Unmanned Aerial Underwater Vehicles: Research Progress and Prospects

Featured Application

Abstract

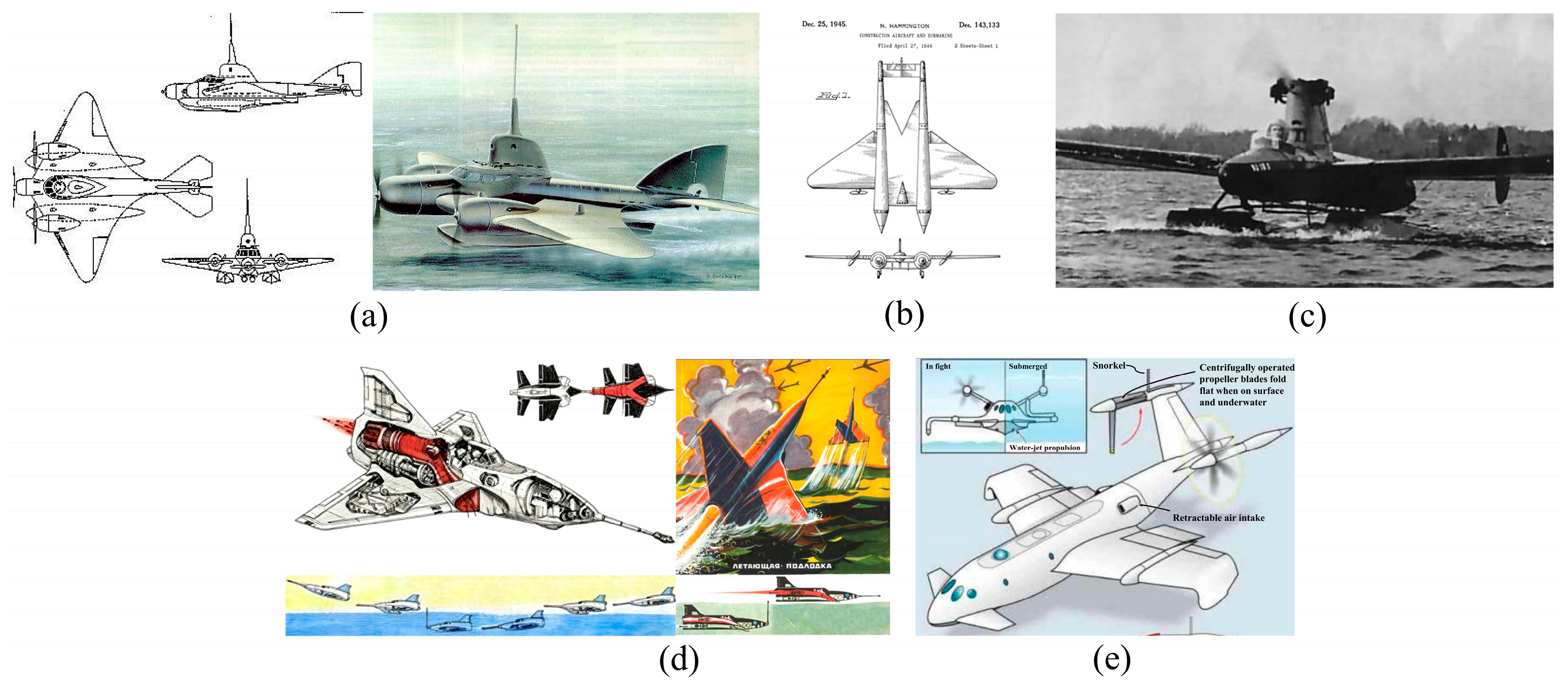

1. Introduction

- A more reasonable classification based on propulsion configuration, along with a comprehensive summary of existing prototypes.

- Guidance for UAUV design focusing on application requirements, covering basic structure, water entry and exit, power, and control systems besides addressing technical challenges such as hydrodynamic calculations, hybrid power systems, and underwater optimization.

- Detailed description of more applications, with specific development prospects for different UAUV configurations.

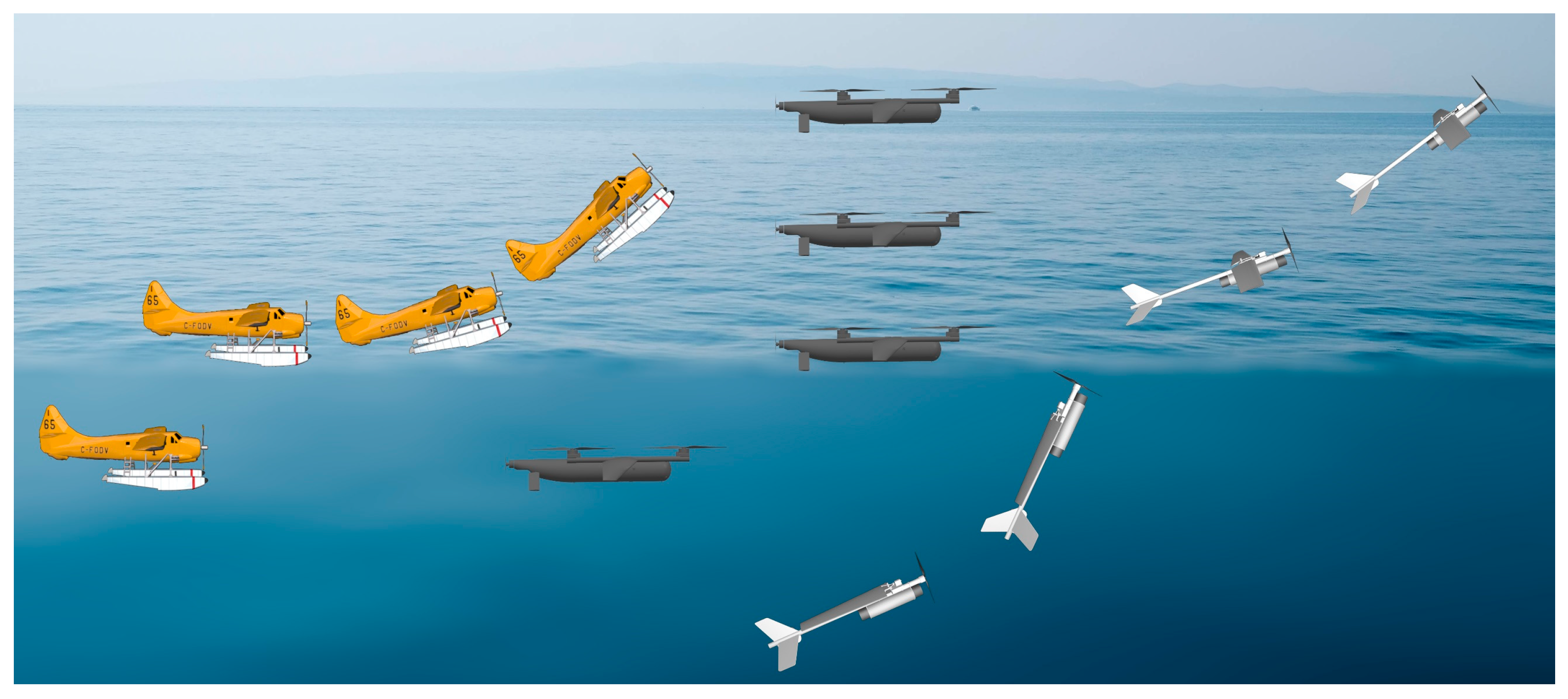

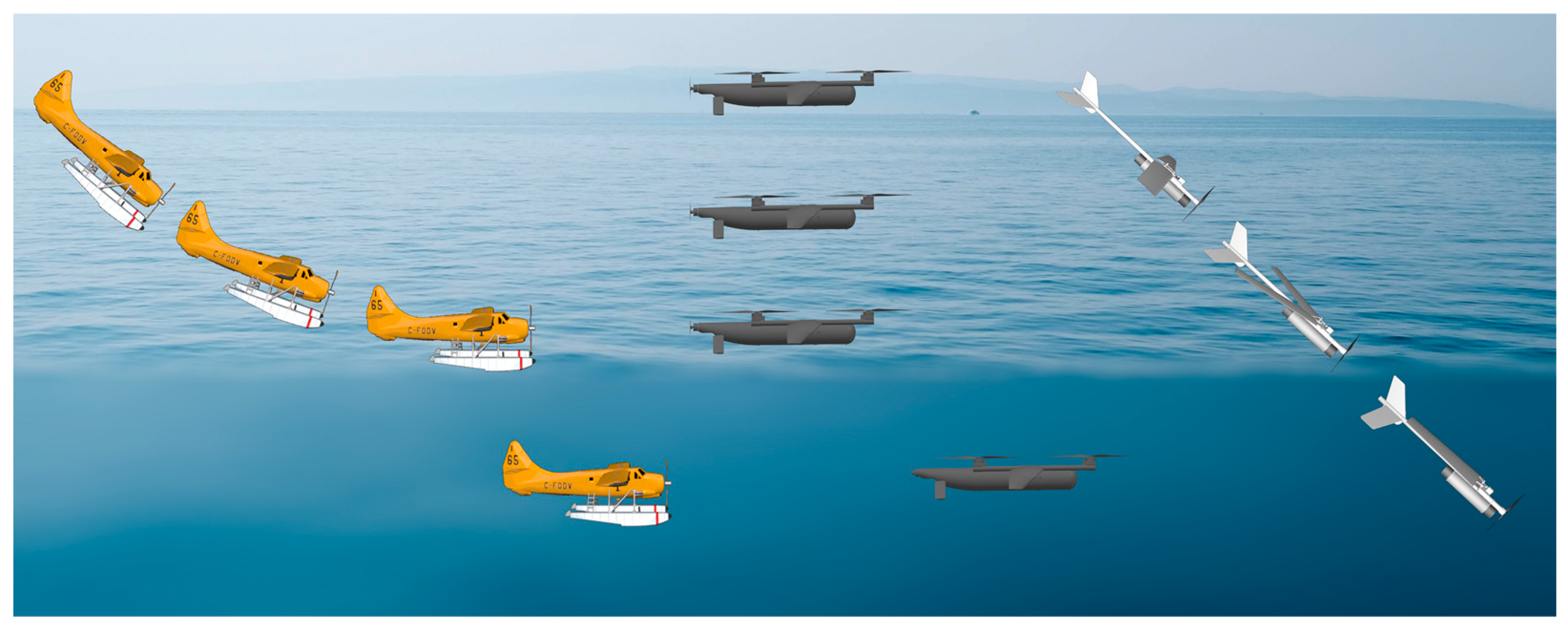

2. Research Progress

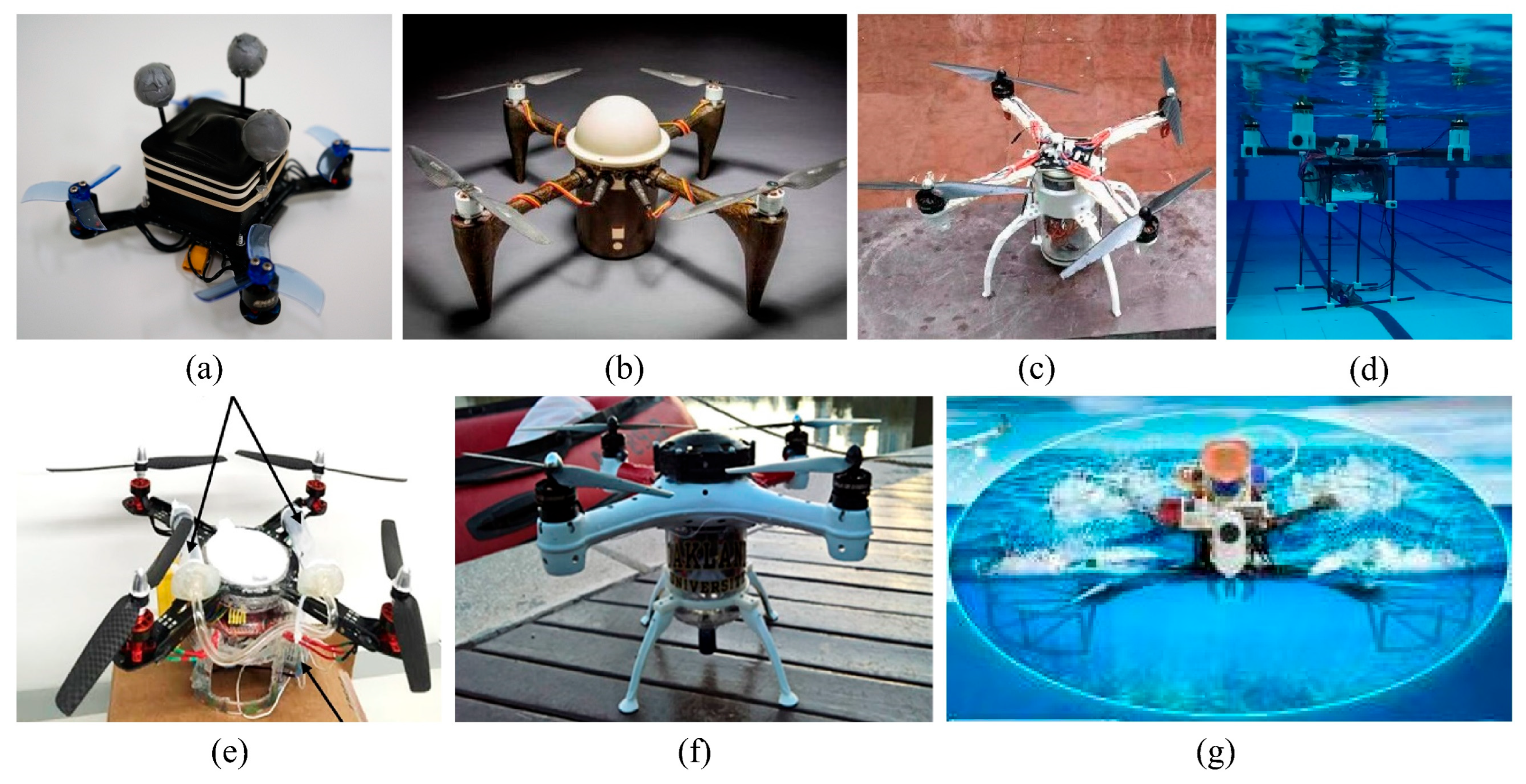

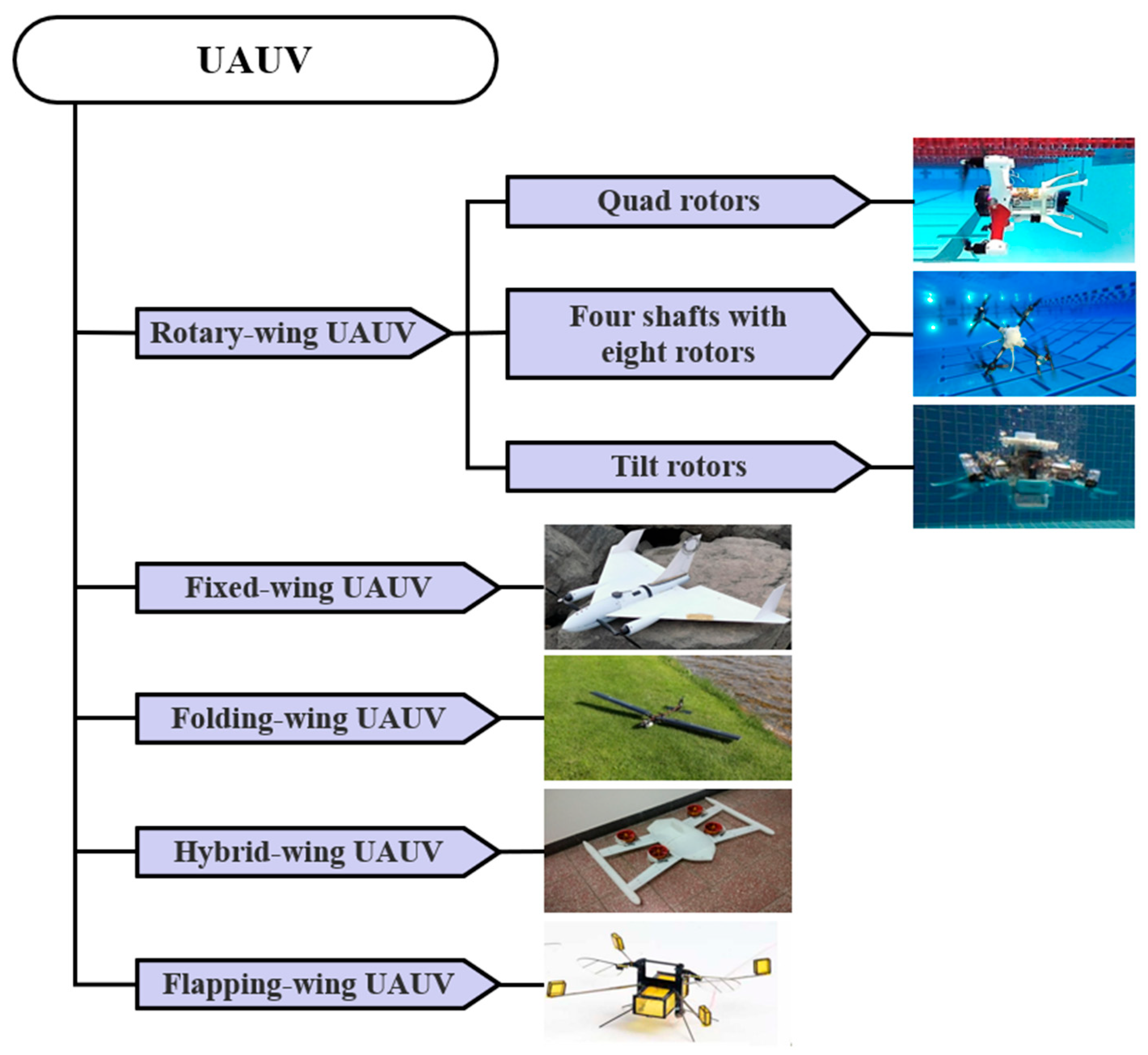

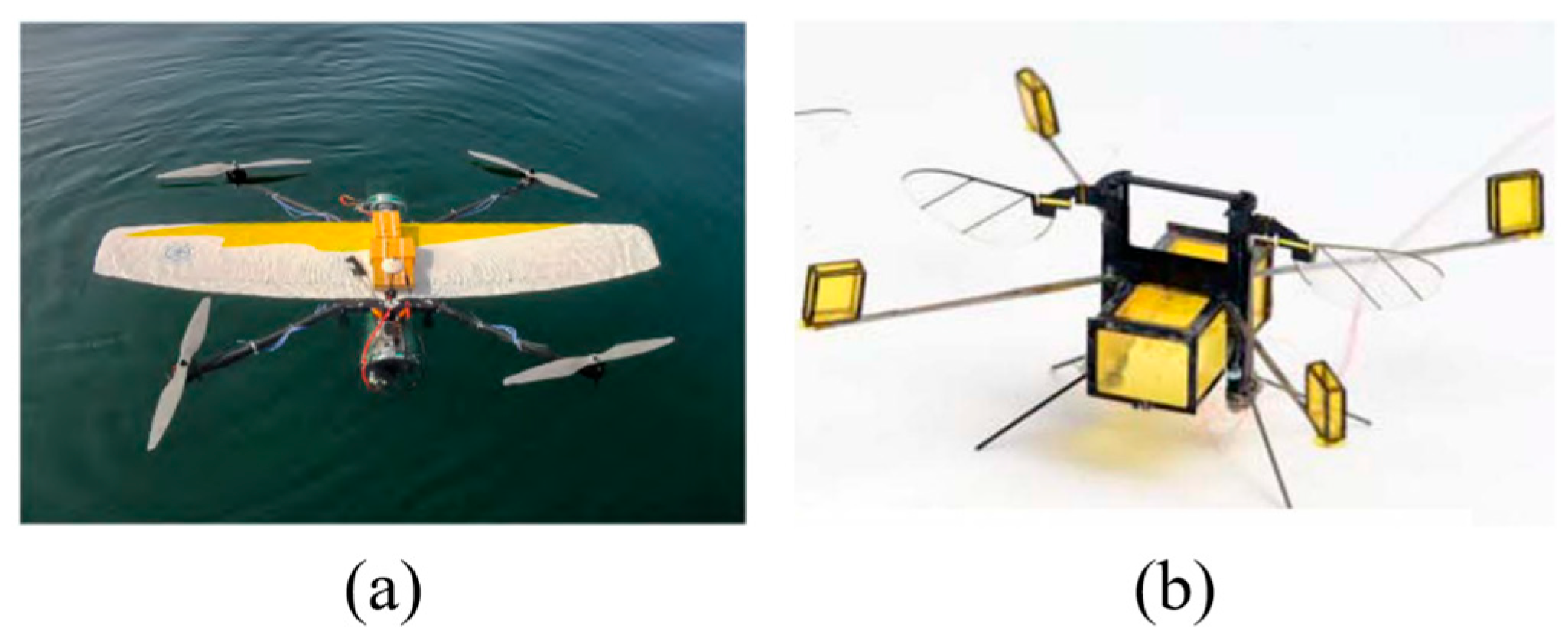

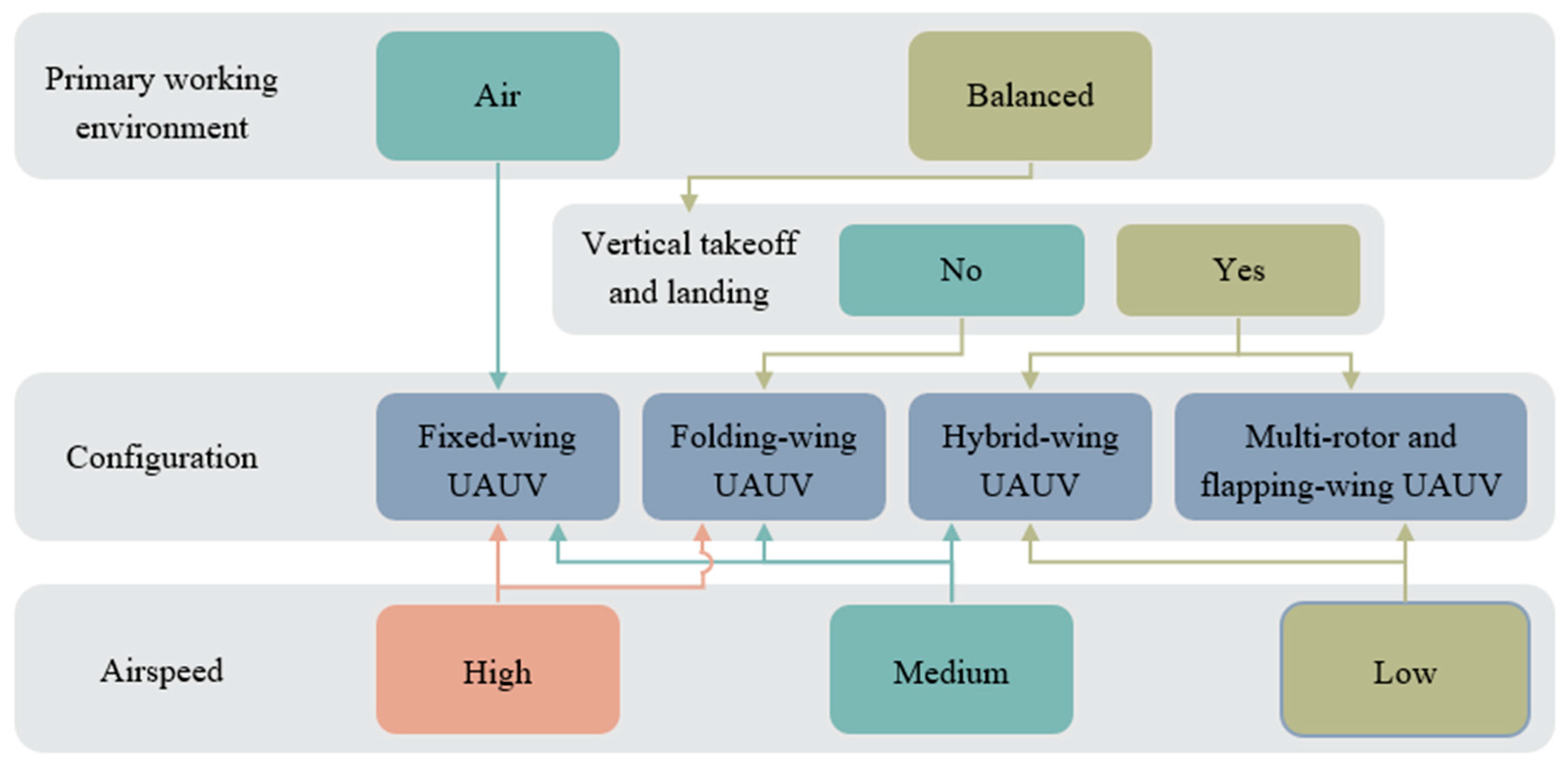

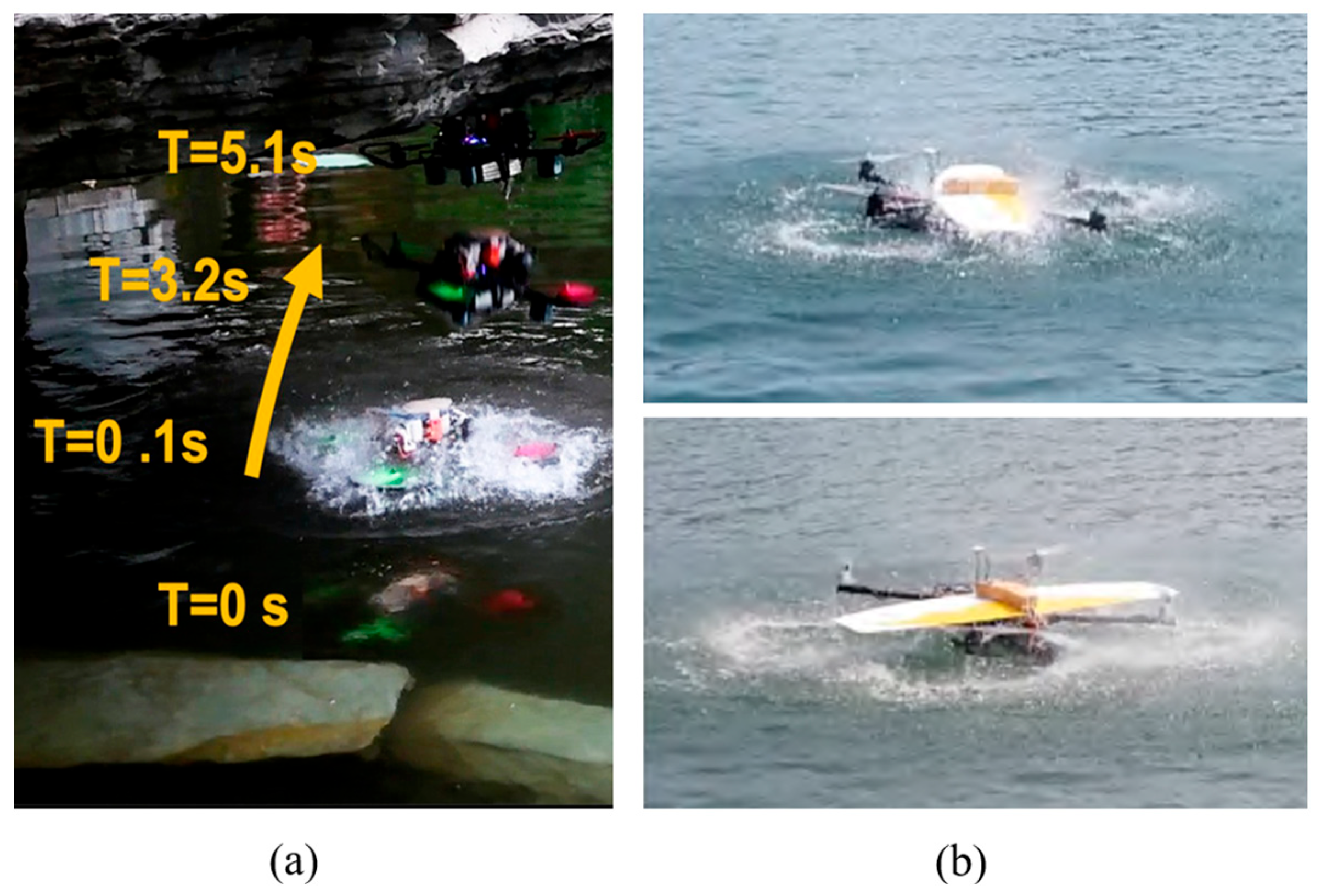

2.1. Rotary-Wing UAUVs

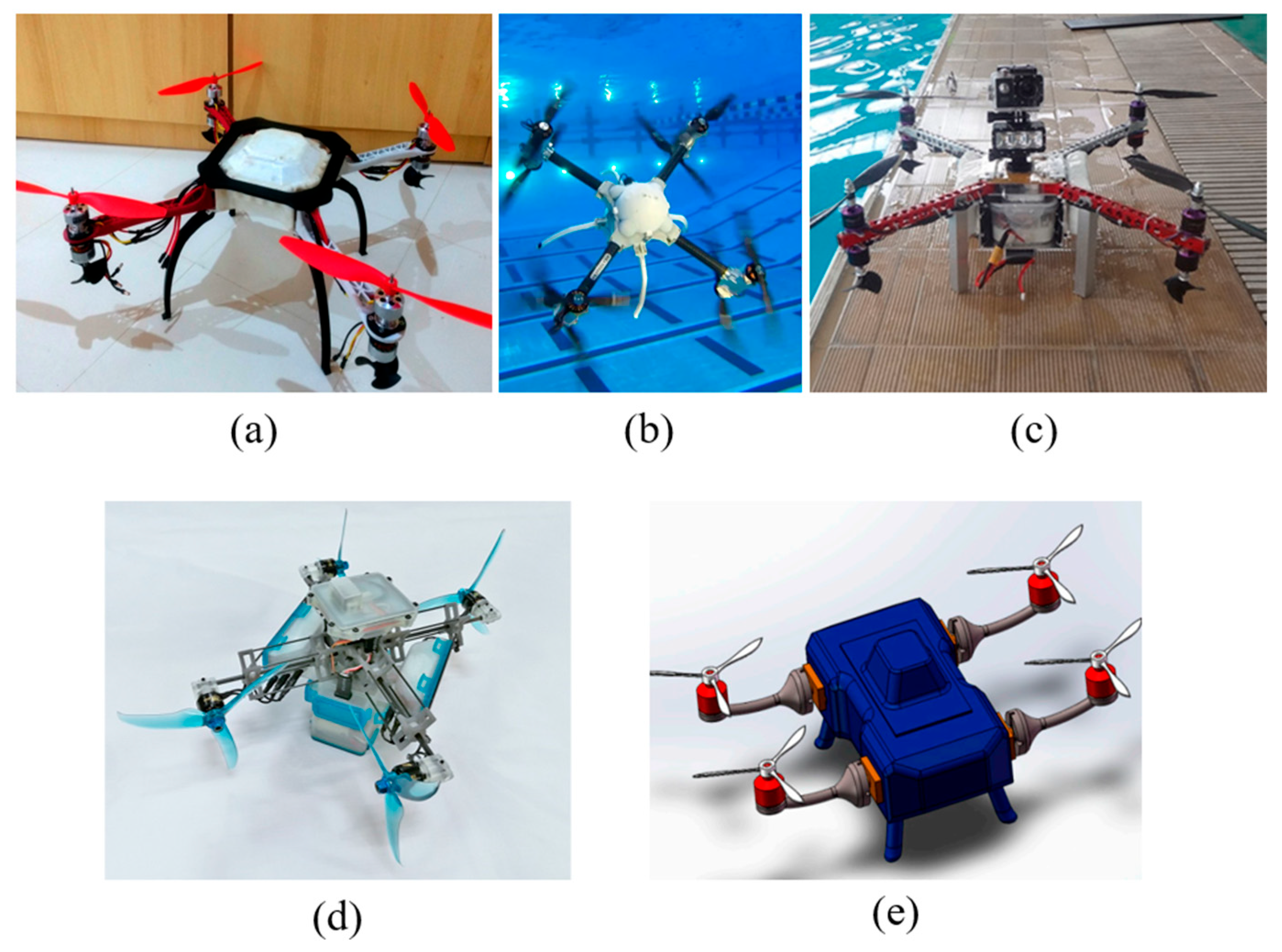

2.1.1. Quad Rotors

2.1.2. Four Shafts with Eight Rotors

2.1.3. Tilt Rotors

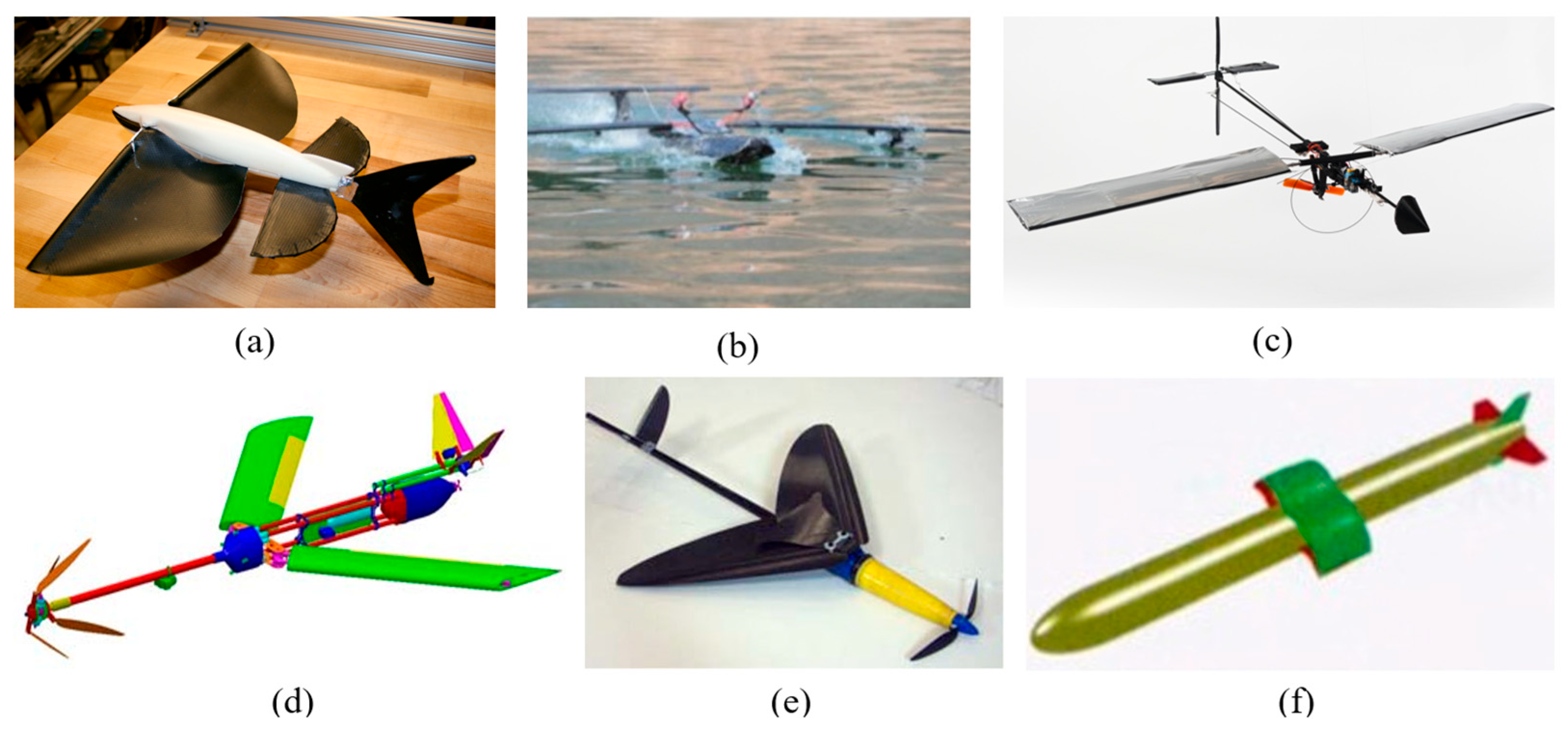

2.2. Fixed-Wing UAUVs

2.3. Folding-Wing UAUVs

2.4. Hybrid-Wing UAUVs

2.5. Flapping-Wing UAUV

3. Design Focus and Technical Difficulties

- Basic appearance and structure

- Water entry and exit mode

- Power and propulsion system

- Control system

3.1. Basic Appearance and Structure

3.1.1. Configuration Selection

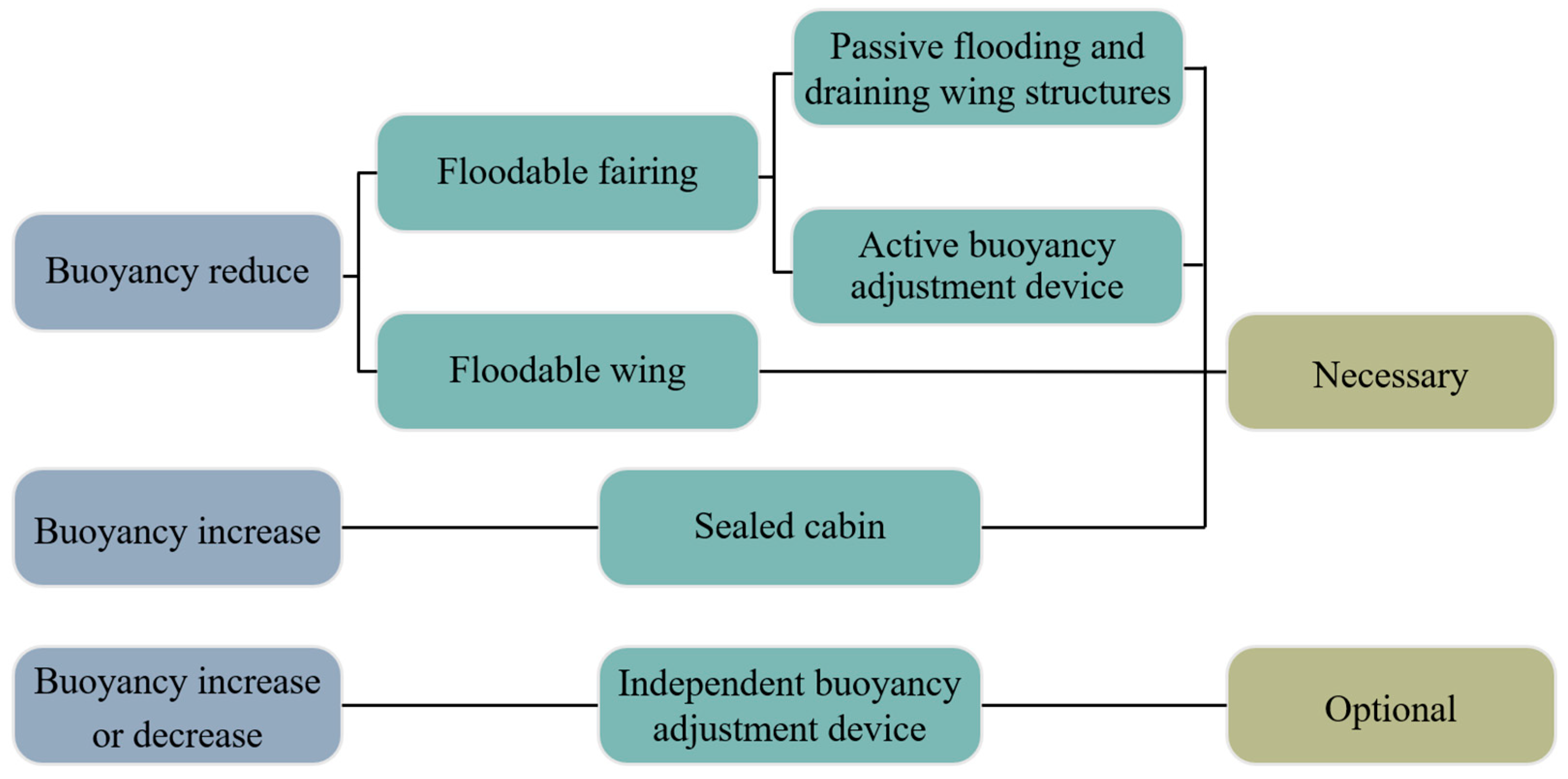

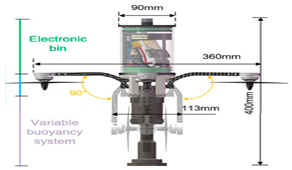

3.1.2. Variable Buoyancy System

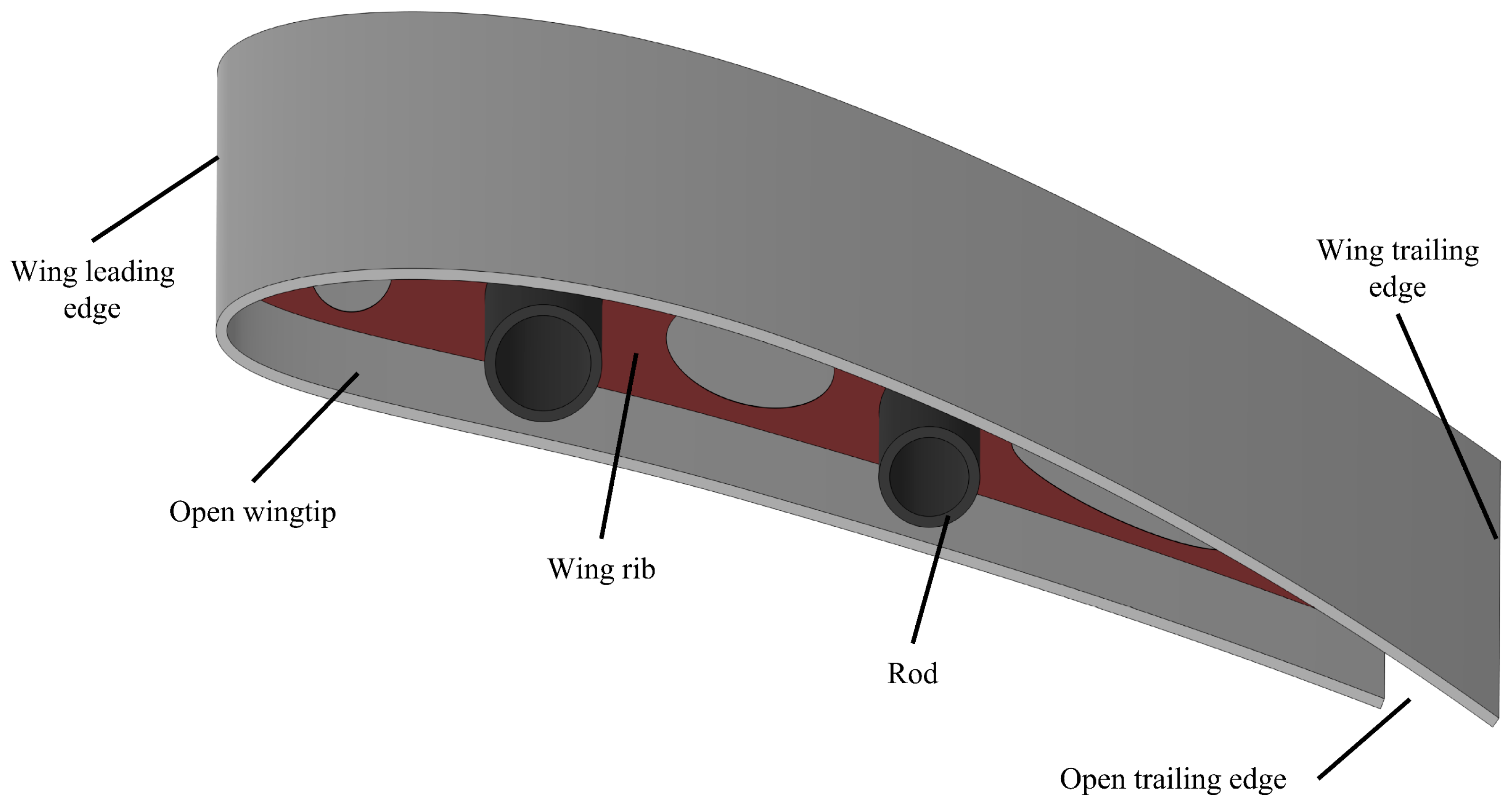

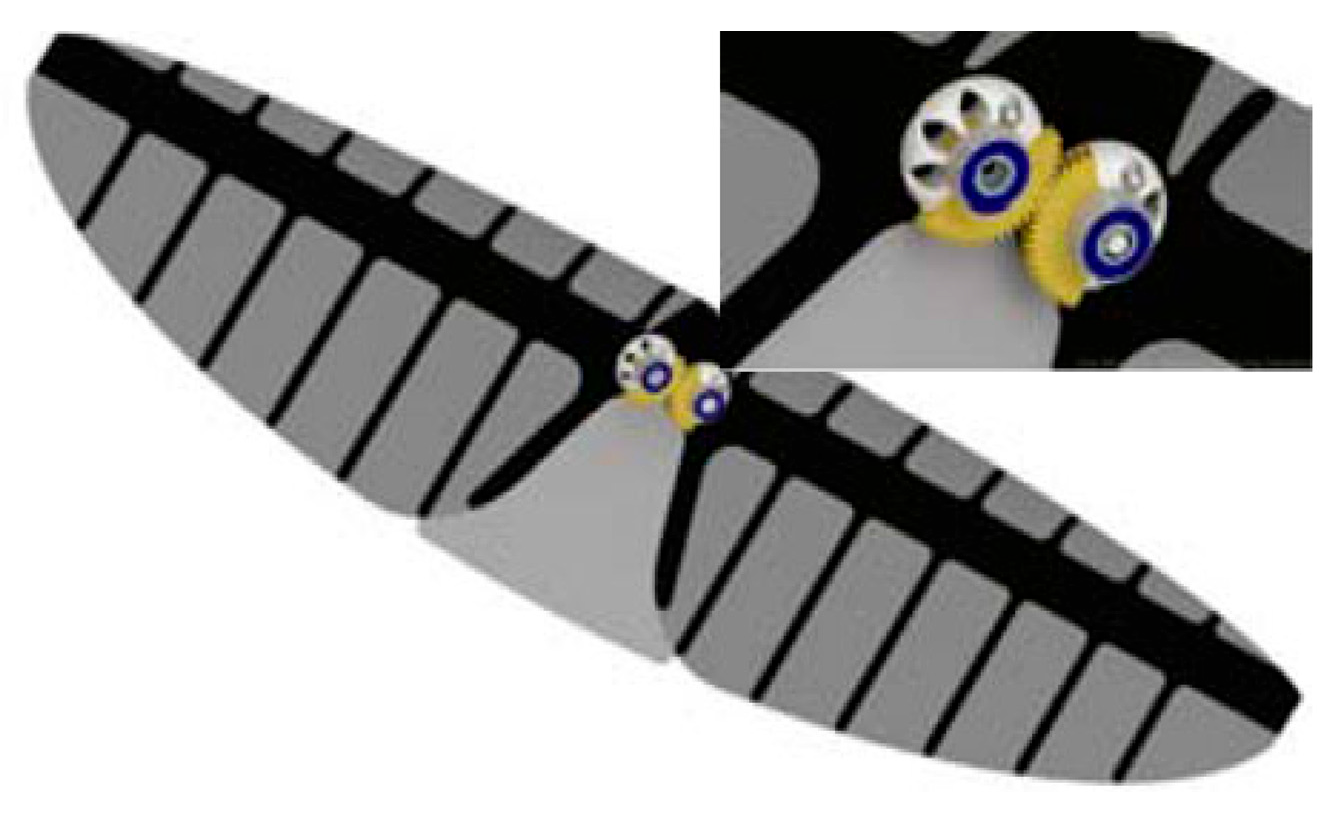

3.1.3. Deformable Wing System

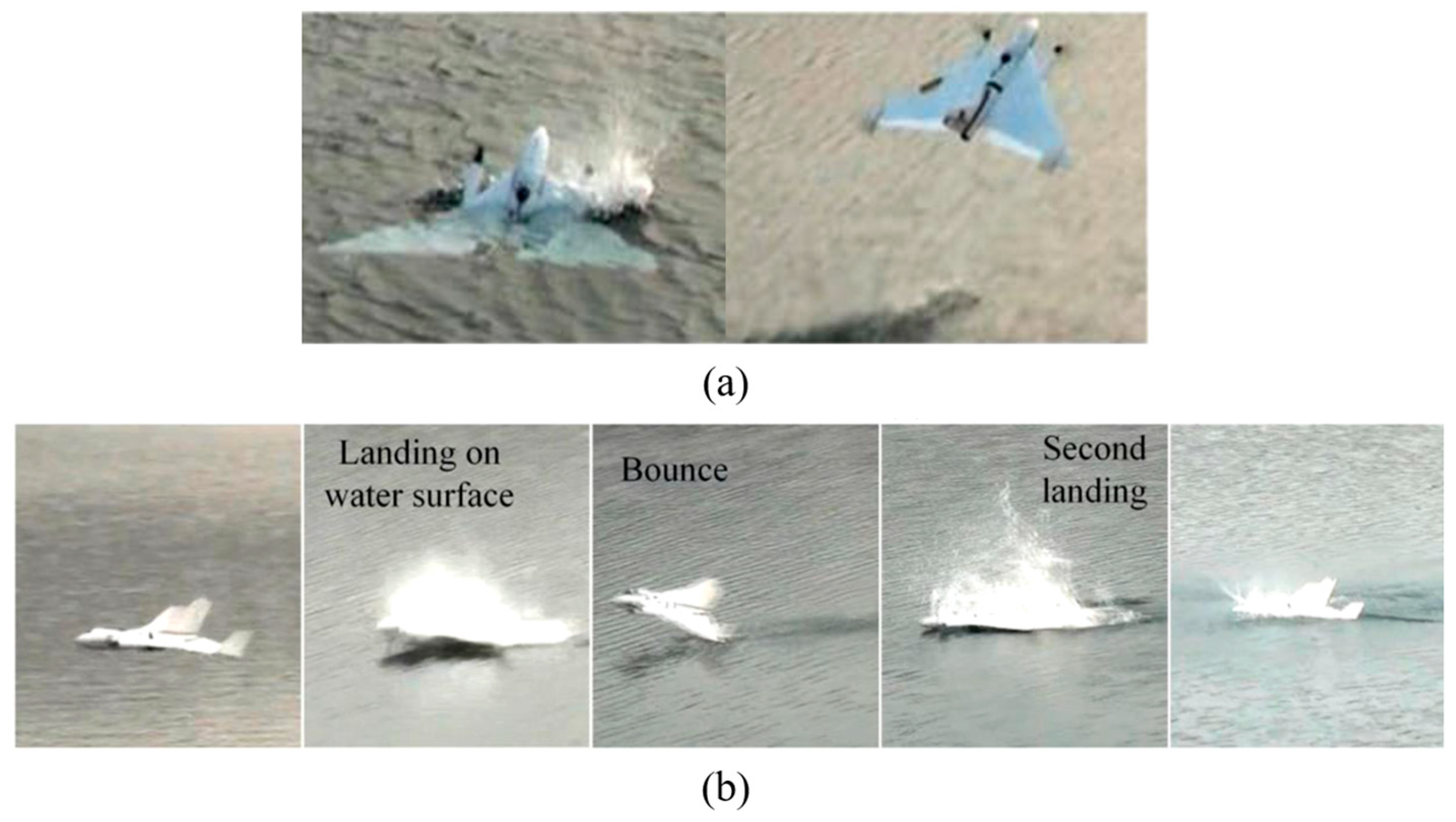

3.2. Water Entry and Exit

3.2.1. Water Entry and Exit Modes

3.2.2. Hydrodynamic Calculation

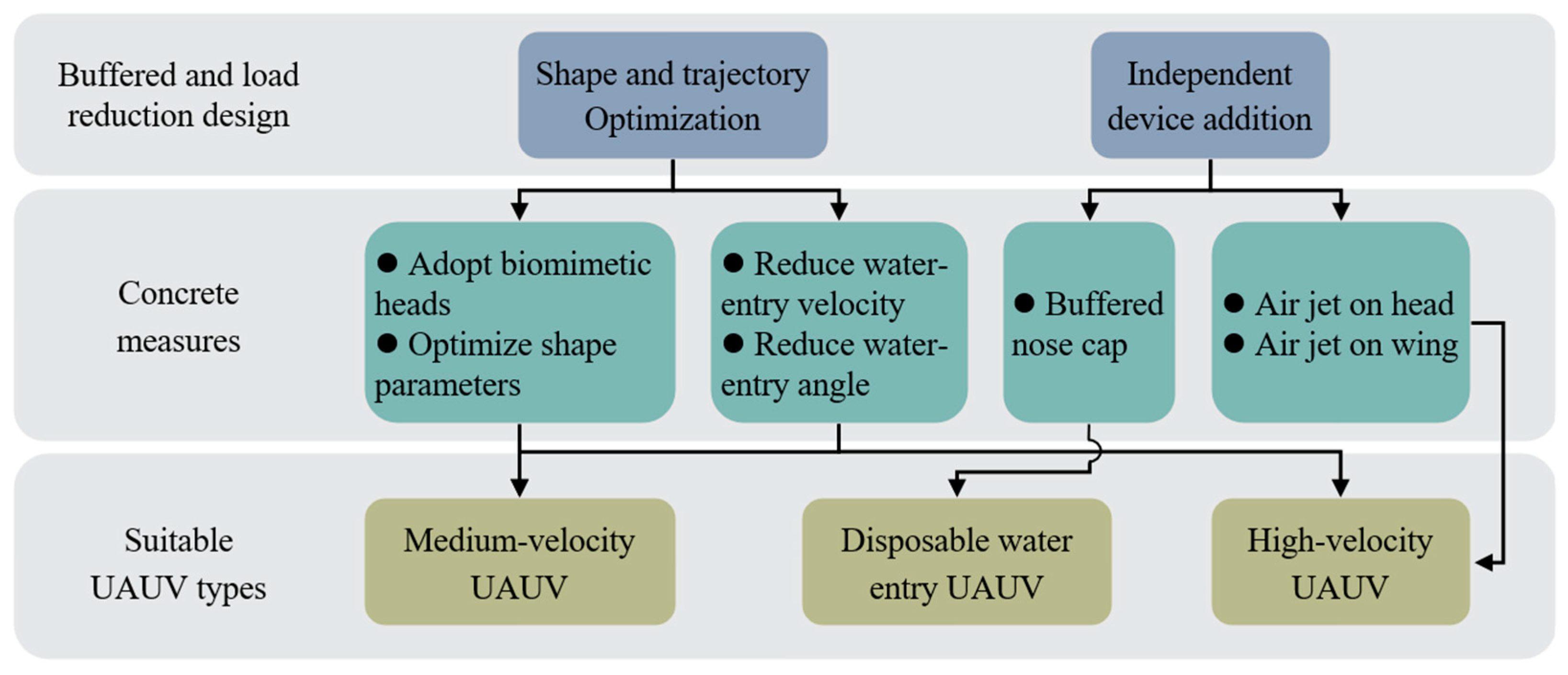

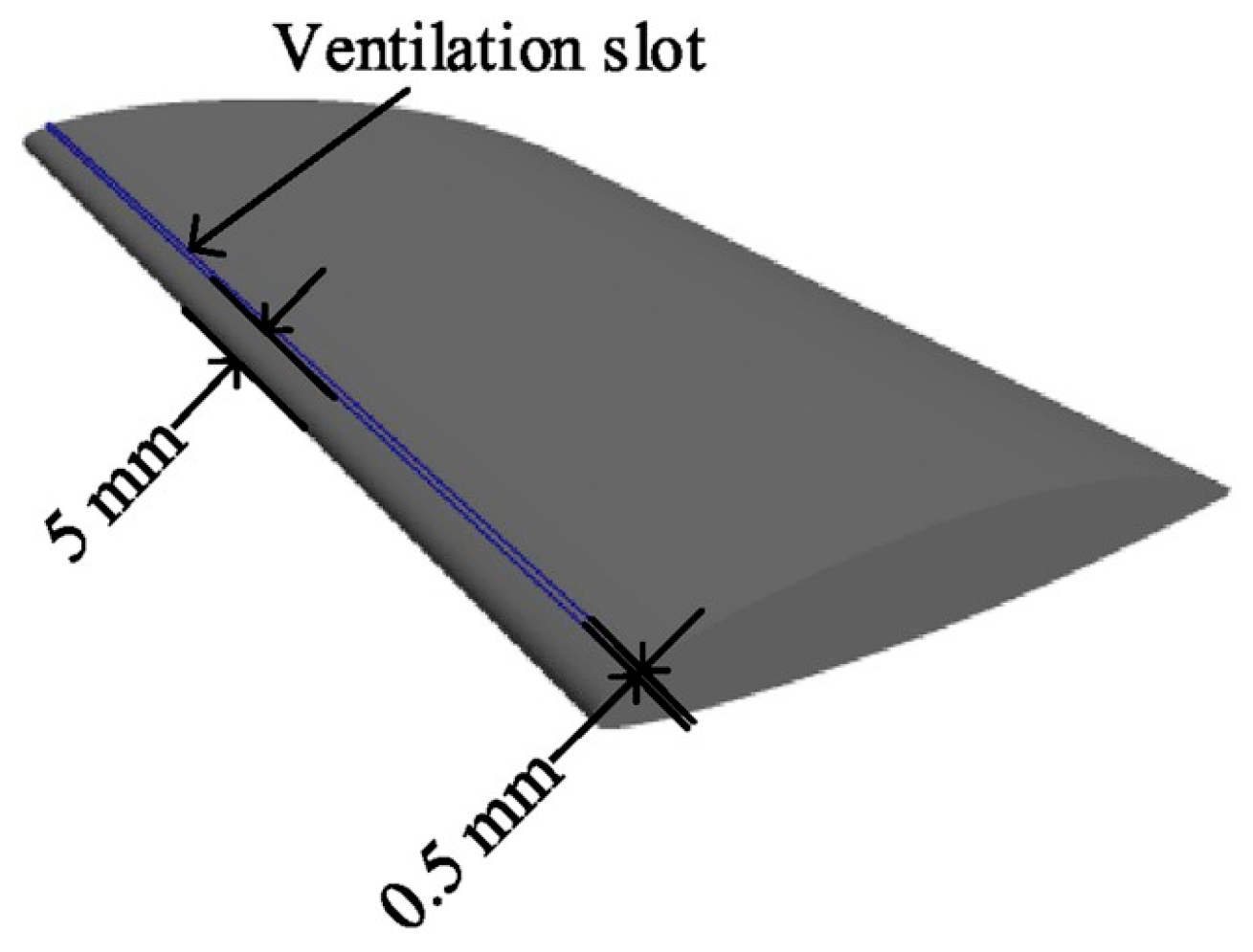

3.2.3. Buffered and Load Reduction Design

3.3. Propulsion and Power System

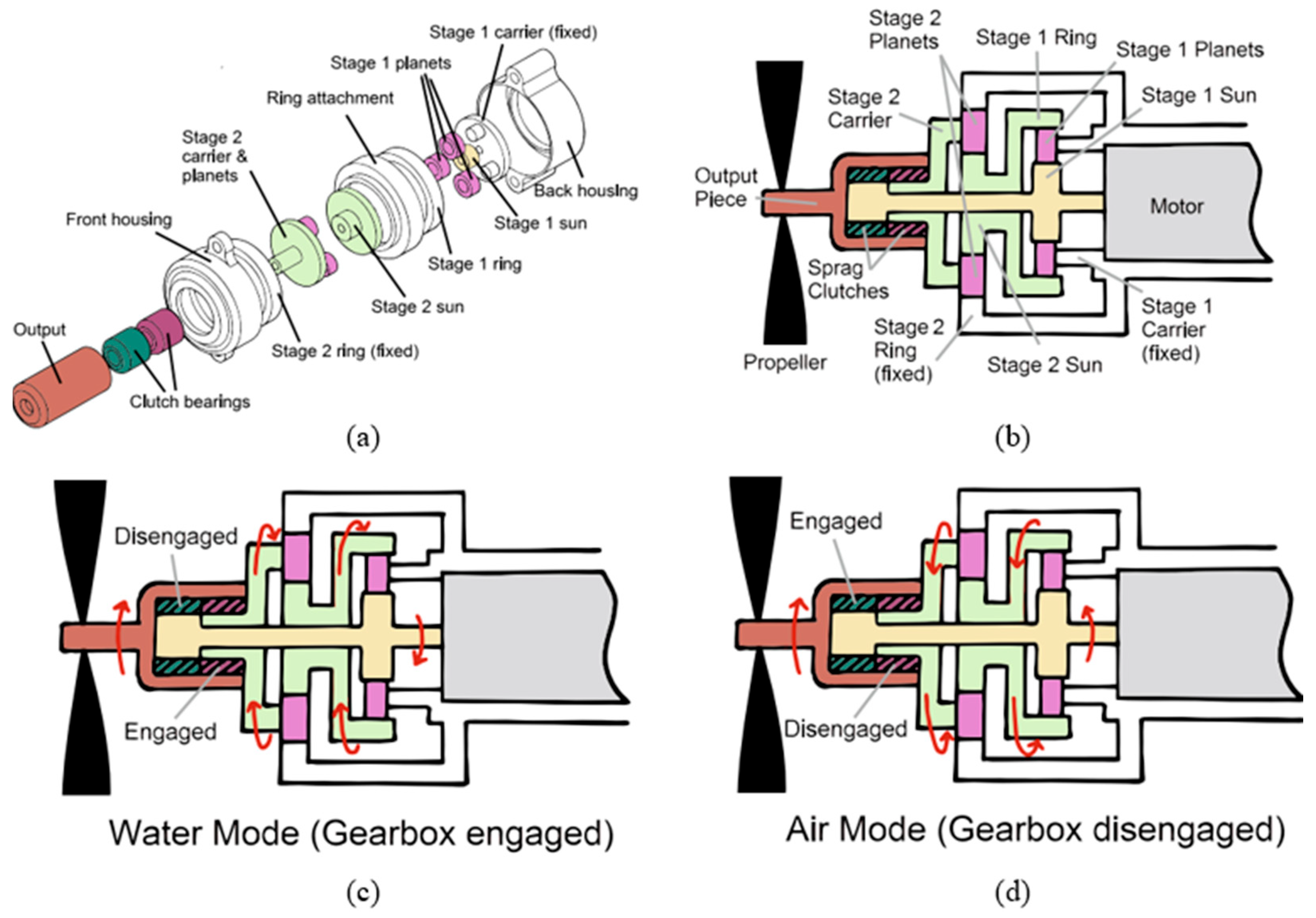

3.3.1. Propulsion

3.3.2. Hybrid Power System

3.4. Control Systems

3.4.1. Optimization of Underwater Controllers

3.4.2. Transition Controllers

3.4.3. Unified Control Frameworks

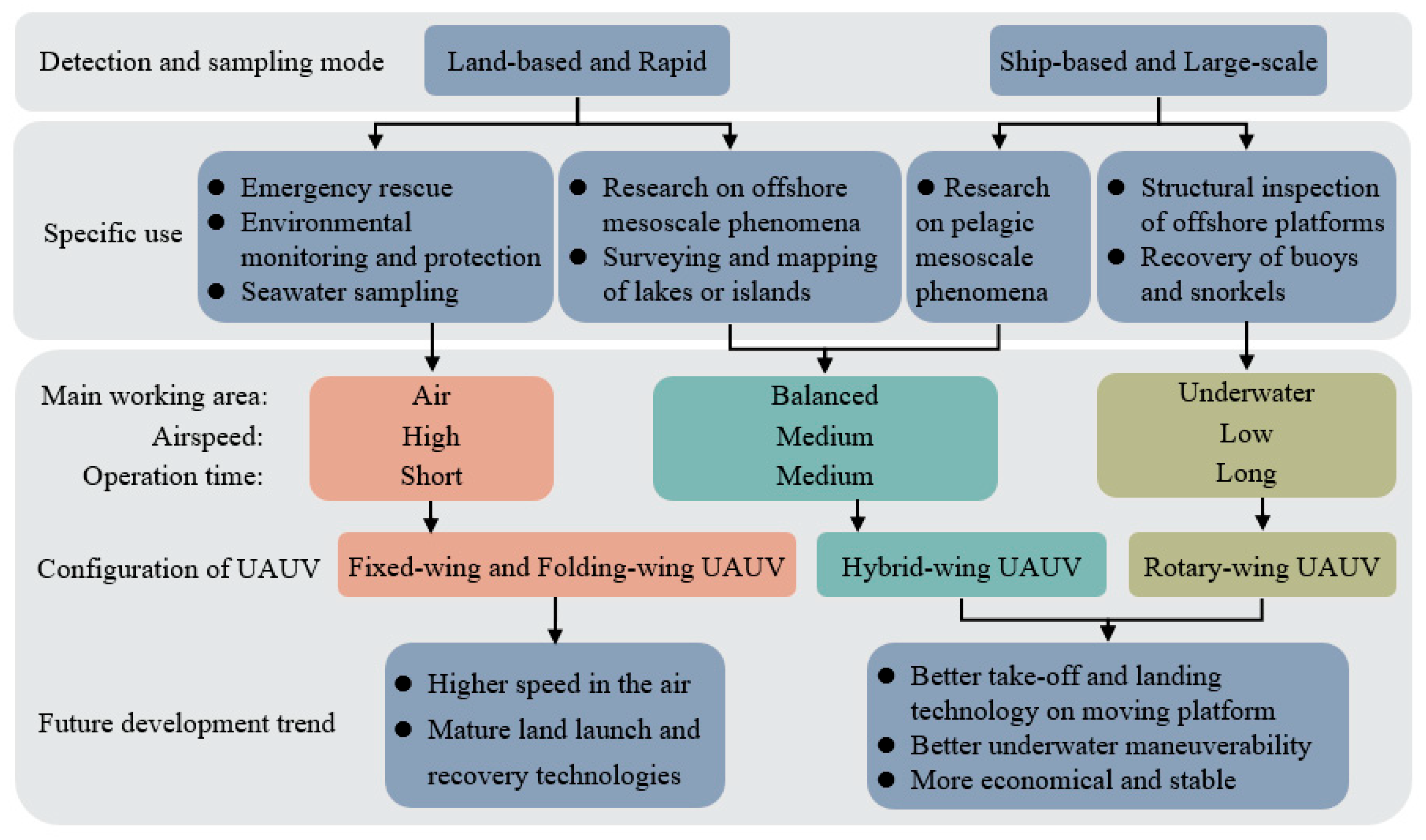

4. Application Prospect and Future Development Trend

4.1. Prospects for Civil Application

4.1.1. Rapid Detection and Sampling

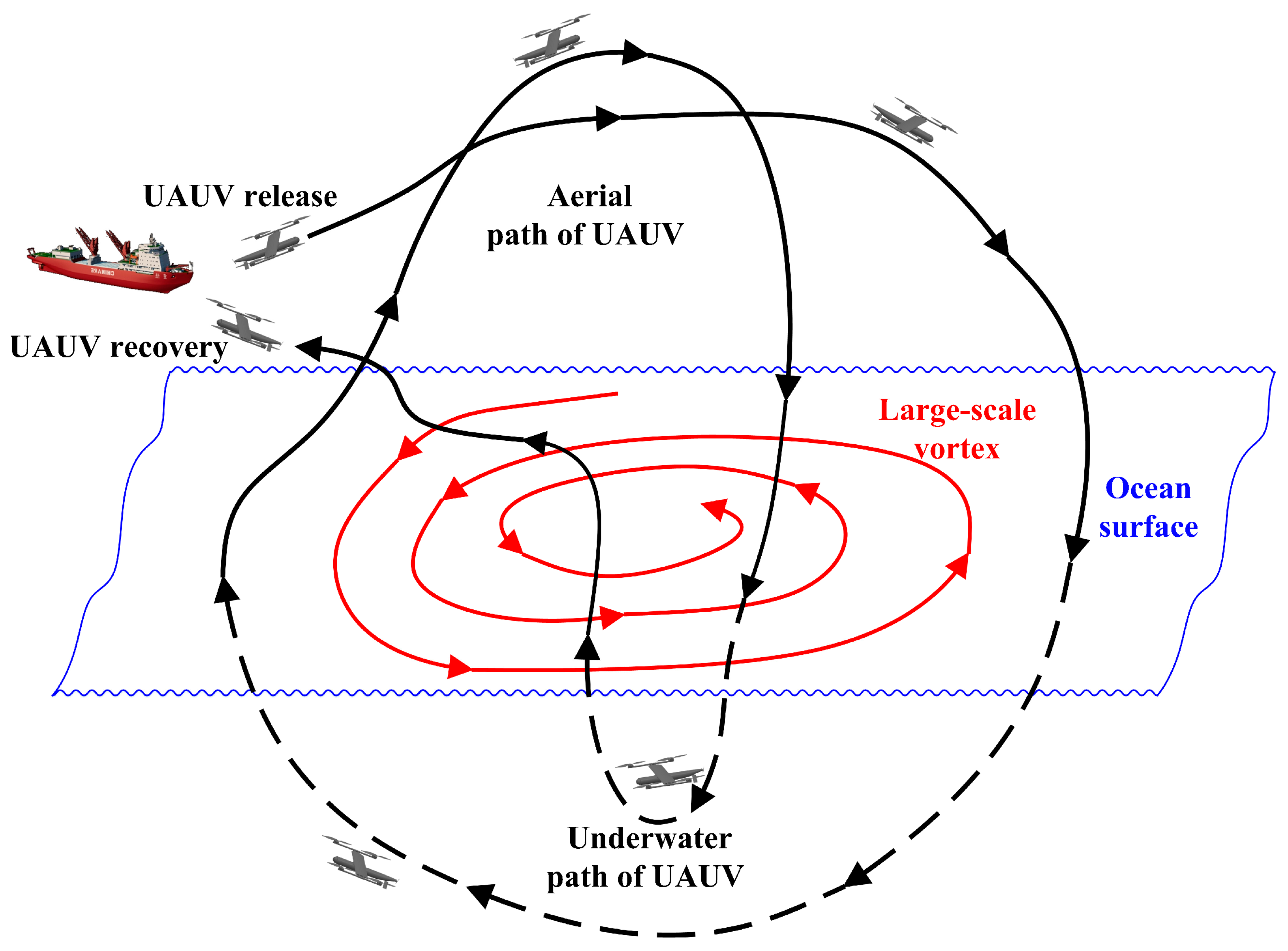

4.1.2. Large-Scale Detection and Sampling

4.2. Future Development

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Webster, P.J.; Lukas, R. TOGA COARE: The coupled ocean–atmosphere response experiment. Bull. Am. Meteorol. Soc. 1992, 73, 1377–1416. [Google Scholar] [CrossRef]

- Zhao, B.; Tang, J.; Lei, X.; Zhang, X.; Duan, W.; Li, H.; Gao, Z.; Qian, C.; Bao, X.; Luo, J.; et al. Progress on the experiment of a multi-platform collaborative field campaign on offshore typhoon. Adv. Earth Sci. 2022, 37, 771. [Google Scholar]

- Murphy, R.R.; Steimle, E.; Griffin, C.; Cullins, C.; Hall, M.; Pratt, K. Cooperative use of unmanned sea surface and micro aerial vehicles at Hurricane Wilma. J. Field Robot. 2008, 25, 164–180. [Google Scholar] [CrossRef]

- Tian, E.; Li, Y.; Ma, T.; Liao, Y.; Li, Y.; Cao, J. Design and experiment of a sea-air heterogeneous unmanned collaborative system for rapid inspection tasks at sea. Appl. Ocean Res. 2024, 143, 103856. [Google Scholar] [CrossRef]

- Moltmann, T.; Turton, J.; Zhang, H.M.; Nolan, G.; Gouldman, C.; Griesbauer, L.; Wills, Z.; Piniellan, A.; Barrell, S.; Zhang, Y.; et al. A global ocean observing system (GOOS), delivered through enhanced collaboration across regions, communities, and new technologies. Front. Mar. Sci. 2019, 6, 291. [Google Scholar] [CrossRef]

- Petrov, G. Flying submarine. J. Fleet 1995, 3, 52–53. [Google Scholar]

- Drews, P.L.J.; Neto, A.A.; Campos, M.F.M. A survey on aerial submersible vehicles. In Proceedings of the IEEE/OES Oceans Conference, Bremen, Germany, 11–14 May 2009. [Google Scholar]

- Handler, E.H. The flying submarine. Proceedings 1964, 4, 144–146. [Google Scholar]

- Donald, V.R. Flying Submarine. U.S. Patent 3092060 A, 4 April 1963. [Google Scholar]

- Reid, B.D. The Flying Submarine: The Story of the Invention of the Reid Flying Submarine, RFS-1; Heritage Books: Beverly Hills, CA, USA, 2012. [Google Scholar]

- He, Z.; Zheng, Z.S.; Ma, D.; Zhou, Q. Development of foreign trans-media aircraft and its enlightenment to China. Ship Sci. Technol. 2016, 38, 152–157. [Google Scholar]

- Van Blyenburgh, P. Unmanned aircraft systems: The current situation. In Proceedings of the Autonomous Surface Ships Symposium 2008, Quebec City, QC, Canada, 23–25 June 2008; Association Technique Maritime Aéronautique Ronautique: Paris, France, 2008; pp. 1–7. [Google Scholar]

- Yang, X.; Wang, T.; Liang, J.; Yao, G.; Liu, M. Survey on the novel hybrid aquatic–aerial amphibious aircraft: Aquatic unmanned aerial vehicle (AquaUAV). Prog. Aerosp. Sci. 2015, 74, 131–151. [Google Scholar] [CrossRef]

- Zufferey, R.; Siddall, R.; Armanini, S.F.; Kovac, M. Between Sea and Sky: Aerial Aquatic Locomotion in Miniature Robots; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Zeng, Z.; Lyu, C.; Bi, Y.; Jin, Y.; Lu, D.; Lian, L. Review of hybrid aerial underwater vehicle: Cross-domain mobility and transitions control. Ocean Eng. 2022, 248, 110840. [Google Scholar] [CrossRef]

- Yao, G.; Li, Y.; Zhang, H.; Jiang, Y.; Wang, T.; Sun, F.; Yang, X. Review of hybrid aquatic-aerial vehicle (HAAV): Classifications, current status, applications, challenges and technology perspectives. Prog. Aerosp. Sci. 2023, 139, 100902. [Google Scholar] [CrossRef]

- Zatout, M.S.; Rezoug, A.; Rezoug, A.; Baizid, K.; Iqbal, J. Optimisation of fuzzy logic quadrotor attitude controller–particle swarm, cuckoo search and BAT algorithms. Int. J. Syst. Sci. 2022, 53, 883–908. [Google Scholar] [CrossRef]

- Saleem, O.; Kazim, M.; Iqbal, J. Robust Position Control of VTOL UAVs Using a Linear Quadratic Rate-Varying Integral Tracker: Design and Validation. Drones 2025, 9, 73. [Google Scholar] [CrossRef]

- Saleem, O.; Tanveer, A.; Iqbal, J. Adaptive Reconfigurable Learning Algorithm for Robust Optimal Longitudinal Motion Control of Unmanned Aerial Vehicles. Algorithms 2025, 18, 180. [Google Scholar] [CrossRef]

- Yang, R.Q.; Sun, J.; Zhang, Y. Rapid Surveying and Mapping Based on the Digital Aerial Photographic System Mounted on Unmanned Aerial Vehicle. Remote Sens. Inf. 2010, 3, 4. [Google Scholar]

- Pérez-Ortiz, M.; Peña, J.M.; Gutiérrez, P.A.; Torres, J.; Hervas, C.; Lopez, F. Selecting patterns and features for between-and within-crop-row weed mapping using UAV-imagery. Expert Syst. Appl. 2016, 47, 85–94. [Google Scholar] [CrossRef]

- Schneider, W., Jr. Defense Science Board Study on Unmanned Aerial Vehicles and Uninhabited Combat Aerial Vehicles; Office of the Under Secretary of Defense: Washington, DC, USA, 2004. [Google Scholar]

- Baba, Y.; Takano, H.; Miyamoto, S.; Ono, K. Air combat guidance law for an UCAV. In Proceedings of the 1st UAV Conference, Portsmouth, VA, USA, 20–23 May 2002; p. 3427. [Google Scholar]

- Ruixuan, W.; Xueren, L. UAV System and Operational Use; National Defense Industrial Press: Beijing, China, 2009. [Google Scholar]

- Boccardo, P.; Chiabrando, F.; Dutto, F.; Giulio Tonolo, F.; Lingua, A. UAV deployment exercise for mapping purposes: Evaluation of emergency response applications. Sensors 2015, 15, 15717–15737. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Tao, P.; Liang, S.X.; Liang, W.L. Research on Application of UAV RS Techniques in Forest Inventories. J. Southwest For. Univ. 2011, 31, 49–53. [Google Scholar]

- Jin, W.; Ge, H.L.; Du, H.Q.; Xu, X.J. A Review on Unmanned Aerial Vehicle Remote Sensing and Its Application. Remote Sens. Inf. 2009, 1, 88–92. [Google Scholar]

- Zhao, P.; Shen, T.Z.; Shan, B.T. The Application of Remote Sensing System for Micro UAV Based on CMOS Image Sensor. Acta Photonica Sin. 2008, 37, 1657–1661. [Google Scholar]

- Liu, Q.Y.; Liu-Hua, X.U.; Shen, C.L.; Wang, L.P. Research on key technology of digital photogrammetry based on UAV remote sensing image. Sci. Surv. Mapp. 2010, 35, 28–30. [Google Scholar]

- Tang, M.W.; Dai, L.H.; Lin, C.H.; Wang, F.D.; Song, F.G. Application of Unmanned Aerial Vehicle in Inspecting Transmission Lines. Electr. Power 2013, 46, 35–38. [Google Scholar]

- Ping, J.T.K.; Ling, A.E.; Quan, T.J.; Dat, C.Y. Generic unmanned aerial vehicle (UAV) for civilian application—A feasibility assessment and market survey on civilian application for aerial imaging. In Proceedings of the 2012 IEEE Conference on Sustainable Utilization and Development in Engineering and Technology (Student), Kuala Lumpur, MY, USA, 6–9 October 2012; IEEE: New York, NY, USA, 2012; pp. 289–294. [Google Scholar]

- Chen, Y.; Lian, L.; Huang, H.C.; Yang, W.J.; Song, J.B. Fundamentals of Marine Technology; China Ocean Press: Beijing, China, 2018. [Google Scholar]

- Woods Hole Oceanographic Institution. HOV Deep Sea Challenger. Available online: http://www.whoi.edu/main/deepseachallenger (accessed on 14 April 2025).

- Zha, J.; Thacher, E.; Kroeger, J.; Taylor, C.N.; Duraisamy, K. Towards breaching a still water surface with a miniature unmanned aerial underwater vehicle. In Proceedings of the 2019 International Conference on Unmanned Aircraft Systems (ICUAS), Atlanta, GA, USA, 11–14 June 2019; IEEE: New York, NY, USA, 2019; pp. 1178–1185. [Google Scholar]

- Hopkins University Applied Physics Laboratory. New UAV Can Launch from Underwater for Aerial Missions. 2016. Available online: https://www.jhuapl.edu/PressRelease/160317#addsearch=cracuns (accessed on 14 April 2025).

- Chen, Q.; Zhu, D.; Liu, Z. Attitude control of aerial and underwater vehicles using single-input FUZZY P+ ID controller. Appl. Ocean Res. 2021, 107, 102460. [Google Scholar] [CrossRef]

- Bershadsky, D.; Haviland, S.; Valdez, P.E.; Saldanha, N. Design considerations of submersible unmanned flying vehicle for communications and underwater sampling. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016; IEEE: New York, NY, USA, 2016; pp. 1–8. [Google Scholar]

- Alzu’bi, H.; Mansour, I.; Rawashdeh, O. Loon copter: Implementation of a hybrid unmanned aquatic–aerial quadcopter with active buoyancy control. J. Field Robot. 2018, 35, 764–778. [Google Scholar] [CrossRef]

- Bai, Y.; Jin, Y.; Liu, C.; Zeng, Z.; Lian, L. Nezha-F: Design and Analysis of a Foldable and Self-Deployable HAUV. IEEE Robot. Autom. Lett. 2023, 8, 2309–2316. [Google Scholar] [CrossRef]

- Li, L.; Wang, S.; Zhang, Y.; Wainwright, D.K.; Kenaley, C.P.; Gong, Z.; Liu, Z.; Liu, H.; Guan, J.; Wang, T.; et al. Aerial-aquatic robots capable of crossing the air-water boundary and hitchhiking on surfaces. Sci. Robot. 2022, 7, eabm6695. [Google Scholar] [CrossRef] [PubMed]

- Horn, A.C.; Pinheiro, P.M.; Silva, C.B.; Souto, H.T.; Santos, R.L. A study on configuration of propellers for multirotor-like hybrid aerial-aquatic vehicles. In Proceedings of the 2019 19th International Conference on Advanced Robotics (ICAR), Belo Horizonte, Brazil, 2–6 December 2019; IEEE: New York, NY, USA, 2019; pp. 173–178. [Google Scholar]

- Mercado, D.; Maia, M.; Diez, F.J. Aerial-underwater systems, a new paradigm in unmanned vehicles. J. Intell. Robot. Syst. 2019, 95, 229–238. [Google Scholar] [CrossRef]

- Chen, G.; Liu, A.; Hu, J.; Feng, J.; Ma, Z. Attitude and altitude control of unmanned aerial-underwater vehicle based on incremental nonlinear dynamic inversion. IEEE Access 2020, 8, 156129–156138. [Google Scholar] [CrossRef]

- Tan, Y.H.; Chen, B.M. A morphable aerial-aquatic quadrotor with coupled symmetric thrust vectoring. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Virtual, 31 May–31 August 2020; IEEE: New York, NY, USA, 2020; pp. 2223–2229. [Google Scholar]

- Chen, Y.; Liu, Y.; Meng, Y.; Sun, W.; Liu, Y. System modeling and simulation of an unmanned aerial underwater vehicle. J. Mar. Sci. Eng. 2019, 7, 444. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Huo, J.; Zhang, Y.; Han, J. Analysis of the hydrodynamic performance of a water-air amphibious trans-medium hexacopter. In Proceedings of the 2020 Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020; IEEE: New York, NY, USA, 2020; pp. 4959–4964. [Google Scholar]

- Weisler, W.; Stewart, W.; Anderson, M.B.; Looft, F.J. Testing and characterization of a fixed wing cross-domain unmanned vehicle operating in aerial and underwater environments. IEEE J. Ocean. Eng. 2018, 43, 969–982. [Google Scholar] [CrossRef]

- Peloquin, R.A.; Thibault, D.; Desbiens, A.L. Design of a passive vertical takeoff and landing aquatic UAV. IEEE Robot. Autom. Lett. 2016, 2, 381–388. [Google Scholar] [CrossRef]

- Moore, J.; Fein, A.; Setzler, W. Design and analysis of a fixed-wing unmanned aerial-aquatic vehicle. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; IEEE: New York, NY, USA, 2018; pp. 1236–1243. [Google Scholar]

- Zufferey, R.; Ancel, A.O.; Farinha, A.; Siddall, R.; Armanini, S.F.; Nasr, M.; Kovac, M. Consecutive aquatic jump-gliding with water-reactive fuel. Sci. Robot. 2019, 4, eaax7330. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Teng, Y.; Meng, X.; Yao, B.; Lian, L. Lifting-principle-based design and implementation of fixed-wing unmanned aerial-underwater vehicle. J. Field Robot. 2022, 39, 694–711. [Google Scholar] [CrossRef]

- Gao, A.; Techet, A.H. Design considerations for a robotic flying fish. In Proceedings of the OCEANS’11 MTS/IEEE KONA, Kona, HI, USA, 19–22 September 2011; IEEE: New York, NY, USA, 2011; pp. 1–8. [Google Scholar]

- Geder, J.D.; Ramamurti, R.; Edwards, D.; Young, T.; Pruessner, M. Swimming performance of a hybrid unmanned air-underwater vehicle. In Proceedings of the OCEANS 2016 MTS/IEEE Monterey, Monterey, CA, USA, 19–23 September 2016; IEEE: New York, NY, USA, 2016; pp. 1–5. [Google Scholar]

- Bao, Y.C. Combinatorial Biomimetic Design of Fluid Dynamic Shape and Analysis of Aerodynamic Characteristics for Cross-Media UAV. Ph.D. Thesis, Jilin University, Changchun, China, 2019. [Google Scholar]

- Yun, Z.; Wen, M.; Luo, Z.R.; Chen, L. Design and plunge-diving analysis of underwater-aerial transmedia vehicle of bionic kingfisher. J. Zhejiang Univ. (Eng. Sci.) 2020, 2, 9. [Google Scholar]

- Liu, W. The Diving Plane Design and the Aerodynamic Shape Structural Design and Analysis. Ph.D. Thesis, Nanchang Hangkong University, Nanchang, China, 2012. [Google Scholar]

- Yao, G.; Liang, J.; Wang, T.; Yang, X.; Liu, M.; Zhang, Y. Submersible unmanned flying boat: Design and experiment. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO 2014), Bali, Indonesia, 5–10 December 2014; IEEE: New York, NY, USA, 2014; pp. 1308–1313. [Google Scholar]

- Fabian, A.; Feng, Y.; Swartz, E.; Thurmer, D.; Wang, R. Hybrid Aerial Underwater Vehicle (MIT Lincoln Lab). 2012. Available online: https://phoenixfiles.olin.edu/do/23bf82e5-0d2c-471c-a8d2-62a51d619b16 (accessed on 14 April 2025).

- Yang, X.; Wang, T.; Liang, J.; Yao, G.; Zhao, W. Submersible unmanned aerial vehicle concept design study. In Proceedings of the 2013 Aviation Technology, Integration, and Operations Conference, Los Angeles, CA, USA, 12–14 August 2013; p. 4422. [Google Scholar]

- Siddall, R.; Ortega Ancel, A.; Kovač, M. Wind and water tunnel testing of a morphing aquatic micro air vehicle. Interface Focus 2017, 7, 20160085. [Google Scholar] [CrossRef]

- Siddall, R.; Kovac, M. Fast aquatic escape with a jet thruster. IEEE/ASME Trans. Mechatron. 2017, 22, 217–226. [Google Scholar] [CrossRef]

- Rockenbauer, F.M.; Jeger, S.; Beltran, L.; Berger, M.; Harms, M.; Kaufmann, N.; Rauch, M.; Reinders, M.; Lawrance, N.; Stastny, T.; et al. Dipper: A Dynamically Transitioning Aerial-Aquatic Unmanned Vehicle. In Robotics: Science and Systems; RSS Foundation: Los Angeles, CA, USA, 2021; pp. 12–16. [Google Scholar]

- Zhang, J.Q.; Feng, J.F.; Xie, Q.F.; Hu, J.H.; Xu, H. Research on concept of conformal semi-ring wing configuration for water-air medium voyage. Acta Aerodyn. Sin. 2012, 30, 685–691. [Google Scholar]

- Feng, X.S.; Li, S. Recent Scientific and Technological Progresses in Marine Robotics; Science Press: Beijing, China, 2020. [Google Scholar]

- Lyu, C.; Lu, D.; Xiong, C.; Hu, R.; Jin, Y.; Wang, J.; Zeng, Z.; Lian, L. Toward a gliding hybrid aerial underwater vehicle: Design, fabrication, and experiments. J. Field Robot. 2022, 39, 543–556. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Helbling, E.F.; Jafferis, N.T.; Zufferey, R.; Ong, A.; Wood, R.J. A biologically inspired, flapping-wing, hybrid aerial-aquatic microrobot. Sci. Robot. 2017, 2, eaao5619. [Google Scholar] [CrossRef] [PubMed]

- Izraelevitz, J.S.; Triantafyllou, M.S. A novel degree of freedom in flapping wings shows promise for a dual aerial/aquatic vehicle propulsor. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; IEEE: New York, NY, USA, 2015; pp. 5830–5837. [Google Scholar]

- Alzu’bi, H.; Akinsanya, O.; Kaja, N.; Waller, C. Evaluation of an aerial quadcopter power-plant for underwater operation. In Proceedings of the 2015 10th International Symposium on Mechatronics and its Applications (ISMA), Sharjah, United Arab Emirates, 8–10 December 2015; IEEE: New York, NY, USA, 2015; pp. 1–4. [Google Scholar]

- Lv, X.P. Overall Design of a Cross Domain Vehicle. CN Patent 116353265 A, 30 June 2023. [Google Scholar]

- Feng, D. Trans-Media Unmanned Aerial Vehicle Device and Control Method Thereof. US Patent 2024/0017854 A1, 18 January 2024. [Google Scholar]

- Wang, Y.; Yang, X.; Chen, Y.; Wainwright, D.K.; Kenaley, C.P.; Gong, Z.; Liu, Z.; Liu, H.; Guan, J.; Wang, T.; et al. A biorobotic adhesive disc for underwater hitchhiking inspired by the remora suckerfish. Sci. Robot. 2017, 2, eaan8072. [Google Scholar] [CrossRef]

- Qi, H.; Hu, S.; Zhang, J.; Wu, G. Review of Hybrid Aerial Underwater Vehicle: Potential Applications in the Field of Underwater Marine Optics. Drones 2025, 9, 667. [Google Scholar] [CrossRef]

- Ma, Z.; Chen, D.; Li, G.; Jing, X.; Xiao, S. Configuration design and trans-media control status of the hybrid aerial underwater vehicles. Appl. Sci. 2022, 12, 765. [Google Scholar] [CrossRef]

- Drews, P.L.J.; Neto, A.A.; Campos, M.F.M. Hybrid unmanned aerial underwater vehicle: Modeling and simulation. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; IEEE: New York, NY, USA, 2014; pp. 4637–4642. [Google Scholar]

- da Rosa, R.T.S.; Evald, P.J.D.O.; Drews, P.L.J.; de Oliveira, G.H.F.; Rosito, J.W. A comparative study on sigma-point kalman filters for trajectory estimation of hybrid aerial-aquatic vehicles. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; IEEE: New York, NY, USA, 2018; pp. 7460–7465. [Google Scholar]

- Maia, M.M.; Mercado, D.A.; Diez, F.J. Design and implementation of multirotor aerial-underwater vehicles with experimental results. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: New York, NY, USA, 2017; pp. 961–966. [Google Scholar]

- Villegas, A.; Mishkevich, V.; Gulak, Y.; Ahmed, A. Analysis of key elements to evaluate the performance of a multirotor unmanned aerial-aquatic vehicle. Aerosp. Sci. Technol. 2017, 70, 412–418. [Google Scholar] [CrossRef]

- Ji, D. Underwater and Aerial Vehicle. US Patent 2022/0314218 A1, 6 October 2022. [Google Scholar]

- Stewart, W.; Weisler, W.; Anderson, M.B.; Looft, F.J. Dynamic modeling of passively draining structures for aerial–aquatic unmanned vehicles. IEEE J. Ocean. Eng. 2019, 44, 840–850. [Google Scholar] [CrossRef]

- Macleod, M.; Bryant, M. Dynamic modeling, analysis, and testing of a variable buoyancy system for unmanned multidomain vehicles. IEEE J. Ocean. Eng. 2017, 42, 511–521. [Google Scholar] [CrossRef]

- Stewart, W.J. Passive Floodable Wing Development for Hybrid Aerial-Aquatic Vehicles. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2018. [Google Scholar]

- Stewart, W.; Weisler, W.; MacLeod, M.; Anderson, M.B. Design and demonstration of a seabird-inspired fixed-wing hybrid UAV-AUV system. Bioinspir. Biomim. 2018, 13, 056013. [Google Scholar] [CrossRef]

- Yahya, H.Z. Hybrid Aquatic Unmanned Aerial and Submersible Vehicle. US Patent 2022/0097812 A1, 31 March 2022. [Google Scholar]

- Yang, X.; Liang, J.; Wang, T.; Yao, G.; Zhao, W.; Zhang, Y.; Han, C. Computational simulation of a submersible unmanned aerial vehicle impacting with water. In Proceedings of the 2013 IEEE International Conference on Robotics and Biomimetics (ROBIO), Shenzhen, China, 12–14 December 2013; IEEE: New York, NY, USA, 2013; pp. 1138–1143. [Google Scholar]

- Liang, J.; Yang, X.; Wang, T.; Yao, G.; Zhao, W. Design and experiment of a bionic gannet for plunge-diving. J. Bionic Eng. 2013, 10, 282–291. [Google Scholar] [CrossRef]

- Liang, J.H.; Yao, G.C.; Wang, T.M.; Yang, X.; Zhao, W.; Song, G.; Zhang, Y. Wing load investigation of the plunge-diving locomotion of a gannet Morus inspired submersible aircraft. Sci. China Technol. Sci. 2014, 57, 390–402. [Google Scholar] [CrossRef]

- Qi, D.; Feng, J.F.; Li, Y.L. Anti-ship weapon with capability of water to air. Aerodyn. Missile J. 2014, 11, 4. [Google Scholar]

- Ma, K.Y.; Chirarattananon, P.; Fuller, S.B.; Wood, R.J. Controlled flight of a biologically inspired, insect-scale robot. Science 2013, 340, 603–607. [Google Scholar] [CrossRef]

- Chen, Y.; Helbling, E.F.; Gravish, N.; Ma, K.; Wood, R.J. Hybrid aerial and aquatic locomotion in an at-scale robotic insect. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; IEEE: New York, NY, USA, 2015; pp. 331–338. [Google Scholar]

- Yang, X.; Liang, J.; Li, Y.; Zhang, H.; Xiao, H. Modeling and analysis of variable buoyancy device imitating waterfowl plumage structure. In Proceedings of the International Offshore and Polar Engineering Conference, Rhodes, Greece, 16–21 June 2011; pp. 230–234. [Google Scholar]

- Yokozeki, T.; Takeda, S.I.; Ogasawara, T.; Ishikawa, T. Mechanical properties of corrugated composites for candidate materials of flexible wing structures. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1578–1586. [Google Scholar] [CrossRef]

- Zhu, L.; Sun, G.; Li, H.; Dong, M. Intelligent and flexible morphing wing technology: A review. J. Mech. Eng. 2018, 54, 28–42. [Google Scholar] [CrossRef]

- Ahmad, D.; Parancheerivilakkathil, M.S.; Kumar, A.; Goswami, M.; Ajaj, R.M.; Patra, K.; Jawaid, M.; Volokh, K.; Zweiri, Y. Recent developments of polymer-based skins for morphing wing applications. Polym. Test. 2024, 135, 108463. [Google Scholar] [CrossRef]

- Bowman, J.; Sanders, B.; Cannon, B.; Kudva, J.; Joshi, S.; Weisshaar, T. Development of next generation morphing aircraft structures. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Waikiki, HI, USA, 23–26 April 2007; p. 1730. [Google Scholar]

- Zhang, X.; Kang, X.; Li, B. Development and investigation for rigid-flexible coupling dynamic performances of the morphing wing with clearance joints. Mech. Syst. Signal Process. 2025, 223, 111871. [Google Scholar] [CrossRef]

- Iafrati, A.; Korobkin, A.A. Initial stage of flat plate impact onto liquid free surface. Phys. Fluids 2004, 16, 2214–2227. [Google Scholar] [CrossRef]

- Gaudet, S. Numerical simulation of circular disks entering the free surface of a fluid. Phys. Fluids 1998, 10, 2489–2499. [Google Scholar] [CrossRef]

- Truscott, T.T.; Epps, B.P.; Techet, A.H. Unsteady forces on spheres during free-surface water entry. J. Fluid Mech. 2012, 704, 173–210. [Google Scholar] [CrossRef]

- Gilbarg, D.; Anderson, R.A. Influence of atmospheric pressure on the phenomena accompanying the entry of spheres into water. J. Appl. Phys. 1948, 19, 127–139. [Google Scholar] [CrossRef]

- May, A. Effect of surface condition of a sphere on its water-entry cavity. J. Appl. Phys. 1951, 22, 1219–1222. [Google Scholar] [CrossRef]

- Truscott, T.T.; Techet, A.H. A spin on cavity formation during water entry of hydrophobic and hydrophilic spheres. Phys. Fluids 2009, 21, 180. [Google Scholar] [CrossRef]

- Sun, T.; Zhou, L.; Yin, Z.; Zong, Z. Cavitation bubble dynamics and structural loads of high-speed water entry of a cylinder using fluid-structure interaction method. Appl. Ocean Res. 2020, 101, 102285. [Google Scholar] [CrossRef]

- Geers, T.L. A boundary-element method for slamming analysis. J. Ship Res. 1982, 26, 117–124. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Qian, Q.; Wang, S.; Liu, Z.H.; Zhu, D.S. Fluid-structure impact analysis with a mixed method of arbitrary Lagrangian-Eulerian BE and FE. Acta Mech. Solida Sin. 1993, 6, 365–376. [Google Scholar]

- Nguyen, V.-T.; Vu, D.-T.; Park, W.-G.; Jung, C.M. Navier-Stokes solver for water entry bodies with moving Chimera grid method in 6DOF motions. Comput. Fluids 2016, 140, 19–38. [Google Scholar] [CrossRef]

- Tassin, A.; Korobkin, A.A.; Cooker, M.J. On analytical models of vertical water entry of a symmetric body with separation and cavity initiation. Appl. Ocean Res. 2014, 48, 33–41. [Google Scholar] [CrossRef]

- Zhao, R.; Faltinsen, O. Water entry of two-dimensional bodies. J. Fluid Mech. 1993, 246, 593–612. [Google Scholar] [CrossRef]

- Hughes, O.F. Solution of the wedge entry problem by numerical conformal mapping. J. Fluid Mech. 1972, 56, 173–192. [Google Scholar] [CrossRef]

- Jalalisendi, M.; Porfiri, M. Water entry of compliant slender bodies: Theory and experiments. Int. J. Mech. Sci. 2018, 149, 514–529. [Google Scholar] [CrossRef]

- Moran, J.P. On the Hydrodynamic Theory of Water-Exit and-Entry; Therm Advanced Research, Inc.: Ithaca, NY, USA, 1965. [Google Scholar]

- Bodily, K.G.; Carlson, S.J.; Truscott, T.T. The water entry of slender axisymmetric bodies. Phys. Fluids 2014, 26, 072108. [Google Scholar] [CrossRef]

- Shi, H.H.; Itoh, M.; Takami, T. Optical observation of the supercavitation induced by high-speed water entry. J. Fluids Eng. 2000, 122, 806–810. [Google Scholar] [CrossRef]

- May, A. Vertical entry of missiles into water. J. Appl. Phys. 1952, 23, 1362–1372. [Google Scholar] [CrossRef]

- Lee, M.; Longoria, R.G.; Wilson, D.E. Cavity dynamics in high-speed water entry. Phys. Fluids 1997, 9, 540–550. [Google Scholar] [CrossRef]

- Bin, J.; Huaiyu, C.; Biao, H.; Luo, X.; Peng, X.; Long, X. Research progresses and prospects of unsteady hydrodynamics characteristics for cavitation. Adv. Mech. 2019, 49, 201906. [Google Scholar]

- Guo, Z.; Zhang, W.; Wang, C. Experimental and theoretical study on the high-speed horizontal water entry behaviors of cylindrical projectiles. J. Hydrodyn. 2012, 24, 217–225. [Google Scholar] [CrossRef]

- Bi, Y.; Jin, Y.; Zhou, H.; Bai, Y.; Lyu, C.; Zeng, Z.; Lian, L. Surfing Algorithm: Agile and Safe Transition Strategy for Hybrid Aerial Underwater Vehicle in Waves. IEEE Trans. Robot. 2023, 39, 4262–4278. [Google Scholar] [CrossRef]

- Jiang, Y.; Lu, Y.; Cai, Y.Z.; Wang, H.; Zhao, Y. Modeling of cross-media process for submersible unmanned flying vehicle. In Proceedings of the 37th Chinese Control Conference, Wuhan, China, 25–27 July 2018; pp. 1637–1642. [Google Scholar]

- Shi, H.H.; Zhou, D.; Wen, J.S.; Jia, H.X. Fluid-solid interaction simulation of elastic cylindrical shell penetrating water based on the ALE method. J. Mech. 2020, 32, 9–14. [Google Scholar]

- Liu, D.K. Research on Load-Reducing Characteristics of Water-Entry Vehicle with Large Scale and High Speed. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2020. [Google Scholar]

- Wang, T.M.; Yang, X.B.; Liang, J.H.; Yao, G.C.; Zhao, W.D. CFD based investigation on the impact acceleration when a gannet impacts with water during plunge diving. Bioinspir. Biomim. 2013, 8, 036006. [Google Scholar] [CrossRef]

- Li, Y.L.; Feng, J.F.; Qi, D.; Liu, X. Movement rule of a vehicle obliquely water-entry at low speed. J. Beijing Univ. Aeronaut. Astronaut. 2016, 42, 2698–2708. [Google Scholar]

- Yu, Z.J.; Feng, J.F.; Hu, J.H.; Zhang, J.L.; Zhang, T. Modeling for Water-Air Crossing Vehicle’s Water-Exit Motion. Comput. Simul. 2015, 32, 101–105. [Google Scholar]

- Li, Y.G.; Wang, C.; Wu, Y.Y.; Zhao, Y.; Liu, J. On the motion characteristics of cavity wall in the high-speed water entry of trans-media vehicle. Acta Armamentarii 2022, 43, 574–585. [Google Scholar]

- Wang, Y.W.; Huang, C.G.; Du, T.Z.; Yao, W.D. Numerical simulation of a submerged body exiting from water with an attack angle. Chin. J. Hydrodyn. 2011, 26, 48–57. [Google Scholar]

- Kirschner, I.N.; Rosenthal, B.J.; Uhlman, J.S. Simplified dynamical systems analysis of supercavitating high-speed bodies. In Proceedings of the 5th International Symposium on Cavitation, Osaka, Japan, 1–4 November 2003; Paper No. Cav03-OS-7-005 2003. pp. 1–8. [Google Scholar]

- Yuan, X.; Zhu, Z. Influence of preset rudder angle on trajectory and hydro-dynamic at high-speed water-entry. Chin. J. Appl. Mech. 2015, 32, 11–16. [Google Scholar]

- Truscott, T.T. Cavity Dynamics of Water Entry for Spheres and Ballistic Projectiles. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2009. [Google Scholar]

- Truscott, T.; Techet, A.; Beal, D. Shallow angle water entry of ballistic projectiles. In Proceedings of the 7th International Symposium on Cavitation, Ann Arbor, MI, USA, 17–22 August 2009. [Google Scholar]

- Sharker, S.I.; Holekamp, S.; Mansoor, M.M.; Fish, F.E.; Truscott, T.T. Water entry impact dynamics of diving birds. Bioinspir. Biomim. 2019, 14, 056013. [Google Scholar] [CrossRef]

- Shi, Y.; Pan, G.; Yim, S.C.; Yan, G.; Zhang, D. Numerical investigation of hydroelastic water-entry impact dynamics of AUVs. J. Fluids Struct. 2019, 91, 102760. [Google Scholar] [CrossRef]

- Shi, Y.; Gao, X.; Pan, G. Design and load reduction performance analysis of mitigator of AUV during high speed water entry. Ocean Eng. 2019, 181, 314–329. [Google Scholar] [CrossRef]

- Hinckley, W.M.; Yang, J.C.S. Analysis of rigid polyurethane foam as a shock mitigator. Exp. Mech. 1975, 15, 177–183. [Google Scholar] [CrossRef]

- Li, Y.; Zong, Z.; Sun, T. Crushing behavior and load-reducing performance of a composite structural buffer during water entry at high vertical velocity. Compos. Struct. 2021, 255, 112883. [Google Scholar] [CrossRef]

- Wei, H.P.; Shi, C.B.; Sun, T.Z.; Bao, W.; Zhang, G. Numerical study on load-shedding performance of a high-speed water-entry vehicle based on an ALE method. Explos. Shock. Waves 2021, 41, 104201. [Google Scholar]

- Pan, L.; Wang, H.R.; Yao, E.R.; Wang, X.B. Mechanism research on the water-entry impact of the head-jetting flat cylinder. K. Cheng Je Wu Li Hsueh Pao/J. Eng. Thermophys. 2015, 36, 1691–1695. [Google Scholar]

- Zhao, H.; Shi, Y.; Pan, G. Numerical simulation of cavitation characteristics in high speed water entry of head-jetting underwater vehicle. Xibei Gongye Daxue Xuebao/J. Northwestern Polytech. Univ. 2021, 39, 810–817. [Google Scholar] [CrossRef]

- Sun, T.; Wang, Z.; Zou, L.; Wang, H. Numerical investigation of positive effects of ventilated cavitation around a NACA66 hydrofoil. Ocean Eng. 2020, 197, 106831. [Google Scholar] [CrossRef]

- Xu, L.; Wang, Z.; Lv, H.; Gao, Z. Coupled dynamic characteristics of the hull and cushioning structure of high-speed water entry vehicle. Eng. Appl. Comput. Fluid Mech. 2025, 19, 2552943. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, J.; Zhang, X.; Yan, Y.; Jiang, L.; Mohagheghian, I.; Dear, J.P.; Charalambides, M.N. Experimental and numerical investigation of high velocity soft impact loading on aircraft materials. Aerosp. Sci. Technol. 2019, 90, 44–58. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, R.; Song, K.; Feng, Y.; Zang, C.; Li, G. Ballistic performance and thickness optimization of TC4/UHMWPE laminates composite structure under high-speed impact. Compos. Commun. 2025, 156, 102411. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Yidris, N.; Mustapha, F. Low velocity and high velocity impact test on composite materials—A review. Int. J. Eng. Sci. 2014, 3, 50–60. [Google Scholar]

- Qiao, P.; Yang, M.; Bobaru, F. Impact mechanics and high-energy absorbing materials. J. Aerosp. Eng. 2008, 21, 235–248. [Google Scholar] [CrossRef]

- Tan, Y.H.; Siddall, R.; Kovac, M. Efficient aerial-aquatic locomotion with a single propulsion system. IEEE Robot. Autom. Lett. 2017, 2, 1304–1311. [Google Scholar] [CrossRef]

- Gao, T.Z.; Hu, Z.Q.; Yang, Y.; Wang, J.X.; Wu, Y. Theoretical analysis and experimental verification on thrust of aquatic aerial amphibious ducted fan propeller. Robot 2019, 41, 222–231. [Google Scholar]

- Shao, D. Analysis to the power system of trans-media vehicle. Aerosp. Power 2020, 1, 4. [Google Scholar]

- Ji, D.; Wang, R.; Zhai, Y.; Gu, H. Dynamic modeling of quadrotor AUV using a novel CFD simulation. Ocean Eng. 2021, 237, 109651. [Google Scholar] [CrossRef]

- Emran, B.J.; Najjaran, H. A review of quadrotor: An underactuated mechanical system. Annu. Rev. Control 2018, 46, 165–180. [Google Scholar] [CrossRef]

- Tian, B.; Liu, L.; Lu, H.; Zuo, Z.; Zong, Q.; Zhang, Y. Multivariable finite time attitude control for quadrotor UAV: Theory and experimentation. IEEE Trans. Ind. Electron. 2017, 65, 2567–2577. [Google Scholar] [CrossRef]

- He, Z.; Wu, S.; Wang, H.; Shao, M.; Wu, S.; Wang, P.; Zhang, J. System Design and Underwater Trajectory Tracking Control of Dual-Rotor Unmanned Aerial-Aquatic Vehicle. In Proceedings of the China Aeronautical Science and Technology Conference, Wuzhen, China, 26–27 September 2023; Springer Nature: Singapore, 2023; pp. 366–373. [Google Scholar]

- Sun, J.; Wang, L.; Wu, T. Research on Cross-Media Control of Amphibious Multi-Rotor Vehicle Based on Sliding Mode Control Technology. In Proceedings of the International Conference on Guidance, Navigation and Control, Harbin, China, 5–7 August 2022; Springer Nature: Singapore, 2022; pp. 2332–2343. [Google Scholar]

- Ali, K.; Ullah, S.; Mehmood, A.; Mostafa, H.; Marey, M.; Iqbal, J. Adaptive FIT-SMC approach for an anthropomorphic manipulator with robust exact differentiator and neural network-based friction compensation. IEEE Access 2022, 10, 3378–3389. [Google Scholar] [CrossRef]

- Xu, J.; Irigoien, X.; Alouini, M.S. State-of-the-Art Underwater Vehicles and Technologies Enabling Smart Ocean: Survey and Classifications. arXiv 2024, arXiv:2412.18667. [Google Scholar]

- Viadero-Monasterio, F.; Nguyen, A.T.; Lauber, J.; Boada, M.J.L.; Boada, B.L. Event-triggered robust path tracking control considering roll stability under network-induced delays for autonomous vehicles. IEEE Trans. Intell. Transp. Syst. 2023, 24, 14743–14756. [Google Scholar] [CrossRef]

- Viadero-Monasterio, F.; Meléndez-Useros, M.; Zhang, N.; Zhang, H.; Boada, B.L.; Boada, M.J.L. Motion planning and robust output-feedback trajectory tracking control for multiple intelligent and connected vehicles in unsignalized intersections. IEEE Trans. Veh. Technol. 2025, 1, 1–13. [Google Scholar] [CrossRef]

- Rehman, F.U. Underwater transportation of a Payload using multiple Hovering Autonomous Underwater Vehicles (HAUVs). Ph.D. Thesis, UCL (University College London), London, UK, 2024. [Google Scholar]

- Bi, Y.; Xu, Z.; Shen, Y.; Zeng, Z.; Lian, L. Design and implementation of a bone-shaped hybrid aerial underwater vehicle. IEEE Robot. Autom. Lett. 2024, 9, 7318–7325. [Google Scholar] [CrossRef]

- Cao, J.; Mao, J.; Li, Y.; Wang, L.; Cao, B. Trajectory-Following Control of an Unmanned Aerial–Aquatic Vehicle under Complex Coupling Interferences. J. Mar. Sci. Eng. 2023, 12, 60. [Google Scholar] [CrossRef]

- Wu, S.; Xie, L.; Xian, J. Finite-time output feedback trans-media tracking control of a slender body trans-media vehicle via neural network extended state observer. Trans. Inst. Meas. Control 2023, 46, 1397–1409. [Google Scholar] [CrossRef]

- Tan, L.; Liang, S.; Su, H.; Qin, Z.; Li, L.; Huo, J. Research on amphibious multi-rotor UAV out-of-water control based on ADRC. Appl. Sci. 2023, 13, 4900. [Google Scholar] [CrossRef]

- Liao, F.; Ye, D. Disturbance Observer-Based Robust Take-Off Control for a Semi-Submersible Permeable Slender Hybrid Unmanned Aerial Underwater Quadrotor. Appl. Sci. 2023, 13, 9318. [Google Scholar] [CrossRef]

- Irfan, S.; Zhao, L.; Ullah, S.; Javaid, U.; Iqbal, J. Differentiator-and observer-based feedback linearized advanced nonlinear control strategies for an unmanned aerial vehicle system. Drones 2024, 8, 527. [Google Scholar] [CrossRef]

- Lu, M.; Liao, F.; Xing, B.; Fan, Z.; Su, Y.; Wu, W. Adaptive Finite-Time Trajectory Tracking Control for Coaxial HAUVs Facing Uncertainties and Unknown Environmental Disturbances. Appl. Sci. 2023, 13, 8026. [Google Scholar] [CrossRef]

- Tan, L.; Li, L.; Su, H.; Novikova, S.V.; Zhang, X.; Mingaliyev, Z.Z. Dynamic step selection algorithm for piecewise linear approximation of complex control trajectories. Ocean Eng. 2023, 280, 114498. [Google Scholar] [CrossRef]

- Lu, M.; Wu, W.; Liao, F.; Fan, Z.; Xing, B. Nonsingular fast terminal sliding-mode tracking control for hybrid aerial underwater vehicles. In Proceedings of the International Conference on Guidance, Navigation and Control, Harbin, China, 5–7 August 2022; Springer Nature: Singapore, 2022; pp. 7253–7264. [Google Scholar]

- Jin, Y.; Zeng, Z.; Lian, L. Nezha-SeaDart: A tail-sitting fixed-wing vertical takeoff and landing hybrid aerial underwater vehicle. J. Field Robot. 2025, 42, 137–152. [Google Scholar] [CrossRef]

- Xie, H.; Jin, Y.; Bi, Y.; Zeng, Z. Nezha-D: Dynamic Characteristics and Design of a Ducted HAUV. J. Intell. Robot. Syst. 2025, 111, 20. [Google Scholar] [CrossRef]

- Lu, M.; Yang, W.; Liao, F.; Wu, S.; Su, Y.; Wu, W. Quaternion-Based Fast SMC–PD Cross-Domain Tracking Control for Coaxial Hybrid Aerial–Underwater Vehicle Under Oceanic Disturbances. Appl. Sci. 2025, 15, 703. [Google Scholar] [CrossRef]

- Schwarzbach, M.; Laiacker, M.; Mulero-Pázmány, M.; Kondak, K. Remote water sampling using flying robots. In Proceedings of the 2014 International Conference on Unmanned Aircraft Systems (ICUAS), Orlando, FL, USA, 27–30 May 2014; IEEE: New York, NY, USA, 2014; pp. 72–76. [Google Scholar]

- Lloyd, S.; Lepper, P.; Pomeroy, S. Evaluation of UAVs as an underwater acoustics sensor deployment platform. Int. J. Remote Sens. 2017, 38, 2808–2817. [Google Scholar] [CrossRef]

- Shkurti, F.; Xu, A.; Meghjani, M.; Higuera, J.C.; Girdhar, Y.; Giguere, P.; Dudek, G. Multi-domain monitoring of marine environments using a heterogeneous robot team. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; IEEE: New York, NY, USA, 2012; pp. 1747–1753. [Google Scholar]

- Stevenson, P. Report on Air Launched Autonomous Underwater Vehicles; National Oceanography Centre: Southampton, UK, 2011. [Google Scholar]

- Stevenson, P.; McPhail, S.D.; Tsimplis, M.; Higgins, E. Air launched platforms-a new approach for underwater vehicles. In Proceedings of the OCEANS 2009-EUROPE, Bremen, Germany, 11–14 May 2009; IEEE: New York, NY, USA, 2009; pp. 1–8. [Google Scholar]

- Sauser, B.; Verma, D.; Ramirez-Marquez, J.; Gove, R. From TRL to SRL: The concept of systems readiness levels. In Proceedings of the Conference on Systems Engineering Research, Los Angeles, CA, USA, 7–8 April 2006. [Google Scholar]

- Vik, J.; Melås, A.M.; Stræte, E.P.; Søraa, R.A. Balanced readiness level assessment (BRLa): A tool for exploring new and emerging technologies. Technol. Forecast. Soc. Change 2021, 169, 120854. [Google Scholar] [CrossRef]

| Part 1 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Category | UAUV Prototype | Name | Year | Development Group | Main Design Parameter | Prototype Experiment | Refs. | ||||||

| Length (m) | Wing Span (m) | Mass (kg) | Max Velocity (m/s) | Endurance (min) | Air | Underwater | |||||||

| Water Entry | Water Exit | ||||||||||||

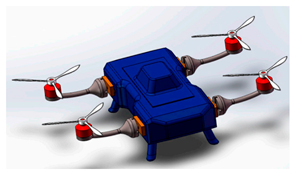

| Rotary -wing UAUV | Quad rotors |  | Miniature UAUV | 2019 | University of California, Berkeley | \ | \ | 0.2 | \ | \ | Y Y N Y | [34] | |

| Aerial covert unmanned nautical system | 2016 | Johns Hopkins University Applied Physics Laboratory | \ | \ | \ | \ | \ | N N N N | [35] | |||

| Aerial and underwater vehicle | 2021 | Shanghai Maritime University | 0.35 | \ | 2.1 | \ | \ | Y Y Y Y | [36] | |||

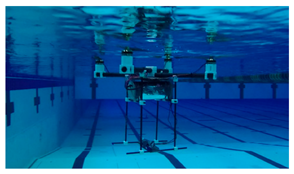

| Cormorant | 2016 | Georgia Institute of Technology | \ | \ | \ | 7.6 (air) 1 (underwater) | 10 (air) 56 (underwater) | Y Y Y Y | [37] | |||

| Loon Copter | 2018 | The University of Auckland | 0.5 | \ | 2.7 | 0.5 (underwater) | 12 (air) 22 (underwater) | Y Y Y Y | [38] | |||

| Nezha-F | 2023 | Shanghai Jiao Tong University (SJTU) | 0.4 | \ | 1.25 | \ | 4 (air) 120 (underwater) | Y Y Y Y | [39] | |||

| Aerial-aquatic hitchhiking robot | 2022 | BeiHang University (BUAA) | 0.4 | 0.13 | 0.95 | \ | \ | Y Y Y Y | [40] | |||

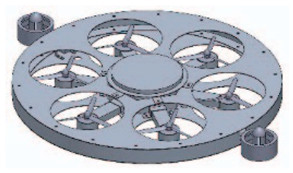

| Four shafts with eight rotors |  | Hybrid UAUV | 2018 | Universidade Federal do Rio Grande (FURG) | \ | 0.27 | 1.45 | \ | \ | N N N N | [41] | ||

| Multirotor aerial- underwater vehicle | 2017 | Rutgers, The State University of New Jersey | \ | \ | 3.85 | 7 (air) 1.1 (underwater) | 72 (air) 150 (underwater) | N Y N N | [42] | |||

| UAUV | 2018 | Air Force Engineering University | \ | \ | 2.57 | \ | \ | N Y N N | [43] | |||

| Tilt rotors |  | Morphable aerial-aquatic quadrotor | 2020 | National University of Singapore | 0.38 | \ | 0.505 | \ | 7(air) | Y Y Y Y | [44] | ||

| UAUV | 2019 | Dalian Maritime University | \ | \ | 1.2 | \ | \ | N N N N | [45] | |||

| Trans-medium hexacopter | 2020 | Bauman Moscow State Technical University | \ | \ | \ | \ | \ | N N N N | [46] | |||

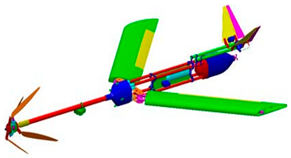

| Fixed-wing UAUV |  | EagleRay | 2017 | North Carolina State University | 1.4 | 1.5 | 5.81 | 22 (air) 0.89 (underwater) | 7.43 (air) | Y Y Y Y | [47] | ||

| Sherbrooke University water-air vehicle | 2017 | The University of Sherbrooke | \ | 1 | 0.584 | 10 (air) | \ | Y Y Y Y | [48] | |||

| Unmanned aerial-aquatic vehicle | 2018 | Johns Hopkins University | \ | 0.61 | 0.2 | \ | \ | Y Y N Y | [49] | |||

| Aerial-aquatic robot | 2019 | Imperial College London | \ | \ | 0.16 | 10 (air) | \ | Y Y N Y | [50] | |||

| Diving beetle—Δ | 2022 | SJTU | 0.93 | 1.2 | 3 | 38 (air) 0.89 (underwater) | 13.9 (air) 77.6 (underwater) | Y Y Y Y | [51] | |||

| Part 2 | |||||||||||||

| Category | UAUV Prototype | Name | Year | Development Group | Main Design Parameter | Prototype Experiment | Refs. | ||||||

| Length (m) | Wing Span (m) | Mass (kg) | Max Velocity (m/s) | Endurance (min) | Air | Underwater | |||||||

| Water Entry | Water Exit | ||||||||||||

| Folding-wing UAUV |  | Robotic flying fish | 2011 | Massachusetts Institute of Technology (MIT) | 0.25 | 0.32 | 0.15 | 10 (underwater) | \ | N N N N | [52] | ||

| Hybrid unmanned air-underwater vehicle | 2016 | U.S. Naval Research Laboratory | 1.1 | \ | 7.6 | 0.34 (underwater) | \ | N Y N N | [53] | |||

| Cross-media UAV | 2019 | Jilin University | 0.8 | 1.2 | 12.91 | 35 | \ | N N N N | [54] | |||

| Underwater aerial transmedia vehicle | 2020 | Center South University | 0.6 | \ | 2.03 | 18 (air) 0.5 (underwater) | 10 (air) 10 (underwater) | N N N N | [55] | |||

| Underwater UAV | 2012 | Nanchang Hangkong University | \ | \ | 7.43 | 30 (air) 1.5 (underwater) | \ | N Y N N | [56] | |||

| Flying fish | 2014 | BUAA | 1.98 | 3.4 | 12 | 0.5 (underwater) | \ | Y Y Y Y | [57] | |||

| Project gannet | 2012 | MIT | \ | \ | \ | 7 (air) | \ | Y Y Y N | [58] | |||

| Submersible UAV | 2013 | BUAA | 2.63 | 1.93 | 12.8 | 20 (air) 0.5 (underwater) | 30 (air) 20 (underwater) | N N Y N | [59] | |||

| Aquatic micro air vehicle | 2017 | Imperial College London | \ | 0.59 | 0.2 | 10 (air) | 14 (air) | Y Y Y N | [60] | |||

| Aquatic micro air vehicle | 2017 | Imperial College London | 0.52 | 0.45 | 0.1 | 11 (air) | \ | Y Y N Y | [61] | |||

| Dipper | 2021 | Swiss Federal Institute of Technology Zurich | 1.16 | 2.1 | 3.1 | 30.5 (air) 0.83 (underwater) | 4 (air) 8 (underwater) | Y Y Y Y | [62] | |||

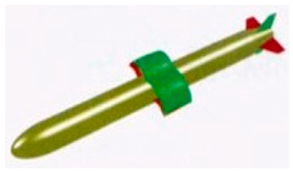

| High-speed folding-wing UAUV | 2012 | Air Force Engineering University | \ | \ | \ | 272(air) | \ | N N N N | [63] | |||

| Hybrid-wing UAUV |  | Hai Kun | 2017 | Shenyang Institute of Automation | 0.71 | 1.15 | 12 | 0.56 (underwater) | \ | Y Y N Y | [64] | ||

| Ne Zha | 2022 | SJTU | 0.96 | 1.5 | 14.68 | 30 (air) 0.3 (underwater) | \ | Y Y Y Y | [65] | |||

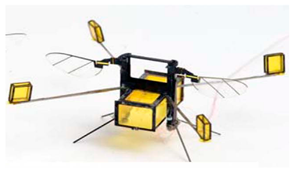

| Flapping-wing UAUV |  | Hybrid aerial-aquatic microrobot | 2017 | Harvard University | \ | \ | 2 × 10−4 | \ | \ | Y Y Y Y | [66] | ||

| Dual aerial/aquatic vehicle | 2015 | MIT | \ | \ | 0.06 | \ | \ | Y Y N N | [67] | |||

| Transition mode | Gliding takeoff and landing | Rotor takeoff and landing | Pull takeoff and swooping landing |

| UAUV configuration | Fixed-wing and folding-wing UAUVs | Rotary-wing and hybrid-wing UAUVs | Fixed-wing and folding-wing UAUVs |

| Angle of attack during the takeoff | Medium | Small | Big |

| Thrust ratios for the individual propellers | Low | Medium | High |

| Time | Long | Medium | Short |

| Impact of the marine environment | Strong | Medium | Medium |

| Propulsion | Both air and underwater propellers | Only air propellers | Dual purpose propellers | Deformable propellers |

| Aerial performance | Good | Excellent | So-so | So-so |

| Underwater performance | Excellent | So-so (without the transmission devices) Good (with the transmission devices) | Good | Good |

| Design key points | Weight reduction and shape optimization | The transmission devices to improve the underwater efficiency | Propeller parameters | Folding or other deformation mechanism |

| Category | R&D Cost | Manufacturing Cost | Practical Deployment Barrier | Commercialization Barrier |

|---|---|---|---|---|

| Rotary-wing | Low | Low |

|

|

| Fixed-wing | Medium | Medium |

| |

| Folding-wing | High | High | ||

| Hybrid-wing | Medium | Medium |

| |

| Flapping-wing | High | High |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Hu, W.; Wei, Z.; Teng, Y.; Dong, L. Unmanned Aerial Underwater Vehicles: Research Progress and Prospects. Appl. Sci. 2025, 15, 11868. https://doi.org/10.3390/app152211868

Zhou H, Hu W, Wei Z, Teng Y, Dong L. Unmanned Aerial Underwater Vehicles: Research Progress and Prospects. Applied Sciences. 2025; 15(22):11868. https://doi.org/10.3390/app152211868

Chicago/Turabian StyleZhou, Hangyu, Weiqiang Hu, Zhaoyu Wei, Yuehui Teng, and Liyang Dong. 2025. "Unmanned Aerial Underwater Vehicles: Research Progress and Prospects" Applied Sciences 15, no. 22: 11868. https://doi.org/10.3390/app152211868

APA StyleZhou, H., Hu, W., Wei, Z., Teng, Y., & Dong, L. (2025). Unmanned Aerial Underwater Vehicles: Research Progress and Prospects. Applied Sciences, 15(22), 11868. https://doi.org/10.3390/app152211868