1. Introduction

Aerodynamics plays a crucial role in the development of racing motorcycles, as it directly influences drag, downforce, stability, and rider control during all phases of motion, including cornering, braking, and acceleration [

1,

2]. In the last decade, its importance has grown dramatically, especially in world championships such as MotoGP, Moto2, Moto3, and SuperBike, where teams continuously experiment with innovative solutions to gain competitive advantages in terms of speed, stability, and handling [

3]. This trend has been further accelerated by regulatory changes and the widespread introduction of aerodynamic appendages such as winglets [

4] and fairing extensions, which have reshaped the design philosophy of modern racing motorcycles [

2,

5]. A decisive factor in this progress has been the rapid evolution of computational methods, particularly Computational Fluid Dynamics (CFD). CFD, which numerically solves the Navier–Stokes equations over discretized meshes, has become an indispensable tool for designers, allowing them to investigate complex flow structures, evaluate wake behaviour, analyse pressure distribution, and quantify aerodynamic forces such as drag and lift both in terrestrial and non-terrestrial applications [

6,

7,

8,

9,

10]. Recent frontier achievements in advanced numerical methods, including multi-field coupling simulations and in situ calibration techniques based on virtual samples and autoencoders [

11,

12], illustrate the increasing capability of modern computational workflows to handle complex, coupled physical phenomena efficiently.

Through CFD, multiple design iterations can be performed efficiently, enabling the optimization of aerodynamic components long before wind tunnel campaigns or on-track testing, and thereby making aerodynamic development both more precise and more cost-effective [

2,

13,

14,

15]. Several studies have investigated the impact of aerodynamic devices on motorcycles, often focusing on front-mounted wing kits and their ability to enhance downforce while balancing the inevitable increase in drag. Chien and Wang [

5] analysed a racing motorcycle equipped with an aerodynamic wing kit based on the NACA 4412 profile, applying CFD simulations with k–ω SST and LES turbulence models, and demonstrated the potential of such devices to improve the downforce-to-drag ratio under different operating conditions. Similarly, Wiński and Piechna [

2] performed comprehensive CFD simulations of a sport motorcycle, including the presence of a rider, and highlighted the aerodynamic complexity arising from exposed wheels, body geometry, and rider posture. More recently, attention has also been directed toward the aerodynamic interaction between leading and pursuing motorcycles, as the vortical wake generated by downforce-producing appendages may alter the pressure field encountered by a following rider.

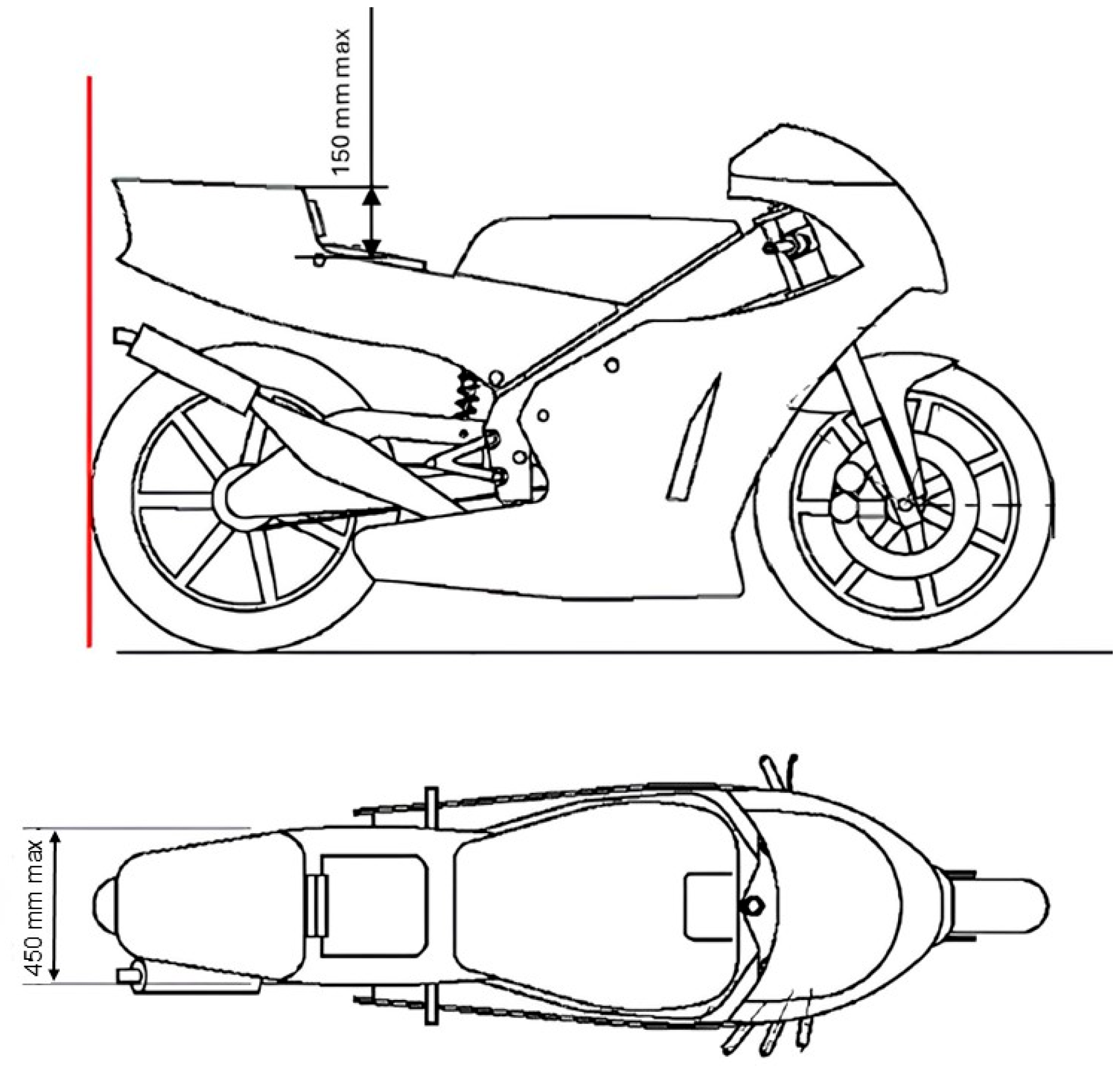

One of the first notable aerodynamic innovations in motorcycle racing emerged around 2011, when Ducati, in collaboration with Valentino Rossi, tested aerodynamic appendages mounted on the flanks of its MotoGP prototype. These side fairing extensions were designed to manipulate airflow, improve attachment, and enhance high-speed stability, although Rossi reportedly found that they did not suit his riding style. A more prominent breakthrough followed in 2015 with the Ducati GP15, ridden by Andrea Iannone, which introduced front-mounted winglets and enlarged side fairing elements. The goal of this configuration was to generate sufficient downforce to reduce front-end lift and wheelies, improving straight-line stability without significantly compromising top speed, given the high power output of MotoGP engines. Photographic documentation from that period shows Ducati experimenting with different winglet geometries and sizes, including fairing extensions around the handlebars to comply with regulatory width limits.

Following Ducati’s success, other manufacturers quickly adopted similar solutions. Honda, for instance, began testing aerodynamic winglets in early 2016 on its factory prototypes. Riders such as Dani Pedrosa and Marc Márquez reported noticeable changes in handling, acknowledging both the benefits in front-end stability and potential drawbacks under specific conditions. These early designs primarily aimed to reduce front lift during acceleration and to improve rear wheel traction and vehicle stability at high speed.

Historically, the pursuit of aerodynamic efficiency in motorcycles dates back even further. The Bimota YB1 (1974–1975), designed by Massimo Tamburini, featured fully enveloping bodywork that minimized drag and reduced the exposed frontal area, demonstrating an early awareness of aerodynamics in racing motorcycle design. Although aerodynamic understanding at the time lacked modern computational tools, the YB1 highlighted the crucial interplay between fairing design, rider position, and overall aerodynamic performance, a principle later refined through Ducati’s modern winglet developments.

From a technical point of view, CFD now allows for a level of detail that was impossible in earlier decades. Mesh generation, turbulence modelling (such as k–ω SST, LES, RANS hybrids) [

16,

17,

18], transient vs. steady simulations, wake structure visualization, and vortex shedding analysis all provide insight into how small shape changes (in winglet angle, size, or position) affect pressure distribution, drag coefficient, lift/downforce, and also dynamic stability under yaw, pitch, and roll. The wake closure phenomenon, where rear fairing shapes or appendices reduce turbulent wake size or promote smoother flow separation, has been recognized in recent academic work as having implications not just for a single motorcycle’s drag and downforce, but also how trailing motorcycles are affected by the disturbed flow field.

While the introduction of aerodynamic appendages in MotoGP and other racing series has driven technological progress, the academic literature has followed with systematic investigations into motorcycle aerodynamics, particularly through CFD and experimental validation. Unlike anecdotal reports from racing teams, these studies provide reproducible results and frameworks for understanding the aerodynamic mechanisms that govern drag, lift, stability, and wake interactions [

19,

20]. One of the earliest comprehensive CFD-based analyses of motorcycle aerodynamics was carried out by Angeletti et al. [

21], who demonstrated the applicability of CFD tools to complex geometries including the rider and rotating wheels. Their work established that accurate modelling of wheel rotation and rider posture is essential to capture realistic flow separation and vortex structures. More recently, Palanivendhan et al. [

22] designed and evaluated a complete aerodynamic kit for a racing motorcycle, showing that relatively small fairing modifications could lead to reductions in drag and improvements in stability without compromising top speed. Similarly, González-Arcos and Gamez-Montero [

3] investigated MotoGP flow redirectors, demonstrating how targeted geometric modifications affect pressure fields, wake dimensions, and aerodynamic load transfer between the wheels. Beyond steady-state CFD analyses, transient and crosswind effects have been addressed in detail. Fintelman et al. [

23] conducted numerical simulations of motorcycles under yawed flow conditions, finding that side winds and unsteady wake interactions substantially affect stability and load distribution, with implications for both safety and performance. These insights underline the importance of studying appendages not only in straight-line configurations but also in dynamic race scenarios. The role of wake interactions between motorcycles has also been investigated. In their study, An and Fung [

24] analysed aerodynamic interactions between cyclists and following motorcycles, showing that leading vehicles generate disturbed flow fields that significantly alter the aerodynamic loads on trailing riders. Although their study focused on cycling, the principles translate directly to motorcycle racing, where rear appendages can either mitigate or exacerbate the slipstreaming advantage of opponents.

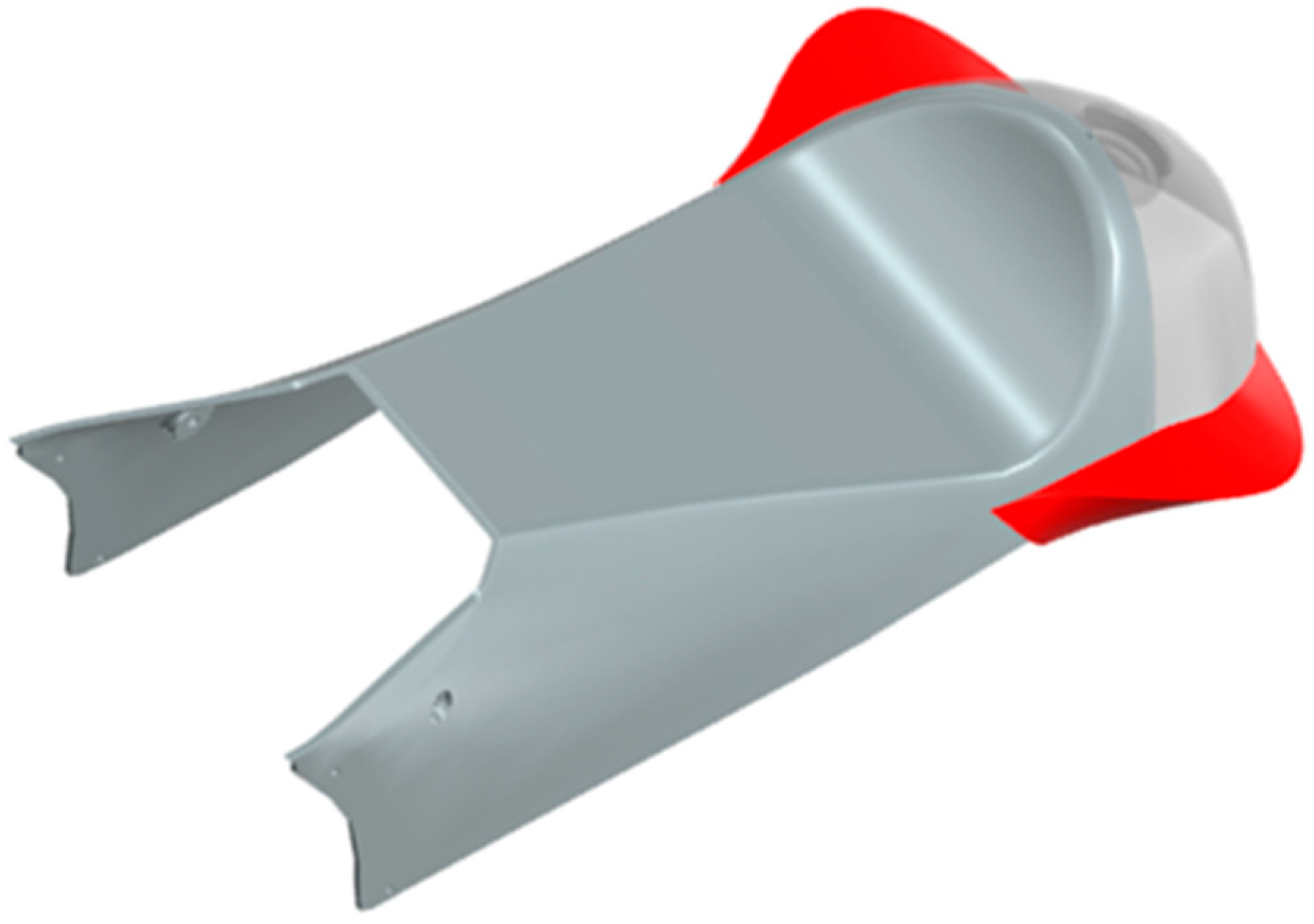

Despite the wealth of developments, there remains limited published literature focusing specifically on rear fairing winglets integrated into the tail section of racing motorcycles, their combined effect on drag reduction, downforce at the rear, wake closure, and stability.

Recent studies on motorcycle aerodynamics have mainly focused on front-mounted winglets and fairing modifications to enhance downforce, stability, and wheelie control through CFD-based analyses and simplified dynamic models. However, peer-reviewed investigations addressing rear aerodynamic appendages, such as fins, spoilers, or swingarm devices, remain limited, despite their growing use in modern racing motorcycles to improve high-speed stability and braking performance. Unlike front wings, tail-mounted components operate within the separated wake behind the rider and rear wheel, where flow mechanisms involve wake contraction, pressure recovery, and rear load redistribution. Recent findings indicate that optimizing tail geometry or integrating extractive passages can shorten wake length, reduce turbulent kinetic energy, and slightly increase rear downforce, offering an effective means to enhance aerodynamic balance and vehicle stability under racing conditions.

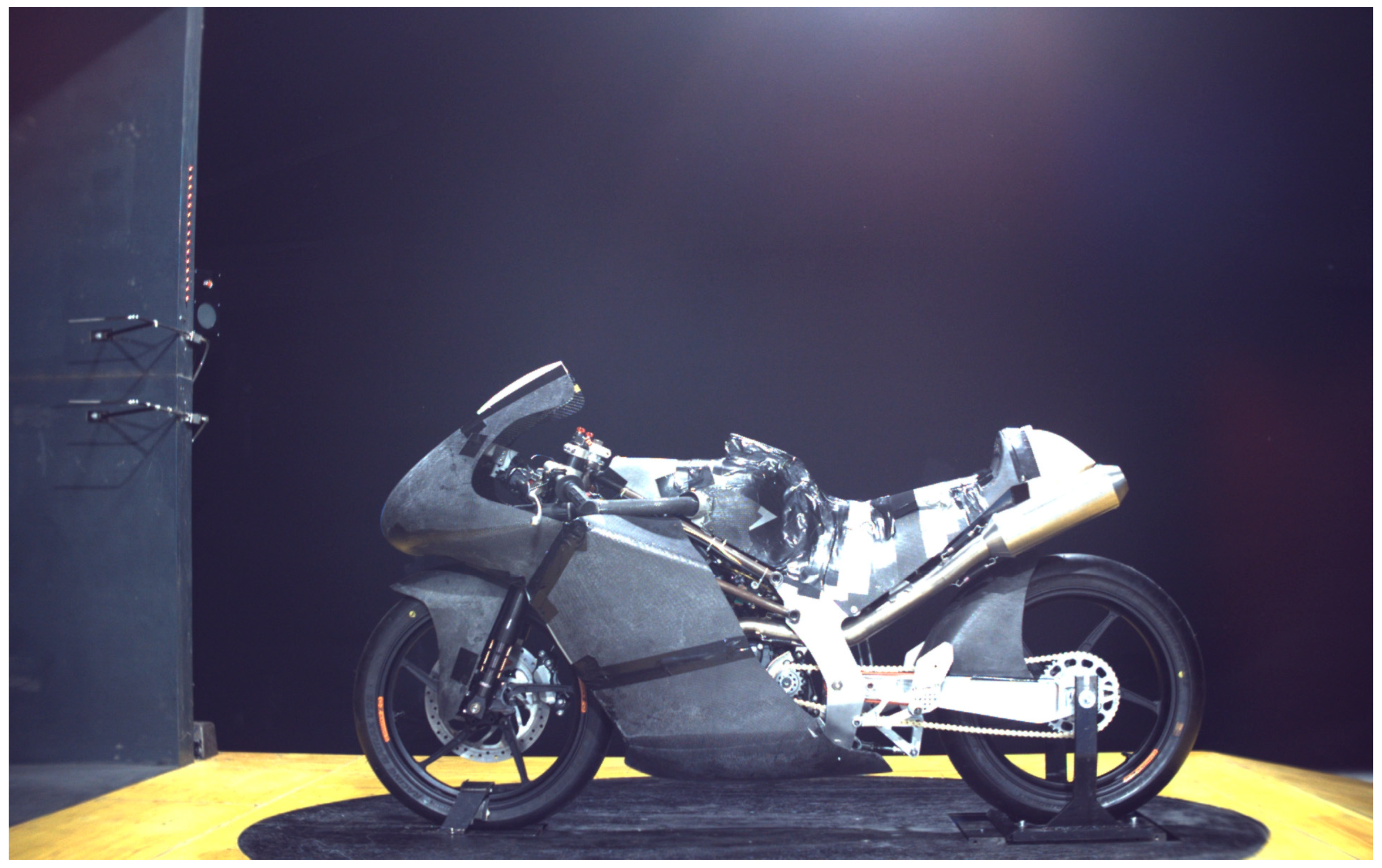

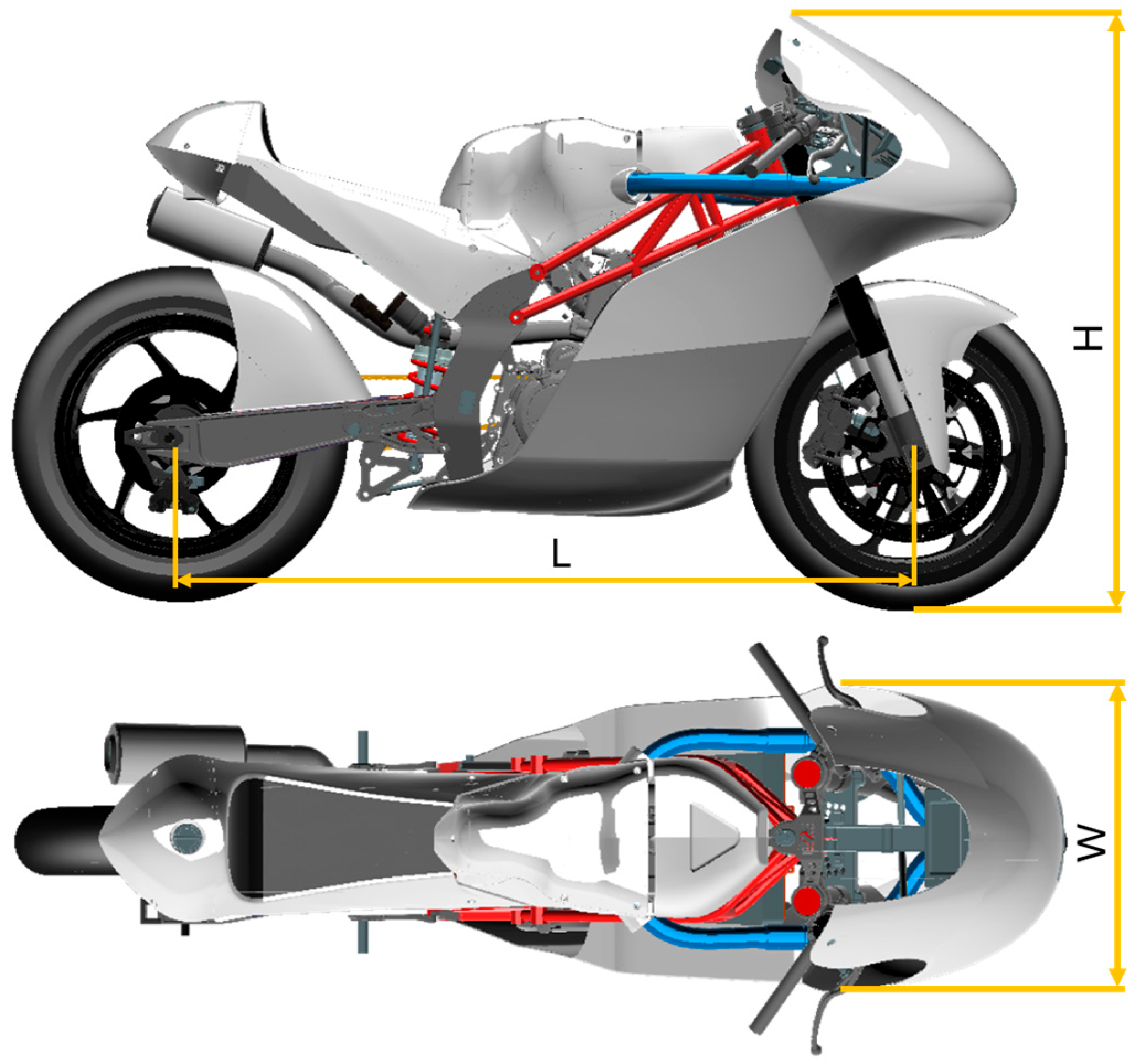

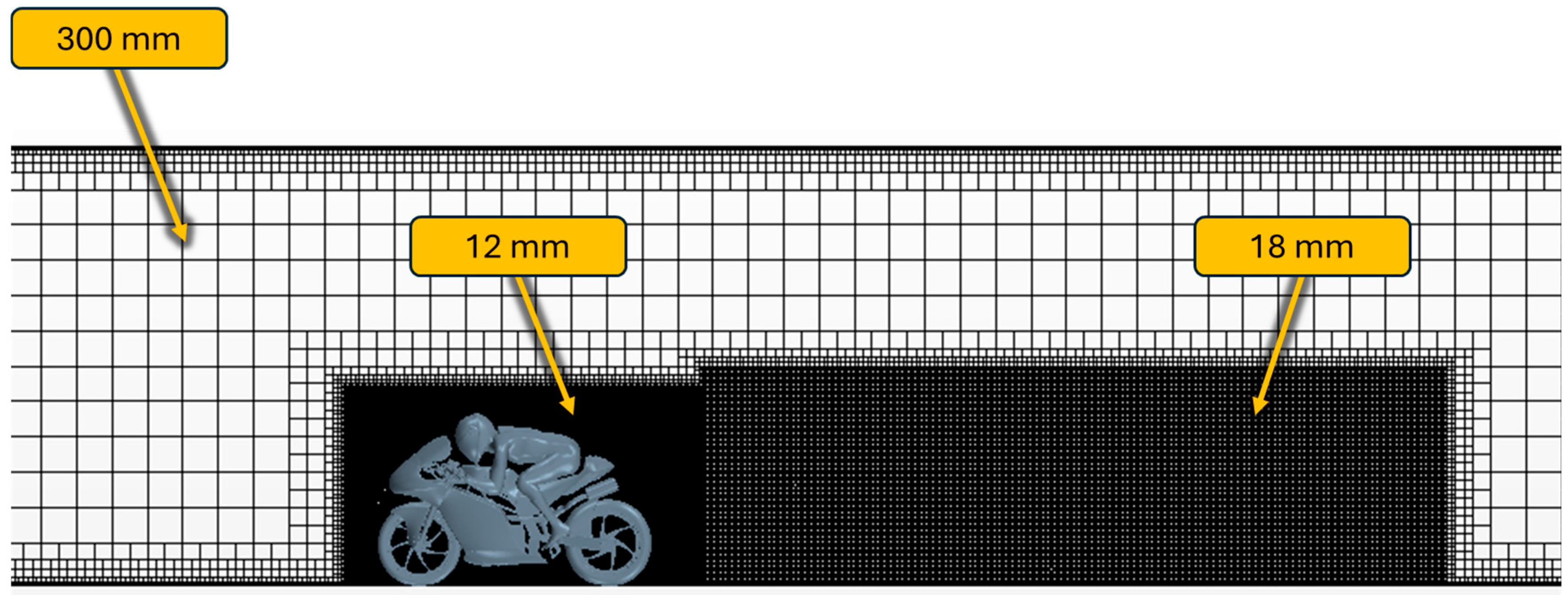

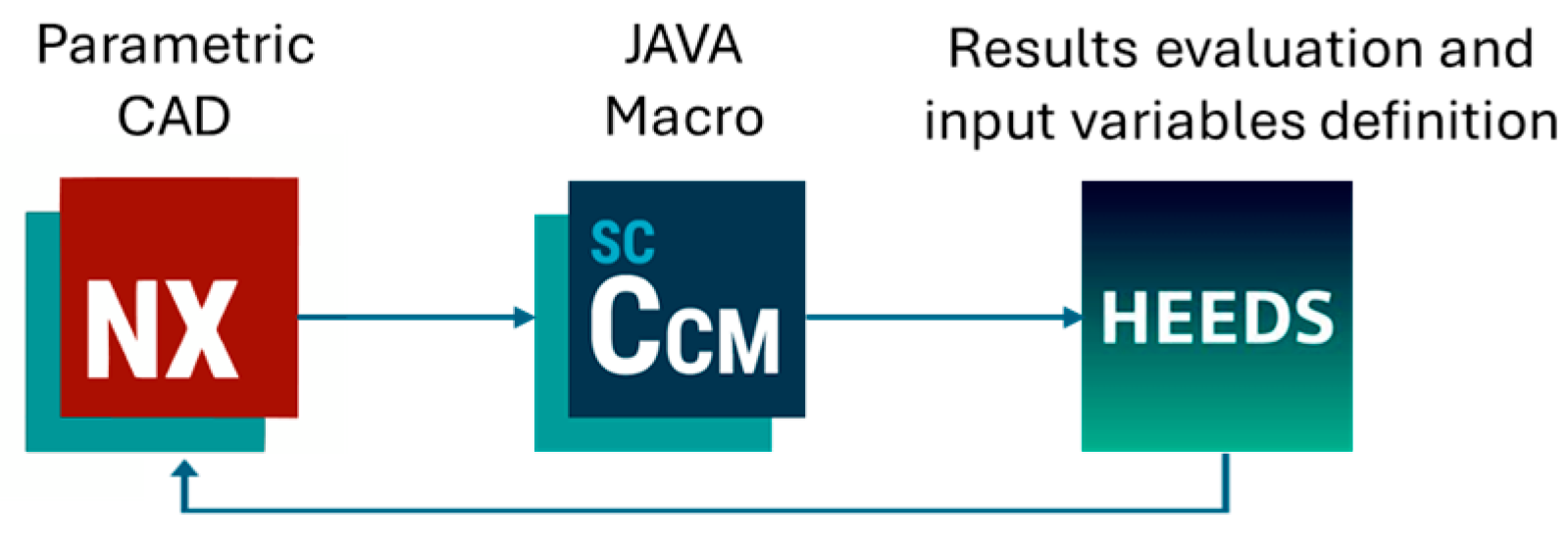

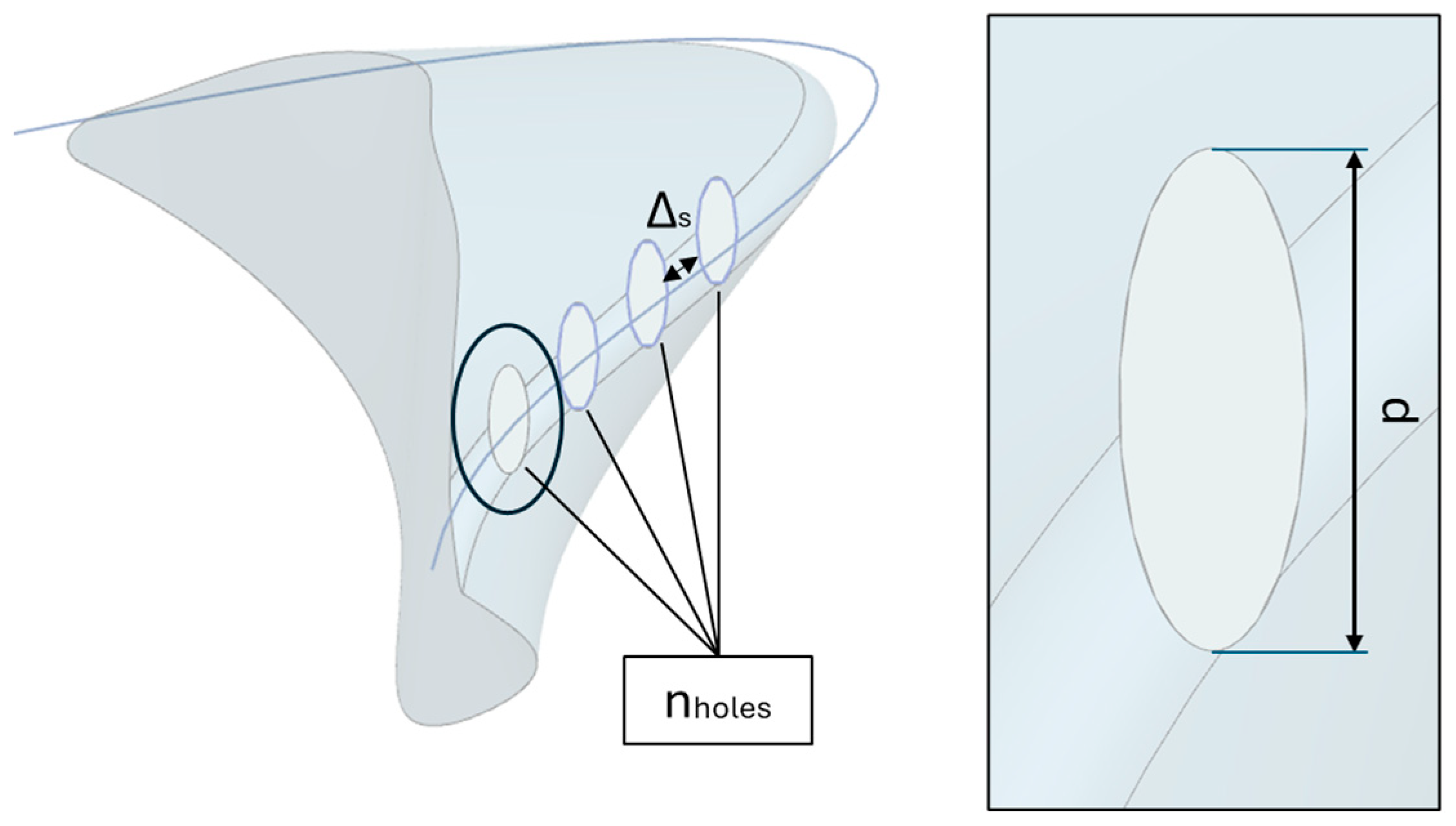

The present study aims to address this research gap by employing a Design Space Exploration (DSE) approach to design and evaluate alternative rear winglet configurations for a racing motorcycle prototype, including the generation of hollow shapes, as done in other fields. The winglet geometries were parametrically modelled in Siemens NX and integrated into a validated CFD environment using Simcenter STAR-CCM+ 2310. Through the DSE workflow, key geometric parameters were systematically varied to assess their influence on aerodynamic performance, with particular focus on drag, lift, wake development, and overall vehicle stability. This iterative, parametric exploration enabled the identification of the configuration that optimally balances the reduction in aerodynamic resistance with the generation of downforce, thereby improving both efficiency and controllability. By leveraging DSE, the study provides deeper insights into the aerodynamic behaviour of rear fairing winglets and establishes a structured methodology for future work involving automated optimization, experimental validation, and investigations into wake interactions between leading and trailing motorcycles.

3. Results and Discussions

The results of the CFD simulations for the various configurations are presented in this chapter. The first configuration tested, serving as a reference, is the motorcycle without any rear winglets. The data related to the aerodynamic forces measured on the entire prototype are reported in

Table 4.

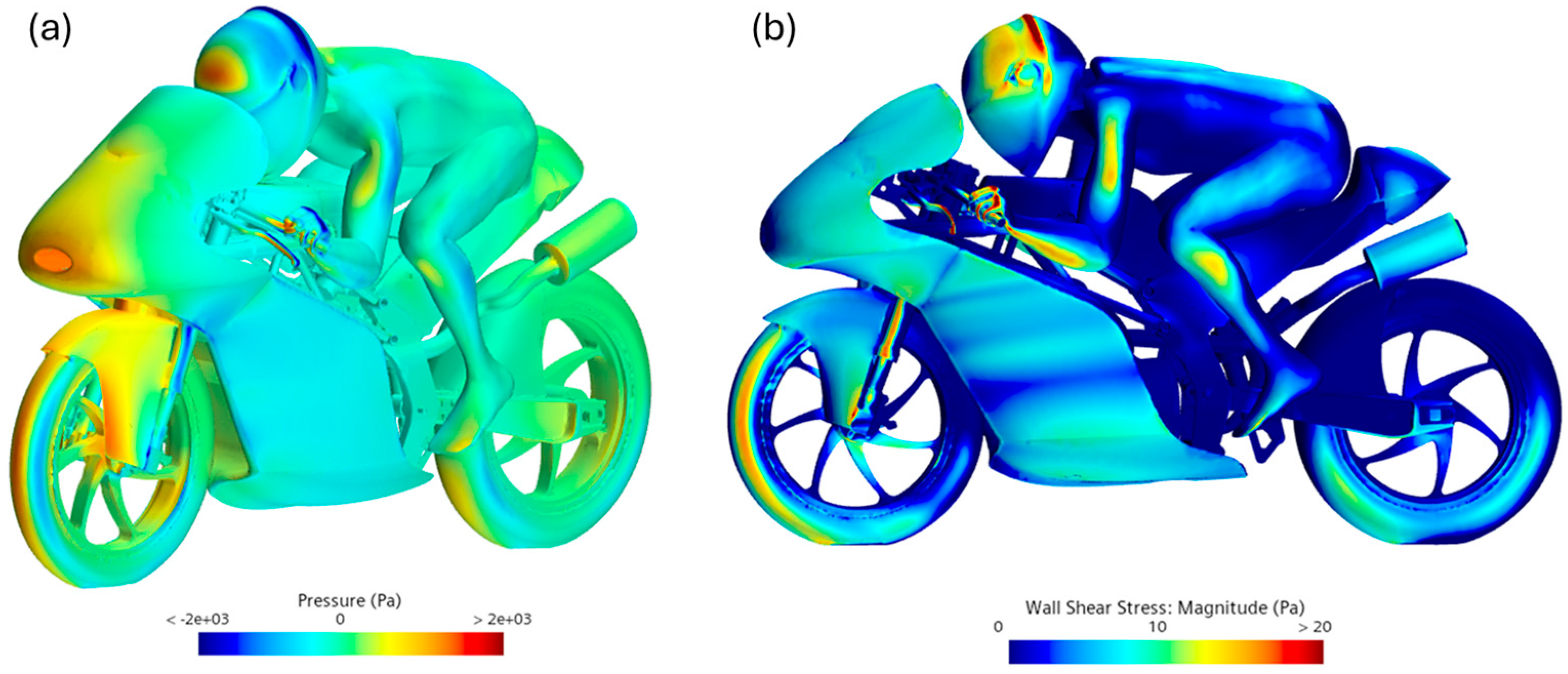

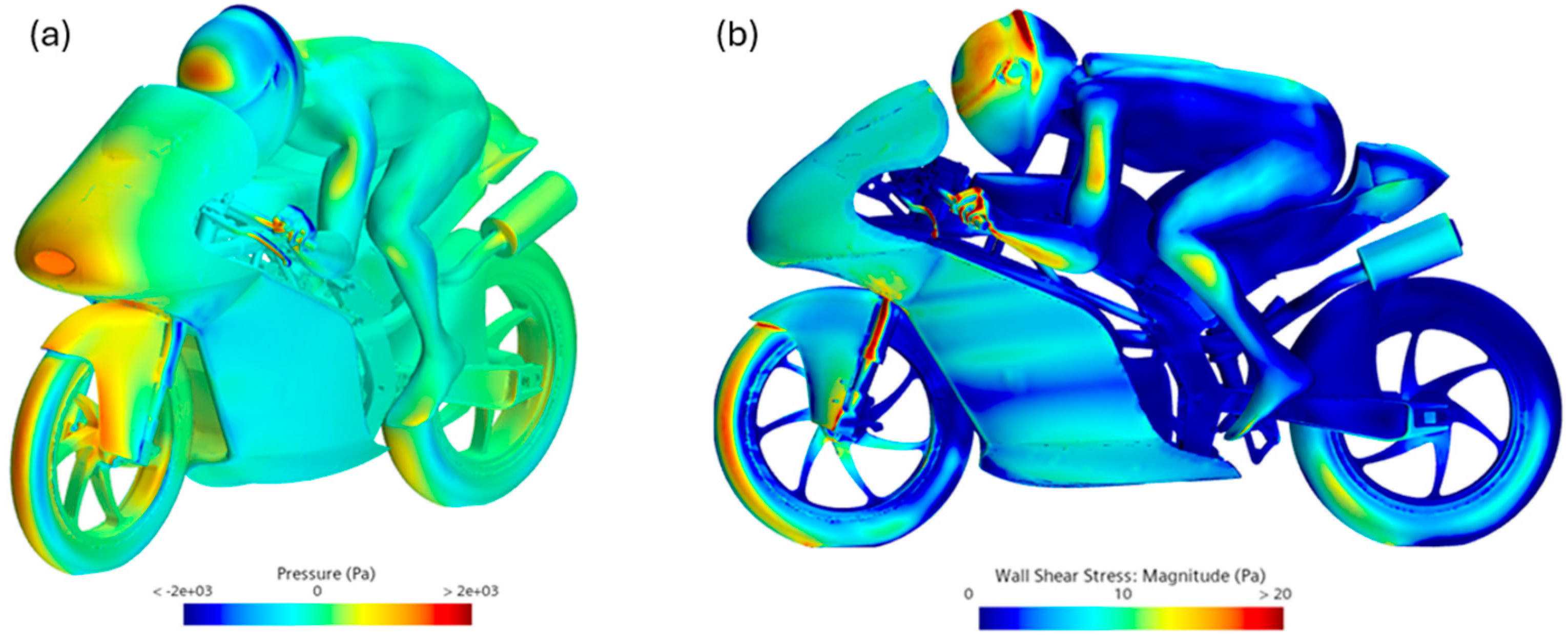

In addition to numerical values, the focus of the evaluation also included the analysis of scalar fields of pressure and wall shear stress magnitude, as shown in

Figure 10.

Figure 10a shows the pressure distribution. Notably, there are regions of high pressure across the front tyre tread, the front fairing, and the rider’s helmet. The most significant low-pressure regions, where the flow is accelerated, are located at the rear of the forks and behind the rider’s helmet.

Figure 10b, on the other hand, illustrates the magnitude of the wall shear stress vector, which indicates how the flow distributes over the motorcycle-rider assembly. Areas with high wall shear correspond to attached flow and good aerodynamic penetration, whereas low values indicate flow separation, which can signal wake regions and increased turbulence. From this perspective, it is evident that the tail section, positioned behind various components, is located in a flow separation zone.

The second simulation was conducted with the baseline rear winglets. The resulting primary aerodynamic coefficients are reported in

Table 5.

The drag has slightly increased compared to the case without winglets; however, the motorcycle, which previously generated a total lift of 5 N, now produces a total, albeit localized, downforce of 1.41 N. This represents a positive outcome, although it is partially offset by the slight increase in drag.

Figure 11 shows the corresponding pressure and wall shear stress fields.

The local modification introduced by the addition of the winglets clearly does not significantly affect the two global fields. In

Figure 11a, a slight increase in pressure is observed on the rear winglet, which can be associated with the recorded increase in drag.

Figure 11b shows that the winglets have increased the wall shear stress in the tail section area, indicating that they are capturing the flow and generating downforce.

At this stage, the evaluation of different winglet shapes was initiated to assess their impact on the prototype’s performance. The objective is to monitor the drag generated by the winglet alone in order to quantify its contribution to the overall design variations.

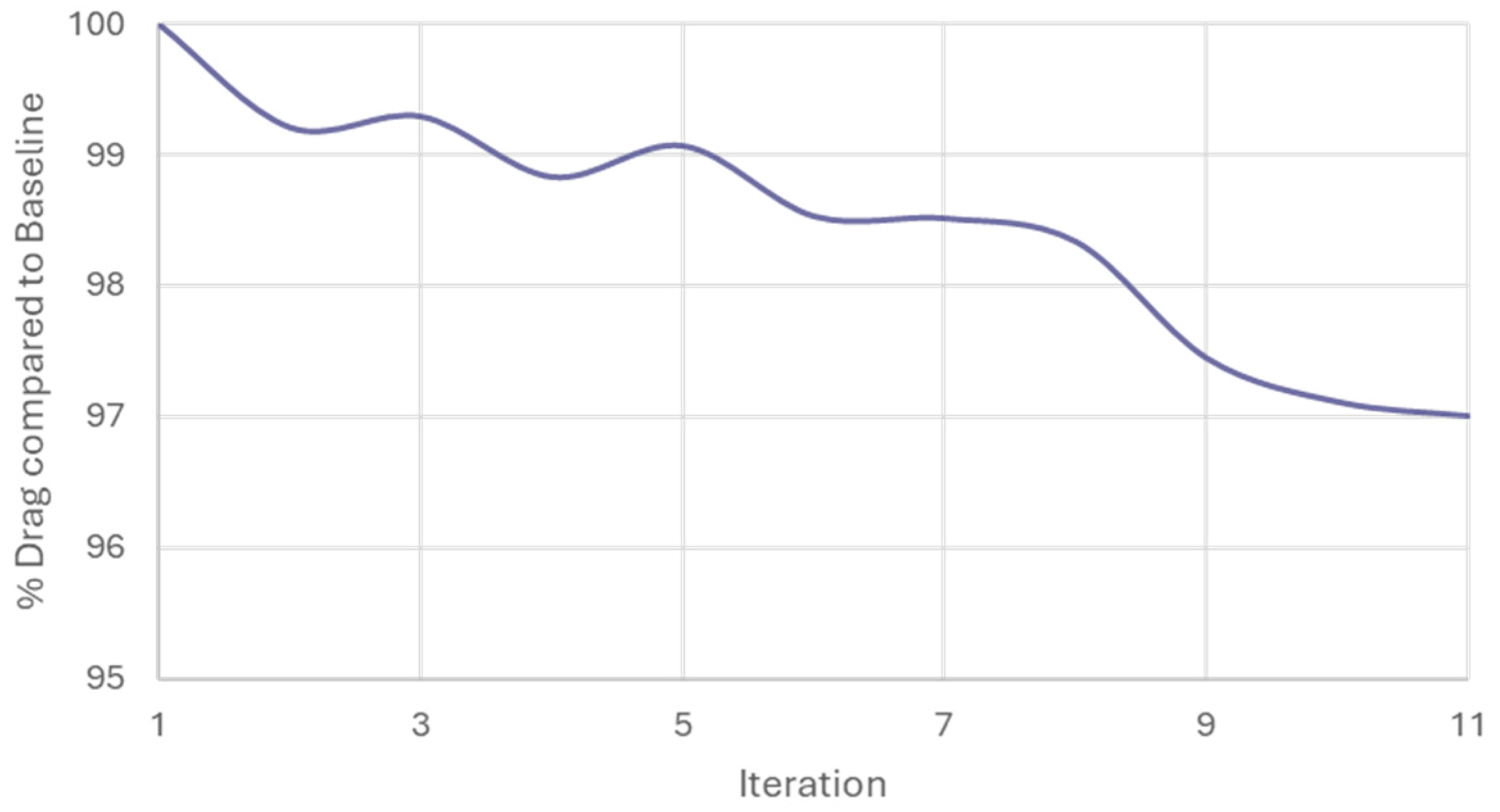

Figure 12 shows the trend of drag variation for a single winglet as its design is modified. The first value, assigned as 100%, corresponds to the initially evaluated perforated design. Subsequent values are expressed as percentages relative to this first design.

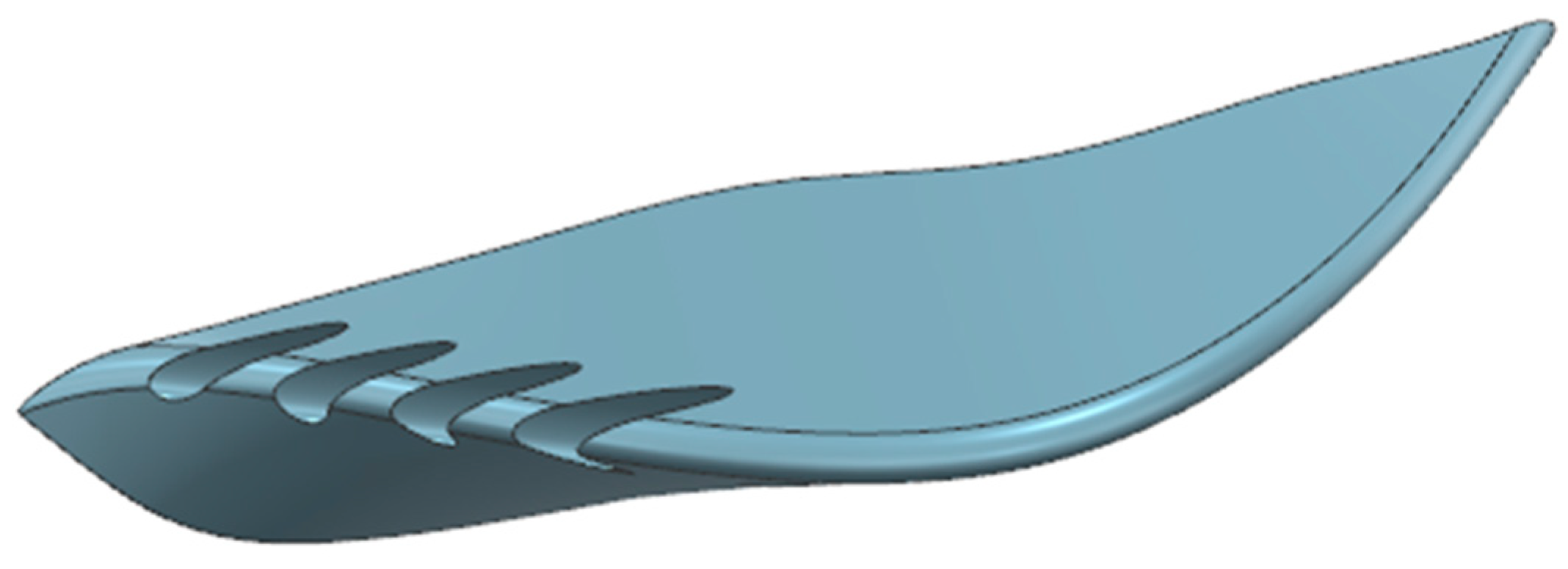

The design obtained at the end of the evaluation cycle, namely the eleventh iteration, is shown in

Figure 13.

In

Table 6 the drag variation and the parameters set by HEEDS during its evaluation cycle are listed for each Design ID.

In

Table 7 the new global values related to the prototype with fins ID 11 are reported.

Following a decrease in drag, the prototype has now returned to a condition of slight lift compared to the case with solid winglets. It is important to note, however, that this value remains significantly lower than that of the prototype without winglets. Although the absolute variation between the first and the last configuration is 3.4 N, a reduction of about 63% in lift is obtained and such variations, despite their small absolute magnitude, can significantly influence the pitch balance and dynamic stability of the motorcycle during high-speed operation.

Even small aerodynamic load variations can influence the pitch equilibrium of a lightweight racing motorcycle, where total aerodynamic forces are comparable to the static load transfer induced by acceleration or braking. The generation of additional rear downforce, even in the range of a few Newtons, contributes to improved rear wheel traction and mitigates the tendency to wheelie during strong acceleration phases. Conversely, the reduction in front-end lift enhances directional stability and rider control at high speed.

Moreover, the observed decrease in drag, though limited in absolute terms, indicates a more favourable pressure recovery and wake closure, which can improve flow attachment and reduce unsteady aerodynamic oscillations acting on the rear section.

Therefore, while the numerical differences in drag and lift coefficients may appear relatively small, their combined aerodynamic effects can substantially enhance the balance and controllability of the motorcycle, especially in competition scenarios where stability margins are inherently tight and rider feedback is highly sensitive to minor aerodynamic variations.

As done previously, the analysis was not limited to numerical evaluation alone; the pressure and WSS fields were once again extracted for further examination.

Figure 14a clearly shows, as expected, that perforating the winglet has created escape channels for the airflow. Consequently, this region now exhibits reduced pressure compared to

Figure 14b. Additionally,

Figure 14b demonstrates an increase in WSS magnitude in the tail section area. This indicates that the channels are effectively functioning as flow extractors, enhancing the interaction with the surrounding airflow.

This behaviour is consistent with what has been observed in automotive and motorsport applications, where flow extractors, such as diffuser channels, hood vents, or small aerodynamic louvers, are used to redirect airflow, improve pressure distribution, and enhance downforce without significantly increasing drag.

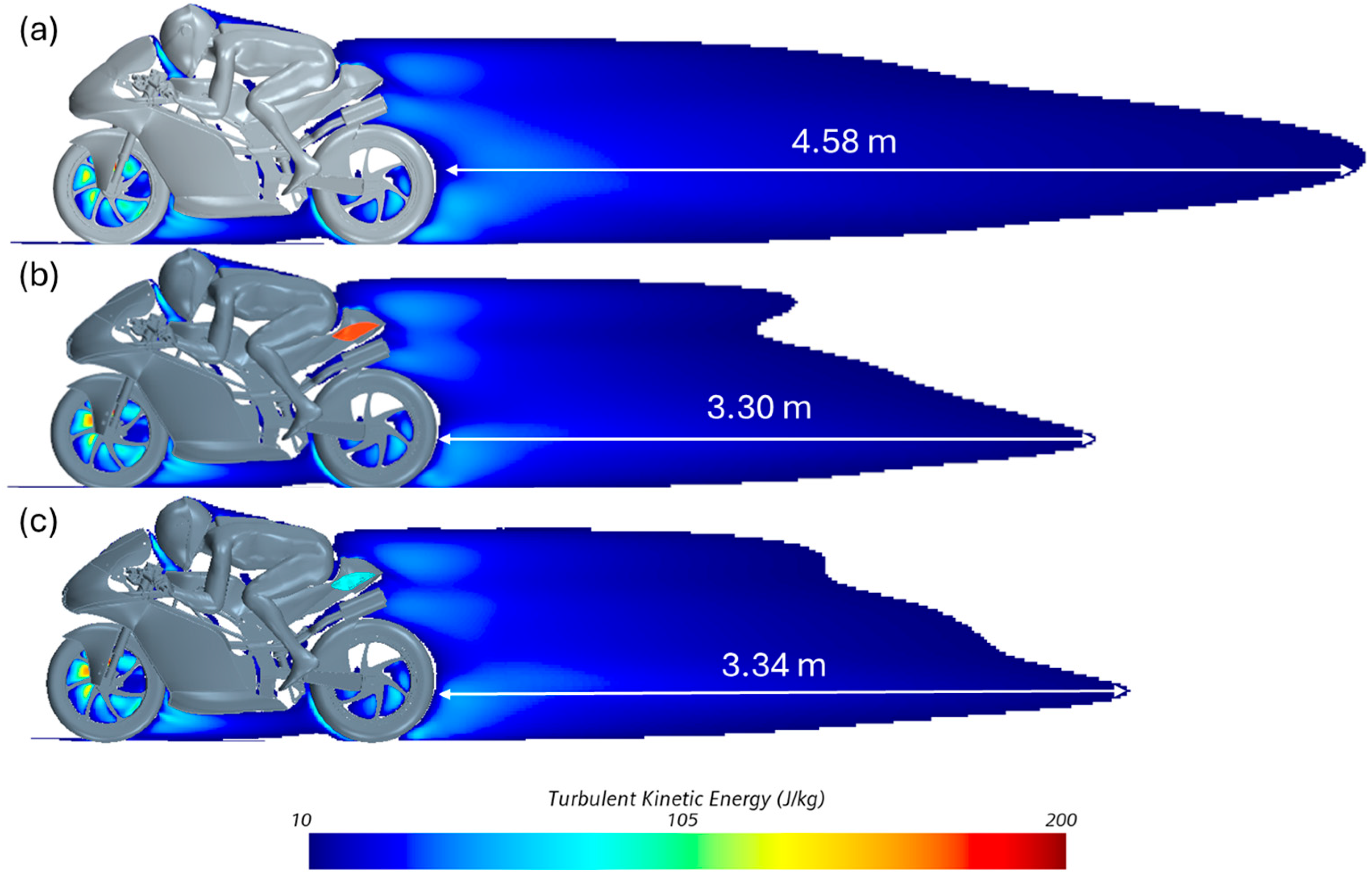

Finally, to conclude the analysis, the turbulent kinetic energy (TKE) within the computational domain was examined. The comparison between the case without winglets, with solid winglets, and with Design ID 11 winglets is shown in

Figure 15.

Figure 15a represents the case without winglets,

Figure 15b shows the case with the baseline winglets, and

Figure 15c corresponds to the case with the final winglets obtained from the evaluation cycle. In all plots, TKE values below 10 were clipped, as values under this threshold are considered indicative of an essentially dissipated wake energy.

Additionally, the distance at which the wake dissipates was calculated. The results show that the baseline wake length has been significantly reduced, with reductions of 1.28 m and 1.32 m for the cases with full and baseline winglets, respectively. These findings confirm that Design ID 11 represents an effective compromise between different aerodynamic characteristics considered in the evaluation.

To deepen the analysis of how the winglets shape the aerodynamic behaviour of the motorcycle, the aero balance was evaluated as a compact and physically meaningful indicator of how aerodynamic load is distributed between the front and rear axles. Aero balance

AB can be defined as in Equation (4).

This formulation expresses the front load fraction relative to the total vertical aerodynamic force. The results are in

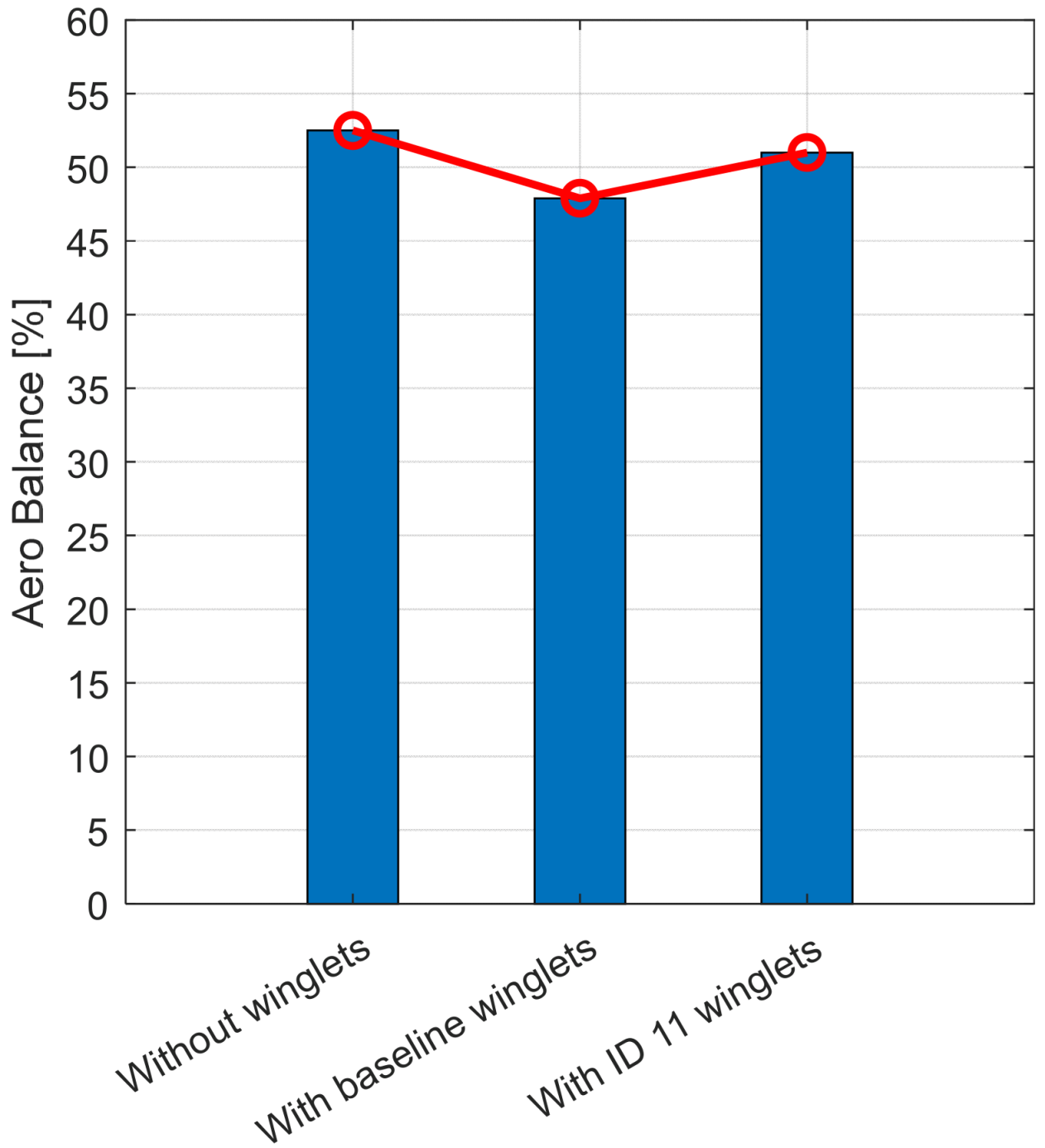

Table 8.

Without winglets, the computed balance indicated a front-heavy condition, consistent with a forward-shifted aerodynamic centre that can amplify oversteer tendencies and increase sensitivity to pitch during braking and turn-in. Introducing the baseline winglets shifted the balance rearward, alleviating the front overload by redistributing the aerodynamic forces and nudging the resultant closer to a more stable position over the wheelbase as speed and attitude vary, yet an overly rear-biased aero balance is undesirable, as it reduces anti-wheelie authority at the front and can encourage front-wheel lift under throttle. With the ID 11 winglets the aero balance approached a neutral value (≈50%), aligning with design practice that targets a centre of aerodynamic pressure near the centre of gravity to minimize handling asymmetries across operating conditions. The AB values are charted in

Figure 16.

In motorcycle engineering specifically, a neutral aero balance is sought for the combined prototype–rider system to limit pitch-induced load migration, stabilize acceleration and braking, and enhance overall rideability as modern appendages generate controllable downforce within regulatory constraints.

4. Conclusions

This study systematically evaluated the aerodynamic influence of rear fairing winglets on a 250 cc Pre-Moto3 racing motorcycle prototype, providing an integrated assessment of their effects on drag, downforce, wake characteristics, and overall stability. The analysis demonstrated that rear aerodynamic appendages can significantly affect the flow behaviour around the motorcycle–rider system, highlighting their potential as performance enhancing elements in racing motorcycle design.

A parametric, multi-software Design Space Exploration (DSE) framework was employed, combining parametric modelling in Siemens NX, automated geometry handling and meshing in Simcenter STAR-CCM+, and iterative optimization via HEEDS using the SHERPA algorithm. This methodology proved effective for systematically evaluating the aerodynamic response of multiple rear winglet geometries, while maintaining high computational efficiency. Design variables such as the number and spacing of perforations and the vertical extension of the winglet base were optimized within realistic manufacturing and regulatory limits.

The baseline configuration, without any rear winglets, established a reference aerodynamic condition at a velocity of 160 km/h. Under these conditions, the motorcycle prototype exhibited a drag force of 226.91 N and a small net lift of 5.34 N, corresponding to a lift-to-drag ratio of 0.0235. Pressure and wall shear stress (WSS) analyses revealed that high-pressure regions were concentrated around the front tire tread, the frontal fairing, and the rider’s helmet, whereas low-pressure zones formed behind the forks and the rider’s head. These low-pressure areas indicated flow separation and recirculation zones, particularly around the tail, confirming the rear section as a critical source of aerodynamic inefficiency and instability.

Introducing baseline rear winglets resulted in measurable aerodynamic changes. Although drag slightly increased from 226.91 N to 228.47 N, the net lift was reduced from 5.34 N to −1.41 N, yielding a lift-to-drag ratio of −0.0062. This indicates that the winglets effectively generated downforce while only marginally increasing drag. The pressure field displayed moderate localized pressure increments on the winglet surfaces, consistent with the drag rise, whereas WSS distributions revealed improved flow attachment and reduced recirculation near the tail. These findings confirm that even simple rear aerodynamic devices can positively influence downforce and wake management, which are key factors in improving rear tire grip and high-speed stability. However, the observed drag increase highlights the inherent trade-off between achieving additional downforce and maintaining low aerodynamic resistance.

A systematic parametric evaluation was then carried out to assess how geometric variations influence aerodynamic performance. Eleven design iterations were performed, varying the number of holes, their spacing, and the winglet base extrusion within defined design boundaries. By isolating the drag contribution of the winglet itself, the analysis clarified the aerodynamic effects of individual design parameters. The optimized configuration, identified as Winglets ID 11, achieved a total drag force of 226.69 N, almost matching the baseline drag of the configuration without winglets, while simultaneously generating a net downforce of 1.94 N. This resulted in a lift-to-drag ratio of 0.0086, representing a favorable compromise between drag reduction and downforce generation.

Detailed flow visualization confirmed that the perforations introduced in the optimized winglets acted as effective flow extractors. WSS distributions showed increased shear stress in the tail section, indicating more controlled flow detachment, while pressure fields exhibited local relief near the perforations, leading to reduced overall drag compared with the solid-winglet baseline. This behaviour aligns with aerodynamic strategies employed in diffusers, hood vents, and louvers, where controlled flow passages allow wake management without excessive resistance.

Analysis of turbulent kinetic energy (TKE) further supported these findings. The wake length behind the motorcycle was reduced by up to 1.32 m for Winglets ID 11 compared with the baseline, confirming that the optimized design improved wake closure and turbulence dissipation. The resulting reduction in turbulent energy implies a smoother aerodynamic environment for trailing vehicles and potentially improved stability during high-speed maneuvers. This effect is particularly relevant in racing contexts, where reduced wake intensity can limit the slipstream advantage of following competitors and enhance predictability in acceleration and cornering phases.

Overall, the results highlight the value of integrating parametric modelling, automated CFD analysis, and optimization algorithms in the aerodynamic development of racing motorcycles. The adopted SHERPA-guided DSE approach effectively balanced global and local optimization goals, identifying configurations that reconcile the conflicting requirements of drag minimization and downforce enhancement. The demonstrated capability to automate complex design evaluations with minimal human input underscores the efficiency and robustness of this workflow for high-performance engineering applications.

From a broader aerodynamic perspective, this investigation contributes to the understanding of rear fairing winglets, a class of appendages less studied than front or side devices. While front-mounted components primarily manage front-end lift and directional stability, rear winglets directly affect rear-tire loading, pitch control, and wake structure. The present results confirm that even modest geometric modifications, such as introducing perforations or adjusting vertical dimensions, can yield measurable improvements in aerodynamic efficiency and stability, outcomes that are especially relevant in performance-sensitive categories.

Dynamic effects such as rider motion, crosswinds, and transient yaw or pitch variations were not captured, nor were wheel rotation and detailed road interactions. All these aspects could be incorporated in future work. Extending the current DSE framework toward advanced optimization schemes, such as genetic algorithms or surrogate-based multi-objective strategies, would further enable comprehensive aerodynamic trade-off analysis under transient or variable conditions. Such developments could support a more holistic aerodynamic optimization process, aimed at optimizing rear downforce, minimizing drag, and controlling wake turbulence for improved performance in competitive racing environments.