Mechanical and Durability Performance of Sustainable Concrete Incorporating Stone Dust as Sand Substitute and Sugarcane Bagasse Ash as Cement Replacement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Preparation

2.2. Concrete Mix Design, Casting, and Testing

2.3. Life Cycle Assessment (LCA) and Economic Analysis

3. Results and Discussion

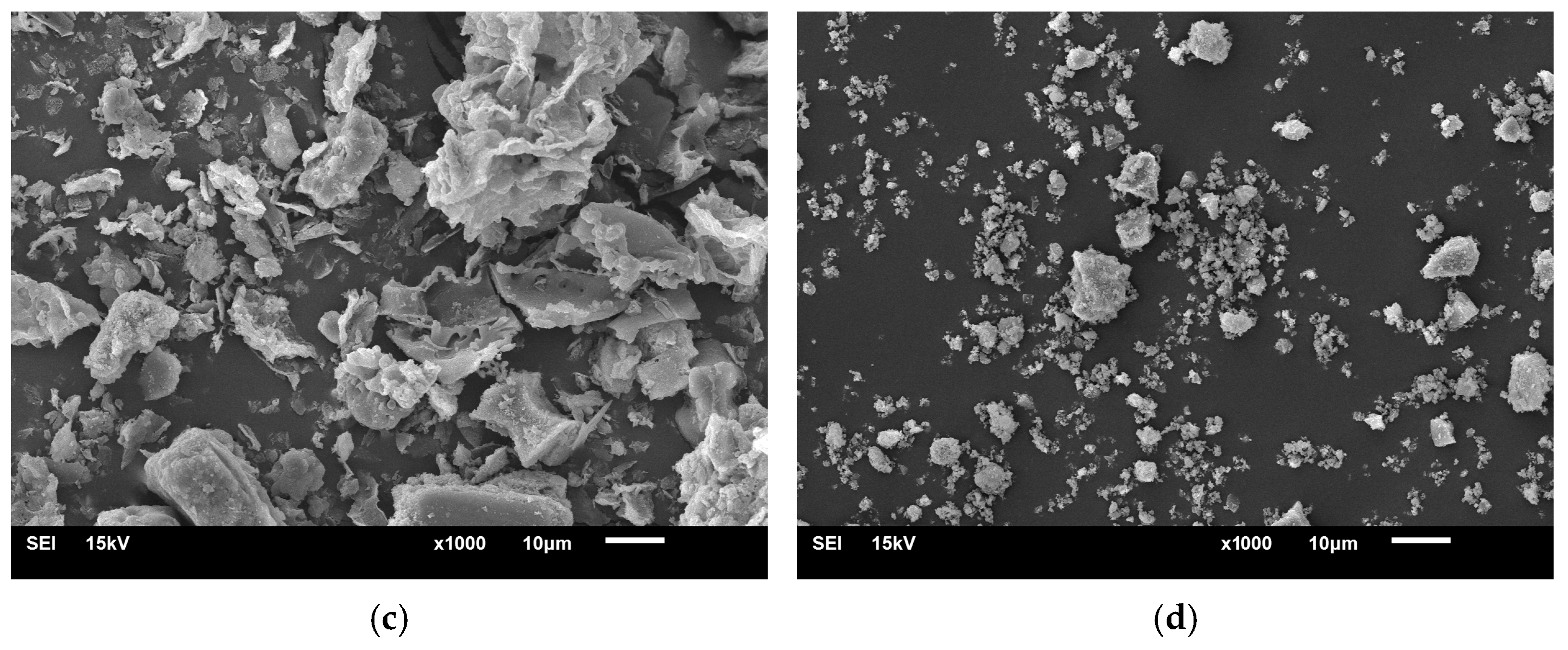

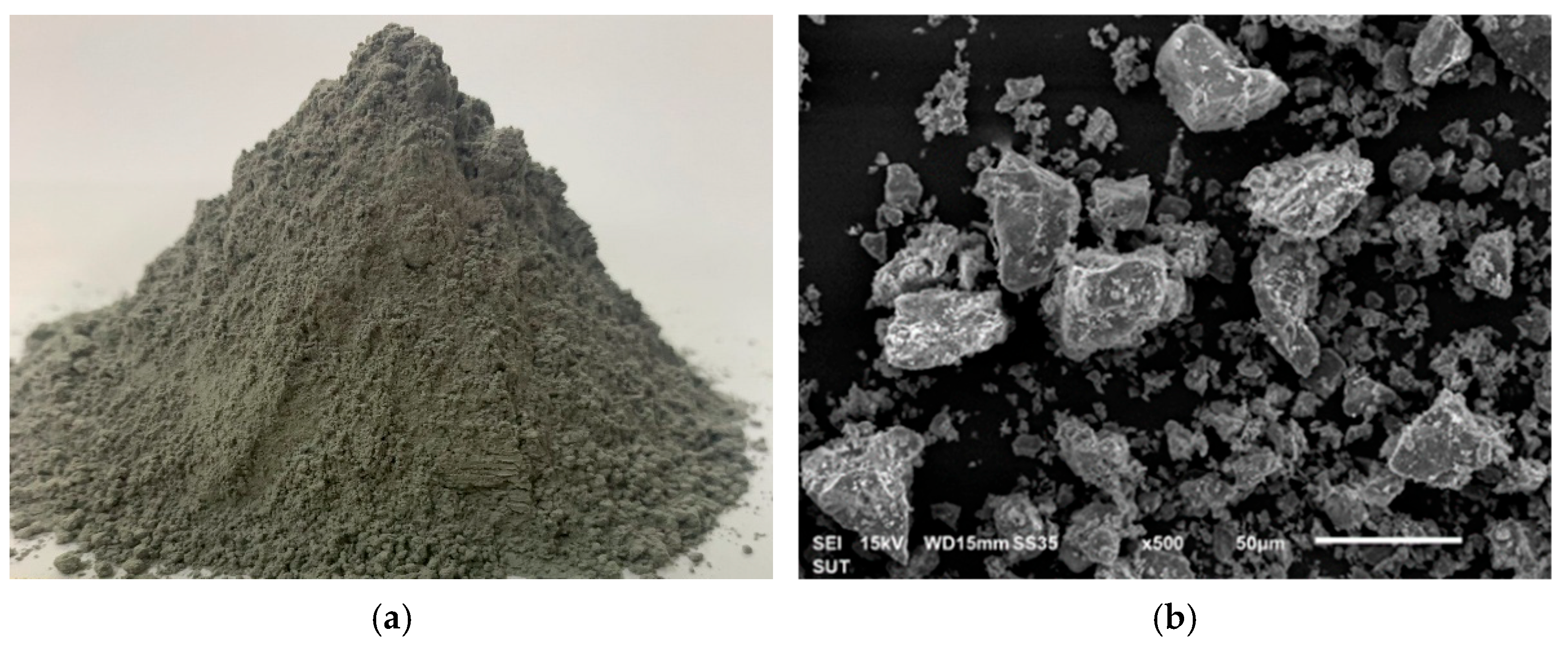

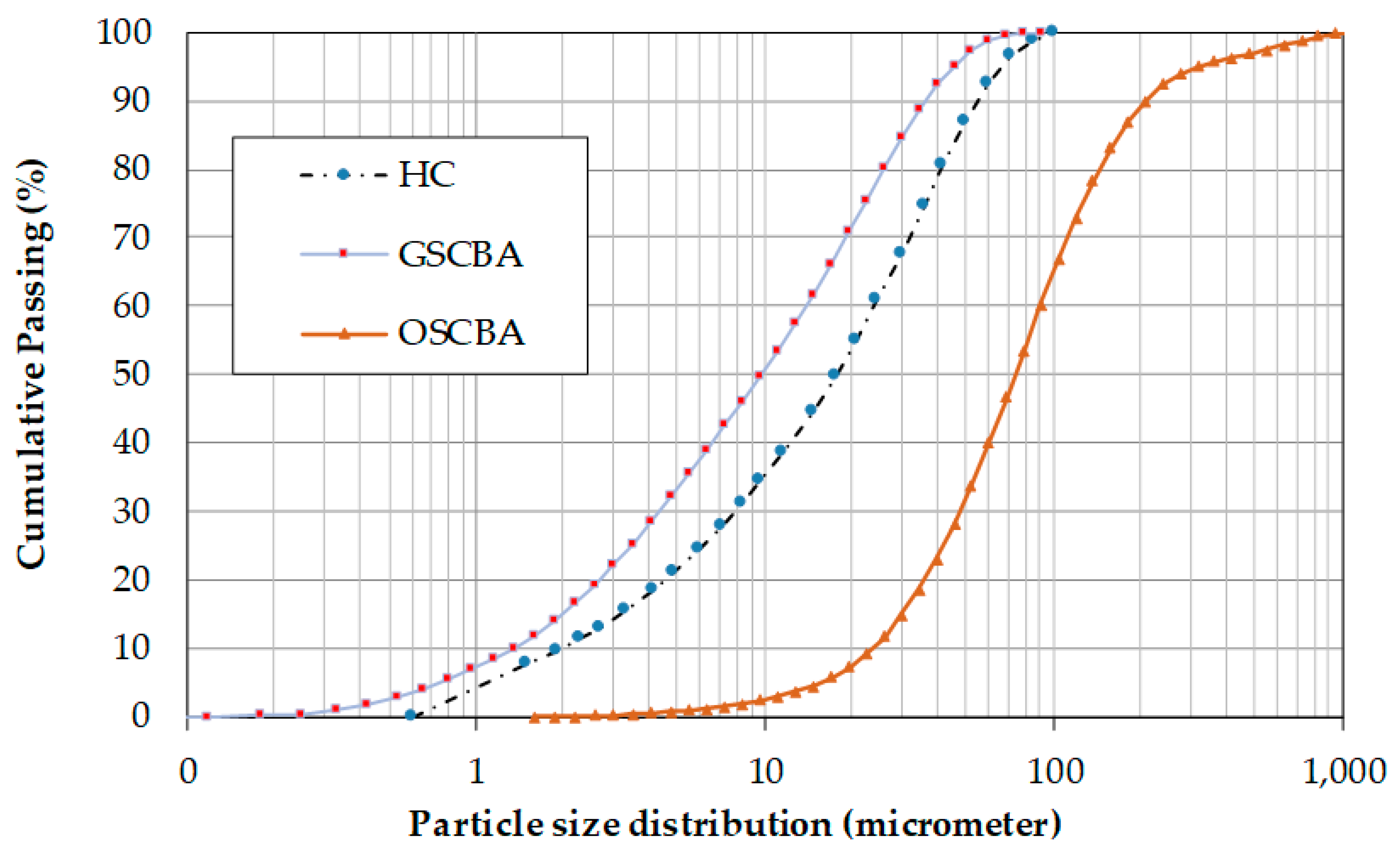

3.1. Physical and Chemical Characteristics of Binder

3.2. Properties of Aggregates

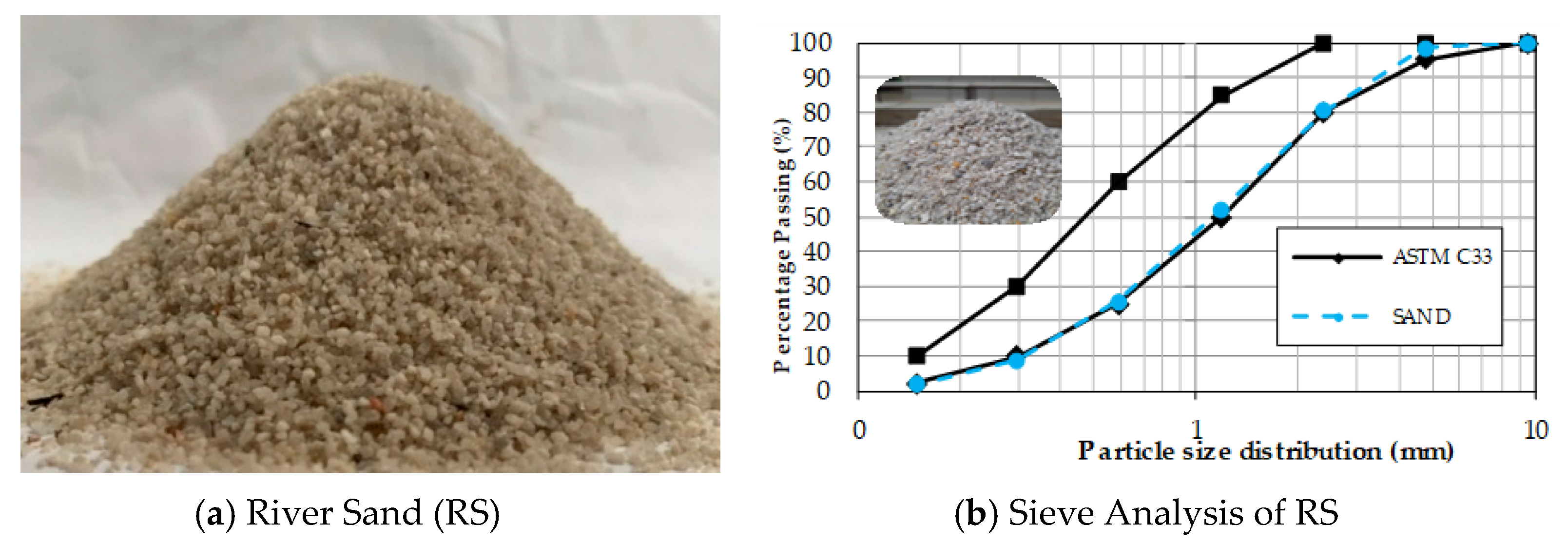

3.2.1. River Sand (RS)

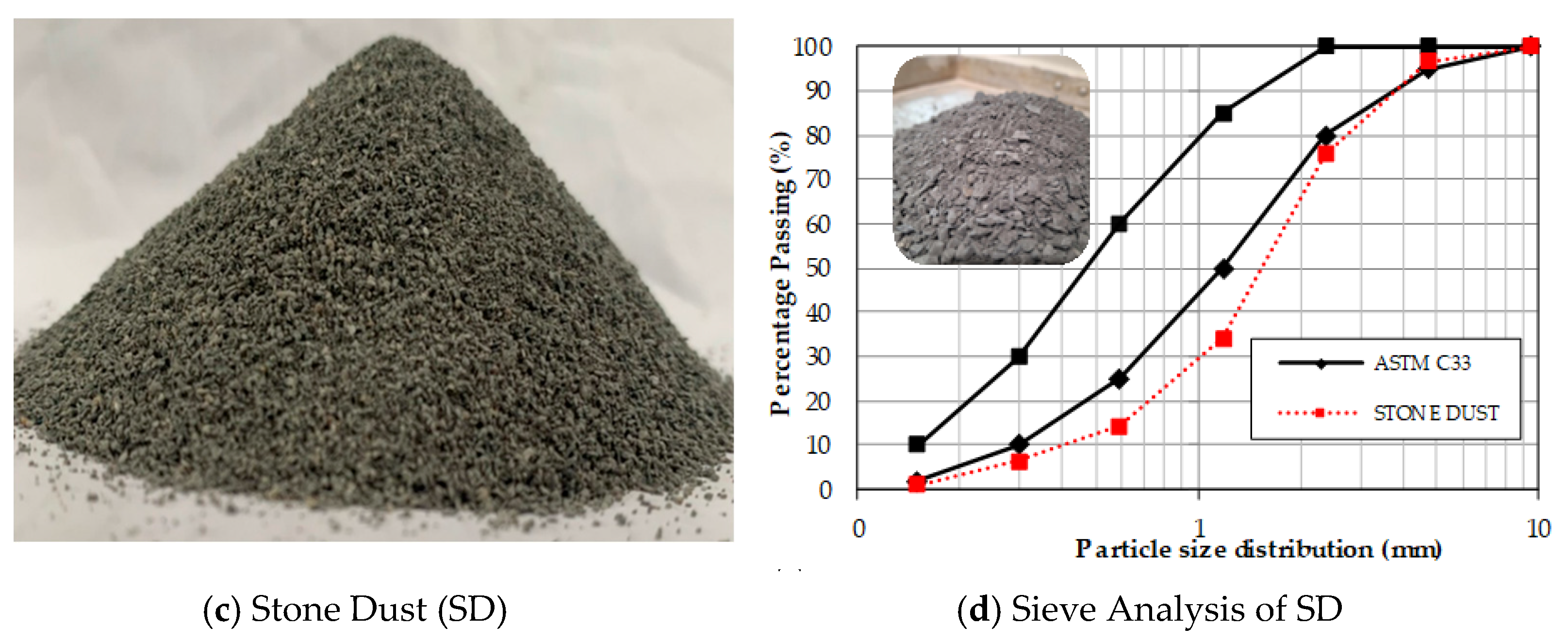

3.2.2. Stone Dust (SD)

3.2.3. Coarse Aggregate

3.3. Mortar Performance with GSCBA as Partial Cement Replacement and Stone Dust as Full Sand Replacement

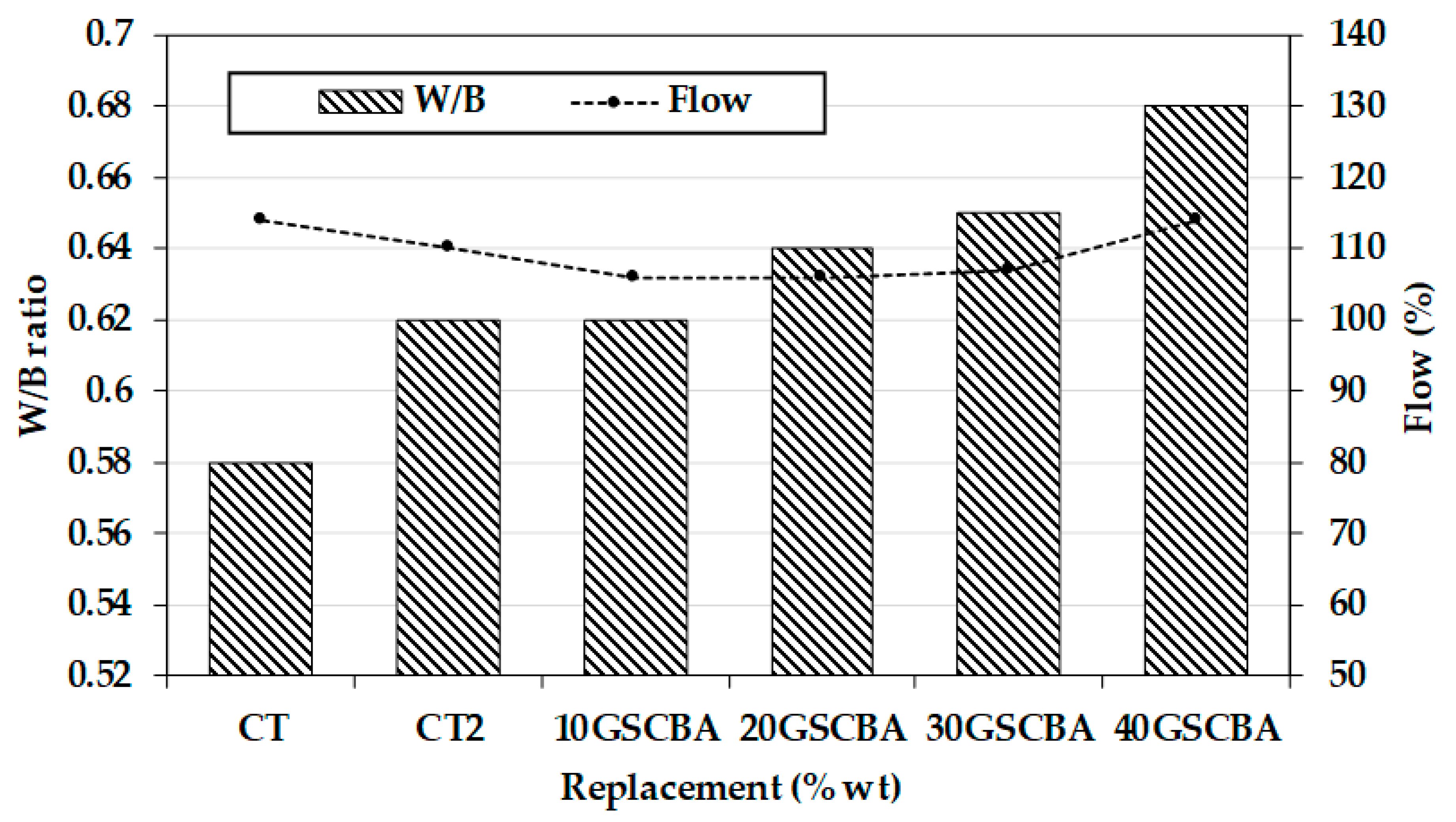

3.3.1. Water Requirement of Mortar

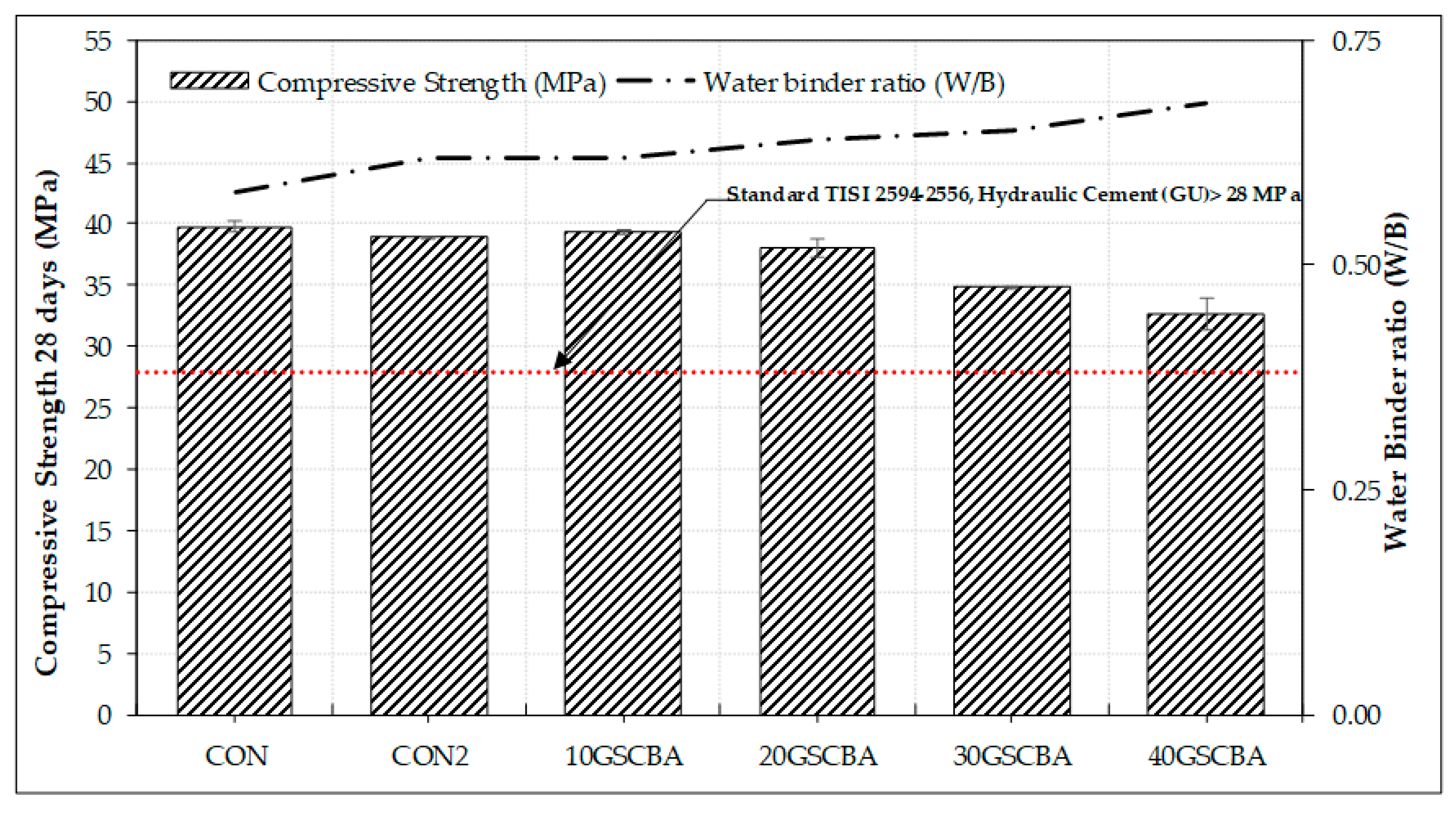

3.3.2. Compressive Strength of Mortar

3.3.3. Relationship Between Compressive Strength and Water Requirement of Mortar at 28 Days

3.4. Concrete Test Results

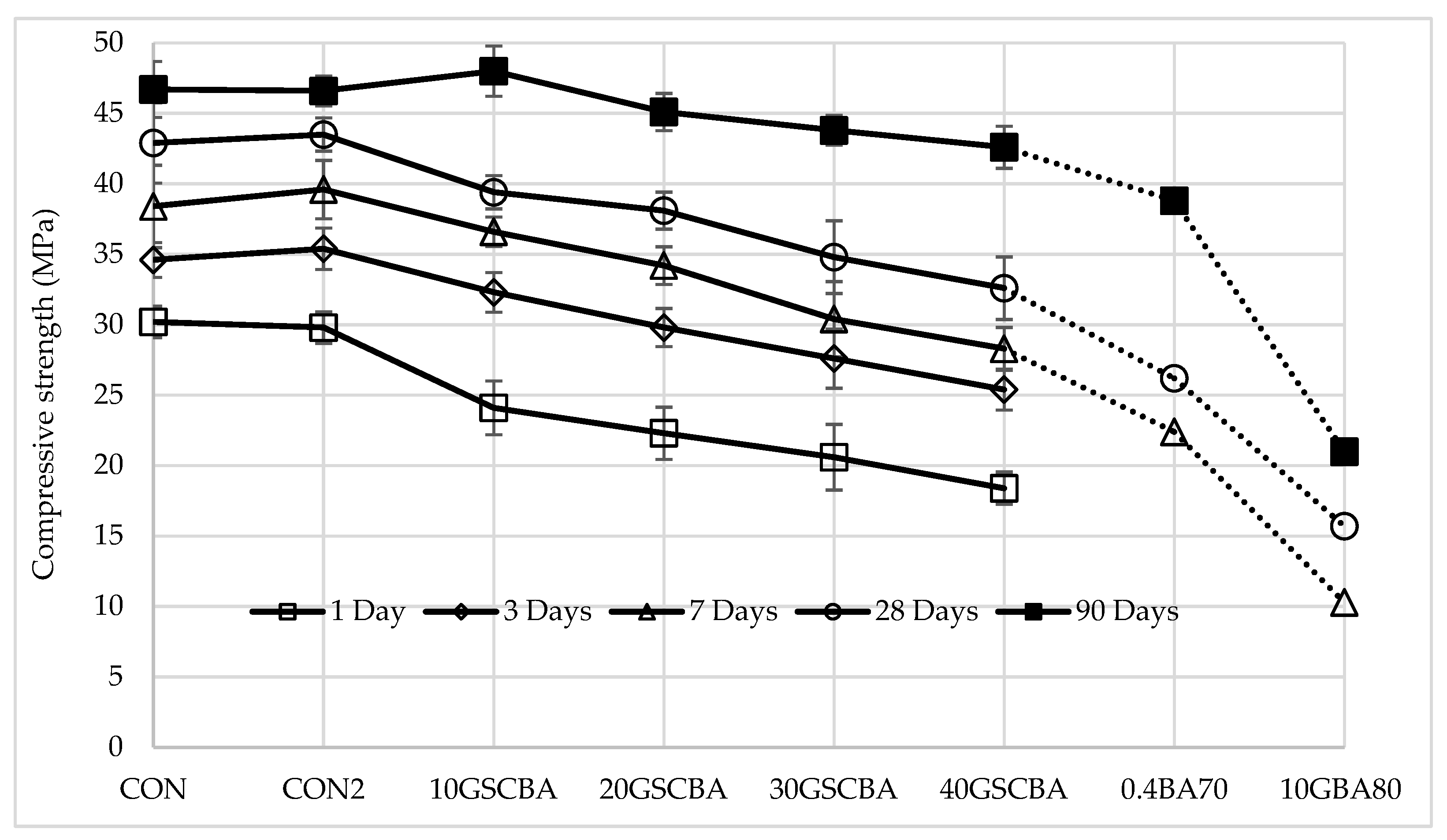

3.4.1. Compressive Strength of Concrete

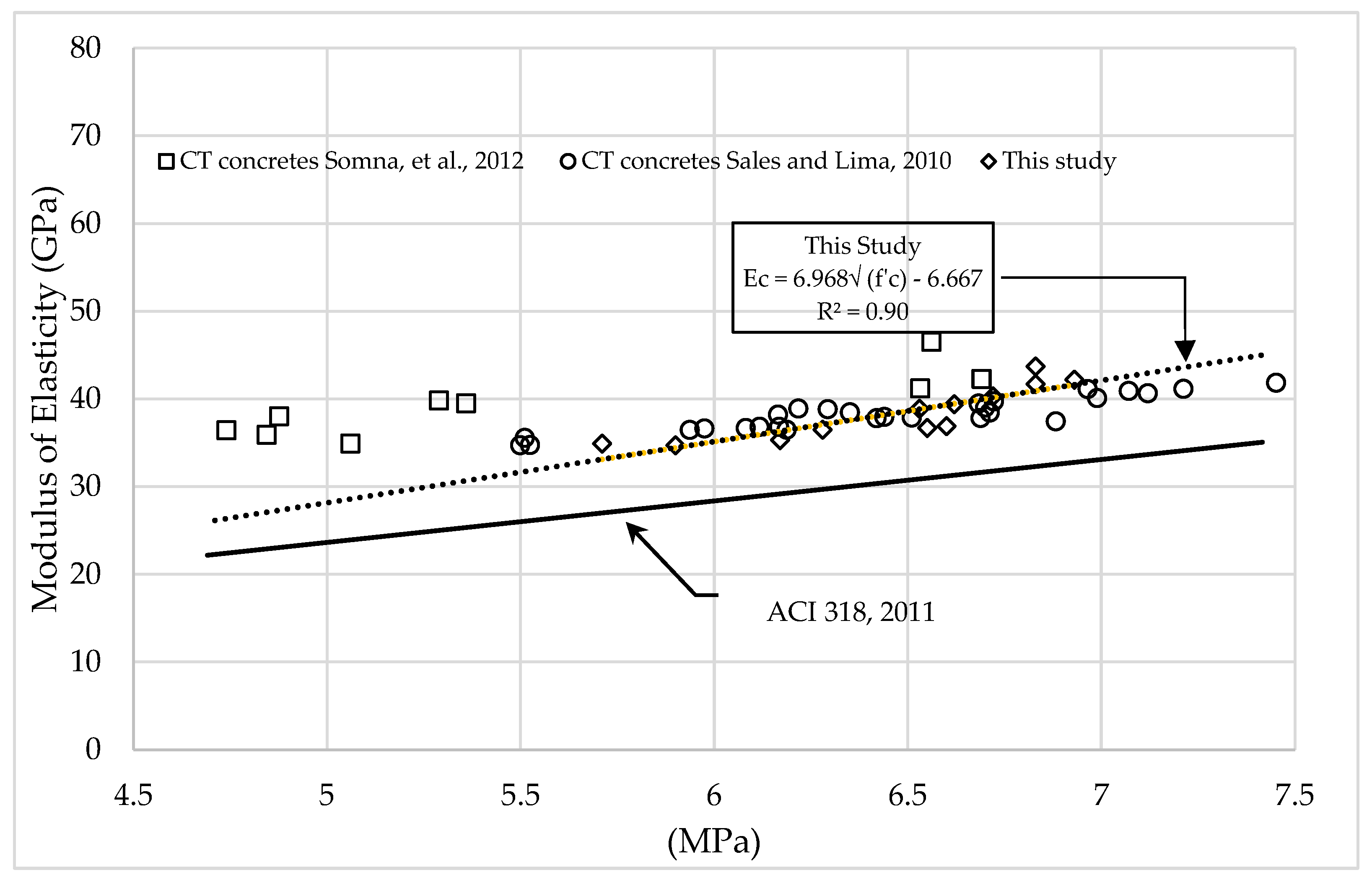

3.4.2. Modulus of Elasticity of Concrete

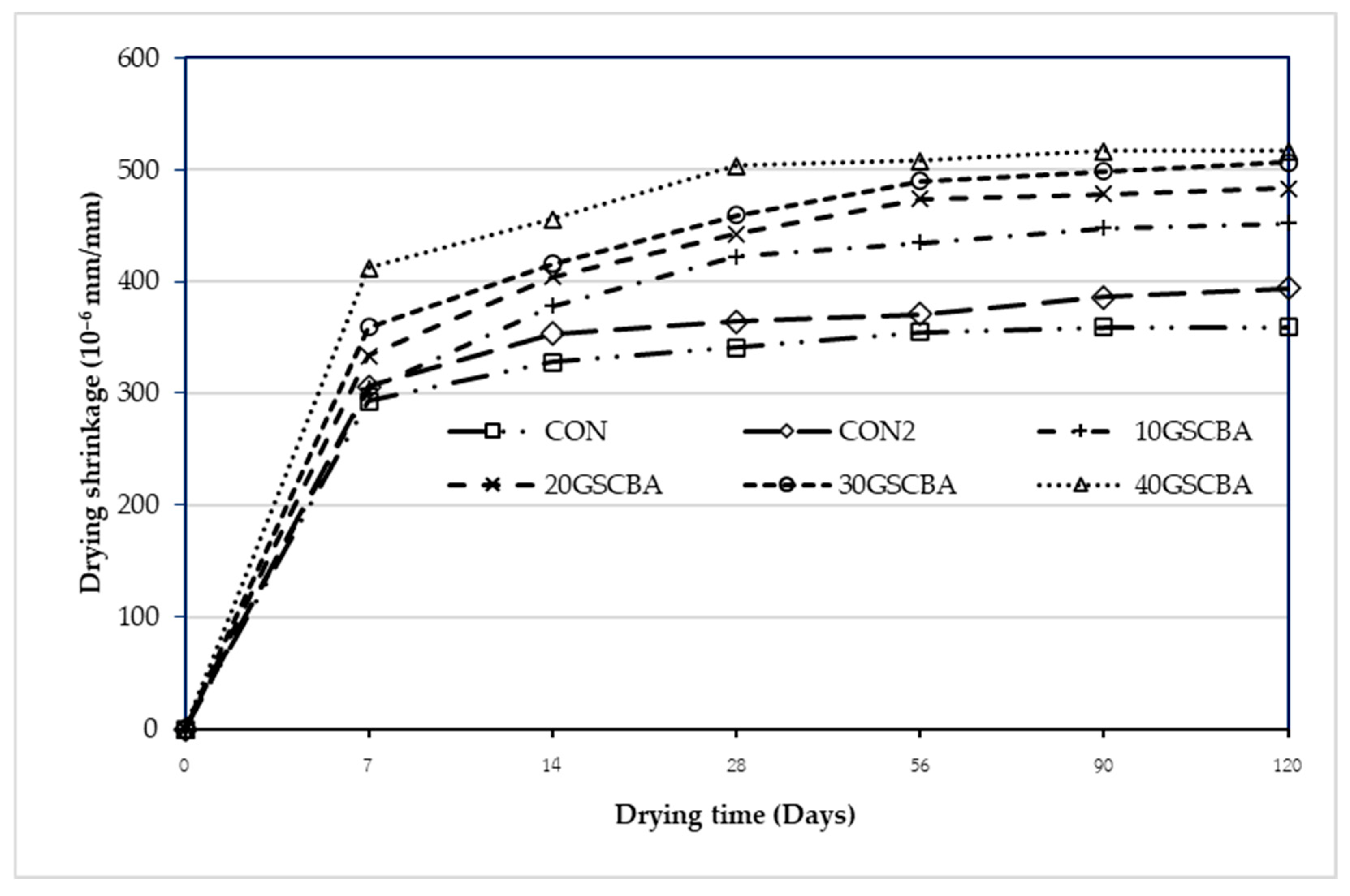

3.4.3. Drying Shrinkage of Concrete

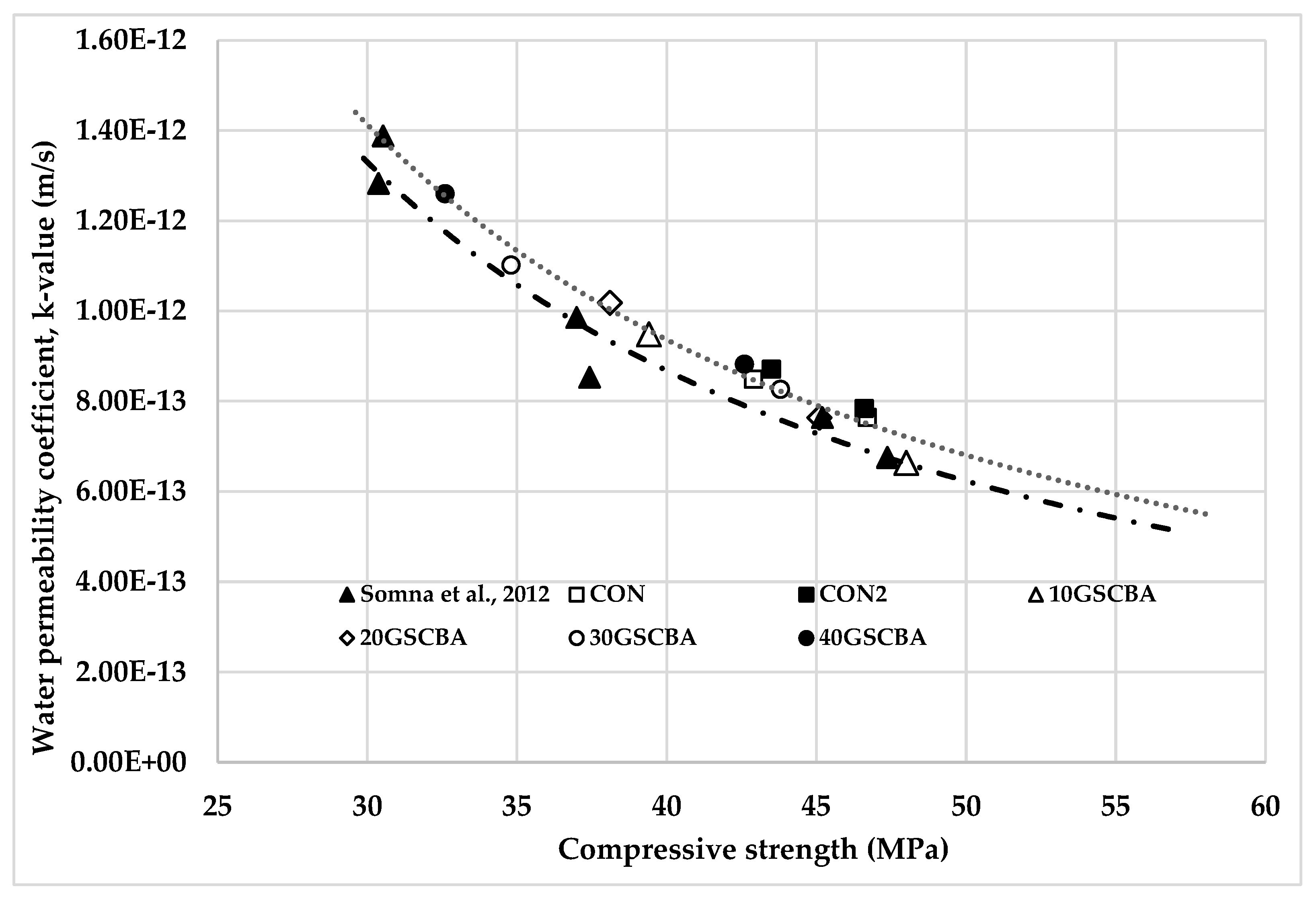

3.4.4. Water Permeability of Concrete

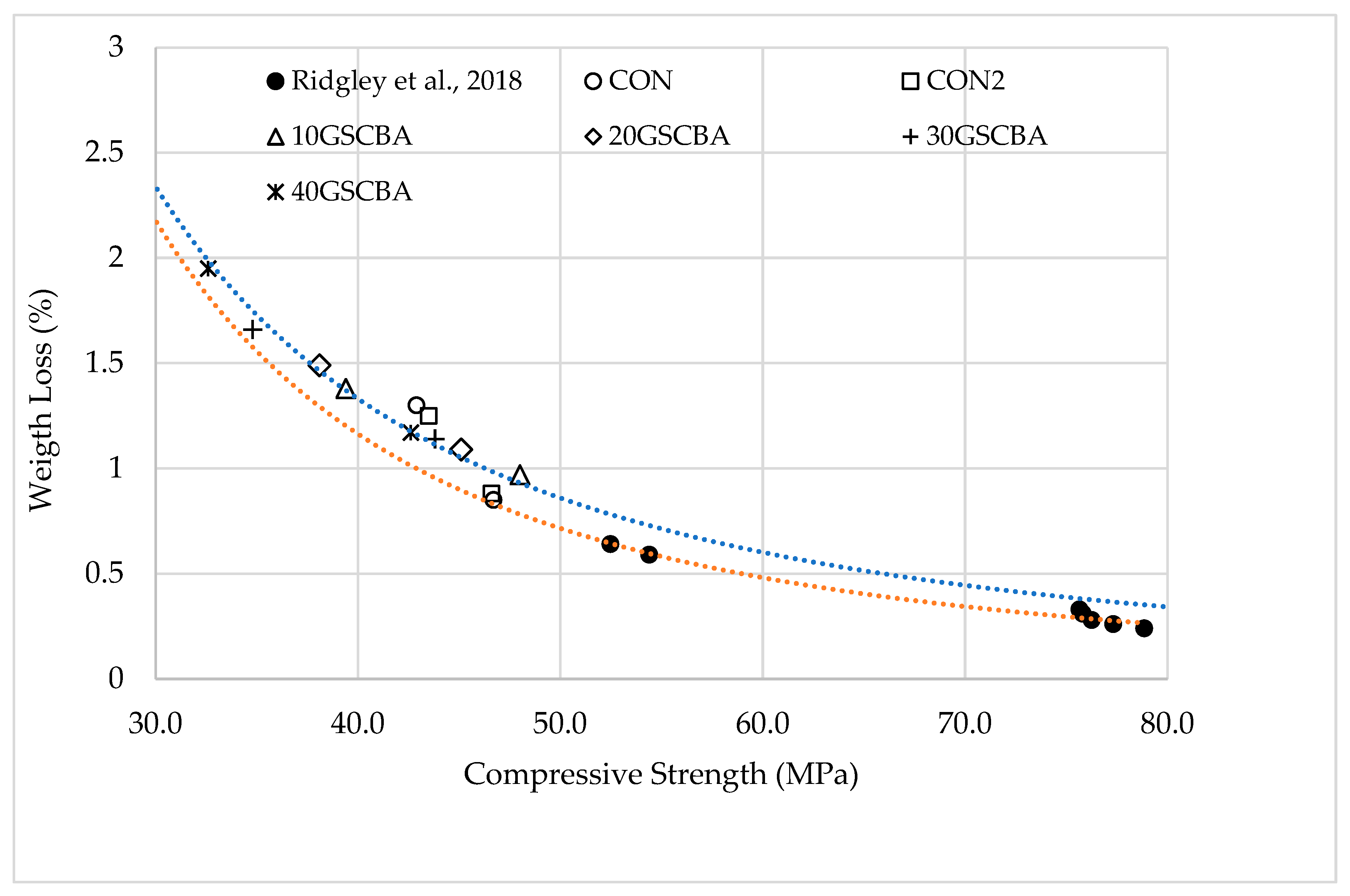

3.4.5. Abrasion Resistance of Concrete

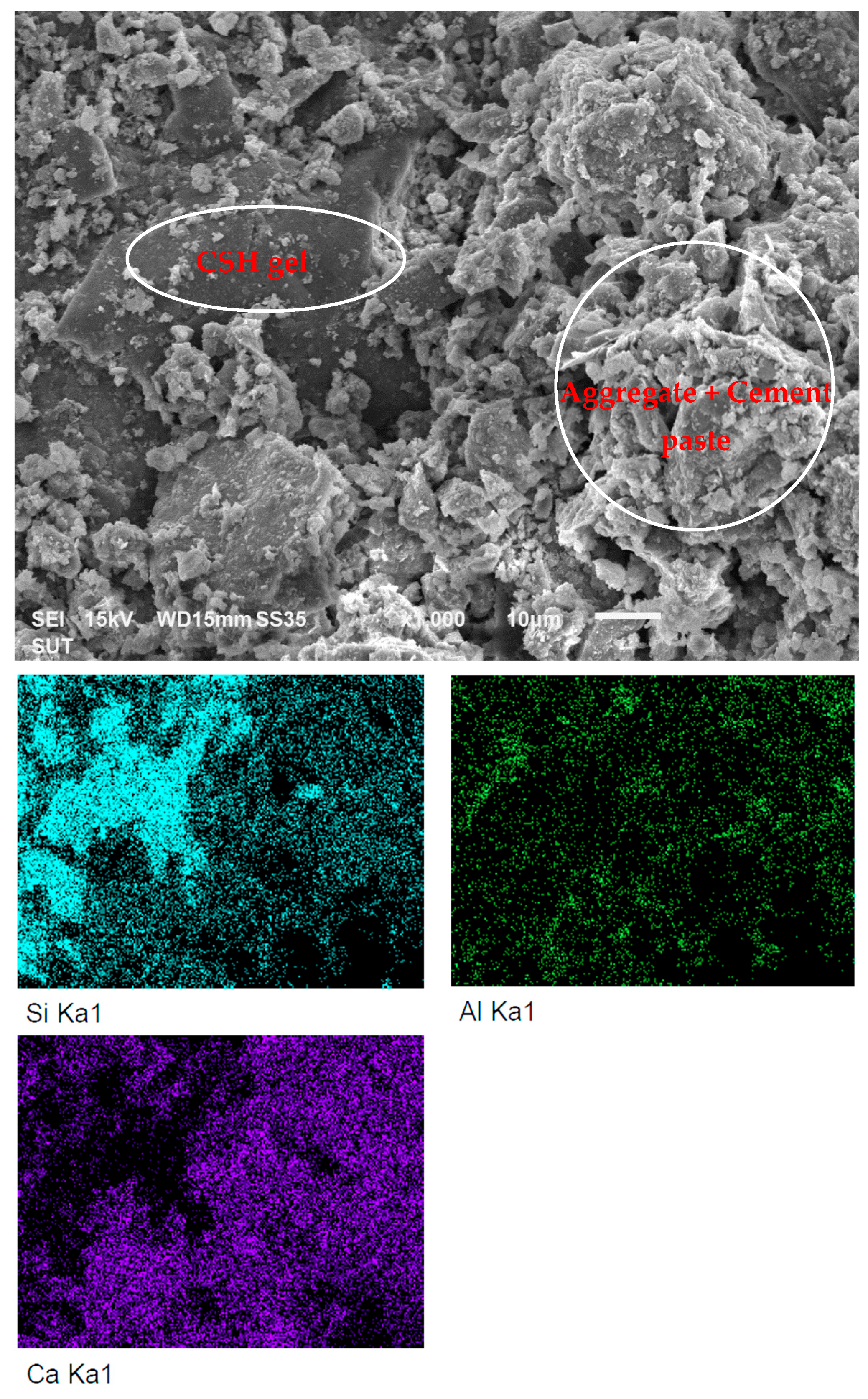

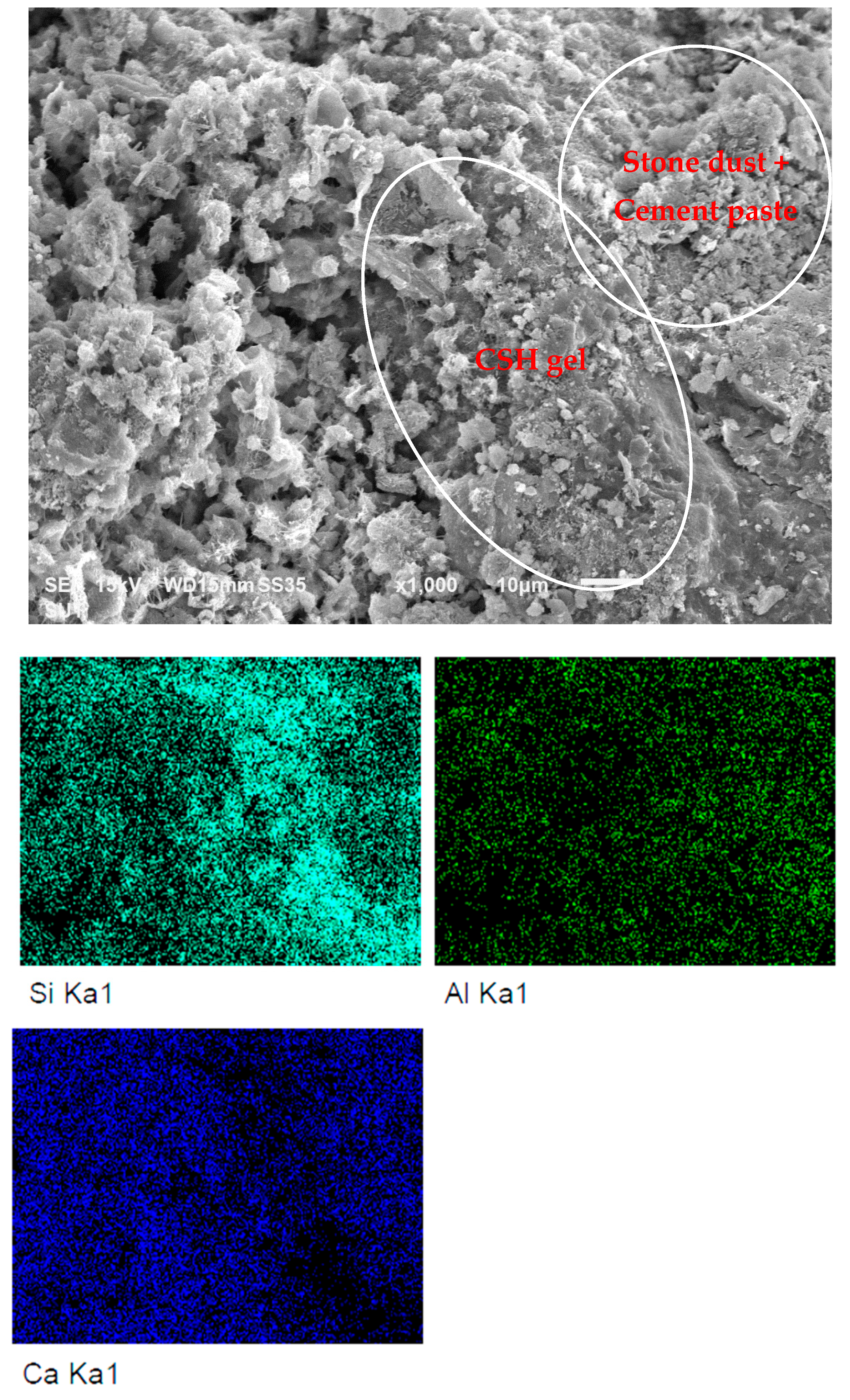

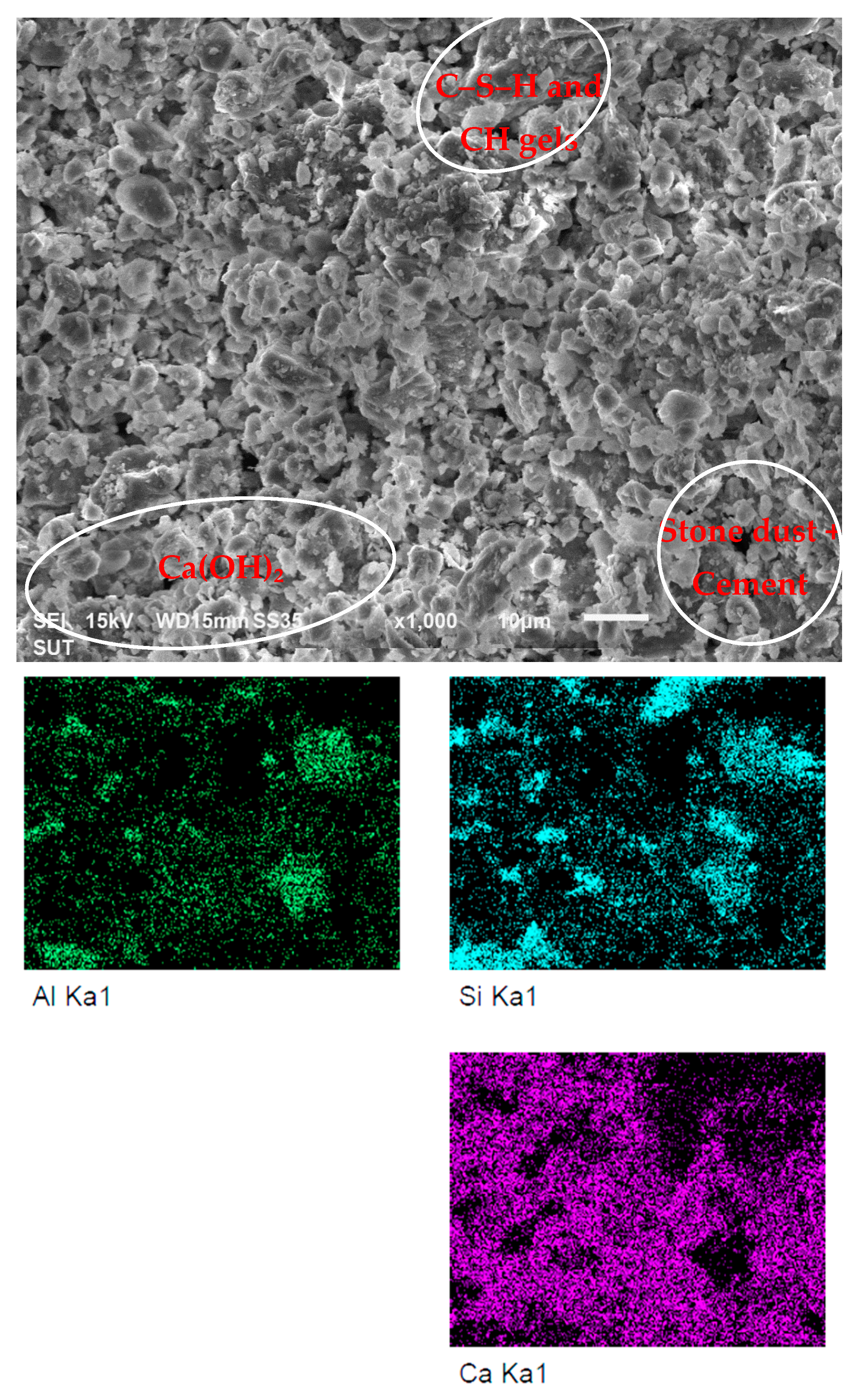

3.4.6. Microstructural Analysis of Concrete Surfaces

3.4.7. Chemical Composition of Bagasse Ash and Concrete with GSCBA and Stone Dust

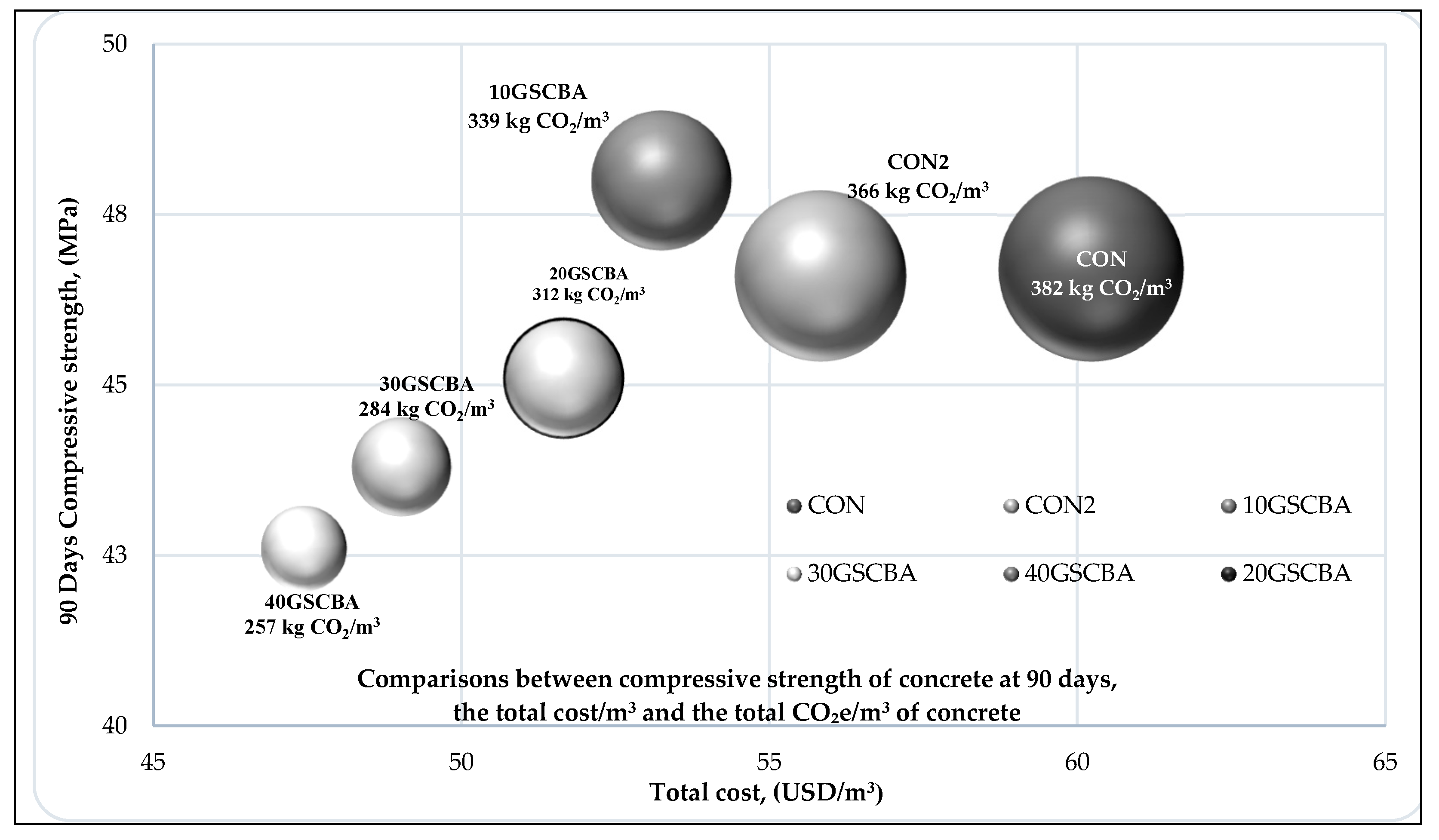

3.4.8. Environmental Assessment and Economic Benefits Comparisons

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CO2e | Carbon dioxide equivalents |

| CON | Control concrete + River Sand |

| CON2 | Control concrete + Stone dust |

| CT | Control mortar + River Sand |

| CT2 | Control mortar + Stone dust |

| GSCBA | Ground sugarcane bagasse ash |

| k-value | Water permeability coefficient |

| ITZ | Interfacial transition zone |

| OSCBA | Original sugarcane bagasse ash |

| RS | River sand |

| SD | Stone dust |

| SP | Superplasticizer |

| USD | United States dollar |

References

- Bahurudeen, A.; Santhanam, M. Influence of different processing methods on the pozzolanic performance of sugarcane bagasse ash. Cem. Concr. Compos. 2015, 56, 32–45. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of bagasse ash as supplementary cementitious material. Cem. Concr. Compos. 2007, 29, 515–524. [Google Scholar] [CrossRef]

- Silva, L.S.; Amario, M.; Stolz, C.M.; Figueiredo, K.V.; Haddad, A.N. A comprehensive review of stone dust in concrete: Mechanical behavior, durability, and environmental performance. Buildings 2023, 13, 1856. [Google Scholar] [CrossRef]

- Bheel, N.; Chohan, I.M.; Alwetaishi, M.; Waheeb, S.A.; Alkhattabi, L. Sustainability assessment and mechanical characteristics of high-strength concrete blended with marble dust powder and wheat straw ash as cementitious materials by using RSM modelling. Sustain. Chem. Pharm. 2024, 39, 101606. [Google Scholar] [CrossRef]

- Khan, M.A.; Zhang, B.; Ahmad, M.; Niekurzak, M.; Khan, M.S.; Sabri, M.M.; Chen, W. Optimizing concrete sustainability with bagasse ash and stone dust and its impact on mechanical properties and durability. Sci. Rep. 2025, 15, 1385. [Google Scholar] [CrossRef]

- Elawadly, N.; Sanad, S.A. Sustainable concrete incorporating sugarcane bagasse ash: A study on workability, mechanical behavior, and microstructure. Innov. Infrastruct. Solut. 2025, 10, 401. [Google Scholar] [CrossRef]

- Abdalla, T.A.; Koteng, D.O.; Shitote, S.M.; Matallah, M. Mechanical properties of eco-friendly concrete made with sugarcane bagasse ash. Civ. Eng. J. 2022, 8, 1227–1239. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Kroehong, W.; Damrongwiriyanupap, N.; Suriyo, W.; Jaturapitakkul, C. Mechanical properties, chloride resistance and microstructure of Portland fly ash cement concrete containing high volume bagasse ash. J. Build. Eng. 2020, 31, 101415. [Google Scholar] [CrossRef]

- Klathae, T.; Tran, T.N.H.; Men, S.; Jaturapitakkul, C.; Tangchirapat, W. Strength, chloride resistance, and water permeability of high-volume sugarcane bagasse ash high-strength concrete incorporating limestone powder. Constr. Build. Mater. 2021, 311, 125326. [Google Scholar] [CrossRef]

- ASTM C1157; Standard Performance Specification for Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C469/C469M; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C78; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C157/C157M; Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM C944; Standard Test Method for Abrasion Resistance of Concrete or Mortar Surfaces by the Rotating-Cutter Method. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2019.

- ISO 14040; Environmental Management—Life Cycle Assessment: Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment: Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- RISC Knowledge Center. How Hydraulic Cement Reduces Global Warming. 2023. Available online: https://risc.in.th/en/knowledge/how-hydraulic-cement-reduces-global-warming (accessed on 28 October 2025).

- Zhu, X.; Zhang, Y.; Liu, Z.; Qiao, H.; Ye, F.; Lei, Z. Research on carbon emission reduction of manufactured sand concrete based on compressive strength. Constr. Build. Mater. 2023, 403, 133101. [Google Scholar] [CrossRef]

- Kalinowski, M.; Woyciechowski, P.; Sokołowska, J. Effect of mechanically-induced fragmentation of polyacrylic superabsorbent polymer (SAP) hydrogel on the properties of cement composites. Constr. Build. Mater. 2020, 263, 120135. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 4th ed.; Longman: London, UK, 1995. [Google Scholar]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.M.R. Effect of calcination temperature on the pozzolanic activity of Sugarcane bagasse ash. Constr. Build. Mater. 2009, 23, 3301–3303. [Google Scholar] [CrossRef]

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006; Available online: https://repositori.mypolycc.edu.my/jspui/handle/123456789/4614 (accessed on 8 October 2025).

- Gedam, B.A.; Singh, S.; Upadhyay, A.; Bhandari, N.M. Improved durability of concrete using supplementary cementitious materials. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies, London, UK, 14–17 July 2019. [Google Scholar]

- Zabade, G.; Ngekpe, B.E.; Zab, I.; Akobo, S. Mechanical and durability properties of rice husk ash blended concrete. Int. J. Sci. Eng. Res. 2022, 13, 419–427. [Google Scholar]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of bagasse ash as a pozzolanic material in concrete. Constr. Build. Mater. 2009, 23, 3352–3358. [Google Scholar] [CrossRef]

- Rukzon, S.; Chindaprasirt, P. Utilization of bagasse ash in high-strength concrete. Mater. Des. 2012, 34, 45–50. [Google Scholar] [CrossRef]

- Ramdane, R.; Kherraf, L.; Assia, A.; Belachia, M. Influence of biomass ash on the performance and durability of mortar. Civ. Environ. Eng. Rep. 2022, 32, 53–71. [Google Scholar] [CrossRef]

- ASTM C33-97; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM C128-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C136-01; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM C117-95; Standard Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing. ASTM International: West Conshohocken, PA, USA, 1995.

- Sata, V.; Tangpagasit, J.; Jaturapitakkul, C.; Chindaprasirt, P. Effect of W/B ratios on pozzolanic reaction of mortars containing biomass ashes. Cem. Concr. Compos. 2012, 34, 94–100. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Kiattikomol, K. Compressive strength and expansion of blended cement mortar containing palm oil fuel ash. J. Mater. Civ. Eng. 2009, 21, 426–431. [Google Scholar] [CrossRef]

- Kroehong, W.; Sinsiri, T.; Jaturapitakkul, C.; Chindaprasirt, P. Effect of palm oil fuel ash fineness on the microstructure of blended cement paste. Constr. Build. Mater. 2011, 25, 4095–4104. [Google Scholar] [CrossRef]

- TIS 2594-2556; Hydraulic Cement. Thai Industrial Standards Institute: Bangkok, Thailand, 2013.

- Klathae, T.; Tanawuttiphong, N.; Tangchirapat, W.; Chindaprasirt, P.; Sukontasukkul, P.; Jaturapitakkul, C. Heat evolution, strengths, and drying shrinkage of concrete containing high-volume ground bagasse ash with different LOIs. Constr. Build. Mater. 2020, 258, 119443. [Google Scholar] [CrossRef]

- ACI 318; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- Sales, A.; Lima, S.A. Use of Brazilian sugarcane bagasse ash in concrete as sand replacement. Waste Manag. 2010, 30, 1114–1122. [Google Scholar] [CrossRef]

- Somna, R.; Jaturapitakkul, C.; Rattanachu, P.; Chalee, W. Effect of ground bagasse ash on mechanical and durability properties of recycled aggregate concrete. Mater. Des. 2012, 36, 597–603. [Google Scholar] [CrossRef]

- Barr, B.; Hoseinian, S.B.; Beygi, M.A. Shrinkage of concrete stored in natural environments. Cem. Concr. Compos. 2003, 25, 19–29. [Google Scholar] [CrossRef]

- ACI Committee 209; Report on Factors Affecting Shrinkage and Creep of Hardened Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2005.

- Ridgley, K.E.; Abouhussien, A.A.; Hassan, A.A.; Colbourne, B. Assessing abrasion performance of self-consolidating concrete containing synthetic fibers using acoustic emission analysis. Mater. Struct. 2018, 51, 119. [Google Scholar] [CrossRef]

- Pachideh, G.; Gholhaki, M.; Ketabdari, H. Effect of pozzolanic wastes on mechanical properties, durability and microstructure of cementitious mortars. J. Build. Eng. 2020, 29, 101178. [Google Scholar] [CrossRef]

- Khankhaje, E.; Kim, T.; Jang, H.; Kim, C.-S.; Kim, J.; Rafieizonooz, M. A review of utilization of industrial waste materials as cement replacement in pervious concrete: An alternative approach to sustainable pervious concrete production. Heliyon 2024, 10, e26188. [Google Scholar] [CrossRef] [PubMed]

- 40 CFR Part 503; Standards for the Use or Disposal of Sewage Sludge. United States Environmental Protection Agency: Washington, DC, USA, 1993.

- EN 12457-2; Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges. European Committee for Standardization: London, UK, 2002.

| Mix | Mix Proportion (kg/m3) | W/B | SP (%) | Slump (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|

| HC | GSCBA | Fine Agg. (RS) | Fine Agg. (SD) | Coarse Agg. (LS) | Water | ||||

| CON | 400 | – | 784 | – | 992 | 180 | 0.45 | 1.00 | 110 |

| CON2 | 400 | – | – | 826 | 993 | 180 | 0.45 | 1.00 | 105 |

| 10GSCBA | 360 | 40 | - | 820 | 984 | 180 | 0.45 | 1.00 | 105 |

| 20GSCBA | 320 | 80 | – | 812 | 976 | 180 | 0.45 | 1.25 | 115 |

| 30GSCBA | 280 | 120 | – | 804 | 965 | 180 | 0.45 | 1.25 | 110 |

| 40GSCBA | 240 | 160 | - | 796 | 957 | 180 | 0.45 | 1.50 | 110 |

| Raw Material | Unit | Emission Factor (kg CO2-eq) | Unit Cost (USD) | Reference |

|---|---|---|---|---|

| Hydraulic cement | kg | 0.795 | 0.075 | [19] |

| Stone dust | kg | 0.0077 | 0.007 | [20] |

| River sand | kg | 0.028 | 0.013 | [9] |

| Coarse aggregate | kg | 0.039 | 0.016 | [9] |

| Sugarcane bagasse ash | kg | 0.110 | 0.015 | [9] |

| Superplasticizer | kg | 0.772 | 1.000 | [9] |

| Water | kg | 0.001 | 0.0009 | [9] |

| Materials | HC | GSCBA | |

|---|---|---|---|

| Physical Properties | Specific gravity | 3.13 | 2.12 |

| Median particle size, d50 (µm) | 17.7 | 6.4 | |

| Chemical Composition (%) | Silicon dioxide (SiO2) | 21.9 | 61.1 |

| Aluminum oxide (Al2O3) | 4.6 | 7.9 | |

| Ferric oxide (Fe2O3) | 3.9 | 6.2 | |

| Calcium oxide (CaO) | 61.6 | 9.2 | |

| Magnesium oxide (MgO) | 2.0 | 1.8 | |

| Potassium oxide (K2O) | 0.5 | 2.9 | |

| Sodium oxide (Na2O) | 0.2 | 0.2 | |

| Sulfur trioxide (SO3) | 3.6 | 1.8 | |

| Loss on ignition (LOI) | 1.5 | 8.9 | |

| SiO2 + Al2O3 + Fe2O3 | - | 75.2 | |

| Properties | Fineness Modulus | Passing No. 200 Sieve (%) | Bulk Specific Gravity (SSD) | Water Absorption (%) |

|---|---|---|---|---|

| River Sand | 2.78 | 7.00 | 2.62 | 1.10 |

| Stone Dust | 3.72 | 15.86 | 2.76 | 1.33 |

| Crushed limestone | 5.52 | - | 2.63 | 0.68 |

| Sample | Mix Proportion by Weight (g) | W/B | Flow (%) | |||

|---|---|---|---|---|---|---|

| HC | GSCBA | River Sand | Stone Dust | |||

| CT | 500 | - | 1375 | - | 0.58 | 114 |

| CT2 | 500 | - | - | 1375 | 0.62 | 110 |

| 10GSCBA | 450 | 50 | - | 1375 | 0.62 | 106 |

| 20GSCBA | 400 | 100 | - | 1375 | 0.64 | 106 |

| 30GSCBA | 350 | 150 | - | 1375 | 0.65 | 107 |

| 40GSCBA | 300 | 200 | - | 1375 | 0.68 | 114 |

| Sample | Compressive Strength (MPa) (Normalized Compressive Strength) (%) | ||||

|---|---|---|---|---|---|

| 1 Day | 3 Days | 7 Days | 28 Days | 60 Days | |

| CT | 14.9 ± 0.36 (100) | 26.6 ± 0.26 (100) | 30.2 ± 0.28 (100) | 39.8 ± 0.43 (100) | 47.7 ± 0.52 (100) |

| CT2 | 14.8 ± 0.27 (99) | 26.4 ± 0.33 (99) | 31.6 ± 0.23 (105) | 38.9 ± 0.06 (98) | 46.6 ± 0.18 (98) |

| 10GSCBA | 13.9 ± 0.15 (93) | 25.2 ± 0.46 (95) | 30.6 ± 0.52 (101) | 39.4 ± 0.22 (99) | 47.9 ± 1.49 (100) |

| 20GSCBA | 13.5 ± 0.22 (91) | 24.6 ± 0.15 (92) | 29.8 ± 1.49 (99) | 38.1 ± 0.52 (96) | 46.4 ± 0.46 (97) |

| 30GSCBA | 12.6 ± 0.65 (85) | 22.5 ± 0.18 (85) | 27.6 ± 0.14 (91) | 34.8 ± 0.08 (87) | 43.5 ± 0.10 (91) |

| 40GSCBA | 10.1 ± 0.60 (68) | 18.5 ± 0.62 (70) | 23.9 ± 0.57 (79) | 32.6 ± 1.32 (82) | 41.2 ± 0.74 (86) |

| Chemical Composition | GSCBA | 40GSCBA |

|---|---|---|

| Al2O3 | 7.609 | 6.125 |

| SiO2 | 74.538 | 36.051 |

| SO3 | 0.547 | 2.818 |

| K2O | 1.463 | 0.622 |

| CaO | 7.173 | 45.808 |

| MgO | 2.917 | 3.334 |

| TiO2 | 0.576 | 0.432 |

| Cr2O3 | 0.019 | 0.047 |

| MnO2 | 0.252 | 0.121 |

| Fe2O3 | 4.846 | 4.290 |

| CuO | 0.014 | 0.020 |

| ZnO | 0.033 | 0.035 |

| SrO | 0.013 | 0.112 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khamput, P.; Masae, M.; Somna, K.; Klathae, T. Mechanical and Durability Performance of Sustainable Concrete Incorporating Stone Dust as Sand Substitute and Sugarcane Bagasse Ash as Cement Replacement. Appl. Sci. 2025, 15, 12076. https://doi.org/10.3390/app152212076

Khamput P, Masae M, Somna K, Klathae T. Mechanical and Durability Performance of Sustainable Concrete Incorporating Stone Dust as Sand Substitute and Sugarcane Bagasse Ash as Cement Replacement. Applied Sciences. 2025; 15(22):12076. https://doi.org/10.3390/app152212076

Chicago/Turabian StyleKhamput, Prachoom, Mahamasuhaimi Masae, Kiatsuda Somna, and Tawich Klathae. 2025. "Mechanical and Durability Performance of Sustainable Concrete Incorporating Stone Dust as Sand Substitute and Sugarcane Bagasse Ash as Cement Replacement" Applied Sciences 15, no. 22: 12076. https://doi.org/10.3390/app152212076

APA StyleKhamput, P., Masae, M., Somna, K., & Klathae, T. (2025). Mechanical and Durability Performance of Sustainable Concrete Incorporating Stone Dust as Sand Substitute and Sugarcane Bagasse Ash as Cement Replacement. Applied Sciences, 15(22), 12076. https://doi.org/10.3390/app152212076