Techno-Economic Feasibility Analysis of Biomethane Production via Electrolytic Hydrogen and Direct Biogas Methanation

Abstract

1. Introduction

1.1. European Policies and Strategies for Biomethane Development

1.2. Power-to-Biomethane Concept

1.3. Research Purpose and Novelty

- A thermochemical model for the direct catalytic methanation system of raw biogas;

- A techno-economic modeling framework that explicitly incorporates renewable resource variability and operational management strategies;

- An optimization approach that jointly evaluates technical and economic performance to identify cost-optimal system configurations.

2. Materials and Methods

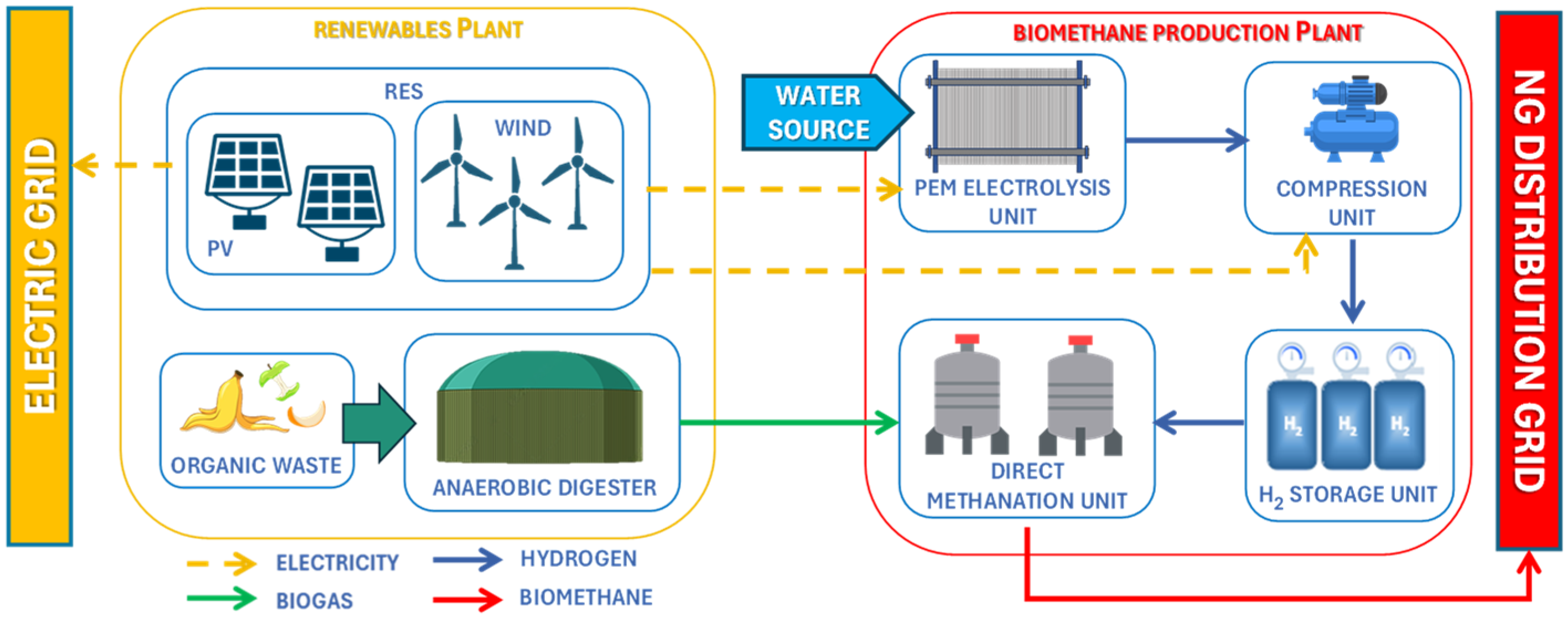

2.1. Description of the PtBM Plant Concept

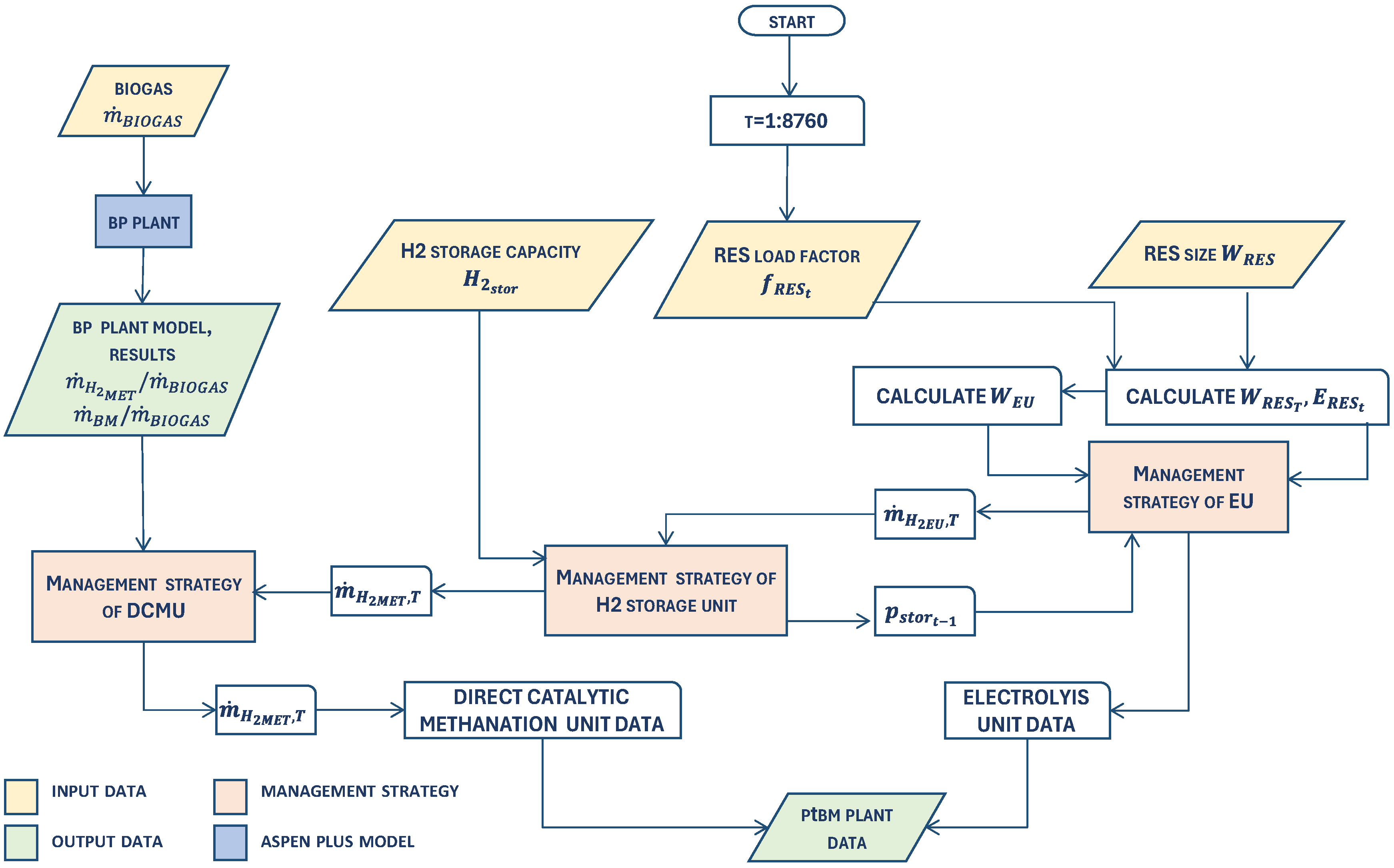

2.2. Methods

2.2.1. Optimization Approach

- (i)

- Problem definition, where both RES plant sizes and H2 storage capacity are set as design variables, LCOBM as the objective, and OPH as a constraint.

- (ii)

- Optimization strategy definition, where the proprietary pilOPT algorithm was selected. This algorithm in modeFRONTIER combines global and local optimization strategies within an adaptive, self-learning framework. Unlike traditional methods, it does not rely on a predefined Design of Experiments; instead, it iteratively generates new designs based on previous evaluations. Convergence is assessed through the stabilization of the objective function and the evolution of the Pareto front, ensuring an efficient balance between exploration and refinement. In this study, a maximum of 200 iterations was adopted.

- (iii)

- Optimization phase, in which the pilOPT algorithm varies the input variables to achieve the defined objective while satisfying the specified constraint.

2.2.2. Techno-Economic Model

- The photovoltaic plant and wind farm (RES) size (kW);

- The hydrogen storage capacity (kg);

- The RES load factor , that is, the hourly specific electric energy production with respect to the RES size (kWh/kW);

- The operating data of the BP plant, which are the biogas flow rate and the hydrogen-to-biogas ratio .

- Electrolysis unit: The electrolyzer operates according to both the available RES power and the storage status. It is characterized by a minimum and maximum input power demand (, ).

- When the RES power output falls within the operating range of the electrolyzer () the electrolyzer runs at partial or full load, directing hydrogen to storage;

- If the RES power output exceeds the electrolyzer’s full load power consumption () the electrolysis unit works at full load, with excess power exported to the grid;

- If, on the contrary, the RES capacity falls below the minimum power requirement of the electrolyzer () or the storage tank is full (=) the electrolyzer enters standby mode and surplus RES electricity is diverted to the grid.

- Hydrogen storage: The hydrogen storage unit is defined by four characteristic pressures: minimum (), shutdown (), restart (), and maximum ().

- When the tank pressure lies between the shutdown and maximum limits (), hydrogen is both stored and delivered to the methanation unit;

- If the pressure drops below the shutdown threshold () the methanation unit is forced into standby, although hydrogen can still be accumulated in the tank;

- Above storage continues until restart conditions are satisfied;

- Once the restart pressure is reached, the conditions for resuming methanation are restored.

- Methanation unit: The direct catalytic methanation unit (DCMU) is directly controlled by the storage pressure.

- At maximum tank pressure , the reactor operates at full load;

- Within the range it follows a partial load regime according to a linear relation (Equation (9));

- If the tank pressure falls to the shutdown value the unit is switched off; at even lower pressures it remains in standby until restart conditions are satisfied ;

- During transitions between shutdown and restart, flushing is performed to ensure safe operation.

2.2.3. Thermochemical Model

2.3. Case Studies

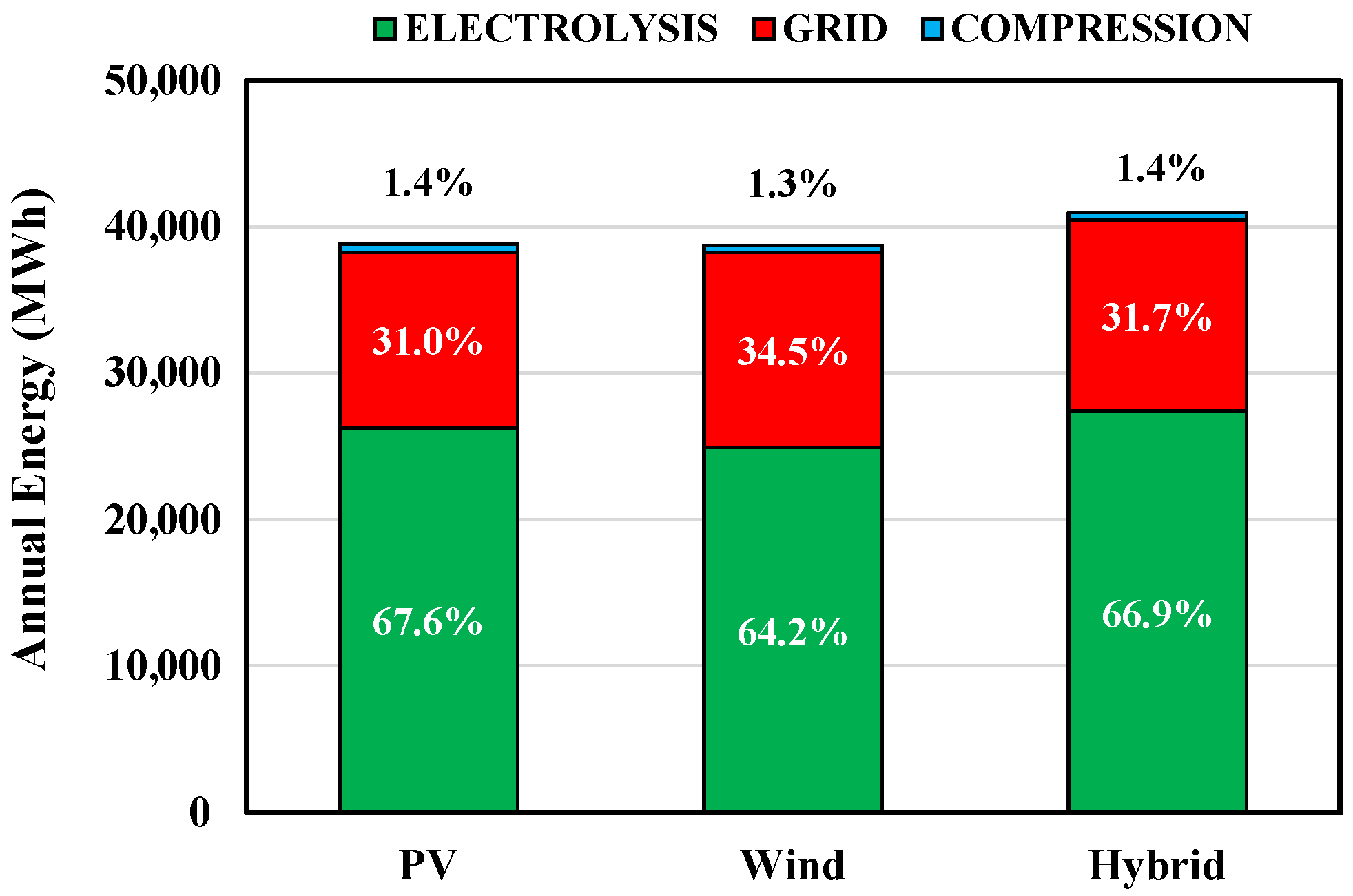

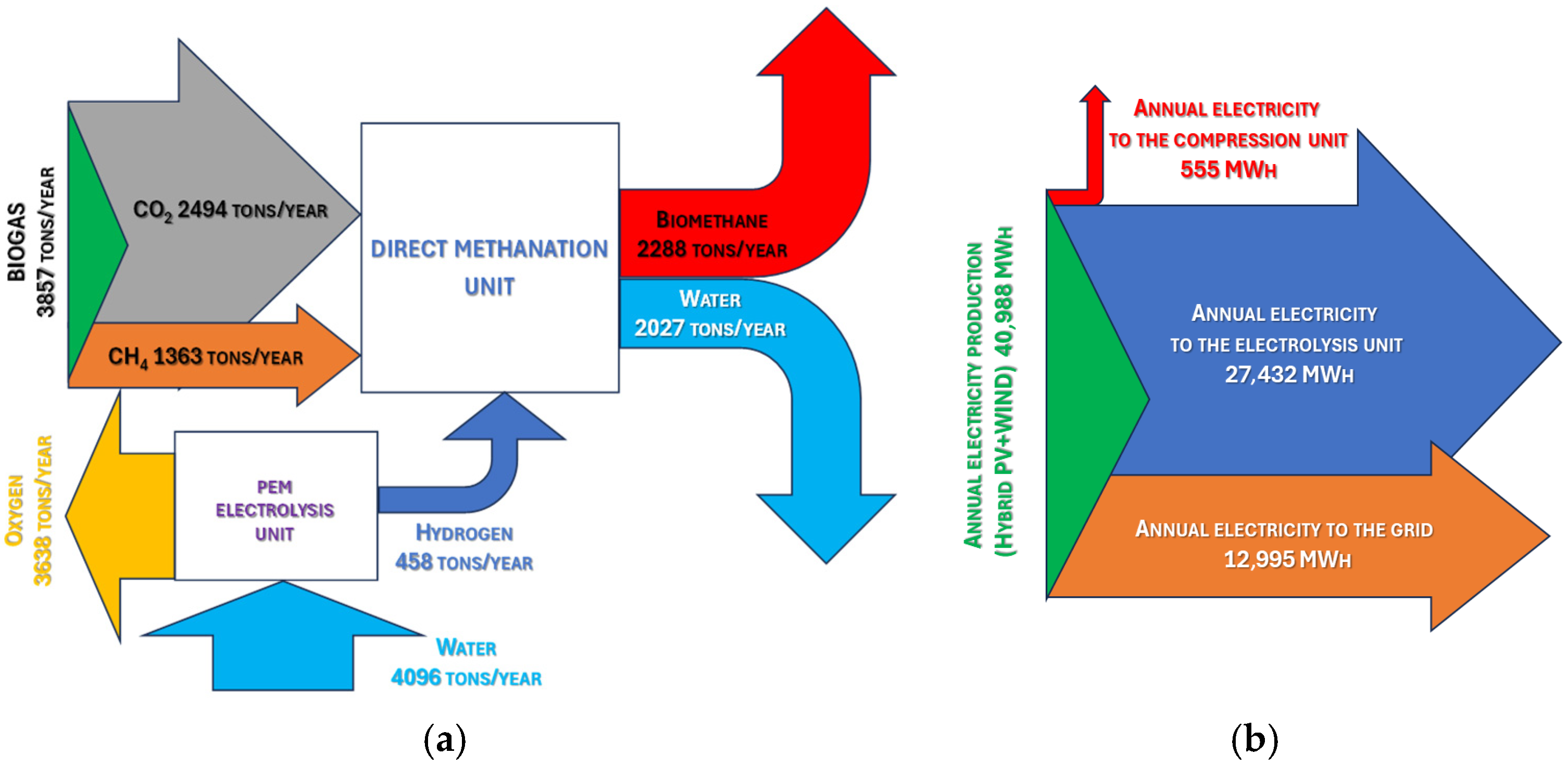

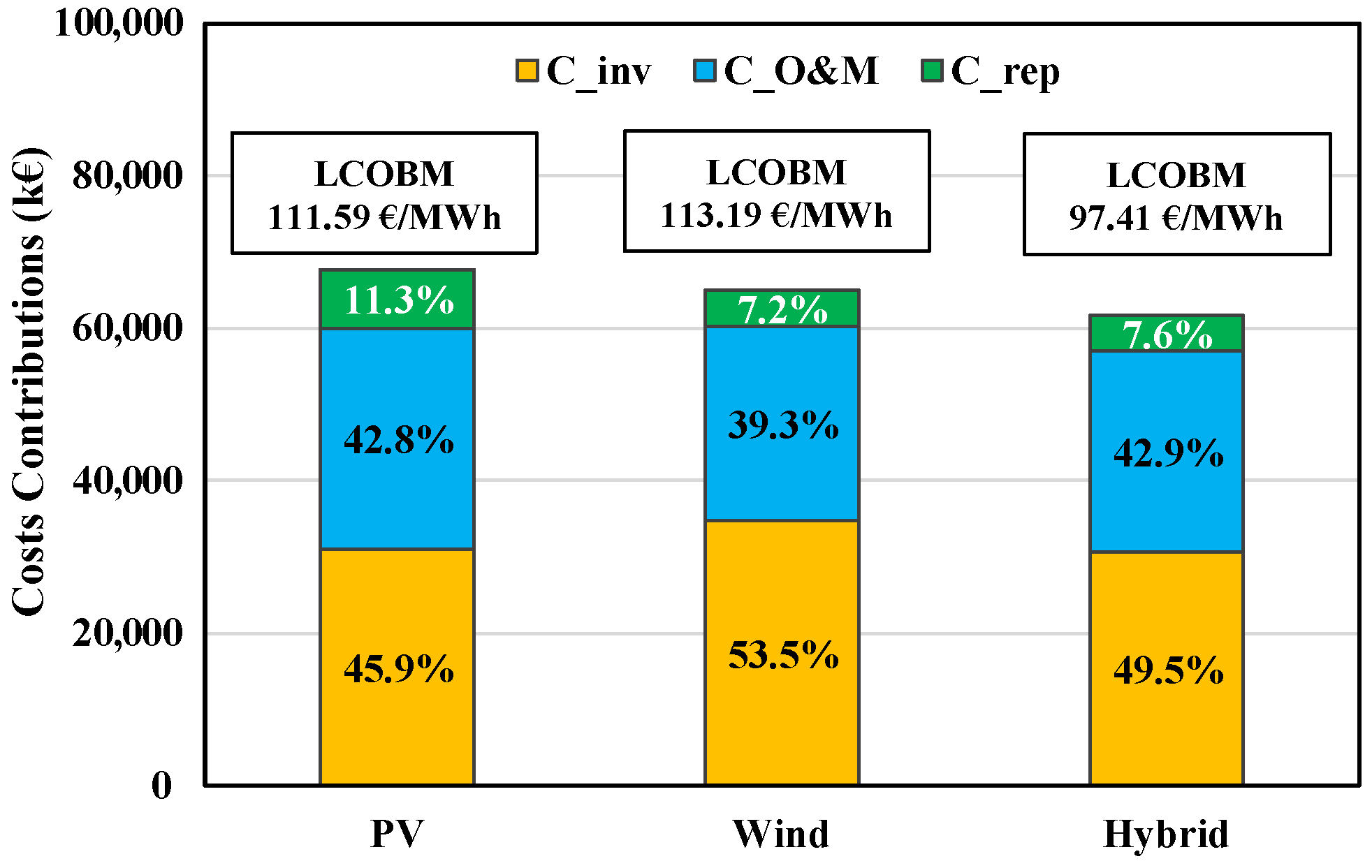

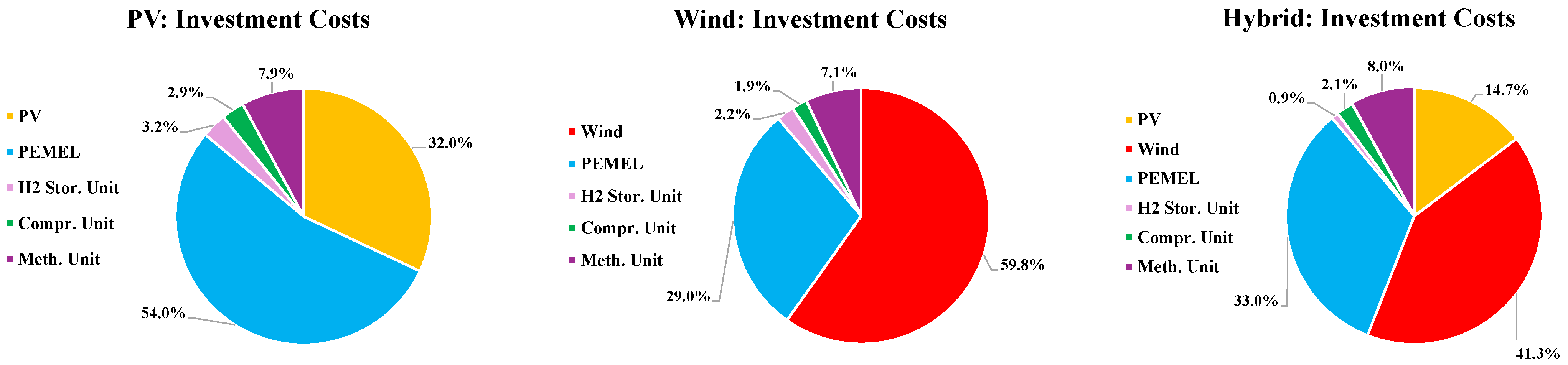

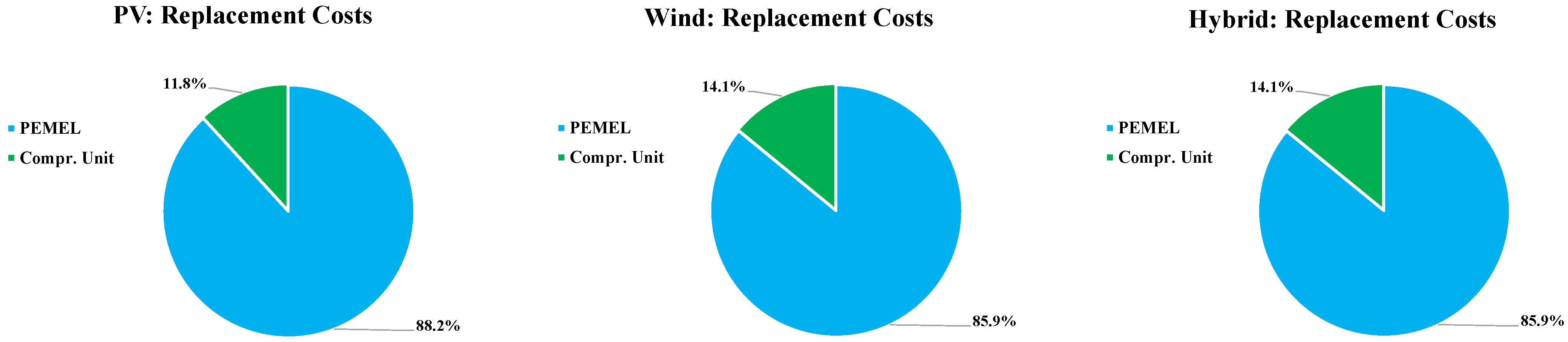

3. Results

Sensitivity Analysis Results

4. Discussion and Perspectives

5. Conclusions

- The hybrid layout balances power supply, increasing system utilization and reducing methanation downtime.

- The hybrid PV–wind configuration achieves the best techno-economic performance, with the highest annual biomethane production (~2288 t) and lowest hydrogen storage (~540 kg);

- The PV system requires the largest capacity (24.5 MW) and storage (2000 kg) due to intermittency, while the wind system has lower costs but reduced production (~2037 t);

- The corresponding LCOBM is lowest for the hybrid system (EUR 97.4/MWh) compared to PV (EUR 111.6/MWh) and wind (EUR 113.2/MWh);

- The DPBP is 8.7 years, which can improve under incentivized biomethane tariffs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | |

| Hydrogen flow to the methanation unit calculation coefficient (kg/s·Pa) | |

| Hydrogen flow to the methanation unit calculation coefficient (kg/s·Pa) | |

| Annualized Investment Costs (EUR) | |

| Annualized Operating and Maintenance Costs (EUR) | |

| Annualized Replacement Costs (EUR) | |

| Capital Recovery Factor | |

| Annual discounted cash flows (EUR) | |

| Annual electric energy consumption of the compression unit (MWh) | |

| Annual electric energy consumption of the electrolysis unit (MWh) | |

| Annual electric energy to the grid (MWh) | |

| Annual electric energy production (MWh) | |

| RES hourly electric energy (kWh) | |

| Inflation rate (%) | |

| RES load factor (kWh/kW) | |

| Nominal interest rate (%) | |

| Real interest rate (%) | |

| H2store | H2 Storage Capacity (kg) |

| Biogas flow rate at full load (kg/h) | |

| Annual biomethane production (tons) | |

| Biomethane flow rate at full load (kg/h) | |

| Hourly biomethane flow rate (kg/h) | |

| Hourly hydrogen flow rate produced by the electrolysis unit (kg/h) | |

| Hydrogen flow rate to the methanation unit at full load (kg/h) | |

| Hourly hydrogen flow rate to the methanation unit (kg/h) | |

| Year | |

| Plant lifetime (year) | |

| Maximum storage pressure (Pa) | |

| Minimum storage pressure (Pa) | |

| Restart pressure (Pa) | |

| Shutdown pressure (Pa) | |

| Storage pressure at time t (Pa) | |

| Annual present value of cash flows (EUR) | |

| Annualized revenues (EUR) | |

| Time-step (hour) | |

| Electrolysis unit size (kW) | |

| Electric power consumption of the electrolysis unit (kW) | |

| Electric power consumption of the electrolysis unit at full load (kW) | |

| Electric power consumption of the electrolysis unit at minimum load (kW) | |

| RES size (kW) | |

| RES power at time t (kW) | |

| Acronyms | |

| AD | Anaerobic Digestion |

| BM | Biomethane |

| BP | Biomethane Production |

| CAPEX | Capital Expenditure |

| CO2 | Carbon Dioxide |

| DCMU | Direct Catalytic Methanation Unit |

| DPBP | Discounted Payback Period |

| EU | Electrolysis Unit |

| HAWT | Horizontal Axis Wind Turbines |

| H2 | Hydrogen |

| LCOBM | Levelized Cost of Biomethane |

| LHV | Low Heating Value |

| O&M | Operating and Maintenance |

| OPH | Operating Hours (h) |

| PEMEL | Proton Exchange Membrane Electrolysis |

| PtBM | Power-to-Biomethane |

| PtG | Power-to-Gas |

| PV | Photovoltaic |

| RES | Renewable Energy Source |

References

- Nemmour, A.; Inayat, A.; Janajreh, I.; Ghenai, C. Green hydrogen-based E-fuels (E-methane, E-methanol, E-ammonia) to support clean energy transition: A literature review. Int. J. Hydrogen Energy 2023, 48, 29011–29033. [Google Scholar] [CrossRef]

- Martin, J.; Neumann, A.; Ødegård, A. Renewable hydrogen and synthetic fuels versus fossil fuels for trucking, shipping and aviation: A holistic cost model. Renew. Sustain. Energy Rev. 2023, 186, 113637. [Google Scholar] [CrossRef]

- Schnuelle, C.; Thoeming, J.; Wassermann, T.; Thier, P.; von Gleich, A.; Goessling-Reisemann, S. Socio-technical-economic assessment of power-to-X: Potentials and limitations for an integration into the German energy system. Energy Res. Soc. Sci. 2019, 51, 187–197. [Google Scholar] [CrossRef]

- Ruth, M.; Goessling-Reisemann, S. Handbook on Resilience of Socio-Technical Systems, 1st ed.; Edward Elgar Publishing: Cheltenham, UK, 2019. [Google Scholar]

- Hasanzad, F.; Rastegar, H. Resilience enhancement of interdependent electricity-natural gas system considering gas storage and power to gas technology. J. Energy Storage 2022, 56, 106025. [Google Scholar] [CrossRef]

- Ghaib, K.; Ben-Fares, F.Z. Power-to-Methane: A state-of-the-art review. Renew. Sustain. Energy Rev. 2018, 81, 433–446. [Google Scholar] [CrossRef]

- Prabhakaran, P.; Graf, F.; Koeppel, W.; Kolb, T. Modelling and validation of energy systems with dynamically operated Power to Gas plants for gas-based sector coupling in de-central energy hubs. Energy Convers. Manag. 2023, 276, 116534. [Google Scholar] [CrossRef]

- Assunção, L.R.C.; Mendes, P.A.S.; Matos, S.; Borschiver, S. Technology roadmap of renewable natural gas: Identifying trends for research and development to improve biogas upgrading technology management. Appl. Energy 2021, 292, 116849. [Google Scholar] [CrossRef]

- Moioli, E.; Schildhauer, T.J. Techno-economic-environmental assessment of the integration of power-to-X and biogas utilization towards the production of electricity, hydrogen, methane and methanol. Sustain. Energy Fuels 2023, 7, 2690–2706. [Google Scholar] [CrossRef]

- IEA Bioenergy. Circular Economy Approaches to Integration of Anaerobic Digestion with Power to X Digestion to X Technologies; IEA Bioenergy: Dublin, Ireland, 2024. [Google Scholar]

- Tayyab, M.; Dreis, M.; Blaudszun, D. Closing the carbon cycle: Challenges and opportunities of CO2 electrolyser designs in light of cross-industrial CO2 source-sink matching in. Energy Environ. Sci. 2025, 18, 6854–6873. [Google Scholar] [CrossRef]

- Christianides, D.; Bagaki, D.A.; Timmers, R.A.; Zrimec, M.B.; Theodoropoulou, A.; Angelidaki, I.; Kougias, P.; Zampieri, G.; Kamergi, N.; Napoli, A.; et al. Biogenic CO2 Emissions in the EU Biofuel and Bioenergy Sector: Mapping Sources, Regional Trends, and Pathways for Capture and Utilisation. Energies 2025, 18, 1345. [Google Scholar] [CrossRef]

- Raimondi, G.; Greco, G.; Ongis, M.; D’Antuono, G.; Lanni, D.; Spazzafumo, G. Techno-Economical Assessment for Combined Production of Hydrogen, Heat, and Power from Residual Lignocellulosic Agricultural Biomass in Huesca Province (Spain). Energies 2024, 17, 813. [Google Scholar] [CrossRef]

- EUR-Lex. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions the European Green Deal. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640 (accessed on 13 October 2025).

- European Commission. Biomethane. 2022. Available online: https://energy.ec.europa.eu/topics/renewable-energy/bioenergy/biomethane_en (accessed on 13 October 2025).

- Menin, L.; Benedetti, V.; Patuzzi, F.; Baratieri, M. Techno-economic modeling of an integrated biomethane-biomethanol production process via biomass gasification, electrolysis, biomethanation, and catalytic methanol synthesis. Biomass Convers. Biorefinery 2023, 13, 977–998. [Google Scholar] [CrossRef]

- European Biogas Association (EBA). EBA Policy Paper: Proposal on the Energy Market Design Revision; European Biogas Association (EBA): Brussels, Belgium, 2023. [Google Scholar]

- EUR-Lex. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the RegioNS REPowerEU Plan. 2022. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52022DC0230 (accessed on 13 October 2025).

- News European Parliament. Reform of EU Gas Market: New Measures to Decarbonise and Secure Supply; European Commission: Brussels, Belgium, 2023; Available online: https://www.europarl.europa.eu/news/en/press-room/20230206IPR72111/reform-of-eu-gas-market-new-measures-to-decarbonise-and-secure-supply (accessed on 13 October 2025).

- Collet, P.; Flottes, E.; Favre, A.; Raynal, L.; Pierre, H.; Capela, S.; Peregrina, C. Techno-economic and Life Cycle Assessment of methane production via biogas upgrading and power to gas technology. Appl. Energy 2017, 192, 282–295. [Google Scholar] [CrossRef]

- Calbry-Muzyka, A.S.; Schildhauer, T.J. Direct Methanation of Biogas—Technical Challenges and Recent Progress. Front. Energy Res. 2020, 8, 570887. [Google Scholar] [CrossRef]

- Witte, J.; Settino, J.; Biollaz, S.M.A.; Schildhauer, T.J. Direct catalytic methanation of biogas—Part I: New insights into biomethane production using rate-based modelling and detailed process analysis. Energy Convers. Manag. 2018, 171, 750–768. [Google Scholar] [CrossRef]

- Hidalgo, D.; Martín-Marroquín, J.M. Power-to-methane, coupling CO2 capture with fuel production: An overview. Renew. Sustain. Energy Rev. 2020, 132, 110057. [Google Scholar] [CrossRef]

- Witte, J.; Calbry-Muzyka, A.; Wieseler, T.; Hottinger, P.; Biollaz, S.M.A.; Schildhauer, T.J. Demonstrating direct methanation of real biogas in a fluidised bed reactor. Appl. Energy 2019, 240, 359–371. [Google Scholar] [CrossRef]

- Furst, O.; Wehrle, L.; Schmider, D.; Dailly, J.; Deutschmann, O. Modeling, optimization and comparative assessment of power-to-methane and carbon capture technologies for renewable fuel production. Appl. Energy 2024, 375, 123972. [Google Scholar] [CrossRef]

- Inkeri, E.; Tynjälä, T.; Karjunen, H. Significance of methanation reactor dynamics on the annual efficiency of power-to-gas-system. Renew. Energy 2021, 163, 1113–1126. [Google Scholar] [CrossRef]

- Janke, L.; Ruoss, F.; Hahn, A.; Weinrich, S.; Nordberg, Å. Modelling synthetic methane production for decarbonising public transport buses: A techno-economic assessment of an integrated power-to-gas concept for urban biogas plants. Energy Convers. Manag. 2022, 259, 115574. [Google Scholar] [CrossRef]

- Bedoić, R.; Dorotić, H.; Schneider, D.R.; Čuček, L.; Ćosić, B.; Pukšec, T.; Duić, N. Synergy between feedstock gate fee and power-to-gas: An energy and economic analysis of renewable methane production in a biogas plant. Renew. Energy 2021, 173, 12–23. [Google Scholar] [CrossRef]

- Ghafoori, M.S.; Loubar, K.; Marin-Gallego, M.; Tazerout, M. Techno-economic and sensitivity analysis of biomethane production via landfill biogas upgrading and power-to-gas technology. Energy 2022, 239, 122086. [Google Scholar] [CrossRef]

- Michailos, S.; Walker, M.; Moody, A.; Poggio, D.; Pourkashanian, M. A techno-economic assessment of implementing power-to-gas systems based on biomethanation in an operating waste water treatment plant. J. Environ. Chem. Eng. 2021, 9, 104735. [Google Scholar] [CrossRef]

- Giglio, E.; Bianco, M.; Zanardi, G.; Catizzone, E.; Giordano, G.; Migliori, M. Direct biogas methanation via renewable-based Power-to-Gas: Techno-economic assessment based on real industrial data. Energy Convers. Manag. 2025, 332, 119775. [Google Scholar] [CrossRef]

- McDonagh, S.; O’Shea, R.; Wall, D.M.; Deane, J.P.; Murphy, J.D. Modelling of a power-to-gas system to predict the levelised cost of energy of an advanced renewable gaseous transport fuel. Appl. Energy 2018, 215, 444–456. [Google Scholar] [CrossRef]

- Brands, M.B.; Beuel, P.; Torres-Rivera, F.; Beckmüller, R.; Ayoub, M.S.; Stenzel, P. Optimization of biomethane production from purified biowaste pyrolysis gas: A comparative techno-economic assessment. Renew. Energy 2025, 245, 122865. [Google Scholar] [CrossRef]

- Fu, Y.; Luo, T.; Mei, Z.; Li, J.; Qiu, K.; Ge, Y. Dry anaerobic digestion technologies for agricultural straw and acceptability in China. Sustainability 2018, 10, 4588. [Google Scholar] [CrossRef]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P.G. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Scarlat, N.; Dallemand, J.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Budzianowska, D.A. Economic analysis of biomethane and bioelectricity generation from biogas using different support schemes and plant con fi gurations. Energy 2015, 88, 658–666. [Google Scholar] [CrossRef]

- Benda, V.; Černá, L. PV cells and modules—State of the art, limits and trends. Heliyon 2020, 6, e05666. [Google Scholar] [CrossRef]

- Lanni, D.; Minutillo, M.; Cigolotti, V.; Perna, A. Biomethane production through the power to gas concept: A strategy for increasing the renewable sources exploitation and promoting the green energy transition. Energy Convers. Manag. 2023, 293, 117538. [Google Scholar] [CrossRef]

- Rehman, S.; Alhems, L.M.; Alam, M.M.; Wang, L.; Toor, Z. A review of energy extraction from wind and ocean: Technologies, merits, efficiencies, and cost. Ocean Eng. 2023, 267, 113192. [Google Scholar] [CrossRef]

- de Carvalho, F.S.; Reis, L.C.B.d.S.; Lacava, P.T.; Araújo, F.H.M.d.; Carvalho, J.A.d. Substitution of Natural Gas by Biomethane: Operational Aspects in Industrial Equipment. Energies 2023, 16, 839. [Google Scholar] [CrossRef]

- Dannesboe, C.; Hansen, J.B.; Johannsen, I. Catalytic methanation of CO2 in biogas: Experimental results from a reactor at full scale. React. Chem. Eng. 2020, 5, 183–189. [Google Scholar] [CrossRef]

- Sdanghi, G.; Maranzana, G.; Celzard, A.; Fierro, V. Review of the current technologies and performances of hydrogen compression for stationary and automotive applications. Renew. Sustain. Energy Rev. 2019, 102, 150–170. [Google Scholar] [CrossRef]

- Gorre, J.; Ruoss, F.; Karjunen, H.; Schaffert, J.; Tynjälä, T. Cost benefits of optimizing hydrogen storage and methanation capacities for Power-to-Gas plants in dynamic operation. Appl. Energy 2020, 257, 113967. [Google Scholar] [CrossRef]

- Makridis, S.S. Hydrogen storage and compression. In MMethane and Hydrogen for Energy Storage; The Institution of Engineering and Technology: Stevenage, UK, 2016; Volume 2, pp. 1–28. [Google Scholar] [CrossRef]

- Wang, K.; Herrando, M.; Pantaleo, A.M.; Markides, C.N. Technoeconomic assessments of hybrid photovoltaic-thermal vs. conventional solar-energy systems: Case studies in heat and power provision to sports centres. Appl. Energy 2019, 254, 113657. [Google Scholar] [CrossRef]

- Perna, A.; Moretti, L.; Ficco, G.; Spazzafumo, G.; Canale, L.; Dell’isola, M. SNG generation via power to gas technology: Plant design and annual performance assessment. Appl. Sci. 2020, 10, 8443. [Google Scholar] [CrossRef]

- Blazquez-Diaz, C. Techno-economic modelling and analysis of hydrogen fuelling stations. Int. J. Hydrogen Energy 2019, 44, 495–510. [Google Scholar] [CrossRef]

- Elgowainy, A.; Reddi, K.; Lee, D.Y.; Rustagi, N.; Gupta, E. Techno-economic and thermodynamic analysis of pre-cooling systems at gaseous hydrogen refueling stations. Int. J. Hydrogen Energy 2017, 42, 29067–29079. [Google Scholar] [CrossRef]

- Gorre, J.; Ortloff, F.; van Leeuwen, C. Production costs for synthetic methane in 2030 and 2050 of an optimized Power-to-Gas plant with intermediate hydrogen storage. Appl. Energy 2019, 253, 113594. [Google Scholar] [CrossRef]

- Wegener, M.; Villarroel Schneider, J.; Malmquist, A.; Isalgue, A.; Martin, A.; Martin, V. Techno-economic optimization model for polygeneration hybrid energy storage systems using biogas and batteries. Energy 2021, 218, 119544. [Google Scholar] [CrossRef]

- Perna, A.; Minutillo, M.; Di Micco, S.; Jannelli, E. Design and Costs Analysis of Hydrogen Refuelling Stations Based on Different Hydrogen Sources and Plant Configurations. Energies 2022, 15, 541. [Google Scholar] [CrossRef]

- Jang, D.; Kim, J.; Kim, D.; Han, W.B.; Kang, S. Techno-economic analysis and Monte Carlo simulation of green hydrogen production technology through various water electrolysis technologies. Energy Convers. Manag. 2022, 258, 115499. [Google Scholar] [CrossRef]

- Perna, A.; Jannelli, E.; Di Micco, S.; Romano, F.; Minutillo, M. Designing, sizing and economic feasibility of a green hydrogen supply chain for maritime transportation. Energy Convers. Manag. 2023, 278, 116702. [Google Scholar] [CrossRef]

- Center, G. Electricity Prices in Europe Fell Significantly in January 2023. Available online: https://gmk.center/en/posts/electricity-prices-in-europe-fell-significantly-in-january-2023/ (accessed on 13 October 2025).

- KGroup. EU ETS Report CO2 Market February 2025; KGroup: Chiba, Japan, 2025. [Google Scholar]

- Lanni, D.; Di Cicco, G.; Minutillo, M.; Cigolotti, V.; Perna, A. Techno-economic assessment of a green liquid hydrogen supply chain for ship refueling. Int. J. Hydrogen Energy 2025, 97, 104–116. [Google Scholar] [CrossRef]

- IEA. Global Hydrogen Review 2023; IEA: Paris, France, 2023. [Google Scholar]

- Terna and Snam. Documento di Descrizione Degli Scenari 2022; Terna Academy: Viverone, Italy, 2022. [Google Scholar]

- EUR-Lex. Directive (EU) 2018/2001 of The European Parliament And Of The Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG&toc=OJ:L:2018:328:TOC (accessed on 13 October 2025).

- EUR-Lex. Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 amending Directive (EU) 2018/2001. Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council. 2023. Available online: https://eur-lex.europa.eu/eli/dir/2023/2413/oj/eng?utm_source=chatgpt.com (accessed on 13 October 2025).

- Eurostat Gas Prices for Non-Household Consumers—Bi-Annual Data (From 2007 Onwards). 2025. Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_pc_203/default/table?lang=en (accessed on 29 September 2025).

- Rodin, V.; Lindorfer, J.; Böhm, H.; Vieira, L. Assessing the potential of carbon dioxide valorisation in Europe with focus on biogenic CO2. J. CO2 Util. 2020, 41, 101219. [Google Scholar] [CrossRef]

- Giglio, E.; Pirone, R.; Bensaid, S. Dynamic modelling of methanation reactors during start-up and regulation in intermittent power-to-gas applications. Renew. Energy 2021, 170, 1040–1051. [Google Scholar] [CrossRef]

| Research | Study Type | Plant Layout | Results |

|---|---|---|---|

| Janke et al. [27] | Dynamic discrete-event simulation, techno-economic assessment | Anaerobic digestion + power-to-gas (synthetic CH4 production, CO2 from AD, electricity from grid/RES) | Constraints on renewable electricity usage and CO2 variability require larger installed plant sizes and larger storage units, increasing complexity and production cost. |

| Bedoić et al. [28] | Mathematical modeling/energy and economic analysis applied to a real biogas plant | Biogas plant + direct methanation powered by PV and wind (with grid backup) | ~60% of electricity demand could be met by RES; a feedstock gate fee of ~EUR 120/t was identified as the factor which ensures the economic feasibility of the system. |

| Ghafoori et al. [29] | Techno-economic assessment + sensitivity analysis comparing landfill biogas upgrading and PtG methanation options | (a) Biogas upgrading (water scrubbing, membrane) and (b) PtG (direct methanation; methanation + upgrading by membrane) | LCOBM in direct methanation: ~EUR 78–131/MWh; LCOBM in methanation + upgrading ~EUR 92–150/MWh. |

| Michailos et al. [30] | Techno-economic assessment with parametric analysis | Wastewater treatment plant integrating bio-methanation (in situ/ex situ) + electrolysis (on-site wind vs. grid electricity scenarios) | Base-case LCOBM reported ≈GBP 127.8–159.8/MWh; with policy incentives and considering oxygen revenues, a reduction ranging from 57 to 75% can be achieved. |

| Giglio et al. [31] | Techno-economic assessment using real industrial anaerobic digestion plant data | Anaerobic digestion + biogas cleaning + direct catalytic methanation (multi-tubular cooled fixed-bed reactors) + PV-powered electrolysis; three storage strategies examined (Buffer H2, Battery, Hybrid). | ~40 MW PV required for hydrogen demand; Buffer case: 35 MW electrolysis + 96 t H2 storage; Battery case: ~7.6 MW electrolysis + 5.8 GWh battery; Hybrid: 15.8 MW electrolysis + 42.8 t H2 + 3.2 GWh battery. Levelized cost of produced gas ranging from EUR 1.09 to 2.01/Sm3. |

| McDonagh et al. [32] | Techno-economic modeling (discounted cash flow) to compute LCOE of PtG systems using real market electricity data | Generic PtG (electrolysis + methanation) with grid/market interactions. | LCOE (*) scenarios reported ~EUR 107–143/MWh (2020 base), EUR 89–121/MWh (2030), EUR 81–103/MWh (2040); |

| Brands et al. [33] | Techno-economic and comparative assessment optimizing gas purification process | Pyrolysis of biowaste + water-gas shift + gas purification/CO2 removal + microbial methanogenesis | Optimized purification reduces H2 process’ demand by ~51% and achieves a minimum LCOBM ≈ EUR 143/MWh. |

| Criterion | PEMEL | AEL | SOEL |

|---|---|---|---|

| Operating temperature | 50–80 °C (low) | 60–80 °C (low) | 700–850 °C (high) |

| Electrolyte type | Solid polymer membrane | Liquid alkaline solution (KOH/NaOH) | Solid ceramic oxide |

| Hydrogen purity | Very high (>99.999%) | High, but requires post-purification | Very high |

| Electrical efficiency | 65–75% (HHV basis) | 60–70% | 80–90% |

| Dynamic response/load flexibility | Excellent (seconds)/ ideal for intermittent RES | Moderate (minutes)/ suited for steady operation | Poor (hours)/ sensitive to cycling |

| Start-up and ramping | Very fast | Slow | Very slow |

| Part-load efficiency | High, stable across a wide load range | Lower, efficiency drops at part-load | Unfavorable, high thermal inertia |

| Maturity (TRL) | Commercially matured (TRL 8–9) | Commercially mature (TRL 9) | Emerging technology (TRL 5–6) |

| System integration | Compact, modular, compatible with dynamic PtBM operation | Simple and robust, but less flexible | Complex integration due to high-temperature requirements |

| Capital cost (EUR/kW) | Medium–High (decreasing with scale-up) | Low | High (prototype stage) |

| Maintenance and durability | Moderate; improving with material advances | Low-cost maintenance; long lifetimes | Challenging due to thermal stress and degradation |

| Suitability for renewable coupling | Excellent (responsive and efficient under variable loads) | Moderate (limited by slower dynamics) | Poor (not suited for frequent cycling) |

| Overall suitability for PtBM | High (optimal balance of efficiency, flexibility, and readiness) | Moderate (robust but inflexible under fluctuating power supply) | Low (at present, promising efficiency but immature and rigid) |

| Parameter | Specific Investment Cost (Cinv,s) | Annual Maintenance Specific Cost | Annual Operating Cost |

|---|---|---|---|

| PV plant costs [46] | EUR 405.5/kW | (EUR/kW) | - |

| Wind plant costs [48] | EUR 1260/kW | EUR | - |

| PEM Electrolyzer costs [47] | EUR 1678/kW | EUR | - |

| Compression unit costs [49] | EUR | EUR | - |

| H2 storage system costs [50] | EUR 490/kg | EUR | - |

| Methanation unit costs [51] | EUR 450/kW | EUR | - |

| Biogas price [52] | - | - | EUR 0.243/m3 |

| Deionized water price [53] | - | - | EUR 0.01/kg |

| PtBM Plant | Unit | PV | Wind | Hybrid |

|---|---|---|---|---|

| PV plant size | MW | 24.5 | - | 11.1 |

| Wind plant size | MW | - | 16.5 | 10.0 |

| RES plant size | MW | 24.5 | 16.5 | 21.1 |

| Biogas flow rate (at digester full load) | Nm3/h | 500 | 500 | 500 |

| Annual electric energy production | MWh | 38,805 | 38,742 | 40,982 |

| Annual electric energy to the grid | MWh | 12,037 | 13,351 | 12,995 |

| Annual biogas consumption | tons | 3693.2 | 3494.9 | 3856.6 |

| Electrolysis unit | kW | 10,000 | 6000 | 6000 |

| Electrolytic hydrogen production (at full load operation) | kg/h | 168.6 | 101.2 | 101.2 |

| Hydrogen to the methanation reactor (at full load operation) | kg/h | 71 | 71 | 71 |

| Hydrogen compression unit | kW | 205 | 123 | 123 |

| Hydrogen storage capacity | kg | 2000 | 1580 | 540 |

| Methanation reactor production capacity | MWth,LHV | 4.92 | 4.92 | 4.92 |

| Biomethane production (at full load operation of the methanation reactor) | kg/h | 355.8 | 355.8 | 355.8 |

| Annual electric energy consumption of the hydrogen compression unit | MWh | 531 | 503 | 555 |

| Annual electric energy consumption of the electrolysis unit | MWh | 26,237 | 24,888 | 27,432 |

| Annual hydrogen production | tons | 438.4 | 415.8 | 458.4 |

| Annual biomethane production | tons | 2190.9 | 2037.2 | 2287.8 |

| Annual avoided CO2 * | tons | 5904.5 | 5492.5 | 6142.7 |

| LCOBM | EUR/MWh | 111.59 | 113.19 | 97.41 |

| DPBP | years | 8.8 | 10.8 | 8.7 |

| DPBP (Year) | Specific Electrolyzer Cost (EUR/kW) | ||||

| 1678 | 1000 | 700 | 400 | ||

| Biomethane selling price (EUR/MWh) | 45.0 | 18.0 | 14.8 | 13.5 | 12.3 |

| 120.0 * | 8.2 | 6.9 | 6.3 | 5.7 | |

| 5–7 | Very good/bankable-quick return low risk | ||||

| 8–9 | Good/sustainable-solid and bankable project | ||||

| 10–12 | Marginal/slow capital recovery | ||||

| >12 | Not profitable/high risk | ||||

| DPBP (Year) | Electricity Selling Price (EUR/kWh) | ||||

| 0.18 | 0.14 | 0.10 | 0.06 | ||

| Biomethane selling price (EUR/MWh) | 45.0 | 11.4 | 14.0 | 18.0 | >20 |

| 120.0 * | 6.3 | 7.1 | 8.2 | 11.1 | |

| 5–7 | Very good/bankable-quick return low risk | ||||

| 8–9 | Good/sustainable-solid and bankable project | ||||

| 10–12 | Marginal/slow capital recovery | ||||

| >12 | Not profitable/high risk | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lanni, D.; Di Cicco, G.; Minutillo, M.; Perna, A. Techno-Economic Feasibility Analysis of Biomethane Production via Electrolytic Hydrogen and Direct Biogas Methanation. Appl. Sci. 2025, 15, 12170. https://doi.org/10.3390/app152212170

Lanni D, Di Cicco G, Minutillo M, Perna A. Techno-Economic Feasibility Analysis of Biomethane Production via Electrolytic Hydrogen and Direct Biogas Methanation. Applied Sciences. 2025; 15(22):12170. https://doi.org/10.3390/app152212170

Chicago/Turabian StyleLanni, Davide, Gabriella Di Cicco, Mariagiovanna Minutillo, and Alessandra Perna. 2025. "Techno-Economic Feasibility Analysis of Biomethane Production via Electrolytic Hydrogen and Direct Biogas Methanation" Applied Sciences 15, no. 22: 12170. https://doi.org/10.3390/app152212170

APA StyleLanni, D., Di Cicco, G., Minutillo, M., & Perna, A. (2025). Techno-Economic Feasibility Analysis of Biomethane Production via Electrolytic Hydrogen and Direct Biogas Methanation. Applied Sciences, 15(22), 12170. https://doi.org/10.3390/app152212170