Impact of LED Light Spatial Distribution on Photosynthetic Radiation Uniformity in Indoor Crops

Abstract

1. Introduction

2. Materials and Methods

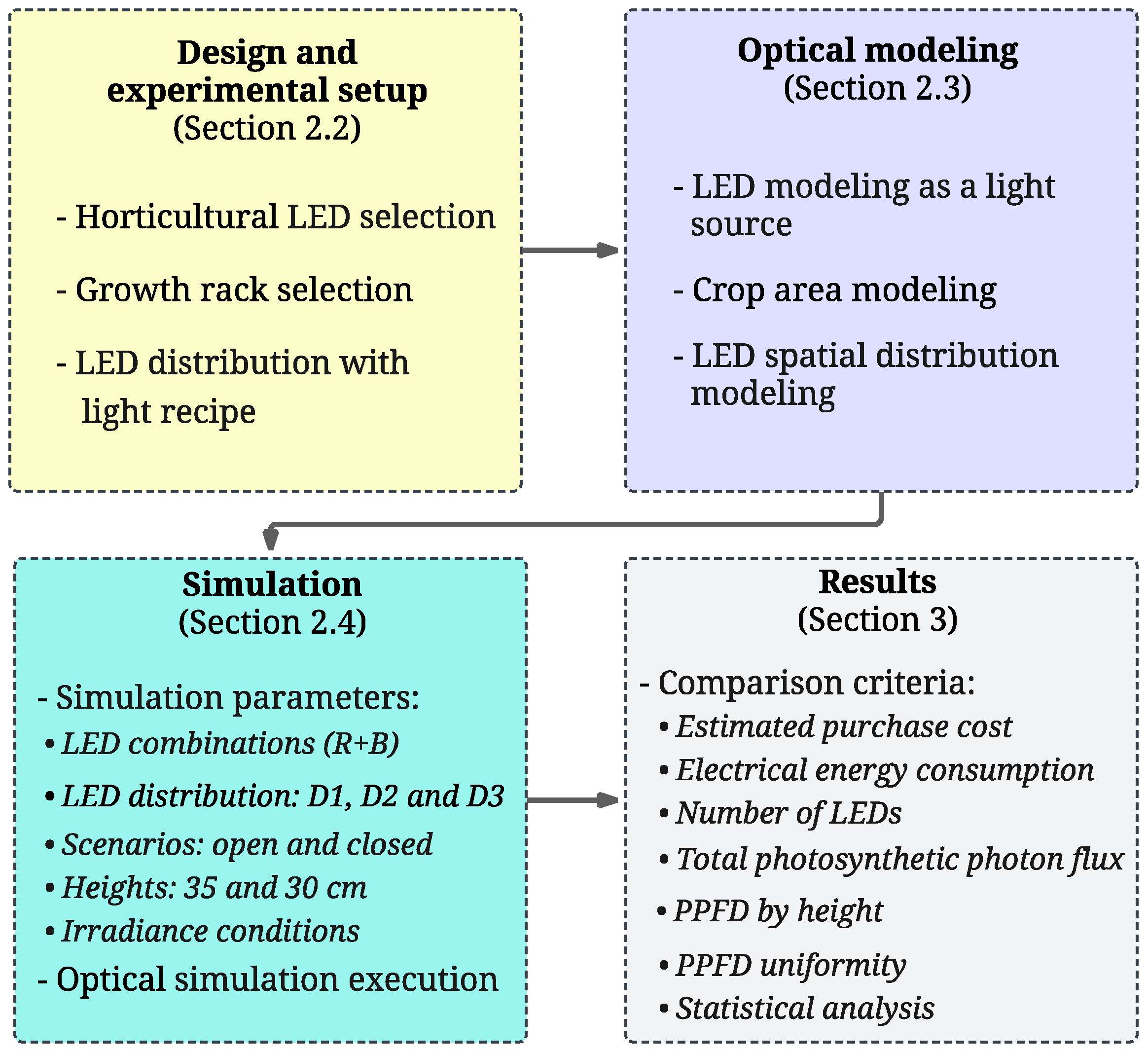

2.1. Summary of Procedure

2.2. Design and Experimental Setup

2.2.1. Horticultural LED Selection

| LED | Brand | Model | λpeak (nm) | Rflux (mW) | PPF (μmol s−1) | θ (o) | V (V) | I (mA) | P (W) | USD 1000 u |

|---|---|---|---|---|---|---|---|---|---|---|

| LED 1 | OSRAM | GH CSSRM5.24 [24] | 660 | 1068 | 5.83 | 120 | 1.99 | 700 | 1.4 | 0.81 |

| LED 2 | SAMSUNG | LH351H 2W [25] | 660 | 1060 | 5.82 | 120 | 2.06 | 700 | 1.4 | 0.665 |

| LED 3 | CREE | XP-G3 Photo Red [26] | 645 | 500 | 2.72 | 123 | 1.99 | 350 | 0.7 | 2.72 |

| LED 4 | OSRAM | GD CSSRM3.14 [27] | 445 | 1555 | 5.75 | 120 | 2.92 | 700 | 2 | 1.07 |

| LED 5 | SAMSUNG | LH351H Blue [28] | 450 | 750 | 2.8 | 130 | 2.86 | 350 | 1 | 0.27 |

| LED 6 | CREE | XP-G3 Royal Blue [26] | 451 | 730 | 2.77 | 130 | 2.79 | 350 | 1 | 1.73 |

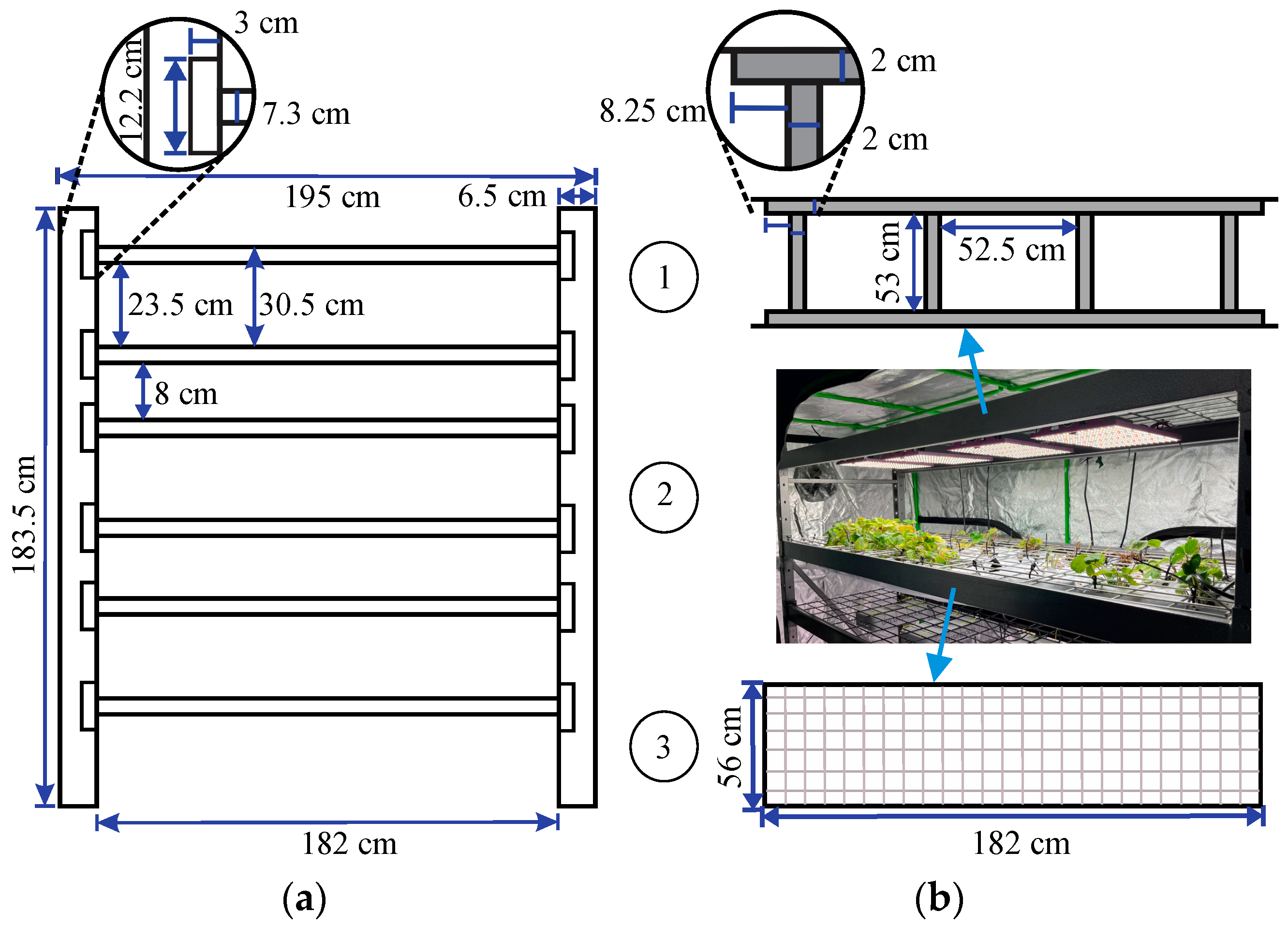

2.2.2. Growth Rack Selection

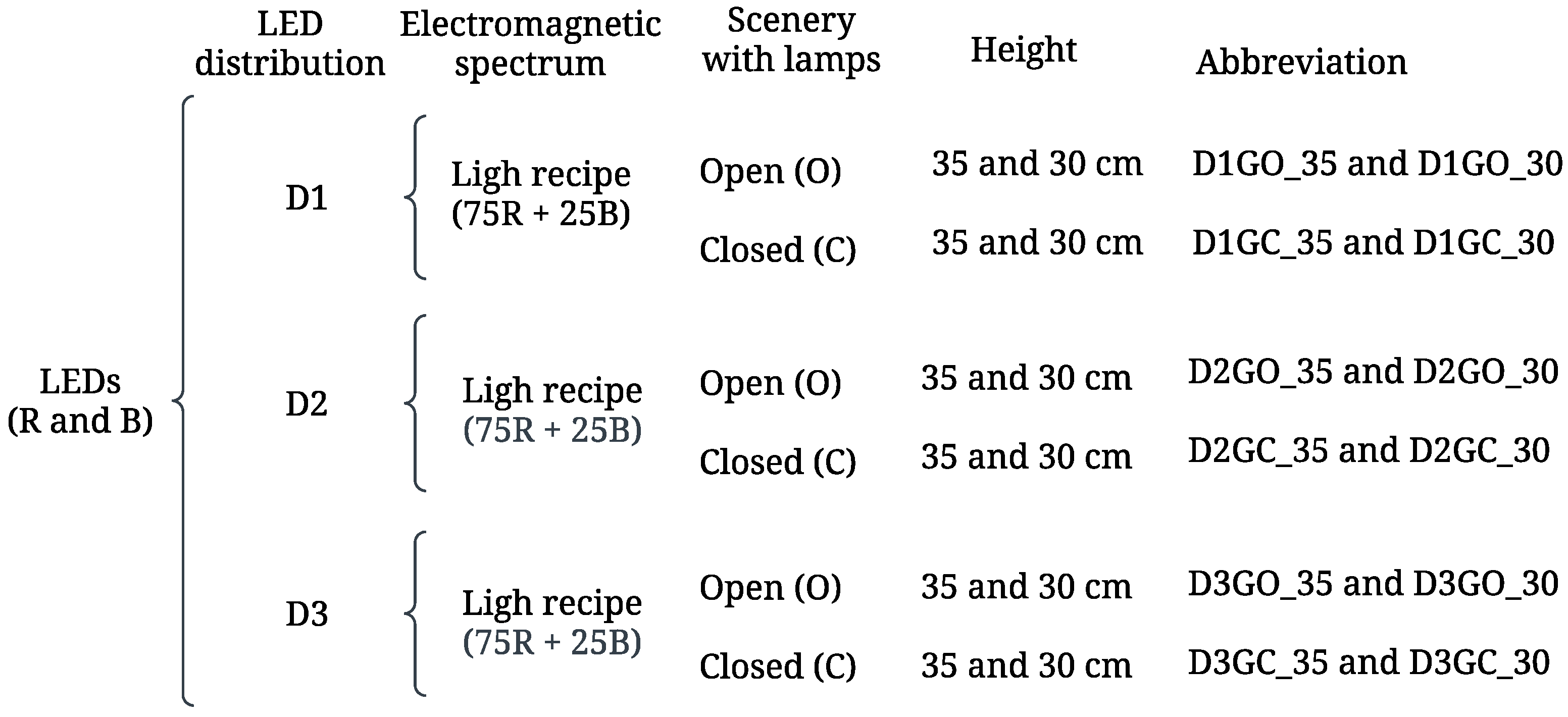

2.2.3. LED Distribution with Light Recipe

2.3. Optical Modeling

2.3.1. LED Modeling as Light Source

2.3.2. Crop Area Modeling

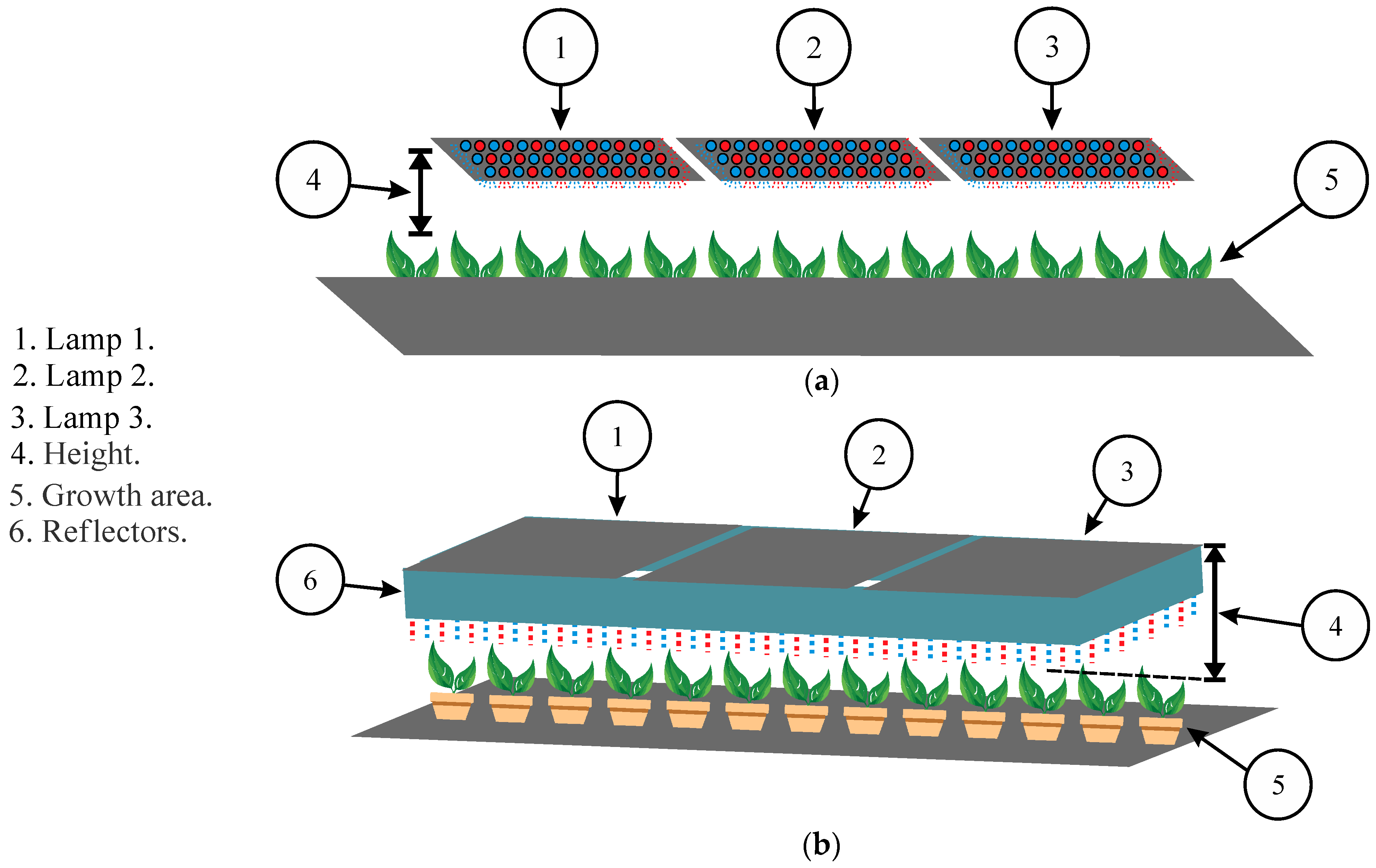

2.3.3. LED Spatial Distribution Modeling

LED Layout 1 (D1)

LED Layout 2 (D2)

LED Layout 3 (D3)

2.4. Optical Simulation Environment

2.4.1. Optical Simulation Parameters

Heights

Irradiance Conditions

2.4.2. Optical Simulation Execution

2.4.3. Comparison Criteria

2.4.4. Statistical Analysis

3. Results

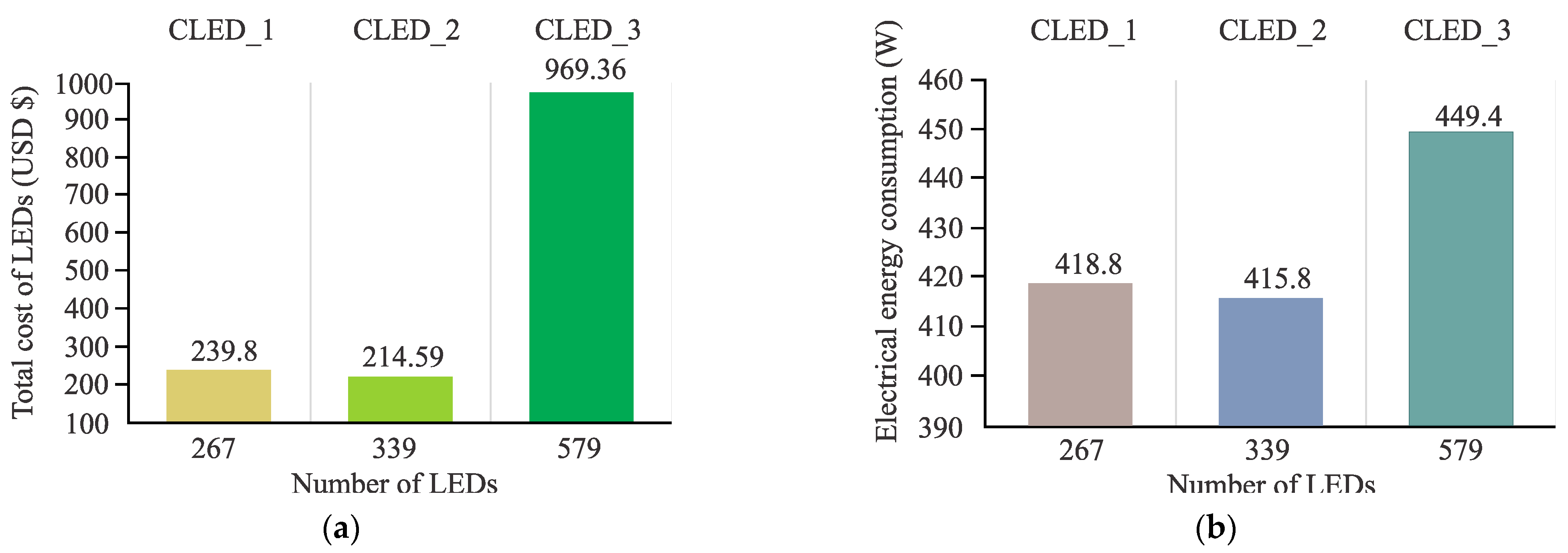

3.1. Comparison by Total Values of Emission and Electrical Energy Consumption

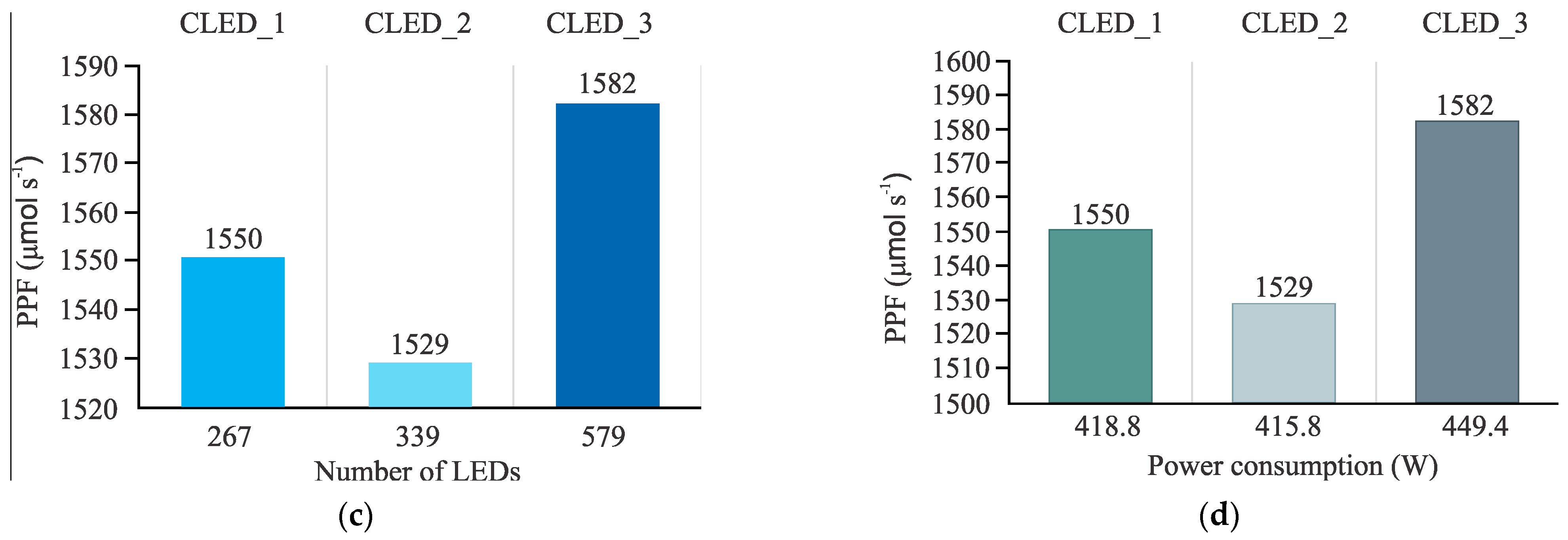

3.2. Comparison by Data Array Values

3.3. Comparison by Irradiance Maps

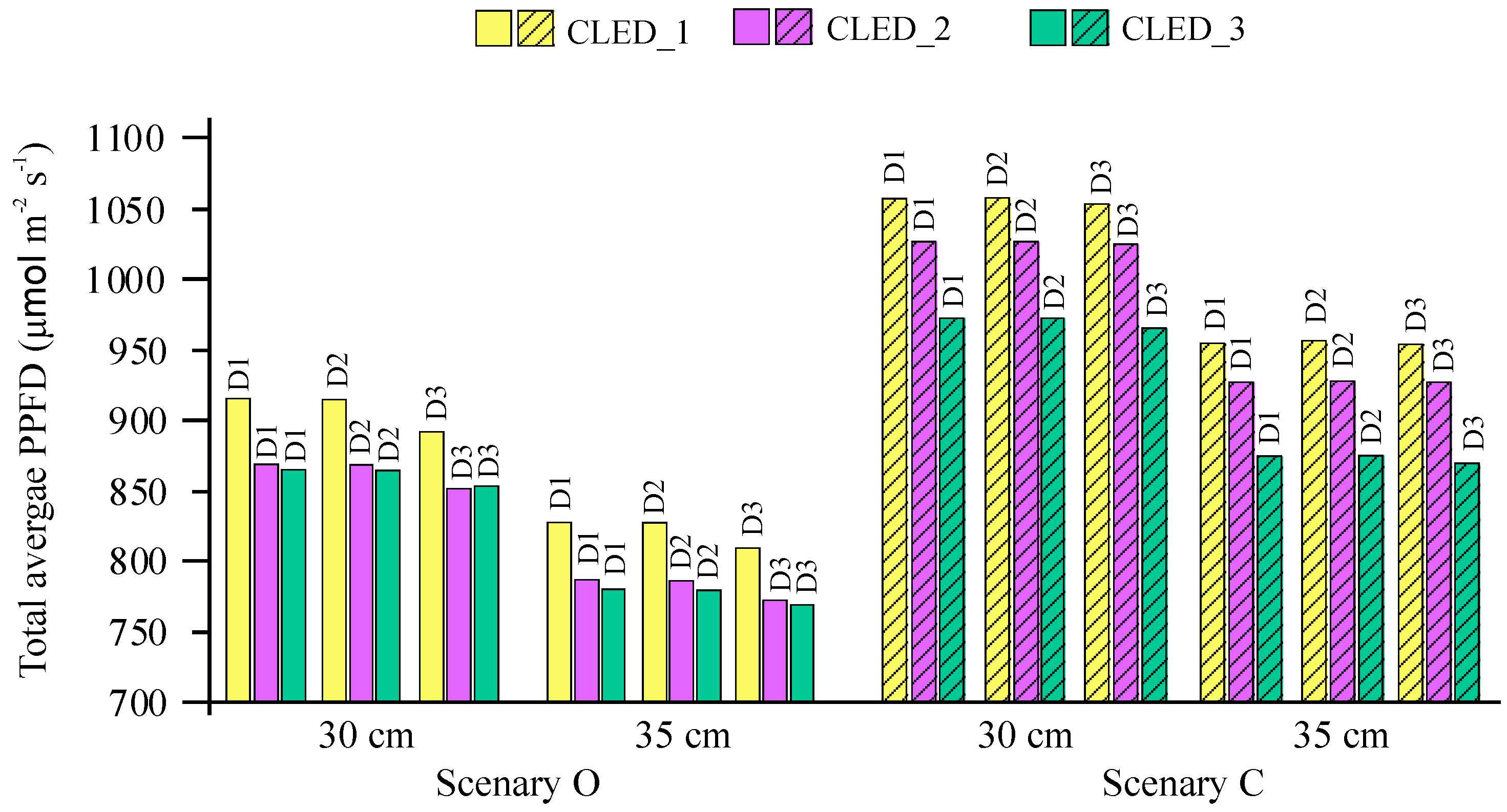

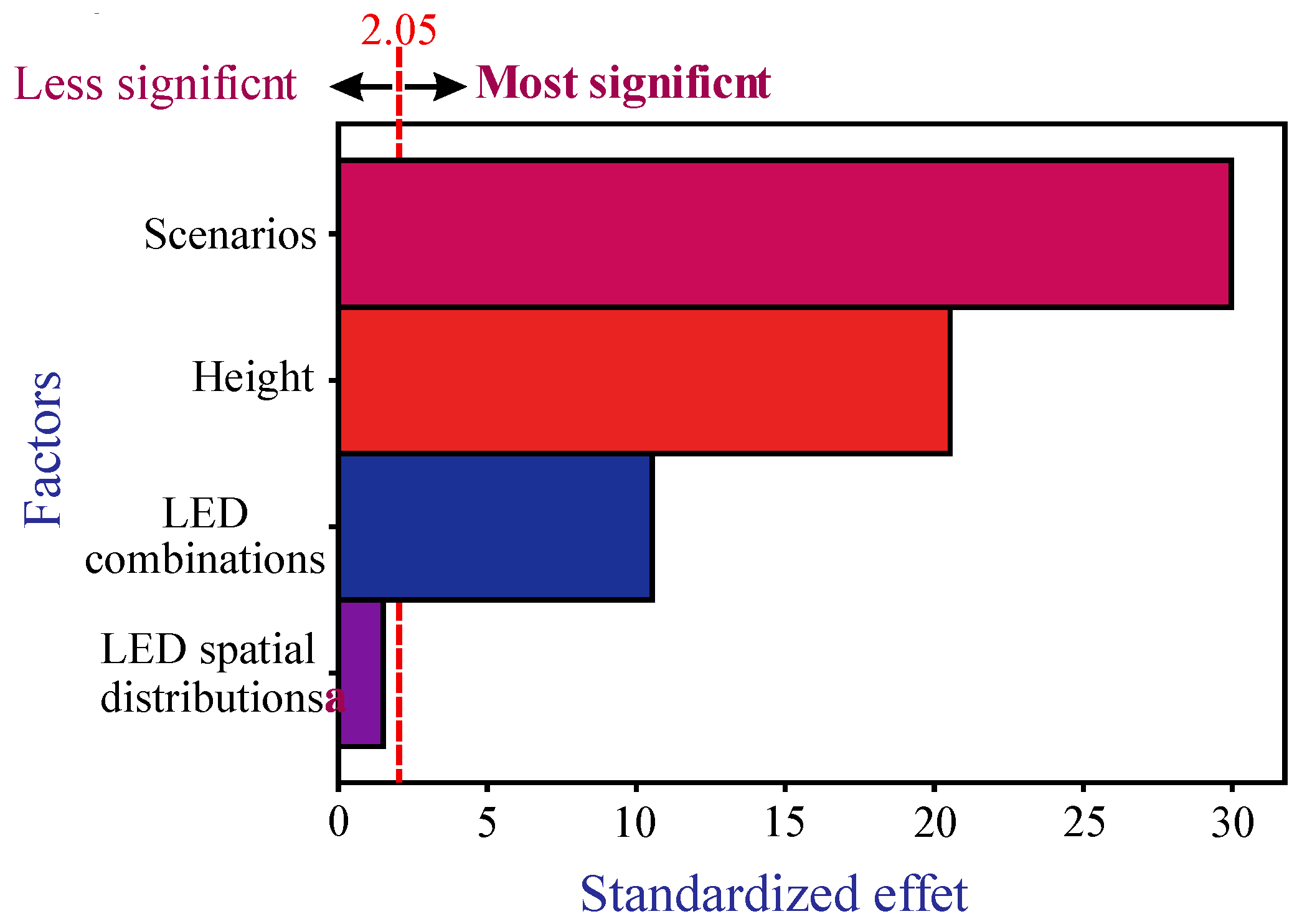

3.4. Comparison by Statistical Data Analysis

3.5. Comparison by Irradiance Area

4. Discussion

5. Conclusions

- -

- Under the same light recipe, maximum differences per lamp can be observed in the following parameters: electrical energy consumption (8.08%), photosynthetic photon flux (3.47%), purchase cost of LEDs (351.72%), and number of components (116.85%).

- -

- The use of reflective walls increased the average photosynthetic photon flux density by up to 18% in LED spatial distributions 1 and 2, and close to 20% in distribution 3, compared to a scenario without reflective walls.

- -

- LED spatial distribution 3 can reduce the difference in photosynthetic photon flux density between the center and the perimeters of the target area by 4% to 8% in scenario O, and by 2.7% to 6.5% in scenario C (to increase irradiance homogeneity).

- -

- Reducing the height from 35 cm to 30 cm increased the photosynthetic photon flux density by up to 10%.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Villagran, E.; Espitia, J.J.; Rodriguez, J.; Gomez, L.; Amado, G.; Baeza, E.; Aguilar-Rodríguez, C.E.; Flores-Velazquez, J.; Akrami, M.; Gil, R.; et al. Use of Lighting Technology in Controlled and Semi-Controlled Agriculture in Greenhouses and Protected Agriculture Systems—Part 1: Scientific and Bibliometric Analysis. Sustainability 2025, 17, 1712. [Google Scholar] [CrossRef]

- Pannico, A.; Arouna, N.; Fusco, G.M.; Santoro, P.; Caporale, A.G.; Nicastro, R.; Pagliaro, L.; De Pascale, S.; Paradiso, R. Enhancing tuber yield and nutraceutical quality of potato by supplementing sunlight with LED red-blue light. Front. Plant Sci. 2025, 16, 1517074. [Google Scholar] [CrossRef] [PubMed]

- Inthima, P.; Supaibulwatana, K. Green LEDs lighting enhances vigorous growth and boosts bacoside production in hydroponically cultivated Bacopa monnieri (L.) Wettst. Hortic. Environ. Biotechnol. 2025, 66, 491–507. [Google Scholar] [CrossRef]

- Khan, Q.; Wang, A.; Li, P.; Hu, J. Quantum Dots Illuminating the Future of Greenhouse Agriculture. Adv. Sustain. Syst. 2025, 9, 2401015. [Google Scholar] [CrossRef]

- Lanoue, J.; Hao, X.; Vaštakaitė-Kairienė, V.; Marcelis, L.F.M. Physiological growth responses to light in controlled environment agriculture. Front. Plant Sci. 2024, 15, 1529062. [Google Scholar] [CrossRef]

- Asgari, N.; Basdeo, A.; Givans, J.; Pearce, J.M. Lighting and Revenue Analysis of Grow Lights in Agrivoltaic Agrotunnel for Lettuces and Swiss Chard. SSRN. 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5104787 (accessed on 1 October 2025).

- Despommier, D. Vertical farming: A holistic approach towards food security. Front. Sci. 2024, 2, 1473141. [Google Scholar] [CrossRef]

- Paucek, I.; Appolloni, E.; Pennisi, G.; Quaini, S.; Gianquinto, G.; Orsini, F. LED Lighting Systems for Horticulture: Business Growth and Global Distribution. Sustainability 2020, 12, 7516. [Google Scholar] [CrossRef]

- Pennisi, G.; Pistillo, A.; Orsini, F.; Cellini, A.; Spinelli, F.; Nicola, S.; Fernandez, J.A.; Crepaldi, A.; Gianquinto, G.; Marcelis, L.F.M. Optimal light intensity for sustainable water and energy use in indoor cultivation of lettuce and basil under red and blue LEDs. Sci. Hortic. 2020, 272, 109508. [Google Scholar] [CrossRef]

- Wang, Y.; Li, T.; Chen, T.; Zhang, X.; Taha, M.F.; Yang, N.; Mao, H.; Shi, Q. Cucumber Downy Mildew Disease Prediction Using a CNN-LSTM Approach. Agriculture 2024, 14, 1155. [Google Scholar] [CrossRef]

- Rouphael, Y.; Ciriello, M. Vertical farming: A toolbox for securing vegetable yield for the food of the future. Front. Sci. 2024, 2, 1491748. [Google Scholar] [CrossRef]

- Asiabanpour, B.; Estrada, A.; Ramirez, R.; Downey, M.S. Optimizing Natural Light Distribution for Indoor Plant Growth Using PMMA Optical Fiber: Simulation and Empirical Study. J. Renew. Energy 2018, 2018, 9429867. [Google Scholar] [CrossRef]

- Bo, Y.; Zhang, Y.; Zheng, K.; Zhang, J.; Wang, X.; Sun, J.; Wang, J.; Shu, S.; Wang, Y.; Guo, S. Light environment simulation for a three-span plastic greenhouse based on greenhouse light environment simulation software. Energy 2023, 271, 126966. [Google Scholar] [CrossRef]

- Park, Y.; Runkle, E.S. Far-red radiation promotes growth of seedlings by increasing leaf expansion and whole-plant net assimilation. Environ. Exp. Bot. 2017, 136, 41–49. [Google Scholar] [CrossRef]

- Yalçın, R.A.; Ertürk, H. Improving crop production in solar illuminated vertical farms using fluorescence coatings. Biosyst. Eng. 2020, 193, 25–36. [Google Scholar] [CrossRef]

- Vu, D.T.; Nghiem, V.T.; Tien, T.Q.; Hieu, N.M.; Minh, K.N.; Vu, H.; Shin, S.; Vu, N.H. Optimizing optical fiber daylighting system for indoor agriculture applications. Sol. Energy 2022, 247, 1–12. [Google Scholar] [CrossRef]

- Lee, H.J.; Moon, Y.H.; An, S.; Sim, H.S.; Woo, U.J.; Hwang, H.; Kim, S.K. Determination of LEDs arrangement in a plant factory using a 3D ray-tracing simulation and evaluation on growth of Cucurbitaceae seedlings. Hortic. Environ. Biotechnol. 2023, 64, 765–774. [Google Scholar] [CrossRef]

- Mei, J.; Zou, J. Optimizing LED Array Irradiance Uniformity with a Particle Swarm Optimization-Based Scheme: Application in a Parallel Photoreactor. Appl. Opt. 2024, 63, 4336–4344. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Li, X.; Hu, L.; Wei, Y.; Gao, T.; Xu, X.; Sun, X. Research on illumination uniformity in edible mushrooms incubator with genetic algorithm. Optik 2021, 239, 166862. [Google Scholar] [CrossRef]

- Xu, K.; Zeng, L.; Li, Z.; Chen, H.; Qiao, Z.; Qu, Y.; Liu, G.; Li, L. Research on illumination uniformity of LD andLED hybrid lighting system applied to plant growth. Appl. Opt. 2022, 61, 10717–10726. [Google Scholar] [CrossRef]

- LAMBDA, R.C. TracePro Software for Design and Analysis of Illumination and Optical Systems. Available online: https://lambdares.com/tracepro (accessed on 20 March 2025).

- Rakutko, S.A.; Rakutko, E.N. Assessment of Lighting Uniformity as a Factor of Energy Efficiency in Greenhouse Horticulture. Eng. Technol. Syst. 2021, 31, 470–486. [Google Scholar] [CrossRef]

- Gao, Q.; Liao, Q.; Li, Q.; Yang, Q.; Wang, F.; Li, J. Effects of LED Red and Blue Light Component on Growth and Photosynthetic Characteristics of Coriander in Plant Factory. Horticulturae 2022, 8, 1165. [Google Scholar] [CrossRef]

- OSRAM. GH CSSRM5.24. Available online: https://look.ams-osram.com/m/b1e8ccf53e9cd4/original/GH-CSSRM5-24.pdf (accessed on 3 June 2025).

- SAMSUNG. LH351H 2W 660nm Deep Red Ver.2. Available online: https://download.led.samsung.com/led/file/resource/2022/05/Data_Sheet_LH351H_660nm_Red_V2_Rev.3.7.pdf (accessed on 19 March 2025).

- CREE. XLamp® XP-G3 LEDs. Available online: https://downloads.cree-led.com/files/ds/x/XLamp-XPG3.pdf (accessed on 21 March 2025).

- OSRAM. GD CSSRM3.14. Available online: https://look.ams-osram.com/m/56f334aabb38c31/original/GD-CSSRM3-14.pdf (accessed on 20 March 2025).

- SAMSUNG. LH351H 450 nm Blue. Available online: https://download.led.samsung.com/led/file/resource/2023/01/Data_Sheet_LH351H_450nm_Blue_Rev.3.8.pdf (accessed on 19 March 2025).

- Sheibani, F.; Bourget, M.; Morrow, R.C.; Mitchell, C.A. Close-canopy lighting, an effective energy-saving strategy for overhead sole-source LED lighting in indoor farming. Front. Plant Sci. 2023, 14, 1215919. [Google Scholar] [CrossRef]

- Wong, T.I.; Zhou, X. Uniform Lighting of High-Power LEDs at a Short Distance to Plants for Energy-Saving and High-Density Indoor Farming. Photonics 2024, 11, 394. [Google Scholar] [CrossRef]

- Chen, X.; Hou, T.; Liu, S.; Guo, Y.; Hu, J.; Xu, G.; Ma, G.; Liu, W. Design of a Micro-Plant Factory Using a Validated CFD Model. Agriculture 2024, 14, 2227. [Google Scholar] [CrossRef]

- Yamada, J.T.; Viana, R.S.E.; Santos, R.R.; de Carvalho, C.P.; de Almeida, M.G.D.; de Barros, J.G.M.; Sampaio, N.A.S. Use of factorial design with significant interaction and Tukey’s Test in agricultural and environmental experiments. Rev. Gestão Secr. (Manag. Adm. Prof. Rev.) 2023, 14, 9815–9828. [Google Scholar] [CrossRef]

- Arif, M.; Ameen, K.; Rafiq, M. Factors affecting student use of Web-based services. Electron. Libr. 2018, 36, 518–534. [Google Scholar] [CrossRef]

- Boynton, G.M. Introduction to Statistics and Data Analysis. Available online: https://courses.washington.edu/psy524a/_book/tests-for-homogeneity-of-variance-and-normality.html (accessed on 4 June 2025).

- Boros, I.F.; Székely, G.; Balázs, L.; Csambalik, L.; Sipos, L. Effects of LED lighting environments on lettuce (Lactuca sativa L.) in PFAL systems—A review. Sci. Hortic. 2023, 321, 112351. [Google Scholar] [CrossRef]

- Ali, A. Basic and Applied Research Approaches for Optimizing the Use of Artificial Light in Vegetable Crops. Ph.D. Thesis, Università degli Studi di Milano, Milano, Italy, 2024. [Google Scholar]

| Category | Element | Description/Levels |

|---|---|---|

| Independent variable | LED type | Blue LED, Red LED |

| Mounting height | 30 cm, 35 cm | |

| Spatial configuration | Aligned layout, Offset layout, proposal | |

| Environment scenario | Open area, enclosed box | |

| Controlled conditions | Spectral composition | 75% Red:25% Blue |

| Power input | Constant (between 418.8 and 449.4 W) | |

| Simulation grid resolution | Fixed (1.42 cm × 1.42 cm cells) | |

| Dependent variable | PPFD | μmol·m−2·s−1 |

| Uniformity index (u) | Dimensionless (0–1) | |

| Optical efficiency (ηₒ) | % of emitted flux captured over the target area |

| LED Combinations | Total LED | LED Distribution | Height | R | B | Recipe | ||

|---|---|---|---|---|---|---|---|---|

| Average PPFD (μmol m−2s−1) | % Recipe | Average PPFD (μmol m−2s−1) | % Recipe | Total Average PPFD (μmol m−2s−1) | ||||

| CLED_1 | 267 | D1 | 30 | 670 | 73.11 | 246 | 26.89 | 915 |

| 267 | D2 | 30 | 669 | 73.19 | 245 | 26.81 | 914 | |

| 267 | D3 | 30 | 656 | 73.54 | 236 | 26.46 | 892 | |

| CLED_2 | 339 | D1 | 30 | 653 | 75.14 | 216 | 24.86 | 869 |

| 339 | D2 | 30 | 652 | 75.12 | 216 | 24.88 | 868 | |

| 339 | D3 | 30 | 639 | 75.09 | 212 | 24.91 | 851 | |

| CLED_3 | 579 | D1 | 30 | 654 | 75.61 | 211 | 24.39 | 865 |

| 579 | D2 | 30 | 653 | 75.58 | 211 | 24.42 | 864 | |

| 579 | D3 | 30 | 645 | 75.62 | 208 | 24.38 | 853 | |

| CLED_1 | 267 | D1 | 35 | 606 | 73.19 | 222 | 26.81 | 828 |

| 267 | D2 | 35 | 606 | 73.28 | 221 | 26.72 | 827 | |

| 267 | D3 | 35 | 595 | 73.55 | 214 | 26.45 | 809 | |

| CLED_2 | 339 | D1 | 35 | 592 | 75.22 | 194 | 24.65 | 787 |

| 339 | D2 | 35 | 592 | 75.32 | 194 | 24.68 | 786 | |

| 339 | D3 | 35 | 580 | 75.13 | 191 | 24.74 | 772 | |

| CLED_3 | 579 | D1 | 35 | 589 | 75.51 | 190 | 24.36 | 780 |

| 579 | D2 | 35 | 589 | 75.61 | 190 | 24.39 | 779 | |

| 579 | D3 | 35 | 582 | 75.68 | 187 | 24.32 | 769 | |

| LED Combinations | Total LED | LED Distribution | Height | R | B | Recipe | ||

|---|---|---|---|---|---|---|---|---|

| Average PPFD (μmol m−2s−1) | % Recipe | Average PPFD (μmol m−2s−1) | % Recipe | Total Average PPFD (μmol m−2s−1) | ||||

| CLED_1 | 267 | D1 | 30 | 769 | 72.75 | 288 | 27.25 | 1057 |

| 267 | D2 | 30 | 768 | 72.66 | 289 | 27.34 | 1057 | |

| 267 | D3 | 30 | 767 | 72.84 | 286 | 27.16 | 1053 | |

| CLED_2 | 339 | D1 | 30 | 760 | 74.07 | 267 | 26.02 | 1026 |

| 339 | D2 | 30 | 760 | 74.07 | 266 | 25.93 | 1026 | |

| 339 | D3 | 30 | 758 | 74.02 | 267 | 26.07 | 1024 | |

| CLED_3 | 579 | D1 | 30 | 712 | 73.15 | 261 | 26.85 | 972 |

| 579 | D2 | 30 | 712 | 73.25 | 260 | 26.75 | 972 | |

| 579 | D3 | 30 | 705 | 73.06 | 260 | 26.94 | 965 | |

| CLED_1 | 267 | D1 | 35 | 695 | 72.77 | 260 | 27.23 | 955 |

| 267 | D2 | 35 | 695 | 72.70 | 261 | 27.30 | 956 | |

| 267 | D3 | 35 | 695 | 72.85 | 259 | 27.15 | 954 | |

| CLED_2 | 339 | D1 | 35 | 688 | 74.11 | 240 | 25.89 | 927 |

| 339 | D2 | 35 | 689 | 74.14 | 240 | 25.86 | 928 | |

| 339 | D3 | 35 | 687 | 74.11 | 240 | 25.89 | 927 | |

| CLED_3 | 579 | D1 | 35 | 641 | 73.26 | 234 | 26.74 | 875 |

| 579 | D2 | 35 | 641 | 73.26 | 234 | 26.74 | 875 | |

| 579 | D3 | 35 | 636 | 73.10 | 234 | 26.90 | 870 | |

| Factors | Degrees of Freedom | Adjusted Treatments | Tight Measurements | Fisher Values | p Values (Tukey) |

|---|---|---|---|---|---|

| Model | 6 | 259,454 | 43,242 | 244.56 | 0.000 |

| Linear relationship | 6 | 259,454 | 43,242 | 244.56 | 0.000 |

| LED combinations | 2 | 25,296 | 12,648 | 71.53 | 0.000 |

| Scenarios | 1 | 158,802 | 158,802 | 898.11 | 0.000 |

| Height | 1 | 74,620 | 74,620 | 422.01 | 0.000 |

| LED spatial distribution | 2 | 735 | 368 | 2.08 | 0.143 |

| Error | 29 | 5128 | 177 | ||

| Total | 35 | 264,582 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero-Lomeli, R.; Escalante-Garcia, N.; Díaz-Ponce, A.; Olvera-Gonzalez, E.; Peña-Cruz, M.I. Impact of LED Light Spatial Distribution on Photosynthetic Radiation Uniformity in Indoor Crops. Appl. Sci. 2025, 15, 11768. https://doi.org/10.3390/app152111768

Romero-Lomeli R, Escalante-Garcia N, Díaz-Ponce A, Olvera-Gonzalez E, Peña-Cruz MI. Impact of LED Light Spatial Distribution on Photosynthetic Radiation Uniformity in Indoor Crops. Applied Sciences. 2025; 15(21):11768. https://doi.org/10.3390/app152111768

Chicago/Turabian StyleRomero-Lomeli, Ricardo, Nivia Escalante-Garcia, Arturo Díaz-Ponce, Ernesto Olvera-Gonzalez, and Manuel I. Peña-Cruz. 2025. "Impact of LED Light Spatial Distribution on Photosynthetic Radiation Uniformity in Indoor Crops" Applied Sciences 15, no. 21: 11768. https://doi.org/10.3390/app152111768

APA StyleRomero-Lomeli, R., Escalante-Garcia, N., Díaz-Ponce, A., Olvera-Gonzalez, E., & Peña-Cruz, M. I. (2025). Impact of LED Light Spatial Distribution on Photosynthetic Radiation Uniformity in Indoor Crops. Applied Sciences, 15(21), 11768. https://doi.org/10.3390/app152111768