Numerical Simulation of Fracture Propagation and Damage Evolution in Coal Seam Under Controlled High-Energy Shock Wave Fracturing

Abstract

1. Introduction

2. Numerical Simulation Model Construction

2.1. Mathematical Model and Basic Assumptions

- (1)

- Deformation Control Equation

- (2)

- Damage Evolution Equation

- (3)

- Fluid Flow Control Equation

- (4)

- Coupling Terms

2.2. Geometry Model Construction

- (1)

- Geometry Model and Parameter Settings

- (2)

- Boundary Conditions

- (3)

- Controlled Repeated High-Energy Shock Wave Pressure–Time History Curve

- (4)

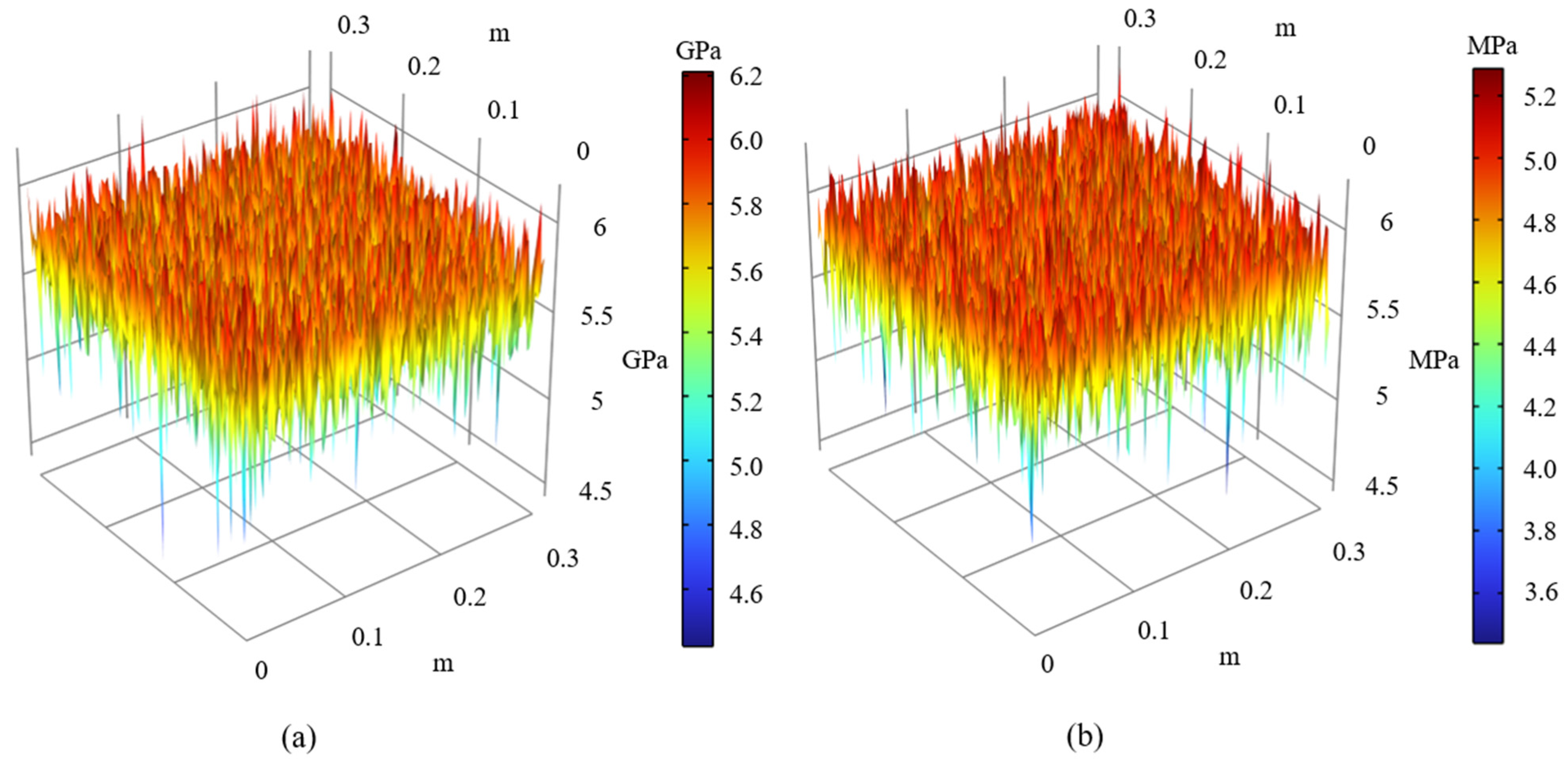

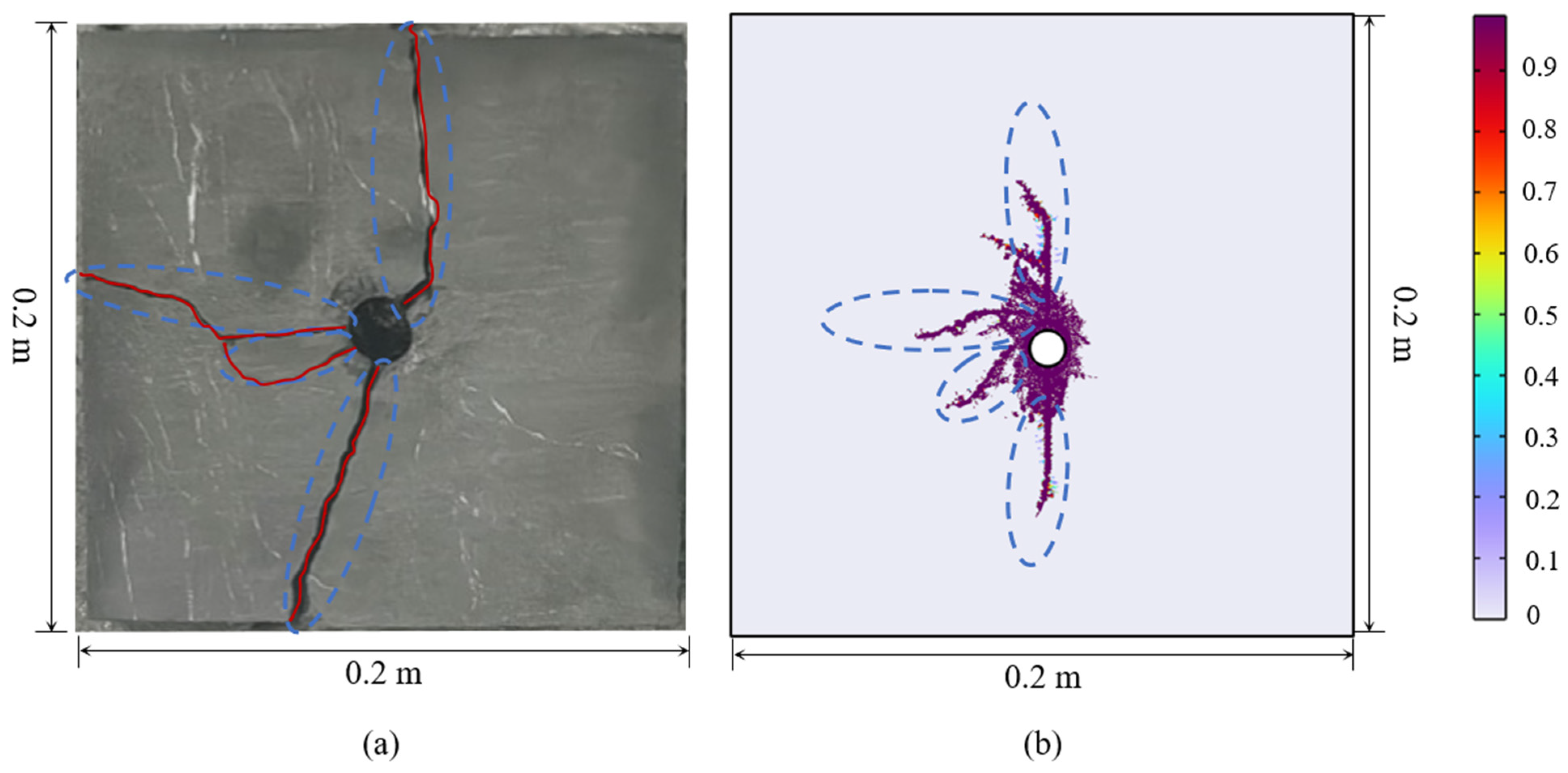

- Model Calculation and Verification

3. Fracture Propagation Influencing Factors Analysis

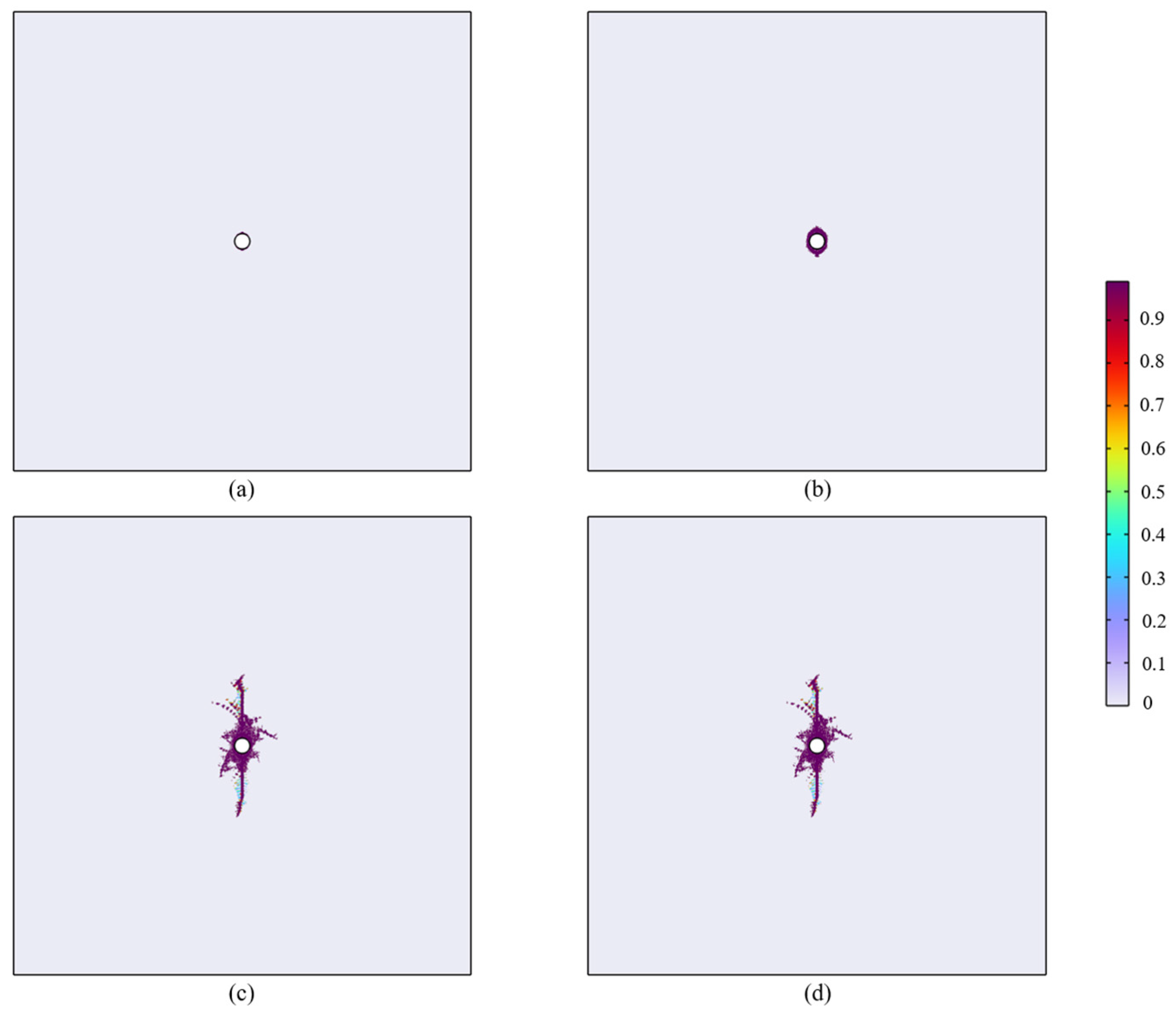

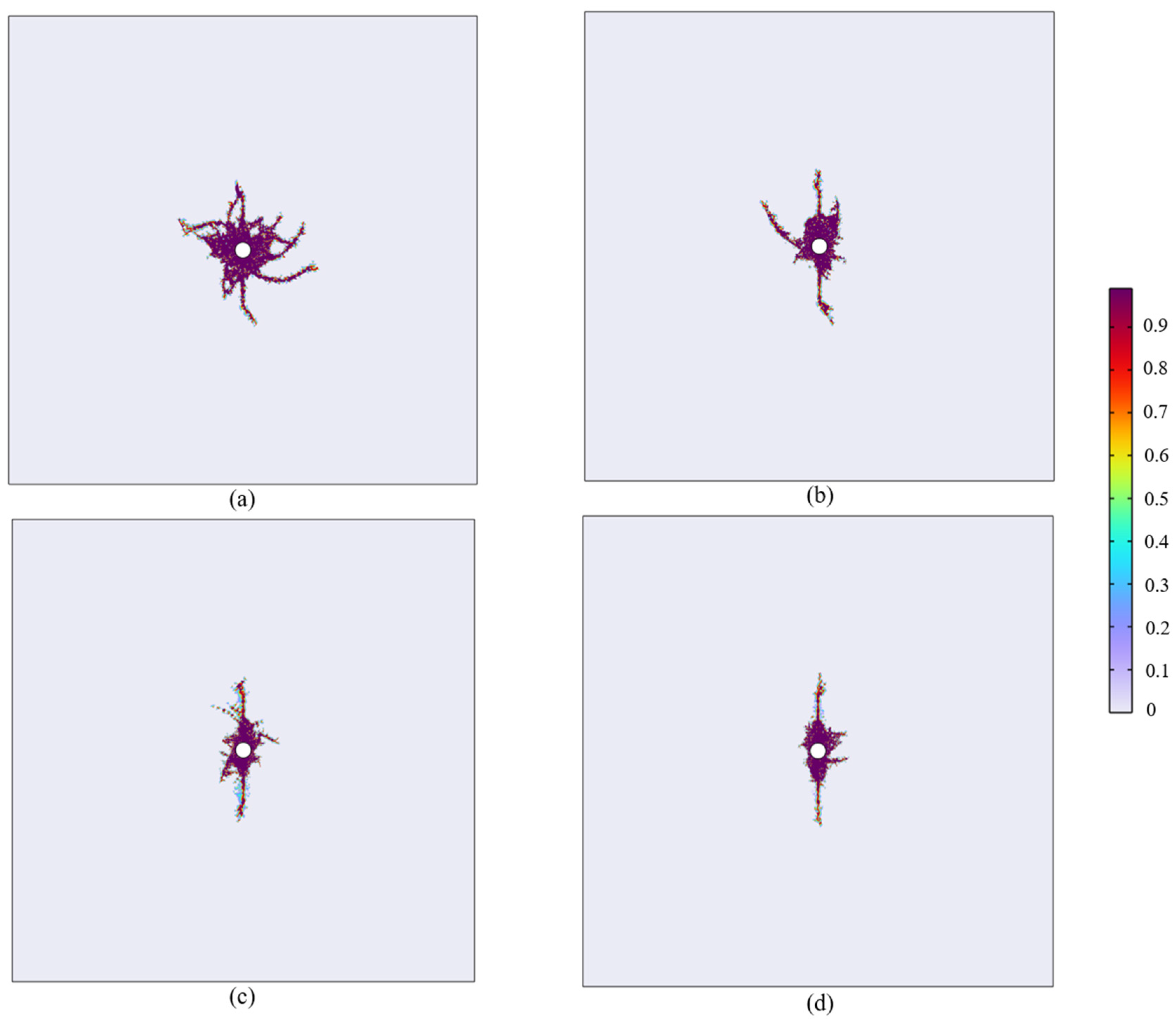

3.1. Numerical Simulation Results and Analysis

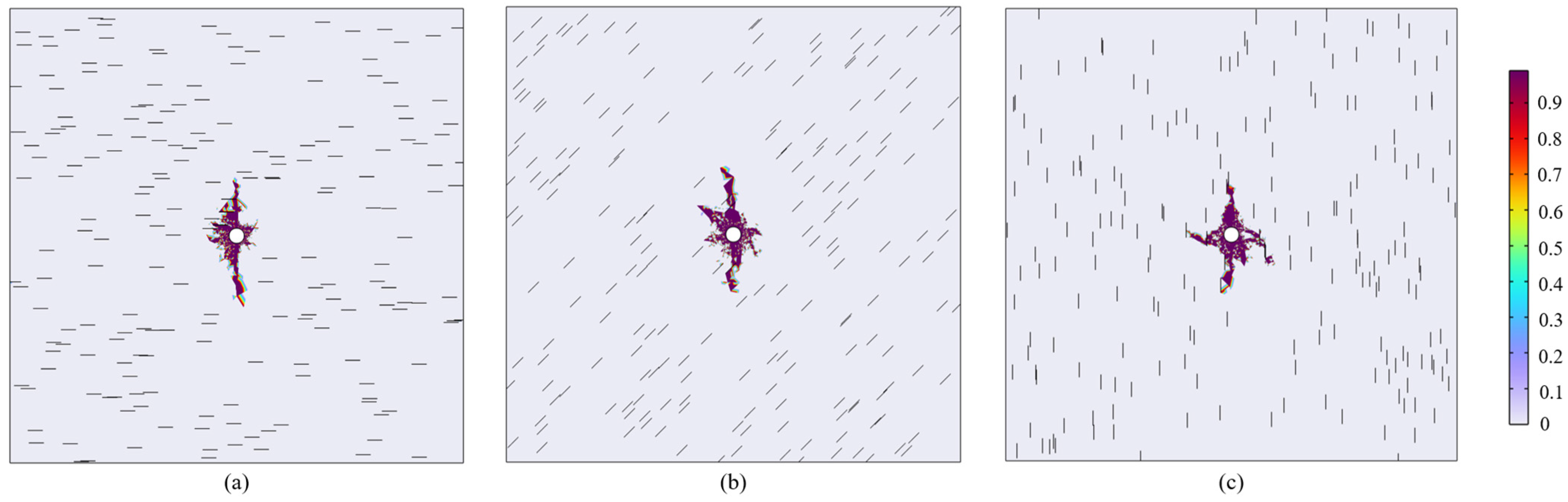

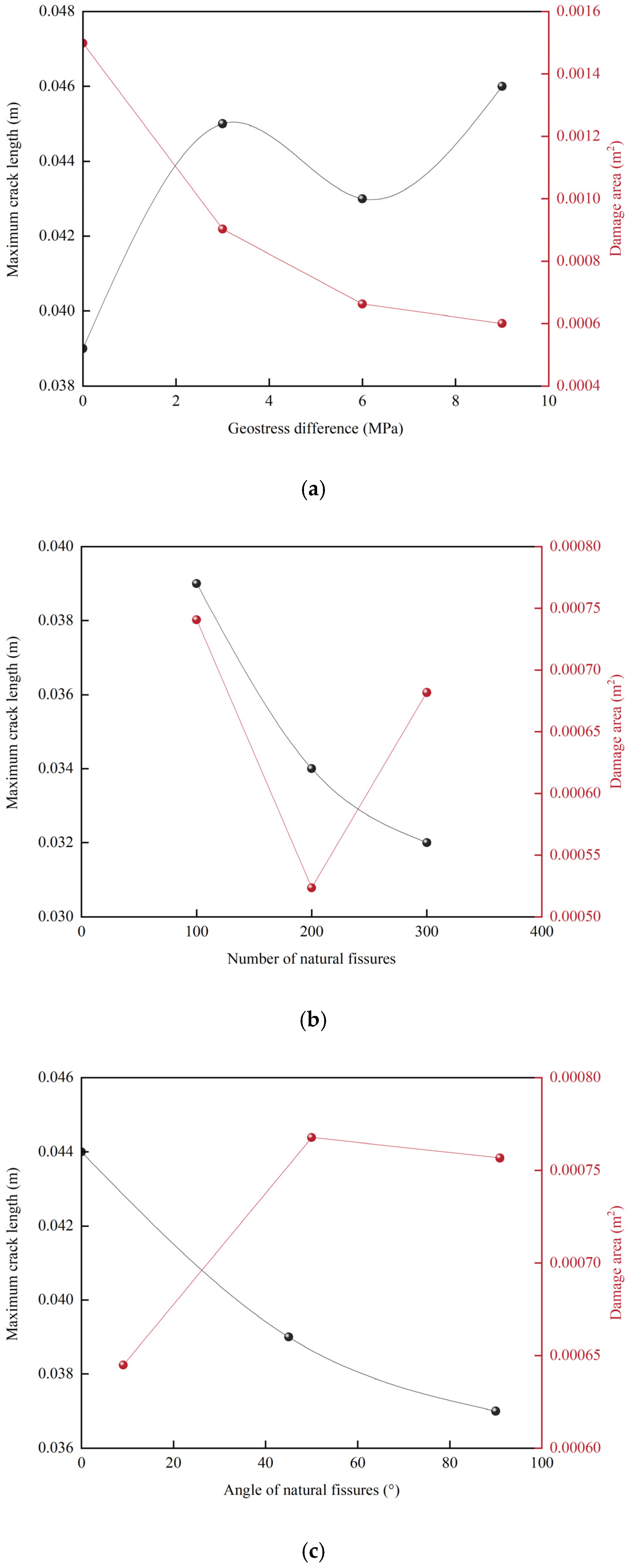

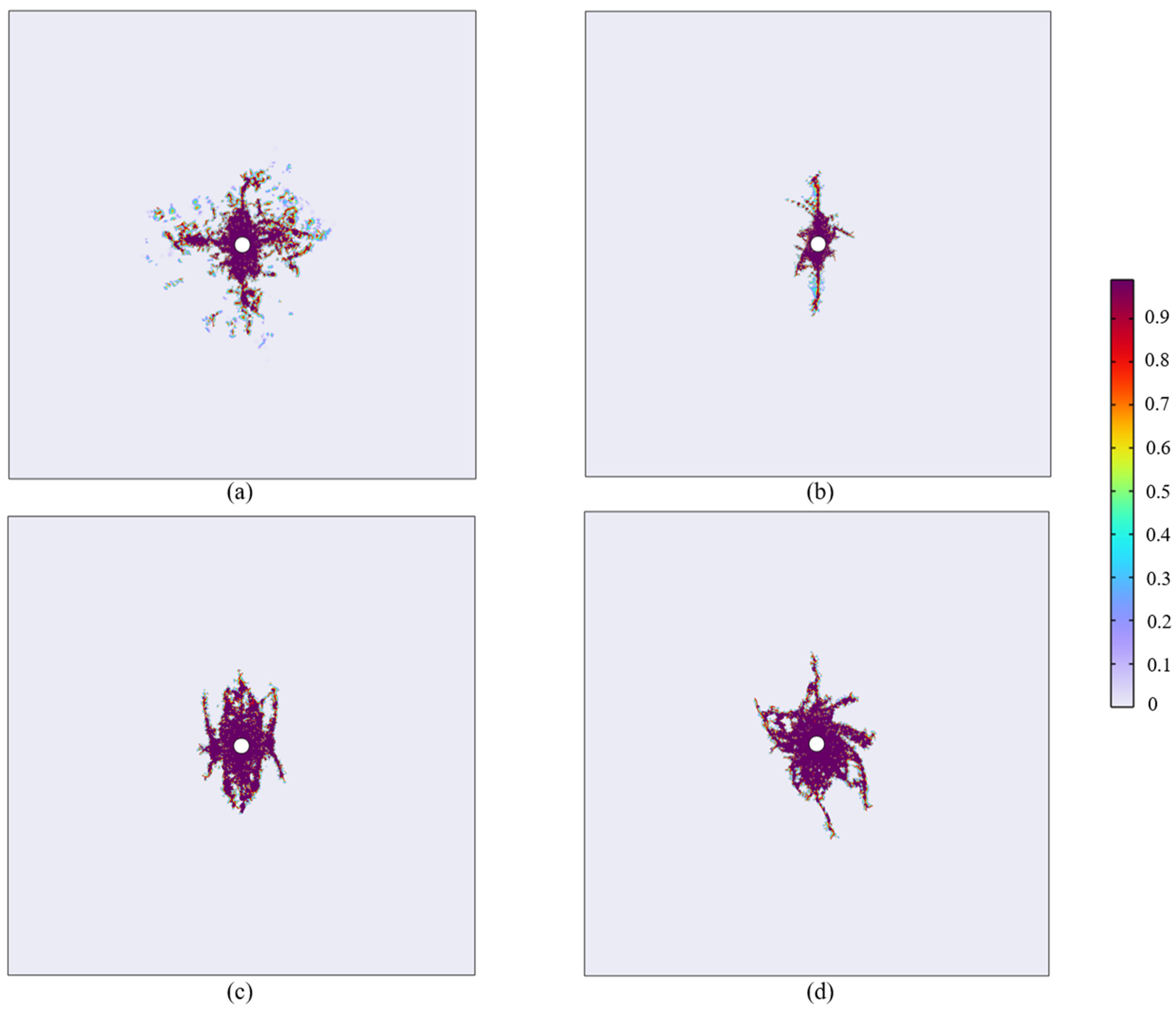

3.2. Effect of Geostress Difference

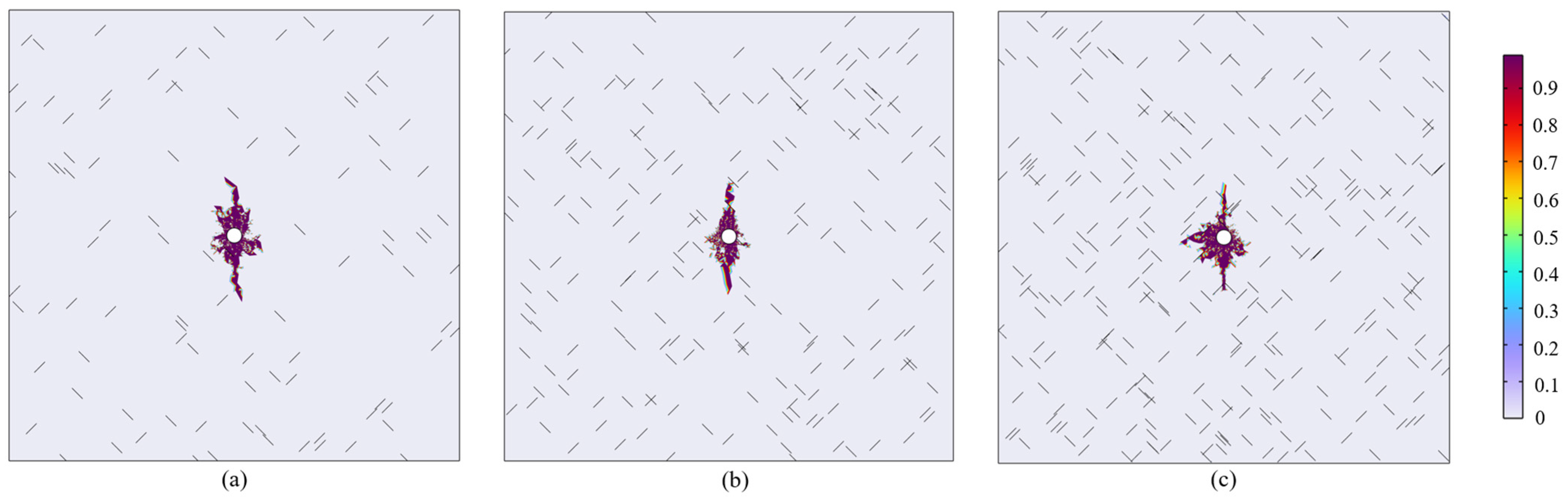

3.3. Effect of Natural Fissure Characteristics on Fracture Propagation

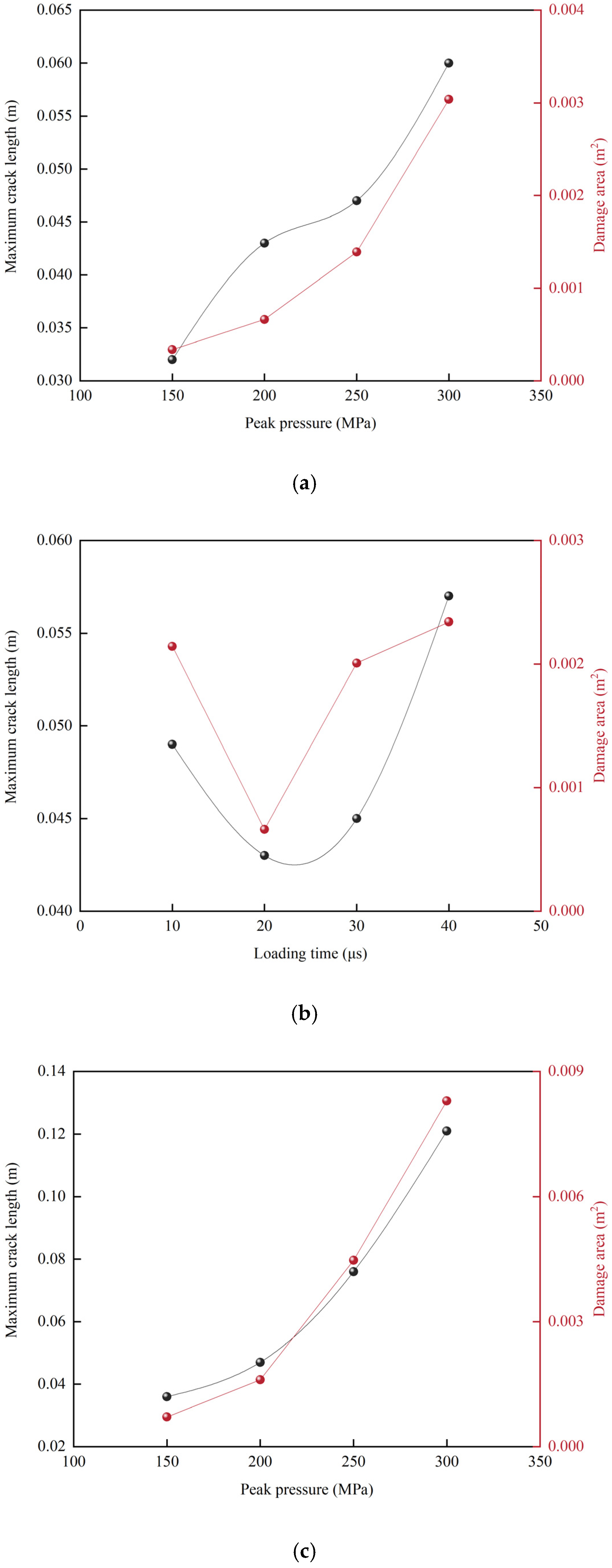

3.4. Effect of Operational Parameters on Fracture Propagation

4. Analysis and Discussion

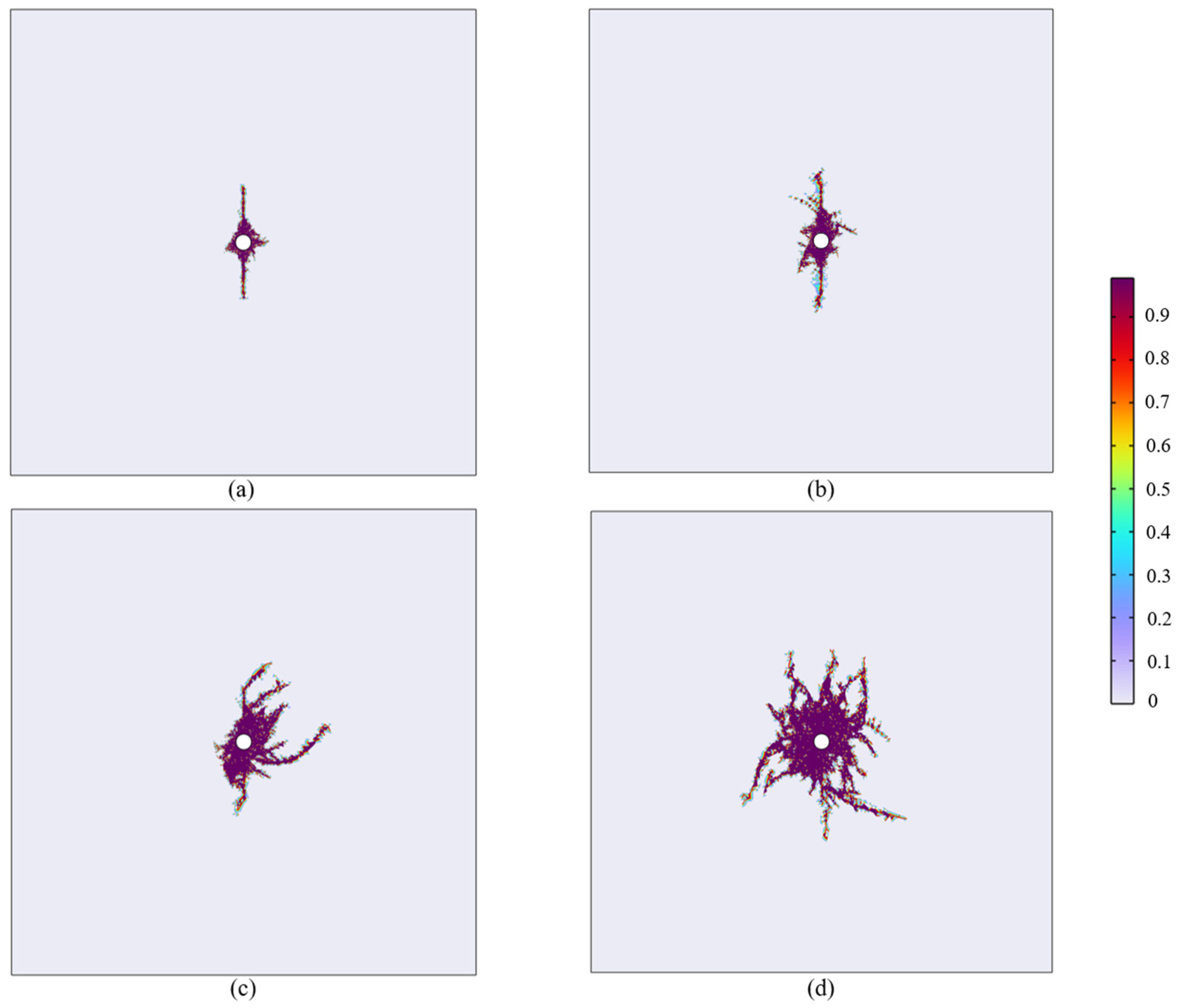

4.1. Sensitivity Analysis of Factors Affecting Fracture Propagation

4.2. Comparison with Hydraulic Fracturing

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, F.Y.; Hou, W.; Xiong, X.Y.; Xu, B.R.; Wu, P.; Wang, H.Y.; Feng, K.; Yun, J.; Li, S.G.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Huo, C.; Guo, H.X.; Wang, L.; Xie, Z.Q.; Pan, H.Y.; Xu, Q.; Zhang, Z.G.; Wang, D.F.; Wang, D.D. Research Progress of Deep Coalbed Methane Exploration and development in China under the dual carbon background. Sci. Technol. Eng. 2025, 25, 5705–5720. [Google Scholar] [CrossRef]

- Ju, W.; Tao, S.; Yang, Z.B.; Cheng, J.X.; Shang, H.Y.; Ning, W.K.; Wu, C.L. Current status and development trends of deep coalbed methane research in China. Pet. Geol. Exp. 2025, 47, 9–16. [Google Scholar] [CrossRef]

- An, Y.S.; Sun, Z.W.; Wang, J.; Zhang, X.Y.; Sun, Y.F. Numerical simulation of deep coalbed methane development based on embedded discrete fracture model: A triple medium flow approach. Energy Sci. Eng. 2025, 13, 3045–3062. [Google Scholar] [CrossRef]

- Liu, J.Z.; Su, Y.C.; Sun, L.C.; Li, C.; Wang, L.; Meng, Y.J.; Li, Y. Research on fracturing optimization of coalbed methane wells aiming at economic benefit—A case study of Liulin block. Energies 2024, 17, 1829. [Google Scholar] [CrossRef]

- Xie, H.G.; Sang, S.S.; Li, X.J.; Yan, Z.H.; Zhou, X.Z.; Liu, S.Q.; Han, S.J.; Cai, J.J. Competitive adsorption-penetration characteristics of multi-component gases in micro-nano pore of coal. Chem. Eng. J. 2025, 506, 159965. [Google Scholar] [CrossRef]

- Xie, H.G.; Sang, S.X.; Li, X.J.; Yan, Z.H.; Liu, S.Q.; Zhou, X.Z.; Han, S.J. Evolution of pore-fracture and permeability prediction in soft coal rock under variable-pressure water saturation. Phys. Fluids 2025, 37, 76646. [Google Scholar] [CrossRef]

- Qiao, G.D.; Liu, Z.G.; Gao, K.; Zhang, Y.M.; Zhao, Y.Z.; Li, Y.Y.; Fu, S.G.; Zhang, J.Y.; Wang, Z.; Yang, S.; et al. Evolutionary patterns of cracking and damage due to anti-reflection of controllable shock waves at the roof of loose and low-permeability coal seams. J. China Coal Soc. 2025. [Google Scholar] [CrossRef]

- Zhao, X.L.; Huang, B.X.; Li, H.Z.; Chen, S.L. Field investigation of multi-stage pulse hydraulic fracturing for improving permeability of coal seam in directional long borehole in underground coal mines. Environ. Earth Sci. 2023, 82, 519. [Google Scholar] [CrossRef]

- Li, N.Y.; Wang, C.; Zhang, S.W.; Yu, J.J. Recent advances in waterless fracturing technology for the petroleum industry: An overview. J. Nat. Gas Sci. Eng. 2021, 92, 103999. [Google Scholar] [CrossRef]

- Xie, H.C.; Ni, G.H.; Xie, J.N.; Cheng, W.M.; Xun, M.; Wang, H.; Wang, G. The effect of SDS synergistic composite acidification on the chemical structure and wetting characteristics of coal. Powder Technol. 2020, 367, 253–265. [Google Scholar] [CrossRef]

- Zhou, X.H.; Li, X.L.; Bai, G.; Chai, L.; Wang, Y.M.; Xiao, M.F.; Xia, S.Y. Research method of pressure relief and permeability enhancement in low permeability coal seam: A review. AIP Adv. 2022, 12, 010702. [Google Scholar] [CrossRef]

- Fan, C.J.; Sun, H.; Li, S.; Yang, L.; Xiao, B.; Yang, Z.H.; Luo, M.K.; Jiang, X.F.; Zhou, L.J. Research advances in enhanced coal seam gas extraction by controllable shock wave fracturing. Int. J. Coal Sci. Technol. 2024, 11, 39. [Google Scholar] [CrossRef]

- Qiao, G.D.; Liu, Z.G.; Zhang, Y.M.; Yi, C.P.; Gao, K.; Fu, S.G.; Zhao, Y.Z. Theoretical analysis and engineering application of controllable shock wave technology for enhancing coalbed methane in soft and low-permeability coal seams. Int. J. Coal Sci. Technol. 2024, 11, 25. [Google Scholar] [CrossRef]

- An, S.G.; Chen, D.B.; Zhang, Y.M.; Kong, D.L.; Li, Y.; Zhang, D.; Wang, Y. Application of controllable electric pulse wave permeability-enhancing technology in the low-permeability coal seams. Coal Geol. Explor. 2020, 48, 138–145. [Google Scholar] [CrossRef]

- Wang, Z. Application of controllable shock wave plugging removal and permeability improvement technology in CBM gas field of Southern Yanchuan. Pet. Reserv. Eval. Dev. 2020, 10, 87–92. [Google Scholar] [CrossRef]

- Wang, S.B.; Zhang, S.; Ma, L.; Zhao, Y.Z.; Gao, L.; Cao, Y.X.; Xie, P.J. Physical simulation experiment on the rock breaking efficiency of pulse type controllable shock wave. ACS Omega 2024, 9, 51554–51569. [Google Scholar] [CrossRef]

- Han, Z.J.; Liu, M.J.; Zhang, J.C. The rock breaking mechanism and application effect of pulse type controllable shock wave. Geomech. Geophys. Geo-Energy Geo-Resour. 2025, 11, 18. [Google Scholar] [CrossRef]

- Chen, H.J.; Chen, Z.; Hu, B.; Hu, Q.Y.; Zhao, Y.Z. Optimization of parameters for controllable shock waves pre-splitting in hard rocks in tectonic zones. J. Xi’an Univ. Sci. Technol. 2024, 44, 857–865. [Google Scholar] [CrossRef]

- Qin, Y.; Li, H.L.; Zhang, Y.M.; Zhao, Y.Z.; Zhao, J.C.; Qiu, A.C. Numerical analysis on CSW fracturing behavior of coal seam under constraint of geological and engineering conditions. Coal Geol. Explor. 2021, 49, 108–118+129. [Google Scholar] [CrossRef]

- Sun, H.; Fan, C.J.; Yang, L.; Luo, M.K.; Wang, L.; Zhou, L.J. Modelling of enhanced gas extraction in low permeability coal seam by controllable shock wave fracturing. Sci. Rep. 2024, 14, 24155. [Google Scholar] [CrossRef] [PubMed]

- Li, H.L. Behavior and Mechanism of Fracturing and Enhanced-Permeability of Coals with Electric Pulse Stress Waves. Ph.D. thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Wang, W.W.; Lv, C.G.; Mu, C. Fractal Characterization of Surrounding Rock and Coal Matrix Stress Response Enhancing Gas Drainage Efficiency. ACS Omega 2025, 10, 10459–10467. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.Q.; Fang, H.H.; Sang, S.X.; Hu, Q.J.; Duan, W.Y.; Jia, H.M.; Mao, C.H. Numerical simulation of gas production for multilayer drainage coalbed methane vertical wells in southern Qinshui Basin. Coal Geol. Explor. 2022, 50, 20–31. [Google Scholar] [CrossRef]

- Wu, L.; Hou, Z.M.; Xie, Y.C.; Luo, Z.F.; Xiong, Y.; Cheng, L.; Wu, X.N.; Chen, Q.J.; Huang, L.C. Fracture initiation and propagation of supercritical carbon dioxide fracturing in calcite-rich shale: A coupled thermal-hydraulic-mechanical-chemical simulation. Int. J. Rock Mech. Min. Sci. 2023, 167, 105389. [Google Scholar] [CrossRef]

- Lin, H.F.; Li, B.T.; Li, S.G.; Song, Z.X.; Wang, F.; Luo, R.W.; Wei, Z.Y.; Qin, L. A thermal-hydraulic-mechanical-damage coupling model of layer coal fracturing by liquid nitrogen. Chin. J. Rock Mech. Eng. 2024, 43, 1110–1123. [Google Scholar] [CrossRef]

- Zhu, W.C.; Wei, C.H.; Tian, J.; Yang, T.H.; Tang, C.A. Coupled thermal-hydraulic-mechanical model during rock damage and its preliminary application. Rock Soil Mech. 2009, 30, 3851–3857. [Google Scholar] [CrossRef]

- Zhang, H.B.; Liu, J.S.; Elsworth, D. How sorption-induced matrix deformation affects gas flow in coal seams: A new FE model. Int. J. Rock Mech. Min. Sci. 2008, 45, 1226–1236. [Google Scholar] [CrossRef]

- Li, S.; Fan, C.J.; Han, S.; Luo, M.K.; Yang, Z.H.; Bi, H.J. A fully coupled thermal-hydraulic-mechanical model with two-phase flow for coalbed methane extraction. J. Nat. Gas Sci. Eng. 2016, 33, 324–336. [Google Scholar] [CrossRef]

- Yang, F.; Li, B.; Wang, K.J.; Wen, H.; Yang, R.Y.; Huang, Z.W. Extreme massive hydraulic fracturing in deep coalbed methane horizontal wells: A case study of the Linxing Block, eastern Ordos Basin, NW China. Pet. Explor. Dev. 2024, 51, 389–398. [Google Scholar] [CrossRef]

- Yan, C.Z.; Sun, G.H.; Zheng, H.; Ge, X.R. Simulation of explosive gas-driven rock fracture by FEM/DEM. Rock Soil Mech. 2015, 36, 2419–2425. [Google Scholar] [CrossRef]

- Wang, E.B.; Zhu, H.Y.; Yi, X.Y.; Li, Q.; Zhao, P.; Marembo, M.; Tan, H.J.; Zhang, Z.P. Numerical simulation of fracture propagation in high-energy gas fracturing of shale reservoir. Geoenergy Sci. Eng. 2025, 252, 213915. [Google Scholar] [CrossRef]

- Ding, J.H.; Liu, M.J.; Zhang, Y.; Sun, X.; Niu, Q.H.; Wang, W.; Wang, W.; Zheng, Y.X.; Yin, C. Experimental and numerical simulation research on controllable shock wave-induced shale fracturing under repeated action. ACS Omega 2024, 9, 13252–13261. [Google Scholar] [CrossRef] [PubMed]

- Lin, M.H. Mechanism on Targeted Blasting Fracturing and Enhanced Permeability in Deep Coal Rock Mass and Its Engineering Application. Ph.D. thesis, China University of Mining and Technology, Xuzhou, China, 2024. [Google Scholar]

| Parameter | Sensitivity Coefficient | Rank |

|---|---|---|

| Geostress difference | 0.0537 | 3 |

| Number of natural fissures | 0.0001 | 6 |

| Angle of natural fissures | 0.0020 | 5 |

| Peak stress | 0.3526 | 2 |

| Loading time | 0.0359 | 4 |

| Repeated shocks | 1.0000 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Liu, W.; Li, Y.; Zhang, L.; Liang, Y.; Liu, X.; Pu, S.; Liang, Y.; Liu, S. Numerical Simulation of Fracture Propagation and Damage Evolution in Coal Seam Under Controlled High-Energy Shock Wave Fracturing. Appl. Sci. 2025, 15, 12279. https://doi.org/10.3390/app152212279

Wang S, Liu W, Li Y, Zhang L, Liang Y, Liu X, Pu S, Liang Y, Liu S. Numerical Simulation of Fracture Propagation and Damage Evolution in Coal Seam Under Controlled High-Energy Shock Wave Fracturing. Applied Sciences. 2025; 15(22):12279. https://doi.org/10.3390/app152212279

Chicago/Turabian StyleWang, Sukai, Wei Liu, Yonglong Li, Lipeng Zhang, Yan Liang, Xionghui Liu, Songling Pu, Yu Liang, and Shiqi Liu. 2025. "Numerical Simulation of Fracture Propagation and Damage Evolution in Coal Seam Under Controlled High-Energy Shock Wave Fracturing" Applied Sciences 15, no. 22: 12279. https://doi.org/10.3390/app152212279

APA StyleWang, S., Liu, W., Li, Y., Zhang, L., Liang, Y., Liu, X., Pu, S., Liang, Y., & Liu, S. (2025). Numerical Simulation of Fracture Propagation and Damage Evolution in Coal Seam Under Controlled High-Energy Shock Wave Fracturing. Applied Sciences, 15(22), 12279. https://doi.org/10.3390/app152212279