1. Introduction

Steel bridges constitute the backbone of modern transportation networks, facilitating economic activity and social connectivity. However, these critical infrastructure elements are continuously subjected to a complex interplay of degrading factors, including repetitive traffic loads, environmental stressors such as temperature fluctuations and corrosion, and potentially extreme events like earthquakes and typhoons. The aging of bridge infrastructure portfolios worldwide, with a significant proportion rated as fair or poor, underscores the urgent need for effective condition assessment and maintenance strategies [

1]. The catastrophic consequences of bridge failures, both in terms of human safety and economic disruption, highlight the non-negotiable imperative for ensuring structural integrity throughout a bridge’s operational lifetime.

Structural Health Monitoring (SHM) has emerged as a vital field dedicated to addressing this imperative. It can be defined as the process of implementing a damage detection and characterization strategy for engineering structures [

2]. In the specific context of steel bridges, SHM involves the use of an array of sensing technologies, data acquisition systems, and analytical tools to monitor the condition of the structure in real-time or near-real-time. The primary objectives are to identify the onset of damage, locate its position, assess its severity, and, in advanced systems, predict the remaining useful life of the structure. This moves maintenance philosophy from a reactive or scheduled-based model to a condition-based and ultimately predictive paradigm, optimizing resource allocation and enhancing safety [

3].

The field of SHM has historically concentrated on techniques to identify damage within various structures, including steel bridges, over the past three decades [

2]. This focus has led to the development of fundamental methodologies that support current SHM practices, guiding the early detection of structural issues before they become severe. The evolution of SHM for steel bridges has been significantly influenced by early literature, which laid the groundwork for current advancements. Between 1996 and 2001, a comprehensive review highlighted the importance of operational evaluation and data acquisition, emphasizing the necessity for robust statistical pattern recognition to transition SHM from theoretical frameworks to practical applications [

4].

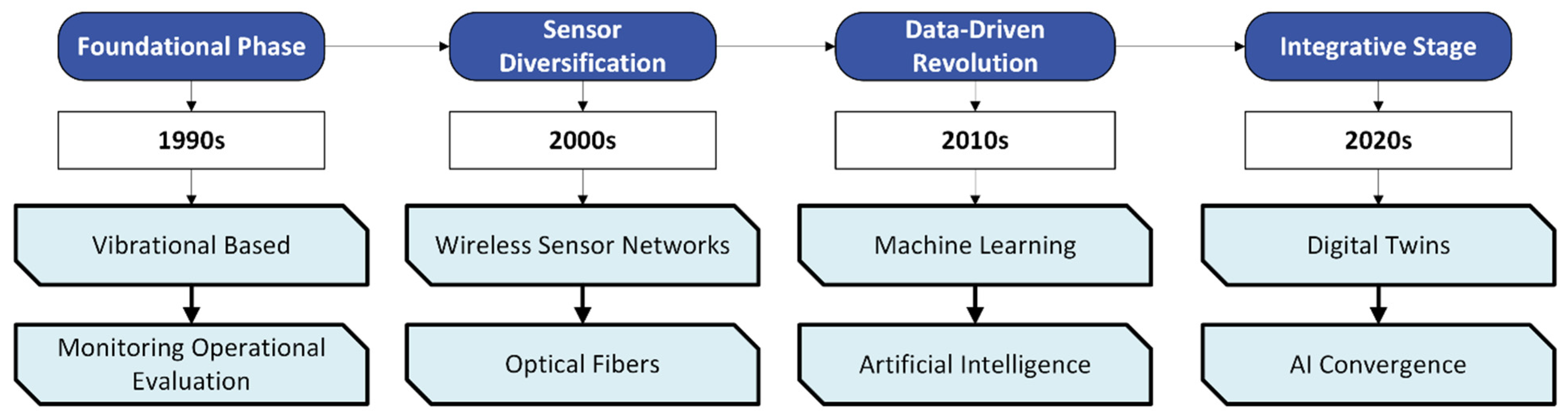

Figure 1 shows the evolution of structure health monitoring between 1990s and 2020s. The evolution of structural health monitoring (SHM) can be summarized as follows. The field began in the 1990s with a Foundational Phase, which established the core principles of Vibrational Based Monitoring Operational Evaluation. This progressed into the Senior Diversification phase of the 2000s, marked by the adoption of new sensing technologies like Wireless Sensor Networks and Optical Fibers. The 2010s ushered in a Data-Driven Revolution, where Machine Learning and Artificial Intelligence became central to analyzing complex data. Finally, the current Integrative Stage (2020s) is characterized by the convergence of these technologies into sophisticated, predictive systems such as Digital Twins and broader AI.

The main theme of the new era is AI Integration, Data-Driven SHM, and Digital Twin techniques. AI Integration is the process of embedding machine learning (ML) models into the SHM data pipeline to perform specific, automated tasks. Operational validation includes: (1) Anomaly Detection, where Convolutional neural networks (CNNs) achieve >94% accuracy in classifying anomalous data patterns by treating signals as images; and (2) Data Reconstruction, where Generative Adversarial Networks (GANs) successfully impute missing sensor data. Data-Driven SHM is a methodology where statistical or machine learning models for damage detection and prognosis are primarily derived from the analysis of large-scale, in situ monitoring data, with minimal reliance on high-fidelity physics-based models. Digital Twin technology is a dynamic, multi-scale, probabilistic model of a physical bridge that is continuously updated via SHM data and simulation to mirror the life of its twin. Its operational core is bi-directional data flow: sensor data updates the model, and the model provides predictive insights (e.g., remaining fatigue life). Most current implementations are advanced visualizations or one-way data feeds, falling short of this operational standard [

5].

Despite the advancements, the literature identified a gap in the rigorous application of these techniques, often limiting the technology’s deployment beyond controlled environments [

4]. Addressing these gaps has been crucial in refining SHM methodologies, ultimately enhancing the precision and effectiveness of damage detection in steel bridge structures, which remains a priority for ensuring long-term infrastructure resilience. While prior surveys have cataloged sensing technologies and AI/ML methods, they typically (i) treat sensing and analytics separately, (ii) summarize findings descriptively without a common yardstick for field readiness, and (iii) stop short of linking SHM outputs to asset-management decisions. Focusing on steel bridges, the review contributes an integrated, practice-oriented synthesis that evaluates each sensing modality and analytics family using a consistent framework—target scale and damage mode, reported sensitivity/specificity, environmental robustness, data burden, validation setting (lab to in-service long-term), deployment difficulty/cost band, interpretability, and technology readiness level (TRL). By coupling these evaluations with hooks to bridge management systems (BMS/BIM/digital twins), the review moves beyond classification to decision support: what works, under what conditions, and with what confidence. This contribution complements and extends recent reviews by providing a maturity-aware, validation-focused, and implementation-ready perspective tailored to steel-bridge SHM.

This literature review aims to provide a comprehensive synthesis of the state-of-the-art in SHM for steel bridges. It will explore the historical progression of the field, detail the core technologies for sensing and data acquisition, critically analyze advanced data interrogation methods, including machine learning and statistical models, and examine specific applications for damage detection. Furthermore, the review will synthesize the key challenges facing widespread implementation and outline future directions for research and development. By consolidating insights from a broad range of studies, this paper seeks to offer a clear overview of how SHM technologies are transforming the management and preservation of steel bridge infrastructure.

Review Methodology

This review targets structural health monitoring (SHM) of steel bridges, emphasizing deployable sensing, data analytics, and evidence from in-service practice as seen in

Figure 2. Our objective is to synthesize what works, under what conditions, and with what level of validation. To do so transparently and reproducibly, we followed a predefined protocol covering information sources, eligibility rules, screening, data extraction, and quality appraisal.

We queried Scopus, Web of Science Core Collection, IEEE Xplore, and the ASCE Library for the period 2000–2025. In addition, some references before 2000 were added as needed to serve the flow of the paper using Boolean combinations of domain and method terms. Representative strings included: steel bridge AND (“structural health monitoring” OR SHM); bridge AND (steel) AND (“damage detection” OR “condition monitoring” OR “fatigue monitoring”); (“wireless sensor*” OR accelerometer* OR “fiber optic” OR “acoustic emission” OR “digital image correlation” OR UAV) AND (bridge); and (“machine learning” OR “deep learning” OR Bayesian OR “Hilbert–Huang” OR PCA) AND (bridge OR “structural health monitoring”). Records were deduplicated before screening.

Eligibility was defined a priori. Inclusion required: (i) a steel-bridge focus (full structures or steel-dominant subsystems); (ii) SHM sensing and/or analytics directly relevant to bridges; (iii) empirical evidence (lab coupon/subassembly, full-scale testbed, field pilot, or in-service data); (iv) peer-reviewed journal article or full conference paper; and (v) English language. Exclusion criteria were non-bridge or non-steel studies without transferable findings; purely conceptual/editorial pieces; papers without data or validation; theses/patents/preprints lacking peer review; and works focused solely on design codes or conventional inspection without sensing/analytics. Screening proceeded in two stages aligned as follows: title/abstract screening to remove clearly out-of-scope records, followed by full-text assessment for eligibility. Two reviewers screened independently; disagreements were resolved by discussion.

Because SHM studies are heterogeneous in setups and metrics, we performed a qualitative risk-of-bias appraisal rather than a statistical meta-analysis. We assessed (1) data representativeness across environmental/loading conditions, (2) safeguards against information leakage (e.g., blocked or site-aware splits), (3) robustness checks (environmental normalization, drift monitoring), and (4) transparency (availability of data/code or sufficient procedural detail to reproduce pipelines). Finally, we note potential selection biases (e.g., English-language restriction and database coverage) and identify gaps where evidence is sparse, which are reflected in the evidence map and discussed in the limitations section.

3. Sensing and Data Acquisition Technologies

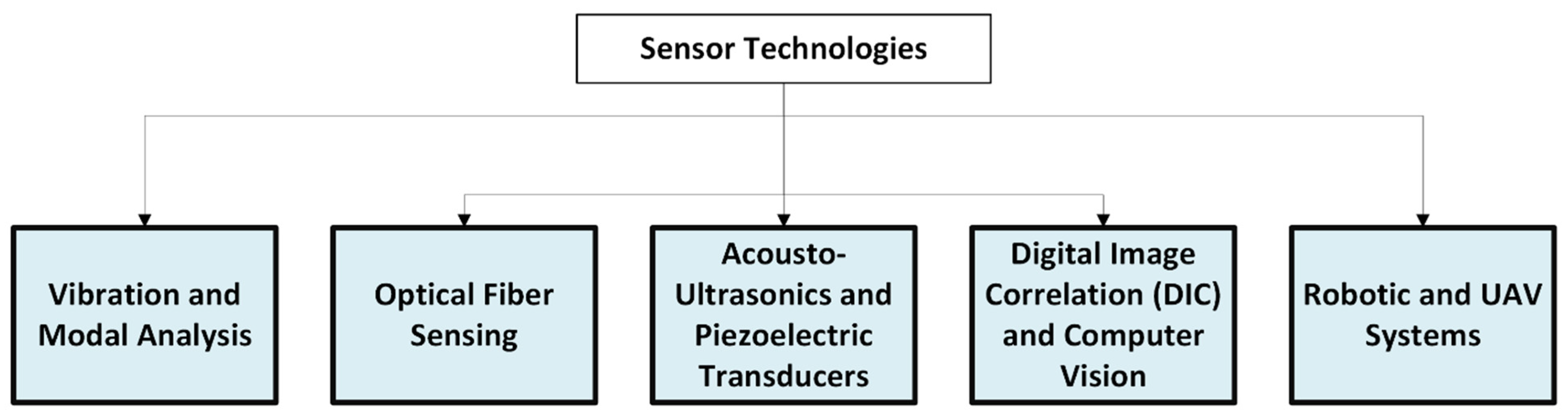

The efficacy of any Structural Health Monitoring system is fundamentally rooted in its ability to accurately capture the physical state of the structure. This has led to the development and deployment of a diverse suite of sensing technologies, each with unique advantages for monitoring different aspects of steel bridge behavior. The transition from traditional wired systems to advanced wireless and non-contact methods represents a significant leap forward in the practicality and scope of SHM, see

Figure 3.

Table 1 provides a comparative overview of primary sensing technologies used in Structural Health Monitoring (SHM) for steel bridges, evaluating them across key practical dimensions. It contrasts the global damage detection capability of vibration-based sensors with the local, high-sensitivity nature of acousto-ultrasonics for pinpointing micro-damage [

12]. Fiber-optic sensors stand out for their distributed sensing and exceptional robustness in harsh environments, while digital image correlation offers non-contact, full-field displacement measurement [

13]. Robotic and UAV systems are highlighted as versatile mobile platforms that enhance accessibility for inspections [

14]. The table further differentiates the modalities by their operational demands, such as data rate and deployment complexity, offering a clear guide for selecting the appropriate technology based on specific monitoring objectives and constraints [

12,

13].

3.1. Wired Versus Wireless Sensor Networks

Traditional SHM systems relied heavily on wired sensors, which presented significant challenges in terms of installation cost, cabling complexity, and long-term maintenance, especially for large-scale structures like bridges [

7]. The advent of wireless smart sensor networks (WSSNs) has addressed many of these limitations, heralding a new era in civil infrastructure maintenance. WSSNs can be considered an advanced subset of WSNs that integrate on-board computing, local data processing, and self-organizing communication capabilities. These low-cost wireless sensing units offer a cost-effective solution for real-time data acquisition, enabling comprehensive analysis of structural integrity without the prohibitive expenses linked to traditional wired systems [

7]. By employing wireless technology, SHM systems can be deployed more widely and flexibly, allowing for the continuous monitoring of steel bridges under various environmental conditions.

Wireless smart sensor networks utilize sophisticated AI resources for data prediction and diagnosis, allowing for continuous monitoring without the need for extensive cabling or manual data retrieval [

15]. By measuring vibrational responses, these sensors can detect alterations in mass, stiffness, and damping values, providing critical insights into the structural integrity of bridges. The deployment of dense sensor arrays enhances the system’s damage detection capabilities, ensuring that even subtle structural deficiencies are identified and addressed promptly [

8]. The real-time data transmission capability of WSNs significantly reduces processing delays, enhancing the timeliness of maintenance decisions [

3]. However, the real-world application of wireless sensor networks in SHM systems still faces challenges, particularly in standardizing protocols to bridge the gap between academic research and practical deployment [

15]. Issues such as power management, data security, and reliable communication in the harsh electromagnetic environment of a bridge site are active areas of research. Despite these challenges, as these issues are addressed, wireless smart sensor networks promise to significantly enhance the efficiency and effectiveness of SHM systems, contributing to safer and more durable bridge infrastructures [

15].

3.2. Diverse Sensing Modalities for Comprehensive Assessment

No single sensor type can capture the full spectrum of a bridge’s structural response. Therefore, a modern SHM system often integrates multiple sensing modalities to form a comprehensive assessment framework.

Vibration and Modal Analysis: This is one of the most established techniques in SHM [

16,

17]. It involves using accelerometers to measure the dynamic response of a bridge to ambient loads like traffic or wind. The resulting data is used to identify modal parameters such as natural frequencies, mode shapes, and damping ratios. Changes in these global dynamic characteristics can indicate a loss of stiffness or other forms of damage [

3,

18]. This approach is excellent for global health monitoring but may be less sensitive to small, localized damage.

To improve sensitivity and automation, recent research has focused on integrating data-driven algorithms, intelligent systems, and model-based updates into vibration-based SHM frameworks. For instance, Khodadoost et al. developed an intelligent vibration-based SHM system that combines signal processing, deep learning, and optimization techniques to enhance modal identification and automate damage detection [

19]. Todorovska et al. applied seismic interferometry to study wave propagation in coupled soil–structure systems, demonstrating sensitivity to local stiffness changes [

20]. Similarly, analyzed variability in structural system frequencies under damage conditions, confirming that wave-based features can serve as reliable indicators of early-stage deterioration [

21].

The integration of vibration-based and wave-based methods thus represents a key direction for future SHM research on steel bridges, providing a more comprehensive assessment that combines global and local diagnostic capabilities. Collectively, these studies confirm that vibration and modal analysis remain fundamental pillars of SHM research and application. Their continuous evolution through intelligent algorithms, model updating, and wave-based sensing is driving a shift from descriptive monitoring toward predictive, autonomous, and adaptive bridge health assessment.

Optical Fiber Sensing: Optical fiber sensors offer several distinct advantages, including immunity to electromagnetic interference, high sensitivity, and the ability to function as distributed sensors over long distances. They are particularly effective for monitoring strain and temperature gradients along the length of a bridge [

3]. This makes them ideal for detecting deformation, cracking, and assessing the effects of thermal loads on large-scale steel bridges.

Acousto-Ultrasonics and Piezoelectric Transducers: This technique typically uses networks of piezoelectric transducers that can act as both actuators and sensors. One transducer generates a high-frequency stress wave, and others detect the wave after it has passed through the structure. Damage, such as cracks or corrosion, alters the wave’s propagation characteristics (e.g., time of flight, amplitude, frequency content), allowing for its detection and localization [

3]. This method is highly sensitive to local damage and is often used for critical connection details.

Digital Image Correlation (DIC) and Computer Vision (CV): DIC has emerged as a significant non-contact advancement in SHM, offering a high-resolution method to assess structural integrity [

22]. This technique involves using target-tracking or natural texture to capture real-time dynamic behavior, allowing for precise measurement of full-field deformation and modal properties under various loads. In controlled laboratory environments, DIC has demonstrated its efficacy by accurately monitoring the response of bridge structures to bidirectional earthquake shaking, providing results comparable to traditional instrumentation [

22]. Furthermore, field applications have shown DIC’s capability in determining vibration frequencies and detecting anomalies in structural performance.

The integration of computer vision (CV), particularly through Unmanned Aerial Vehicles (UAVs), offers a transformative approach to bridge diagnostics, especially for visual inspection tasks [

23]. By utilizing UAVs equipped with advanced image processing capabilities, this method significantly reduces the costs and complexities associated with traditional monitoring techniques. The system focuses on identifying visual markers, such as corrosion and rivet displacement, which are critical indicators of structural deterioration in steel truss bridges [

23]. This innovative approach not only facilitates more frequent inspections but also enhances the precision of condition assessments, ensuring timely maintenance interventions. The fusion of sensor technology with computer vision allows for more accurate and comprehensive monitoring of bridge conditions, facilitating real-time data collection and processing and enabling early warning systems to identify anomalies before they evolve into critical problems [

13].

Table 2 synthesizes key Computer Vision (CV) applications in SHM. Image Recognition automates inspection, using methods from edge detection to Convolutional neural networks (CNNs) [

24,

25,

26] to find cracks and corrosion. Motion Analysis techniques, like motion magnification [

27], measure structural vibrations from video to identify mode shapes without physical sensors. Scene Understanding creates 3D models via laser scanning [

28] or learning-based methods [

29] for digital twins and analysis. Finally, Spatio-Temporal Load Identification fuses CV with weigh-in-motion data to track vehicle loads across a bridge in real-time [

30]. This shows CV’s role as a versatile, multi-purpose tool in modern SHM.

3.3. Advanced Platforms for Data Collection: Robotic and UAV Systems

Beyond fixed sensors, the integration of intelligent robotic systems represents another frontier in SHM technology advancement [

14]. These systems, which include mobile robots, wall-climbing robots, and flying drones, are specifically designed to conduct comprehensive inspections and gather dynamic response data from bridges. Their ability to traverse challenging terrains and access hard-to-reach areas enhances the thoroughness of inspections, particularly in detecting surface and subsurface defects [

14]. Moreover, the versatility and adaptability of multimodal robotic systems promise significant improvements in modal identification and cable tension force estimation, crucial for maintaining bridge integrity. As these robotic technologies evolve, they are expected to complement existing SHM frameworks, offering a robust, efficient, and scalable solution for ongoing bridge maintenance and safety enhancement efforts, particularly for detailed, localized inspections that may not justify a permanent sensor installation.

4. Data Interrogation, Analysis, and Computational Intelligence

The vast and often complex data streams generated by modern sensor networks are of little use without sophisticated methods for analysis and interpretation. The transition from simple data visualization to advanced computational intelligence represents the “brain” of modern SHM systems, transforming raw data into actionable knowledge.

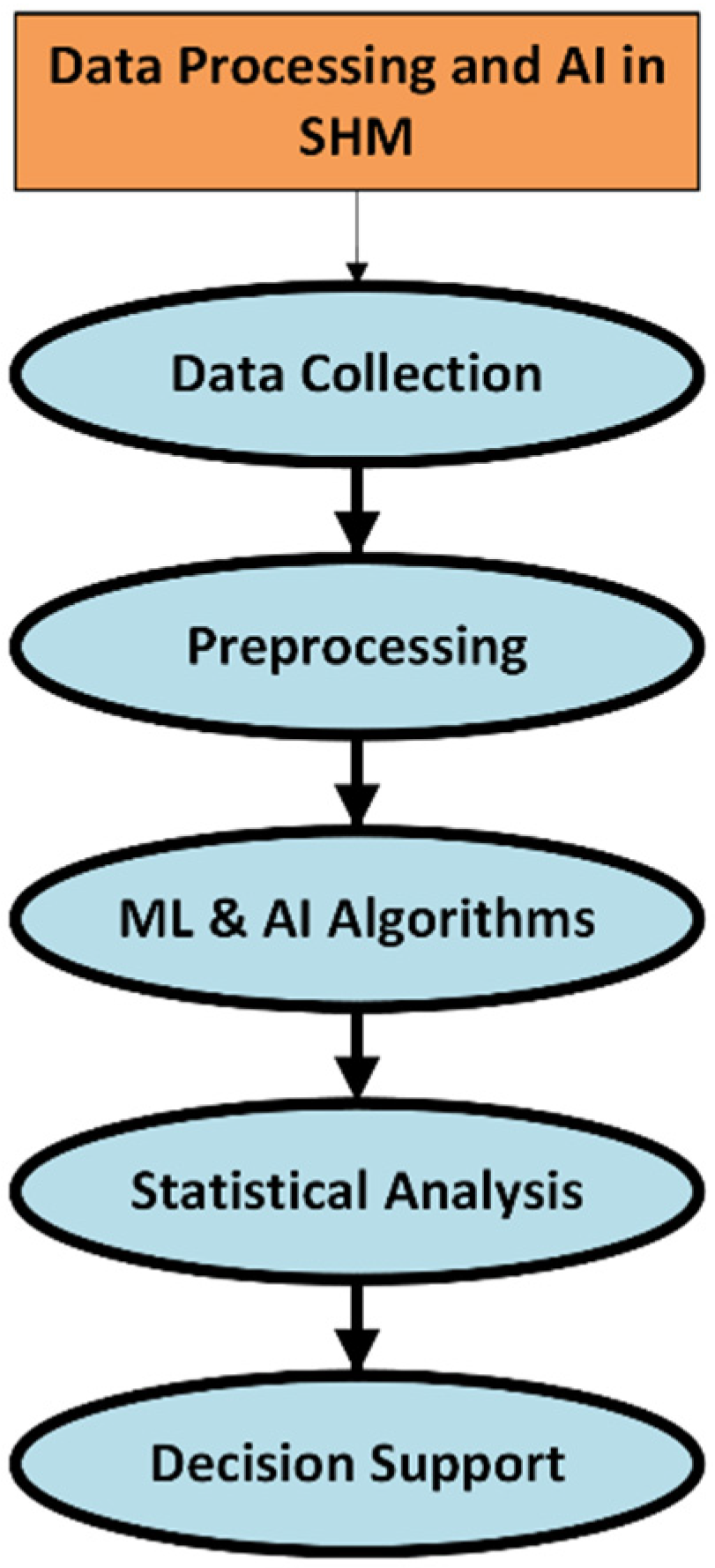

Figure 4 shows an SHM data pipeline: collect raw measurements, clean and normalize them, apply ML/AI models, evaluate results statistically, and convert insights into decision support for maintenance and operations.

4.1. The Paradigm Shift to Data-Driven Methodologies

A major shift in SHM is the move from purely model-based approaches to data-driven methods. In data-driven SHM, statistical/ML models for detection and prognosis are learned from large, in situ datasets with minimal dependence on high-fidelity physics models. This has been shown in unsupervised anomaly detection on vibration data [

35] and ML-based fatigue assessment from long-term strain histories [

36]. While model-based methods require detailed FE models and updating—often costly and sensitive to modeling error—data-driven approaches infer patterns directly from measurements and can detect both local and global damage without an explicit physical model [

37]. These methods surface damage signatures that traditional workflows may miss, strengthening preventative maintenance for existing bridges. By grounding decisions in observed behavior across diverse operating conditions, data-driven SHM improves robustness, precision, and the overall reliability of bridge management.

4.2. Machine Learning and Artificial Intelligence in SHM

Machine learning (ML) and artificial intelligence (AI) are the cornerstones of the data-driven revolution in SHM, offering transformative approaches to enhance the assessment capabilities for steel bridges [

12,

38,

39,

40,

41,

42,

43]. As an example, anomalous data detection is very important for an automatic intelligent SHM system because otherwise, the SHM system may mistakenly process the erroneous data as the data from extreme events and create a false warning [

12]. Bao and Li proposed anomalous data detection procedure that transformed anomalous data diagnosis to an image classification problem that can be analyzed by deep learning network.

Knowledge-Driven versus Data-Driven AI Approaches: The integration of AI into SHM can be broadly categorized into two paradigms. Knowledge-driven AI approaches, noted for their interpretability and stability, offer a robust framework for understanding complex structural behaviors but are often constrained by their limited adaptability to novel situations [

44]. Conversely, data-driven AI methods excel in efficiency and accuracy, rapidly processing vast datasets to detect anomalies and predict structural performance changes, yet they occasionally falter due to instability in dynamic environments and their “black-box” nature [

44]. To mitigate these challenges, a hybrid knowledge-data-driven approach is proposed, leveraging the strengths of both methodologies to enhance reliability and safety in practical SHM applications. This synergy not only improves diagnostic precision but also facilitates adaptive learning, enabling the SHM systems to evolve alongside the structures they monitor, thus ensuring long-term structural safety and resilience [

44].

Specific Machine Learning Algorithms and their Applications: Various ML algorithms have been successfully applied to SHM tasks. Convolutional neural networks (CNNs), for instance, have proven highly effective in image-based analysis, identifying specific issues such as steel corrosion and concrete cracks from visual data [

38]. Meanwhile, recurrent neural networks (RNNs) offer promising advancements in predicting direct structural responses from time-series data, such as acceleration or strain measurements, thereby improving the accuracy of health assessments over time [

38]. Unsupervised learning methods hold potential for streamlining data processing by automatically labeling training data, which could significantly reduce the time and effort required for manual data categorization [

38]. Other algorithms, including artificial neural networks (ANN) and support vector machines (SVM), are used for hierarchical classification of damage levels, improving decision-making processes for maintenance and repair [

45]. The application of these algorithms, alongside sophisticated preprocessing techniques, facilitates the extraction of critical features and the management of uncertainties, which are crucial for accurate structural assessments [

45].

Case Studies on Knowledge-Driven Versus Data-Driven AI

A representative knowledge-guided, data-driven framework for bridge SHM is the Tsing Ma Bridge study [

46], where an LSTM temperature model is explicitly coupled with a physics-based heat-transfer analysis. The Tsing Ma—a long-span steel suspension bridge (455 m–1377 m–300 m) with an orthotropic deck (Vierendeel cross-frames, longitudinal trusses) carrying highway (upper) and rail/emergency (lower)—is instrumented by WASHMS, which continuously records structural/air temperatures, wind, and solar radiation. Using ~14 months of hourly data from sensors near the Tsing Yi and Ma Wan towers, Stage 1 trains an LSTM to map climatic inputs (air temperature, solar radiation, wind, precipitation) to measured deck-node temperatures, capturing nonlinear environmental effects. Stage 2 enforces the LSTM-predicted nodal temperatures as constraints in a numerical heat-transfer model of the deck cross-section (thin-walled assumptions; conduction–convection–radiation on a discretized 2D grid). Domain knowledge—geometry, materials, boundary conditions, and heat-transfer laws—governs the spatio-temporal field, ensuring mechanical plausibility. This integration constrains and extends the learned model, improving accuracy, robustness, and interpretability; it exemplifies how AI-based SHM and digital-twin workflows can move beyond purely empirical regression while remaining consistent with structural engineering principles.

4.3. Statistical and Probabilistic Frameworks for Damage Assessment

While ML offers powerful pattern recognition, statistical and probabilistic methods provide a rigorous framework for dealing with the inherent uncertainties in SHM, such as varying environmental conditions and noise measurement.

Statistical Pattern Recognition and Time Series Analysis: The core of many SHM systems is statistical pattern recognition, which involves comparing features extracted from current data with a baseline model of the healthy structure [

2,

10]. Advanced time series analysis is used to process long-term dynamic strain data, for example, to derive a standard daily stress spectrum that accounts for a variety of stressors such as highway and railway traffic [

36]. This comprehensive approach not only enhances the accuracy of fatigue life predictions but also facilitates the early diagnosis of potential weaknesses. Innovative approaches like unsupervised meta-learning address the complexities of managing large datasets and environmental variables [

35]. This technique enhances the accuracy of damage detection by employing a locally unsupervised feature selection approach known as nearest cluster selection, alongside a robust Mahalanobis distance for effective anomaly detection. Such advancements are crucial, given the diverse environmental conditions that steel bridges often endure, which can obscure or mimic signs of structural stress.

Bayesian Methods for Uncertainty Quantification: Bayesian methods have become integral to enhancing SHM, particularly for assessing the condition of specific steel bridge components like expansion joints [

47]. These methods utilize long-term SHM data to develop probabilistic models that account for various uncertainties, allowing for a more nuanced understanding of bridge performance over time. By employing a Bayesian regression model alongside reliability theory, researchers can formulate a reliability-based anomaly index, which evaluates the probability of damage and issues alarms when necessary [

47]. This approach not only facilitates the prediction of potential failures but also improves the accuracy of damage detection by quantifying prediction uncertainties, thus ensuring timely maintenance interventions. This probabilistic framework is also valuable in fault detection methods for railway bridges, where Bayesian belief networks can refine the understanding of failure probabilities, enhancing decision-making processes for maintenance planning [

48].

4.4. Advanced Signal Processing Techniques: The Hilbert-Huang Transform

Beyond statistical and ML methods, advanced signal processing techniques offer unique tools for analyzing non-stationary and nonlinear data. The Hilbert-Huang Transform (HHT) presents a novel approach to SHM of steel bridges, offering significant advancements over traditional methods like Fourier analysis [

49]. By employing a nondestructive technique, the HHT-based method allows for continuous monitoring and real-time assessment of bridge conditions. This innovative approach enhances the precision of damage detection through its ability to decompose complex signals into intrinsic mode functions, providing detailed insights into the structural dynamics of bridges [

49]. The criteria for evaluating the structural health of bridges using HHT are well-defined, ensuring consistent and reliable assessments that can guide maintenance decisions. As SHM technologies advance, incorporating the HHT method promises to refine the accuracy and efficiency of monitoring practices, particularly for analyzing transient events and nonlinear structural responses.

The developments discussed in previous sections–which include sensing technologies, data acquisition, and AI-based analytical models–form the technical basis for practical SHM applications. Linking these technological frameworks to real-world applications is essential to verifying their effectiveness and reliability under complex field conditions. Therefore, the following section focuses on applied studies and case examples, illustrating how these (SHM) techniques can be applied in steel bridge environments.

These examples demonstrate the transition from theoretical development to practical application, highlighting the performance, limitations, and future potential of current solids material management (SHM) systems.

6. Synthesis, Challenges, and Future Directions

The collective body of literature presents a compelling vision for the future of bridge management, yet it also clearly outlines the significant obstacles that must be overcome to realize the full potential of SHM.

Figure 6 summarizes key obstacles and opportunities for Structural Health Monitoring (SHM). On the left, it highlights practical hurdles—cost, data reliability, data management, calibration, and standardization—that often limit deployment and comparability across projects. On the right, it points to strategic pathways forward: digital twins and AI integration enable predictive maintenance and real-time analytics, while tighter integration with BIM connects SHM insights to design and asset management workflows. Together, the diagram frames SHM’s roadmap: address foundational challenges to unlock data-driven, proactive.

6.1. Integration of SHM into Bridge Management Systems

For SHM to deliver value, it must be embedded within the bridge management system (BMS) rather than operate as a standalone add-on. Long-span bridge SHM is best designed as a modular architecture—sensing, data acquisition/transmission, and data processing/control—so that performance evaluation is reliable, scalable, and maintainable [

59]. This architecture enables near-real-time collection and analytics, accelerating the identification of emerging issues and linking SHM outputs to inspection, maintenance, and budgeting workflows in the BMS. When SHM indicators (e.g., condition states, alarms with uncertainty) are mapped to actionable decisions—inspection triggers, prioritization of repairs, and resource allocation—bridge owners gain defensible, data-driven plans [

18]. The approach supports proactive (not just reactive) maintenance, improves reliability and safety of steel bridges, and enhances lifecycle sustainability. Effective integration typically requires fusing technologies across disciplines (sensing, communications, analytics, asset management) to provide a comprehensive, timely view of bridge condition and to coordinate both routine maintenance and emergency response [

18].

6.2. Persistent Challenges in SHM Implementation

Despite the technological advancements, several persistent challenges hinder the widespread adoption of SHM.

Cost, Complexity, and Standardization: SHM of steel bridges, despite its potential, remains infrequently utilized in practical applications, primarily due to cost and complexity concerns [

60]. The initial investment for a sophisticated SHM system can be substantial, and the expertise required for its installation, operation, and data interpretation is specialized. Furthermore, a significant challenge is the lack of standardization in protocols, sensor types, and data formats, which creates a gap between academic research and practical deployment [

15]. Developing industry-wide standards is crucial for making SHM systems more interoperable, reliable, and accessible to bridge owners and operators.

Data Management and Environmental Variability: The deployment of dense sensor networks and the use of high-frequency data acquisition generate enormous volumes of data, leading to challenges in data storage, transmission, and processing—often referred to as the “big data” challenge [

11]. Moreover, the diverse environmental conditions that steel bridges endure can obscure or mimic signs of structural stress, making it difficult to distinguish between normal environmental effects and actual damage [

35]. Developing robust algorithms that can reliably perform under these variable conditions remains a key research focus.

Data Quality Dependency: The performance of machine learning models in SHM is critically dependent on data quality, creating a major barrier to practical use. While algorithms excel with clean, curated data, real-world monitoring data is often compromised by noise, sensor faults, and missing value [

12]. Furthermore, environmental effects like temperature changes can cause structural responses that dwarf damage-related signals, leading to false alarms if not properly normalized [

35]. This data quality dependency means an ML system’s reliability is determined not just by its algorithm, but by the entire data pipeline’s ability to deliver clean, representative data.

Algorithmic overfitting: Algorithmic overfitting presents a significant barrier to the real-world deployment of machine learning in SHM. Models trained on limited or overly specific datasets—such as those from a single bridge under controlled conditions—can learn the noise and unique characteristics of that particular environment rather than the underlying physical principles of damage. This results in a model that performs exceptionally well on its training data but fails to generalize to other structures, different sensor layouts, or even the same bridge under previously unobserved environmental conditions [

10]. Consequently, an overfitted model loses its diagnostic value in practice, as it cannot reliably distinguish true structural damage from the idiosyncrasies of its training set, undermining the goal of a robust and universally applicable monitoring system.

Health Monitoring of the SHM System Itself: An often-overlooked aspect is ensuring the health of the monitoring systems themselves, as they are susceptible to deterioration, calibration drift, or damage over time [

61]. This is particularly relevant for steel bridges, where the reliability of SHM systems directly impacts the accuracy of data gathered for maintenance and safety assessments. If an SHM system provides faulty data, it can lead to misguided and potentially dangerous infrastructure management decisions. By extending the classical Value of Information (VoI) framework, researchers have demonstrated how monitoring the state of SHM systems can offer significant benefits, providing more reliable data for decision-making processes [

61].

Sensitivity to environmental conditions: Environmental variability is a fundamental challenge for SHM and can confound damage detection across modalities. Vibration-based monitoring is highly temperature-sensitive: stiffness and boundary changes shift modal parameters and may mask or mimic damage. Computer-vision systems degrade under variable lighting, weather, and camera motion, reducing displacement/vibration accuracy. Acousto-ultrasonics exhibits temperature-dependent wave speeds and attenuation, and wireless networks face interference and power/telemetry instability that affect data quality. Advancing SHM therefore requires environmental normalization and filtering to separate ambient effects from true degradation—e.g., temperature compensation and co-located reference sensors, site-aware/blocked cross-validation, domain adaptation and drift monitoring, and robust fusion of multi-modal measurements.

6.3. Vision for the Future: Intelligent, Proactive, and Resilient Infrastructure

The future of SHM for steel bridges is pointed towards increasingly intelligent, integrated, and proactive systems. The fusion of BD and AI in SHM not only improves the accuracy and reliability of current monitoring systems but also paves the way for future innovations [

11]. The concept of “digital twins”, a high-fidelity virtual model of a physical bridge that is continuously updated with SHM data, is gaining traction and has been revolutionized by tools like virtual and augmented reality, enabling engineers to visualize and interact with bridge data more effectively [

5]. This allows for scenario planning, predictive maintenance, and optimized management throughout the bridge’s entire lifecycle. The cross-application of SHM technologies from other demanding domains, such as aerospace, where diagnosing damage autonomously is critical, could lead to more resilient and sustainable bridge designs, ensuring longevity and reducing maintenance costs over time [

62]. Ultimately, the goal is to evolve from SHM as a diagnostic tool to SHM as a core component of an intelligent transportation system, where data from bridges, traffic, and the environment are integrated to create a truly resilient and adaptive infrastructure network [

63].

7. Conclusions

This review has synthesized the significant progress and current state of Structural Health Monitoring (SHM) for steel bridges. The field has evolved from early vibration-based methods and statistical pattern recognition into a sophisticated, multidisciplinary discipline that integrates advanced sensing, data-centric analytics, and deployment-oriented applications.

7.1. Key Conclusions

The core technological pillars—advanced sensing (wireless networks, fiber optics, and non-contact vision/UAV), data interrogation (statistical models, machine learning, and AI), and application methodologies (from fatigue assessment to vehicle-assisted monitoring)—now enable a more continuous, evidence-based understanding of structural behavior.

The literature indicates a shift in bridge management from reactive, time-based practices to proactive, condition- and prediction-based strategies.

This shift is essential for addressing aging infrastructure, increasing traffic demands, and constrained maintenance budgets.

Early damage detection, accurate fatigue-life assessment, and real-time monitoring of critical components contribute directly to public safety, optimized resource allocation, and extended service life of steel bridges.

7.2. Future Recommendations

Address barriers related to cost, system complexity, data management/governance, standardization, and long-term reliability through coordinated research, development, and partnerships across academia, industry, and agencies.

Pursue deeper integration of sensing, computation, and modeling toward intelligent systems and digital twins that diagnose current condition, quantify uncertainty, and predict future performance under realistic environmental variability.

7.3. Implications for Research and Standardization

The proposed evaluative framework—linking sensing/analytics to target damage modes, environmental robustness, validation setting (coupon → subassembly → full-scale → in-service), interpretability, cost band, and TRL—can directly steer future work and codification. Researchers can use it to set clear study goals (e.g., advancing promising methods to long-term in-service validation with comparable Pd/FA and uncertainty metrics) and to design experiments that explicitly test environmental normalization and drift monitoring. Standards bodies and owners can adopt the framework to define minimum reporting checklists, a shared validation taxonomy/TRL rubric, and BMS integration hooks (data schemas, action thresholds). Establishing open benchmarks by bridge type/task with reference pipelines under this rubric will make results comparable, reproducible, and deployable, accelerating the path from research to practice.