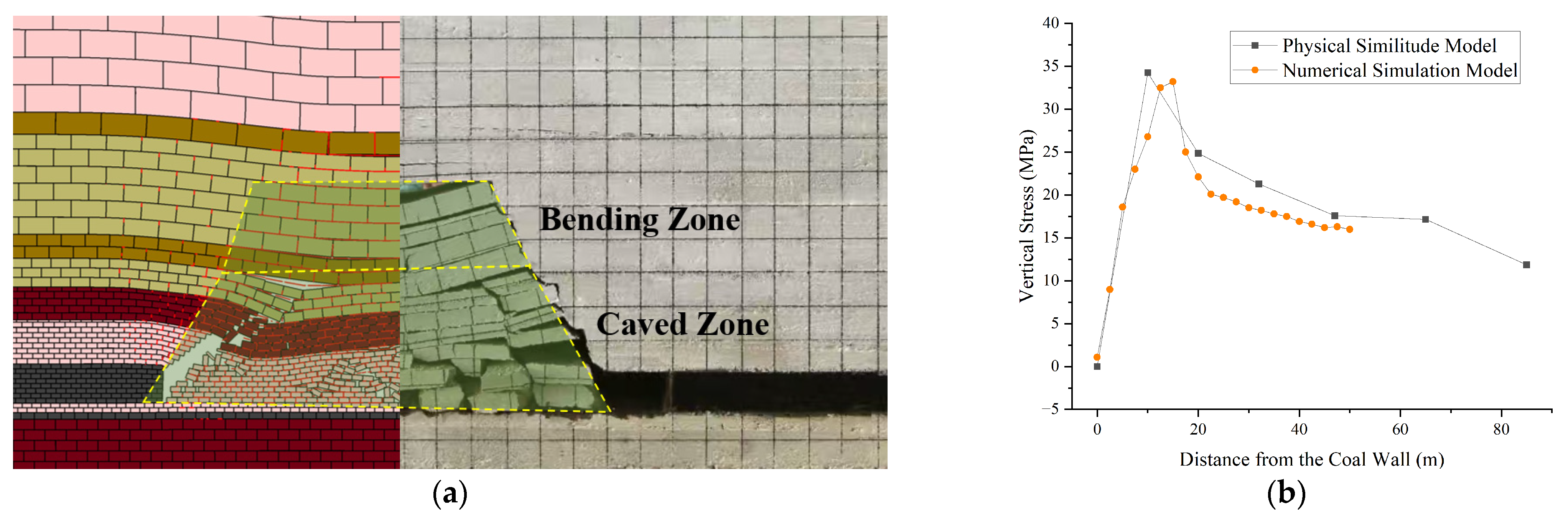

3.2. Overlying Strata Movement Behavior of Large-Mining-Height Face

3.2.1. Analysis of Overlying Strata Movement Characteristics in Stope

- (1)

- Early stage (Cut opening to Step 4)

- (2)

- Middle stage (Steps 5–10)

- (3)

- Late stage (Steps 11–16)

3.2.2. Analysis of Surrounding Rock Displacement in the Working Face

- (1)

- Pre-caving stage (Steps 1–4)

- (2)

- Development and upward propagation (Steps 5–10)

- (3)

- Periodic caving stage (Steps 11–16)

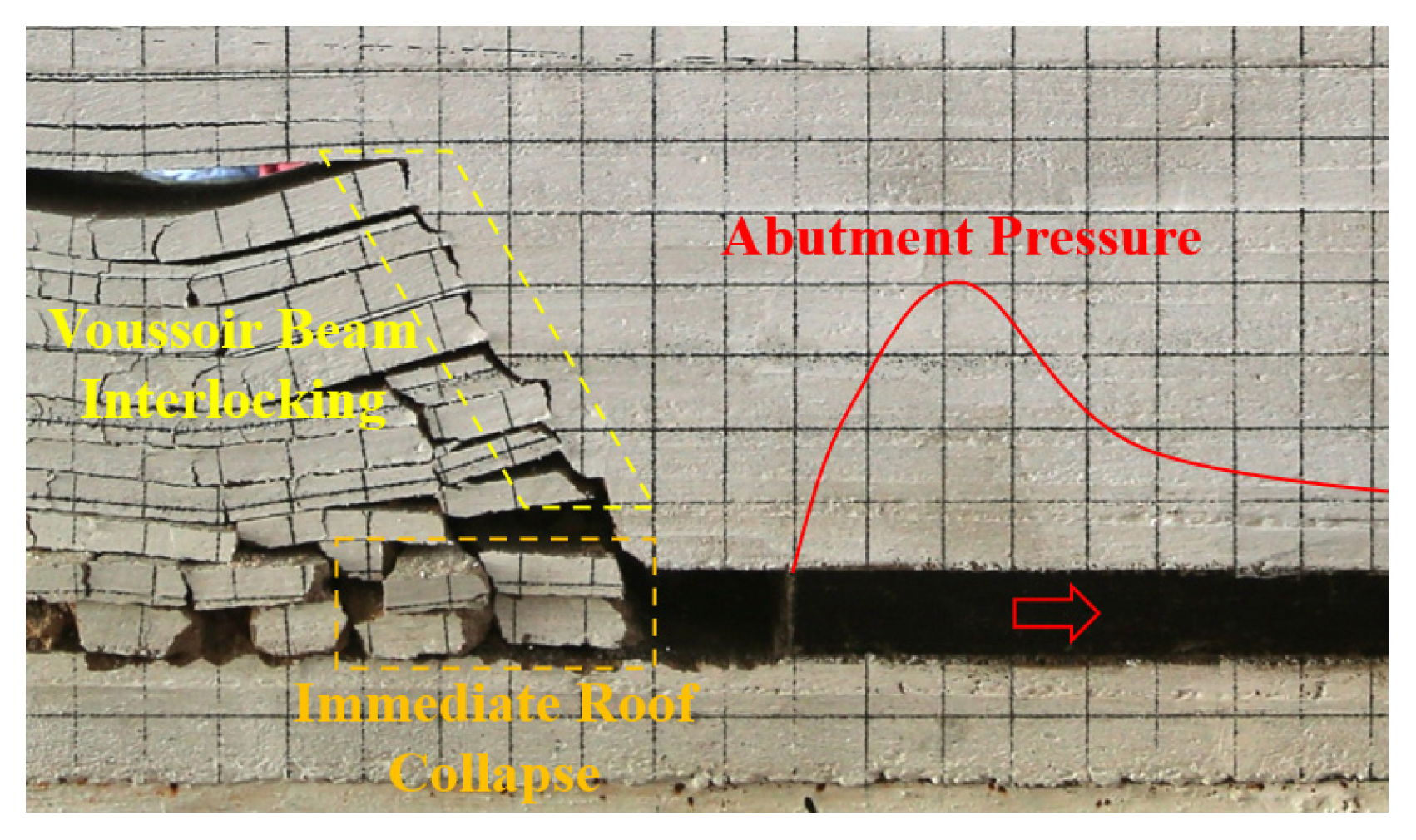

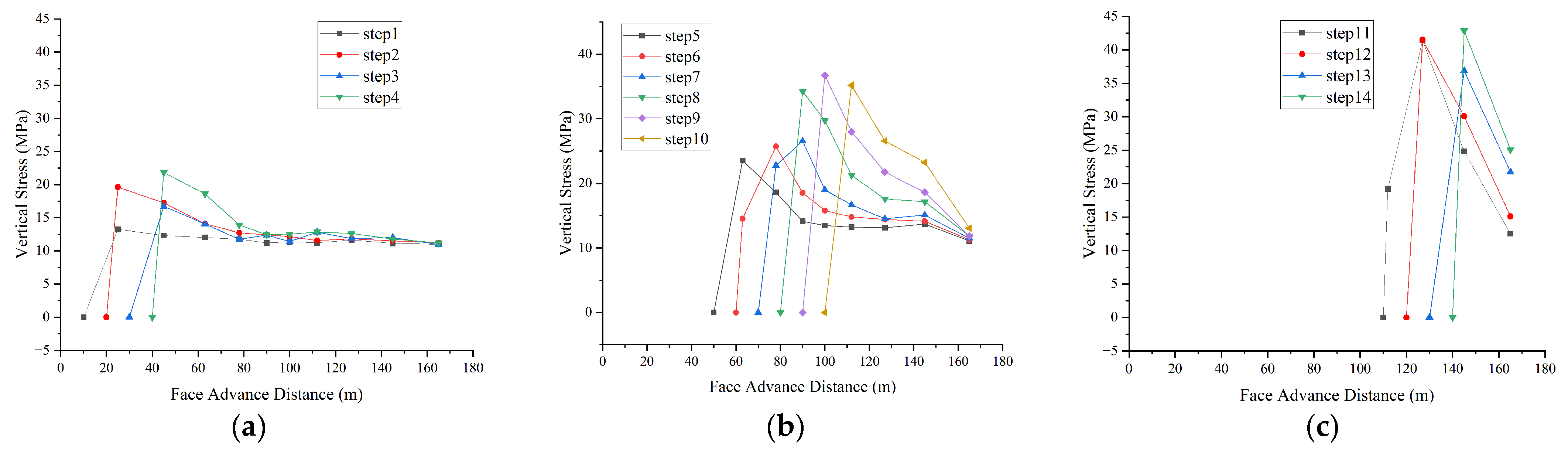

3.2.3. Analysis of Mining-Induced Stress Variation in the Working Face

- (1)

- Initial stage (Steps 1–4)

- (2)

- Middle stage (Steps 5–10)

- (3)

- Final stage (Steps 11–14)

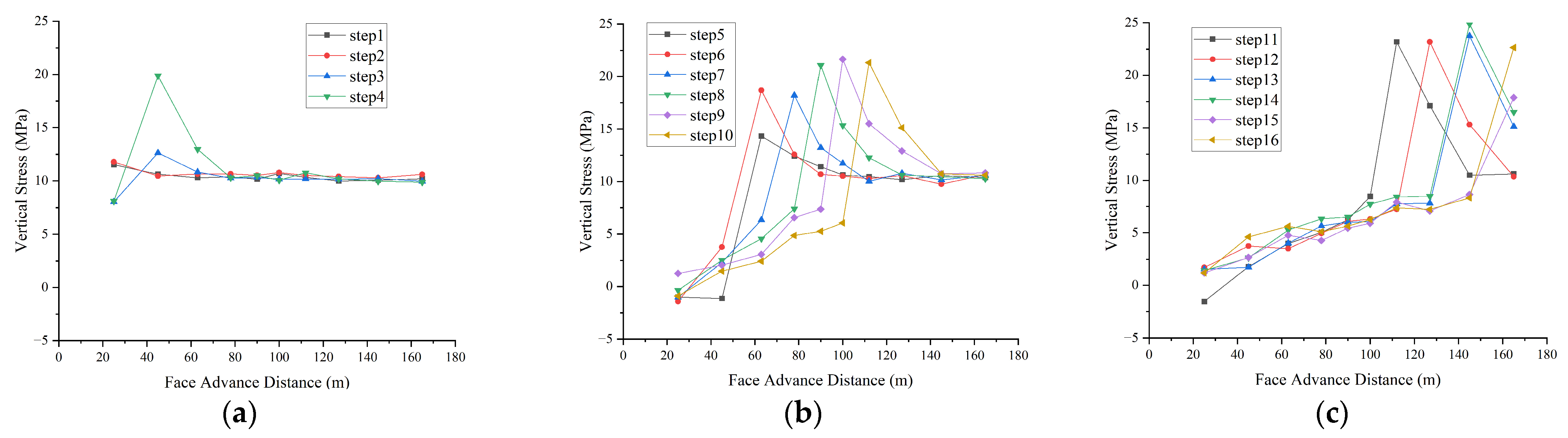

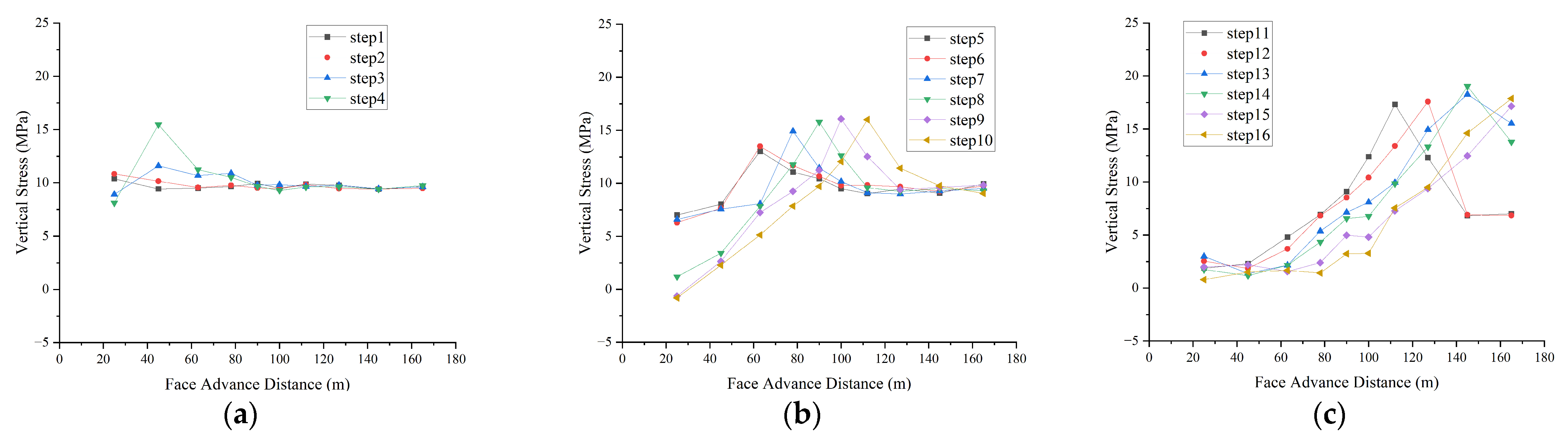

3.2.4. Analysis of Roof Stress Variation

- (1)

- Main roof

- (2)

- Key strata

- (3)

- Coupled evolution and stress transfer

4. Study on the Influence Mechanism of Coal Wall Spalling Based on Numerical Simulation

4.1. Numerical Model of Coal Wall Spalling and Fracture Evolution

4.1.1. Establishment of the Numerical Model and Mechanical Parameters

- (1)

- Model construction

- (2)

- Simulation scheme and parameter setting

4.1.2. Numerical Simulation of Coal Body Fracture Evolution

4.2. Numerical Simulation of Coal Wall Instability

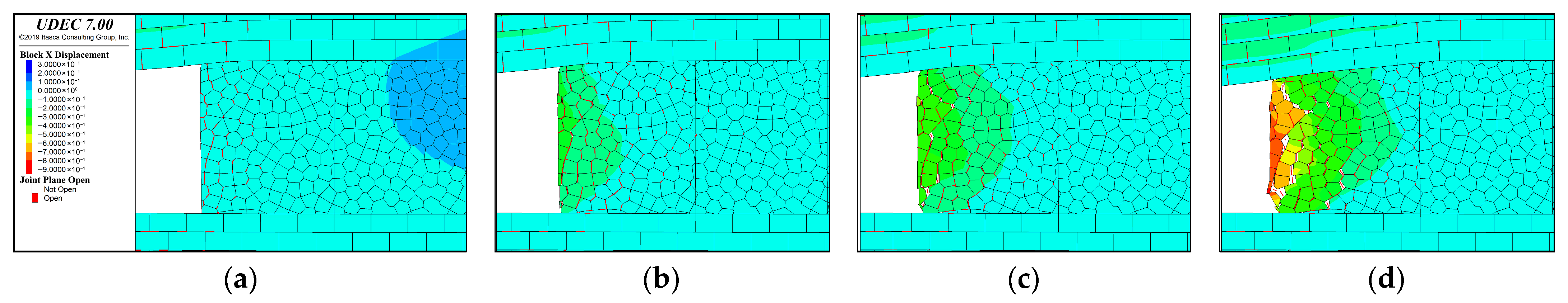

4.2.1. Effect of Mining Depth on Coal Wall Spalling

- (1)

- Coal wall and roof displacement

- (2)

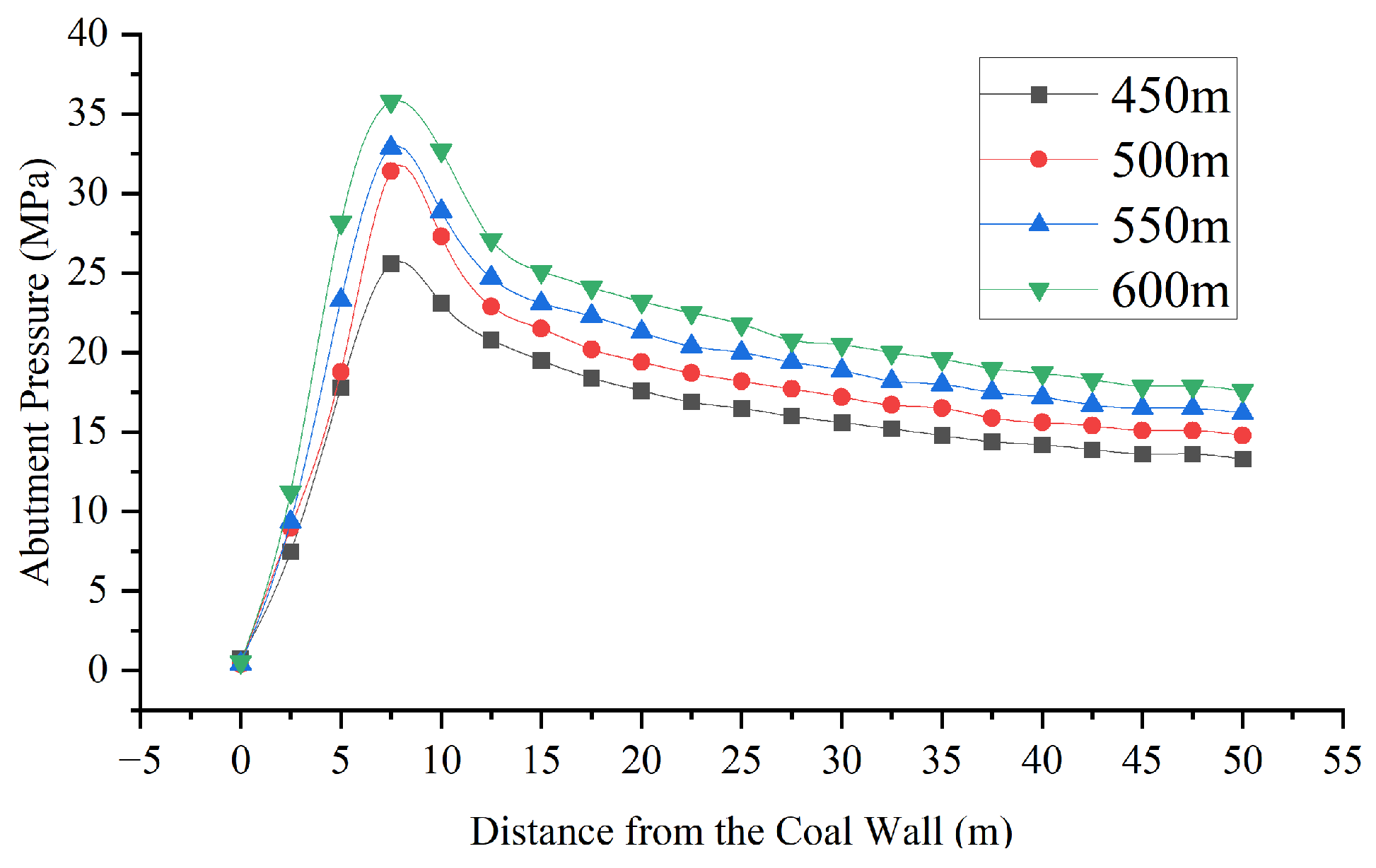

- Abutment stress distribution

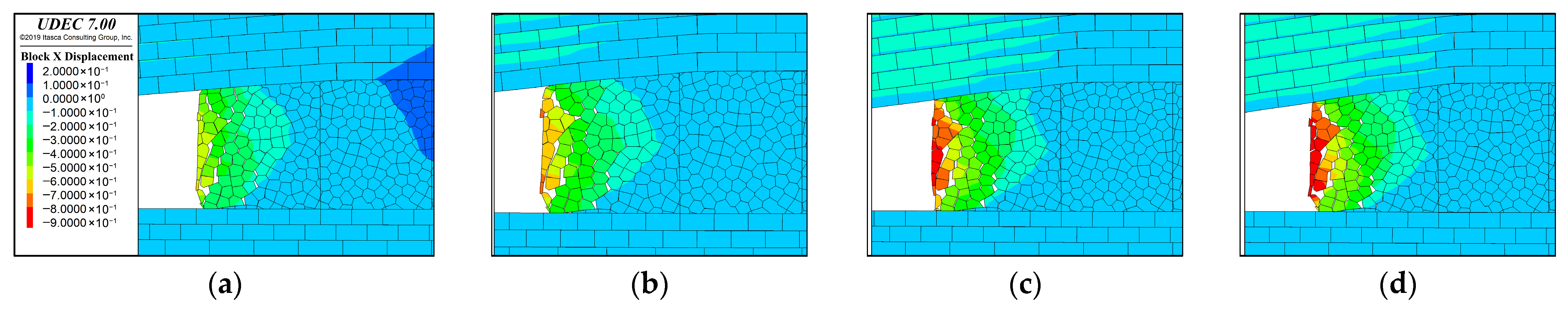

4.2.2. Influence of Mining Height on Coal Wall Spalling

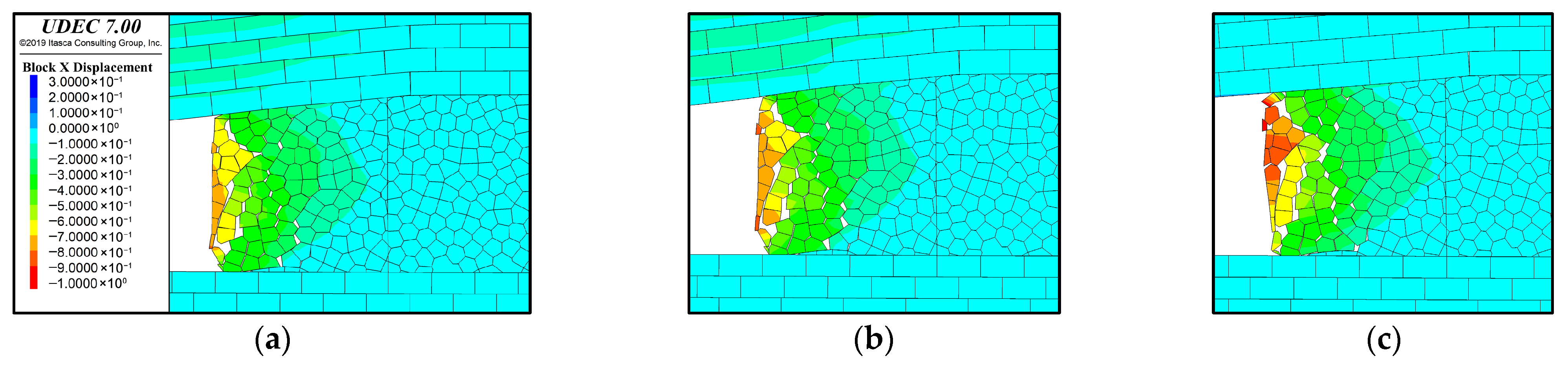

- (1)

- Displacement Field Evolution

- (2)

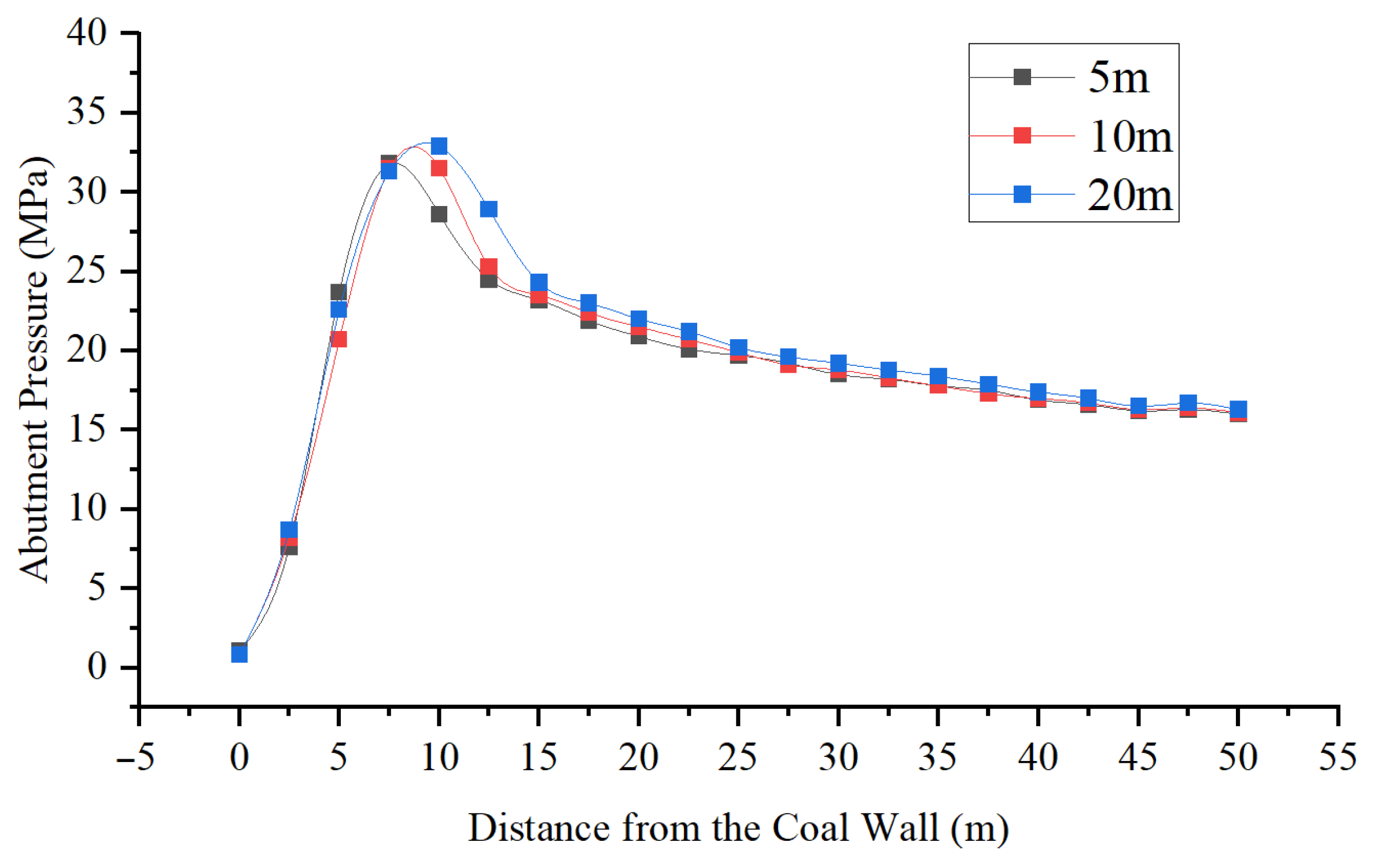

- Advance Abutment Stress

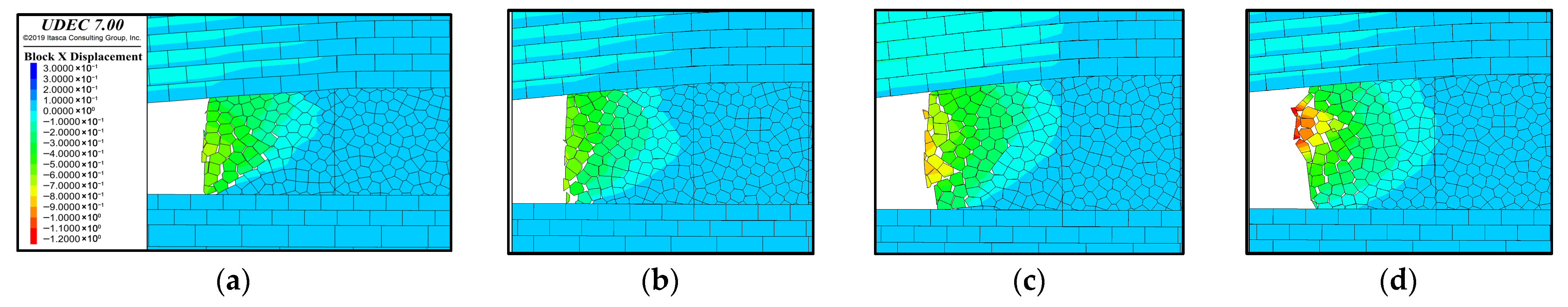

4.2.3. Influence of Mining Step Size on Coal Wall Spalling

- (1)

- Evolution of coal wall and roof displacement

- (2)

- Distribution of advance abutment stress

4.2.4. Influence of Coal Seam Dip Angle on Coal Wall Spalling

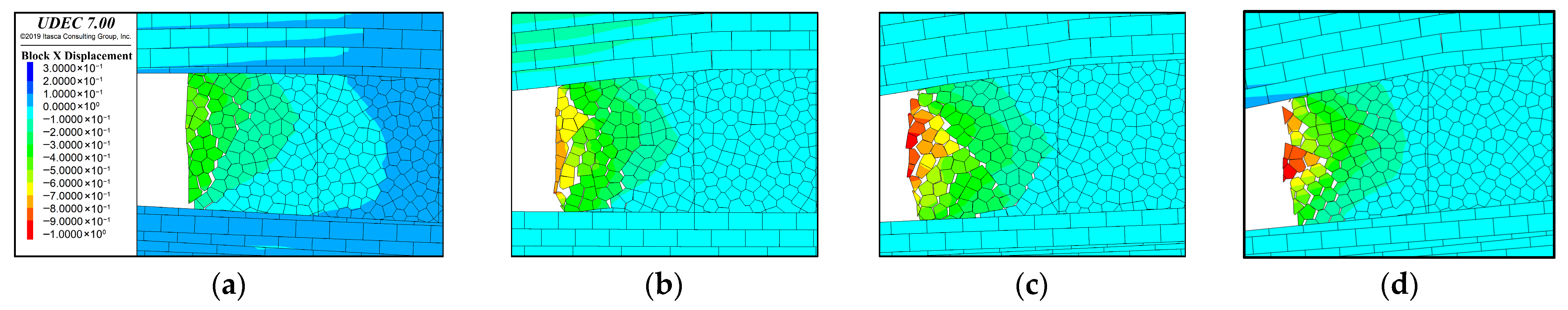

- (1)

- Evolution of coal wall and roof displacement

- (2)

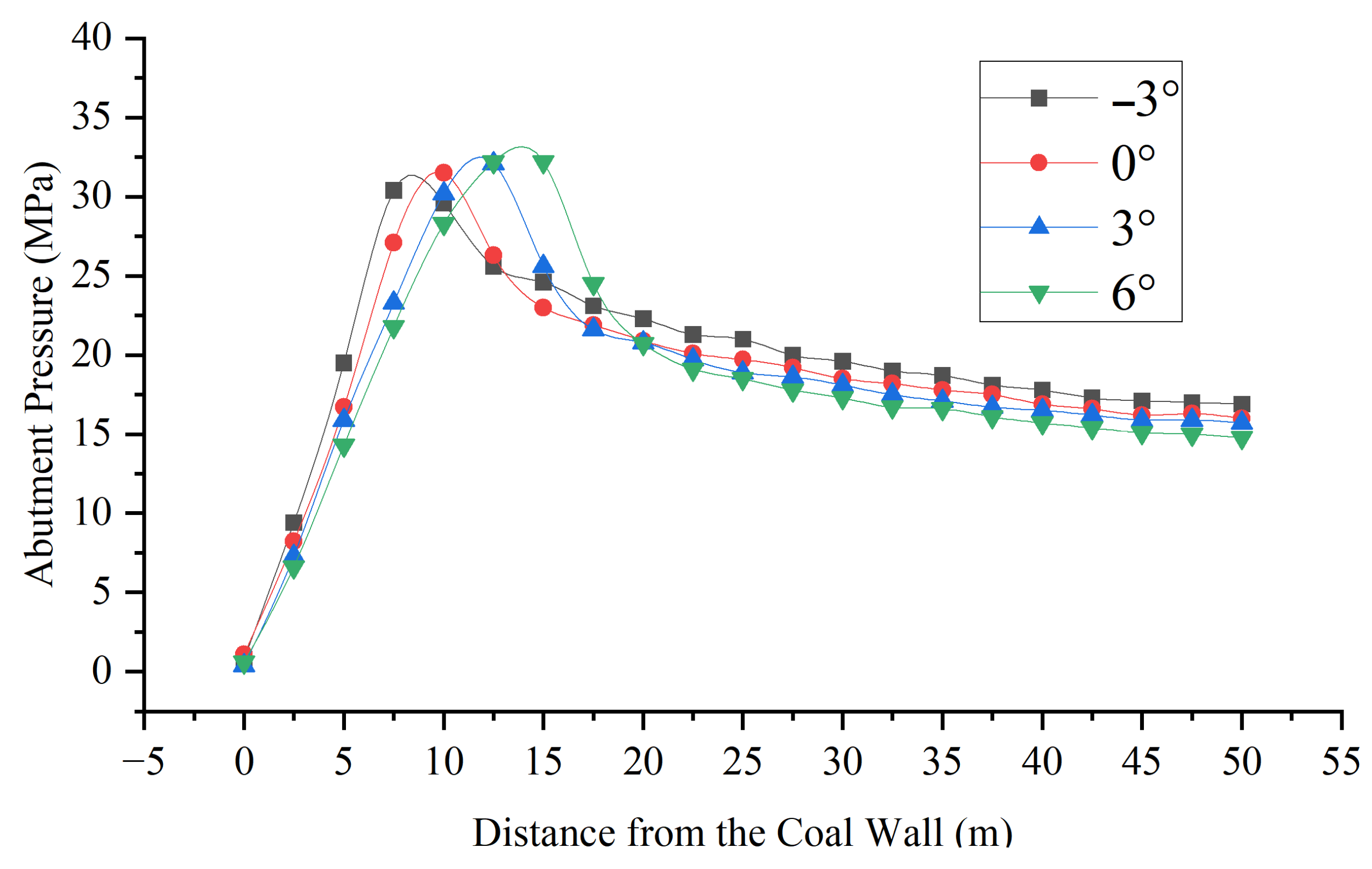

- Distribution of advance abutment stress

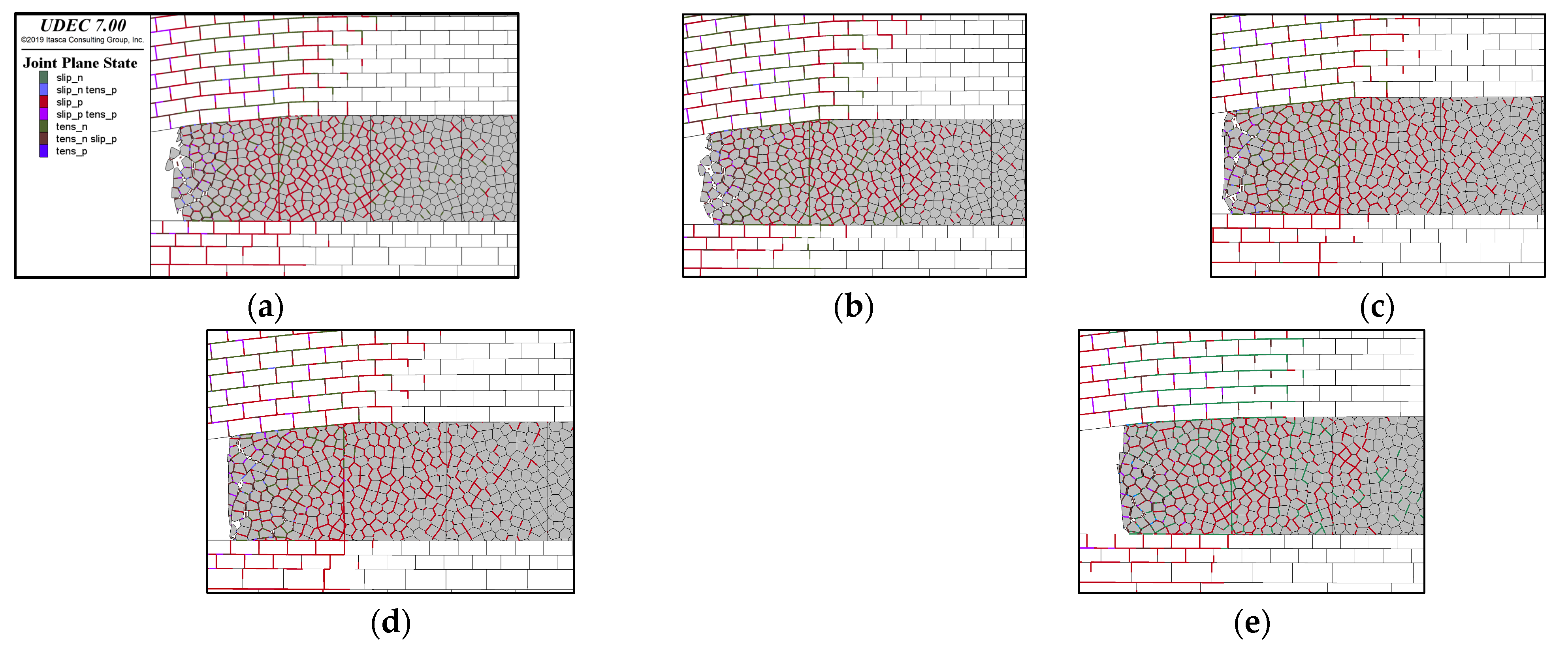

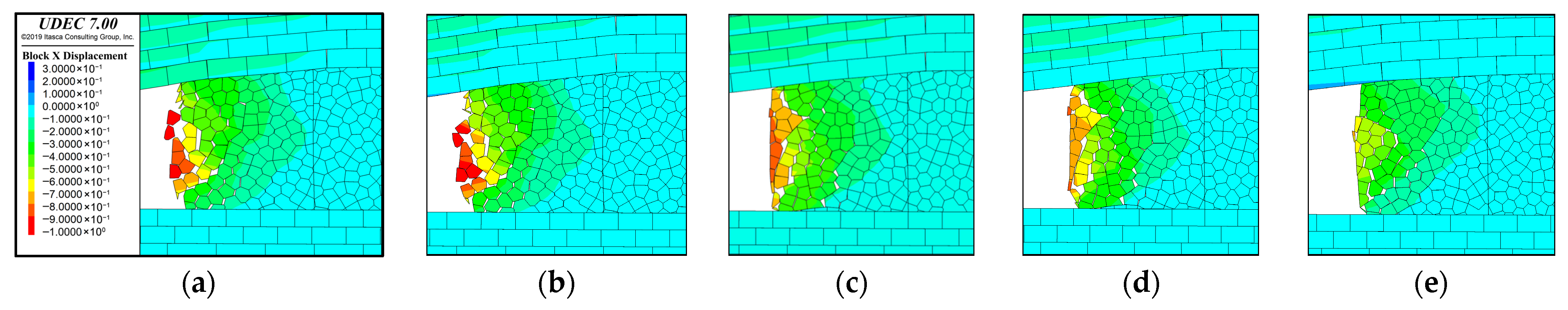

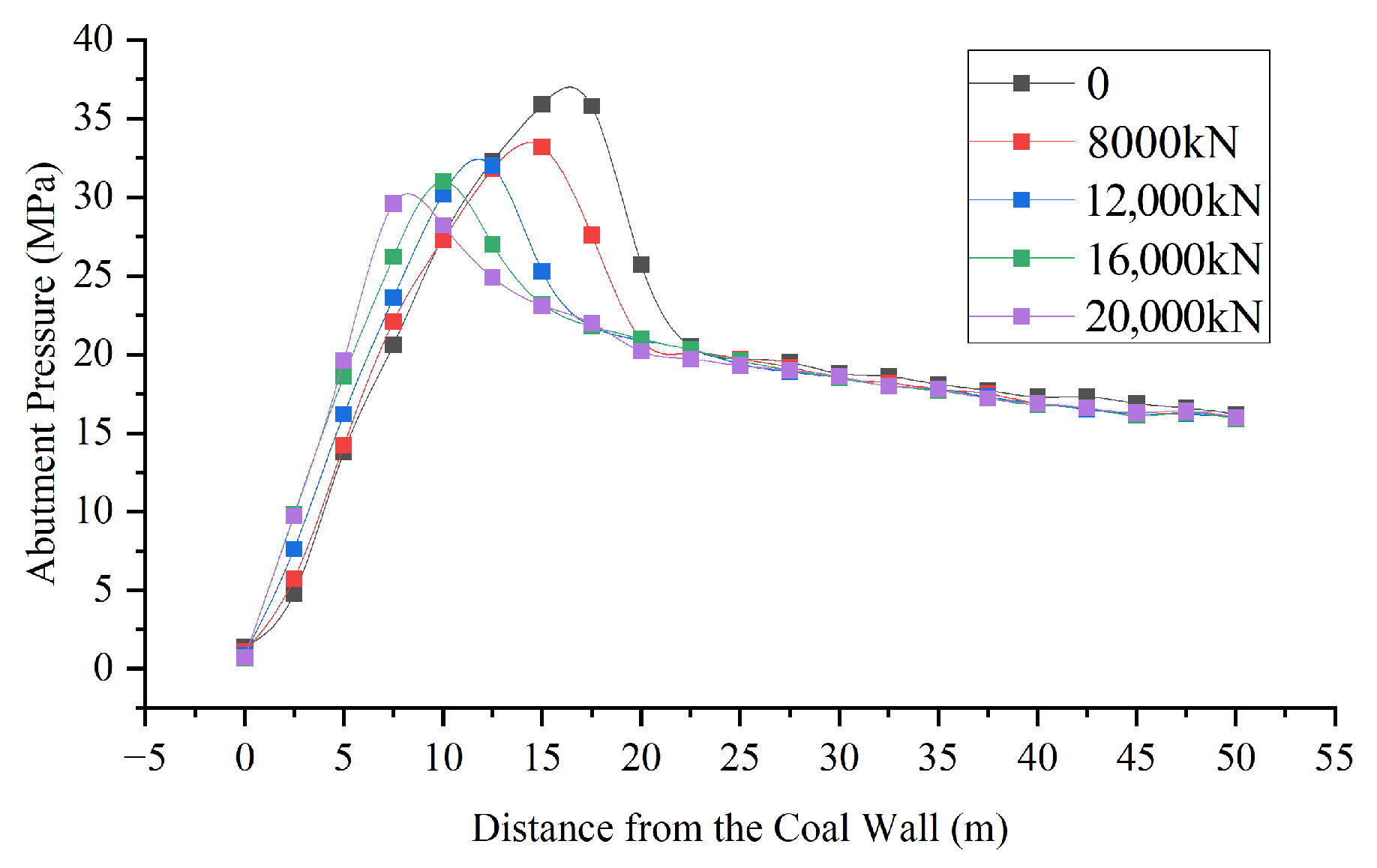

4.2.5. Influence of Support Resistance on Coal Wall Spalling

- (1)

- Development of the plastic zone

- (2)

- Evolution of coal wall and roof displacement

- (3)

- Distribution of advance abutment stress

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, S.; Yu, T. Study on overlying rock movement and mine pressure behavior in shallow-buried close coal multi-seam mining. Alex. Eng. J. 2024, 105, 578–587. [Google Scholar] [CrossRef]

- Zhang, J.; He, M.; Shimada, H.; Wang, Y.; Hou, S.; Liu, B.; Yang, G.; Zhou, P.; Li, H.; Wu, X. Similar model study on the principle of balanced mining and overlying strata movement law in shallow and thin coal seam based on N00 mining method. Eng. Fail. Anal. 2023, 152, 107457. [Google Scholar] [CrossRef]

- Chen, L.; Kong, D.; Li, L.; Liu, Q.; Zhang, P.; Zhang, L.; Yujun, Z. Analysis of the impact of key strata failure on overlying strata and surface transport patterns. Eng. Fail. Anal. 2024, 163, 108532. [Google Scholar] [CrossRef]

- Yuan, F.; Tang, J.; Kong, L. Movement Law of Overlying Strata and Abutment Pressure Redistribution Characteristic Based on Rigid Block. Lithosphere 2022, 2022, 2520477. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Zhang, J.; Li, M.; Qiao, M.; Wang, F. The Influences of Key Strata Compound Breakage on the Overlying Strata Movement and Strata Pressure Behavior in Fully Mechanized Caving Mining of Shallow and Extremely Thick Seams: A Case Study. Adv. Civ. Eng. 2019, 2019, 5929635. [Google Scholar] [CrossRef]

- Ren, H.; Song, Y.; Dai, L.; Zou, J.; Zhu, C. Influence of Overlying Strata Movement on the Stability of Coal in Fully Mechanized Top-Coal Caving Mining. Appl. Sci. 2023, 13, 8470. [Google Scholar] [CrossRef]

- Wu, F.; Yue, X.; Yang, J.; Du, B.; Zhang, J.; Lv, B. Model of Overlying Strata Structure in Large Mining Height Excavating Condition and Calculation of Support Working Resistance. Geofluids 2022, 2022, 5894735. [Google Scholar] [CrossRef]

- Chai, J.; Tian, Z.; Ouyang, Y.; Liu, Y.; Zhang, D.; Yang, J. Experimental Study on Overlying Strata Movement Characteristics and Distributed Optical Fiber Characterization of Stope. J. Sens. 2022, 2022, 4016357. [Google Scholar] [CrossRef]

- Sun, Y.; Zuo, J.; Karakus, M.; Wen, J. A Novel Method for Predicting Movement and Damage of Overburden Caused by Shallow Coal Mining. Rock Mech. Rock Eng. 2019, 53, 1545–1563. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Qin, Q.; Wang, Y.; Gao, X. Study on overlying strata movement patterns and mechanisms in super-large mining height stopes. Bull. Eng. Geol. Environ. 2023, 82, 142. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, W.-J.; Jia, Z.-Z.; Wang, G. Numerical simulation on tendency mining fracture evolution characteristics of overlying strata and coal seams above working face with large inclination angle and mining depth. Arab. J. Geosci. 2017, 10, 82. [Google Scholar] [CrossRef]

- Rong, H.; He, L.; Wei, S.; Li, J.; Wang, Y.; Wei, X.; Yang, S.; Chen, L. Overlying strata movement law and rockburst prevention & control for fully mechanized top coal caving face in extra-thick coal seams. Sci. Rep. 2025, 15, 4750. [Google Scholar] [CrossRef]

- Xu, X.; Kong, D.; Xiong, Y.; Chen, F. Evolution Regularity and Control Technology of Coal Face Rupture Induced by the movement of Overlying Strata Under the Influence of Mining. Min. Metall. Explor. 2023, 40, 435–452. [Google Scholar] [CrossRef]

- Tian, M.; Zhang, A.; Yin, D.; Xiao, H.; Han, L.; Liu, Z. Research on Mechanical Characteristics and Failure Mechanism of Coal-Rock Combined Bodies with Equal Strength. KSCE J. Civ. Eng. 2024, 28, 4678–4691. [Google Scholar] [CrossRef]

- Tian, M.; Han, L.; Xiao, H.; Meng, Q. Experimental study of deformations and failures of the coal wall in a longwall working face. Eng. Fail. Anal. 2021, 125, 105428. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Zhang, J.; Liu, H.; Zhu, G.; Wang, Y. Study on the controller factors associated with roof falling and ribs spalling in deep mine with great mining height and compound roof. Eng. Fail. Anal. 2021, 129, 105723. [Google Scholar] [CrossRef]

- Yao, Q.; Li, X.; Sun, B.; Ju, M.; Chen, T.; Zhou, J.; Liang, S.; Qu, Q. Numerical investigation of the effects of coal seam dip angle on coal wall stability. Int. J. Rock Mech. Min. Sci. 2017, 100, 298–309. [Google Scholar] [CrossRef]

- Lu, S.; Liu, S.; Wan, Z.; Cheng, J.; Yang, Z.; Shi, P. Dynamic Damage Mechanism of Coal Wall in Deep Longwall Face. Adv. Civ. Eng. 2019, 2019, 3105017. [Google Scholar] [CrossRef]

- Meng, G.; Zhang, J.; Wang, C.; Zhou, N.; Li, M. Analysis of Influencing Factors and Prevention of Coal Wall Deformation and Failure of Coal Wall in Caving Face with Large Mining Height: Case Study. Appl. Sci. 2023, 13, 7173. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Wei, Y.; Li, Z.; Dong, L. Research on Overburdened Rock Structures and Support Resistance of Shallow Buried Large Mining Heights Based on Sheet Gangs. Appl. Sci. 2025, 15, 4730. [Google Scholar] [CrossRef]

- Wang, S.; Li, X.; Qin, Q. Study on Surrounding Rock Control and Support Stability of Ultra-Large Height Mining Face. Energies 2022, 15, 6811. [Google Scholar] [CrossRef]

- Guo, W.; Li, Y.; Wang, G. The Instability Characteristics and Displacement Law of Coal Wall Containing Joint Fissures in the Fully Mechanized Working Face with Great Mining Height. Energies 2022, 15, 9059. [Google Scholar] [CrossRef]

- Wang, H.; Feng, L.; Zhao, Z.; Li, Y.; Cao, P.; Jiao, J.; Jiang, B.; Liu, Y. Coal-wall spalling prevention mechanism using advance-grooving pressure relief in the large-mining-height working face of a shallow coal seam. Energy Sci. Eng. 2024, 12, 5105–5118. [Google Scholar]

- Murmu, S.; Budi, G. Study on the Mechanism, Prediction, and Control of Coal Wall Spalling in Deep Longwall Panels Utilizing Advanced Numerical Simulation Methodology. Geofluids 2022, 2022, 5622228. [Google Scholar] [CrossRef]

- Xue, B.; Wang, Y.; Wang, C.; Zhang, W.; Lu, X. Quantitative research on sensitive factors of coal wall rib spalling in full mechanized caving face with large mining height. Bull. Eng. Geol. Environ. 2025, 84, 80. [Google Scholar] [CrossRef]

- Pang, Y.; Wang, G.; Yao, Q. Double-factor control method for calculating hydraulic support working resistance for longwall mining with large mining height. Arab. J. Geosci. 2020, 13, 252. [Google Scholar] [CrossRef]

- Fu, G. Research on the Stability Control Effect of Surrounding Rock in the Centralized Main Roadway Under the Influence of Mining Movement. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2024. [Google Scholar]

- Zhang, L.; Wang, M.; Ren, Y.; Wang, J.; Yi, W. Experimental study on overlying strata migration law in fully mechanized top coal caving mining of extra-thick coal seam with interburden. China Min. Mag. 2025, 34, 125–133. [Google Scholar]

| Rock Mass Type | Rock Mass Parameters | Similar Material Parameters | ||||

|---|---|---|---|---|---|---|

| Density (g/cm3) | Uniaxial Compressive Strength (MPa) | Elastic Modulus (GPa) | Density (g/cm3) | Uniaxial Compressive Strength (MPa) | Elastic Modulus (MPa) | |

| Medium-grained sandstone | 2.82 | 80.97 | 10.77 | 1.90 | 1.32 | 232.66 |

| Fine-grained sandstone | 2.72 | 53.90 | 7.68 | 1.92 | 1.16 | 184.22 |

| Siltstone | 2.67 | 52.24 | 9.70 | 2.05 | 1.02 | 156.21 |

| Mudstone | 2.49 | 16.95 | 2.47 | 1.94 | 0.35 | 137.54 |

| Coal | 1.46 | 3.25 | 0.12 | 1.93 | 0.21 | 52.97 |

| Stratum No. | Lithology | Model Thickness (cm) | Ratio (River Sand/ Gypsum/Calcium Carbonate) | River Sand (kg) | Gypsum (kg) | Calcium Carbonate (kg) | Total Dry Weight (kg) |

|---|---|---|---|---|---|---|---|

| 13 | Medium-grained sandstone | 31.00 | 6:0.5:0.5 | 372.00 | 31.00 | 31.00 | 434.00 |

| 12 | Mudstone | 7.50 | 7:0.5:0.5 | 90.00 | 6.43 | 6.43 | 102.86 |

| 11 | Fine-grained sandstone | 20.50 | 6:0.4:0.6 | 246.00 | 16.40 | 24.60 | 287.00 |

| 10 | Mudstone | 6.00 | 7:0.5:0.5 | 72.00 | 5.14 | 5.14 | 82.29 |

| 9 | Siltstone | 30.50 | 7:0.6:0.4 | 366.00 | 31.37 | 20.91 | 418.29 |

| 8 | Mudstone | 3.50 | 7:0.5:0.5 | 42.00 | 2.63 | 2.63 | 47.25 |

| 7 | Medium-grained sandstone | 15.00 | 6:0.5:0.5 | 180.00 | 15.00 | 15.00 | 210.00 |

| 6 | Mudstone | 3.50 | 7:0.5:0.5 | 42.00 | 2.63 | 2.63 | 47.25 |

| 5 | Medium-grained sandstone | 4.50 | 6:0.5:0.5 | 54.00 | 4.50 | 4.50 | 63.00 |

| 4 | Fine-grained sandstone | 5.00 | 6:0.4:0.6 | 60.00 | 4.00 | 6.00 | 70.00 |

| 3 | Siltstone | 6.50 | 7:0.6:0.4 | 78.00 | 6.69 | 4.46 | 89.14 |

| 2 | 2-coal | 6.00 | 8:0.5:0.5 | 72.00 | 4.50 | 4.50 | 81.00 |

| 1 | Floor strata | 10.5 | 6:0.4:0.6 | 126.00 | 8.40 | 12.60 | 147.00 |

| Strata No. | Lithology | Thickness (m) | Density (g·cm−3) | Elastic Modulus (GPa) | Poisson’s Ratio | Internal Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| 12 | Siltstone | 30.4 m | 2.48 | 8.2 | 0.20 | 35 | 4.5 | 5.8 |

| 11 | Mudstone | 3.3 m | 2.45 | 5.0 | 0.24 | 30 | 3.2 | 3.0 |

| 10 | Medium-grained sandstone | 15.2 m | 2.5 | 8.8 | 0.19 | 34 | 4.0 | 5.0 |

| 9 | Mudstone | 3.6 m | 2.45 | 5.0 | 0.24 | 30 | 3.2 | 3.0 |

| 8 | Medium-grained sandstone | 4.3 m | 2.5 | 8.8 | 0.19 | 34 | 4.0 | 5.0 |

| 7 | Fine-grained sandstone | 4.9 m | 2.50 | 9.3 | 0.18 | 36 | 5.0 | 6.0 |

| 6 | Siltstone | 6.6 m | 2.48 | 8.2 | 0.20 | 35 | 4.5 | 5.8 |

| 5 | 2-coal | 5.9 m | 1.40 | 2.0 | 0.30 | 25 | 1.5 | 1.8 |

| 4 | Siltstone | 1.4 m | 2.48 | 8.2 | 0.20 | 35 | 4.5 | 5.8 |

| 3 | 3-coal | 1.0 m | 1.40 | 2.0 | 0.30 | 25 | 1.5 | 1.8 |

| 2 | Fine-grained sandstone | 7.9 m | 2.50 | 9.3 | 0.18 | 36 | 5.0 | 6.0 |

| 1 | Mudstone | 5.8 m | 2.45 | 5.0 | 0.24 | 30 | 3.2 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, W.; Han, L. Overburden Behavior and Coal Wall Spalling Characteristics Under Large-Mining-Height Conditions. Appl. Sci. 2025, 15, 12303. https://doi.org/10.3390/app152212303

Fan W, Han L. Overburden Behavior and Coal Wall Spalling Characteristics Under Large-Mining-Height Conditions. Applied Sciences. 2025; 15(22):12303. https://doi.org/10.3390/app152212303

Chicago/Turabian StyleFan, Wenze, and Lijun Han. 2025. "Overburden Behavior and Coal Wall Spalling Characteristics Under Large-Mining-Height Conditions" Applied Sciences 15, no. 22: 12303. https://doi.org/10.3390/app152212303

APA StyleFan, W., & Han, L. (2025). Overburden Behavior and Coal Wall Spalling Characteristics Under Large-Mining-Height Conditions. Applied Sciences, 15(22), 12303. https://doi.org/10.3390/app152212303