Simulation-Driven Mining Logistics Towards Sustainable and Reliable Production

Abstract

1. Introduction

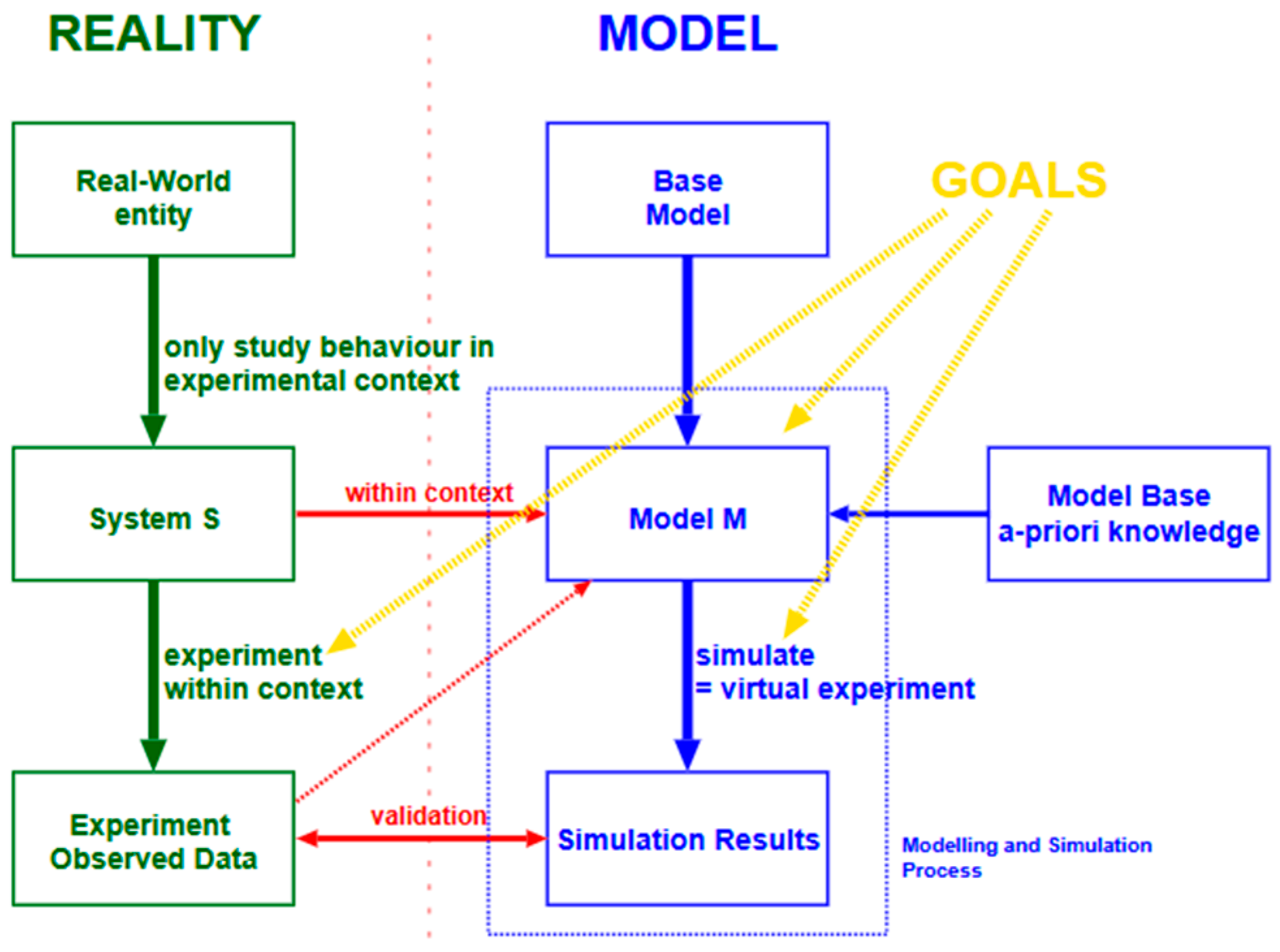

2. Materials and Methods

- System analysis;

- Selection of the simulation tool;

- Preparation of input parameters;

- Modeling and validation of model segments;

- Synthesis of the comprehensive model;

- Validation of the comprehensive model;

- Model experimentation;

- Presentation and implementation of suitable solutions.

3. Results and Discussion

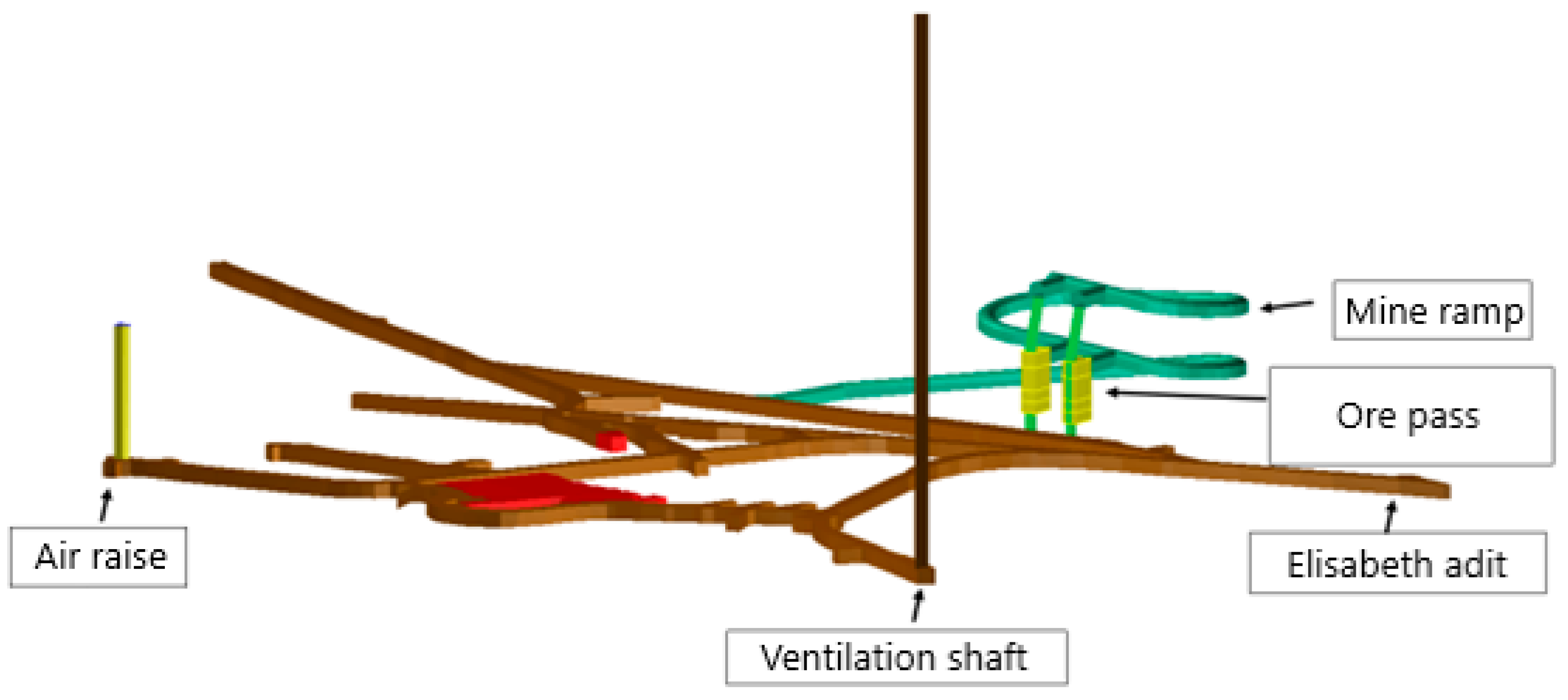

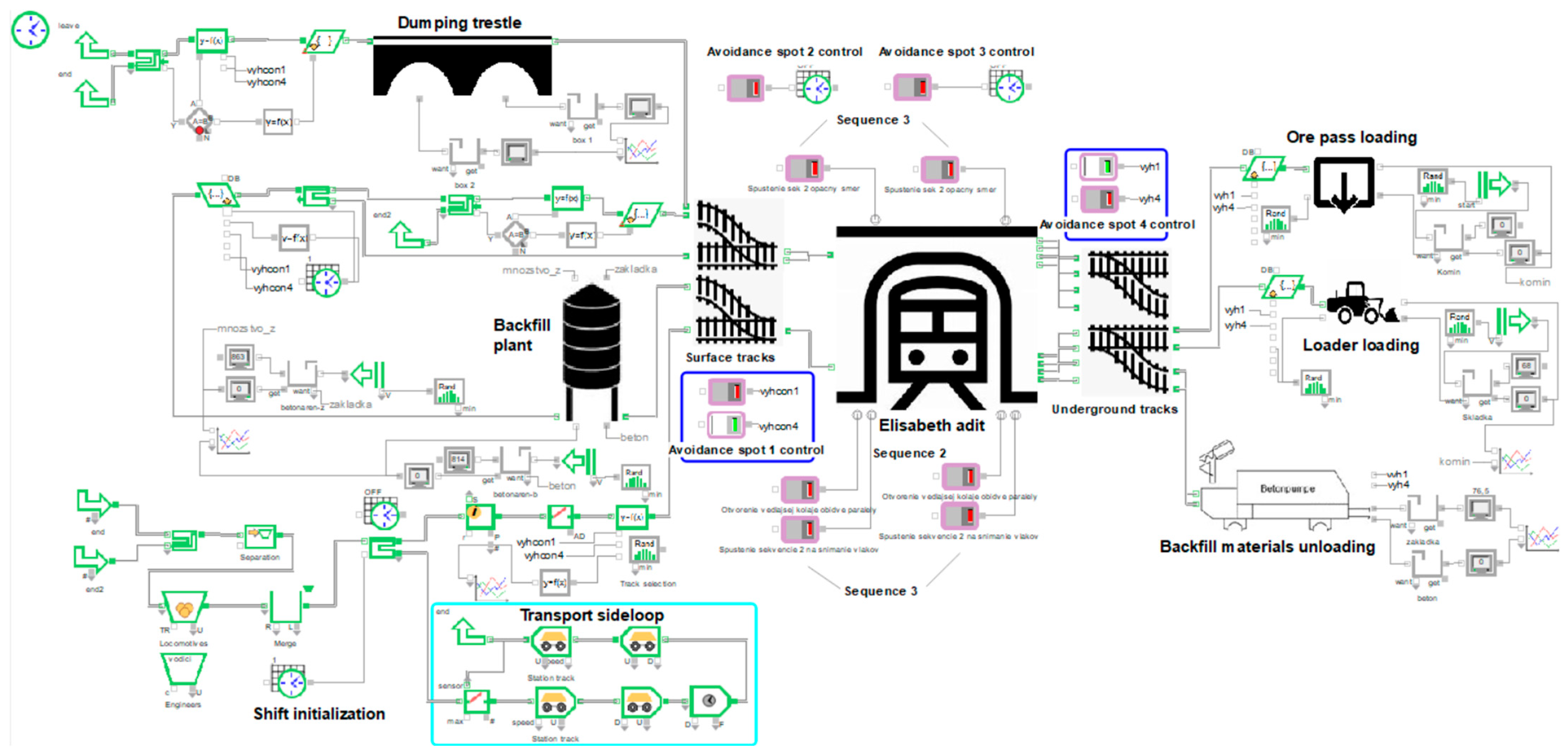

3.1. System Analysis

- Ore passes (+40 m)—haulage of raw material using four mine cars, each with a capacity of 10 m3.

- Loader (+160 m)—haulage of raw material using four mine cars, each with a capacity of 8 m3.

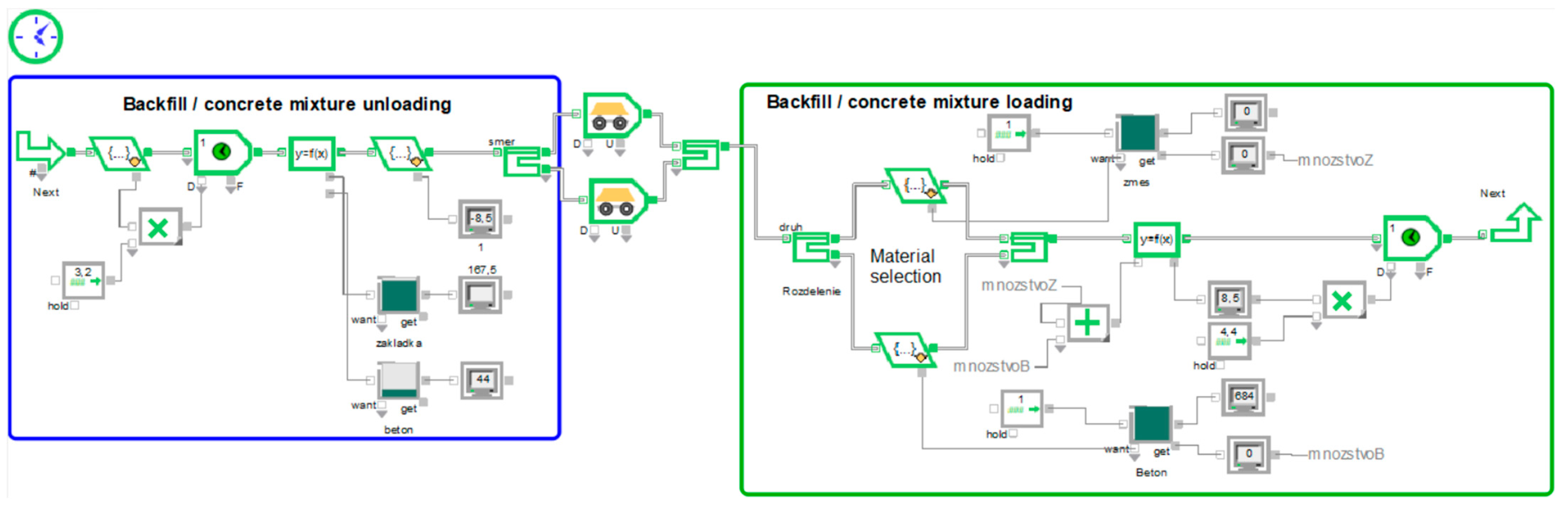

- Backfill mixture pump (+195 m/+275 m)—haulage of the mixture by dedicated backfill mine car (8.5 m3 capacity). For concrete haulage, the procedure is identical except that a different mine car type is used (11 m3 capacity).

- Ore haulage has priority over all other processes in the transportation system.

- Locomotives must push mine cars into loading and unloading positions—their position is changed at avoidance spots 1 or 4.

- All other underground and surface transportation is performed using automotive (road) vehicles.

- Raw material is delivered to the ore passes by a loader with a bucket capacity of 4 m3.

- Only one loader is available—simultaneous loading of material at both locations is therefore not possible.

- Ore blasts from different parts of the deposit must not be mixed in the ore pass.

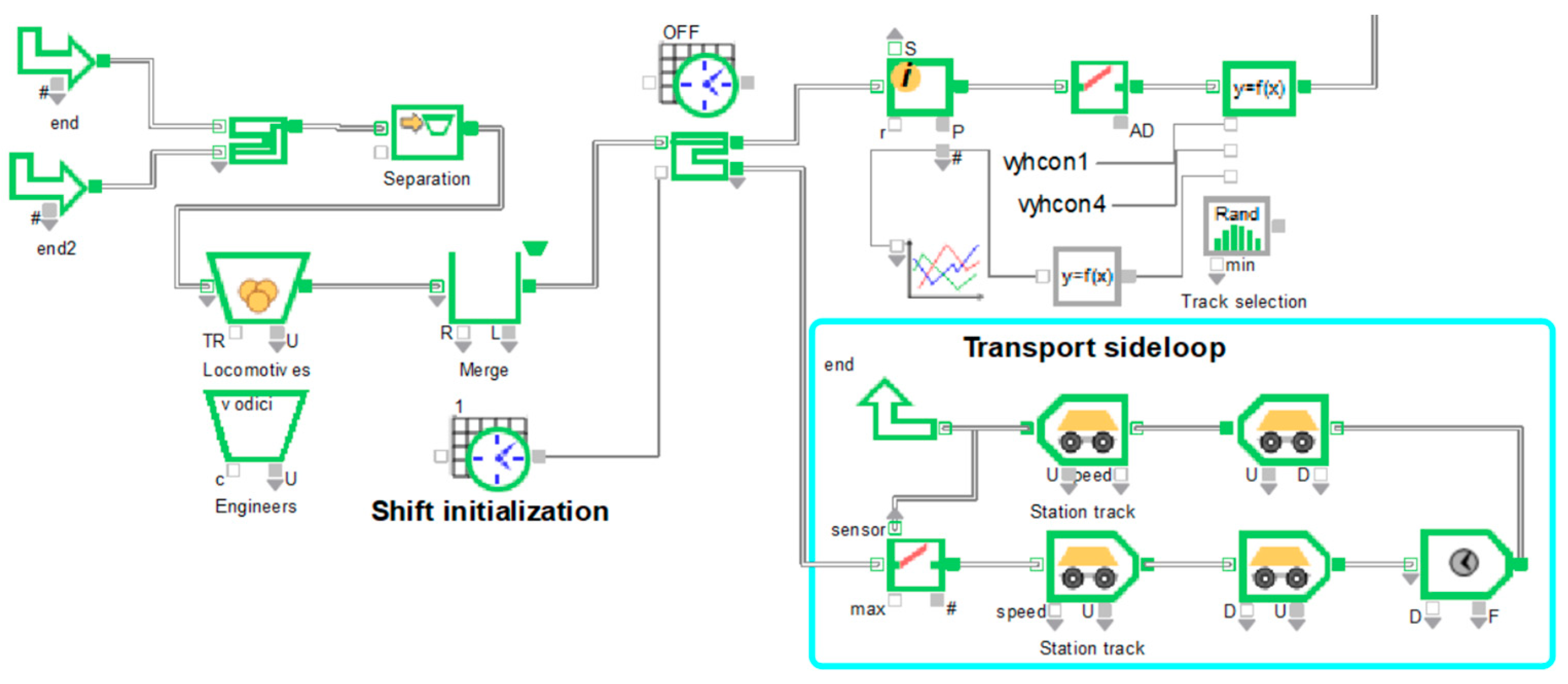

- The number of locomotive drivers is low, preventing the simultaneous operation of all locomotives.

- The mechanical equipment of locomotives and mine cars shows a high failure rate.

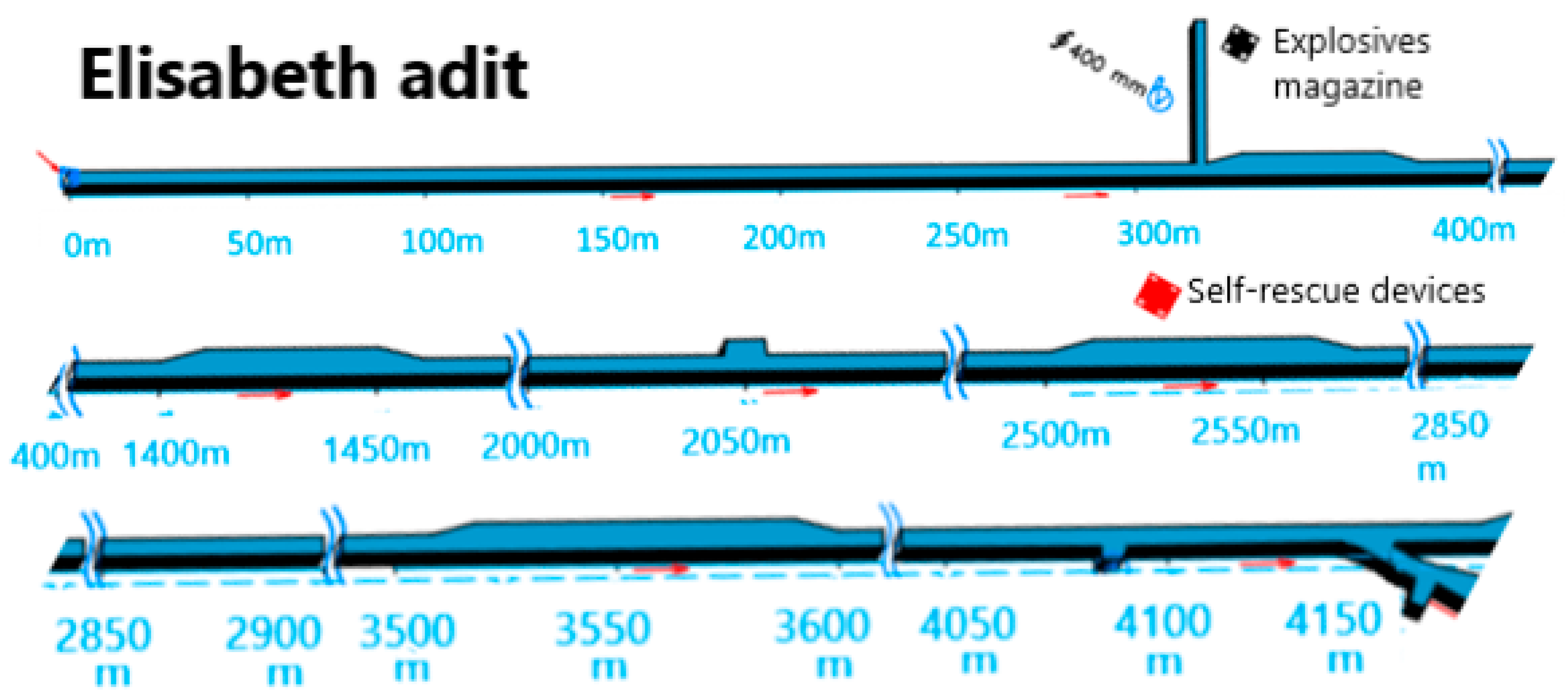

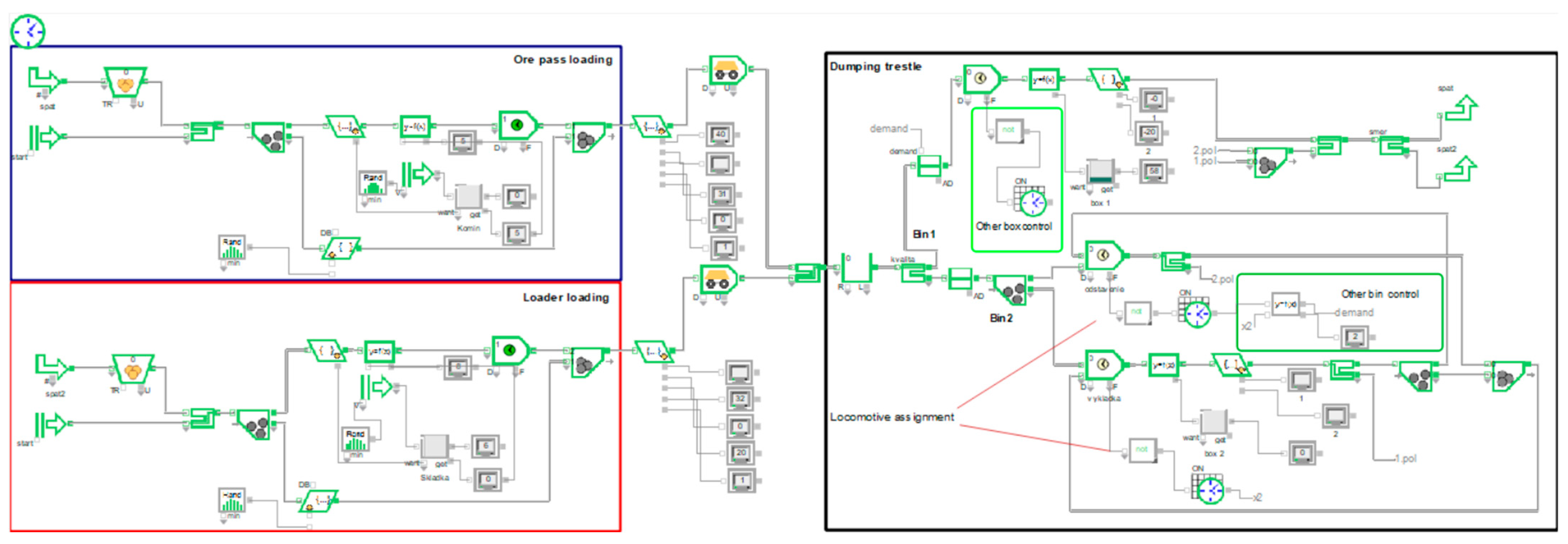

3.2. Modeling of the Transportation System

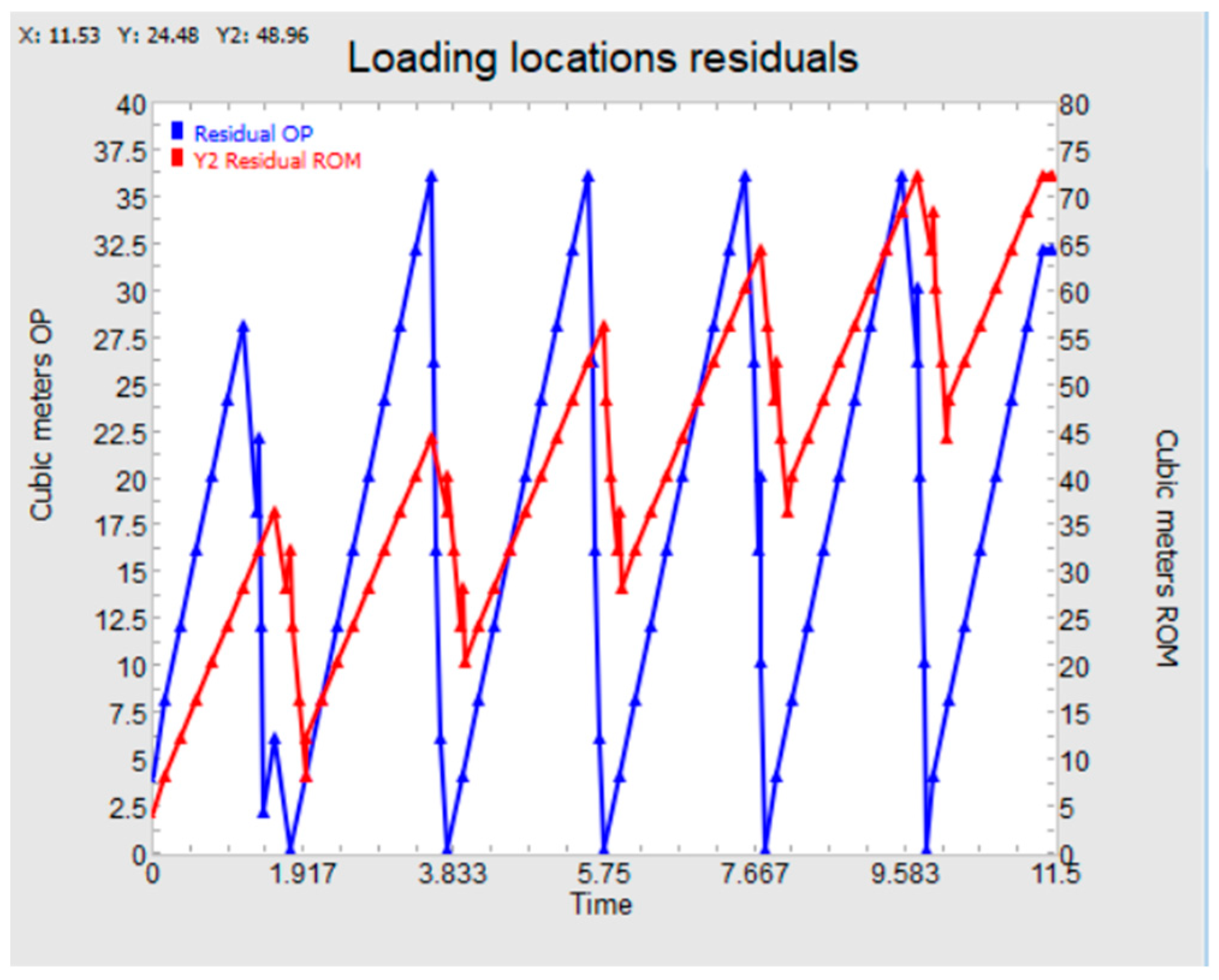

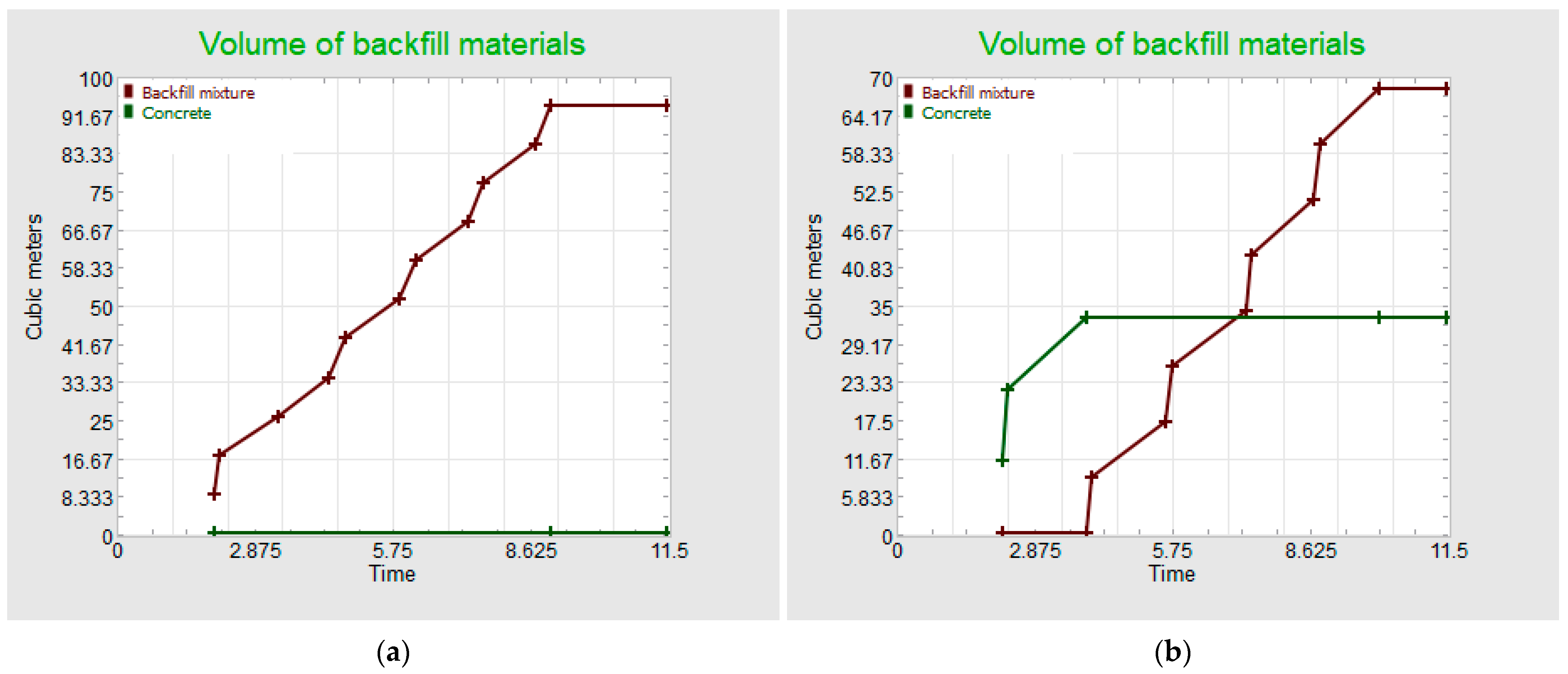

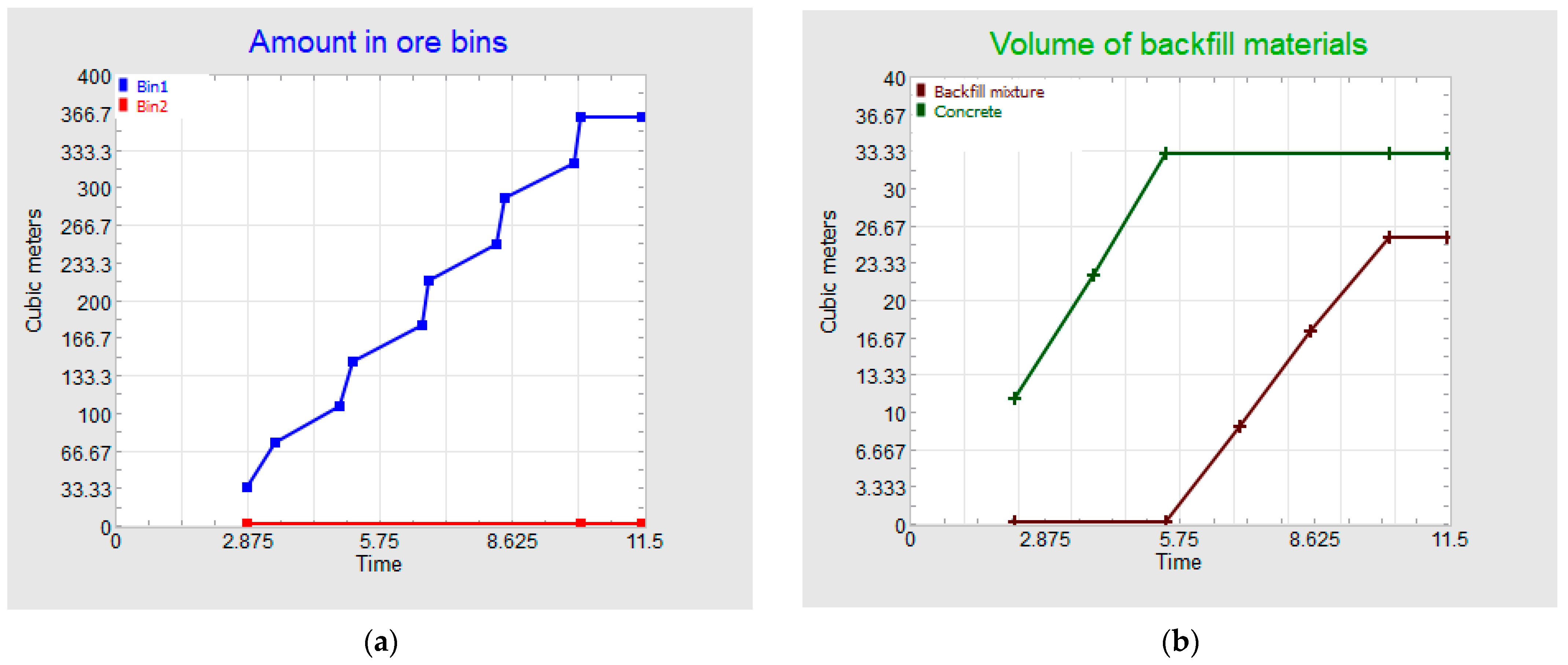

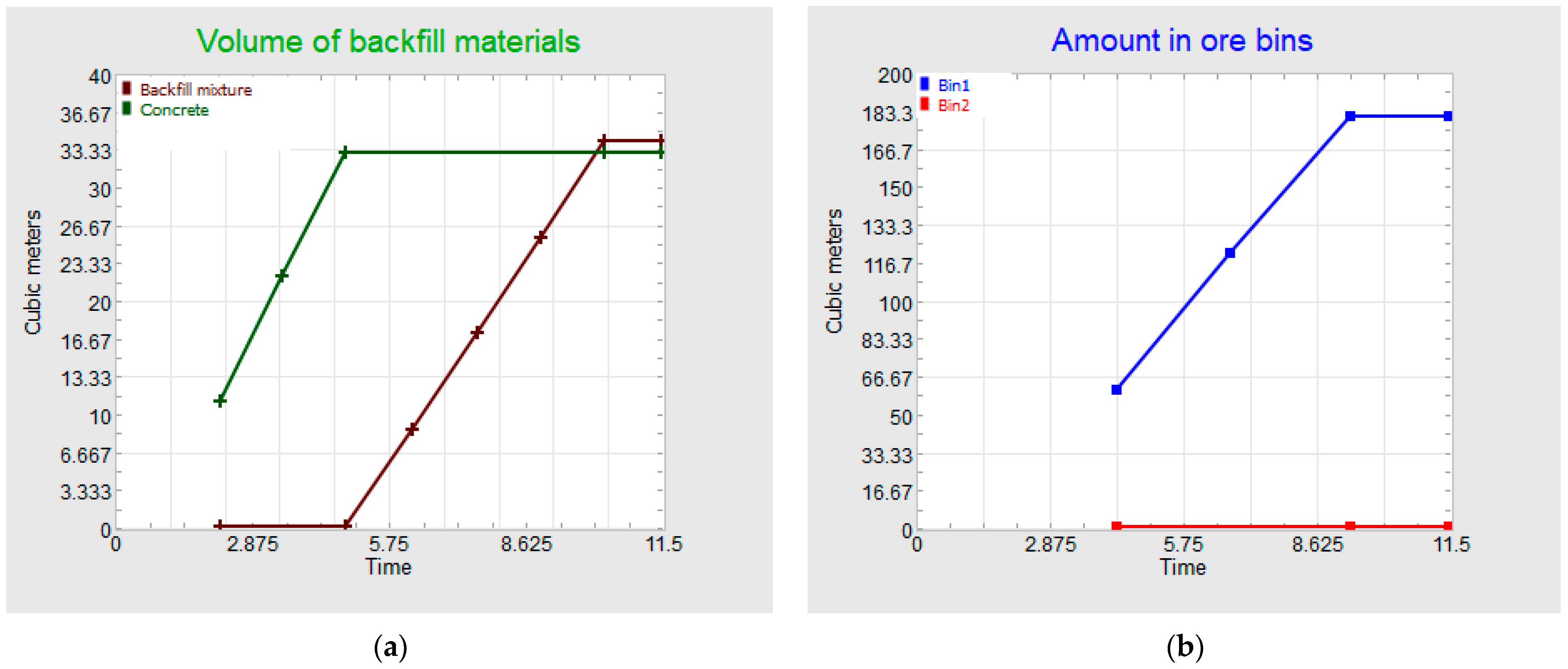

3.3. Simulation Model Experimentation

- Two locomotives with a single driver when ore haulage is carried out concurrently;

- Two locomotives with two drivers when no ore haulage takes place.

- Replacement of S24 rails with S30 profile rails mounted on steel sleepers.

- Comprehensive overhaul of all mechanical systems within the fleet and equipment.

- Adoption of an integrated condition-based and planned maintenance program engaging all employees.

- Implementation of centralized dispatch control for the transportation system, supported by digital technologies.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Operation | Amount [m3] | Time Measurements Samples [mm:ss] | Distribution [mm:ss] |

|---|---|---|---|

| Ore pass loading | 10 | 02:12, 02:16, 02:22, 2:50, 02:25, 02:31, 02:24, 02:37 | 02:12–02:50 |

| ROM loader loading | 8 | 04:49, 04:35, 04:40, 04:27, 04:56, 05:01, 04:44, 05:00 | 04:27–05:01 |

| Stope loader loading | 8 | 15:52, 15:42, 15:45, 15:44, 15:55, 15:53, 15:59, 16:01 | 15:49 ± 00:07 |

| Mine car tipping | 8/10 | 00:14, 00:14, 00:15, 00:14, 00:15, 00:16, 00:14, 00:16 | 00:14–00:16 |

| Second bin train set splitting | NA | 03:30, 04:44, 04:15, 03:45, 12:12, 16:44, 03:38, 04:02 | 03:30; 16:44; 04:08 |

| Locomotive repositioning | NA | 02:52, 03:01, 05:21, 03:04, 02:58, 04:26, 03:14, 03:12 | 02:52; 05:21; 03:04 |

| Mixtures loading | 1 | 04:20, 04:24, 04:24, 04:24, 04:23, 04:24 | 04:24 |

| Mixtures unloading | 1 | 03:19, 03:18, 03:19, 03:19, 03:17, 03:19 | 03:19 |

| Supplementary and personnel transportation | NA | 27:18, 27:55, 27:25, 27:17, 26:55, 26:42 | 27:10 ± 00:27 |

| Mine car entry and exit activities | NA | 04:12, 04:10, 04:25, 04:54, 04:50, 04:28 | 04:10–04:54 |

References

- Leontiev, R.; Barchukov, A.; Nemchaninova, M. Mining Logistics Systems: Classification, Identification, Innovation. E3S Web Conf. 2020, 192, 03016. [Google Scholar] [CrossRef]

- Jaekel, F. Fundamentals of Logistics Systems. In Cloud Logistics. Produktion und Logistik; Springer Gabler: Wiesbaden, Germany, 2019; pp. 9–51. [Google Scholar] [CrossRef]

- Dušan, M.; Spišák, D.; Drábik, J.; Gross, L. Teória Logistiky; Karnat: Košice, Slovakia, 2007; 215p, ISBN 978-80-8073-893-8. [Google Scholar]

- Mochalova, L.; Sokolova, O.; Yurak, V. Logistics System of Waste Management at the Mining Enterprises. J. Environ. Manag. Tour. 2019, 10, 202–209. [Google Scholar] [CrossRef]

- Goncharenko, S.N.; Ivakhnenko, A. Optimization of Ore Concentrate Transportation Indicators of a Mining Enterprise Based on a Logistic Analysis of Alternative Options for Organizing a Transportation System. In Intelligent Technologies and Electronic Devices in Vehicle and Road Transport Complex (TIRVED); IEEE: New York, NY, USA, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Marasová, D.; Petruf, M.; Taraba, V.; Saderova, J. Logistika Dopravy, 1st ed.; Technical University of Košice: Košice, Slovakia, 2007; 326p, ISBN 978-80-8073-892-1. [Google Scholar]

- Yaqot, M.; Menezes, B.C. Integrating Mineral Mining and Metallurgical Supply Chains: A Qualogistics Approach. In Computer Aided Chemical Engineering; Elsevier BV: Amsterdam, The Netherlands, 2023; Volume 52, pp. 1759–1764. [Google Scholar]

- Marasová, D.; Šaderová, J. Technológie Vnútropodnikovej Dopravy, 1st ed.; Technical University of Košice: Košice, Slovakia, 2017; 109p, ISBN 978-80-553-3125-6. [Google Scholar]

- Ren, X.; Guo, H.; Wang, C.F.; Gao, Y.Y.; Kai, S.; Ma, G. Real-Time Path Planning of Driver-Less Mining Trains with Time-Dependent Physical Constraints. Appl. Sci. 2022, 13, 3729. [Google Scholar] [CrossRef]

- Pei, S.; Yang, J. Multi-Agent Deep Reinforcement Learning to Improve Efficiency of Autonomous Mining Transportation. 2023. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4604945 (accessed on 31 July 2025).

- Guo, L.; Cao, K.; Yang, R.; Yue, C.; Yang, L.; Li, H.; Liu, P.; Jiao, J.; Wang, Y.; Sun, S.; et al. Mine Material Transportation Dispatching System and Method. CN148 0812A, 2019.

- Straka, M. Distribution and Supply Logistics; Cambridge Scholars Publishing: Newcastle upon Tyne, UK, 2019; 607p, ISBN 978-1-5275-3607-4. [Google Scholar]

- Šaderová, J.; Šofranko, M. Aktívne a Pasívne Prvky Logistických Reťazcov, 1st ed.; Vysoká škola báňská—Technická Univerzita Ostrava: Ostrava, Czech Republic, 2021; 190p, ISBN 978-80-248-4559-3. [Google Scholar]

- Grygárek, J. Základy Hornictví; VŠB–Technical University of Ostrava: Ostrava, Czech Republic, 2004; ISBN 20-248-0690-8. [Google Scholar]

- Soofastaei, A. Advanced Analytics in Mining Engineering; Springer International Publishing: Cham, Switzerland, 2022; 747p, ISBN 978-3-030-91588-9. [Google Scholar]

- Rupprecht, S.M. Underground Track Design, Construction and Maintenance. In Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection—MPES 2018, Las Condes, Chile, 19–23 November 2018; Springer: Cham, Switzerland, 2019; pp. 509–520, ISBN 978-3-319-99219-8. [Google Scholar]

- Paraszczak, J.; Svedlund, E.; Fytas, K.; Laflamme, M. Electrification of Loaders and Trucks—A Step Towards More Sustainable Underground Mining. Renew. Energy Power Qual. J. 2014, 12, 81–86. [Google Scholar] [CrossRef]

- Bende, N.; Bârã, A. A Study on the Role of Automation and AI in Operational Efficiency and Sustainable Mining. Indian Sci. J. Res. Eng. Manag. 2024, 8, 1–5. [Google Scholar] [CrossRef]

- Zhironkina, O.; Zhironkin, S. Technological and Intellectual Transition to Mining 4.0: A Review. Energies 2023, 16, 1427. [Google Scholar] [CrossRef]

- Nobahar, P.; Xu, C.; Dowd, P.; Faradonbeh, R.S. Exploring digital twin systems in mining operations: A review. Green Smart Min. Eng. 2024, 1, 474–492. [Google Scholar] [CrossRef]

- Eleftherios, E.; Papatsaroucha, D.; Markakis, E.K. Leveraging Industrial IoT Infrastructure for Remote Sensing and Edge Computing in the Mining Sector. In Proceedings of the 2024 5th International Conference in Electronic Engineering, Information Technology & Education (EEITE), Chania, Greece, 29–31 May 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Kurniasih, J.; Abas, Z.A.; Asmai, S.A.; Wibowo, A.B. Process Mining and Simulation Modeling in Production System: A Review. LogForum 2024, 20, 429–453. [Google Scholar] [CrossRef]

- Pourbafrani, M.; van der Aalst, W.M.P. Data-Driven Simulation In Process Mining: Introducing A Reference Model. In Proceedings of the 37th ECMS International Conference on Modelling and Simulation (ECMS 2023), Florence, Italy, 20–23 June 2023; pp. 411–420. [Google Scholar] [CrossRef]

- Ferreira, W.D.P.; Armellini, F.; de Santa-Eulalia, L.A.; Rebolledo, C. Modelling and Simulation in Industry 4.0. In Artificial Intelligence in Industry 4.0; Dingli, A., Haddod, F., Klüver, C., Eds.; Springer: Cham, Switzerland, 2021; Volume 928, pp. 57–72. [Google Scholar]

- Malindžák, D. Metódy Analýzy Logistických Systémov; Technical University of Košice: Košice, Slovakia, 2015; 41p, ISBN 978-80-553-2150-9. [Google Scholar]

- Birta, L.G.; Arbez, G. Modelling and Simulation, 3rd ed.; Springer Nature: Cham, Switzerland, 2019; 551p, ISBN 978-3-030-18868-9. [Google Scholar]

- Straka, M. Teoretické Východiská Simulácie: Simulačný Systém ExtendSIM 9.x; Technical University of Košice: Košice, Slovakia, 2017; 99p, ISBN 978-80-553-3143-0. [Google Scholar]

- Vangheluwe, H. Foundations of Modelling and Simulation of Complex Systems. In Proceedings of the Seventh International Workshop on Graph Transformation and Visual Modeling Techniques (GT-VMT 2008), Budapest, Hungary, 29–30 March 2008; Volume 10, pp. 1–12, ISSN 1863-2122. [Google Scholar]

- Li, X.; Zhang, J.; Peng, S.; Wang, Y.; He, M.; Yao, Z. Numerical Simulation of Surface Subsidence and Backfill Material Movement Induced by Underground Mining. Adv. Civ. Eng. 2019, 2019, 2724370. [Google Scholar] [CrossRef]

- Huerta, J.R.; Silva, R.S.; De Tomi, G.; da Silva, A.L.M. A Dynamic Simulation Approach to Support Operational Decision-Making in Underground Mining. Simul. Model. Pract. Theory 2022, 115, 102458. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Mujumdar, A.S. CFD Simulation of Methane Dispersion and Innovative Methane Management in Underground Mining Faces. Appl. Math. Model. 2014, 38, 3467–3484. [Google Scholar] [CrossRef]

- Ondov, M.; Špirková, S.; Ďuriška, M.; Kleinová, L. Modular Elements of Mining Transport Systems in a Simulation Program. Acta Logist. Moravica 2023, 13, 41–49. Available online: https://vslg.cz/wp-content/uploads/2023/10/ALM.2023.1.pdf (accessed on 13 August 2025).

- Mishkurov, P.; Fridrikhson, O.; Lukyanov, V.; Kornilov, S.; Say, V. Simulated Transport and Logistics Model of a Mining Enterprise. Transp. Res. Procedia 2021, 54, 411–418. [Google Scholar] [CrossRef]

- Wang, X.; Long, S.; Meng, X. Simulation and Optimization of Mining-Separating-Backfilling Integrated Coal Mine Production Logistics System. Energy Explor. Exploit. 2022, 40, 908–925. [Google Scholar] [CrossRef]

- Hashemi, A.; Sattarvand, J. Application of ARENA Simulation Software for Evaluation of Open Pit Mining Transportation Systems—A Case Study. In Proceedings of the 12th International Symposium Continuous Surface Mining—Aachen 2014, Aachen, Germany, 21–25 September 2014; Springer: Cham, Switzerland, 2015; pp. 213–224, ISBN 978-3-319-12301-1. [Google Scholar] [CrossRef]

- Pop-Andonov, G.; Mirakovski, D.; Despodov, Z. Simulation Modeling and Analyzing in Underground Haulage Systems with Arena Simulation Software. Int. J. Sci. Tech. Innov. Ind. MTM (Mach. Technol. Mater.) 2012, 48–50. [Google Scholar]

- Saderová, J.; Rosová, A.; Kacmary, P.; Sofranko, M.; Bindzar, P.; Malkus, T. Modelling as a Tool for the Planning of the Transport System Performance in the Conditions of a Raw Material Mining. Sustainability 2020, 12, 8051. [Google Scholar] [CrossRef]

- Saderova, J.; Ambrisko, L.; Marasova, D.; Muchova, P. Proposal of a Transport Planning Model for the Removal of Quarry Stone Using a Simulation. Appl. Sci. 2024, 14, 5130. [Google Scholar] [CrossRef]

- Bardzinski, P.J.; Krol, R.; Jurdziak, L. Empirical Model of Discretized Copper Ore Flow Within the Underground Mine Transport System. Int. J. Simul. Model. 2019, 18, 279–289. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z.; Bi, L.; Wang, L.; Gu, Q. Determination of Truck–Shovel Configuration of Open-Pit Mine: A Simulation Method Based on Mathematical Model. Sustainability 2022, 14, 12338. [Google Scholar] [CrossRef]

- Greberg, J.; Salama, A.J.; Gustafson, A.; Skawina, B. Alternative Process Flow for Underground Mining Operations: Analysis of Conceptual Transport Methods Using Discrete Event Simulation. Minerals 2016, 6, 65. [Google Scholar] [CrossRef]

- Salama, A.; Greberg, J. Optimization of Truck-Loader Haulage System in an Underground Mine: A Simulation Approach Using SimMine. In Proceedings of the International Conference & Exhibition on Mass Mining, Sudbury, ON, Canada, 10–14 June 2012; Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A1011835&dswid=-4791 (accessed on 13 August 2025).

- Fedorko, G.; Vasil, M. The Use of Simtalk Program for Modelling Disconnection of Rail Vehicles in the Mineral Raw Materials Mining. In Proceedings of the 17th International Multidisciplinary Scientific GeoConference SGEM, Albena, Bulgaria, 29 June–5 July 2017; Volume 17, pp. 703–709, ISBN 978-619-7408-05-8. [Google Scholar]

- Ondov, M.; Saderova, J.; Sofrankova, A.; Horizral, L.; Kacmary, P. Transport System Digitalization in the Mining Industry. Sustainability 2025, 17, 6038. [Google Scholar] [CrossRef]

- Hou, J.; Li, G.; Chen, L.; Wang, H.; Hu, N. Optimization of Truck–Loader Matching Based on a Simulation Method for Underground Mines. Sustainability 2022, 15, 216. [Google Scholar] [CrossRef]

- Smith, A.; Linderoth, J.; Luedtke, J. Optimization-Based Dispatching Policies for Open-Pit Mining. Optim. Eng. 2021, 22, 1347–1387. [Google Scholar] [CrossRef]

- ANDRITZ Inc. ExtendSim. Available online: https://extendsim.com/ (accessed on 7 August 2025).

- Imagine That Inc. ExtendSim User Guide; Imagine That Inc.: San Jose, CA, USA, 2021; 776p, Available online: https://extendsim.com/solutions/publications/documentation (accessed on 7 August 2025).

- Machineryline. Sandvik LH410 Underground Mining Loader for Sale, Billingham, United Kingdom. Available online: https://machineryline.info/-/sale/underground-mining-loaders/Sandvik/LH410--23081903104047782300 (accessed on 20 August 2025).

| Simulation Software | Scale of the Simulation Models | Findings/Limitations |

|---|---|---|

| AnyLogic | Model for regulating the duration of transport and technological operations 1 [33]. | Uneven utilization of system elements adversely affects car downtime rate and transport services. |

| Model for the optimization of the logistics system for production and development 1 [34]. | Model optimization improves production efficiency. The complexity of coordinating mining logistics processes remains a challenge. | |

| ARENA | Model for assigning trucks to loaders and the dispatch simulation model 1 [35]. | Proposed dispatching systems increase production rate. The simulation also identifies key bottlenecks and enables flexible testing. |

| Comparing four variants of tunnel layout and transportation strategies 1 [36]. | The model yields detailed visualization and helps optimize transport costs. | |

| ExtendSim | Model of loading raw material into two vehicles, ExtendSim8 [37]. | Discrete-event simulation methods reflect realistic operational conditions and variability. Modeling provides a basis for improving transport system key indicators. |

| Model for planning a quarry transportation system, ExtendSim8 [38]. | Simulation improves transport system performance and decision-making. The model simplifies certain stochastic aspects of the transport system. | |

| FlexSim | Model for comparing two mining transportation systems 1 [39]. | Simulation represents ore movement as discrete units. Assumptions in the discretization process may oversimplify complex interactions. |

| Model for configuring trucks in the transportation system, FlexSim 19.0.0. [40]. | Simulation results demonstrate improved mining efficiency, reduced operating costs, and minimized truck idle times. | |

| SimMine | Interlevel ore haulage model, SimMine 1.19. [41]. | Highlights that simulation combined with validation is a suitable method for analyzing mine operations. |

| Variable fleet mine transportation system model, SimMine 1.19. [42]. | Demonstrates potential improvements in haulage efficiency, cycle time reduction, and operational savings. | |

| Tecnomatix Plant Simulation | Mine car uncoupling model 1 [43]. | Highlights the practical application of simulation combined with programming tools for enhanced accuracy. |

| Transportation system control and scheduling, Tecnomatix Plant Simulation v2302.0004 [44]. | Digitalization facilitates adaptive management capable of responding to evolving mine conditions and operational requirements. | |

| Custom simulation program | Model for the optimization of loaders and trucks [45]. | Simulation optimizes loaders and trucks number under various constraints including dynamic factors. |

| Model for truck dispatching [46]. | Two novel dispatching policies are proposed. The optimization approach can control ore quality and manage truck queue sizes. |

| Fleet Element | Model Allocation | Restriction |

|---|---|---|

| Locomotives | Resource Item block initial number | Drivers |

| Locomotive downtime caused by degraded track | Transport blocks speed | Maximum 5 km/h |

| DHD 20 utilization | Transport sideloop for supplementary materials | Mining activities are performed by Schoema locomotives |

| DHD 15 utilization | Transport sideloop for personnel | A 100% mining task rejection due to failure |

| Mine cars | Automatically assigned after task selection in the Equation block | Four for raw material and only one for mixtures (due to pump performance) |

| Mine car degraded mechanisms | Activity blocks at avoidance spots 1 and 4 and the second bin splitting activity | A high maximum value in a triangular distribution |

| Drivers | Resource Pool allocation | User defined value (currently 2) |

| Tasks | Drivers | Locomotives | Loaders | Mine Cars |

|---|---|---|---|---|

| One-point raw material haulage | 1 | 1 | 1 | 4 (10 or 8 m3) |

| One-point double raw material haulage | 2 | 2 | 1 | 8 (10 and 8 m3) |

| Mixture haulage | 1 | 2 | 0 | 3 (concrete or backfill) |

| Double mixture haulage | 2 | 2 | 0 | 3 (concrete or backfill) |

| Mixed raw material and mixture haulage | 2 | 3 | 1 | 4 (10 or 8 m3) and 3 (concrete or backfill) |

| Operation | Location and Volume | Train Sets/Engineers | Measured Process Duration (hh:mm) | Simulated Process Duration (hh:mm) | Discrepancy |

|---|---|---|---|---|---|

| Haulage | B488—161.8 t | 2/2 1/1 | 05:14 05:48 | 04:44 07:01 | 9.55% 20.98% |

| Haulage | C492—114.1 t | 2/2 1/1 | 04:39 06:55 | 04:29 06:05 | 3.58% 12.05% |

| Backfilling | C—M3—834 m3 | 1/1 | 216:00 | 235:29 | 9.02% |

| Backfilling | C—M3—583 m3 | 1/1 | 168:00 | 149:39 | 10.92% |

| Backfilling | C—M3—615 m3 | 1/1 | 192:00 | 144:42 | 24.63% |

| Backfilling | C—M3—611 m3 | 1/1 | 144:00 | 172:31 | 19.80% |

| Backfilling | B—M4—366 m3 | 1/1 | 96:00 | 103:20 | 7.65% |

| Backfilling | B—M4—828 m3 | 1/1 | 264:00 | 233:47 | 11.44% |

| Backfilling | B—M4—613 m3 | 1/1 | 120:00 | 157:21 | 31.12% |

| Operation | Discrepancy | Locomotive Repositioning | Train Set Speed Input Change | ||

|---|---|---|---|---|---|

| Input Change −30% | Input Change +30% | Input Change −30% | Input Change +30% | ||

| Output Discrepancy | |||||

| Haulage/B488—161.8 t/2/2 | 9.55% | 9.25% (343.07 min) | 16.97% (260.71 min) | ||

| Haulage/B488—161.8 t/1/1 | 20.98% | 18.7% | 22.4% | 4.31% (363 min) | 43.7% (500 min) |

| Haulage/C492—114.1 t/2/2 | 3.58% | 12.12% (312.84 min) | 14.38% (238.87 min) | ||

| Haulage/C492—114.1 t/1/1 | 12.05% | 6.07% (440.22 min) | 23.87% (315.9 min) | ||

| Backfilling/C—M3—834 m3 | 9.02% | 42.9% (308.71 h) | 6.57% (201.80 h) | ||

| Backfilling/C—M3—583 m3 | 10.92% | 7.69% (180.92 h) | 29.18% (118.97 h) | ||

| Backfilling/C—M3—615 m3 | 24.63% | 25.73% | 22.9% | 3.5% (185.23 h) | 35.12% (124.56 h) |

| Backfilling/C—M3—611 m3 | 19.80% | 57.17% (226.33 h) | 2.78% (148.01 h) | ||

| Backfilling/B—M4—366 m3 | 7.95% | 41.2% (135.56 h) | 7.65% (88.65 h) | ||

| Backfilling/B—M4—828 m3 | 11.44% | 16.44% (307.42 h) | 23.65% (201.51 h) | ||

| Backfilling/B—M4—613 m3 | 31.12% | 28.9% | 33.6% | 13.55% (206.5 h) | 72% (136.26 h) |

| Train Sets | Loading Type | Ore Bin | Raw Material Source * | Shortest Duration [h] | Longest Duration [h] |

|---|---|---|---|---|---|

| 1 | Ore pass | 1 | OP | 10.55 | 10.67 |

| 2 | OP | 12.21 | 12.41 | ||

| Loader | 1 | ROM | 12.78 | 13.01 | |

| S | 18.21 | 18.41 | |||

| 2 | ROM | 14.47 | 15.15 | ||

| S | 19.95 | 20.72 | |||

| 2 | Ore pass | 1 | OP | 5.49 | 5.59 |

| 2 | OP | 6.30 | 6.89 |

| Interval [min] | 4.5 to 5.5 | 15 ± 2 | 10 ± 1.5 | 5 to 15, Most Likely 10 | |

|---|---|---|---|---|---|

| Loading Type | Volume per Shift (11.5 h) [m3] | ||||

| One Train Set (OP) | Bin | 312 | 152 | 213 | 235 |

| Residual | 263 | 38 | 35 | 38 | |

| Two Train Sets (OP) | Bin | 480 | 120 | 200 | 208 |

| Residual | 77 | 34 | 33 | 35 | |

| One Train Set (ROM) | Bin | 211 | 136 | 181 | 192 |

| Residual | 331 | 26 | 52 | 58 | |

| One Train Set (OP) and One Train Set (ROM) | Bin | 432 | 248 | 379 | 392 |

| Residual OP | 275 | 31 | 39 | 42 | |

| Residual ROM | 337 | 28 | 88 | 86 | |

| Robust Conclusions | Tentative Conclusions |

|---|---|

| The model appropriately represents the real system | Backfilling can be performed after the raw material haulage process using two train sets |

| Speed is a crucial input parameter | Safety and waste management improve through process alternation—KPIs needed |

| The target of 10,000 tons per month is achievable | Improvements in mechanism reliability can be achieved through restructuring of maintenance systems |

| Backfilling can be performed on a reduced scale when using one train set for raw material | The model is suitable for operational process planning |

| Continuity secures proposed frequencies | Developing a digital twin requires further research and software modification |

| A second loader allows more haulage options with higher production | Sustainable underground logistics system is still nascent—quantification is needed |

| Replacement of rails increases the actual speed of locomotives | The problem-solving methodology can be transferred and adapted across different mining contexts |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sofrankova, A.; Ondov, M.; Sofranko, M. Simulation-Driven Mining Logistics Towards Sustainable and Reliable Production. Appl. Sci. 2025, 15, 11722. https://doi.org/10.3390/app152111722

Sofrankova A, Ondov M, Sofranko M. Simulation-Driven Mining Logistics Towards Sustainable and Reliable Production. Applied Sciences. 2025; 15(21):11722. https://doi.org/10.3390/app152111722

Chicago/Turabian StyleSofrankova, Andrea, Marek Ondov, and Marian Sofranko. 2025. "Simulation-Driven Mining Logistics Towards Sustainable and Reliable Production" Applied Sciences 15, no. 21: 11722. https://doi.org/10.3390/app152111722

APA StyleSofrankova, A., Ondov, M., & Sofranko, M. (2025). Simulation-Driven Mining Logistics Towards Sustainable and Reliable Production. Applied Sciences, 15(21), 11722. https://doi.org/10.3390/app152111722