Multidimensional Maintenance Maturity Modeling: Fuzzy Predictive Model and Case Study on Ensuring Operational Continuity Under Uncertainty

Featured Application

Abstract

1. Introduction

- (i)

- Embedding fuzzy reasoning into a hierarchical, multi-potential maturity structure that jointly evaluates dependability, adaptability, and sustainability, integrating strategic dimensions (P3: Resilience and P5: Sustainability) often neglected by established frameworks (e.g., M-SCOR, M3);

- (ii)

- Introducing two new fuzzy input parameters, Technology Adoption Capability and Energy-Aware Maintenance Level, to reflect the digitalization and sustainability dimensions of modern maintenance;

- (iii)

- Linking fuzzy outputs directly to strategic decision-support insights that identify maturity gaps and prioritize resilience-enhancing actions, a capability absent in purely diagnostic, deterministic models.

- (1)

- Define a hierarchical maturity framework integrating resilience and sustainability;

- (2)

- Identify input parameters based on key knowledge areas;

- (3)

- Develop a fuzzy inference system for evaluation under uncertainty;

- (4)

- Validate the model through an industrial case study.

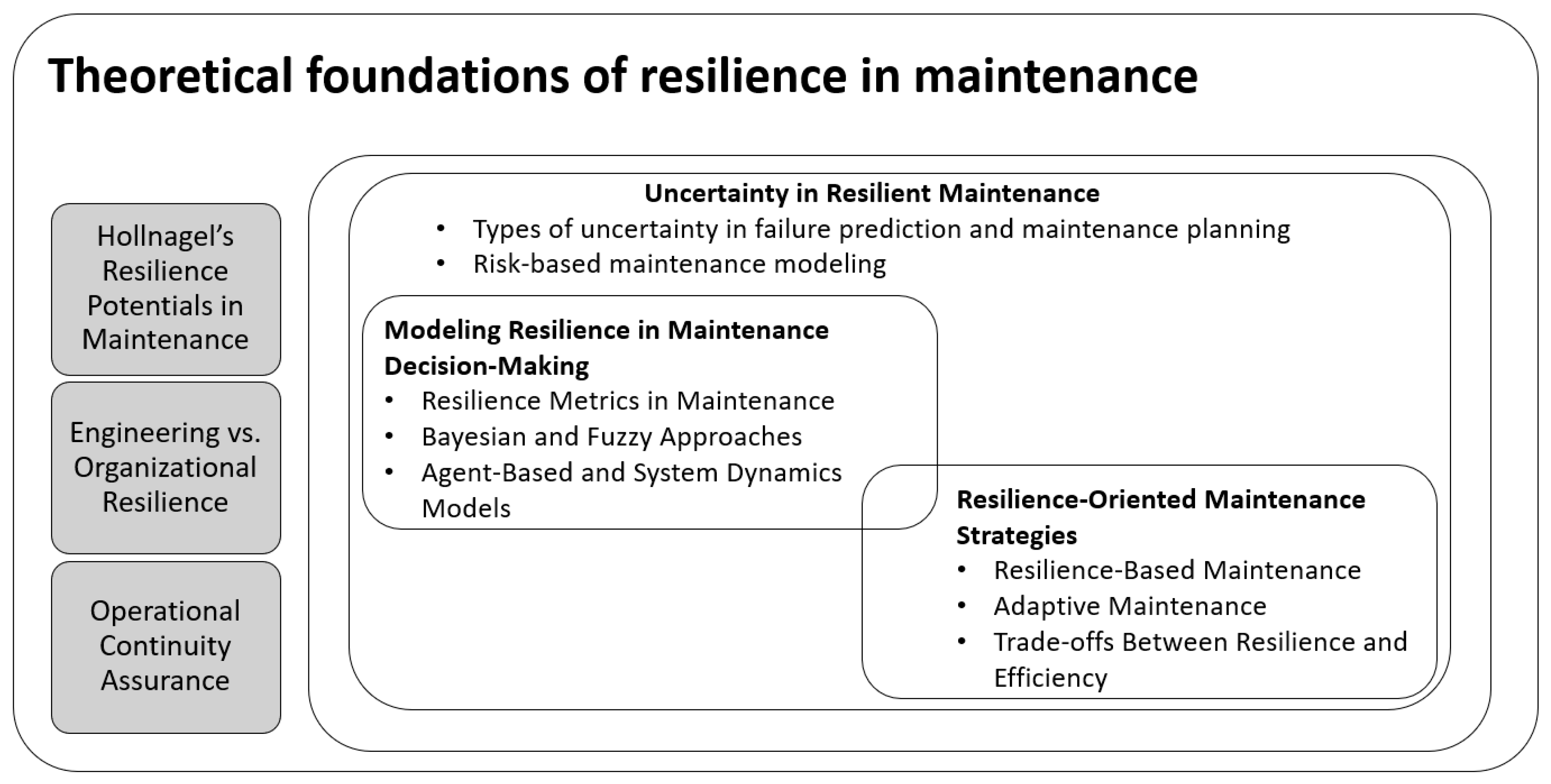

2. Theoretical Background

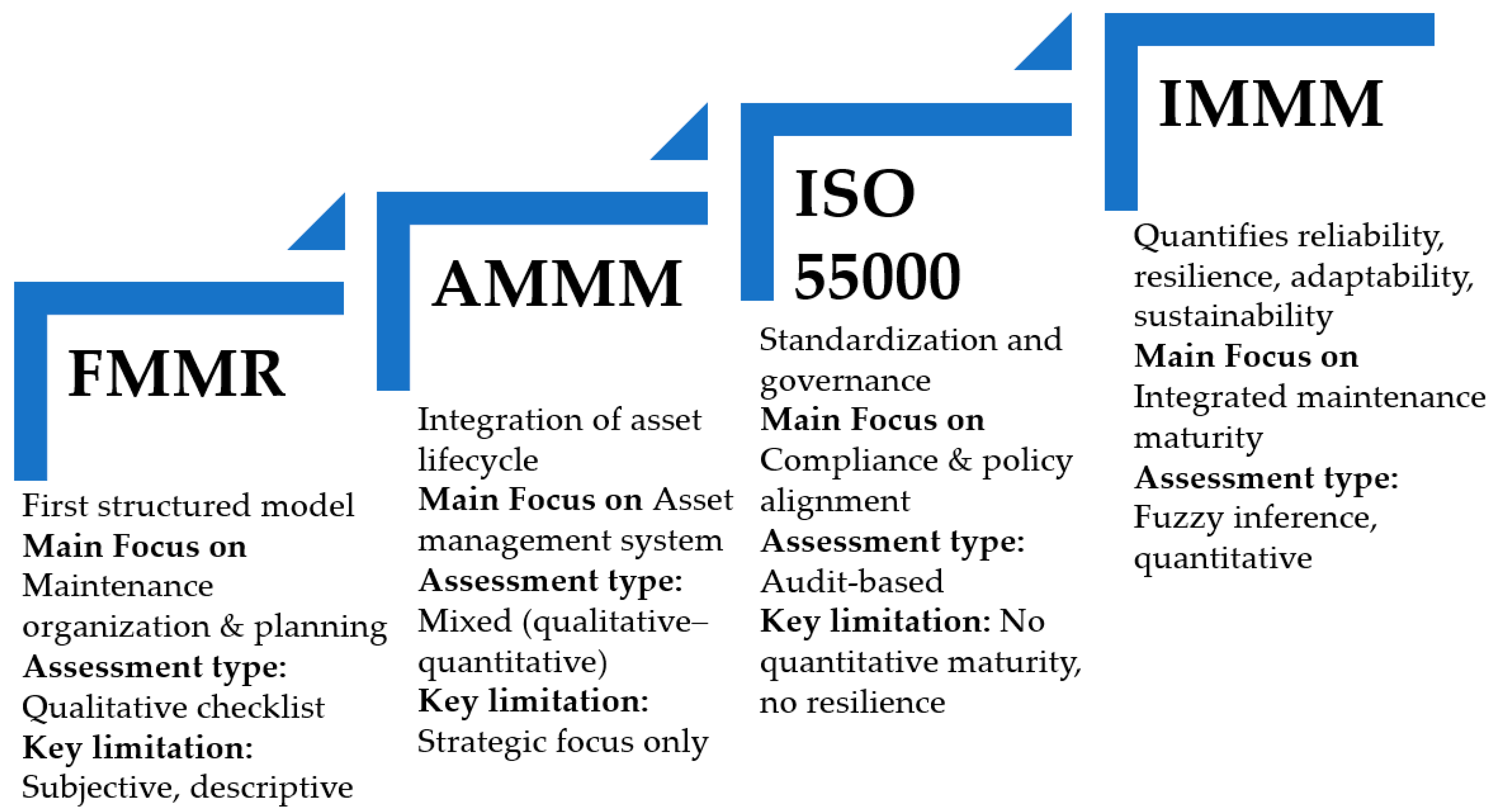

2.1. One-Dimensional Maintenance Maturity Models

2.2. Two-Dimensional Maintenance Perspective

2.3. Unified Multidimensional Maintenance Perspective

| Ref. | Model Name | Publ. Year | Dimension Type | Key Dimensions Covered | Number of Maturity Levels | Methodological Basis | Assessment Approach | Application Context |

|---|---|---|---|---|---|---|---|---|

| [25] | Reliability Centred Maintenance Maturity | 2003 | One-dimensional | Maintenance | 5 | RCM-based approach | Conceptual | Various industries |

| [55] | Software Maintenance Capability Maturity Model (SMCMM) | 2004 | One-dimensional | Maintenance | 4 | Capability maturity modeling | Model architecture | Software |

| [56] | The House of Maintenance-based Capability maturity model | 2009 | One-dimensional | Maintenance | 5 | Capability maturity modeling | Workshop, questionnaire | Various industries |

| [57] | Maintenance Management Information Maturity model | 2012 | One-dimensional | Maintenance | 2 | IT-maturity based | Not specified | Various industries |

| [1] | Organization maturity level for maintenance management | 2012 | One-dimensional | Maintenance | 3 | Maintenance strategy | Interview | Various industries |

| [58] | Maintenance Maturity Assessment method | 2013 | One-dimensional | Maintenance | 5 | Capability maturity modeling | Maturity assessment based on scorecards | Manufacturing industry |

| [59] | PriMa-X Reference Model | 2018 | One-dimensional | Maintenance | 3 layers | Prescriptive maintenance strategy | Reference model based on ML | Various industries |

| [60] | Knowledge-based Maintenance Maturity model | 2019 | One-dimensional | Maintenance | 4 | Knowledge-based maintenance strategy | Performance indicators-based assessment | Cyber-physical production systems |

| [26] | Maintenance Maturity Level based on TPM Pillars | 2020 | One-dimensional | Maintenance | 8 | TPM-based approach | Multi-attributive Border Approximation method | Public service sector |

| [61] | Organization performance maturity level for maintenance management | 2020 | One-dimensional | Maintenance | 5 | World-class concept based | Self-assessment based on reading the tables’ content | Various industries |

| [62] | Asset Management Maturity model | 2022 | One-dimensional | Maintenance | 6 | ISO 55001:2014-based | Interviews, direct observation, correlation index, scoring method | Heavy equipment |

| [63] | M3AIN4SME | 2022 | One-dimensional | Maintenance | 5 | Literature review, expert validation | Survey-based assessment | SMEs |

| [3] | Asset maintenance maturity model (AMMM) | 2013 | Multi-dimensional | People and environment, functional and technical aspects, maintenance budget | 3 | Capability maturity modeling | Performance measurement, ANP method | Asset maintenance domain |

| [6] | FMMR (Fuzzy Maintenance Maturity Rating) | 2021 | Multi-dimensional | Resilience, risk, maintenance performance | 5 | Fuzzy logic, expert input | Fuzzy assessment model | Industrial systems |

| [41] | Maintenance Maturity and Sustainability Assessment Model | 2023 | Multi-dimensional | Environmental, social and economic dimensions of maintenance; sustainability | 5 | Literature, expert opinion, analytical assessment | Survey research, mathematical formulations for maturity evaluation | Manufacturing companies |

| Our model | IMMM (Integrated Maintenance Maturity Model) | 2025 | Multi-dimensional | Reliability, Safety, Resilience, Flexibility, Sustainability | 5 | Fuzzy Logic, Multi-Potential Framework | Quantitative Score from Linguistic Input, Predictive Scenario Analysis | Industrial Systems (Cross-sectoral applicability) |

3. Proposed Maintenance Maturity Model

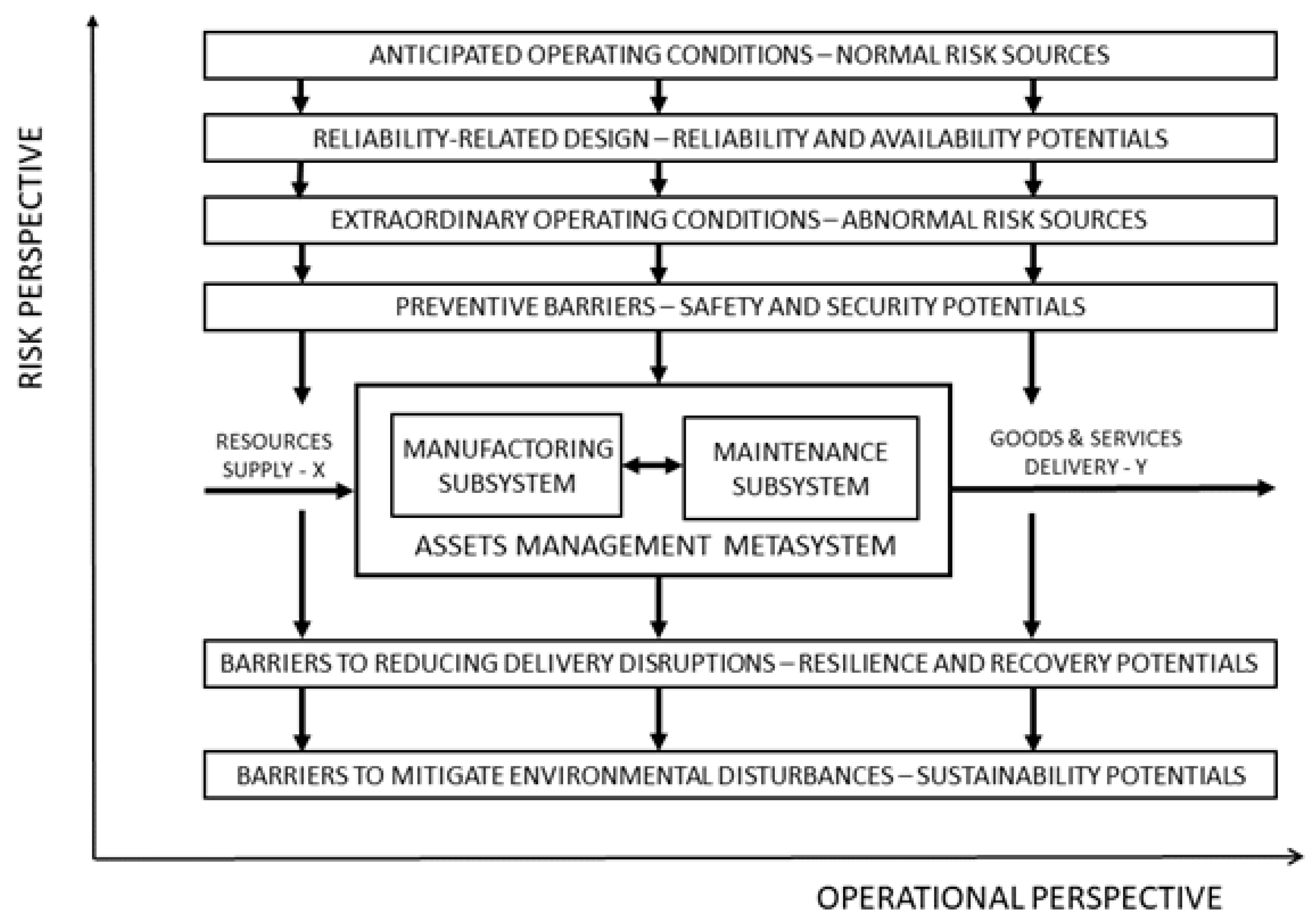

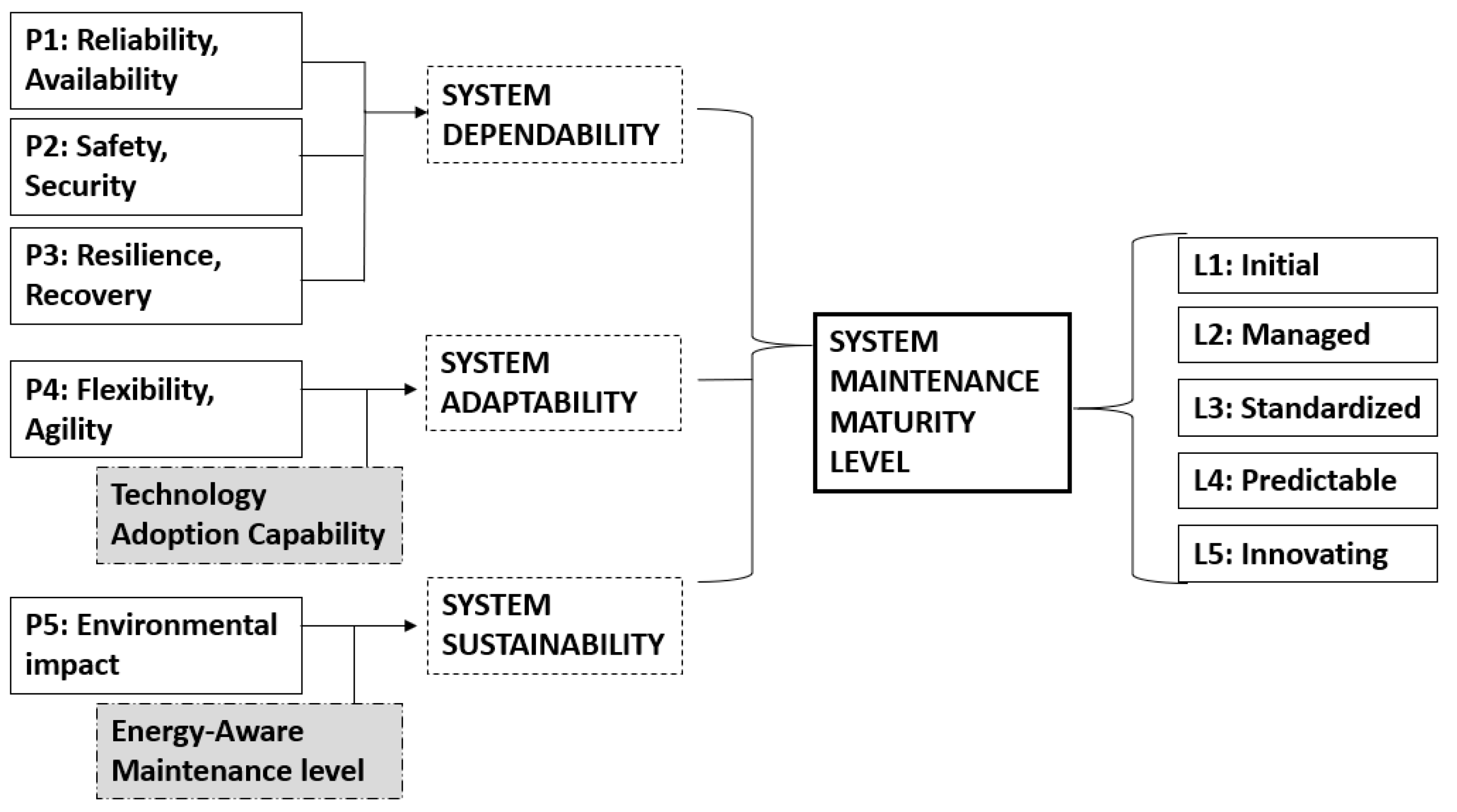

3.1. Conceptual Framework for IMMM

- Preventive barriers—safety and security potentials: representing the system’s first line of defense, this layer encompasses proactive maintenance strategies to anticipate and avoid failures before they occur. Examples include condition-based maintenance, safety inspections, digital diagnostics, and security protocols. These activities form the foundation of a resilient operation by enhancing predictability and reducing the likelihood of incidents, tightly coupling maintenance with reliability engineering and preventive risk management.

- Disruption mitigation barriers—resilience and recovery potentials: when disturbances do occur, this second layer enables the system to absorb shocks and quickly recover. Key mechanisms include contingency planning, emergency maintenance procedures, flexible resource allocation, workforce cross-training, and redundancy in critical components. Maintenance plays a central role here as an enabler of adaptive capacity, facilitating real-time decision-making, repair prioritization, and recovery orchestration without significant performance degradation.

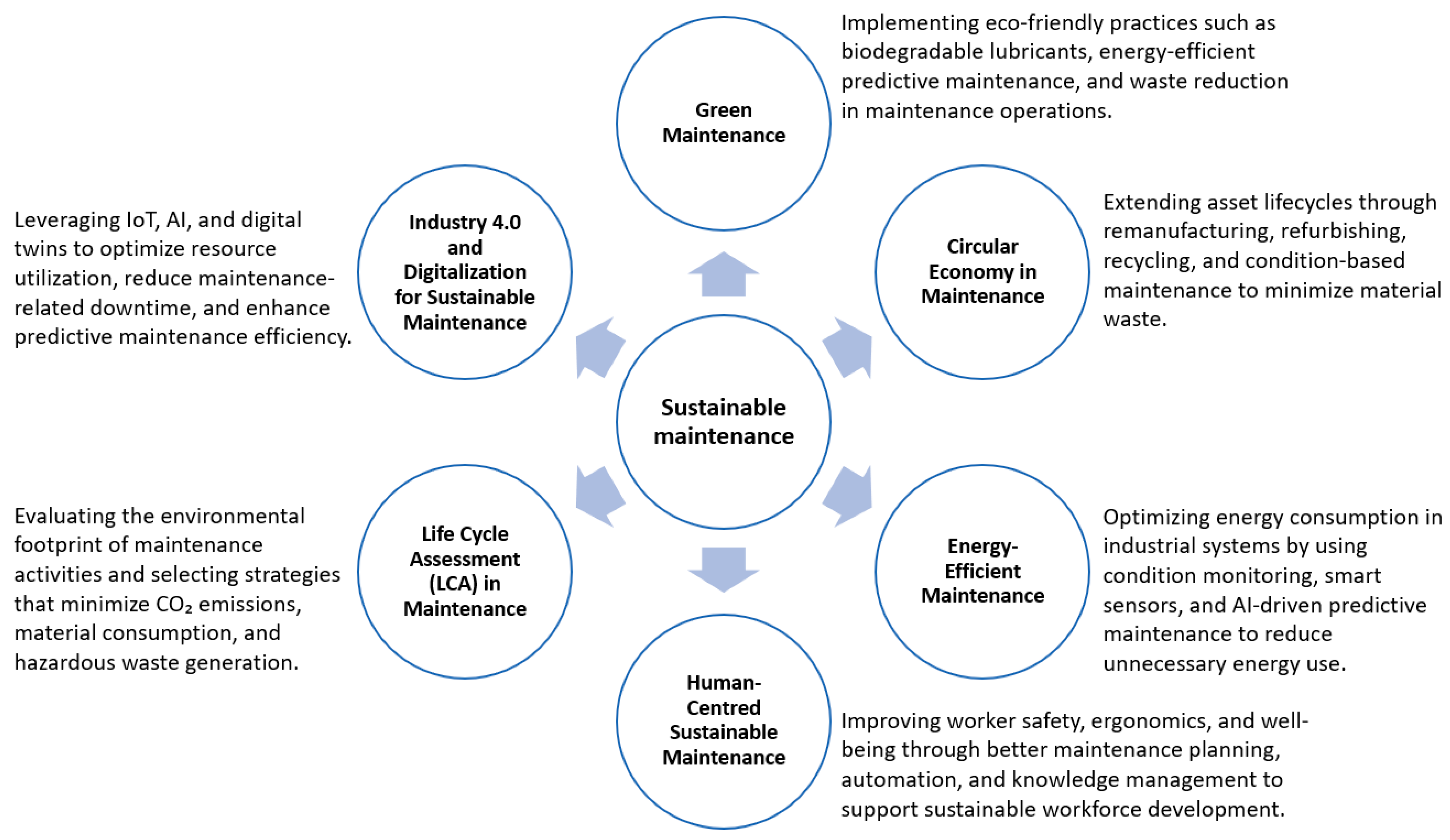

- Environmental disturbance mitigation barriers—sustainability potentials: the third layer embeds sustainability into maintenance practices, supporting the system’s long-term economic and ecological performance. Current analysis focuses primarily on energy and material usage, lifecycle extension, waste reduction, and circular economy principles. Due to data availability constraints, full life-cycle aspects of equipment, including procurement, decommissioning, and remanufacturing, are not directly assessed. Future research and model applications should integrate life-cycle assessment (LCA) metrics and circular economy indicators, such as remanufacturing rates or material recovery rates, to more comprehensively capture sustainability performance. Maintenance here acts as both an operational function and a strategic lever contributing to eco-efficiency, regulatory compliance, and alignment with ESG goals.

- Reliability and safety align with preventive barriers.

- Resilience and flexibility support disruption recovery and short-term adaptation.

- Sustainability addresses long-term environmental and resource concerns. It should be noted that the current quantitative assessment primarily focuses on energy consumption and carbon emissions. Due to limited operational data availability, a full life-cycle perspective, covering procurement, decommissioning, and remanufacturing, is not included. Future applications of the IMMM may incorporate life-cycle assessment (LCA) metrics or circular economy indicators, such as remanufacturing rates or material recovery rates, to more comprehensively evaluate sustainability performance.

- Technology Adoption Capability (TAC), introduced as an additional input to the System Adaptability dimension, reflects the organization’s capability to adopt, integrate, and scale new technologies (e.g., digital tools, automation, AI). While Flexibility/Agility (P4) measures operational adaptability in maintenance, Technology Adaptability captures the infrastructure and cultural readiness for change, thus ensuring a more comprehensive view of adaptive potential.

- Energy-Aware Maintenance level (EAML), added as a complementary input to the System Sustainability dimension, evaluates how effectively the organization incorporates energy efficiency considerations in its maintenance processes. This includes adopting energy-efficient technologies, scheduling maintenance in energy-optimized windows, and reducing energy consumption during maintenance activities. While Environmental Impact (P5) focuses on the outcome side (e.g., emissions, waste), EAML addresses the organization’s internal practices aimed at minimizing energy consumption, further strengthening the sustainability pillar from both operational and strategic perspectives.

3.2. Fuzzy Logic-Based Assessment Methodology

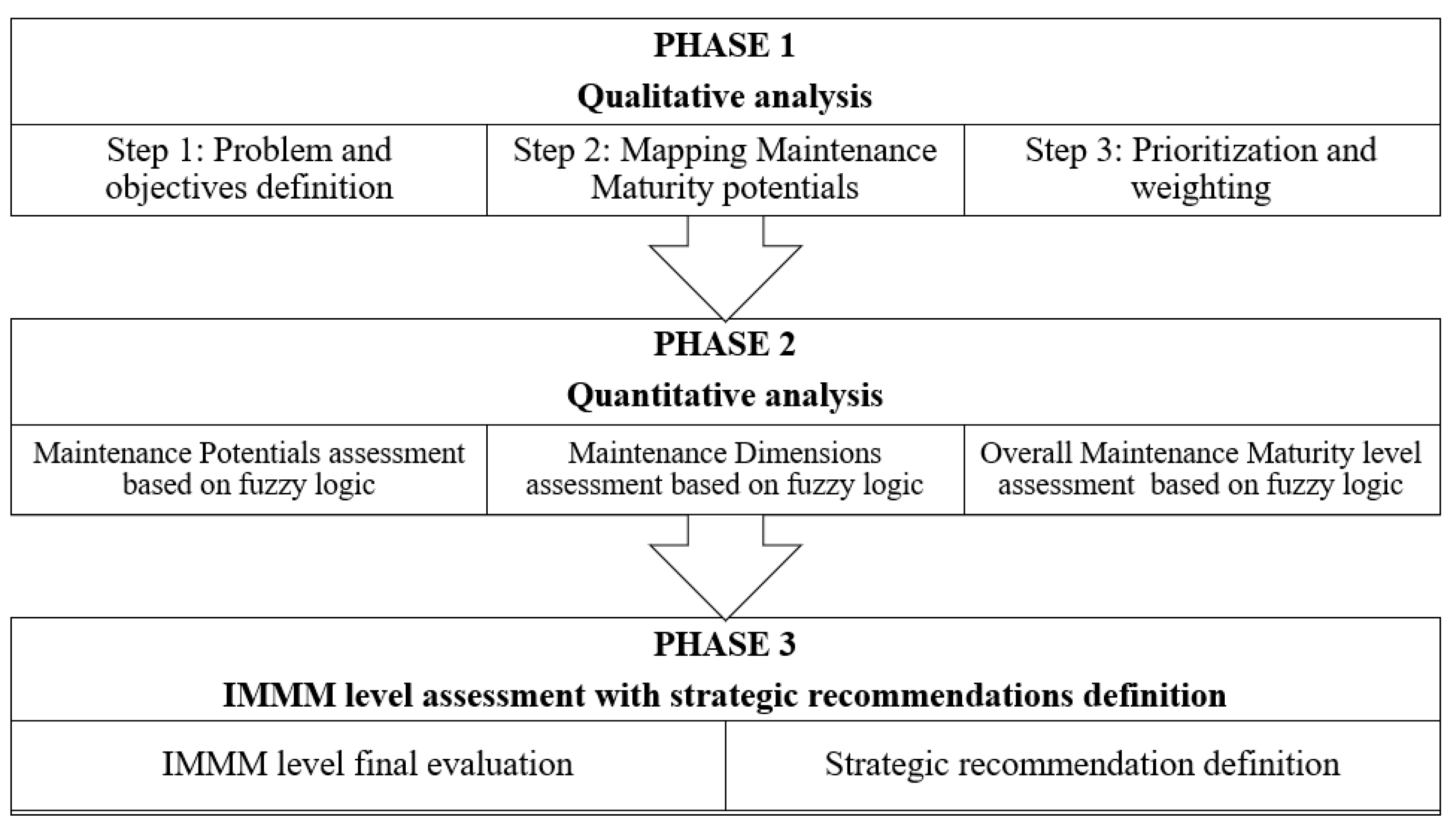

3.2.1. Qualitative Analysis—Identification and Structuring of Maintenance Maturity Potentials

- Step 1: Problem and objectives definition

- Step 2: Mapping Maintenance Maturity potentials (P1–P5)

- P1: Reliability and Availability—potential that captures the system’s ability to perform its required functions under stated conditions over a defined period.

- P2: Safety and Security—the dimension that protects personnel, assets, and data. It includes occupational health and safety performance, incident rates, risk mitigation strategies, and cybersecurity readiness in maintenance activities.

- P3: Resilience and Recovery—potential assesses the system’s ability to absorb disturbances, adapt to changing conditions, and recover quickly from failures or disruptions. It involves redundancy strategies, emergency procedures, and continuity plans.

- P4: Flexibility and Agility—a potential related to how quickly and efficiently the maintenance system can respond to internal and external changes, such as shifts in production priorities or unexpected breakdowns. It includes responsiveness, reconfigurability, and decision-making agility.

- P5: Environmental impact—potential that reflects the environmental and social responsibility of the maintenance system. It includes energy consumption, resource efficiency, waste reduction, and alignment with ESG (Environmental, Social, Governance) goals.

- Step 3: Prioritization and weighting

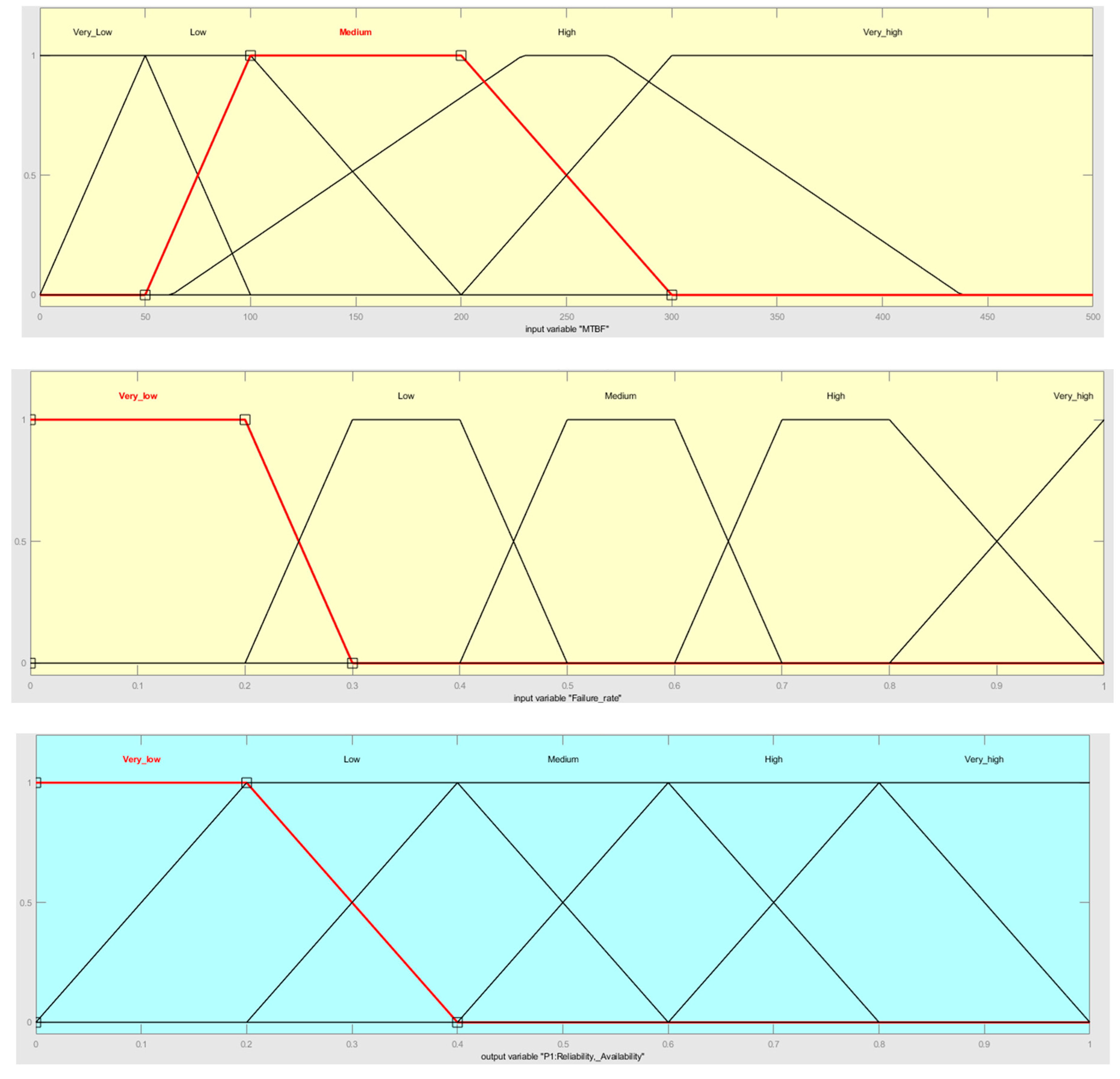

3.2.2. Qualitative Analysis—Expert Evaluation and Fuzzy Aggregation

- Fuzzification—Converts linguistic variables provided by experts into fuzzy numbers (in this case, TFNs), enabling a representation of values on a normalized scale from 0 to 1.

- Knowledge base—Comprises a set of IF-THEN rules and corresponding membership functions for each input indicator across the five maturity potentials (e.g., reliability, safety, resilience).

- Fuzzy Inference Mechanism (FIS)—Employs fuzzy logic operations to process the rules. Specifically, the MIN operator is used to model logical conjunctions and implications. In contrast, the MAX operator aggregates fuzzy results from multiple rules.

3.2.3. Integrated Maintenance Maturity Level Assessment with Strategic Recommendations Definition

4. Case Study

4.1. Qualitative Analysis

- Step 1: Problem and Objectives Definition

- Step 2: Mapping Maintenance Maturity Potentials (P1–P5)

- P1: Reliability and Availability: This potential reflects the company’s ability to ensure uninterrupted operation of production equipment through predictive maintenance, real-time condition monitoring, and optimization of preventive activities. The company’s reliance on high-precision machining and safety-critical assemblies makes uptime and reliability a top priority. Knowledge areas include reliability-centered maintenance (RCM), sensor-based diagnostics, and predictive analytics.

- P2: Safety and Security: Given the organization’s focus on safety-related components such as braking and stabilization systems, maintenance must ensure strict compliance with safety protocols for operators and end-products. This includes occupational safety, risk mitigation procedures, and cybersecurity readiness. Key knowledge areas include risk assessment methodologies, human–machine interface (HMI) safety, and maintenance cybersecurity protocols.

- P3: Resilience and Recovery: The company’s exposure to supply chain fluctuations and the complexity of its production setup demand high resilience. Quick recovery from breakdowns, availability of critical spares, and structured emergency procedures are essential. This potential includes knowledge areas such as failure mode analysis, recovery time optimization, and emergency scenario planning.

- P4: Flexibility and Agility: Due to high product diversity and changing client requirements, maintenance systems must be agile enough to adapt to evolving production schedules and machine configurations. The ability to shift resources quickly and adjust maintenance plans is critical. Related knowledge areas include modular maintenance planning, digital work order systems, agile resource scheduling.

- P5: Environmental impact: As the company aligns with global ESG objectives, it seeks to improve energy efficiency, minimize waste, and reduce emissions from maintenance activities. Efforts are made to integrate circular economy principles into equipment lifecycle management. Knowledge areas include energy monitoring systems, green maintenance practices, and environmental impact assessment.

- Step 3: Prioritization and Weighting

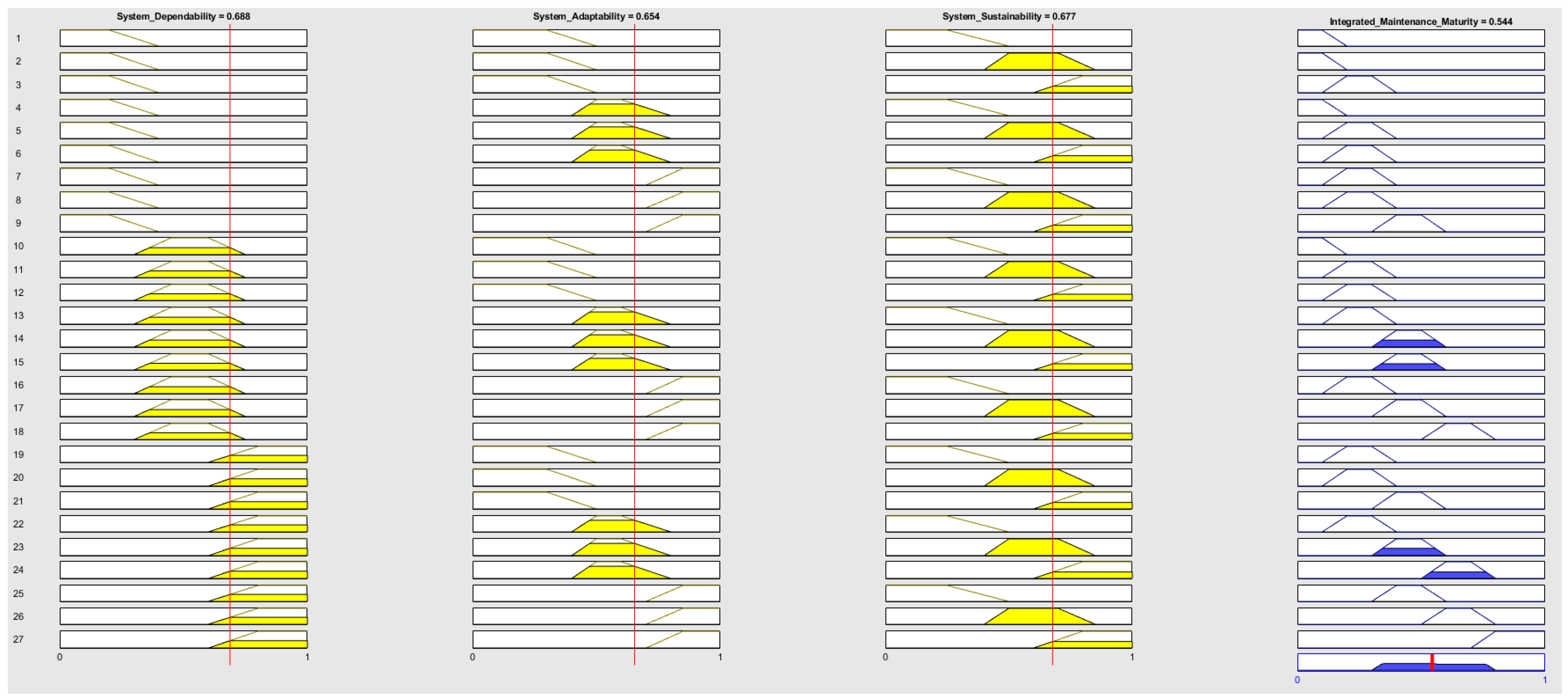

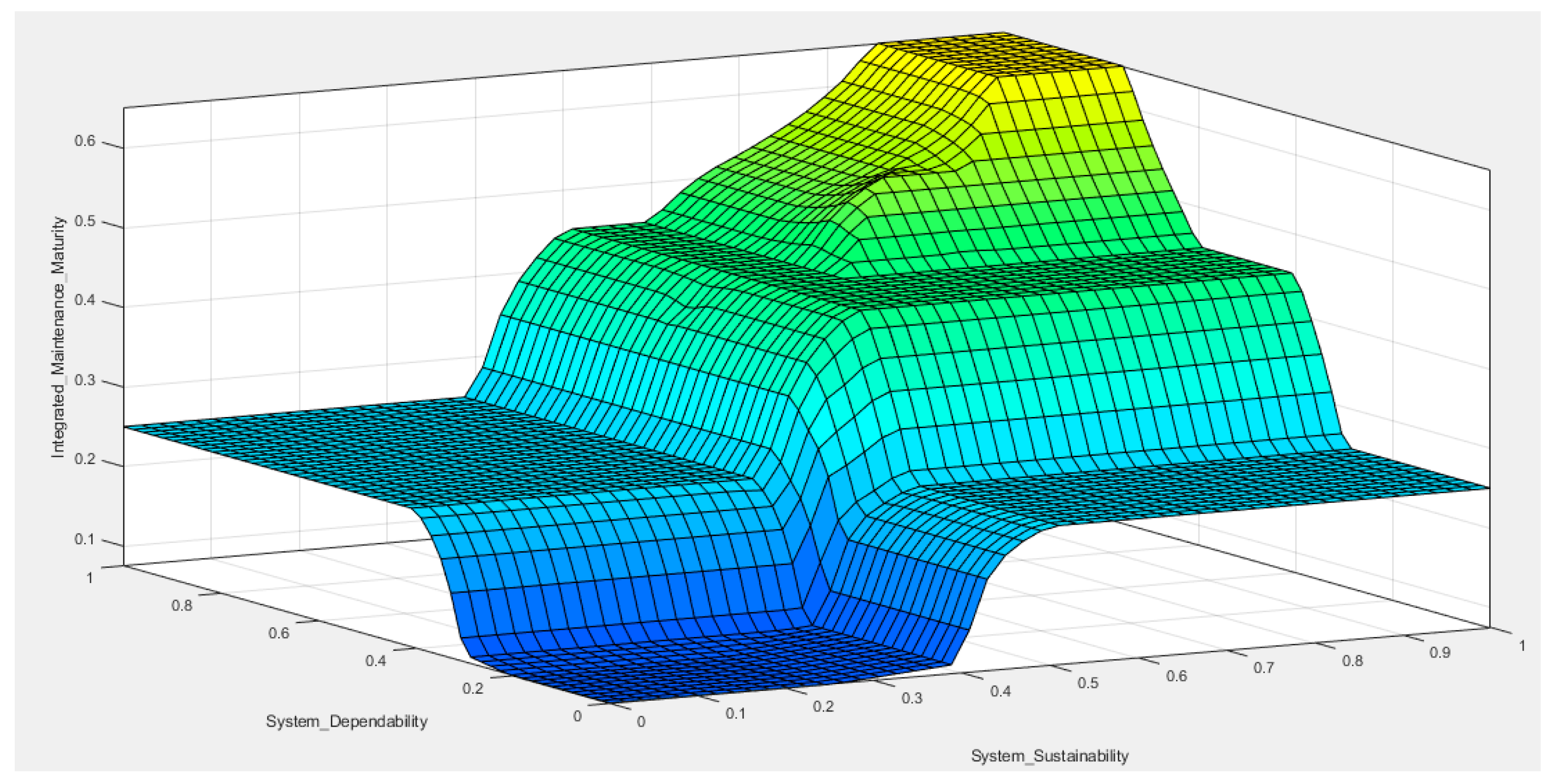

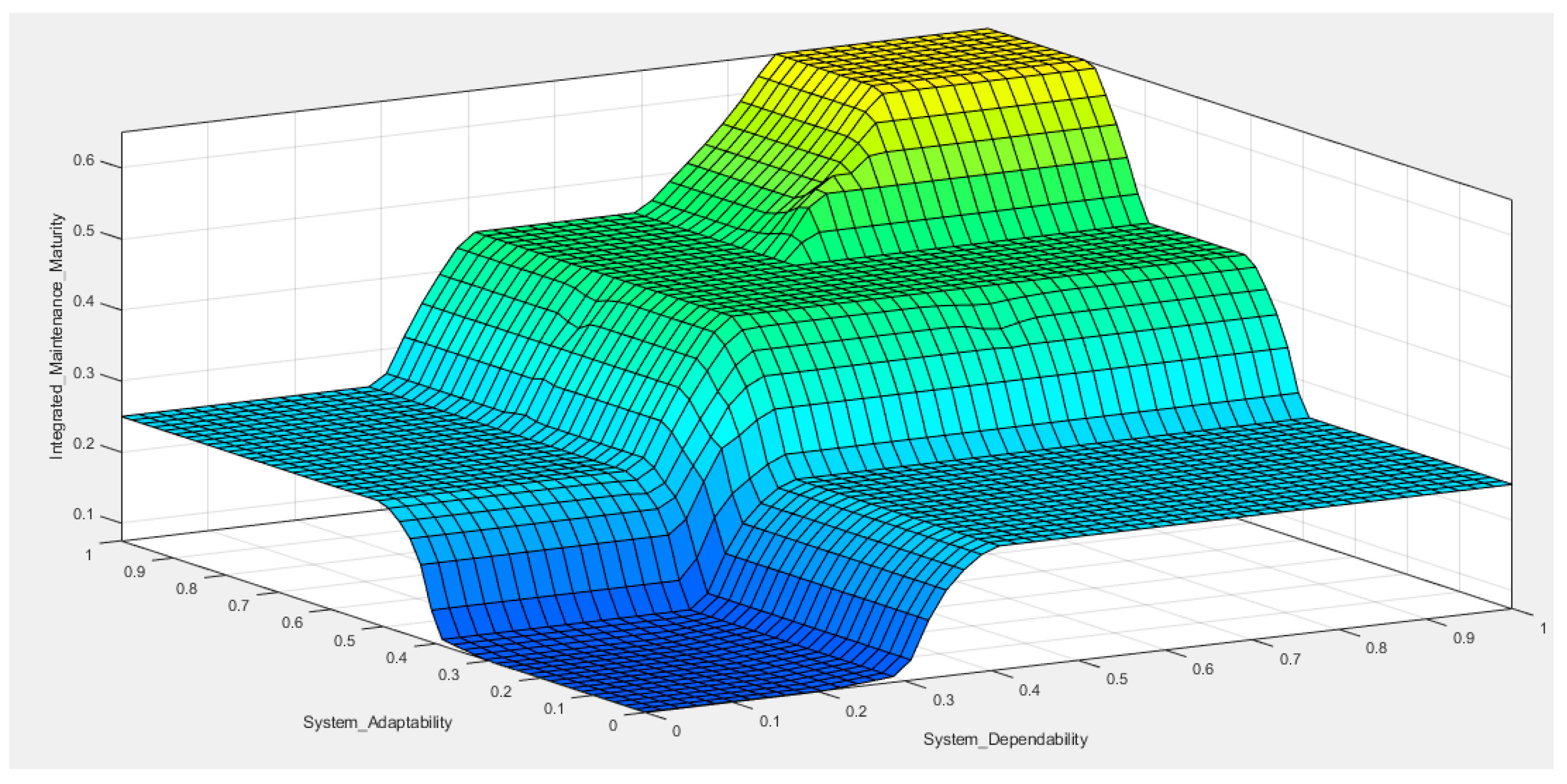

4.2. Quantitative Analysis

- At a basic level, L1 and L2 levels emphasize the presence or absence of System Dependability features (reliability, safety, resilience).

- L3 is reached when Dependability is standardized, and Adaptability begins to emerge systematically.

- L4 requires high Dependability complemented by proactive Adaptability and evolving Sustainability.

- L5 demands excellent performance across all three dimensions, where innovation and continuous improvement are embedded into maintenance practices.

- Rule P1.1 (sample):

- Rule P1.2 (sample):

- Rule SD.1 (sample):

- Rule IMM.1 (sample):

4.3. Integrated Maintenance Maturity Level Assessment and Definition of Strategic Recommendations for the Case Company

- Areas with the lowest maturity scores;

- Potentials of strategic relevance (e.g., safety, dependability, sustainability);

- Organizational availability in terms of resources, infrastructure, and change management capacity.

4.4. Comparative Analysis of Maintenance Maturity Frameworks and Case Study Evaluation

4.4.1. Conceptual Alignment of IMMM and ISO 55000

4.4.2. Comparative Case Study: IMMM vs. ISO 55000

- Quantitative assessment of maintenance performance and maturity potentials;

- Explicit inclusion of resilience, adaptability, and sustainability as measurable dimensions;

- Integration capability with CMMS, IoT, and digital twin systems for continuous maturity tracking;

- Compatibility with ISO 55000 governance principles, enabling dual implementation.

5. Results and Discussion

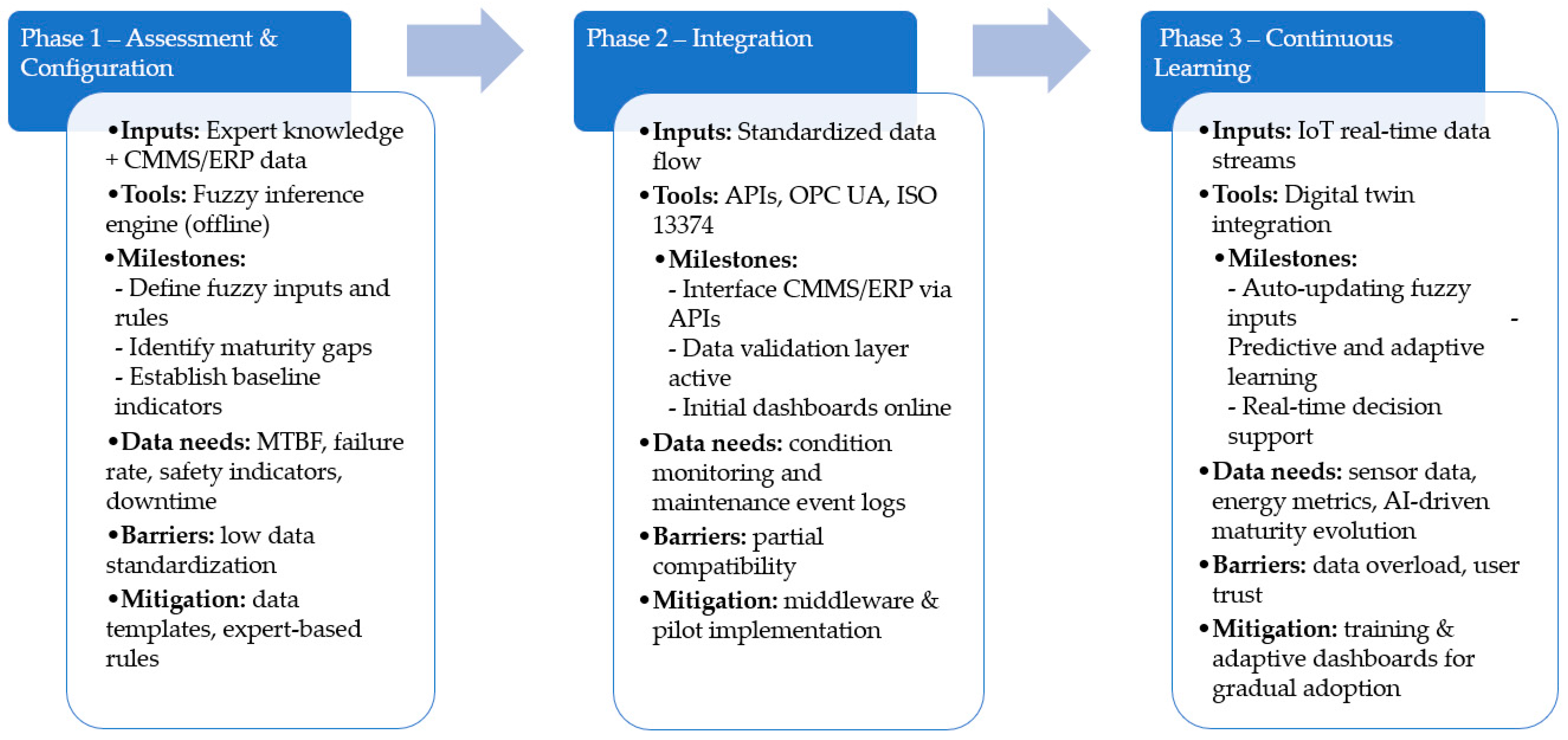

5.1. IMMM Integration Roadmap and Enterprise System Alignment

- Phase 1—Assessment and Configuration: Fuzzy inputs and rule bases are defined using available CMMS or ERP maintenance data together with expert evaluations. This step enables the identification of maturity gaps and the establishment of baseline indicators.

- Phase 2—Integration: IMMM outputs are connected to existing enterprise dashboards or digital twins, enabling real-time visualization of maturity indicators alongside performance metrics such as downtime, MTBF, and energy use. Integration can be achieved using standard data protocols (e.g., OPC UA).

- Phase 3—Continuous Monitoring and Learning: The IMMM is linked to IoT-enabled monitoring systems that update fuzzy inputs dynamically as new operational data become available. This phase supports adaptive maintenance management and continuous improvement under uncertainty.

5.2. Generalizability and Cross-Sectoral Applicability

- Universal Potentials: The five potentials (Reliability, Safety, Resilience, Flexibility, Sustainability) are strategic, top-level objectives essential to any asset-intensive industry (e.g., Energy, Logistics, Mining, and Manufacturing). For example, Resilience (P3) is equally critical for a power plant facing grid instability as it is for an automotive plant facing supply chain shocks.

- Flexible Implementation: The IMMM is agnostic to the underlying technical metrics (KPIs) used for data input. While a pharmaceutical plant might prioritize regulatory compliance data (feeding P2 and P5), a mining operation might prioritize machine utilization and hazard reporting (feeding P1 and P2). The fuzzy inference engine remains valid as long as the inputs accurately map to the linguistic variables (Low, Medium, High), regardless of the input data source (CMMS, MES, or expert opinion).

5.3. Model Scalability and Scaling Challenges

- Mechanism: When scaling down, the model relies on its core strength: expert-driven linguistic input. This flexibility directly addresses the problem of data scarcity, making the model highly practical for SMEs.

- Potential Problem: The main challenge when scaling down is the subjectivity bias of expert input. If the maintenance manager’s judgment is overly optimistic or lacks critical objectivity, the maturity score may be inflated.

- Mitigation: This is mitigated by the structured multidimensionality of the IMMM and its clear rule base, which forces experts to assess distinct potentials based on defined criteria, increasing accountability and transparency compared to single-dimensional checklist models.

- Mechanism: When scaling up to large corporations (like the one in the case study), the model seamlessly integrates with Big Data streams from CMMS/EAM systems. Fuzzification simply becomes the process of converting complex, precise KPIs (e.g., MTBF = 450 h) into the required linguistic variables (High).

- Potential Problem: The primary challenge is computational complexity and system integration overhead. As the number of input variables and the size of the rule base grow (to account for increasing complexity at Maturity Levels 4 and 5), the computational load of the fuzzy inference system increases.

- Mitigation: This is managed by implementing the IMMM fuzzy core as a dedicated, decoupled software layer (as detailed in Section 5.2) that operates independently from legacy ERP/CMMS systems, ensuring that performance bottlenecks are isolated and minimized. Furthermore, the hierarchical structure of the IMMM limits the exponential growth of the rule base by grouping lower-level indicators under five main potentials, ensuring computational efficiency.

5.4. Prescriptive Findings and Strategic Guidance

- The organization has achieved a moderate level of dependability and sustainability, but its adaptability is somewhat lacking, suggesting that further work is needed in integrating adaptive systems and processes.

- There is a need for more robust predictive maintenance strategies to ensure better forecasting of disruptions and to develop proactive measures to mitigate their impact.

- The current maintenance practices could be enhanced by focusing more on sustainability and environmental impact, which could further increase the overall system resilience.

- Strengthen adaptability: Implement systems that enhance the organization’s ability to adapt to changing conditions and disruptions. This could include improving response times to changes in operational conditions and investing in flexible maintenance processes.

- Focus on sustainability: Integrate more sustainable practices into maintenance activities, such as reducing energy consumption, minimizing waste, and increasing resource efficiency.

- Develop predictive maintenance capabilities: Enhance forecasting and predictive maintenance capabilities to improve readiness for potential failures and reduce unplanned downtime.

- Improve system dependability: Further develop the organization’s maintenance practices to improve reliability and uptime. This can be achieved by enhancing preventive maintenance strategies and ensuring that spare parts and resources are available when needed.

5.5. Methodological Limitations and Applicability

6. Conclusions and Future Research Directions

- Indicator reduction: SMEs can initially prioritize the fundamental dimensions, such as P1: Reliability/Availability and P2: Safety/Compliance, while temporarily excluding advanced indicators related to complex Predictive Analytics (Level 4/5) until their underlying processes mature. The fuzzy structure remains functional even with a reduced set of critical inputs.

- Expert-driven data collection: In a data-scarce environment, all input variables can be sourced entirely from structured interviews with a limited number of subject matter experts (SMEs), rather than relying on automated data streams. This eliminates the heavy investment required for IoT sensors or full-scale CMMS implementation, providing a low-cost, high-value diagnostic tool for small businesses to start their maintenance improvement journey.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AHP | Analytic Hierarchy Process |

| AI | Artificial Intelligence |

| AMMM | Asset Maintenance Maturity Model |

| ANFIS | Adaptive Neuro-Fuzzy Inference Systems |

| ANP | Analytic Network Process |

| API | Application Programming Interface |

| BWM | the Best-Worst Method |

| CBM | Condition-based Maintenance |

| CMMS | Computerized Maintenance Management System |

| CSR | Corporate Social Responsibility |

| DEMATEL | DEcision-Making Trial and EVALuation Lab |

| EAM | Enterprise Asset Management |

| EAML | Energy-Aware Maintenance level |

| ERP | Enterprise Resource Planning |

| ESG | Environmental, Social, and Governance |

| FIS | Fuzzy Interference System |

| FMEA | Failure Mode and Effect Analysis |

| FMMR | Fuzzy Maintenance Maturity Rating |

| HMI | Human–Machine Interface |

| IMMM | Integrated Maintenance Maturity Model |

| IoT | Internet of Things |

| IT | Information Technology |

| KPIs | Key Performance Indicators |

| LCA | Life Cycle Assessment |

| MAD | Mean Absolute Deviation |

| MES | Manufacturing Execution System |

| MFs | Membership functions |

| ML | Machine Learning |

| MMMs | Maintenance Maturity Models |

| M-SCOR | Maintenance Supply Chain Operations Reference |

| MTBF | Mean Time Between Failures |

| MTTR | Mean Time To Recovery |

| OPC UA | Open Platform Communications Unified Architecture |

| PCA | Principal Component Analysis |

| PM | Preventive Maintenance |

| PROMETHEE | Preferences Ranking Organisation Method for Enrichment Evaluation |

| RCA | Root Cause Analysis |

| RCM | Reliability-Centered Maintenance |

| RESTful | REpresentational State Transfer |

| RTO | Recovery Time Objective |

| SMEs | Small and Medium Enterprises |

| TAC | Technology Adoption Capability |

| TFNs | Triangular Fuzzy Numbers |

| TOPSIS | Technique for Order Preference by Similarity to an Ideal Solution |

| TPM | Total Productive Maintenance |

| TRIR | Total Recordable Incident Rate |

Appendix A

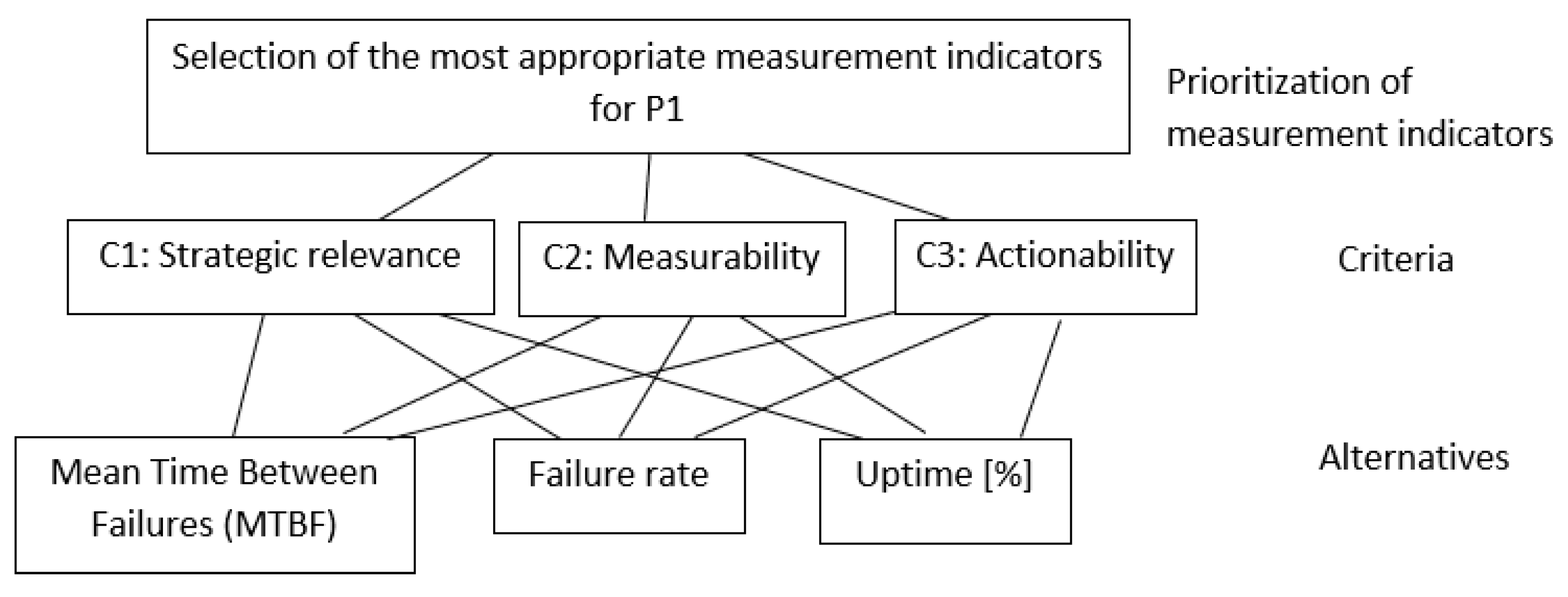

Appendix A.1. AHP-Based Prioritization of Measurement Indicators for P1: Reliability and Availability

- Step 1: Hierarchical Structure Definition

- Step 2: Pairwise Comparisons and Judgement Matrices

| C1 | C2 | C3 | |

| C1 | 1 | 2 | 3 |

| C2 | 1/2 | 1 | 2 |

| C3 | 1/3 | 1/2 | 1 |

- C1 (Strategic relevance): 0.54

- C2 (Measurability): 0.29

- C3 (Actionability): 0.17

| I1 | I2 | I3 | |

| I1 | 1 | 2 | 3 |

| I2 | 1/2 | 1 | 2 |

| I3 | 1/3 | 1/2 | 1 |

- Under C1: I1: 0.54, I2: 0.29, I3: 0.17

- Under C2: I1: 0.30, I2: 0.50, I3: 0.20

- Under C3: I1: 0.40, I2: 0.30, I3: 0.30

- Step 3: Synthesis of Priorities

- I1 (MTBF): 0.4716

- I2 (Failure rate): 0.3511

- I3 (Uptime [%]): 0.1773

- Step 4: Consistency Check

- Step 5: Result Interpretation

- MTBF (Mean Time Between Failures)—most relevant indicator due to its strategic alignment and strong predictive capability in reliability assessment

- Failure rate—valuable for short-term monitoring and reactive decision-making

- Uptime [%]—useful as a general performance indicator but less actionable and specific for reliability engineering.

Appendix A.2. Linguistic Variables for Maintenance Maturity Potentials P2–P5 and Two Input Variables: Technology Adaptability and Resource Efficiency

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Very Low (VL) | System exhibits poor safety and security performance. Frequent safety incidents and very low compliance with safety standards. | [0, 0, 0.4, 0.6] |

| Low (L) | System has below-average safety and security performance. Noticeable safety events occur, and compliance is insufficient. | [0.4, 0.6, 0.7, 0.8] |

| Medium (M) | System shows moderate safety and security performance. Some incidents occur, but basic compliance is maintained. | [0.6, 0.75, 0.85, 0.9] |

| High (H) | System is mostly safe and secure with rare events. Compliance is high, and safety culture is effective. | [0.8, 0.9, 0.95, 0.98] |

| Very High (VH) | System achieves excellent safety and security. Virtually no incidents; compliance is near-perfect or perfect. | [0.95, 0.98, 1.0, 1.0] |

| Number of Safety Events | ||

|---|---|---|

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very High (VH) | The number of safety events is extremely high. The system is unsafe, with frequent accidents, near misses, or violations, indicating severe safety management deficiencies. | [20, 25, 30, 30] |

| High (H) | The number of safety events is above acceptable levels, suggesting elevated risk. There are recurring safety incidents, requiring urgent attention. | [15, 18, 22, 26] |

| Medium (M) | A moderate number of events occur. Some incidents happen, but they are not severe or systemic. Safety practices are partially effective. | [8, 12, 15, 18] |

| Low (L) | Few safety events occur. The system generally performs safely, with only minor, isolated cases. | [3, 5, 8, 12] |

| Very Low (VL) | The number of safety events is negligible or zero. The system is highly safe, with proactive safety culture and strong incident prevention. | [0, 0, 2, 4] |

| Safety Compliance Rate (%) | ||

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very Low (VL) | Compliance with safety standards is critically low (<40%). The system neglects essential safety protocols, and non-conformities are common. | [0, 0, 30, 40] |

| Low (L) | The system meets some safety requirements but still shows significant gaps. Compliance is insufficient for safe operations. | [30, 45, 55, 65] |

| Medium (M) | The system shows average compliance (~60–80%). Most safety regulations are followed, but occasional lapses or documentation issues persist. | [60, 70, 80, 90] |

| High (H) | The system generally complies with safety rules (>80%), and audits confirm adherence, with only minor corrective actions needed. | [80, 90, 95, 98] |

| Very High (VH) | Compliance is near perfect (≥95%). All safety protocols are well documented, implemented, and verified. Audits show full conformance. | [95, 98, 100, 100] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Very Low (VL) | System has extremely poor resilience and recovery capabilities. Failures cause prolonged downtime and critical disruptions. | [0, 0, 0.2, 0.4] |

| Low (L) | System shows below-average resilience. Recovery after failure is slow and resource-intensive. | [0.2, 0.4, 0.5, 0.6] |

| Medium (M) | System demonstrates moderate resilience. Some failures cause moderate downtime, but recovery processes exist. | [0.4, 0.5, 0.7, 0.8] |

| High (H) | System is resilient, with quick and effective recovery from failures. | [0.6, 0.7, 0.85, 0.95] |

| Very High (VH) | System has excellent resilience. Failures have minimal impact, and recovery is almost immediate. | [0.85, 0.95, 1.0, 1.0] |

| Mean Time to Recovery (MTTR) | ||

|---|---|---|

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very High (VH) | Recovery is extremely slow. The system takes a very long time to resume operation after a failure, indicating poor recovery capacity and low resilience. | [16, 20, 30, 30] |

| High (H) | Recovery is slow. Although the system eventually resumes operations, the delays are significant and impact availability. | [10, 14, 18, 22] |

| Medium (M) | Recovery time is moderate. The system shows acceptable ability to bounce back, though there may be room for improvement. | [5, 8, 12, 16] |

| Low (L) | Recovery is fast. The system resumes operation relatively quickly, minimizing downtime and maintaining workflow. | [2, 4, 6, 10] |

| Very Low (VL) | Recovery is immediate or near-immediate. The system demonstrates excellent resilience and quick restoration of function. | [0, 0, 2, 4] |

| Downtime After Failure | ||

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very High (VH) | The downtime after failure is very long, causing major disruptions. The system lacks robustness and flexibility to continue or quickly resume operations. | [12, 16, 20, 24] |

| High (H) | Downtime is extended. Failures result in substantial operational delays and indicate inefficient recovery procedures. | [8, 12, 16, 20] |

| Medium (M) | Downtime is moderate. Failures cause noticeable, but not critical, delays. System resilience is average. | [4, 6, 10, 14] |

| Low (L) | Downtime is short. The system recovers efficiently, and the impact of failures is limited. | [1, 2, 4, 6] |

| Very Low (VL) | Downtime is minimal or nonexistent. The system is highly resilient, with redundancy or quick recovery strategies that mitigate failure effects. | [0, 0, 1, 2] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Very Low (VL) | System is extremely rigid. It reacts very slowly or not at all to changes. Adaptation to new conditions is ineffective or absent, often leading to severe delays and inefficiencies. | [0, 0, 0.2, 0.4] |

| Low (L) | System shows low agility. Changes are possible but require significant effort and time. Reconfigurations are rarely seamless and often disrupt workflow. | [0.2, 0.4, 0.5, 0.6] |

| Medium (M) | System has moderate flexibility. It can adapt to changes with a reasonable degree of effort. Adjustments are usually planned but not immediate. | [0.4, 0.5, 0.7, 0.8] |

| High (H) | System is agile and responsive. It adjusts rapidly to new requirements, allowing reconfiguration with minimal delay and overhead. | [0.6, 0.7, 0.85, 0.95] |

| Very High (VH) | System is extremely flexible and agile. It responds to changes immediately and effortlessly, maintaining continuity and performance even under dynamic conditions. | [0.85, 0.95, 1.0, 1.0] |

| Response Time to Changes | ||

|---|---|---|

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very High (VH) | The system reacts very slowly to changes. It may take weeks to adjust processes, technologies, or workforce. This indicates very low agility. | [10, 15, 20, 25] |

| High (H) | Response to changes is slow. Adjustments require significant planning and time, which affects operational flexibility. | [7, 10, 14, 18] |

| Medium (M) | The system adapts at a moderate speed. Response to change is adequate, but still leaves room for optimization. | [3, 5, 8, 12] |

| Low (L) | The system reacts quickly to changes. Minor disruptions occur, but the organization adapts with relative ease. | [1, 2, 4, 6] |

| Very Low (VL) | The system responds almost immediately. It is highly flexible and agile, with structures in place to absorb and implement changes quickly. | [0, 0, 1, 2] |

| Maintenance Agility Index | ||

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very High (VH) | Maintenance processes are rigid and highly reactive. The system struggles to plan or execute changes efficiently. | [0.0, 0.0, 0.2, 0.3] |

| High (H) | Maintenance exhibits limited agility. There is some capability to respond to change, but it’s slow and inefficient. | [0.2, 0.3, 0.4, 0.5] |

| Medium (M) | Maintenance agility is moderate. The system can handle change with some effort, showing both planned and reactive elements. | [0.4, 0.5, 0.6, 0.7] |

| Low (L) | Maintenance teams are agile. They respond quickly to changes and implement adaptations effectively with minimal delay. | [0.6, 0.7, 0.8, 0.9] |

| Very Low (VL) | Maintenance processes are highly agile and proactive. The system anticipates changes and reacts seamlessly with minimal impact on operations. | [0.8, 0.9, 1.0, 1.0] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Very Low (VL) | The system operates with minimal environmental awareness. Emissions and waste are poorly managed, and no environmental goals are pursued. System lacks environmental control | [0.0, 0.0, 0.2, 0.3] |

| Low (L) | Some basic environmental controls exist, but performance remains below acceptable levels. Limited tracking of environmental indicators. | [0.25, 0.35, 0.45, 0.55] |

| Medium (M) | Environmental performance is average. The system complies with basic standards, but lacks proactive strategies. | [0.50, 0.60, 0.70, 0.78] |

| High (H) | The system demonstrates good environmental stewardship. Emissions and waste are actively monitored and reduced. | [0.75, 0.82, 0.90, 0.95] |

| Very High (VH) | The system achieves excellent environmental performance. Operations are optimized for sustainability with near-zero environmental footprint. | [0.90, 0.95, 1.00, 1.00] |

| Carbon Emissions from Maintenance Activities | ||

|---|---|---|

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very High (VH) | Maintenance generates extremely high CO2 emissions, indicating unsustainable practices and high environmental burden. | [350, 400, 500, 600] |

| High (H) | Emissions are high, suggesting inefficient practices, frequent energy-intensive repairs, or lack of green planning. | [250, 300, 400, 500] |

| Medium (M) | Emissions are at a moderate level. Some sustainable efforts are visible, but there’s room for optimization. | [150, 200, 300, 400] |

| Low (L) | Maintenance activities are relatively efficient with low carbon impact due to optimized processes and energy-conscious actions. | [50, 100, 150, 200] |

| Very Low (VL) | The system is extremely environmentally friendly. Emissions are minimal, indicating use of green technologies and preventive strategies. | [0, 0, 50, 100] |

| Resource Efficiency Index | ||

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very Low (VL) | The system wastes significant resources. Processes are inefficient, leading to overuse of materials, energy, and time. | [0.0, 0.0, 0.2, 0.3] |

| Low (L) | Some efficiency exists, but many processes still consume excess resources or produce waste. | [0.2, 0.3, 0.4, 0.5] |

| Medium (M) | Resource use is moderate. The system makes some effort to optimize but lacks full integration of sustainable practices. | [0.4, 0.5, 0.6, 0.7] |

| High (H) | The system uses resources effectively with minimal waste. It shows conscious management and lean operations. | [0.6, 0.7, 0.8, 0.9] |

| Very High (VH) | Resource efficiency is excellent. Operations are highly optimized, eco-friendly, and sustainable. | [0.8, 0.9, 1.0, 1.0] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Very Low (VL) | System is extremely resistant to the adoption or integration of new technologies. Updates are rare, legacy systems dominate, and digital transformation is absent. | [0, 0, 0.2, 0.4] |

| Low (L) | System has limited ability to adapt to technological change. New tools and solutions are adopted slowly and often with significant implementation issues. | [0.2, 0.4, 0.5, 0.6] |

| Medium (M) | System shows moderate adaptability to new technologies. Adoption occurs gradually with some integration effort and moderate efficiency. | [0.4, 0.5, 0.7, 0.8] |

| High (H) | System effectively adopts and integrates new technologies. Transition processes are well-managed, and digital tools are used proficiently. | [0.6, 0.7, 0.85, 0.95] |

| Very High (VH) | System is fully adaptive to new technologies. Innovations are rapidly absorbed, enabling cutting-edge performance and seamless digital evolution. | [0.85, 0.95, 1.0, 1.0] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Very Low (VL) | Energy awareness in maintenance is practically non-existent. There is no energy-saving policy, no actions aimed at minimizing energy consumption. Old, energy-intensive equipment is used, and maintenance schedules do not consider energy optimization. | [0, 0, 0.1, 0.3] |

| Low (L) | The organization takes small steps toward energy savings in maintenance, but these efforts are sporadic and incomplete. Inefficient equipment may still be in operation, and maintenance schedules are only partially optimized. | [0.1, 0.3, 0.4, 0.6] |

| Medium (M) | Maintenance activities demonstrate a moderate level of energy awareness. The organization plans maintenance in an energy-conscious manner, and some equipment and processes have been modernized to improve energy efficiency. Energy consumption is monitored, but significant improvements are still possible. | [0.3, 0.5, 0.6, 0.8] |

| High (H) | The organization has a well-developed energy-saving policy within maintenance management. Modern, energy-efficient technologies are applied. Maintenance schedules are well optimized, and energy consumption is regularly monitored and controlled. | [0.6, 0.7, 0.8, 0.9] |

| Very High (VH) | The organization has a comprehensive energy-saving strategy, using state-of-the-art technologies and methods to minimize energy use. Energy-efficient equipment is employed, maintenance schedules are fully optimized, and regular energy consumption analyses are conducted, ensuring minimal environmental impact. | [0.8, 0.9, 1.0, 1.0] |

References

- Oliveira, M.A.; Lopes, I.; Figueiredo, D.L. Maintenance Management Proposal Based on Organization Maturity Level. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Istanbul, Turkey, 3–6 July 2012; p. ID328.1-10. [Google Scholar]

- Werbińska-Wojciechowska, S.; Winiarska, K. Maintenance Performance in the Age of Industry 4.0: A Bibliometric Performance Analysis and a Systematic Literature Review. Sensors 2023, 23, 1409. [Google Scholar] [CrossRef]

- Chemweno, P.; Pintelon, L.; Van Horenbeek, A.; Muchiri, P.N. Asset Maintenance Maturity Model: Structured Guide to Maintenance Process Maturity. Int. J. Strateg. Eng. Asset Manag. 2015, 2, 119. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Introna, V.; Santolamazza, A.; Cesarotti, V. Maintenance Transformation through Industry 4.0 Technologies: A Systematic Literature Review. Comput. Ind. 2020, 123, 103335. [Google Scholar] [CrossRef]

- Bukowski, L.A. Cognitive Dependability Engineering: Managing Risks in Cyber-Physical-Social Systems Under Deep Uncertainty; CRC Press: Boca Raton, FL, USA, 2023; ISBN 9781000919004. [Google Scholar]

- Bukowski, L.; Werbińska-Wojciechowska, S. Using Fuzzy Logic to Support Maintenance Decisions According to Resilience-Based Maintenance Concept. Eksploat. Niezawodn. Maint. Reliab. 2021, 23, 294–307. [Google Scholar] [CrossRef]

- Mollentze, F.J. Asset Management Auditing—The Roadmap to Asset Management Excellence; University of Pretoria: Pretoria, South Africa, 2005. [Google Scholar]

- Moerman, J.; Braaksma, J.; Van Dongen, L. Resilient Performance in Maintenance Operations: Managing Unexpected Failures. In Proceedings of the Event 24th International Annual EurOMA Conference 2017: Inspiring Operations Management, Edinburgh, UK, 1–5 July 2017; pp. 1–10. [Google Scholar]

- Okoh, P.; Haugen, S. Improving the Robustness and Resilience Properties of Maintenance. Process Saf. Environ. Prot. 2015, 94, 212–226. [Google Scholar] [CrossRef]

- Abdul-Nour, G.; Gauthier, F.; Diallo, I.; Komljenovic, D.; Vaillancourt, R.; Côté, A. Development of a Resilience Management Framework Adapted to Complex Asset Systems: Hydro-Québec Research Chair on Asset Management. In 14th WCEAM Proceedings, Proceedings of the 14th World Congress on Engineering Asset Management (WCEAM), Singapore, 28–31 July 2019; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2021; pp. 126–136. [Google Scholar] [CrossRef]

- Tazi, D.; Amalberti, R. Resilience of Maintenance Organization in a Refining Plant. In Proceedings of the Second Resilience Engineering Symposium, Antibes-Juan-les-Pins, France, 8–10 November 2006; Ecole des mines de Paris: Paris, France; 2006. [Google Scholar]

- Sun, H.; Yang, M.; Wang, H. Resilience-Based Approach to Maintenance Asset and Operational Cost Planning. Process Saf. Environ. Prot. 2022, 162, 987–997. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Voisin, A.; Franciosi, C.; Roda, I.; Bocewicz, G. Recent Advances in Smart and Sustainable Maintenance. In Proceedings of the 10th International Federation of Automatic Control (IFAC) Conference, Austin, TX, USA, 24–27 October 2021; p. 2021. [Google Scholar]

- Franciosi, C.; Roda, I.; Voisin, A.; Miranda, S.; Franciosi, C.; Roda, I.; Voisin, A.; Miranda, S.; Macchi, M. Sustainable Maintenance Performances and EN 15341:2019: An Integration Proposal. In Proceedings of the FIP International Conference on Advances in Production Management Systems, APMS 2021, Nantes, France, 5–9 September 2021; pp. 401–409. [Google Scholar]

- Cox, R.A.; Nielsen, S.B. Sustainable Resilience in Property Maintenance: Encountering Changing Weather Conditions. In Proceedings of the CIB Facilities Management Conference, Denmark, Copenhagen, 21–23 May 2014; pp. 329–339. [Google Scholar]

- Sandu, G.; Varganova, O.; Samii, B. Managing Physical Assets: A Systematic Review and a Sustainable Perspective. Int. J. Prod. Res. 2023, 61, 6652–6674. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Gola, A. Maintenance 4.0 Technologies for Sustainable Manufacturing–An Overview. IFAC-PapersOnLine 2019, 52, 91–96. [Google Scholar] [CrossRef]

- Sagharidooz, M.; Soltanali, H.; Farinha, J.T.; Raposo, H.D.N.; de-Almeida-e-Pais, J.E. Reliability, Availability, and Maintainability Assessment-Based Sustainability-Informed Maintenance Optimization in Power Transmission Networks. Sustainability 2024, 16, 6489. [Google Scholar] [CrossRef]

- Briatore, F.; Braggio, M. Resilience and Sustainability Plants Improvement through Maintenance 4.0: IoT, Digital Twin and CPS Framework and Implementation Roadmap. IFAC-PapersOnLine 2024, 58, 365–370. [Google Scholar] [CrossRef]

- Wireman, T. Benchmarking Best Practices for Maintenance, Reliability and Asset Management; Industrial Press: New York, NY, USA, 2015; ISBN 2013206534. [Google Scholar]

- Deepak Prabhakar, P.; Jagathy Raj, V.P. CBM, TPM, RCM and A-RCM—A Qualitative Comparison of Maintenance Management Strategies. Int. J. Manag. Bus. Stud. 2014, 4, 49–56. [Google Scholar]

- Helgesson, Y.Y.L.; Host, M.; Weyns, K. A Review of Methods for Evaluation and Maturity Models for Process Improvement. J. Softw. Maint. Evol. Res. Pract. 2012, 24, 436–454. [Google Scholar] [CrossRef]

- Tubis, A.A.; Werbińska-Wojciechowska, S. Risk Management Maturity Model for Logistic Processes. Sustainability 2021, 13, 659. [Google Scholar] [CrossRef]

- Bukowski, L.; Werbinska-Wojciechowska, S. Towards Maintenance 5.0: Resilience-Based Maintenance in AI-Driven Sustainable and Human-Centric Industrial Systems. Sensors 2025, 25, 5100. [Google Scholar] [CrossRef]

- Hauge, B.S.; Mercier, B.A. Reliability Centered Maintenance Maturity Level Roadmap. In Proceedings of the Annual Reliability and Maintainability Symposium, Tampa, FL, USA, 27–30 January 2003; pp. 226–231. [Google Scholar] [CrossRef]

- Alidrisi, H. Maintenance Maturity Level Identification Using MABAC Method: An Adaptation of TPM Pillars in a Public Service Sector. J. Sci. Ind. Res. 2020, 79, 914–917. [Google Scholar] [CrossRef]

- Albliwi, S.A.; Antony, J.; Arshed, N. Critical Literature Review on Maturity Models for Business Process Excellence. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor, Malaysia, 9–12 December 2014; pp. 79–83. [Google Scholar] [CrossRef]

- Hollnagel, E. Safety-II in Practice: Developing the Resilience Potentials; Routledge, Taylor & Francis Group: London, UK; New York, NY, USA, 2018; ISBN 9781138708921. [Google Scholar]

- Hollnagel, E. Resilience Engineering: A New Understanding of Safety. J. Ergon. Soc. Korea 2016, 35, 185–191. [Google Scholar] [CrossRef]

- Durán, O.; Vergara, B. Maintenance Strategies Definition Based on Systemic Resilience Assessment: A Fuzzy Approach. Mathematics 2022, 10, 1677. [Google Scholar] [CrossRef]

- Asadzadeh, S.M.; Maleki, H.; Tanhaeean, M. A Resilience Engineering-Based Approach to Improving Service Reliability in Maintenance Organizations. Int. J. Syst. Assur. Eng. Manag. 2020, 11, 909–922. [Google Scholar] [CrossRef]

- Sincorá, L.A.; de Oliveira, M.P.V.; Zanquetto-Filho, H.; Alvarenga, M.Z. Developing Organizational Resilience from Business Process Management Maturity. Innov. Manag. Rev. 2023, 20, 147–161. [Google Scholar] [CrossRef]

- Pilanawithana, N.M.; Feng, Y.; London, K.; Zhang, P. Framework for Measuring Resilience of Safety Management Systems in Australian Building Repair and Maintenance Companies. J. Saf. Res. 2023, 85, 405–418. [Google Scholar] [CrossRef]

- Pilanawithana, N.M.; Feng, Y.; London, K.; Zhang, P. Developing Resilience for Safety Management Systems in Building Repair and Maintenance: A Conceptual Model. Saf. Sci. 2022, 152, 105768. [Google Scholar] [CrossRef]

- Bredebach, C. Is Sustainable Maintenance A Support-Or Standalone Function? A Definition. In Proceedings of the 4th Conference on Production Systems and Logistics (CPSL 2023-1), Santiago de Querétaro, Mexico, 28 February–2 March 2023; pp. 23–33. [Google Scholar] [CrossRef]

- Franciosi, C.; Iung, B.; Miranda, S.; Riemma, S. Maintenance for Sustainability in the Industry 4.0 Context: A Scoping Literature Review. IFAC-PapersOnLine 2018, 51, 903–908. [Google Scholar] [CrossRef]

- Saihi, A.; Ben-Daya, M.; As’ad, R.A. Maintenance and Sustainability: A Systematic Review of Modeling-Based Literature. J. Qual. Maint. Eng. 2023, 29, 155–187. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Antosz, K. The Concept of Sustainable Maintenance Criteria Assessment. In Proceedings of the IFIP International Conference on Advances in Production Management Systems (APMS), Nantes, France, 5–9 September 2021; pp. 427–436. [Google Scholar]

- Jasiulewicz-Kaczmarek, M.; Żywica, P. The Concept of Maintenance Sustainability Performance Assessment by Integrating Balanced Scorecard with Non-Additive Fuzzy Integral. Eksploat. Niezawodn. 2018, 20, 650–661. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Żywica, P.; Gola, A. Fuzzy Set Theory Driven Maintenance Sustainability Performance Assessment Model: A Multiple Criteria Approach. J. Intell. Manuf. 2021, 32, 1497–1515. [Google Scholar] [CrossRef]

- Franciosi, C.; Tortora, A.M.R.; Miranda, S. A Maintenance Maturity and Sustainability Assessment Model for Manufacturing Systems. Manag. Prod. Eng. Rev. 2023, 14, 137–155. [Google Scholar] [CrossRef]

- Jasiulewicz-Kaczmarek, M.; Legutko, S.; Kluk, P. Maintenance 4.0 Technologies—New Opportunities for Sustainability Driven Maintenance. Manag. Prod. Eng. Rev. 2020, 11, 74–87. [Google Scholar] [CrossRef]

- Madreiter, T.; Trajanoski, B.; Martinetti, A.; Ansari, F. Sustainable Maintenance: What Are the Key Technology Drivers for Ensuring Positive Impacts of Manufacturing Industries? IFAC-PapersOnLine 2024, 58, 616–621. [Google Scholar] [CrossRef]

- Fiksel, J. Sustainability and Resilience: Toward a Systems Approach. Sustain. Sci. Pract. Policy 2006, 2, 14–21. [Google Scholar] [CrossRef]

- Thomas, A.; Byard, P.; Francis, M.; Fisher, R.; White, G.R.T. Profiling the Resiliency and Sustainability of UK Manufacturing Companies. J. Manuf. Technol. Manag. 2016, 27, 82–99. [Google Scholar] [CrossRef]

- Simion, D.; Postolache, F.; Fleacă, B.; Fleacă, E. AI-Driven Predictive Maintenance in Modern Maritime Transport—Enhancing Operational Efficiency and Reliability. Appl. Sci. 2024, 14, 9439. [Google Scholar] [CrossRef]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 898. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Shaikh, M.F.; Chouhan, A.P.; Kandasamy, J. Developing a Framework for Achieving Optimal Sustainability and Resilience in Circular Sharing Network. Environ. Dev. Sustain. 2024, 26, 18267–18295. [Google Scholar] [CrossRef]

- Zhai, Q.; Ye, Z.S. Robust Degradation Analysis with Non-Gaussian Measurement Errors. IEEE Trans. Instrum. Meas. 2017, 66, 2803–2812. [Google Scholar] [CrossRef]

- Zhai, Q.; Ye, Z.S.; Yang, J.; Zhao, Y. Measurement Errors in Degradation-Based Burn-In. Reliab. Eng. Syst. Saf. 2016, 150, 126–135. [Google Scholar] [CrossRef]

- Faiz, R.B.; Edirisinghe, E.A. Decision Making for Predictive Maintenance in Asset Information Management. Interdiscip. J. Inf. Knowl. Manag. 2009, 4, 23–36. [Google Scholar] [CrossRef][Green Version]

- Lu, K.Y.; Sy, C.C. A Real-Time Decision-Making of Maintenance Using Fuzzy Agent. Expert Syst. Appl. 2009, 36, 2691–2698. [Google Scholar] [CrossRef]

- Ross, T.J. Fuzzy Logic with Engineering Application, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 9780470743768. [Google Scholar]

- Wu, H.; Xu, Z.S. Fuzzy Logic in Decision Support: Methods, Applications and Future Trends. Int. J. Comput. Commun. Control 2021, 16, 4044. [Google Scholar] [CrossRef]

- April, A.; Hayes, J.H.; Abran, A.; Dumke, R. Software Maintenance Maturity Model (SMmm): The Software Maintenance Process Model. J. Softw. Maint. Evol. 2005, 17, 197–223. [Google Scholar] [CrossRef]

- Schuh, G.; Lorenz, B.; Winter, C.P.; Gudergan, G. The House of Maintenance-Identifying the Potential for Improvement in Internal Maintenance Organisations by Means of a Capability Maturity Model. In Engineering Asset Lifecycle Management, Proceedings of the 4th World Congress on Engineering Asset Management (WCEAM 2009), Athens, Greece, 28–30 September 2009; Springer: Berlin/Heidelberg, Germany, 2009; pp. 15–24. [Google Scholar] [CrossRef]

- Kans, M.; Ehsanifard, K.; Moniri, A. Criteria and Model for Assessing and Improving Information Technology Maturity within Maintenance. J. Phys. Conf. Ser. 2012, 364, 012097. [Google Scholar] [CrossRef]

- Macchi, M.; Fumagalli, L. A Maintenance Maturity Assessment Method for the Manufacturing Industry. J. Qual. Maint. Eng. 2013, 19, 295–315. [Google Scholar] [CrossRef]

- Nemeth, T.; Ansari, F.; Sihn, W.; Haslhofer, B.; Schindler, A. PriMa-X: A Reference Model for Realizing Prescriptive Maintenance and Assessing Its Maturity Enhanced by Machine Learning. Procedia CIRP 2018, 72, 1039–1044. [Google Scholar] [CrossRef]

- Nemeth, T.; Ansari, F.; Sihn, W. A Maturity Assessment Procedure Model for Realizing Knowledge-Based Maintenance Strategies in Smart Manufacturing Enterprises. Procedia Manuf. 2019, 39, 645–654. [Google Scholar] [CrossRef]

- Oliveira, M.; Andrade, W.; Dos Santos, I.; Amaral, M.; Cintra, G. Evaluation of Maintenance Management of a Thermoplastic Industry Using a Maintenance Maturity Model: A Case in Manaus Industrial Pole. Proc. Eng. Sci. 2022, 4, 543–550. [Google Scholar] [CrossRef]

- Siswantoro, N.; Priyanta, D.; Gautama, S.; Zaman, M.B.; Pitana, T.; Prastowo, H.; Ratu Balqis, F.; Yulianto, A.N. The Evaluation of Maturity Level on Heavy Equipment Maintenance Management According to ISO 55001:2014. IOP Conf. Ser. Earth Environ. Sci. 2022, 972, 012033. [Google Scholar] [CrossRef]

- Tortora, A.M.R.; Di Pasquale, V.; Iannone, R. A Maintenance Maturity Model for Assessing Information Management Practices for Small and Medium Enterprises (M3AIN4SME). Appl. Sci. 2022, 12, 9282. [Google Scholar] [CrossRef]

- Liao, S.H. Expert System Methodologies and Applications-a Decade Review from 1995 to 2004. Expert Syst. Appl. 2005, 28, 93–103. [Google Scholar] [CrossRef]

- Sabaei, D.; Erkoyuncu, J.; Roy, R. A Review of Multi-Criteria Decision Making Methods for Enhanced Maintenance Delivery. Procedia CIRP 2015, 37, 30–35. [Google Scholar] [CrossRef]

- ISO 55000:2014; Asset Management—Overview, Principles and Terminology. ISO: Geneva, Switzerland, 2014.

- BS EN 15341:2007; Maintenance—Maintenance Key Performance Indicators. British Standard: Milton Keynes, UK, 2007.

- Vaidya, O.S.; Kumar, S. Analytic Hierarchy Process: An Overview of Applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Kruse, R.; Doell, C. Fuzzy Systems. Fuzzy Sets and Fuzzy Logic; University Magdeburg: Magdeburg, Germany, 2020. [Google Scholar]

- Savitha, M.T.; George, M. New Methods for Ranking of Trapezoidal Fuzzy Numbers. Adv. Fuzzy Math. 2017, 12, 1159–1170. [Google Scholar]

- Zimmermann, H.J. Fuzzy Set Theory. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 317–332. [Google Scholar] [CrossRef]

- Vaníček, J.; Vrana, I.; Aly, S. Fuzzy Aggregation and Averaging for Group Decision Making: A Generalization and Survey. Knowl. Based Syst. 2009, 22, 79–84. [Google Scholar] [CrossRef]

- Mamdani, E.H.; Assilian, S. An Experiment in Linguistic Synthesis with a Fuzzy Logic Controller. Int. J. Man. Mach. Stud. 1975, 7, 1–13. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Dongre, J.K.; Raundale, A.R. Examining the Fuzzy Inference on Mamdani Fuzzy Inference System and Takagi-Sugeno Fuzzy Model. J. Harbin Eng. Univ. 2023, 44, 291–299. [Google Scholar]

- Kozlov, O. Optimal Selection of Membership Functions Types for Fuzzy Control and Decision Making Systems. In Proceedings of the CEUR Workshop Proceedings, Naples, Italy, 4–5 October 2021; Volume 2853, pp. 238–247. [Google Scholar]

- Chi, H.T.X.; Yu, V.F. Ranking Generalized Fuzzy Numbers Based on Centroid and Rank Index. Appl. Soft Comput. J. 2018, 68, 283–292. [Google Scholar] [CrossRef]

- Chu, T.C.; Tsao, C.T. Ranking Fuzzy Numbers with an Area between the Centroid Point and Original Point. Comput. Math. Appl. 2002, 43, 111–117. [Google Scholar] [CrossRef]

| Li\Pi | P1: Reliability, Availability | P2: Safety, Security | P3: Resilience, Recovery | P4: Flexibility, Agility | P5: Sustainability |

|---|---|---|---|---|---|

| L1: Initial | Failures are logged, but no predictive or preventive measures exist. Downtime tracking is inconsistent. | Safety incidents are logged ad hoc, with no systematic analysis or response strategies. | Recovery times are inconsistent, with no clear RTOs or contingency plans. Systems often experience prolonged downtime after incidents. | Changes are addressed reactively, leading to inefficiencies and delays; processes are slow and often reactive. | Environmental impact is not systematically tracked, and no formal sustainability initiatives exist. |

| L2: Managed | Regular maintenance stabilizes uptime, MTBF is tracked at a basic level, and failure rates are analyzed post-mortem. | Some safety protocols are established, but there are inconsistencies in implementation across units; response times to threats vary significantly. | Recovery protocols are established for local units, but recovery times are still unpredictable; RTOs are loosely defined. | Basic adaptability measures exist, but response times are inconsistent across different units. | Some environmental initiatives exist, but sustainability efforts are not fully integrated into maintenance workflows. |

| L3: Standardized | Standard processes for preventive maintenance are established and utilized across all units, improving consistency in MTBF and reducing failure rates. | Safety procedures are standardized, with routine training, safety incident reporting, and structured risk mitigation. | Recovery procedures are standardized, with defined RTOs and downtime reduction strategies in place. | Standardized processes improve response times to operational changes, but adaptation is still slow in unpredictable conditions. | Sustainability goals (e.g., carbon footprint reduction, waste management) are integrated into maintenance practices, with measurable goals. |

| L4: Predictable | Downtime events are statistically analyzed, predictive maintenance models are developed, and real-time failure trends are monitored. | Data analysis proactively manages safety risks, leading to faster response times and reduced incident frequency. | Recovery strategies are optimized based on statistical analysis, ensuring predictable RTOs and minimal disruptions. | Processes are dynamically adjusted based on statistical models, improving response times and flexibility. | Sustainability metrics (e.g., resource efficiency, CO2 reduction) are actively tracked, with consistent improvements in resource efficiency and waste reduction. |

| L5: Innovating | Proactive reliability improvement programs using real-time data analytics, AI-driven predictive maintenance, and reliability optimization to reduce failures and maximize system availability. | Advanced safety technologies (e.g., AI-based threat detection) continuously improve security and risk mitigation. | Continuous improvement of recovery strategies, integrating real-time monitoring and analysis to reduce RTO and downtime and enhance system resilience. | Highly flexible systems capable of rapid adaptation, with continuous feedback loops to optimize response to changes. Self-optimizing processes dynamically adjust based on AI-driven analytics, ensuring rapid adaptation. | Innovative sustainability practices are continuously implemented, focusing on achieving long-term environmental goals and reducing the organization’s carbon footprint. |

| Maintenance Potential | Knowledge Areas | Measurement Indicators (Inputs) | Performance Objectives |

|---|---|---|---|

| P1: Reliability, Availability | Real-time condition monitoring Reliability-Centered Maintenance (RCM) Predictive analytics and diagnostics | MTBF (Mean Time Between Failures) Failure rate per asset class Equipment Uptime [%] | Improve technical availability Reduce unplanned downtime Enhance system reliability |

| P2: Safety, Security | Occupational risk and hazard analysis Maintenance safety management systems Data protection & cybersecurity protocols | Number of safety events linked to maintenance TRIR (Total Recordable Incident Rate) Safety Compliance Rate | Eliminate maintenance-related incidents Comply with safety and regulatory standards Protect technical systems from threats |

| P3: Resilience, Recovery | Emergency and corrective maintenance planning Business continuity protocols Spare parts redundancy and backup planning | RTO (Recovery Time Objective) Downtime After Failure MTTR (Mean Time To Recovery) | Recover from disruptions rapidly Maintain service continuity Limit operational losses |

| P4: Flexibility, Agility | Agile maintenance planning and scheduling Modular equipment configuration Workforce multi-skilling and redeployment | Response Time to Changes in Production Needs Maintenance Agility Index % of personnel trained for multiple stations | Rapidly adapt to production changes Minimize the time required for system reconfiguration Increase organizational responsiveness |

| P5: Environmental impact | Energy consumption and waste management Circular maintenance and asset lifecycle strategies Compliance with ESG and environmental policies | Carbon emissions from maintenance activities Resource Efficiency index % reduction in hazardous waste | Minimize environmental impact Increase eco-efficiency of maintenance actions Align maintenance with sustainability goals |

| Maintenance Potential | Weight |

|---|---|

| P1: Reliability, Availability | 0.30 |

| P2: Safety, Security | 0.20 |

| P3: Resilience, Recovery | 0.20 |

| P4: Flexibility, Agility | 0.15 |

| P5: Environmental impact | 0.15 |

| MTBF (Mean Time Between Failures) | ||

|---|---|---|

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very Low (VL) | MTBF is extremely short, and the system fails very often. This means the system is highly unreliable and has frequent breakdowns, leading to operational interruptions. | [0, 0, 50, 100] |

| Low (L) | MTBF is below average, and the system experiences failures more frequently. This may result in decreased performance and increased downtime. | [0, 50, 100, 200] |

| Medium (M) | MTBF is average, and failures occur at a manageable rate. The system operates with an acceptable level of reliability, with periodic but manageable interruptions. | [50, 100, 200, 300] |

| High (H) | MTBF is above average, and failures are rare. The system is considered reliable, with few breakdowns or interruptions, contributing to stable operations. | [100, 200, 300, 400] |

| Very High (VH) | MTBF is very long, and the system experiences very few failures. The system is extremely reliable, with prolonged uptime and minimal disruptions to operations. | [200, 300, 500, 500] |

| Failure Rate | ||

| Linguistic Term | Description | Range of Fuzzy Membership Function |

| Very High (VH) | The failure rate is extremely high, meaning the system is unreliable and often fails. A high failure rate leads to continuous disruptions in operations, poor system performance, and frequent maintenance. | [0.8, 1.0, 1.0, 1.0] |

| High (H) | The failure rate is above average, and the system fails frequently. The system experiences noticeable performance issues due to the relatively high number of breakdowns and disruptions. | [0.6, 0.7, 0.8, 1.0] |

| Medium (M) | The failure rate is moderate, and the system performance is average. While there are occasional failures, they do not significantly disrupt the system. The overall reliability is acceptable, but there may still be room for improvement. | [0.4, 0.5, 0.6, 0.7] |

| Low (L) | The failure rate is below average, and the system is relatively reliable. The system experiences few failures, and its performance remains stable, with only rare interruptions. | [0.2, 0.3, 0.4, 0.5] |

| Very Low (VL) | The failure rate is minimal, and the system is extremely reliable. The system operates with few failures, ensuring consistent performance and limited downtime. | [0, 0, 0.2, 0.3] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Very Low (VL) | The system exhibits poor reliability and availability. The system frequently experiences failures and downtime, making it unreliable and unavailable most of the time. | [0, 0, 0.2, 0.4] |

| Low (L) | The system shows below-average reliability and availability. The system experiences frequent failures and extended downtime, affecting its overall performance. | [0, 0.2, 0.4, 0.6] |

| Medium (M) | The system has moderate reliability and availability. Failures and downtime are manageable and may occur occasionally, but the system performs adequately overall. | [0.2, 0.4, 0.6, 0.8] |

| High (H) | The system is mostly reliable and available with occasional issues. The system experiences rare failures and minimal downtime and generally meets performance expectations. | [0.4, 0.6, 0.8, 1.0] |

| Very High (VH) | The system is highly reliable and available with minimal issues. The system rarely experiences failures, and downtime is extremely low, ensuring optimal performance. | [0.6, 0.8, 1.0, 1.0] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Low (L) | The system is highly unreliable, with frequent failures and significant downtime. Low performance in reliability (P1), safety (P2), and resilience (P3) leads to a high risk of operational disruptions, poor recovery from failures, and frequent safety incidents. | [0, 0, 0.2, 0.4] |

| Medium (M) | The system is moderately dependable. There are occasional failures and some downtime, but recovery is generally fast. The system has reasonable reliability, safety measures, and resilience, with a moderate risk of disruptions. | [0.3, 0.45, 0.6, 0.75] |

| High (H) | The system is highly dependable, with minimal downtime and failures. Reliability (P1), safety (P2), and resilience (P3) are well-optimized, resulting in smooth operations with rare interruptions or safety incidents. | [0.6, 0.8, 1, 1] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Low (L) | The system is not very adaptable, showing resistance to change. It struggles to respond to shifting conditions and is slow to adjust to new requirements, as reflected by low agility (P4). Changes in operational or market demands lead to delays and inefficiencies. | [0, 0, 0.3, 0.5] |

| Medium (M) | The system can moderately adapt to changes. Agility (P4) is acceptable, allowing adjustments that take time and resources. While change is manageable but not always seamless, improvements are still possible. | [0.4, 0.5, 0.6, 0.8] |

| High (H) | The system is highly adaptable and can quickly and efficiently respond to changes. It demonstrates strong agility (P4), allowing it to adjust swiftly to new requirements or external changes, ensuring minimal disruption and continuous improvement. | [0.7, 0.85, 1, 1] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| Low (L) | The system has a significant environmental impact. Resource efficiency (P5) is low, resulting in high energy consumption, waste production, and carbon emissions. This leads to sustainability concerns and long-term operational inefficiencies. | [0, 0, 0.25, 0.5] |

| Medium (M) | The system demonstrates moderate sustainability. Resource efficiency (P5) is acceptable, with some efforts made to minimize environmental impact. However, there is room for improvement in reducing the carbon footprint and optimizing resource usage. | [0.4, 0.5, 0.7, 0.85] |

| High (H) | The system is highly sustainable, with excellent resource efficiency (P5), low environmental impact, and minimal waste and emissions. It contributes to long-term environmental and operational sustainability with reduced operational costs and ecological footprint. | [0.75, 0.9, 1, 1] |

| Linguistic Term | Description | Range of Fuzzy Membership Function |

|---|---|---|

| L1—Initial | The system operates reactively. Failures and safety incidents are logged inconsistently. Recovery and change responses are slow and uncoordinated. Sustainability is virtually absent. Maintenance processes are largely corrective with minimal structure. | [0.0, 0.0, 0.1, 0.2] |

| L2—Managed | Maintenance activities and reliability measures are partially formalized. Some safety and recovery procedures exist, but inconsistencies remain. Minor adaptability measures and limited sustainability initiatives are observable. Maintenance still reacts primarily to problems but with an improving organization. | [0.1, 0.2, 0.3, 0.4] |

| L3—Standardized | Preventive maintenance, standardized safety procedures, and structured recovery plans are applied consistently. Early stages of system adaptability and sustainability are integrated. Maintenance processes are standardized across units and processes. | [0.3, 0.4, 0.5, 0.6] |

| L4—Predictable | Predictive maintenance practices, proactive safety management, optimized recovery strategies, and dynamic change adaptation are evident. Sustainability metrics are systematically monitored and improved. Maintenance is becoming predictive and data-driven. | [0.5, 0.6, 0.7, 0.8] |

| L5—Innovating | Maintenance is fully strategic and innovation-driven. Advanced technologies (AI, real-time analytics) continuously optimize reliability, safety, adaptability, and sustainability. The organization demonstrates self-optimizing, highly resilient, and sustainable maintenance practices aligned with long-term goals. | [0.7, 0.8, 1.0, 1.0] |

| Variable/Potential | Type of Membership Function | Linguistic Terms | Example of Fuzzy Rule |

|---|---|---|---|

| MTBF (Mean Time Between Failures) | Trapezoidal | Very Low (VL), Low (L), Medium (M), High (H), Very High (VH) | - |

| Failure Rate | |||

| Number of safety events | |||

| Safety Compliance Rate | |||

| MTTR (Mean Time to Recovery) | |||

| Downtime After Failure | |||

| Response Time to Changes | |||

| Maintenance Agility Index | |||

| Carbon Emissions from Maintenance Activities | |||

| Resource Efficiency Index | |||

| Technology Adoption Capability | |||

| Energy-Aware Maintenance level | |||

| System Potentials (P1, P2, P3, P4, P5) | VL, L, M, H, VH | IF MTBF is High AND Failure Rate is Low THEN P1 = High | |

| System Dimensions (Dependability, Adaptability, Sustainability) | Low, Medium, High | IF P1, P2, P3 are High THEN System Dependability = High | |

| Output: Maintenance Maturity Level (MML) | L1–Initial, L2–Managed, L3–Standardized, L4–Predictable, L5–Innovating | IF System Dependability is High AND System Sustainability is Medium THEN System MML = L4 (Predictable) |

| Potential | Input 1 | Input 2 | ||

|---|---|---|---|---|

| Definition | Value | Definition | Value | |

| P1: Reliability, Availability | Mean Time Between Failures | High | Failure Rate | Low |

| P2: Safety, Security | Number of safety events | Low | Safety Compliance Rate | High |

| P3: Resilience, Recovery | MTTR (Mean Time To Recovery) | Medium | Downtime After Failure | Medium |

| P4: Flexibility, Agility | Response Time to Changes | Medium | Maintenance Agility Index | Medium |

| P5: Environmental impact | Carbon emissions from maintenance activities | Low | Resource Efficiency Index | High |

| Potential | Fuzzified Evaluation | Score |

|---|---|---|

| P1: Reliability, Availability | High | 0.847 |

| P2: Safety, Security | Medium | 0.645 |

| P3: Resilience, Recovery | Medium | 0.723 |

| P4: Flexibility, Agility | Medium | 0.743 |

| P5: Environmental impact | Medium | 0.689 |

| Additional Parameter | Fuzzified Evaluation | Score |

|---|---|---|

| Technology Adaptation Capability | Medium | 0.70 |

| Energy-Aware Maintenance Level | High | 0.75 |

| System Dimension | Aggregated Score | Maturity Level |

| Dependability | 0.687 | L3—Standardized |

| Adaptability | 0.654 | L3—Standardized |

| Sustainability | 0.677 | L3—Standardized |

| Overall IMMM index | 0.544 | L3—Standardized |

| Maturity Dimension | Possible Recommendations | Organizational Context | Maturity Ambition | Resource Capabilities |

|---|---|---|---|---|

| Dependability | Implement condition-based and predictive maintenance (CBM/PM) | Industrial systems with high failure impact | Level 3 → 4 or 4 → 5 | Medium to High (IoT, sensors required) |

| Apply FMEA, bow-tie, or fault tree analyses for critical assets | Regulated/high-risk industries (e.g., mining, energy) | Level 2 → 3 | Medium | |

| Enhance root cause analysis (RCA) and incident reporting culture | Organizations with repeated failures or poor diagnostics | Level 2 → 4 | Low to Medium | |

| Introduce maintenance standardization across departments | Multi-site organizations or siloed structures | Level 3 → 4 | Medium | |

| Adaptability | Develop and test business continuity and emergency maintenance plans | Dynamic environments or service-critical operations | Level 2 → 3 or 3 → 4 | Medium |

| Implement flexible scheduling and resource sharing (e.g., modular shifts) | Environments with fluctuating workloads | Level 3 → 5 | Low to Medium | |

| Introduce cross-functional training programs for maintenance staff | Organizations seeking workforce agility | Level 2 → 4 | Low | |

| Integrate real-time decision support systems (e.g., digital twins) | Digitally advanced or innovation-driven firms | Level 4 → 5 | High | |

| Sustainability | Track and reduce energy and material use in maintenance tasks | Organizations with high ESG exposure or energy-intensive assets | Level 3 → 4 | Medium |

| Implement remanufacturing, reuse, and recycling programs | Circular economy-aligned organizations | Level 2 → 4 | Medium | |

| Align with GRI, or ESG frameworks in maintenance reporting | Companies under ESG (Environmental, Social, and Governance) scrutiny or with sustainability KPIs | Level 3 → 5 | Medium to High | |

| Introduce green maintenance practices (e.g., biodegradable lubricants, eco-spares) | Organizations in environmentally sensitive sectors | Level 2 → 3 | Low to Medium | |

| Promote employee well-being and safety through ergonomic and psychosocial risk programs | Labor-intensive or high-risk maintenance environments | Level 2 → 4 | Medium | |

| Optimize cost-effectiveness of maintenance through life-cycle cost analysis and lean practices | Organizations with cost pressures or seeking efficiency | Level 3 → 5 | Medium | |

| Digitalization Pathways | Implement CMMS or EAM (Enterprise Asset Management) systems to support data-driven decision-making | Any context aiming for structured maintenance | Level 2 → 3 | Medium |

| Use IoT for real-time condition monitoring | Asset-intensive industries with high downtime costs | Level 3 → 5 | Medium to High | |

| Adopt AI/ML tools for failure prediction and diagnostics | Innovation-driven or research-intensive organizations | Level 4 → 5 | High |

| Framework | Focus Area | Assessment Method | Key Dimensions | Limitations | IMMM Extension |

|---|---|---|---|---|---|

| FMMR | Maintenance organization and process standardization | Qualitative checklist | Organization, process control | Lacks quantification; subjective | Adds measurable performance indicators |

| AMMM | Asset lifecycle management | Mixed qualitative–quantitative | Reliability, cost, lifecycle | No direct link to real-time data | Adds real-time adaptability, recovery focus |

| ISO 55000 | Governance and risk-based asset management | Compliance-based audit | Risk, lifecycle, policy, improvement | Static evaluation; qualitative | Introduces fuzzy quantification, resilience, sustainability |

| IMMM | Multi-dimensional maintenance maturity | Fuzzy quantitative model | Reliability, Safety, Resilience, Agility, Sustainability | — | Fully quantitative, adaptive, resilience-oriented |

| Category | Data/Information Required | Source |

|---|---|---|

| Maintenance process data | MTBF, MTTR, number of failures, maintenance backlog | CMMS reports |

| Asset management policies | maintenance procedures, risk assessment reports | internal documentation |

| Organizational data | competence, training, responsibilities | HR records |

| Compliance data | audits, safety certifications | management systems |

| Sustainability aspects (optional) | energy consumption, waste generation | environmental reports |

| Aspect | ISO 55000 Framework | Integrated Maintenance Maturity Model (IMMM) | Added Value of IMMM |

|---|---|---|---|

| Core philosophy | Asset management and compliance orientation | System maturity and performance orientation | Focus on evolution and learning capacity of maintenance systems |

| Evaluation logic | Qualitative checklist or audit grid | Fuzzy logic inference and defuzzification | Quantitative, uncertainty-aware evaluation |

| Maturity dimensions | Leadership, Risk, Lifecycle, Performance, Improvement | System Dependability, Adaptability, Sustainability | Adds resilience and flexibility potentials |

| Data requirements | Static process and policy data | Real-time or expert-based technical indicators (e.g., MTBF, energy use) | Enables dynamic data linkage (IoT, CMMS) |

| Output type | Ordinal (1–5 levels) | Continuous (0–1 scale, defuzzified maturity value) | Higher diagnostic resolution |

| Integration | Documentation- and audit-driven | Digitally integrable with ERP/CMMS/IoT | Supports automation and feedback learning |

| Improvement path | Periodic audit and gap analysis | Adaptive, feedback-based learning cycle | Enables predictive and self-improving systems |

| Dimension/Potential | ISO 55000 Assessment | IMMM Assessment | Key Differences/Added Value |

|---|---|---|---|

| Reliability/Availability | Level 3—processes partially standardized; MTBF tracked; preventive maintenance applied | Level 4 (score = 0.847)—predictive maintenance integrated; downtime statistically analyzed; real-time monitoring implemented | IMMM adds quantitative tracking and predictive features, enabling continuous evaluation of reliability trends |

| Safety/Security | Level 3—formal safety procedures and compliance monitoring; incident tracking reactive | Level 4 (score = 0.645)—safety incidents monitored in real time; AI-assisted risk detection; proactive safety audits | IMMM supports dynamic risk assessment and continuous improvement beyond compliance |