Predictive Modeling of Tool Wear and Mass in Honing Processes Using Machine Learning and Grain Size Optimization

Abstract

1. Introduction

2. Materials and Methods

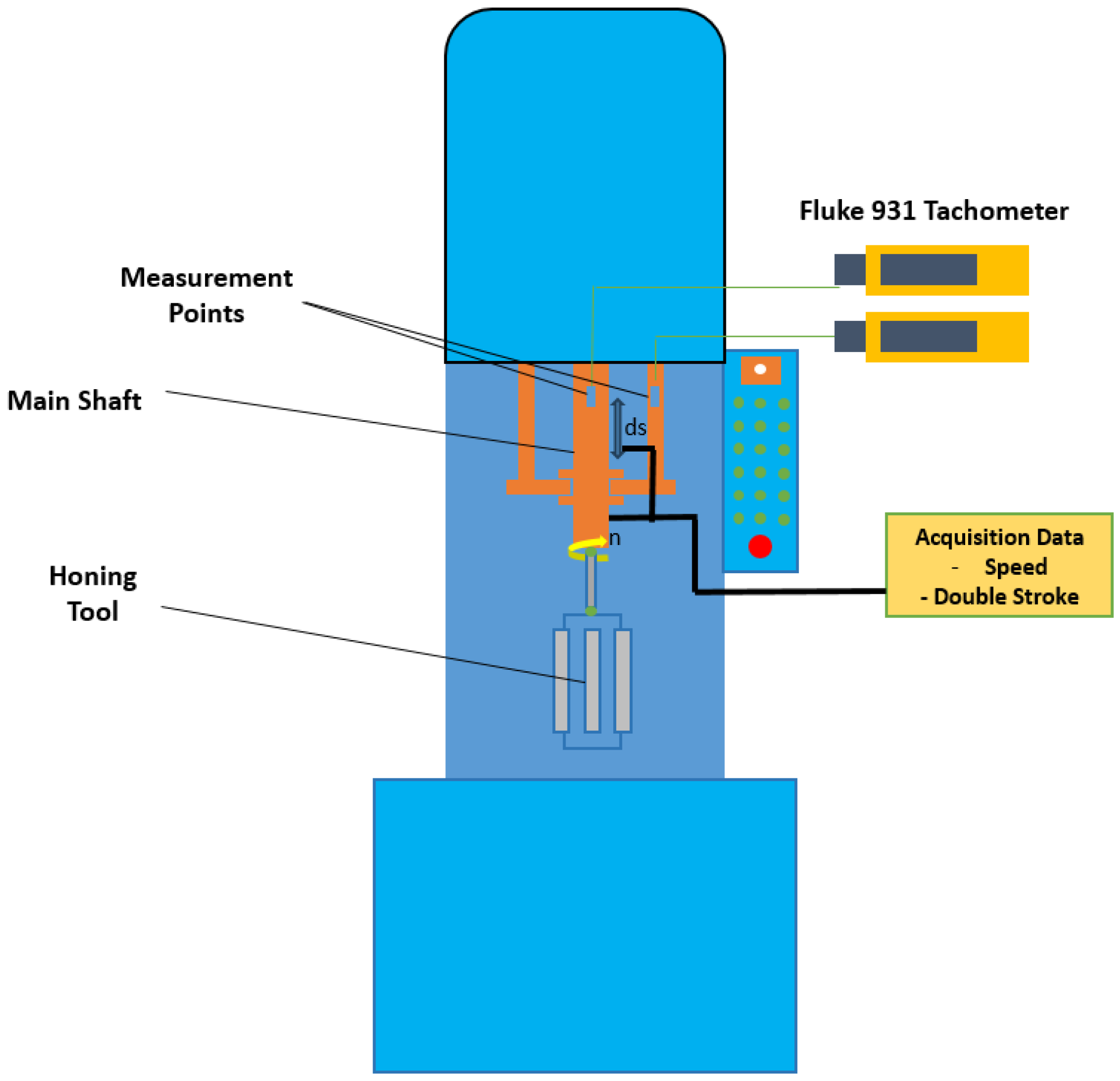

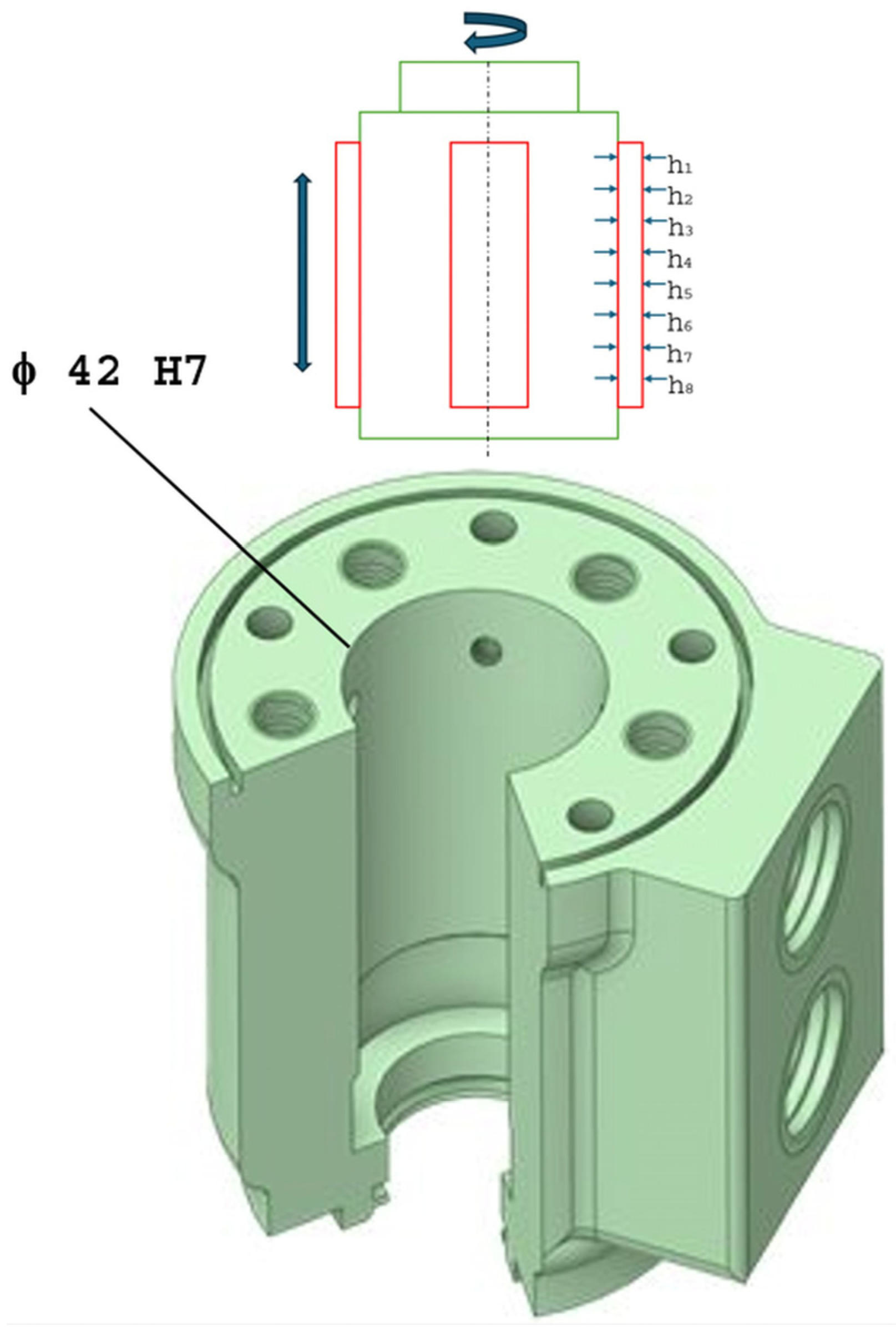

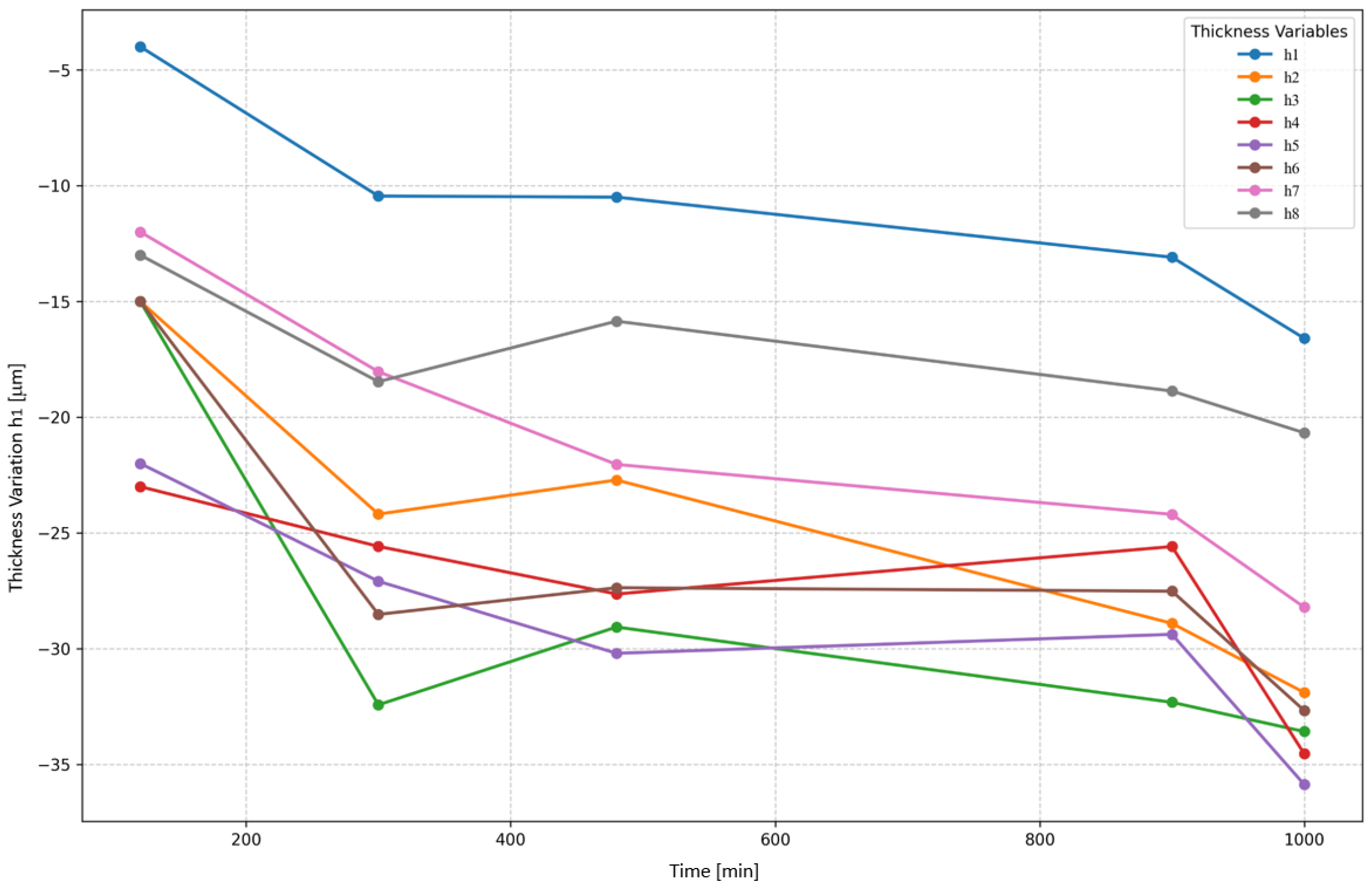

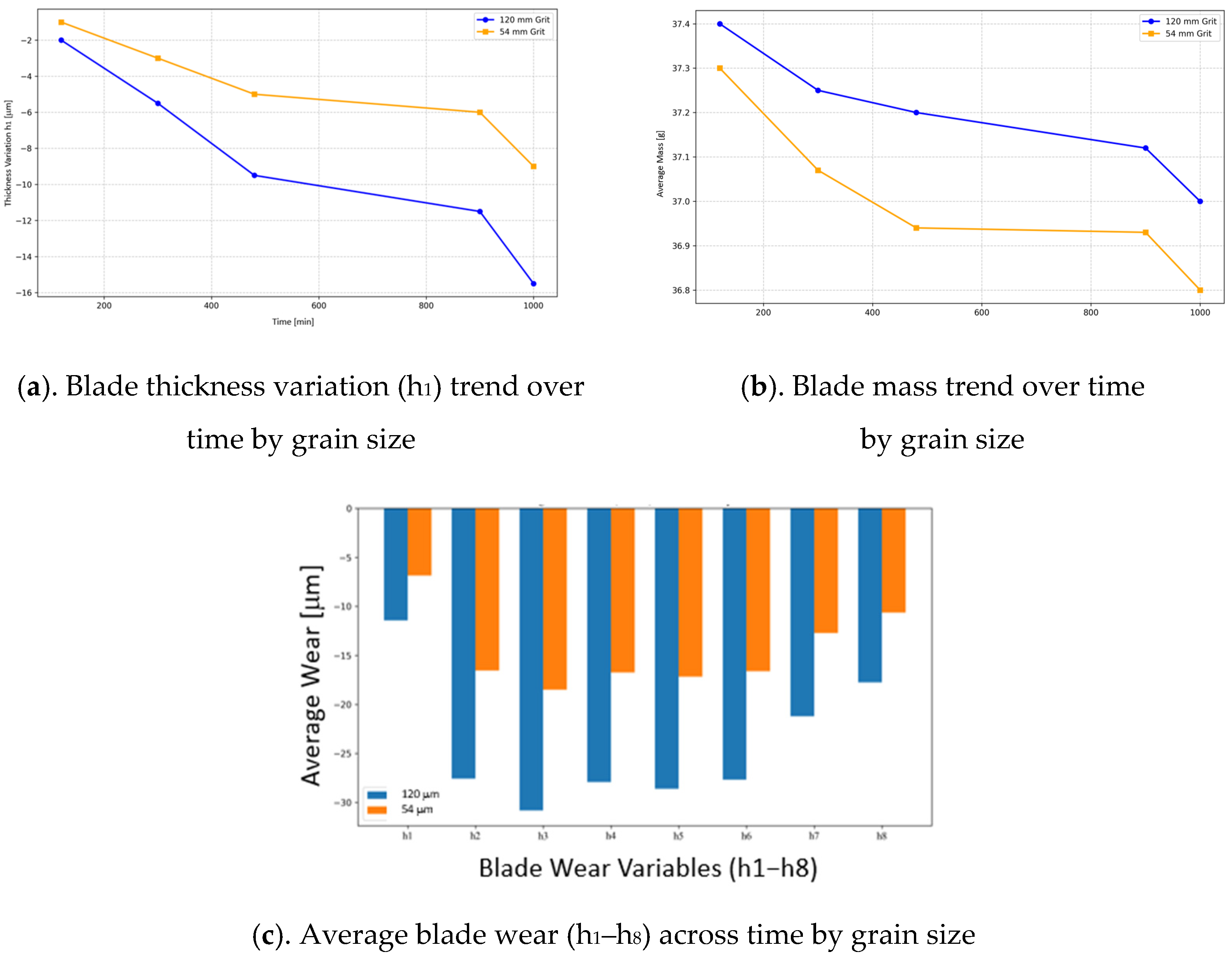

Experimental Setup

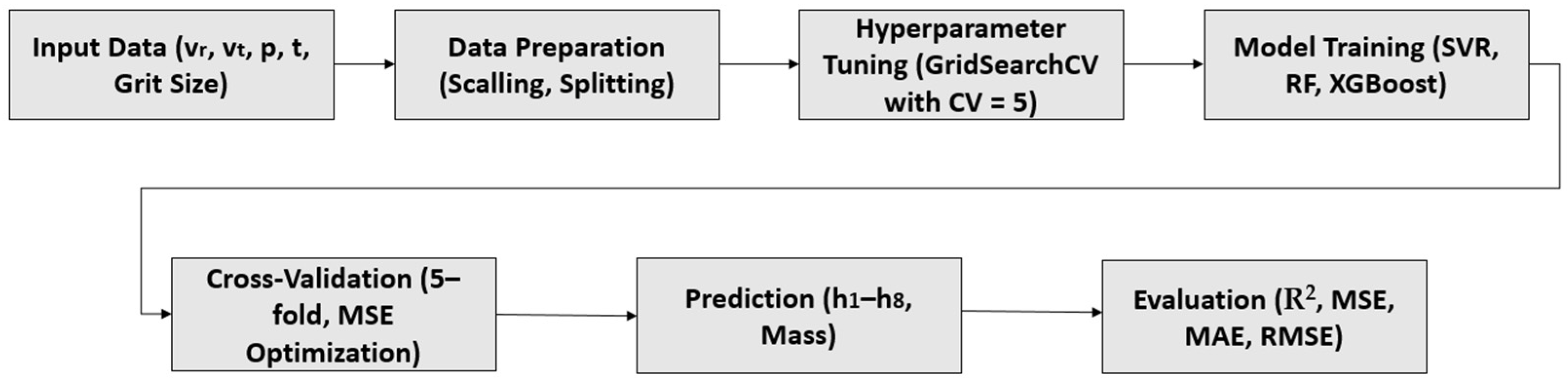

3. Predictive Modeling of Tool Wear and Mass

3.1. Data Preprocessing

3.2. Model Evaluation

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalpakjian, S.; Schmid, S.; Vijay Sekar, K.S. Manufacturing Engineering and Technology, 7th ed.; Pearson Education Limited: London, UK, 2021. [Google Scholar]

- Buj-Corral, I.; Sivatte-Adroer, M.; Llanas-Parra, X. Adaptive Indirect Neural Network Model for Roughness in Honing Processes. Tribol. Int. 2020, 141, 105891. [Google Scholar] [CrossRef]

- Rief, S.; Ströer, F.; Kieß, S.; Eifler, M.; Seewig, J. An Approach for the Simulation of Ground and Honed Technical Surfaces for Training Classifiers. Technologies 2017, 5, 66. [Google Scholar] [CrossRef]

- Singh, B.; Bansal, S.; Mishra, P. Artificial Neural Network Modeling and Optimization in Honing Process. Int. J. Comput. Eng. Technol. (IJCET) 2016, 7, 67–77. [Google Scholar]

- Sivatte-Adroer, M.; Llanas-Parra, X.; Buj-Corral, I.; Vivancos-Calvet, J. Indirect Model for Roughness in Rough Honing Processes based on Artificial Neural Networks. Precis. Eng. 2016, 43, 505–513. [Google Scholar] [CrossRef]

- Buj-Corral, S.; Sender, P.; Luis-Pérez, C.J. Modeling of Surface Roughness in Honing Processes by Using Fuzzy Artificial Neural Networks. J. Manuf. Mater. Process. 2023, 7, 23. [Google Scholar] [CrossRef]

- Klein, S.; Schorra, S.; Bähre, D. Quality Prediction of Honed Bores with Machine Learning Based on Machining and Quality Data to Improve the Honing Process Control. In Proceedings of the 53rd CIRP Conference on Manufacturing Systems, Chicago, IL, USA, 1–3 July 2020; pp. 1322–1327. [Google Scholar]

- Deng, Q.; Li, D.; Wang, H.; Cao, P.; Wu, Y. Study of Noise Reduction by Optimizing Ultra-High Speed Milling Parameters by DOE Method. UPB. Sci. Bull. Ser. D 2023, 85, 319–332. [Google Scholar]

- Yang, X.; Li, Y.; Shen, Z.; Chen, R. An Experimental Investigation of Element Diffusion between Cemented Carbide Tools and Titanium Alloys in High Speed Machining Processes. UPB. Sci. Bull. 2020, 82, 225–236. [Google Scholar]

- Gejii, A.; Shukla, S.; Pimparkar, S.; Pattharwala, T.; Bewoor, A. Using a Support Vector Machine for Building a Quality Prediction Model for Center-less Honing Process. Procedia Manuf. 2020, 46, 600–607. [Google Scholar] [CrossRef]

- Qin, F.; Chen, Q.; Tian, X.; Liu, L. Honing Technology based on Intelligent Manufacturing Technology. J. Eng. Mech. Mach. 2022, 7, 12–16. [Google Scholar] [CrossRef]

- Sender, P.; Buj-Corral, I. Influence of Honing Parameters on the Quality of the Machined Parts and Innovations in Honing Processes. Metals 2023, 13, 140. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, X.; An, Q.; Chen, M.; Hun, G.; He, Y. A Tool Wear Prediction and Monitoring Method based on Machining Power Signals. Int. J. Adv. Manuf. Technol. 2023, 129, 5387–5401. [Google Scholar] [CrossRef]

- Chauhan, S.; Trehan, R.; Singh, R.P.; Sharma, V.S. Assessment of Machining Performance for Intelligent Tool Wear Prediction Using Hybrid Extreme Learning Machine. IEEE Sens. J. 2024, 24, 22. [Google Scholar] [CrossRef]

- Mishra, D.; Awasthi, U.; Pattipati, K.R.; Bollas, G.M. Tool Wear Classification in Precision Machining using Distance Metrics and Unsupervised Machine Learning. J. Intell. Manuf. 2025, 36, 331–355. [Google Scholar] [CrossRef]

- Tambake, N.; Deshmukh, B.; Pardeshi, S.; Salunkhe, S.; Cep, R.; Nasr, E. Condition Monitoring of a CNC Hobbing Cutter using Machine Learning Approach. Adv. Mech. Eng. 2024, 16, 16878132241275750. [Google Scholar] [CrossRef]

- Fang, S.; Schorr, S.; Bähre, D. Efficient Machine Learning-Based Forecasting of Key Control Parameters for Analyzing Honing Stone Cutting Performance. In Proceedings of the ASME 20th International Manufacturing Science and Engineering Conference, Greenville, SC, USA, 23–27 June 2025. [Google Scholar]

- Airao, J.; Gupta, A.; Nirala, C.; Wen-Jeng Hsue, A. Bayesian Neural Networks Modeling for Tool Wear Prediction in Milling Al 6061 T6 under MQL Conditions. Int. J. Adv. Manuf. Technol. 2024, 135, 2777–2788. [Google Scholar] [CrossRef]

- Chang, S.H.; Farris, T.N.; Chandrasekar, S. Contact Mechanics of Superfinishing. J. Tribol. ASME 2000, 122, 388–393. [Google Scholar] [CrossRef]

- Heng, L.; Kim, J.S.; Song, J.H.; Mun, S.D. A Review on Surface Finishing Techniques for Difficult-to-Machine Ceramics by Non-Conventional Finishing Processes. Materials 2022, 15, 1227. [Google Scholar] [CrossRef]

- Aslanbaş, İ.G.; Akar, S. Superfinishing Process of Ball Bearings. Çankaya Univ. J. Sci. Eng. 2024, 21, 63–70. [Google Scholar]

- Onishi, T.; Ohashi, K.; Higashi, K.; Morinaka, Y.; Banno, S.; Kitagawa, T.; Tsukamoto, S. In-Process Monitoring of the Machining State in Superfinishing by Measuring the Dynamic Machining Forces. Adv. Mater. Res. 2016, 1136, 592–596. [Google Scholar] [CrossRef]

- Horvath, R.; Dregelyi-Kiss, A.; Matyasi, G. The Examination of Surface Roughness Parameters in the Fine Turning of Hypereutectic Aluminium Alloys. UPB. Sci. Bull. Ser. D 2015, 77, 205–216. [Google Scholar]

- Wang, W.; Shi, S.; Zhang, B.; Jiang, N.; Tang, J. Abrasive Flow Machining Ground Surfaces with Grinding Marks of Different Directions: Parameters Optimization and Mechanisms. J. Manuf. Process. 2025, 148, 212–223. [Google Scholar] [CrossRef]

- Bhowmik, A.; Raja Praveen, K.N.; Bhosle, N.; Gagneja, K. Performance Evaluation of Machine Learning Algorithms in Predicting Machining Responses of Superalloys. AIP Adv. 2024, 14, 105027. [Google Scholar] [CrossRef]

- Lee, S.; Chen, Z.; Luo, Y.; Li, X.; Lu, M. Enhanced Prediction Accuracy in High-speed Grinding of Brittle Materials using Advanced Machine Learning Technique. J. Intell. Manuf. 2024, 36, 5415–5439. [Google Scholar] [CrossRef]

- Kim, G.; Park, S.; Choi, J.; Yang, M.; Lim, S. Developing a Data-Driven System for Grinding Process Parameter Optimization using Machine Learning and Metaheuristic Algorithms. CIRP J. Manuf. Sci. Technol. 2024, 51, 20–35. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Rodero-de-Lamo, L.; Marco-Almagro, L. Optimization and Sensitivity Analysis of the Cutting Conditions in Rough, Semi-Finish and Finish Honing. Materials 2022, 15, 75. [Google Scholar] [CrossRef]

- Fluke 931 Contact and Non-Contact Dual-Purpose Tachometers. Available online: https://www.fluke.com/en-sg/product/building-infrastructure/hvac-tools/fluke-931 (accessed on 23 September 2025).

- National Instruments NI USB-600. Available online: https://www.ni.com/ro-ro/shop/model/usb-6001.html (accessed on 11 September 2025).

- Ohaus Explorer EX124. Available online: https://us.ohaus.com/en-us/products/balances-scales/analytical-balances/explorer-analytical/ex124 (accessed on 22 September 2025).

- Carl Zeiss Universal Microscope. Available online: https://www.zeiss.com/microscopy/en/home.html (accessed on 22 September 2025).

- Ciaburro, G. Regression Analysis with R; Packt Publishing Ltd.: Birmingham, UK, 2018; ISBN 978-1-78862-730-6. [Google Scholar]

- Harrell, F. Regression Modelling Strategies with Applications to Linear Models, Logistic and Ordinal Regression, and Survival Analysis, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

| Process Parameter | −2 | −1 | 0 | 1 | 2 |

|---|---|---|---|---|---|

| Rotation Speed [m/min] | 35 | 41 | 47 | 53 | 59 |

| Translation Speed [m/min] | 10 | 14 | 20 | 22 | 30 |

| Pressure [daN/cm2] | 20 | 25 | 30 | 35 | 40 |

| Blade No. | Time [min] | Thickness Variation of Abrasive Blade | Mass [g] | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| h1 [μm] | h2 [μm] | h3 [μm] | h4 [μm] | h5 [μm] | h6 [μm] | h7 [μm] | h8 [μm] | |||

| 1 | 120 | −4 | −15 | −15 | −23 | −22 | −15 | −12 | −13 | 37.500 |

| 2 | 120 | −3 | −24 | −28 | −41 | −41 | −32 | −30 | −14 | 37.309 |

| 3 | 120 | −4 | −30 | −34 | −34 | −26 | −31 | −24 | −15 | 37.012 |

| 4 | 120 | −9 | −29 | −31 | −31 | −21 | −26 | −23 | −30 | 37.342 |

| 5 | 120 | −2 | −29 | −39 | −17 | −31 | −25 | −22 | −4 | 37.456 |

| 1 | 480 | −2 | −7 | −10 | −9 | −8 | −2 | −9 | −23 | 36.983 |

| 2 | 480 | −4 | −26 | −35 | −35 | −33 | −32 | −22 | −8 | 37.301 |

| 3 | 480 | −8 | −24 | −24 | −20 | −19 | −21 | −19 | −5 | 37.002 |

| 4 | 480 | −3 | −17 | −25 | −28 | −22 | −16 | 0 | −10 | 37.342 |

| 5 | 480 | 0 | −22 | −33 | −13 | −39 | −29 | −24 | −14 | 36.904 |

| 1 | 1000 | −19 | 0 | −3 | 0 | −4 | −13 | −2 | −5 | 36.968 |

| 2 | 1000 | −6 | −20 | −22 | −27 | −29 | −24 | −29 | −3 | 37.267 |

| 3 | 1000 | −8 | −20 | −10 | −13 | −17 | −21 | −6 | −6 | 36.995 |

| 4 | 1000 | −15 | −18 | −10 | −27 | −13 | −14 | −5 | −8 | 37.268 |

| 5 | 1000 | −4 | −24 | −32 | −21 | −23 | −30 | −3 | −3 | 36.851 |

| Thickness Honing Blade [μm] | Best Method | Full Best Parameters | R2 | MSE [μm2] | MAE [μm] |

|---|---|---|---|---|---|

| h1 | SVR | kernel = “rbf”, C = 100, epsilon = 0.1, gamma = 0.01 | 0.9609 | 0.0880 | 0.22 |

| h2 | SVR | kernel = “rbf”, C = 10, epsilon = 0.01, gamma = “scale” | 0.9646 | 0.0797 | 0.21 |

| h3 | SVR | kernel = “linear”, C = 1, epsilon = 0.1, gamma = “auto” | 0.9778 | 0.0500 | 0.17 |

| h4 | XGBoost | n_estimators = 200, learning_rate = 0.05, max_depth = 3, subsample = 0.8 | 0.9678 | 0.0725 | 0.20 |

| h5 | RF | n_estimators = 100, max_depth = 10, min_samples_split = 5, min_samples_leaf = 1 | 0.9730 | 0.0608 | 0.19 |

| h6 | SVR | kernel = “rbf”, C = 100, epsilon = 0.5, gamma = 0.01 | 0.9782 | 0.0491 | 0.17 |

| h7 | SVR | kernel = “rbf”, C = 1000, epsilon = 0.1, gamma = 0.001 | 0.9659 | 0.0767 | 0.21 |

| h8 | SVR | kernel = “rbf”, C = 100, epsilon = 0.01, gamma = 0.1 | 0.9745 | 0.0574 | 0.18 |

| Process Parameter | Mean SHAP Value | % Contribution | Interpretation |

|---|---|---|---|

| Pressure p | 3.45 | 35.2% | Non-linear force-penetration effect |

| Translation Speed vt | 2.95 | 30.1% | Uniform wear distribution |

| Rotation Speed vr | 2.49 | 25.4% | Friction-heat contribution |

| Interactions/Noise | 0.91 | 9.3% | Combined effects and residuals |

| Wear and Mass of the Honing Blades | Time [min] | Bootstrap 95% Interval |

|---|---|---|

| h1 [μm] | 500 | [−4.65, −3.58] |

| h1 [μm] | 1000 | [−7.82, −6.91] |

| h2 [μm] | 500 | [−4.58, −3.65] |

| h2 [μm] | 1000 | [−7.75, −6.98] |

| h3 [μm] | 500 | [−4.51, −3.72] |

| h3 [μm] | 1000 | [−7.68, −7.05] |

| h4 [μm] | 500 | [−4.44, −3.79] |

| h4 [μm] | 1000 | [−7.61, −7.12] |

| h5 [μm] | 500 | [−4.37, −3.86] |

| h5 [μm] | 1000 | [−7.54, −7.19] |

| h6 [μm] | 500 | [−4.30, −3.93] |

| h6 [μm] | 1000 | [−7.47, −7.26] |

| h7 [μm] | 500 | [−4.23, −4.00] |

| h7 [μm] | 1000 | [−7.40, −7.33] |

| h8 [μm] | 500 | [−4.16, −4.07] |

| h8 [μm] | 1000 | [−7.33, −7.20] |

| Mass [grams] | 500 | [36.40, 36.80] |

| Mass [grams] | 1000 | [36.35, 36.85] |

| Thickness Variation [μm] | R2 for XGBoost | R2 for Random Forest | R2 for SVR |

|---|---|---|---|

| h1 [μm] | 0.912 | 0.878 | 0.845 |

| h2 [μm] | 0.934 | 0.901 | 0.867 |

| h3 [μm] | 0.923 | 0.889 | 0.856 |

| h4 [μm] | 0.945 | 0.912 | 0.878 |

| h5 [μm] | 0.931 | 0.898 | 0.864 |

| h6 [μm] | 0.917 | 0.884 | 0.851 |

| h7 [μm] | 0.905 | 0.872 | 0.839 |

| h8 [μm] | 0.889 | 0.856 | 0.823 |

| Response Thickness Honing Blade [μm] | Dominant Terms (p < 0.05) | F-Statistic | Lack of Fit |

|---|---|---|---|

| h1 | vt, p, vr*p, vt*p | 19.45 (<0.00001) | 0.456 |

| h2 | vt, p, vr*p, vt*p | 25.12 (<0.00001) | 0.378 |

| h3 | vt, p, vr*p, vt*p | 27.03 (<0.00001) | 0.345 |

| h4 | vt, p, vr*p, vt*p | 18.92 (<0.00001) | 0.234 |

| h5 | vt, p, vr*p, vt*p | 20.12 (<0.00001) | 0.412 |

| h6 | vt, p, vr*p, vt*p | 22.45 (<0.00001) | 0.387 |

| h7 | vt, p, vr*p, vt*p | 18.78 (<0.00001) | 0.399 |

| h8 | vt, p, vr*p, vt*p | 17.12 (<0.00001) | 0.412 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gheorghita, V. Predictive Modeling of Tool Wear and Mass in Honing Processes Using Machine Learning and Grain Size Optimization. Appl. Sci. 2025, 15, 12207. https://doi.org/10.3390/app152212207

Gheorghita V. Predictive Modeling of Tool Wear and Mass in Honing Processes Using Machine Learning and Grain Size Optimization. Applied Sciences. 2025; 15(22):12207. https://doi.org/10.3390/app152212207

Chicago/Turabian StyleGheorghita, Vlad. 2025. "Predictive Modeling of Tool Wear and Mass in Honing Processes Using Machine Learning and Grain Size Optimization" Applied Sciences 15, no. 22: 12207. https://doi.org/10.3390/app152212207

APA StyleGheorghita, V. (2025). Predictive Modeling of Tool Wear and Mass in Honing Processes Using Machine Learning and Grain Size Optimization. Applied Sciences, 15(22), 12207. https://doi.org/10.3390/app152212207