Additive Manufacturing for Next-Generation Batteries: Opportunities, Challenges, and Future Outlook

Abstract

1. Introduction

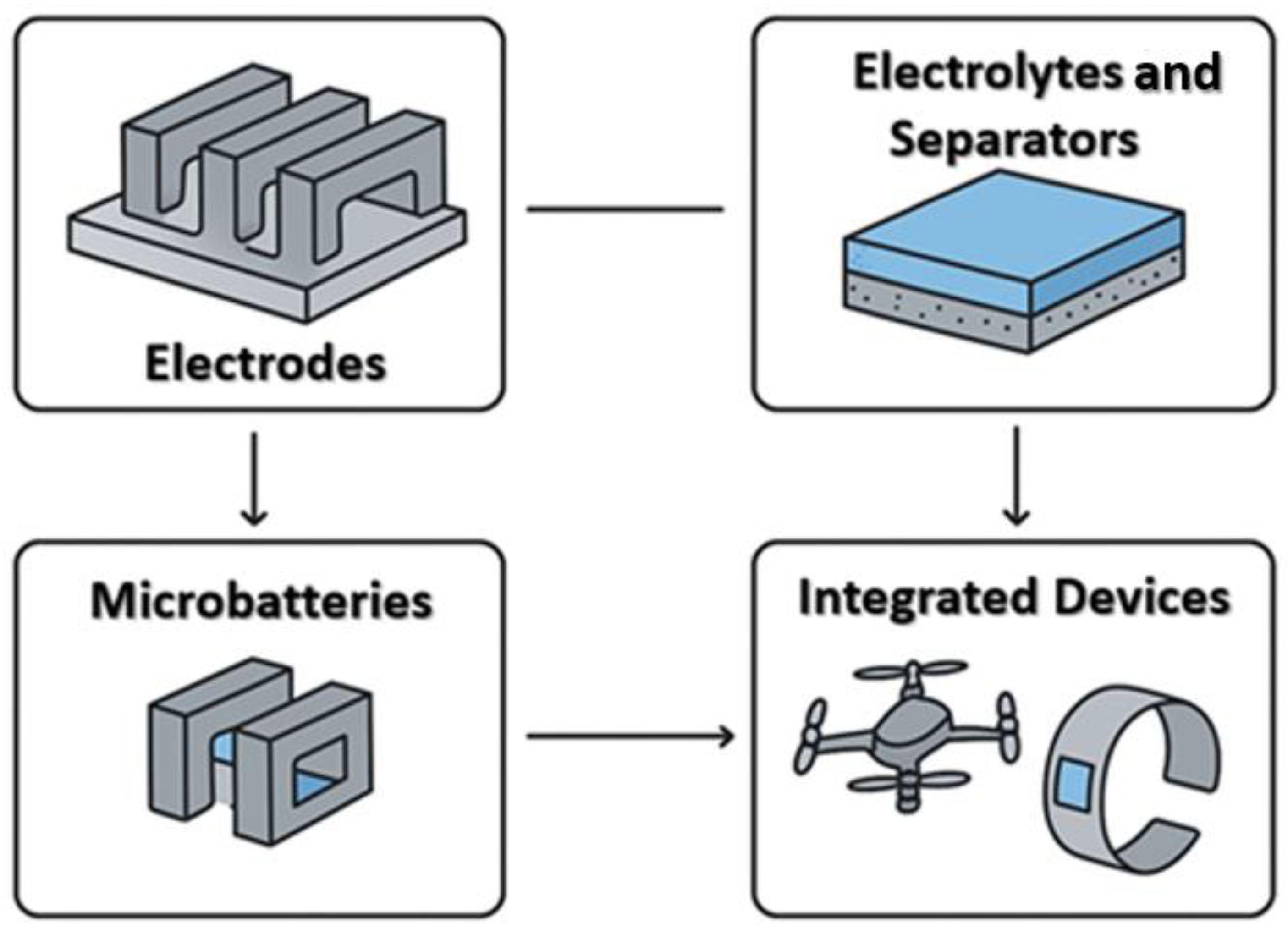

2. Advances in 3D Printing for Energy Storage

2.1. Printing of Electrodes

2.2. Printing of Electrolytes and Separators

2.3. Microbatteries, Flexible and Wearable Systems

2.4. Examples of Device Integration

3. Opportunities and Added Value

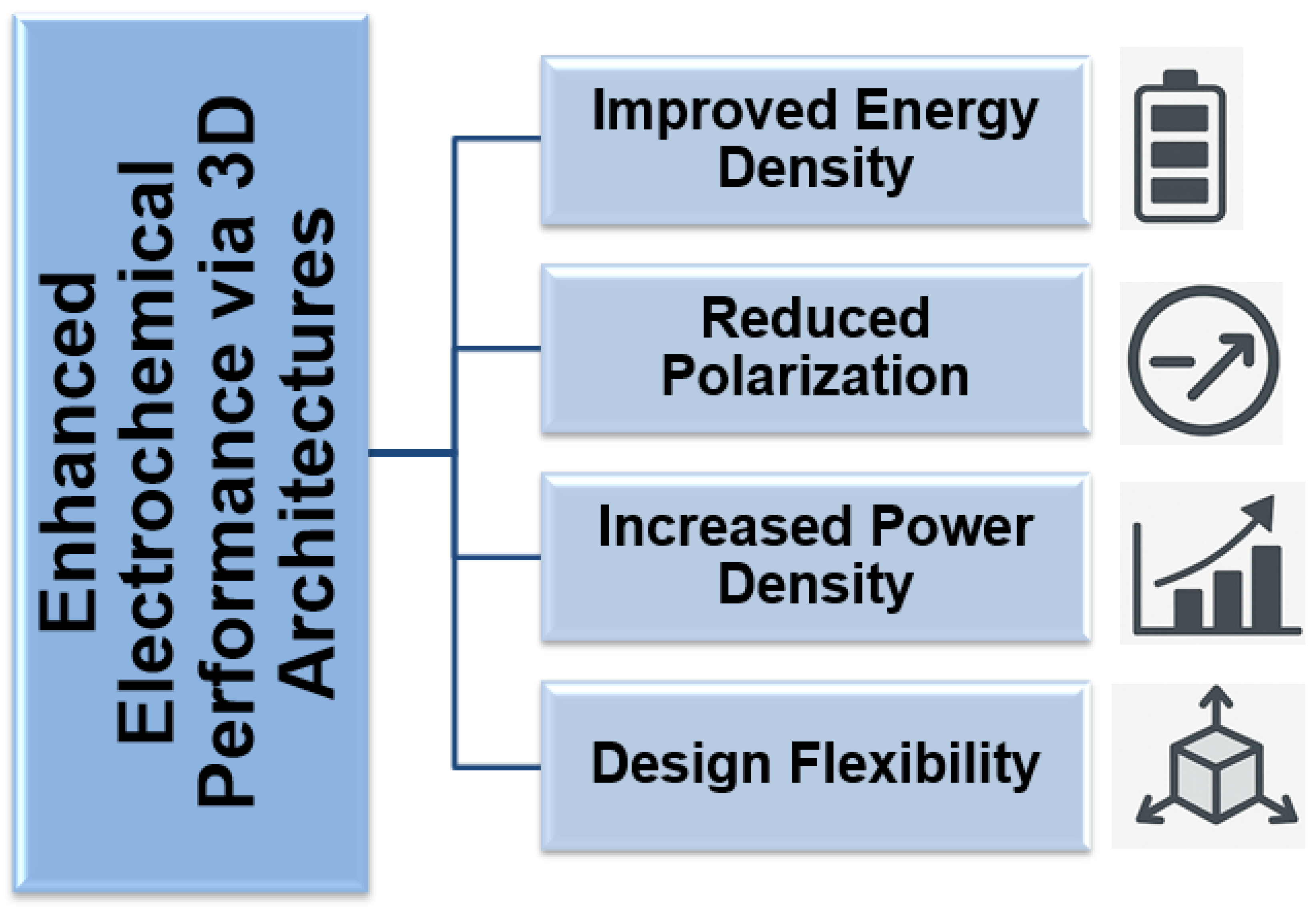

3.1. Enhanced Electrochemical Performance via 3D Architectures

3.2. Design-Driven Integration into Devices and Structures

3.3. Potential for Sustainable Manufacturing and Material Efficiency

4. Challenges and Limitations

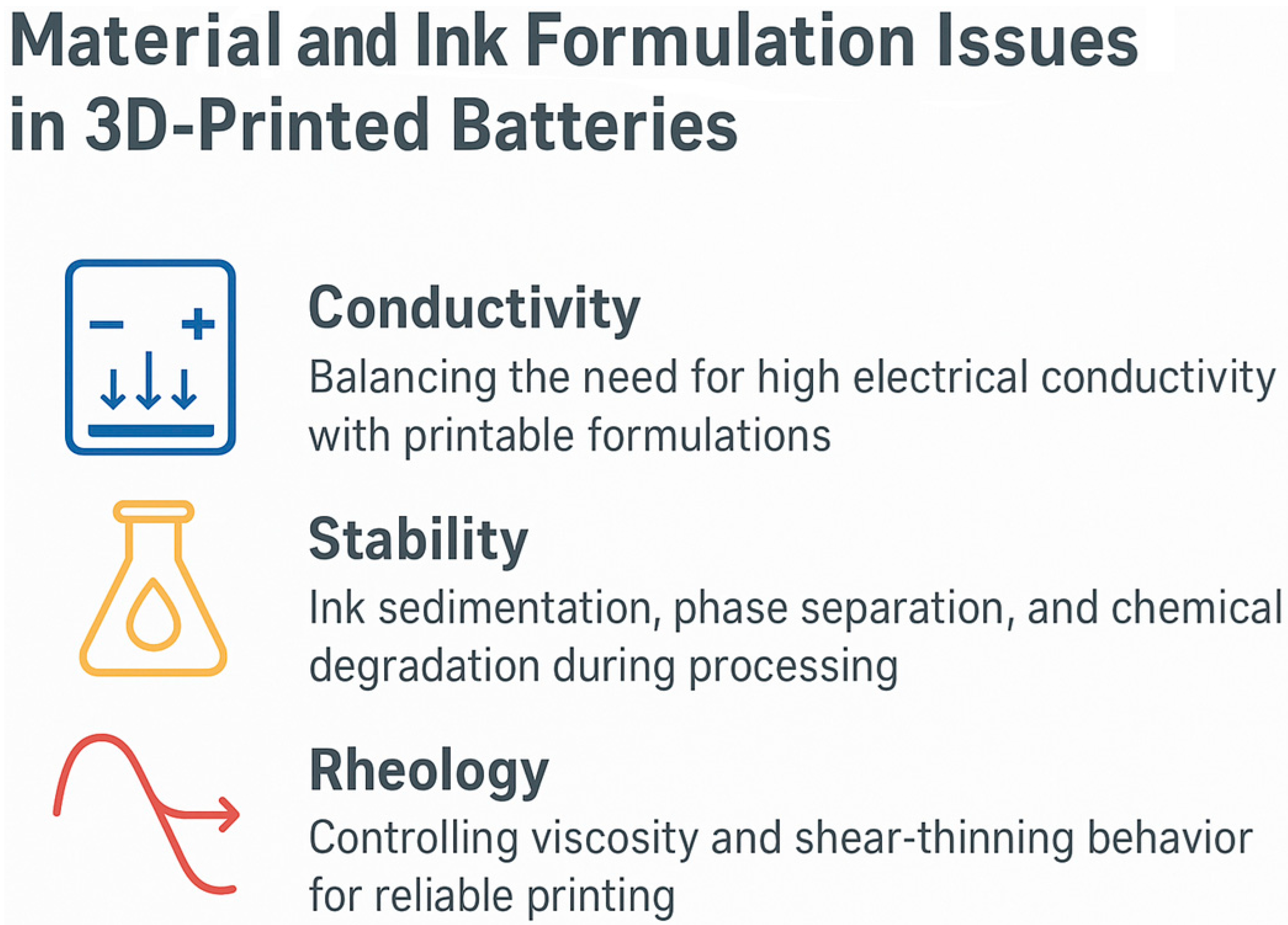

4.1. Materials and Ink Formulation Issues (Conductivity, Stability, Rheology)

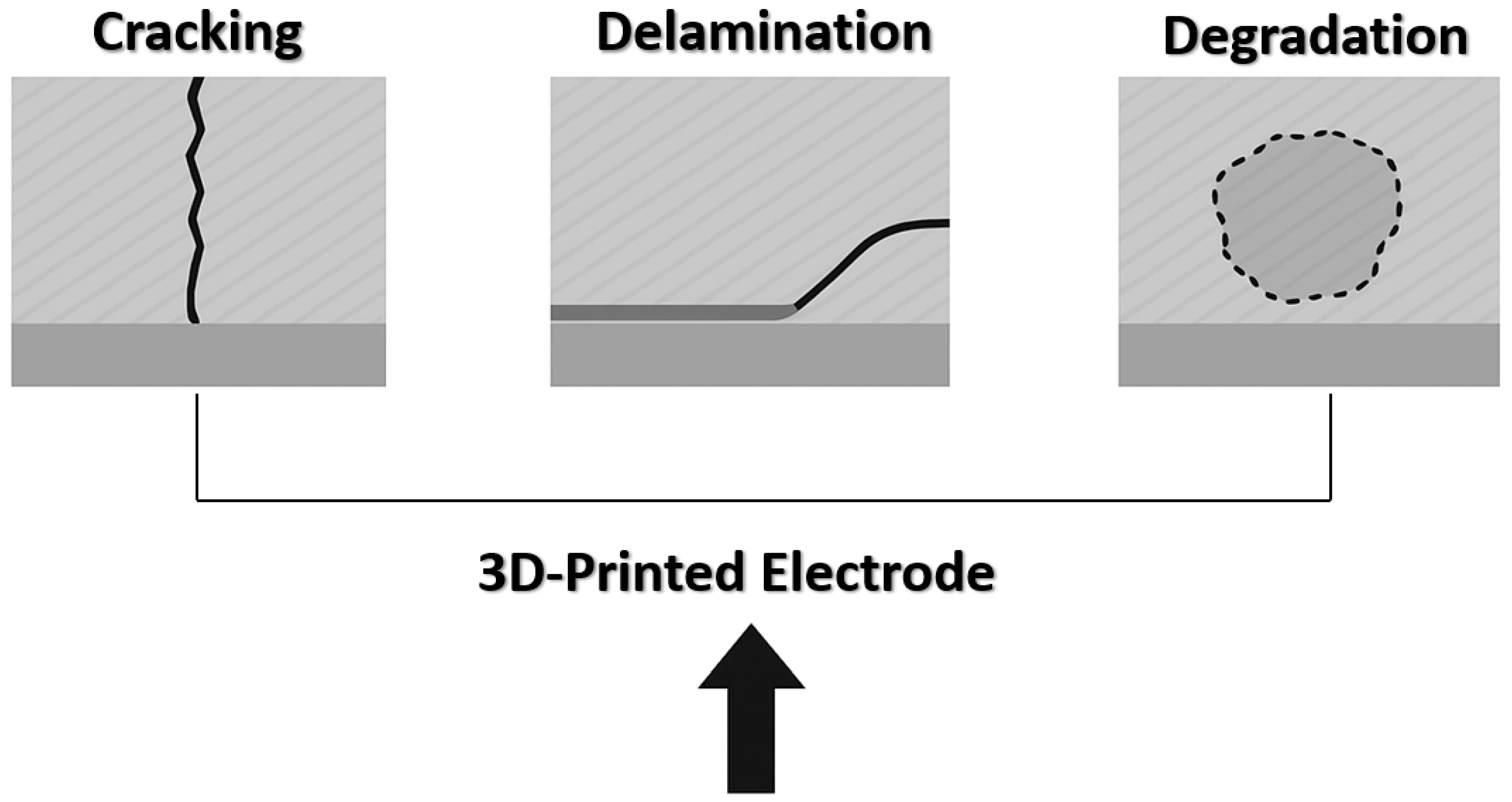

4.2. Reproducibility, Reliability, and Long-Term Performance

4.3. Scale-Up and Economic Feasibility

4.4. Regulatory and Standardization Gaps

5. Discussion and Future Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| AM | Additive Manufacturing |

| DIW | Direct Ink Writing |

| EV | Electric Vehicle |

| IEC | International Electrotechnical Commission |

| IoT | Internet of Things |

| SDGs | Sustainable Development Goals |

| SLA | Stereolithography |

| UL | Underwriters Laboratories |

| UV | Ultraviolet |

References

- Liang, Y.; Zhao, C.-Z.; Yuan, H.; Chen, Y.; Zhang, W.; Huang, J.-Q.; Yu, D.; Liu, Y.; Titirici, M.-M.; Chueh, Y.-L.; et al. A Review of Rechargeable Batteries for Portable Electronic Devices. InfoMat 2019, 1, 6–32. [Google Scholar] [CrossRef]

- Rangarajan, S.S.; Sunddararaj, S.P.; Sudhakar, A.V.V.; Shiva, C.K.; Subramaniam, U.; Collins, E.R.; Senjyu, T. Lithium-Ion Batteries—The Crux of Electric Vehicles with Opportunities and Challenges. Clean Technol. 2022, 4, 908–930. [Google Scholar] [CrossRef]

- Shi, C.; Takeuchi, S.; Alexander, G.V.; Hamann, T.; O’Neill, J.; Dura, J.A.; Wachsman, E.D. High Sulfur Loading and Capacity Retention in Bilayer Garnet Sulfurized-polyacrylonitrile/Lithium-metal Batteries with Gel Polymer Electrolytes. Adv. Energy Mater. 2023, 13, 2301656. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J. Key Challenges for Grid-scale Lithium-ion Battery Energy Storage. Adv. Energy Mater. 2022, 12, 2202197. [Google Scholar] [CrossRef]

- Pokhriyal, A.; Rueda-García, D.; Gómez-Romero, P. To Flow or Not to Flow. A Perspective on Large-Scale Stationary Electrochemical Energy Storage. Sustain. Energy Fuels 2023, 7, 5473–5482. [Google Scholar] [CrossRef]

- Rong, G.; Zheng, Y.; Sawan, M. Energy Solutions for Wearable Sensors: A Review. Sensors 2021, 21, 3806. [Google Scholar] [CrossRef]

- Shuvo, M.M.H.; Titirsha, T.; Amin, N.; Islam, S.K. Energy Harvesting in Implantable and Wearable Medical Devices for Enduring Precision Healthcare. Energies 2022, 15, 7495. [Google Scholar] [CrossRef]

- Bourdena, A.; Mavromoustakis, C.; Markakis, E.K.; Mastorakis, G.; Pallis, E. Intelligent Technologies for Healthcare Business Applications; Springer Nature: Cham, Switzerland, 2024; ISBN 9783031585272. [Google Scholar]

- Dotoli, M.; Rocca, R.; Giuliano, M.; Nicol, G.; Parussa, F.; Baricco, M.; Ferrari, A.M.; Nervi, C.; Sgroi, M.F. A Review of Mechanical and Chemical Sensors for Automotive Li-Ion Battery Systems. Sensors 2022, 22, 1763. [Google Scholar] [CrossRef]

- Tran, M.-K.; Panchal, S.; Khang, T.D.; Panchal, K.; Fraser, R.; Fowler, M. Concept Review of a Cloud-Based Smart Battery Management System for Lithium-Ion Batteries: Feasibility, Logistics, and Functionality. Batteries 2022, 8, 19. [Google Scholar] [CrossRef]

- Hassan, Q.; Pawela, B.; Hasan, A.; Jaszczur, M. Optimization of Large-Scale Battery Storage Capacity in Conjunction with Photovoltaic Systems for Maximum Self-Sustainability. Energies 2022, 15, 3845. [Google Scholar] [CrossRef]

- Dong, Z.; Tao, Y.; Lai, S.; Wang, T.; Zhang, Z. Powering Future Advancements and Applications of Battery Energy Storage Systems across Different Scales. Energy Storage Appl. 2025, 2, 1. [Google Scholar] [CrossRef]

- Chu, T.; Park, S.; Fu, K. (kelvin) 3D Printing-enabled Advanced Electrode Architecture Design. Carbon Energy 2021, 3, 424–439. [Google Scholar] [CrossRef]

- Mottaghi, M.; Pearce, J.M. A Review of 3D Printing Batteries. Batteries 2024, 10, 110. [Google Scholar] [CrossRef]

- Andries, V.; Zaharia, S.-M. Generative Design, Simulation, and 3D Printing of the Quadcopter Drone Frame. Appl. Sci. 2025, 15, 9647. [Google Scholar] [CrossRef]

- Xiao, J.; Anwer, N.; Huang, H.; Bonnard, R.; Eynard, B.; Huang, C.; Pei, E. Information Exchange and Knowledge Discovery for Additive Manufacturing Digital Thread: A Comprehensive Literature Review. Int. J. Comput. Integr. Manuf. 2025, 38, 1052–1077. [Google Scholar] [CrossRef]

- Singh, V.; Kuthe, S.; Skorodumova, N.V. Electrode Fabrication Techniques for Li Ion Based Energy Storage System: A Review. Batteries 2023, 9, 184. [Google Scholar] [CrossRef]

- Scheffler, S.; Jagau, R.; Müller, N.; Diener, A.; Kwade, A. Calendering of Silicon-Containing Electrodes and Their Influence on the Mechanical and Electrochemical Properties. Batteries 2022, 8, 46. [Google Scholar] [CrossRef]

- Bai, S.; Frigerio, N.; Matta, A. Current Status and Future Perspective in Electric Vehicle Battery Stacking: A Review. Energy Technol. 2025, 13, 2500042. [Google Scholar] [CrossRef]

- Pavlovskii, A.A.; Pushnitsa, K.; Kosenko, A.; Novikov, P.; Popovich, A.A. 3D-Printed Lithium-Ion Battery Electrodes: A Brief Review of Three Key Fabrication Techniques. Materials 2024, 17, 5904. [Google Scholar] [CrossRef]

- Czerwiński, A.; Słojewska, M.; Jurczak, J.; Dębowski, M.; Zygadło-Monikowska, E. FFF/FDM 3D-Printed Solid Polymer Electrolytes Based on Acrylonitrile Copolymers for Lithium-Ion Batteries. Molecules 2024, 29, 4526. [Google Scholar] [CrossRef]

- Shi, H.; Cao, J.; Sun, Z.; Ghazi, Z.A.; Zhu, X.; Han, S.; Ren, D.; Lu, G.; Lan, H.; Li, F. 3D Printing Enables Customizable Batteries. Batter. Supercaps 2023, 6, e202300161. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, H.; Chen, H.; Gao, H.; Yu, J.; Mo, F.; Wang, N. Recent Progress on the Research of 3D Printing in Aqueous Zinc-Ion Batteries. Polymers 2025, 17, 2136. [Google Scholar] [CrossRef]

- Qian, J.; Chen, Q.; Hong, M.; Xie, W.; Jing, S.; Bao, Y.; Chen, G.; Pang, Z.; Hu, L.; Li, T. Toward Stretchable Batteries: 3D-Printed Deformable Electrodes and Separator Enabled by Nanocellulose. Mater. Today 2022, 54, 18–26. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Y.; Hao, J.; Wallace, G.G.; Beirne, S.; Chen, J. 3D-printed Wearable Electrochemical Energy Devices. Adv. Funct. Mater. 2022, 32, 2103092. [Google Scholar] [CrossRef]

- Habboush, S.; Rojas, S.; Rodríguez, N.; Rivadeneyra, A. The Role of Interdigitated Electrodes in Printed and Flexible Electronics. Sensors 2024, 24, 2717. [Google Scholar] [CrossRef]

- Zhang, S.; Xue, S.; Wang, Y.; Zhang, G.; Arif, N.; Li, P.; Zeng, Y.-J. Three-Dimensional Printing, an Emerging Advanced Technique in Electrochemical Energy Storage and Conversion. Batteries 2023, 9, 546. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Ganetsos, T. From Stents to Smart Implants Employing Biomimetic Materials: The Impact of 4D Printing on Modern Healthcare. Biomimetics 2025, 10, 125. [Google Scholar] [CrossRef]

- Moser, S.; Kenel, C.; Wehner, L.A.; Spolenak, R.; Dunand, D.C. 3D Ink-Printed, Sintered Porous Silicon Scaffolds for Battery Applications. J. Power Sources 2021, 507, 230298. [Google Scholar] [CrossRef]

- Li, M.; Zhou, S.; Cheng, L.; Ren, W.; Chen, L.; Yu, S.; Wei, J. Vertical-Channel Hierarchically Porous 3D Printed Electrodes with Ultrahigh Mass Loading and Areal Energy Density for Li-Ion Batteries. Energy Storage Mater. 2024, 72, 103754. [Google Scholar] [CrossRef]

- Chen, X.; Lawrence, J.M.; Wey, L.T.; Schertel, L.; Jing, Q.; Vignolini, S.; Howe, C.J.; Kar-Narayan, S.; Zhang, J.Z. 3D-Printed Hierarchical Pillar Array Electrodes for High-Performance Semi-Artificial Photosynthesis. Nat. Mater. 2022, 21, 811–818. [Google Scholar] [CrossRef]

- Polychronopoulos, N.D.; Brouzgou, A. Direct Ink Writing for Electrochemical Device Fabrication: A Review of 3D-Printed Electrodes and Ink Rheology. Catalysts 2024, 14, 110. [Google Scholar] [CrossRef]

- Huang, H.; Liao, L.; Lin, Z.; Pan, D.; Nuo, Q.; Wu, T.-T.; Jiang, Y.; Bai, H. Direct Ink Writing of Pickering Emulsions Generates Ultralight Conducting Polymer Foams with Hierarchical Structure and Multifunctionality. Small 2023, 19, e2301493. [Google Scholar] [CrossRef]

- Fapanni, T.; Sardini, E.; Serpelloni, M.; Tonello, S. 3D Electrochemical Sensor and Microstructuration Using Aerosol Jet Printing. Sensors 2021, 21, 7820. [Google Scholar] [CrossRef]

- Jeong, H.; Lee, J.H.; Kim, S.; Han, S.; Moon, H.; Song, J.-Y.; Park, A.-Y. Optimization of Process Parameters in Micro-Scale Pneumatic Aerosol Jet Printing for High-Yield Precise Electrodes. Sci. Rep. 2023, 13, 21297. [Google Scholar] [CrossRef] [PubMed]

- Perilli, S.; Di Pietro, M.; Mantini, E.; Regazzetti, M.; Kiper, P.; Galliani, F.; Panella, M.; Mantini, D. Development of a Wearable Electromyographic Sensor with Aerosol Jet Printing Technology. Bioengineering 2024, 11, 1283. [Google Scholar] [CrossRef]

- Chen, X.; Gong, M.; Li, J.; Yang, W.; Xu, X. Engineering Hierarchical Porous Electrodes Integrated with Conformal Ultrathin Nanosheets for Achieving Rapid Kinetics in High-Power Microbatteries. Batteries 2025, 11, 81. [Google Scholar] [CrossRef]

- Han, D.-Y.; Son, H.B.; Han, S.H.; Song, C.K.; Jung, J.; Lee, S.; Choi, S.S.; Song, W.-J.; Park, S. Hierarchical 3D Electrode Design with High Mass Loading Enabling High-Energy-Density Flexible Lithium-Ion Batteries. Small 2023, 19, e2305416. [Google Scholar] [CrossRef]

- Pigłowska, M.; Kurc, B.; Galiński, M.; Fuć, P.; Kamińska, M.; Szymlet, N.; Daszkiewicz, P. Challenges for Safe Electrolytes Applied in Lithium-Ion Cells-A Review. Materials 2021, 14, 6783. [Google Scholar] [CrossRef]

- Mu, X.; Ding, H.; Wu, Y.; Hu, H.; Yu, B. Nonflammable Liquid Electrolytes for Safe Lithium Batteries. Small Struct. 2023, 4, 2300179. [Google Scholar] [CrossRef]

- Machín, A.; Morant, C.; Márquez, F. Advancements and Challenges in Solid-State Battery Technology: An in-Depth Review of Solid Electrolytes and Anode Innovations. Batteries 2024, 10, 29. [Google Scholar] [CrossRef]

- Aruchamy, K.; Ramasundaram, S.; Divya, S.; Chandran, M.; Yun, K.; Oh, T.H. Gel Polymer Electrolytes: Advancing Solid-State Batteries for High-Performance Applications. Gels 2023, 9, 585. [Google Scholar] [CrossRef]

- Tu, Z.; Chen, K.; Liu, S.; Wu, X. 3D Printing of Solid Electrolyte and the Application in All-Solid-State Batteries. Small Methods 2025, 9, e2401912. [Google Scholar] [CrossRef]

- Junoh, H.; Awang, N.; Zakria, H.S.; Zainuddin, N.A.S.; Nordin, N.A.H.M.; Suhaimin, N.S.; Enoki, T.; Uno, T.; Kubo, M. Advancements in Polyethylene Oxide (PEO)-Active Filler Composite Polymer Electrolytes for Lithium-Ion Batteries: A Comprehensive Review and Prospects. Materials 2024, 17, 4344. [Google Scholar] [CrossRef] [PubMed]

- Castillo, J.; Robles-Fernandez, A.; Cid, R.; González-Marcos, J.A.; Armand, M.; Carriazo, D.; Zhang, H.; Santiago, A. Dehydrofluorination Process of Poly(Vinylidene Difluoride) PVdF-Based Gel Polymer Electrolytes and Its Effect on Lithium-Sulfur Batteries. Gels 2023, 9, 336. [Google Scholar] [CrossRef] [PubMed]

- Waidha, A.I.; Vanita, V.; Clemens, O. PEO Infiltration of Porous Garnet-Type Lithium-Conducting Solid Electrolyte Thin Films. Ceramics 2021, 4, 421–436. [Google Scholar] [CrossRef]

- Man, B.; Zeng, Y.; Liu, Q.; Chen, Y.; Li, X.; Luo, W.; Zhang, Z.; He, C.; Jie, M.; Liu, S. A Comprehensive Review of Sulfide Solid-State Electrolytes: Properties, Synthesis, Applications, and Challenges. Crystals 2025, 15, 492. [Google Scholar] [CrossRef]

- Fan, K.; Yu, M.; Lei, J.; Mu, S. Advanced Preparation Methods for Ceramic Membrane Materials in Electrochemical Applications. Crystals 2024, 14, 623. [Google Scholar] [CrossRef]

- Marković, M.-P.; Žižek, K.; Soldo, K.; Sunko, V.; Zrno, J.; Vrsaljko, D. 3D Printed Microfluidic Separators for Solid/Liquid Suspensions. Appl. Sci. 2024, 14, 7856. [Google Scholar] [CrossRef]

- Enchinton, A.; Martinez, A.C.; Gonzalez, K.R.; Fernandez, C.A.; Balivada, S.; Merrill, L.C.; Cardenas, J.A.; Panier, S.; Maurel, A. 3D Printing of Highly Porous Polypropylene Separators for Lithium-ion Batteries Using Fused Deposition Modeling and Thermally Induced Phase Separation. Adv. Mater. Technol. 2025, e00912. [Google Scholar] [CrossRef]

- Choi, C.S.; Whang, G.J.; McNeil, P.E.; Dunn, B.S. Photopatternable Porous Separators for Micro-Electrochemical Energy Storage Systems. Adv. Mater. 2022, 34, e2108792. [Google Scholar] [CrossRef]

- Kang, C.-Y.; Su, Y.-S. Smart Manufacturing Processes of Low-Tortuous Structures for High-Rate Electrochemical Energy Storage Devices. Micromachines 2022, 13, 1534. [Google Scholar] [CrossRef] [PubMed]

- Mirbagheri, S.; Gibertini, E.; Magagnin, L. Inkjet-Printed Silver Lithiophilic Sites on Copper Current Collectors: Tuning the Interfacial Electrochemistry for Anode-Free Lithium Batteries. Batteries 2024, 10, 369. [Google Scholar] [CrossRef]

- Pinto, R.S.; Serra, J.P.; Barbosa, J.C.; Gonçalves, R.; Silva, M.M.; Lanceros-Méndez, S.; Costa, C.M. Direct-ink-writing of Electroactive Polymers for Sensing and Energy Storage Applications. Macromol. Mater. Eng. 2021, 306, 2100372. [Google Scholar] [CrossRef]

- Ji, D.; Zheng, H.; Zhang, H.; Liu, W.; Ding, J. Coaxial 3D-Printing Constructing All-in-One Fibrous Lithium-, Sodium-, and Zinc-Ion Batteries. Chem. Eng. J. 2022, 433, 133815. [Google Scholar] [CrossRef]

- Fassler, A.L.; Kohlmeyer, R.R.; Rajput, S.; Horrocks, G.A.; Deneault, J.R.; Durstock, M.F. Study on the Feasibility of Combined 3D Printing for Integrated and Conformal Batteries. J. Power Sources 2024, 600, 234241. [Google Scholar] [CrossRef]

- Deng, L.; Lin, Q.; Li, Z.; Cao, J.; Sun, K.; Wei, T. Cathodes for Zinc-Ion Micro-Batteries: Challenges, Strategies, and Perspectives. Batteries 2025, 11, 57. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Chen, M.; Li, W.; Wei, X. Photocuring in Lithium-Ion Battery Fabrication: Advances towards Integrated Manufacturing. Batteries 2025, 11, 282. [Google Scholar] [CrossRef]

- Shaju, A.; Ummer, R.P.; Thomas, S.; Kandasubramanian, B. Novel Approaches in 3D Printing Techniques for the Development of High-Performance Micro-Batteries. J. Electron. Mater. 2024, 54, 1531–1552. [Google Scholar] [CrossRef]

- Ribeiro, A.I.; Alves, C.; Fernandes, M.; Abreu, J.; Pedroso de Lima, F.; Padrão, J.; Zille, A. Gel Electrolytes in the Development of Textile-Based Power Sources. Gels 2025, 11, 392. [Google Scholar] [CrossRef]

- Ma, J.; Quhe, R.; Zhang, W.; Yan, Y.; Tang, H.; Qu, Z.; Cheng, Y.; Schmidt, O.G.; Zhu, M. Zn Microbatteries Explore Ways for Integrations in Intelligent Systems. Small 2023, 19, e2300230. [Google Scholar] [CrossRef]

- Zainal Abidin, A.R.; Zambry, N.S.; Ibrahim, F.; Nor Rashid, N.; Jamaluddin, N.F.; Wan Kamarul Zaman, W.S. Current Advances in Biocompatibility Assessment for MEMS in Biomedical Applications. Microfluid. Nanofluidics 2025, 29, 32. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, Y.; Fu, Y.-F.; Fan, Y.; Chen, Y.; Kim, D.; Lu, X.; Yu, B.; Chen, Y.I. 3D-Printed Topological-Structured Electrodes with Exceptional Mechanical Properties for High-Performance Flexible Li-Ion Batteries. Energy Storage Mater. 2024, 70, 103560. [Google Scholar] [CrossRef]

- Han, Y.; Cui, Y.; Liu, X.; Wang, Y. A Review of Manufacturing Methods for Flexible Devices and Energy Storage Devices. Biosensors 2023, 13, 896. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A Review of Conductive Carbon Materials for 3D Printing: Materials, Technologies, Properties, and Applications. Materials 2021, 14, 3911. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Wang, Q. Novel Structural Janus Hydrogels for Battery Applications: Structure Design, Properties, and Prospects. Colloids Interfaces 2025, 9, 48. [Google Scholar] [CrossRef]

- Orisekeh, D.; Roh, B.-M.; Xiao, X. Solid-to-Solid Manufacturing Processes for High-Performance Li-Ion Solid-State Batteries. Polymers 2025, 17, 1788. [Google Scholar] [CrossRef]

- Hwang, E.; Hong, J.; Yoon, J.; Hong, S. Direct Writing of Functional Layer by Selective Laser Sintering of Nanoparticles for Emerging Applications: A Review. Materials 2022, 15, 6006. [Google Scholar] [CrossRef]

- Gupta, V.; Alam, F.; Verma, P.; Kannan, A.M.; Kumar, S. Additive Manufacturing Enabled, Microarchitected, Hierarchically Porous Polylactic-Acid/Lithium Iron Phosphate/Carbon Nanotube Nanocomposite Electrodes for High Performance Li-Ion Batteries. J. Power Sources 2021, 494, 229625. [Google Scholar] [CrossRef]

- Lyu, Z.; Lim, G.J.H.; Koh, J.J.; Li, Y.; Ma, Y.; Ding, J.; Wang, J.; Hu, Z.; Wang, J.; Chen, W.; et al. Design and Manufacture of 3D-Printed Batteries. Joule 2021, 5, 89–114. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Wang, Z.; Chen, J.; Yang, L.; Xia, J.; Zhang, Y.; Zhang, J.; Zhu, W.; Zhang, H.; et al. Additive Manufacturing in Construction Using Unmanned Aerial Vehicle: Design, Implementation, and Material Properties. J. Build. Eng. 2024, 98, 111363. [Google Scholar] [CrossRef]

- Kantaros, A.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. Composite Filament Materials for 3D-Printed Drone Parts: Advancements in Mechanical Strength, Weight Optimization and Embedded Electronics. Materials 2025, 18, 2465. [Google Scholar] [CrossRef]

- Szcześniak, P.; Grobelna, I.; Novak, M.; Nyman, U. Overview of Control Algorithm Verification Methods in Power Electronics Systems. Energies 2021, 14, 4360. [Google Scholar] [CrossRef]

- Yang, H.; Fang, H.; Wang, W.; Zhang, D.; Zhu, J.; Chen, K.; Sun, Y.; Wang, P.; Zhou, Q.; Qi, C.; et al. 3D Printing of Flexible Batteries for Wearable Electronics. J. Power Sources 2024, 602, 234350. [Google Scholar] [CrossRef]

- NajafiKhoshnoo, S.; Kim, T.; Tavares-Negrete, J.A.; Pei, X.; Das, P.; Lee, S.W.; Rajendran, J.; Esfandyarpour, R. A 3D Nanomaterials-printed Wearable, Battery-free, Biocompatible, Flexible, and Wireless pH Sensor System for Real-time Health Monitoring. Adv. Mater. Technol. 2023, 8, 2201655. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Z.; Li, M.; Li, Z.; Hu, X.; Xu, Q.; Wang, Y.; Liu, H.; Wang, Y. 3D Printed Flexible Zinc Ion Micro-batteries with High Areal Capacity toward Practical Application. Adv. Funct. Mater. 2024, 34, 2310966. [Google Scholar] [CrossRef]

- Li, P.; Liao, M.; Li, J.; Ye, L.; Cheng, X.; Wang, B.; Peng, H. Rechargeable Micro-batteries for Wearable and Implantable Applications. Small Struct. 2022, 3, 2200058. [Google Scholar] [CrossRef]

- Huo, S.; Sheng, L.; Su, B.; Xue, W.; Wang, L.; Xu, H.; He, X. 3D Printing Manufacturing of Lithium Batteries: Prospects and Challenges toward Practical Applications. Adv. Mater. 2024, 36, e2310396. [Google Scholar] [CrossRef]

- Mu, Y.B.; Chu, Y.Q.; Pan, L.; Wu, B.K.; Zou, L.F.; He, J.F.; Han, M.S.; Zhao, T.S.; Zeng, L. 3D Printing Critical Materials for Rechargeable Batteries: From Materials, Design and Optimization Strategies to Applications. Int. J. Extreme Manuf. 2023, 5, 042008. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, R.; Wang, J.; Wang, Y. Current and Future Lithium-Ion Battery Manufacturing. iScience 2021, 24, 102332. [Google Scholar] [CrossRef]

- Davis, J.T.; Jayathilake, B.S.; Chandrasekaran, S.; Wong, J.J.; Deotte, J.R.; Baker, S.E.; Beck, V.A.; Duoss, E.B.; Worsley, M.A.; Lin, T.Y. 3D Printed Optimized Electrodes for Electrochemical Flow Reactors. Sci. Rep. 2024, 14, 22662. [Google Scholar] [CrossRef]

- Ben-Barak, I.; Schneier, D.; Kamir, Y.; Goor, M.; Golodnitsky, D.; Peled, E. Drop-on-Demand 3D-Printed Silicon-Based Anodes for Lithium-Ion Batteries. J. Solid State Electrochem. 2022, 26, 183–193. [Google Scholar] [CrossRef]

- Xue, X.; Lin, D.; Li, Y. Low Tortuosity 3D-printed Structures Enhance Reaction Kinetics in Electrochemical Energy Storage and Electrocatalysis. Small Struct. 2022, 3, 2200159. [Google Scholar] [CrossRef]

- Örüm Aydin, A.; Zajonz, F.; Günther, T.; Dermenci, K.B.; Berecibar, M.; Urrutia, L. Lithium-Ion Battery Manufacturing: Industrial View on Processing Challenges, Possible Solutions and Recent Advances. Batteries 2023, 9, 555. [Google Scholar] [CrossRef]

- Kim, C.; Ahn, B.Y.; Cho, S.-H.; Jung, J.-W.; Kim, I.-D. 3D Printing for Energy Storage Devices: Advances, Challenges, and Future Directions. Adv. Mater. 2025, 37, e05943. [Google Scholar] [CrossRef] [PubMed]

- Aghmadi, A.; Mohammed, O.A. Energy Storage Systems: Technologies and High-Power Applications. Batteries 2024, 10, 141. [Google Scholar] [CrossRef]

- Liu, F.; Lu, J.; Hao, Y.; Chang, Y.; Yu, K.; Liu, S.; Chu, Z. Structure Design and Characterization of 3D Printing System of Thermal Battery Electrode Ink Film. Micromachines 2023, 14, 1147. [Google Scholar] [CrossRef]

- Duan, K.; Orabi, M.; Warchock, A.; Al-Akraa, Z.; Ajami, Z.; Chun, T.-H.; Lo, J.F. Monolithically 3D-Printed Microfluidics with Embedded µTesla Pump. Micromachines 2023, 14, 237. [Google Scholar] [CrossRef]

- Liu, C.; Li, C.; Li, J.; Huang, K.; Liu, Z.; Chen, Z.; Zhang, L. Conformal 3D Printing towards Shape-Conformal Batteries: A Topical Review. Virtual Phys. Prototyp. 2025, 20, e2461752. [Google Scholar] [CrossRef]

- Paek, S.W.; Balasubramanian, S.; Stupples, D. Composites Additive Manufacturing for Space Applications: A Review. Materials 2022, 15, 4709. [Google Scholar] [CrossRef]

- Ali, F.; Koc, M. 3D Printed Polymer Piezoelectric Materials: Transforming Healthcare through Biomedical Applications. Polymers 2023, 15, 4470. [Google Scholar] [CrossRef]

- Zhu, Y.; Qin, J.; Shi, G.; Sun, C.; Ingram, M.; Qian, S.; Lu, J.; Zhang, S.; Zhong, Y.L. A Focus Review on 3D Printing of Wearable Energy Storage Devices. Carbon Energy 2022, 4, 1242–1261. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, G. Research Progress and Prospect of Printed Batteries. In Innovative Technologies for Printing and Packaging; Lecture Notes in Electrical Engineering; Springer Nature: Singapore, 2023; pp. 561–569. ISBN 9789811990236. [Google Scholar]

- Gao, X.; Zheng, M.; Yang, X.; Sun, R.; Zhang, J.; Sun, X. Emerging Application of 3D-Printing Techniques in Lithium Batteries: From Liquid to Solid. Mater. Today 2022, 59, 161–181. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Gao, X.; Wang, C.; Li, W.; Holness, F.B.; Zheng, M.; Li, R.; Price, A.D.; Sun, X.; et al. Toward High Areal Energy and Power Density Electrode for Li-Ion Batteries via Optimized 3D Printing Approach. ACS Appl. Mater. Interfaces 2018, 10, 39794–39801. [Google Scholar] [CrossRef]

- Li, J.; Fleetwood, J.; Hawley, W.B.; Kays, W. From Materials to Cell: State-of-the-Art and Prospective Technologies for Lithium-Ion Battery Electrode Processing. Chem. Rev. 2022, 122, 903–956. [Google Scholar] [CrossRef]

- Verdier, N.; Foran, G.; Lepage, D.; Prébé, A.; Aymé-Perrot, D.; Dollé, M. Challenges in Solvent-Free Methods for Manufacturing Electrodes and Electrolytes for Lithium-Based Batteries. Polymers 2021, 13, 323. [Google Scholar] [CrossRef]

- Artigas-Arnaudas, J.; Sánchez-Romate, X.F.; Sánchez, M.; Ureña, A. Effect of Electrode Surface Treatment on Carbon Fiber Based Structural Supercapacitors: Electrochemical Analysis, Mechanical Performance and Proof-of-Concept. J. Energy Storage 2023, 59, 106599. [Google Scholar] [CrossRef]

- Pei, M.; Shi, H.; Yao, F.; Liang, S.; Xu, Z.; Pei, X.; Wang, S.; Hu, Y. 3D Printing of Advanced Lithium Batteries: A Designing Strategy of Electrode/Electrolyte Architectures. J. Mater. Chem. A Mater. Energy Sustain. 2021, 9, 25237–25257. [Google Scholar] [CrossRef]

- Shen, F.; Tang, C.; Sun, X.; Song, Y.; Cai, J. Recent Advances in 3D Printing Technologies for Lithium-Sulfur Batteries. Small 2025, 21, e2412182. [Google Scholar] [CrossRef]

- Łapińska, A.; Panas, A.J.; Przekop, R.; Sztorch, B.; Pakuła, D.; Głowacka, J.; Gołofit, T.; Dużyńska, A.; Płatek, P.; Cieplak, K.; et al. Comparison of Thermal and Fire Properties of PLA-Based Composites Based on FDM Printed Graphite/Molybdenum Disulfide and Siloxene. Int. J. Heat Mass Transf. 2025, 250, 127276. [Google Scholar] [CrossRef]

- Kantaros, A. Intellectual Property Challenges in the Age of 3D Printing: Navigating the Digital Copycat Dilemma. Appl. Sci. 2024, 14, 11448. [Google Scholar] [CrossRef]

- Kantaros, A.; Zacharia, P.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations. Appl. Sci. 2025, 15, 3719. [Google Scholar] [CrossRef]

- Gulzar, U.; Egorov, V.; Zhang, Y.; O’Dwyer, C. Recyclable 3D-printed Aqueous Lithium-ion Battery. Adv. Energy Sustain. Res. 2023, 4, 2300029. [Google Scholar] [CrossRef]

- Li, C.; Du, J.; Gao, Y.; Bu, F.; Tan, Y.H.; Wang, Y.; Fu, G.; Guan, C.; Xu, X.; Huang, W. Stereolithography of 3D Sustainable Metal Electrodes towards High-performance Nickel Iron Battery. Adv. Funct. Mater. 2022, 32, 2205317. [Google Scholar] [CrossRef]

- The 17 Goals. Available online: https://sdgs.un.org/goals/goal17 (accessed on 17 September 2025).

- Goal 12. Available online: https://sdgs.un.org/goals/goal12 (accessed on 17 September 2025).

- Goal 7. Available online: https://sdgs.un.org/goals/goal7 (accessed on 17 September 2025).

- Goal 13. Available online: https://sdgs.un.org/goals/goal13 (accessed on 17 September 2025).

- Goal 9. Available online: https://sdgs.un.org/goals/goal9 (accessed on 17 September 2025).

- Nuhu, B.A.; Bamisile, O.; Adun, H.; Abu, U.O.; Cai, D. Effects of Transition Metals for Silicon-Based Lithium-Ion Battery Anodes: A Comparative Study in Electrochemical Applications. J. Alloys Compd. 2023, 933, 167737. [Google Scholar] [CrossRef]

- Tao, R.; Gu, Y.; Sharma, J.; Hong, K.; Li, J. A Conformal Heat-Drying Direct Ink Writing 3D Printing for High-Performance Lithium-Ion Batteries. Mater. Today Chem. 2023, 32, 101672. [Google Scholar] [CrossRef]

- Szabó, Z.; Broda, B.; Marosfői, B.; Kováts, A. Sedimentation Study on Modified Lead Dioxide Particles—For Screening of Potentially Effective Additives for Lead-Acid Batteries. J. Power Sources 2021, 513, 230547. [Google Scholar] [CrossRef]

- Hasany, M.; Kohestanian, M.; Rezaei, B.; Keller, S.S.; Mehrali, M. Hygroscopic Nature of Lithium Ions: A Simple Key to Super Tough Atmosphere-Stable Hydrogel Electrolytes. ACS Nano 2024, 18, 30512–30529. [Google Scholar] [CrossRef]

- Gao, X.; Li, X.; Yang, J.; Li, K.; Qiao, Z.; Ruan, D.; Wang, Y. Effect of Direct Writing Process Parameters and Rheological Behavior of LiFePO4 Ink on 3D Electrode Structure and Electrochemical Performance. Appl. Mater. Today 2025, 46, 102876. [Google Scholar] [CrossRef]

- Jackson, S.; Dickens, T. Rheological and Structural Characterization of 3D-Printable Polymer Electrolyte Inks. Polym. Test. 2021, 104, 107377. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.; Ungureanu, L.; Munteanu, I. Post-Production Finishing Processes Utilized in 3D Printing Technologies. Processes 2024, 12, 595. [Google Scholar] [CrossRef]

- Ma, J.; Zheng, S.; Fu, Y.; Wang, X.; Qin, J.; Wu, Z.-S. The Status and Challenging Perspectives of 3D-Printed Micro-Batteries. Chem. Sci. 2024, 15, 5451–5481. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Bao, Y.; Li, N.; Lu, B.; Song, Y.; Zhang, J.; Fang, D. Customizable 3D-Printed Decoupled Structural Lithium-Ion Batteries with Stable Cyclability and Mechanical Robustness. Compos. Sci. Technol. 2024, 256, 110783. [Google Scholar] [CrossRef]

- Nagaraju, G.; Tagliaferri, S.; Panagiotopoulos, A.; Och, M.; Quintin-Baxendale, R.; Mattevi, C. Durable Zn-Ion Hybrid Capacitors Using 3D Printed Carbon Composites. J. Mater. Chem. A Mater. Energy Sustain. 2022, 10, 15665–15676. [Google Scholar] [CrossRef]

- Yang, F.W.; Shen, Y.J.; Zhang, Z.P.; Ruan, W.H.; Rong, M.Z.; Zhang, M.Q. Ultra-Long Life Solid-State Lithium Metal Batteries Enabled by 3D-Printing of Integrated Porous Cathode/Composite Polymer Electrolyte with Dynamic Covalent Bonds. Adv. Mater. 2025, 37, e09057. [Google Scholar] [CrossRef]

- White, M.; Choi, M.; Hu, B.; Chandrasekaran, S.; Xue, X.; Worsley, M.; Li, Y.; Dunn, B. Recent Advances in Scalable, High-Mass Loaded Electrodes for Grid-Scale Energy Storage. Adv. Mater. 2025, e2417128. [Google Scholar] [CrossRef]

- Saeed, G.; Kang, T.; Byun, J.S.; Min, D.; Kim, J.S.; Sadavar, S.V.; Park, H.S. Two-Dimensional (2D) Materials for 3D Printed Micro-Supercapacitors and Micro-Batteries. Energy Mater. 2024, 4, 400023. [Google Scholar] [CrossRef]

- Chen, A.; Qu, C.; Shi, Y.; Shi, F. Manufacturing Strategies for Solid Electrolyte in Batteries. Front. Energy Res. 2020, 8, 571440. [Google Scholar] [CrossRef]

- Maurel, A.; Grugeon, S.; Fleutot, B.; Courty, M.; Prashantha, K.; Tortajada, H.; Armand, M.; Panier, S.; Dupont, L. Three-Dimensional Printing of a LiFePO4/Graphite Battery Cell via Fused Deposition Modeling. Sci. Rep. 2019, 9, 18031. [Google Scholar] [CrossRef]

- Alandur Ramesh, B.R.; Basnet, B.; Huang, R.; Jeong, J.; Lee, H.; Kyu, T.; Choi, J.-W. The Promise of 3D Printed Solid Polymer Electrolytes for Developing Sustainable Batteries: A Techno-Commercial Perspective. Int. J. Precis. Eng. Manuf.-Green. Technol. 2024, 11, 321–352. [Google Scholar] [CrossRef]

- Zacharia, P.T.; Nearchou, A.C. Multi-Objective Fuzzy Assembly Line Balancing Using Genetic Algorithms. J. Intell. Manuf. 2012, 23, 615–627. [Google Scholar] [CrossRef]

- Kantaros, A.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. The Role of 3D Printing in Advancing Automated Manufacturing Systems: Opportunities and Challenges. Automation 2025, 6, 21. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- IEC. Available online: https://www.iec.ch/taxonomy/term/353 (accessed on 18 September 2025).

- Battery Standards Overview. Available online: https://www.ul.com/resources/battery-standards-overview (accessed on 18 September 2025).

- Kwon, S.; Hwang, D. Understanding and Resolving 3D Printing Challenges: A Systematic Literature Review. Processes 2025, 13, 1772. [Google Scholar] [CrossRef]

- Michalec, P.; Faller, L.-M. 3-D-Printing and Reliability Evaluation of an Easy-to-Fabricate Position Sensing System for Printed Functional Wearable Assistive Devices. IEEE Sens. J. 2024, 24, 4137–4149. [Google Scholar] [CrossRef]

- Ferrero Guillén, R. From Enemies to Allies: 3D Printing, IP and Sustainability. J. Intellect. Prop. Law Pract. 2023, 18, 375–381. [Google Scholar] [CrossRef]

- Malaquias, P. The 3d Printing Revolution: An Intellectual Property Analysis. SSRN Electron. J. 2014. [Google Scholar] [CrossRef]

- Bernal, P.N.; Florczak, S.; Inacker, S.; Kuang, X.; Madrid-Wolff, J.; Regehly, M.; Hecht, S.; Zhang, Y.S.; Moser, C.; Levato, R. The Road Ahead in Materials and Technologies for Volumetric 3D Printing. Nat. Rev. Mater. 2025, 10, 826–841. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Z.; Zhao, Z.; Zhang, D.; Feng, J.; Yu, L.; Lin, Z.; Guo, Q.; Huang, J.; Mao, J.; et al. 3D Printing of Micro-Nano Devices and Their Applications. Microsyst. Nanoeng. 2025, 11, 35. [Google Scholar] [CrossRef]

- Martinez, A.C.; Maurel, A.; Yelamanchi, B.; Talin, A.A.; Grugeon, S.; Panier, S.; Dupont, L.; Aranzola, A.; Schiaffino, E.; Sreenivasan, S.T.; et al. Combining 3D Printing of Copper Current Collectors and Electrophoretic Deposition of Electrode Materials for Structural Lithium-Ion Batteries. Adv. Manuf. 2024, 13, 462–475. [Google Scholar] [CrossRef]

- Jain, A.; Goyal, A.; Raj, A.; Rajora, A.; Bhardwaj, L.; Chandrakar, A.S.; Gupta, H.; Layal, P.K.; Raj, T.; Sharma, G.S.; et al. A Bibliometric Study of Additively Manufactured Batteries. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 19, 4605–4623. [Google Scholar] [CrossRef]

- Barbosa, T.G.; da Silva, D.N.; Borges, M.M.C.; da Trindade, S.O.D.; de Oliveira Cândido, T.C.; Pereira, A.C. Influence of Surface Treatments on the Electrochemical Performance of Lab-Made 3D-Printed Electrodes. Analytica 2025, 6, 9. [Google Scholar] [CrossRef]

- Konieczna, R.; Przekop, R.E.; Pakuła, D.; Głowacka, J.; Ziętkowska, K.; Kozera, R.; Sztorch, B. Functional Silsesquioxanes-Tailoring Hydrophobicity and Anti-Ice Properties of Polylactide in 3D Printing Applications. Materials 2024, 17, 4850. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Ji, Y.; Cao, J.; Xu, S.; Luo, P.; Liu, J.; Ma, L.; Gao, G.; Wu, Y.; et al. Self-Healing Polyurethane Elastomers with Dynamic Crosslinked Networks for Complex Structure 3D Printing. Chem. Eng. J. 2025, 507, 160193. [Google Scholar] [CrossRef]

- Crespilho, F.N.; Costa, C.M.; Lanceros-Méndez, S. Sustainable Battery Biomaterials. ChemElectroChem 2024, 12, e202400530. [Google Scholar] [CrossRef]

- Shaju, A.; Harinarayanan, A.; Kandasubramanian, B. Sustainable Hydrogen Peroxide Sensors: Integrating 3D Printing with Battery Recycling. J. Solid State Electrochem. 2025, 29, 4281–4288. [Google Scholar] [CrossRef]

- Dai, S.; Lin, Z.; Hu, H.; Wang, Y.; Zeng, L. 3D Printing for Sodium Batteries: From Material Design to Integrated Devices. Appl. Phys. Rev. 2024, 11, 041319. [Google Scholar] [CrossRef]

- Wang, T.; Wang, W.; Tian, X.; Tian, Y.; Wang, D.; Zhou, K.; Zhao, Y. A Universal Multiscale Ion–Electron Dual Regulation for On-demand all-3D-printed High-voltage Full Batteries. Adv. Funct. Mater. 2025, 2507097. [Google Scholar] [CrossRef]

- Chu, Z.; Zhou, Y.; Li, S.; Xu, Q.; Pan, L. Implantable Medical Electronic Devices: Sensing Mechanisms, Communication Methods, and the Biodegradable Future. Appl. Sci. 2025, 15, 7599. [Google Scholar] [CrossRef]

- Wu, Y.; He, Q.; Zhou, Y.; Liu, X.; Yang, M. Zinc-Ion Batteries at Elevated Temperatures: Linking Material Design to Wearable/Biocompatible Applications. Adv. Compos. Hybrid Mater. 2025, 8, 130. [Google Scholar] [CrossRef]

- Xiao, J.; Anwer, N.; Durupt, A.; Le Duigou, J.; Eynard, B. Information Exchange Standards for Design, Tolerancing and Additive Manufacturing: A Research Review. Int. J. Interact. Des. Manuf. (IJIDeM) 2018, 12, 495–504. [Google Scholar] [CrossRef]

- Atanasov, B.; Atanasov, N.; Atanasova, G. The Design and Performance Evaluation of a Compact, Low-Cost Rectenna on a 3D-Printed Composite Substrate for Sustainable IoT Devices. Electronics 2025, 14, 2625. [Google Scholar] [CrossRef]

- Maji, S.; Kwak, M.; Kumar, R.; Lee, H. 3D Printing Assisted Wearable and Implantable Biosensors. Biosensors 2025, 15, 619. [Google Scholar] [CrossRef]

- Bihn, S.; Rinner, J.; Witzenhausen, H.; Krause, F.; Ringbeck, F.; Sauer, D.U. Physics-Based Equivalent Circuit Model Motivated by the Doyle–Fuller–Newman Model. Batteries 2024, 10, 314. [Google Scholar] [CrossRef]

- Lou, X.; Zhao, L.; Gao, Y.; Nan, X. 3D-Printed Electrode/Electrolyte Architectures for High-Performance Lithium-Ion Batteries: Mechanisms, Materials, and Challenges. ACS Omega 2025, 10, 28630–28642. [Google Scholar] [CrossRef]

- Maurel, A.; Pavone, A.; Stano, G.; Martinez, A.C.; MacDonald, E.; Percoco, G. Manufacturing-Oriented Review on 3D Printed Lithium-Ion Batteries Fabricated Using Material Extrusion. Virtual Phys. Prototyp. 2023, 18, e2264281. [Google Scholar] [CrossRef]

- Soares, D.M.; Ren, Z.; Mujib, S.B.; Mukherjee, S.; Martins Real, C.G.; Anstine, M.; Zanin, H.; Singh, G. Additive Manufacturing of Electrochemical Energy Storage Systems Electrodes. Adv. Energy Sustain. Res. 2021, 2, 2000111. [Google Scholar] [CrossRef]

- Glynn, C.; Jadhav, V.V.; McNulty, D.; Geaney, H.; O’Hanlon, S.; O’Dwyer, C. Voltammetric Priming for Electrochemically Stable 3D Printed Aqueous Gel Li-Ion Rechargeable Batteries in Various Form Factors. ECS Adv. 2025, 4, 030501. [Google Scholar] [CrossRef]

- Rehman, F.U.; Vu, T.T.; Kim, J.; Kim, Y.; Choi, H.; Singha, N.R.; Chang, M. 3D-Printed Solid-State Electrolytes for next-Generation Batteries: Advances in Design, Challenges, and Future Opportunities. EnergyChem 2025, 7, 100174. [Google Scholar] [CrossRef]

- Li, S.; Sun, M.; Gao, C.; Wang, M.; Li, C.; Hu, X.; Wang, H.; Wang, P.; Zhao, D.; Zhang, N.; et al. 3D Printing Integrated Lipophilic Additives Engineering to Enhance Wettability of Thick Electrodes Achieving High Rate and High Areal Capacity. ACS Appl. Mater. Interfaces 2025, 17, 40476–40487. [Google Scholar] [CrossRef]

- Sztymela, K.; Bienia, M.; Rossignol, F.; Mailley, S.; Ziesche, S.; Varghese, J.; Cerbelaud, M. Fabrication of Modern Lithium Ion Batteries by 3D Inkjet Printing: Opportunities and Challenges. Heliyon 2022, 8, e12623. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Pallis, E.; Papoutsidakis, M. Smart Design Aided by Mathematical Approaches: Adaptive Manufacturing, Sustainability, and Biomimetic Materials. Designs 2025, 9, 102. [Google Scholar] [CrossRef]

- Sagias, V.D.; Zacharia, P.; Tempeloudis, A.; Stergiou, C. Adaptive Neuro-Fuzzy Inference System-Based Predictive Modeling of Mechanical Properties in Additive Manufacturing. Machines 2024, 12, 523. [Google Scholar] [CrossRef]

- Wolstrup, A.F.; Spangenberg, J.; Yamamoto, A.; Gleadall, A.; Zsurzsan, G. Advances in 3D Printed Electromechanical Sensors: Performance Comparison, Trends, and Future Directions. Addit. Manuf. 2025, 106, 104799. [Google Scholar] [CrossRef]

- Aftab, M.; Ikram, S.; Ullah, M.; Khan, N.; Naeem, M.; Khan, M.A.; Bakhtiyor o’g’li, R.B.; Qizi, K.S.S.; Erkinjon Ugli, O.O.; Abdurasulovna, B.M.; et al. Recent Trends and Future Directions in 3D Printing of Biocompatible Polymers. J. Manuf. Mater. Process. 2025, 9, 129. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Guo, C.; Zhou, X.; Zhang, J.; Wang, J.; Chen, Y.; Lyu, Z. 3D Printing of Multiscale Biomimetic Structural Electrodes: Achieving Ultrahigh Deformability and Areal Capacity for Li-Ion Batteries. Energy Storage Mater. 2025, 74, 103958. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Lang, X.; Li, Z.; Zhang, C.; Feng, X.; Shi, C. 3D Printed Composite Solid Electrolytes for High-Performance Solid-State Batteries. Chem. Eng. J. 2025, 508, 160824. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Grobelna, I. Formal Verification of Control Modules in Cyber-Physical Systems. Sensors 2020, 20, 5154. [Google Scholar] [CrossRef]

- Xiao, J.; Terzi, S.; Macchi, M.; Rosa, P. Intelligent Disassembly System for End-of-Life Product Using Human Robot Collaboration on a Digital Twin Platform. Procedia CIRP 2025, 136, 654–658. [Google Scholar] [CrossRef]

| Category | 3D Printing Methods | Ink/Binder Class | Feature Size | Representative Performance |

|---|---|---|---|---|

| Electrodes [26,27,28,29,30,31,32,33,34,35,36,37,38] | Direct ink writing (DIW), extrusion-based printing, aerosol jet printing | Slurry-based inks with polymeric binders (e.g., PVDF, CMC), conductive carbon inks, and graphene/CNT-enhanced inks | ~10–200 µm (printed lines/features); hierarchical porosity from micro- to mesoscale | 20–40% improved rate capability; enhanced ionic/electronic transport; >90% capacity retention after high-rate cycling |

| Electrolytes and Separators [39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56] | Extrusion, inkjet printing, stereolithography (SLA) | Solid polymer electrolytes (e.g., PEO-based), ceramic-infused inks (LLZO, LATP), UV-curable resins for patterned separators | ~20–150 µm (electrolyte layers); ≤50 µm pore/alignment resolution in patterned separators | 25–50% increase in ionic conductivity; improved mechanical robustness; enhanced thermal and interfacial stability |

| Microbatteries and Flexible/Wearable Systems [57,58,59,60,61,62,63,64,65,66,67,68] | Inkjet, DIW, extrusion | Stretchable elastomeric inks, Ag- or CNT-based conductive inks, gel polymer electrolytes | ~10–100 µm for interdigitated microelectrodes; sub-mm thin flexible cell stacks | High areal energy density (up to 1–5 mWh cm−2); stable performance under bending (≥1000 cycles) and stretching (up to 20–50%) |

| Device Integration [69,70,71,72,73,74,75,76,77,78,79] | Hybrid/multi-process printing combining the above methods | Multi-material inks for structural, conductive, and electrochemical integration (e.g., TPU, PEDOT:PSS, composite structural inks) | Application-dependent; mm–cm conformal integration with 50–200 µm printed features | Reduced form factor and wiring losses; >30% volume savings via structural integration; enhanced device ergonomics and multifunctionality |

| Aspect | Gigafactory Production | 3D Printing of Batteries |

|---|---|---|

| Production Volume [127,128] | Extremely high (millions of cells/year) | Low to moderate (small-batch, device-specific) |

| Manufacturing Speed [127] | Fast, optimized through roll-to-roll and slurry casting | Relatively slow, limited by printing resolution and deposition rates |

| Economies of Scale [129] | Strong cost reduction via mass production | Limited; costs remain high due to specialized inks and equipment |

| Customization [122] | Minimal; standardized formats dominate | High; tailored geometries and device-specific integration possible |

| Capital Investment [125] | Very high (multi-billion-dollar facilities) | Moderate to high (equipment, materials, but scalable at smaller facilities) |

| Material Utilization [126] | Established, but waste from cutting and coating processes | Potentially higher efficiency with additive deposition, though ink formulation challenges remain |

| Environmental Impact [125,126] | Large footprint, but improving through renewable integration | Dependent on material sources and energy use; potential benefits via localized production |

| Market Fit [123] | Mass markets (EVs, grid storage) | Niche/specialized markets (wearables, sensors, medical devices, rapid prototyping) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Ganetsos, T.; Pallis, E.; Papoutsidakis, M.; Laskaris, N. Additive Manufacturing for Next-Generation Batteries: Opportunities, Challenges, and Future Outlook. Appl. Sci. 2025, 15, 11907. https://doi.org/10.3390/app152211907

Kantaros A, Ganetsos T, Pallis E, Papoutsidakis M, Laskaris N. Additive Manufacturing for Next-Generation Batteries: Opportunities, Challenges, and Future Outlook. Applied Sciences. 2025; 15(22):11907. https://doi.org/10.3390/app152211907

Chicago/Turabian StyleKantaros, Antreas, Theodore Ganetsos, Evangelos Pallis, Michail Papoutsidakis, and Nikolaos Laskaris. 2025. "Additive Manufacturing for Next-Generation Batteries: Opportunities, Challenges, and Future Outlook" Applied Sciences 15, no. 22: 11907. https://doi.org/10.3390/app152211907

APA StyleKantaros, A., Ganetsos, T., Pallis, E., Papoutsidakis, M., & Laskaris, N. (2025). Additive Manufacturing for Next-Generation Batteries: Opportunities, Challenges, and Future Outlook. Applied Sciences, 15(22), 11907. https://doi.org/10.3390/app152211907