Bayesian Optimisation with Dimensionless Groups: A Synergy of Performance and Fundamental Understanding

Abstract

1. Introduction

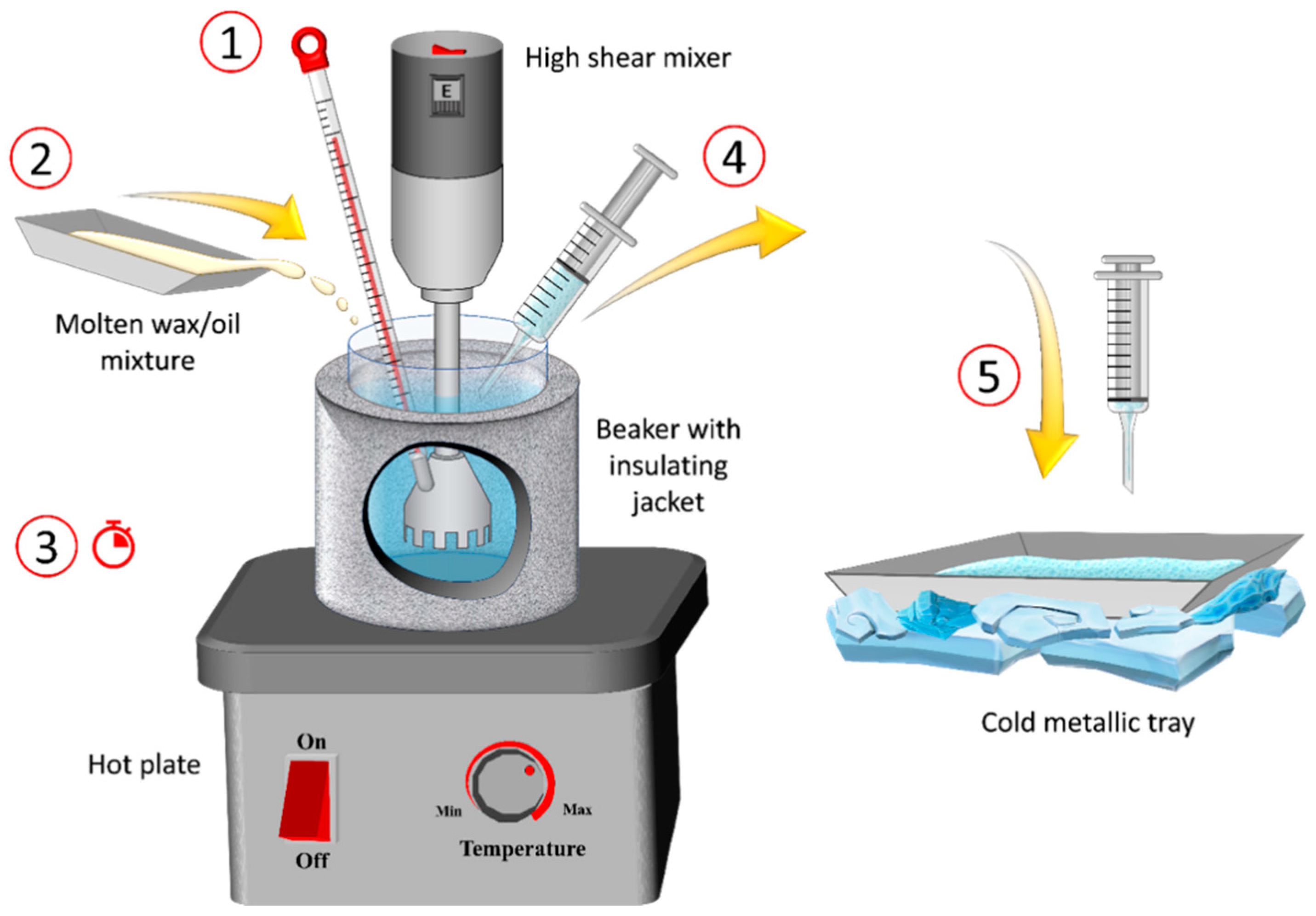

2. Materials and Methods

3. Approach

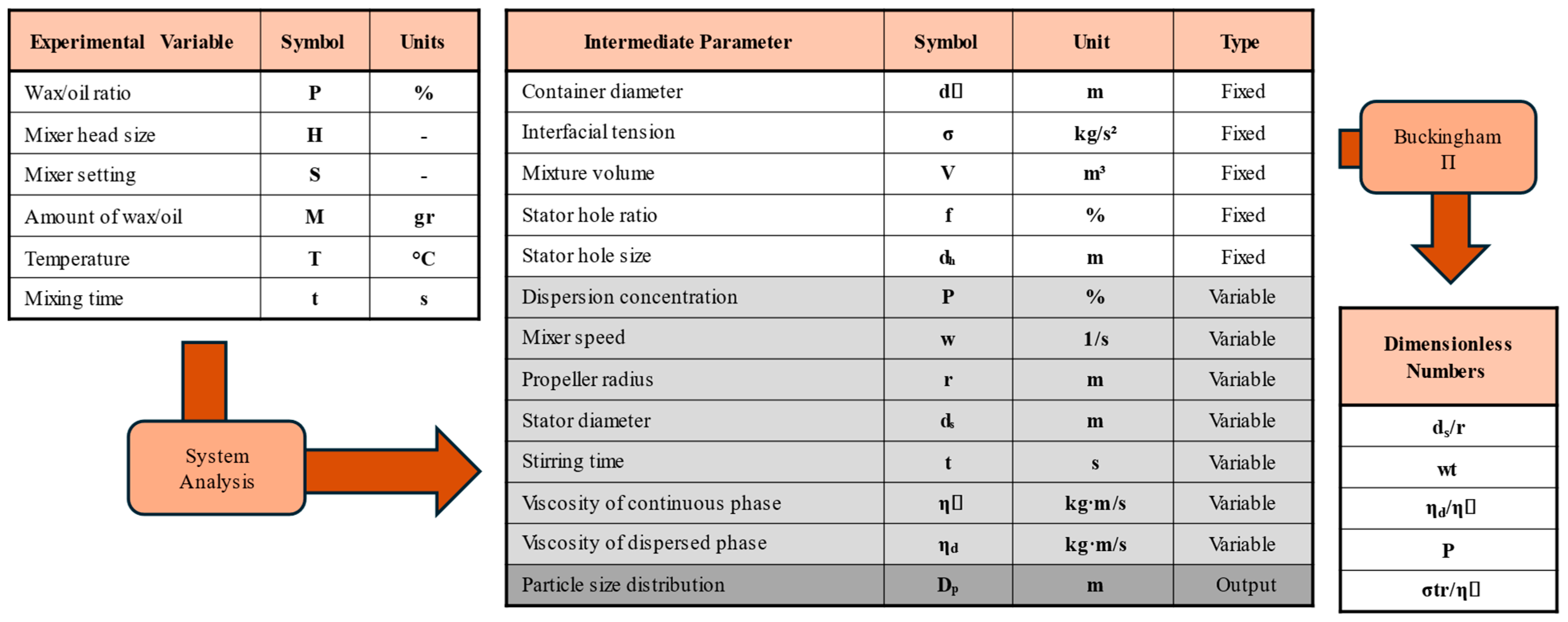

3.1. Derivation of the Dimensionless Numbers

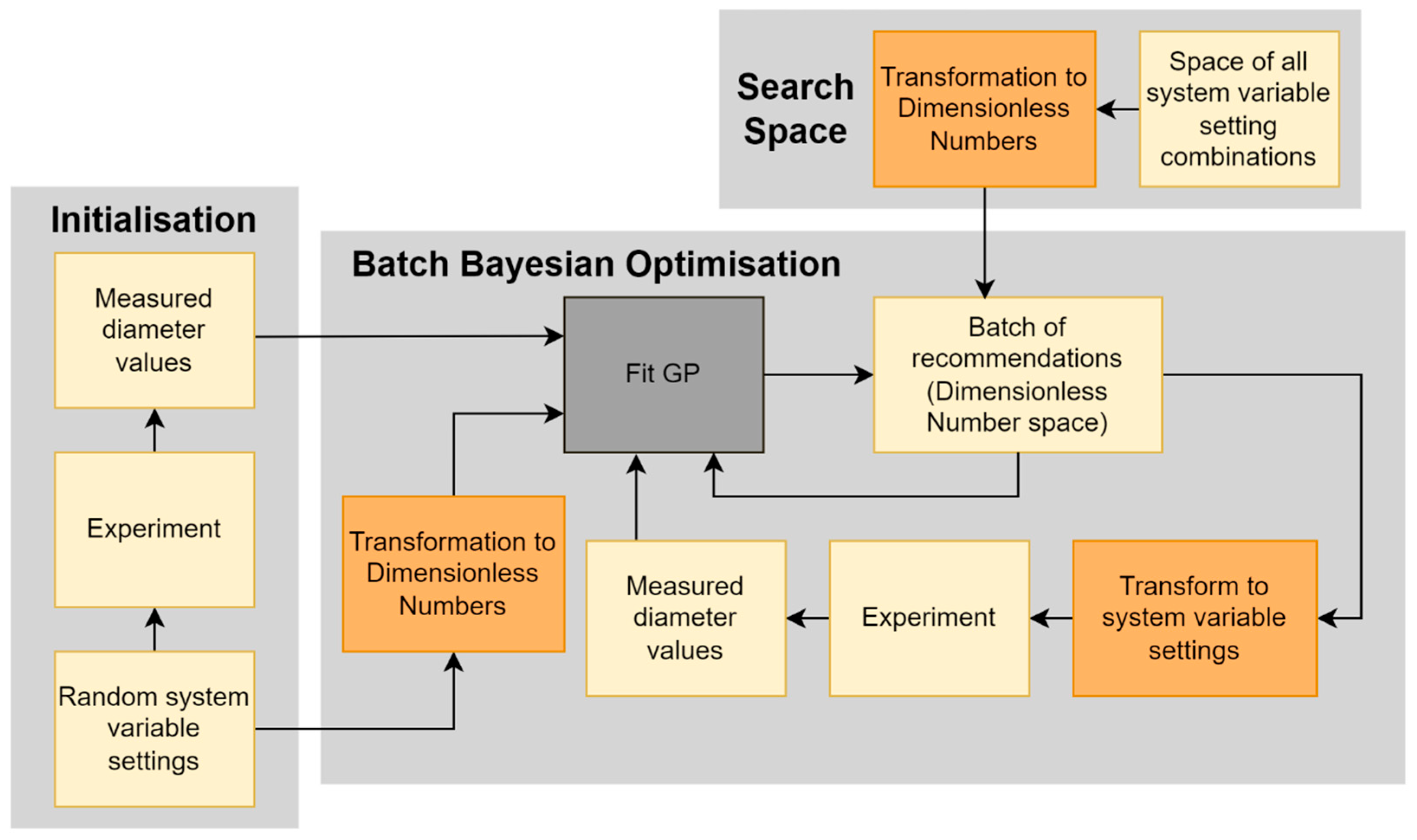

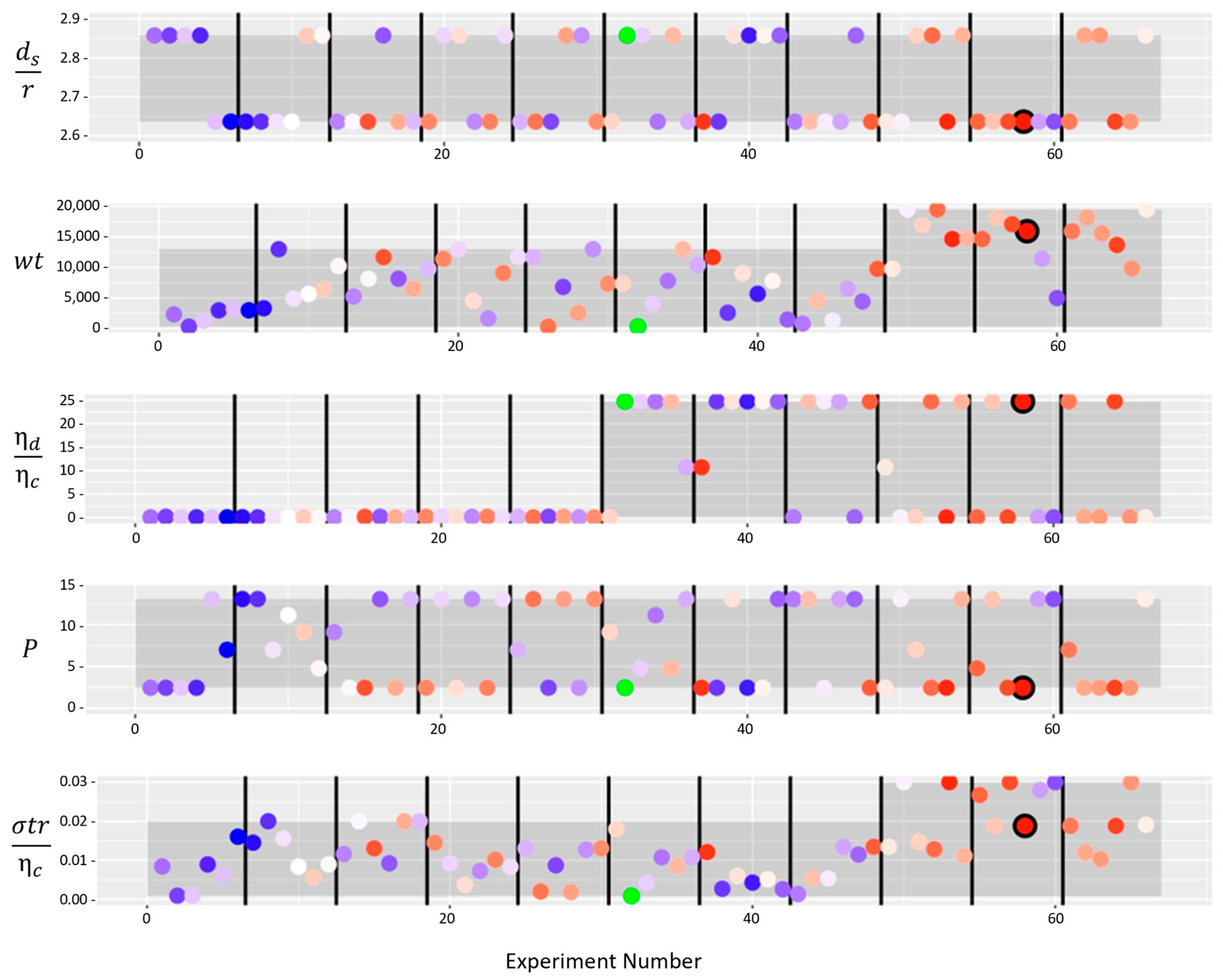

3.2. Batch Bayesian Optimisation for Dimensionless Number Analysis and Particle Diameter Minimisation

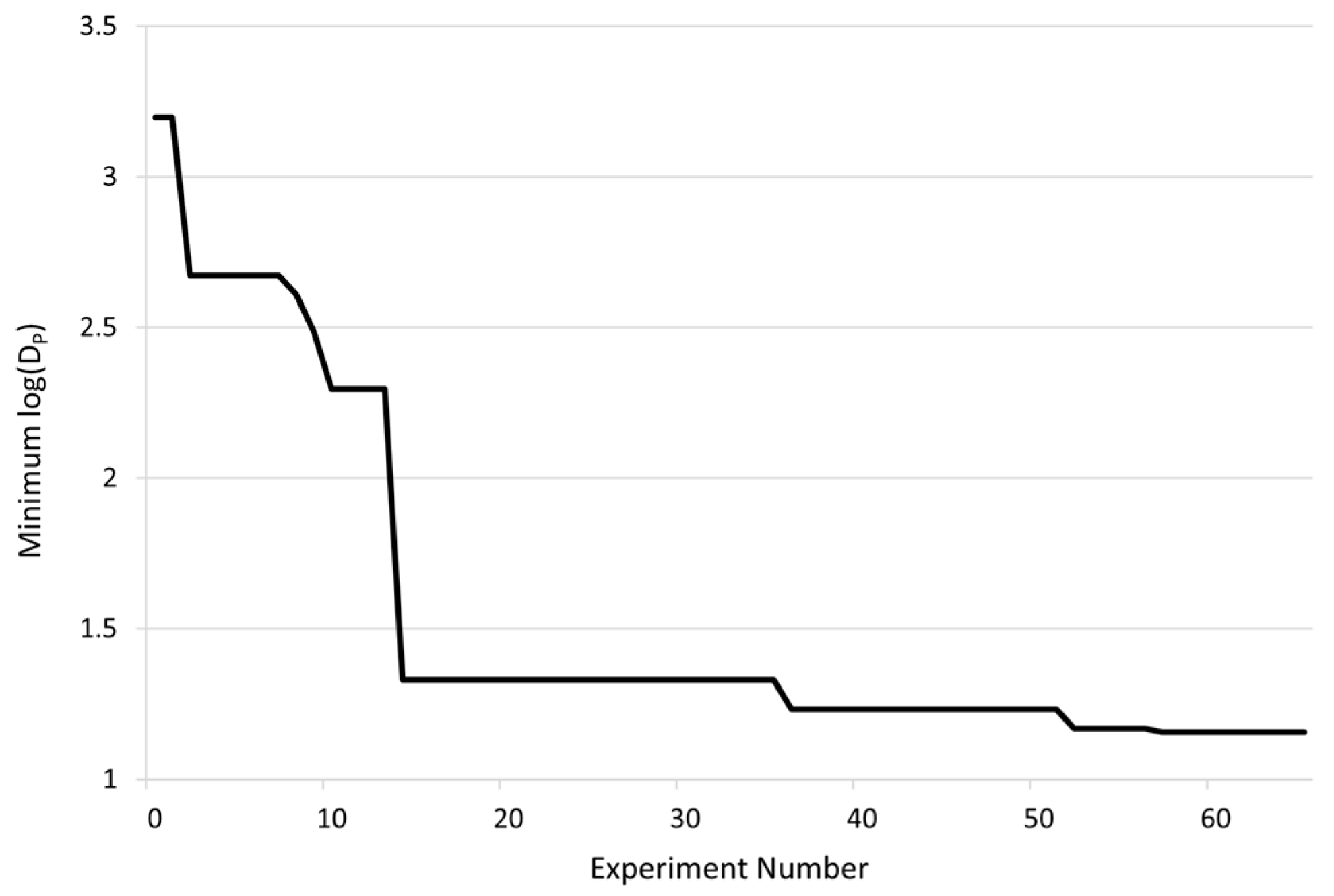

4. Discussion

4.1. Engineering Approach Aspects

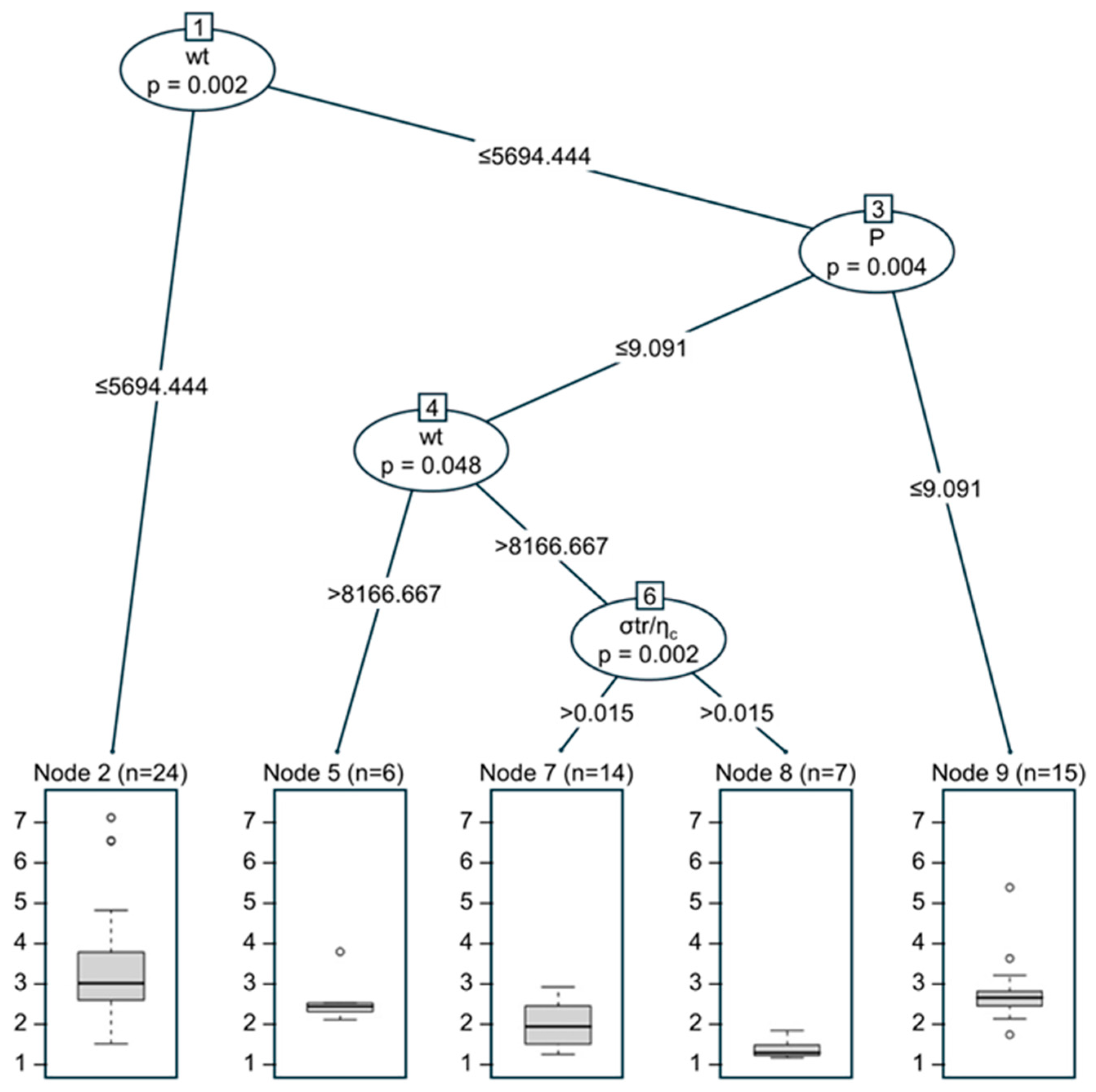

4.2. Regression Trees

- Difficulty tuning an appropriate length scale for GP for dimensionless parameters that have a coarse resolution;

- BO is more suitable for small data problems, as fitting a GP with a large amount of data becomes difficult (inversion of the matrix). BO is mostly suitable when the number of data points are relatively small (typically 100–1000 s) and can struggle with numerical precision beyond that;

- Choosing the correct parameters, such as kernels and kernel hyper-parameters, for a Gaussian process can be difficult and requires several samples. Thus, if the starting parameters are far from optimal, then, in the beginning, BO, without the experimenter’s input, can sample in a way that may seem almost meaningless to an expert;

- The complexity of parameter estimation scales with the number of dimensions, which, in turn, can be high. Thus, BO can be difficult to run in high-dimensional problems. In the case of this experiment, there were only five dimensionless parameters. Applying this same process may become difficult with more parameters (>16).

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Utada, A.S.; Chu, L.Y.; Fernandez-Nieves, A.; Link, D.R.; Holtze, C.; Weitz, D.A. Dripping, Jetting, Drops, and Wetting: The Magic of Microfluidics. MRS Bull. 2007, 32, 702–708. [Google Scholar] [CrossRef]

- Eggersdorfer, M.L.; Seybold, H.; Ofner, A.; Weitz, D.A.; Studart, A.R. Wetting controls of droplet formation in step emulsification. Proc. Natl. Acad. Sci. USA 2018, 115, 9479–9484. [Google Scholar] [CrossRef]

- Ravishankar, P.; Khang, A.; Laredo, M.; Balachandran, K. Using Dimensionless Numbers to Predict Centrifugal Jet-Spun Nanofiber Morphology. J. Nanomater. 2019, 2019, 4639658. [Google Scholar] [CrossRef]

- Utada, A.S.; Fernandez-Nieves, A.; Stone, H.A.; Weitz, D.A. Dripping to Jetting Transitions in Coflowing Liquid Streams. Phys. Rev. Lett. 2007, 99, 094502. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, R.; Rahnejat, H. Enhanced performance of optimised partially textured load bearing surfaces. Tribol. Int. 2018, 117, 272–282. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, R.; Zhu, X.; Pan, X.; Short, M.; Liu, L.; Bussemaker, M. Machine learning modelling of sonochemical systems using physically-derived dimensionless groups. Ultrason. Sonochemistry 2025, 122, 107593. [Google Scholar] [CrossRef]

- Greenhill, S.; Rana, S.; Gupta, S.; Vellanki, P.; Venkatesh, S. Bayesian Optimization for Adaptive Experimental Design: A Review. IEEE Access 2020, 8, 13937–13948. [Google Scholar] [CrossRef]

- Lee, H.; Moon, H.; Lee, J.; Ryu, S. Toward Knowledge-Guided AI for Inverse Design in Manufacturing: A Perspective on Domain, Physics, and Human–AI Synergy. Adv. Intell. Discov. 2025, e2500107. [Google Scholar] [CrossRef]

- Karkaria, V.; Goeckner, A.; Zha, R.; Chen, J.; Zhang, J.; Zhu, Q.; Cao, J.; Gao, R.; Chen, W. Towards a digital twin framework in additive manufacturing: Machine learning and Bayesian optimization for time series process optimisation. J. Manuf. Syst. 2024, 75, 322–332. [Google Scholar] [CrossRef]

- Khatamsaz, D.; Vela, B.; Singh, P.; Johnson, D.D.; Allaire, D.; Arróyave, R. Multi-objective materials Bayesian optimization with active learning of design constraints: Design of ductile refractory multi-principal-element alloys. Acta Mater. 2022, 236, 118133. [Google Scholar] [CrossRef]

- Lei, B.; Kirk, T.Q.; Bhattacharya, A.; Pati, D.; Qian, X.; Arróyave, R.; Mallick, B.K. Bayesian optimisation with adaptive surrogate models for automated experimental design. NPJ Comput. Mater. 2021, 7, 194. [Google Scholar] [CrossRef]

- Roussel, R.; Edelen, A.L.; Boltz, T.; Kennedy, D.; Zhang, Z.; Ji, F.; Huang, X.; Ratner, D.; Garcia, A.S.; Xu, C.; et al. Bayesian optimization algorithms for accelerator physics. Phys. Rev. Accel. Beams 2024, 27, 084801. [Google Scholar] [CrossRef]

- Wang, K.; Dowling, A.W. Bayesian optimisation for chemical products and functional materials. Curr. Opin. Chem. Eng. 2022, 36, 100728. [Google Scholar] [CrossRef]

- Paulson, J.; Tsay, C. Bayesian optimization as a flexible and efficient design framework for sustainable process systems. Curr. Opin. Green Sustain. Chem. 2025, 51, 100983. [Google Scholar] [CrossRef]

- Karam, M.; Saad, T. BuckinghamPy: A Python software for dimensional analysis. SoftwareX 2021, 16, 100851. [Google Scholar] [CrossRef]

- Brochu, E.; Cora, V.M.; Freitas, N.d. A Tutorial on Bayesian Optimization of Expensive Cost Functions, with Application to Active User Modelling and Hierarchical Reinforcement Learning. arXiv 2010, arXiv:1012.2599. [Google Scholar] [CrossRef]

- Srinivas, N.; Krause, A.; Kakade, S.M.; Seeger, M.W. Information-Theoretic Regret Bounds for Gaussian Process Optimization in the Bandit Setting. IEEE Trans. Inf. Theory 2012, 58, 3250–3265. [Google Scholar] [CrossRef]

- González, J.; Dai, Z.; Hennig, P.; Lawrence, N. Batch Bayesian Optimization via Local Penalization. arXiv 2016, arXiv:1505.08052. [Google Scholar] [CrossRef]

- Gupta, S.; Rubin, D.; Sutti, A.; Dorin, T.; Height, M.; Sanders, P.; Venkatesh, S. Process-constrained batch Bayesian optimisation. Adv. Neural Inf. Process. Syst. 2017, 30, 3417–3426. Available online: https://dl.acm.org/doi/10.5555/3294996.3295100 (accessed on 9 November 2025).

- Wilson, J.; Hutter, F.; Deisenroth, M. Maximizing acquisition functions for Bayesian optimization. arXiv 2018, arXiv:1805.10196. [Google Scholar] [CrossRef]

- Contal, E.; Buffoni, D.; Robicquet, A.; Vayatis, N. Parallel Gaussian Process Optimization with Upper Confidence Bound and Pure Exploration. In Lecture Notes in Computer Science; Springer: New York, NY, USA, 2013; Volume 8188. [Google Scholar] [CrossRef]

- Yue, X.; Wen, Y.; Hunt, J.H.; Shi, J. Active Learning for Gaussian Process Considering Uncertainties With Application to Shape Control of Composite Fuselage. IEEE Trans. Autom. Sci. Eng. 2021, 18, 36–46. [Google Scholar] [CrossRef]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; MIT Press Academic: Cambridge, MA, USA, 2005. [Google Scholar]

- Seeger, M. Bayesian model selection for Support Vector machines, Gaussian processes and other kernel classifiers. Adv. Neural Inf. Process. Syst. 1999, 12. Available online: https://proceedings.neurips.cc/paper_files/paper/1999/file/404dcc91b2aeaa7caa47487d1483e48a-Paper.pdf (accessed on 9 November 2025).

- Bishop, C.M.; Nasrabadi, N.M. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006; Volume 4, p. 738. [Google Scholar]

- Liu, C.; Li, M.; Han, R.; Li, J.; Liu, C. Rheology of Water-in-Oil Emulsions with Different Drop Sizes. J. Dispers. Sci. Technol. 2016, 37, 333–344. [Google Scholar] [CrossRef]

- Carbone, M.R. When not to use machine learning: A perspective on potential and limitations. MRS Bull. 2022, 47, 968–974. [Google Scholar] [CrossRef]

| Variable | Symbol | Units | Steps | Settings | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wax/oil ratio | P | % | 6 | 0 | 10 | 20 | 30 | 40 | 50 | ||||

| Mixer head size | H | - | 2 | s | B | ||||||||

| Mixer setting | S | - | 7 | A | B | C | D | E | F | G | |||

| Amount of wax/oil | M | gr | 6 | 5 | 10 | 15 | 20 | 25 | 30 | ||||

| Temperature | T | °C | 7 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | |||

| Mixing time | t | s | 10 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Sample ID | Wax/Oil Ratio | Mixer Head Size | Mixer Setting | Amount of Wax/Oil | Temperature | Mixing Time |

|---|---|---|---|---|---|---|

| (P, %) | (H) | (S) | (M, gr) | (T, °C) | (t, s) | |

| 1 | 20 | S | A | 5 | 85 | 14 |

| 2 | 0 | S | A | 5 | 65 | 2 |

| 3 | 20 | S | G | 5 | 65 | 2 |

| 4 | 0 | S | A | 5 | 70 | 18 |

| 5 | 0 | B | D | 30 | 70 | 8 |

| 6 | 40 | B | A | 15 | 80 | 18 |

| Iteration | |||||

|---|---|---|---|---|---|

| 0 | 0.6 | 0.0100 | 0.60 | 0.6 | 0.6000 |

| 1 | 0.6 | 0.0307 | 0.60 | 0.6 | 0.1792 |

| 2 | 0.6 | 0.0369 | 0.60 | 0.6 | 0.2284 |

| 3 | 0.6 | 0.0423 | 0.60 | 0.6 | 0.2483 |

| 4 | 0.6 | 0.0423 | 0.08 | 0.6 | 0.2455 |

| 5 | 0.6 | 0.0411 | 0.60 | 0.6 | 0.2487 |

| 6 | 0.6 | 0.0406 | 0.60 | 0.6 | 0.2551 |

| 7 | 0.6 | 0.0249 | 0.60 | 0.6 | 0.1649 |

| 8 | 0.6 | 0.0242 | 0.60 | 0.6 | 0.1646 |

| 9 | 0.6 | 0.0247 | 0.60 | 0.6 | 0.1785 |

| 10 | 0.6 | 0.0359 | 0.60 | 0.6 | 0.5113 |

| Variable | Symbol | Units | Steps | Settings | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wax/oil ratio | O | % | 6 | 0 | 10 | 20 | 30 | 40 | 50 | |||||||||

| Mixer head size | S | - | 2 | s | B | |||||||||||||

| Mixer setting | H | - | 7 | A | B | C | D | E | F | G | ||||||||

| Amount of wax/oil | M | gr | 6 | 5 | 10 | 15 | 20 | 25 | 30 | |||||||||

| Temperature | T | °C | 7 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | ||||||||

| Stirring time | t | s | 10 | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 |

| O | H (Encoded) | S | m | T | t |

|---|---|---|---|---|---|

| 0.6 | 0.0986 | 0.2322 | 0.0756 | 0.2817 | 0.0127 |

| Dimensionless Number | Minimum | Maximum |

|---|---|---|

| wt | 0.015 | - |

| p | - | 9.091 |

| 8166.667 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senadeera, M.; Rubin de Celis Leal, D.; Rana, S.; Subianto, S.; Thompson, N.; Gupta, S.; Venkatesh, S.; Sutti, A. Bayesian Optimisation with Dimensionless Groups: A Synergy of Performance and Fundamental Understanding. Appl. Sci. 2025, 15, 12215. https://doi.org/10.3390/app152212215

Senadeera M, Rubin de Celis Leal D, Rana S, Subianto S, Thompson N, Gupta S, Venkatesh S, Sutti A. Bayesian Optimisation with Dimensionless Groups: A Synergy of Performance and Fundamental Understanding. Applied Sciences. 2025; 15(22):12215. https://doi.org/10.3390/app152212215

Chicago/Turabian StyleSenadeera, Manisha, David Rubin de Celis Leal, Santu Rana, Surya Subianto, Nathan Thompson, Sunil Gupta, Svetha Venkatesh, and Alessandra Sutti. 2025. "Bayesian Optimisation with Dimensionless Groups: A Synergy of Performance and Fundamental Understanding" Applied Sciences 15, no. 22: 12215. https://doi.org/10.3390/app152212215

APA StyleSenadeera, M., Rubin de Celis Leal, D., Rana, S., Subianto, S., Thompson, N., Gupta, S., Venkatesh, S., & Sutti, A. (2025). Bayesian Optimisation with Dimensionless Groups: A Synergy of Performance and Fundamental Understanding. Applied Sciences, 15(22), 12215. https://doi.org/10.3390/app152212215