On the Process Optimization, Microstructure Characterization and Mechanical Performance of Ti65 Titanium Alloy Produced by Laser Powder Bed Fusion

Abstract

1. Introduction

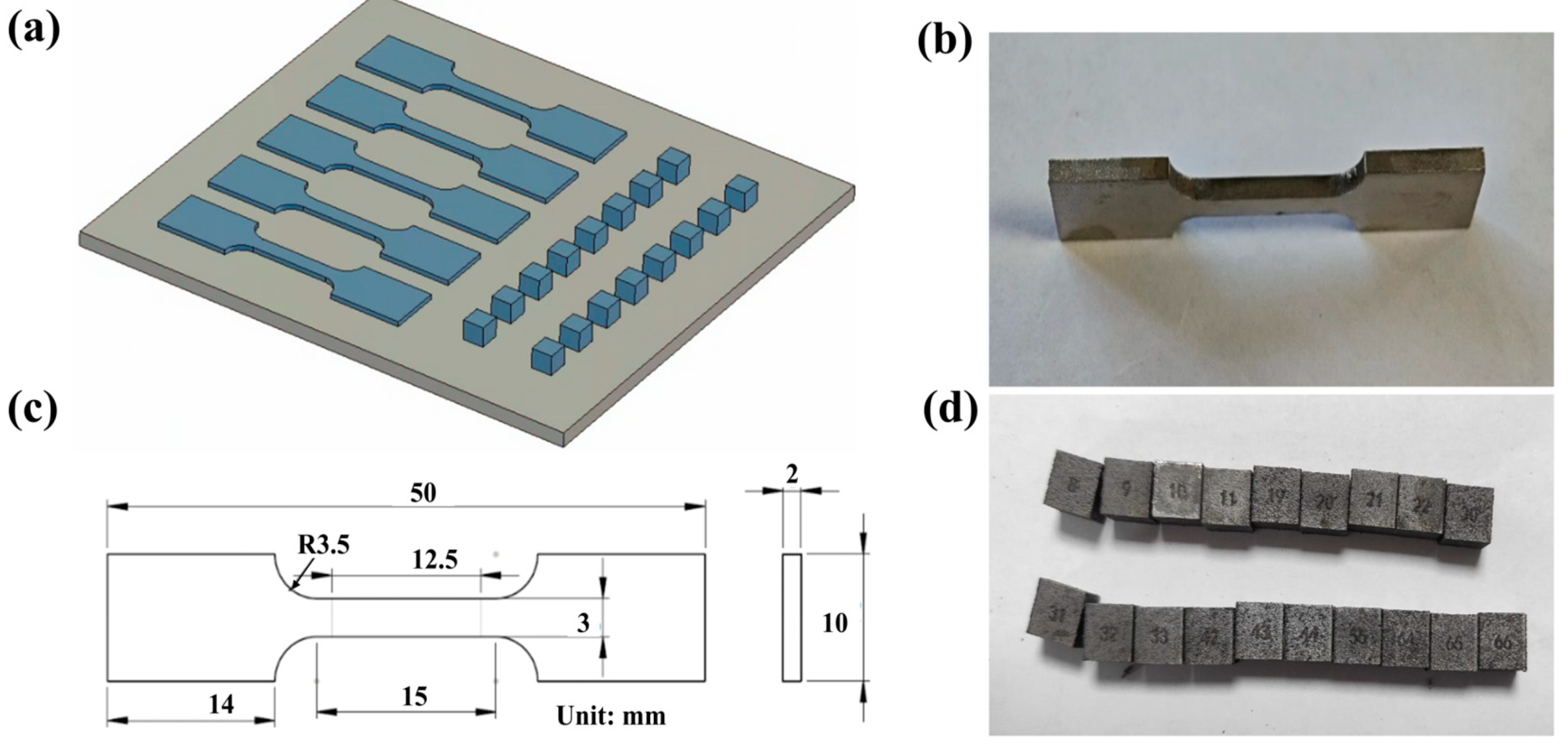

2. Materials and Methods

2.1. Powder Materials

2.2. Experimental Process

2.3. Characterization

3. Results and Discussion

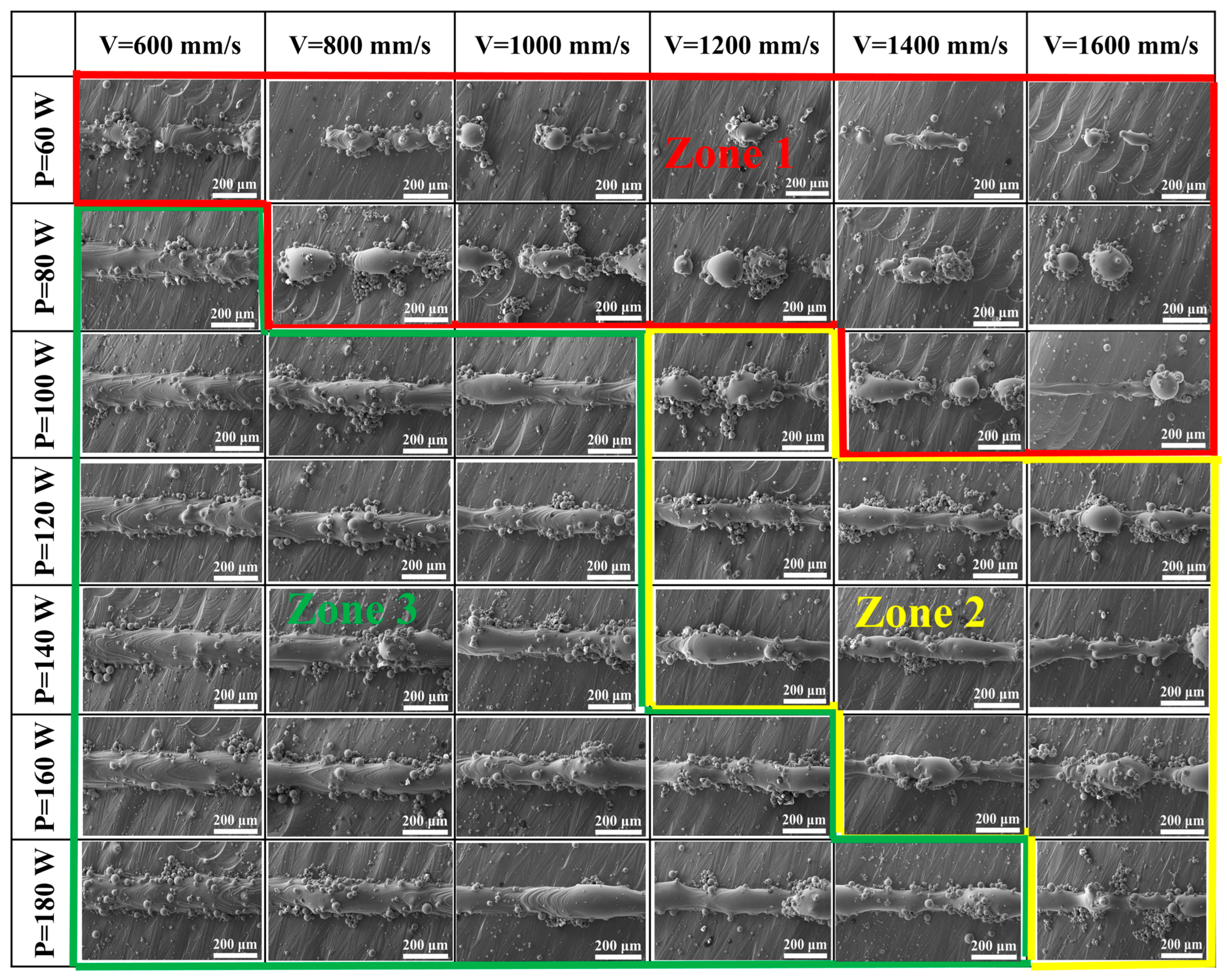

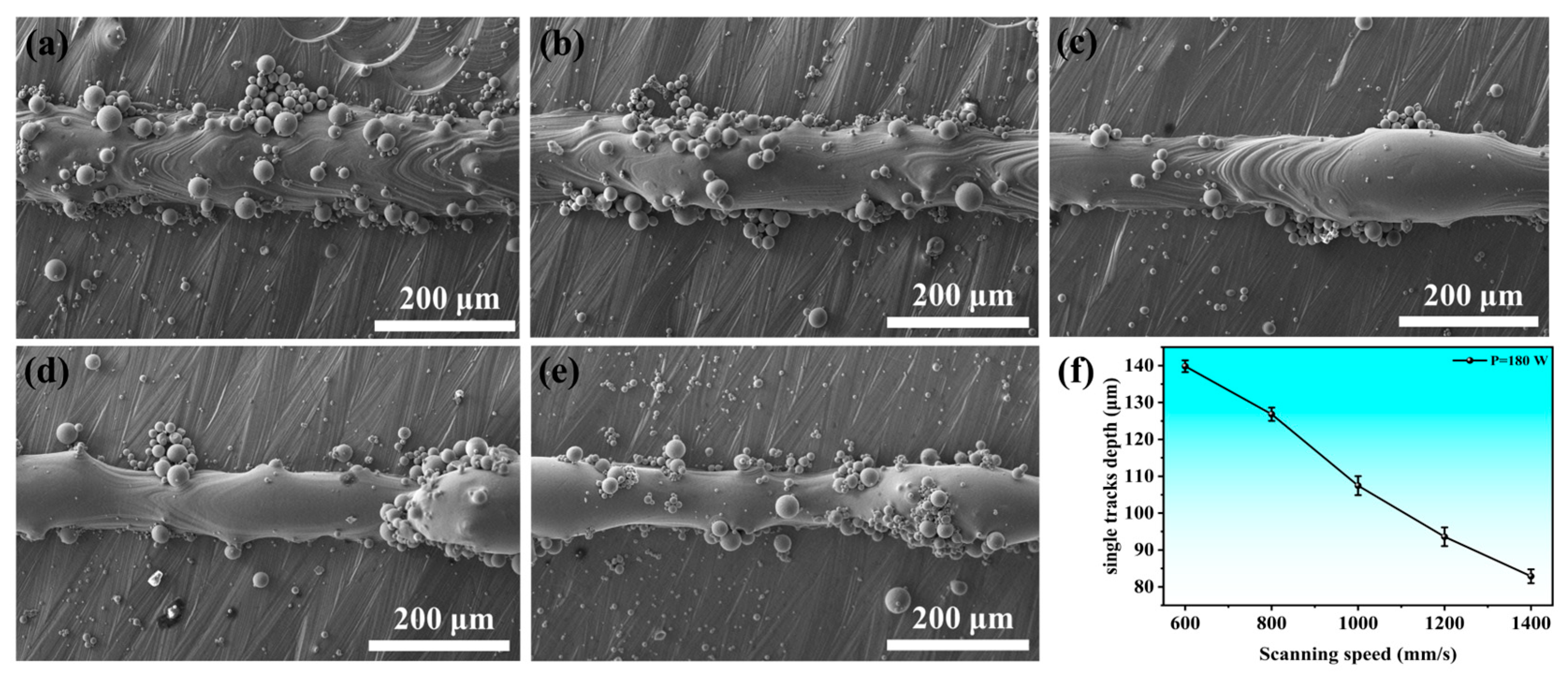

3.1. Surface Morphology of Single Tracks

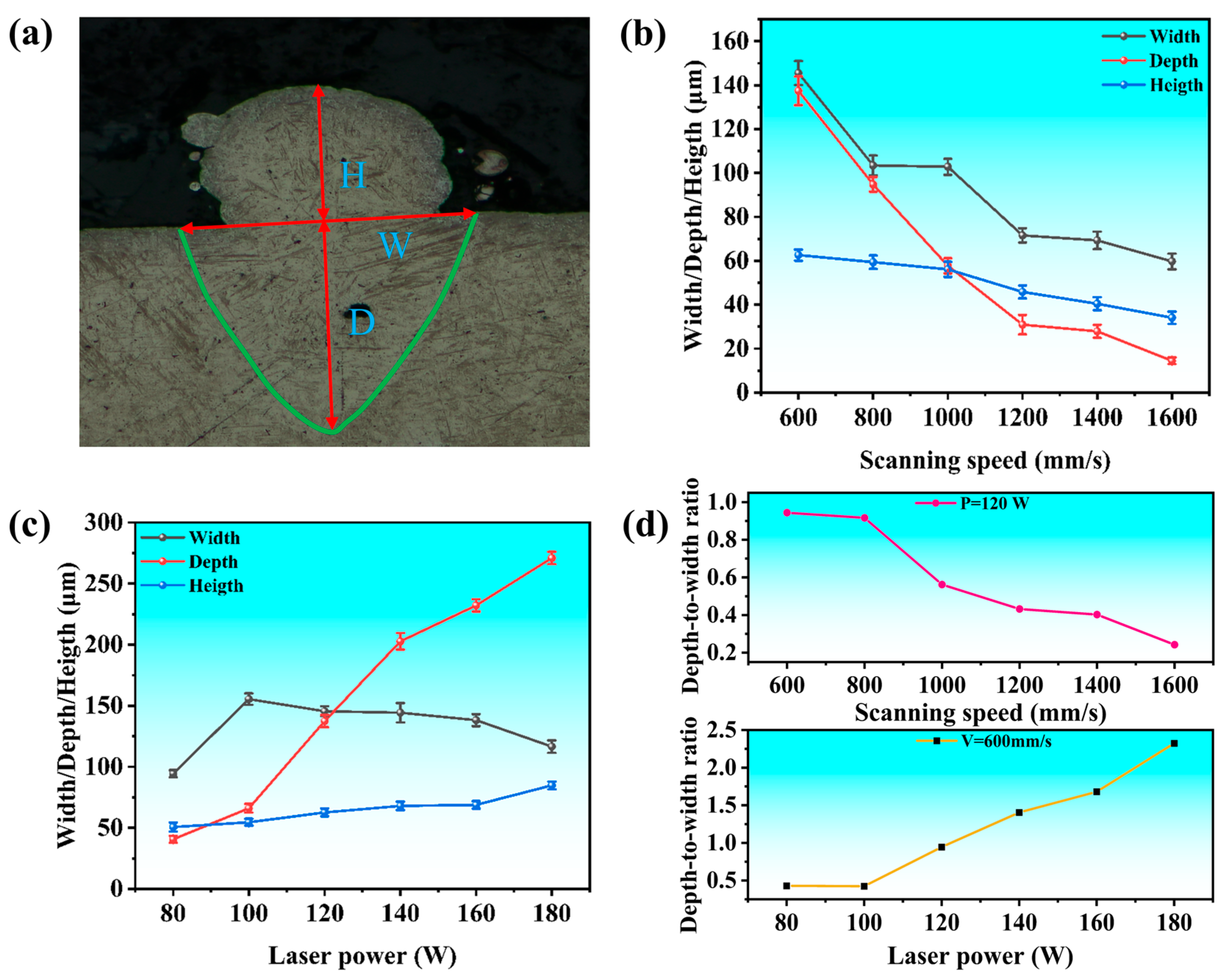

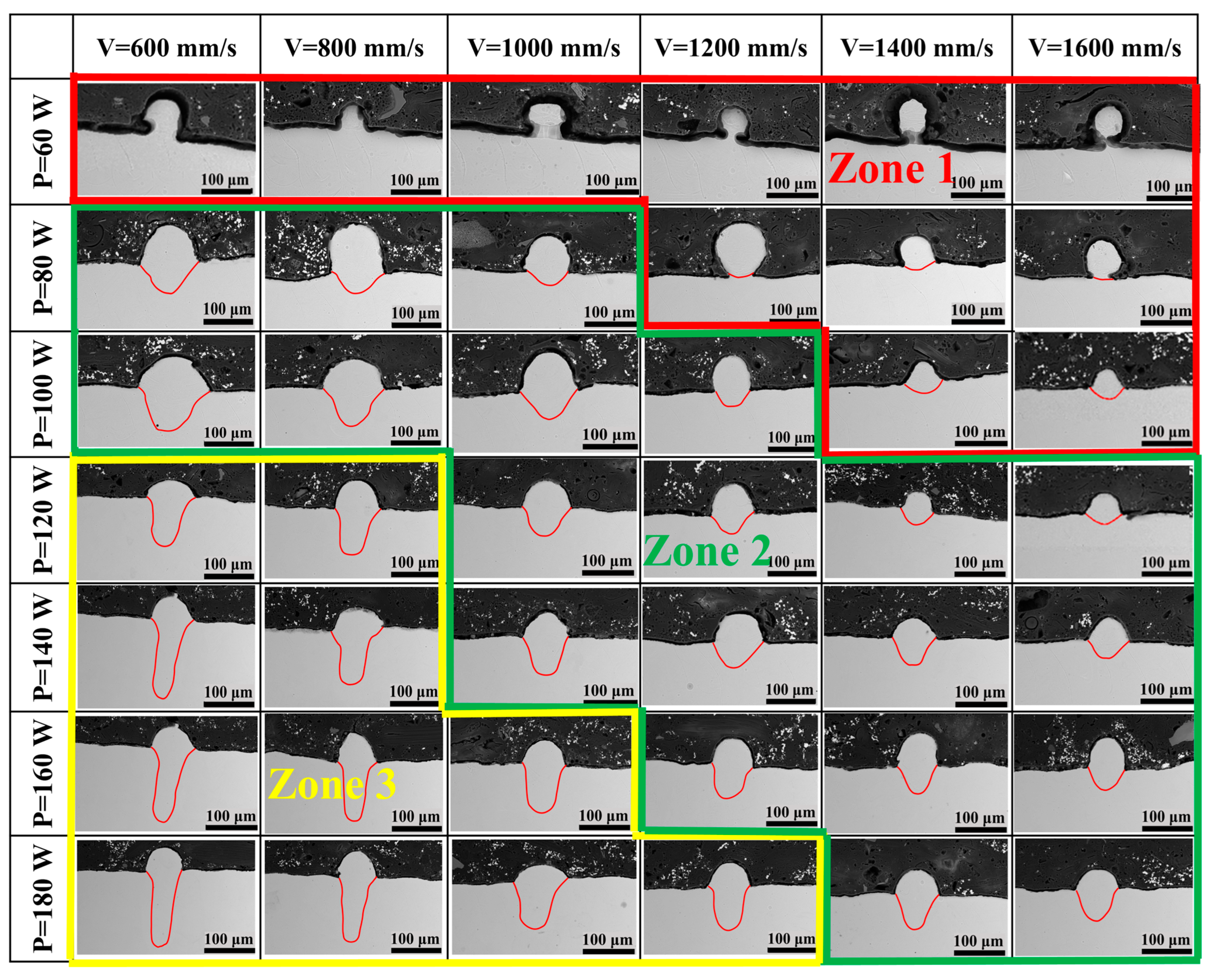

3.2. Geometric Characteristic of Molten Pool

3.3. Surface Morphology of Multi Tracks

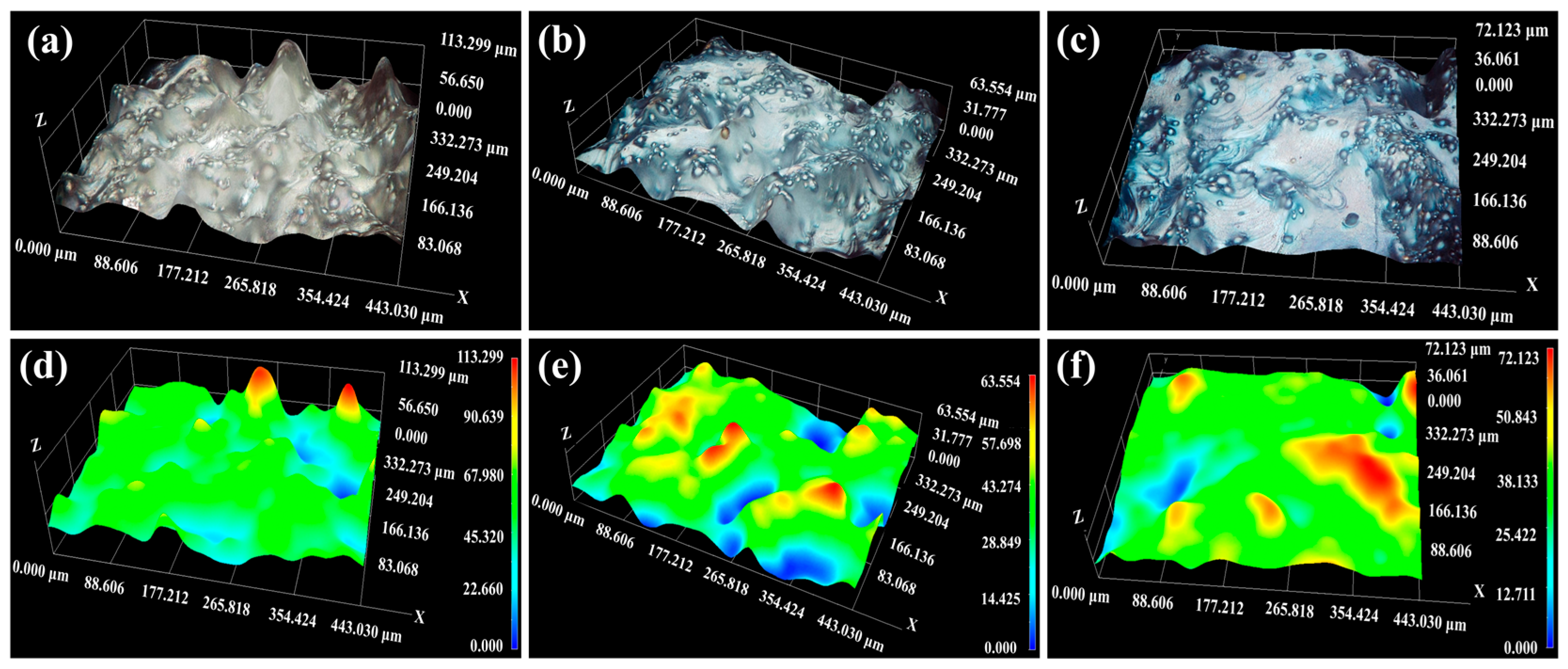

3.4. Surface Morphology of Cubic Samples

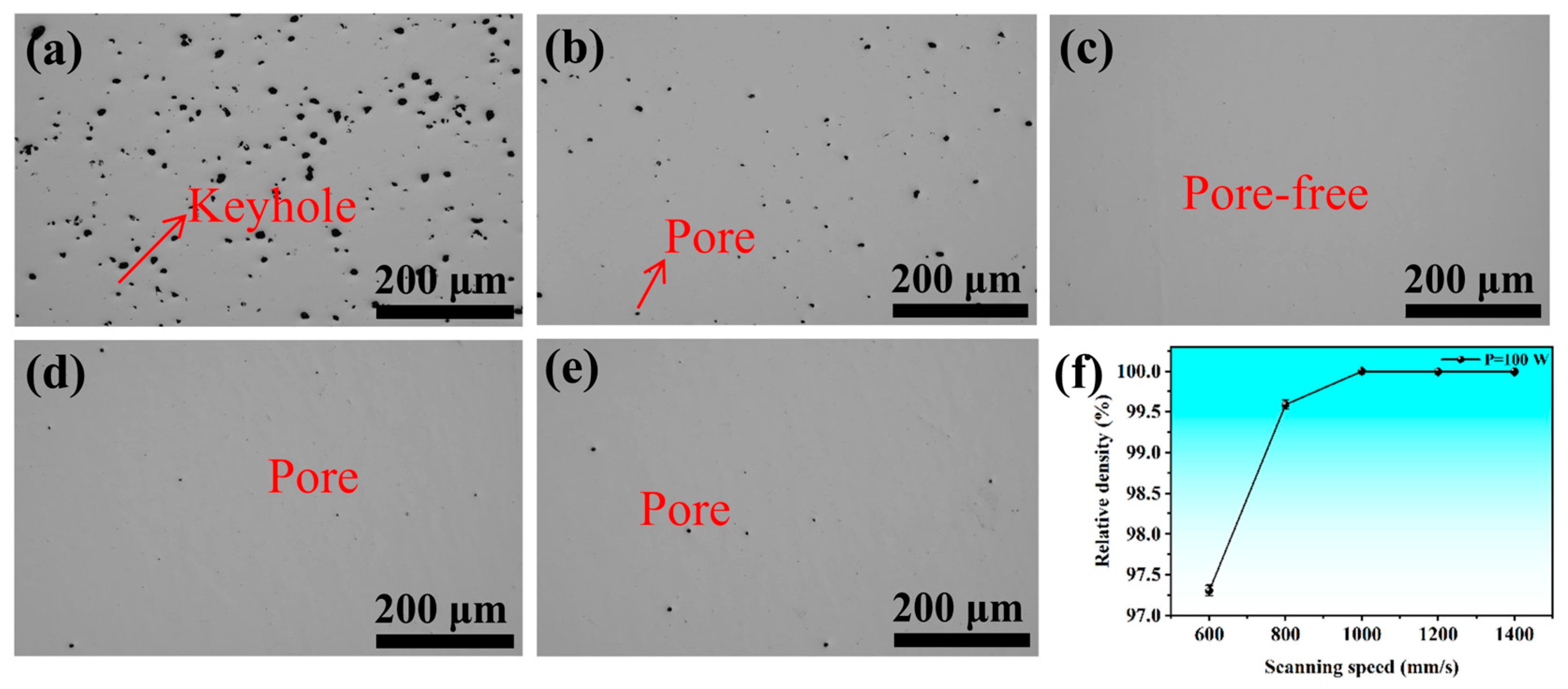

3.4.1. Relative Density of Samples

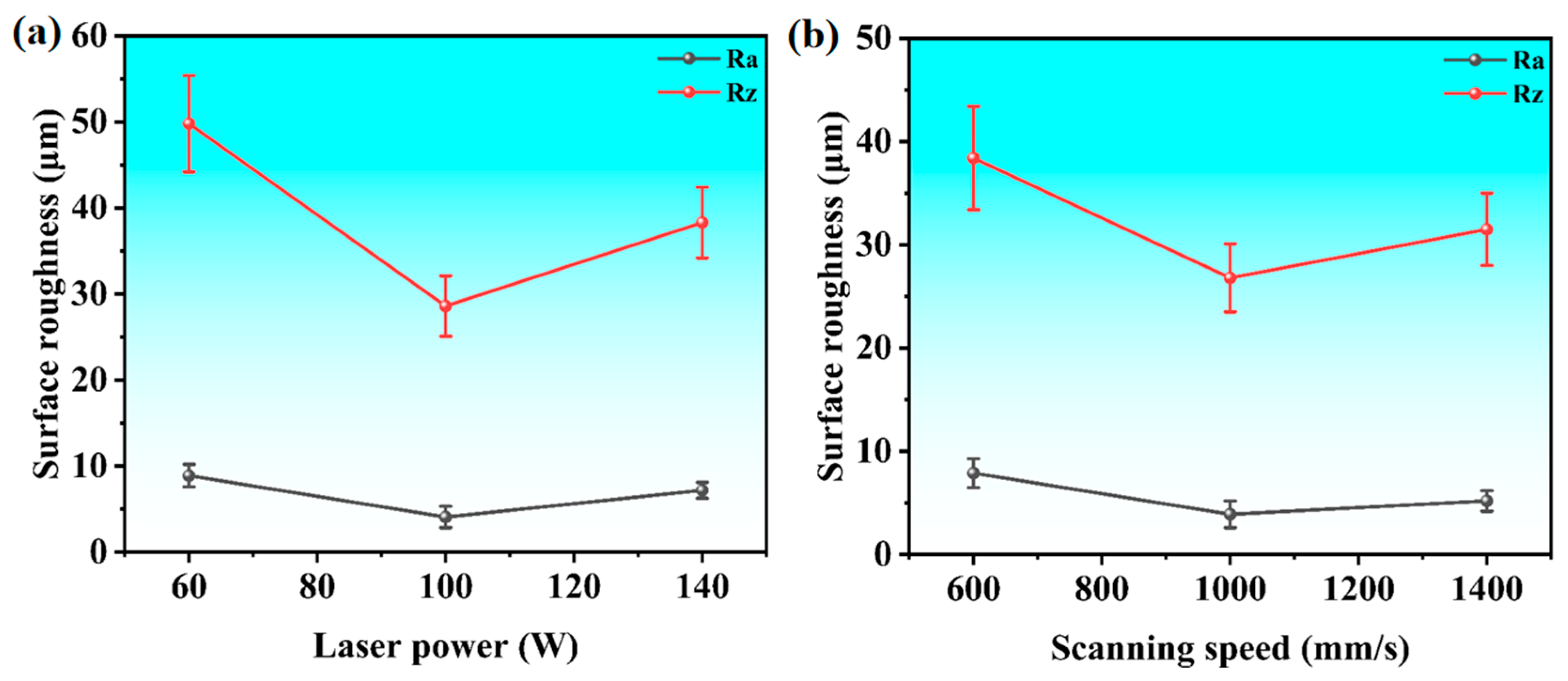

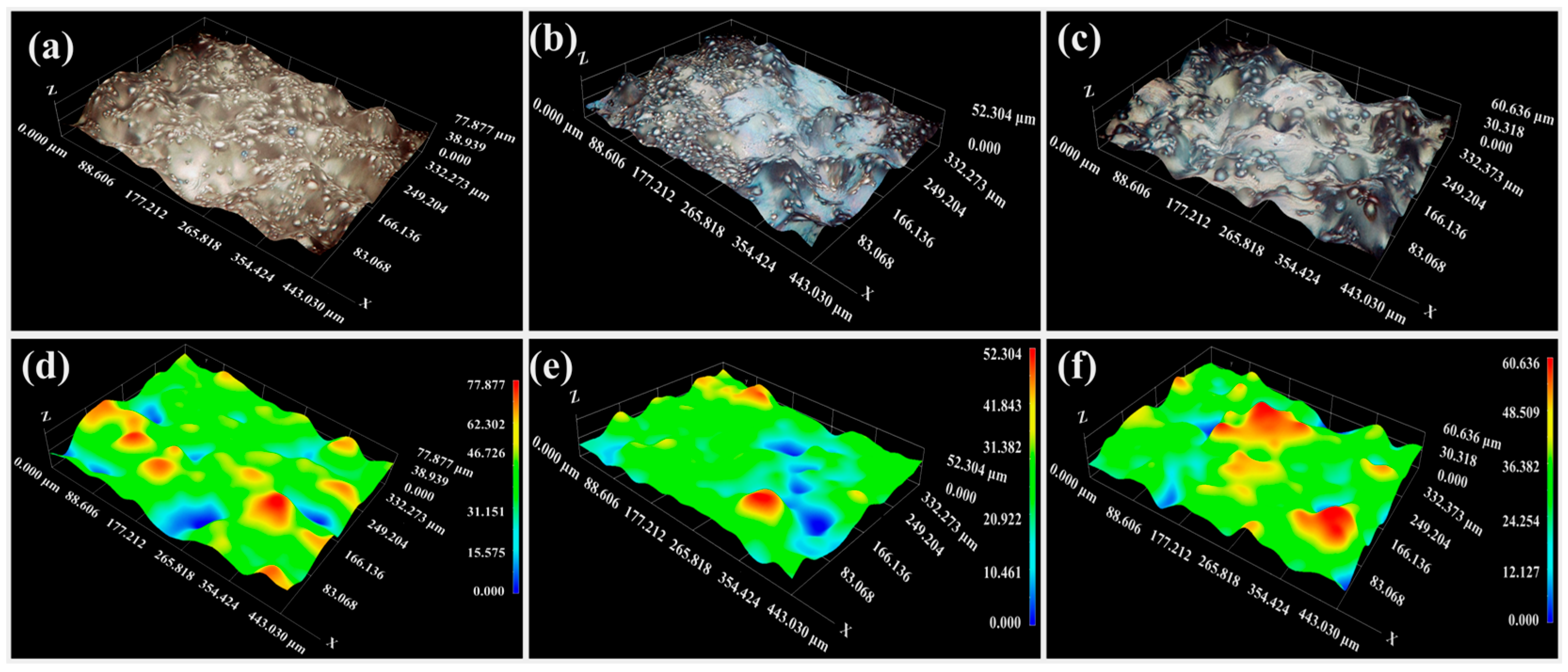

3.4.2. Surface Roughness of the Sample

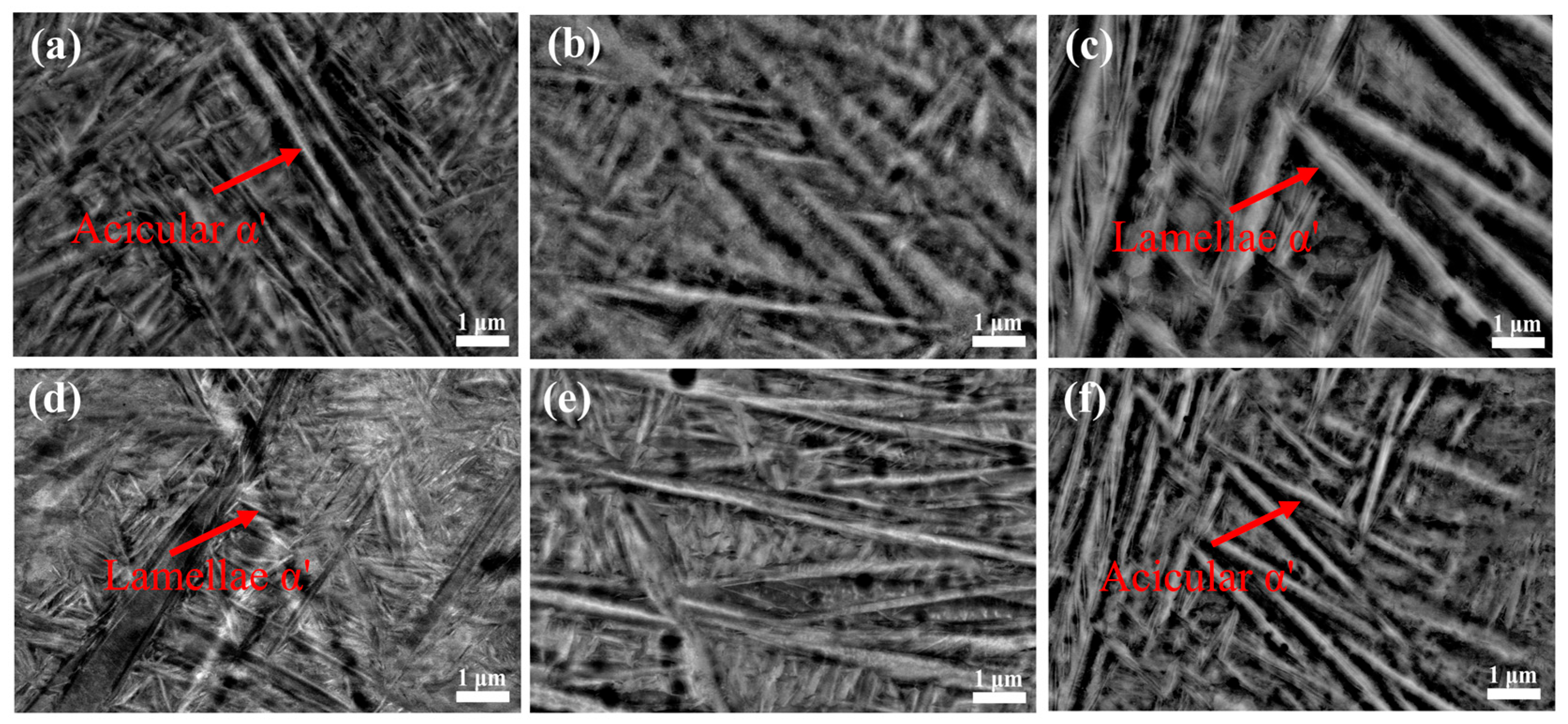

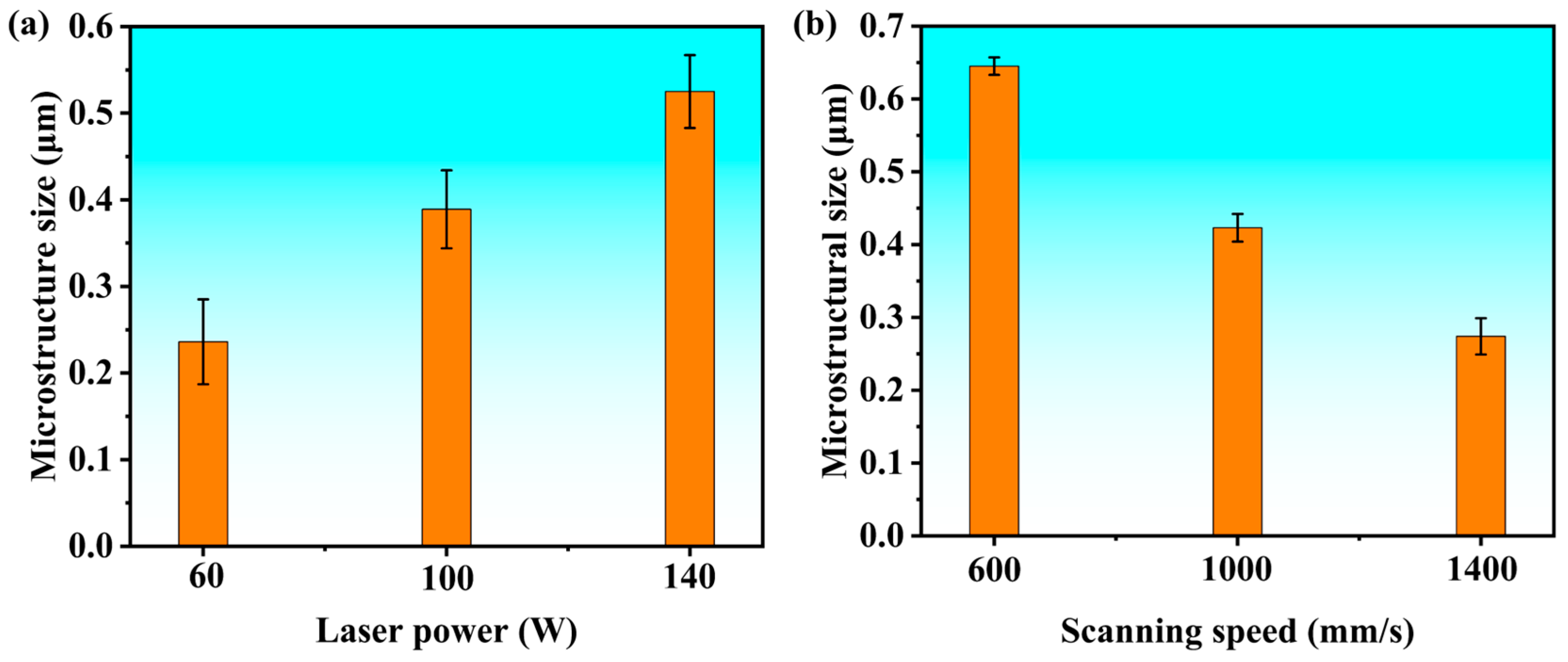

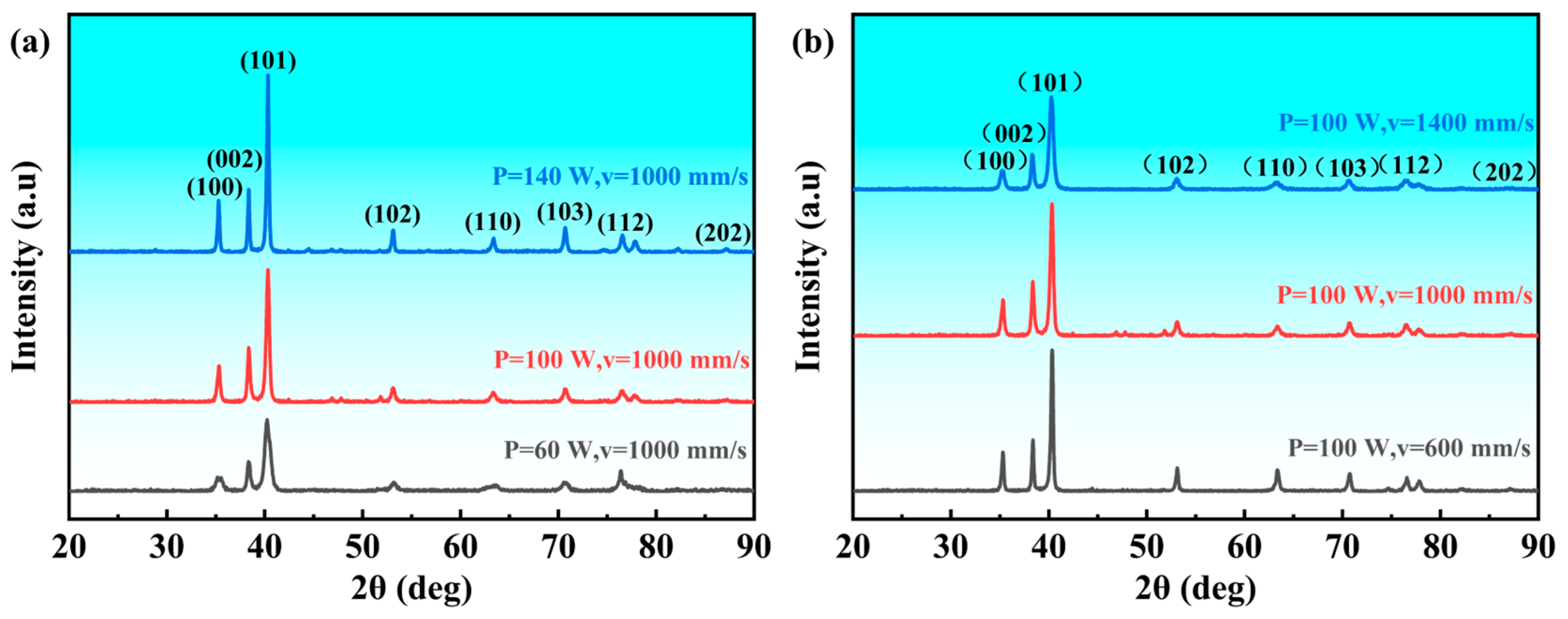

3.5. Microstructural Analysis

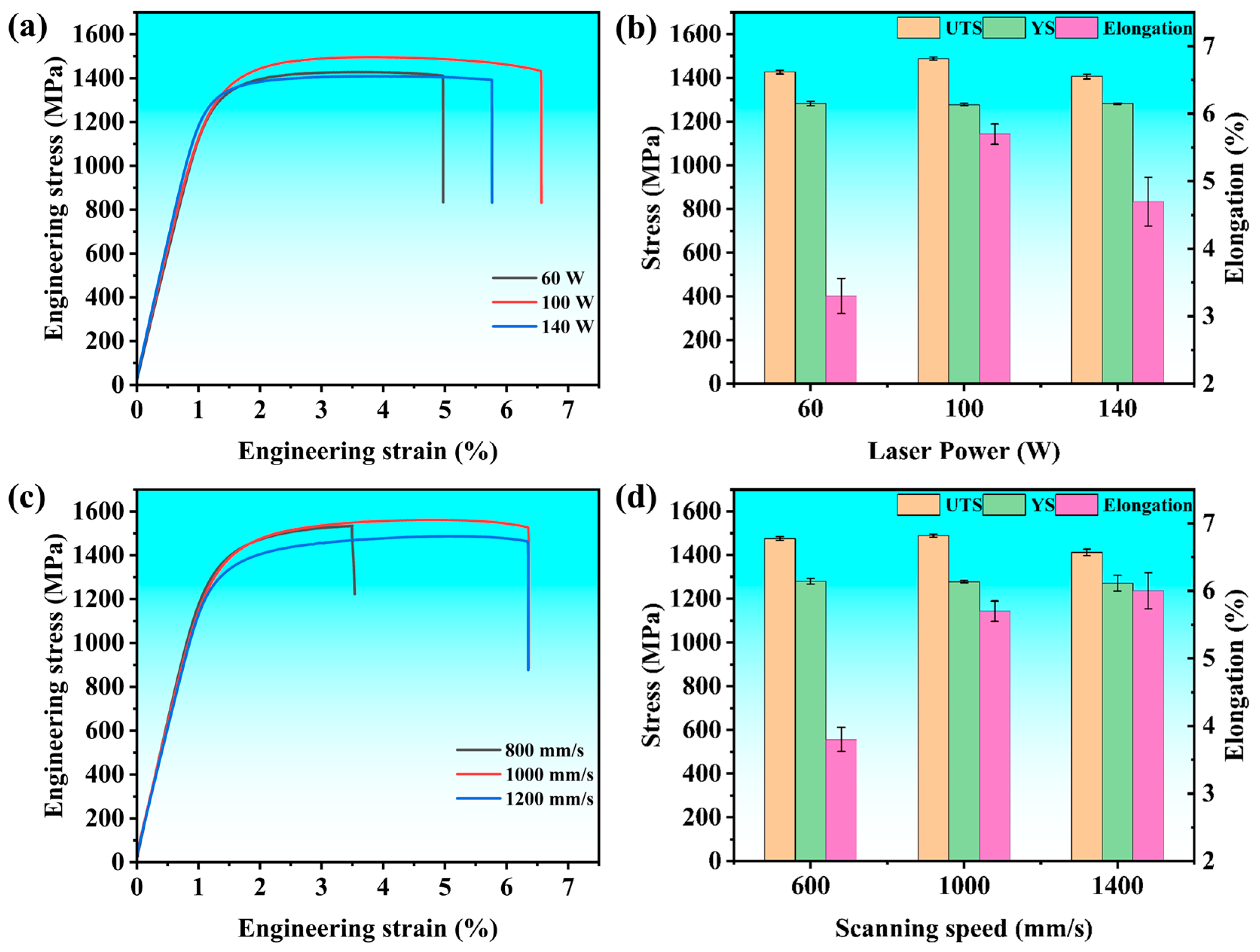

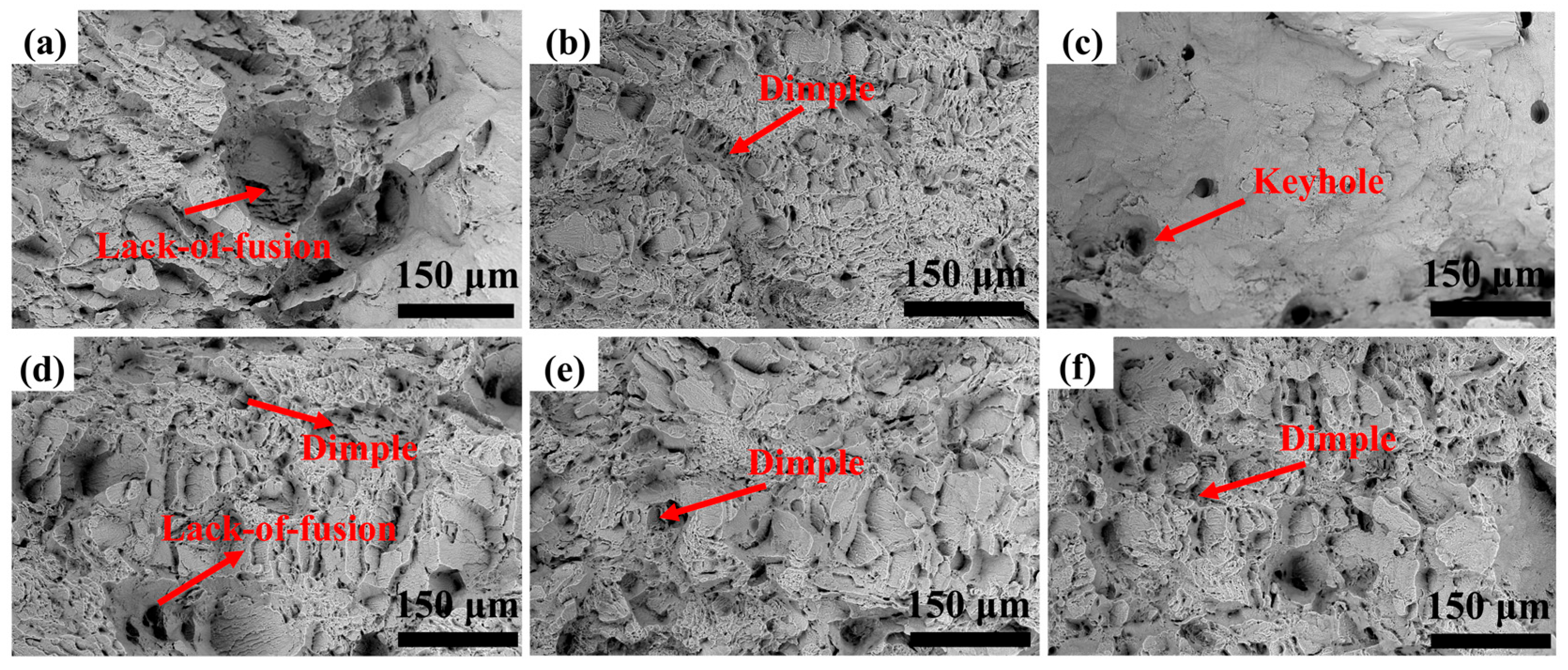

3.6. Mechanical Performance

4. Discussion

4.1. Microstructural Evolution and Controlling Mechanisms

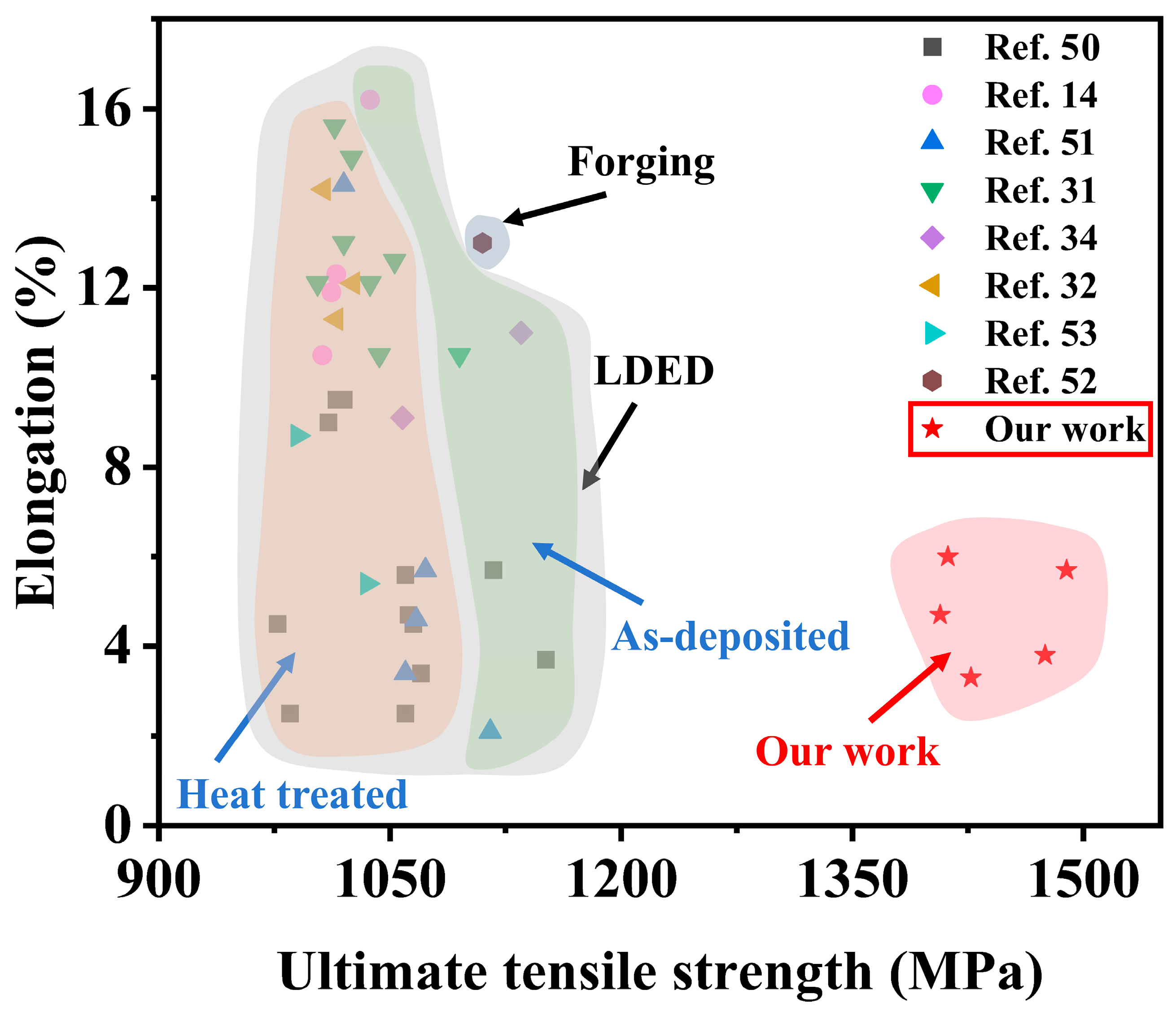

4.2. Mechanical Performance and Comparative Analysis

5. Conclusions and Outlook

5.1. Conclusions

- (1)

- Synergistic regulation of key process parameters effectively enhanced the forming quality. Through single-track, multi-track, and cubic sample experiments, the effects of laser power, scanning speed, and hatch spacing on molten pool behavior, defect formation, and microstructural evolution were elucidated. The optimized parameter combination (100 W laser power, 1000 mm/s scanning speed, 60 μm hatch spacing) achieved near-full densification (>99.99%) with minimal surface roughness (Ra = 3.9 ± 1.3 μm).

- (2)

- Microstructural evolution is predominantly governed by the synergistic effects of laser power and scanning speed. Microstructural analysis reveals that under low power or high scanning speed conditions, rapid cooling promotes the formation of fine acicular α′ phase (width: 0.236–0.274 μm), whereas under high power or low scanning speed conditions, it favors the development of coarse lamellar α′ martensite (width: 0.525–0.645 μm). This demonstrates that volumetric energy density serves as a critical factor in controlling the morphology and dimensions of the Ti65 alloy’s microstructure.

- (3)

- The mechanical properties were directly governed by the resulting microstructure. Specimens fabricated under the optimized parameters exhibited excellent mechanical performance, achieving an ultimate tensile strength of 1489 ± 7.5 MPa, yield strength of 1278 ± 5.2 MPa, elongation of 5.7 ± 0.15%, and microhardness of 446.7 ± 1.7 HV0.2, which is attributed to the synergistic effect of near-full densification and the refined mixed microstructure.

5.2. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium Alloys for Aerospace Applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Meng, B.; Wan, M.; Zhao, R.; Zou, Z.; Liu, H. Micromanufacturing Technologies of Compact Heat Exchangers for Hypersonic Precooled Airbreathing Propulsion: A Review. Chin. J. Aeronaut. 2021, 34, 79–103. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y.; Wang, L. Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Yang, Q.; Sun, J.; Gao, Y.; Lu, Y.; Shen, Z.; Ma, L.; Yang, T.; Meng, F. Integrated Design and Performance of Microwave Absorbing-Mechanical Load Bearing: Metasurface Aramid Unidirectional Cloth Composites Based on PEDOT: PSS Conductive Ink. Adv. Compos. Hybrid. Mater. 2025, 8, 250. [Google Scholar] [CrossRef]

- Kang, L.; Yang, C. A Review on High-Strength Titanium Alloys: Microstructure, Strengthening, and Properties. Adv. Eng. Mater. 2019, 21, 1801359. [Google Scholar] [CrossRef]

- Li, S.; Deng, T.; Zhang, Y.; Liang, Y.; Li, R.; Dong, T. Review on the Creep Resistance of High-Temperature Titanium Alloy. Trans. Indian Inst. Met. 2021, 74, 215–222. [Google Scholar] [CrossRef]

- Zhao, D.; Fan, J.; Zhang, Z.; Liu, X.; Wang, Q.; Chen, Z.; Tang, B.; Kou, H.; Jia, S.; Li, J. Microstructure and Texture Variations in High Temperature Titanium Alloy Ti65 Sheets with Different Rolling Modes and Heat Treatments. Materials 2020, 13, 2466. [Google Scholar] [CrossRef]

- Chi, S.; Zhu, R.; Du, P.; Yuan, B.; Peng, C.; Zhang, L.; Chen, J. Enhanced Mechanical Properties of Near-α Ti60 Alloy by Laser Powder Bed Fusion. J. Mater. Res. Technol. 2025, 35, 3968–3979. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, J.; Tang, B.; Kou, H.; Wang, J.; Wang, X.; Wang, S.; Wang, Q.; Chen, Z.; Li, J. Microstructural Evolution and FCC Twinning Behavior during Hot Deformation of High Temperature Titanium Alloy Ti65. J. Mater. Sci. Technol. 2020, 49, 56–69. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A Review on 3D Micro-Additive Manufacturing Technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by Selective Laser Melting and Mechanical Behavior of Commercially Pure Titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- He, B.; Sun, J.; Yang, G.; Li, C.; Yi, J.; Li, X.; Ni, J. Microstructure and Mechanical Properties of Laser-Deposited Ti65 near-Alpha Titanium Alloy. Appl. Phys. A 2022, 128, 825. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal Additive Manufacturing in the Commercial Aviation Industry: A Review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Tepylo, N.; Huang, X.; Patnaik, P.C. Laser-Based Additive Manufacturing Technologies for Aerospace Applications. Adv. Eng. Mater. 2019, 21, 1900617. [Google Scholar] [CrossRef]

- Dubey, D.; Singh, S.P.; Behera, B.K. A Review on Recent Advancements in Additive Manufacturing Techniques. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024. [Google Scholar] [CrossRef]

- He, T.; Yip, W.S.; Yan, E.H.; Tang, J.; Rehan, M.; Teng, L.; Wong, C.H.; Sun, L.; Zhang, B.; Guo, F.; et al. 3D Printing for Ultra-Precision Machining: Current Status, Opportunities, and Future Perspectives. Front. Mech. Eng. 2024, 19, 23. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, Y.; Xiao, R.; Bai, Y.; Song, C.; Wang, D. Evaluation of Topology-Optimized Lattice Structures Manufactured via Selective Laser Melting. Mater. Des. 2018, 143, 27–37. [Google Scholar] [CrossRef]

- Chandravanshi, V.; Sarkar, R.; Kamat, S.V.; Nandy, T.K. Effects of Thermomechanical Processing and Heat Treatment on the Tensile and Creep Properties of Boron-Modified Near Alpha Titanium Alloy Ti-1100. Metall. Mater. Trans. A 2013, 44, 201–211. [Google Scholar] [CrossRef]

- Ding, C.; Shi, Q.; Liu, X.; Zheng, L.; Li, R.; Hang, Z.; Yu, B.; Wu, W. Microstructure and Mechanical Properties of PM Ti600 Alloy after Hot Extrusion and Subsequent Annealing Treatment. Mater. Sci. Eng. A 2019, 748, 434–440. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser Powder Bed Fusion Additive Manufacturing of Metals; Physics, Computational, and Materials Challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Sabzi, H.E.; Aboulkhair, N.T.; Liang, X.; Li, X.-H.; Simonelli, M.; Fu, H.; Rivera-Díaz-del-Castillo, P.E.J. Grain Refinement in Laser Powder Bed Fusion: The Influence of Dynamic Recrystallization and Recovery. Mater. Des. 2020, 196, 109181. [Google Scholar] [CrossRef]

- Zanini, F.; Bonato, N.; Michieletto, D.; Alberti, L.; Carmignato, S. Laser Powder Bed Fusion Process Optimization for the Production of High-Performance and Efficient High-Silicon Steel Electrical Motor Components. Prog. Addit. Manuf. 2025, 10, 6581–6592. [Google Scholar] [CrossRef]

- Wei, K.; Wang, Z.; Zeng, X. Preliminary Investigation on Selective Laser Melting of Ti-5Al-2.5Sn α-Ti Alloy: From Single Tracks to Bulk 3D Components. J. Mater. Process Technol. 2017, 244, 73–85. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A Study of the Microstructural Evolution during Selective Laser Melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Yang, J.; Han, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Role of Molten Pool Mode on Formability, Microstructure and Mechanical Properties of Selective Laser Melted Ti-6Al-4V Alloy. Mater. Des. 2016, 110, 558–570. [Google Scholar] [CrossRef]

- Luo, X.; Yang, C.; Fu, Z.Q.; Liu, L.H.; Lu, H.Z.; Ma, H.W.; Wang, Z.; Li, D.D.; Zhang, L.C.; Li, Y.Y. Achieving Ultrahigh-Strength in Beta-Type Titanium Alloy by Controlling the Melt Pool Mode in Selective Laser Melting. Mater. Sci. Eng. A 2021, 823, 141731. [Google Scholar] [CrossRef]

- Li, B.; Li, X.; Yin, J.; Ren, Y.; Wang, Y.; Yang, G. Influence of Scanning Strategies on Microstructure, Texture and Mechanical Properties of Ti65 High-Temperature Titanium Alloy by Laser Deposition Manufacturing. J. Manuf. Process 2025, 136, 162–176. [Google Scholar] [CrossRef]

- He, B.; Sun, J.; Ren, Y.; Li, C.; Yang, G.; Li, X.; Ni, J. Effect of Heat Treatment on Microstructure and Mechanical Properties of Laser-Deposited Ti65 near-Alpha Titanium Alloy. J. Mater. Res. 2022, 37, 1464–1474. [Google Scholar] [CrossRef]

- Sun, J.; Lu, H.; Wang, Z.; Luo, K.; Lu, J. High-Temperature Oxidation Behaviour of Ti65 Titanium Alloy Fabricated by Laser Direct Energy Deposition. Corros. Sci. 2024, 229, 111866. [Google Scholar] [CrossRef]

- Sun, J.; Lu, H.; Zhang, H.; Luo, K.; Lu, J. Effect of Thermal Exposure on Microstructure and Mechanical Properties of Ti65 High-Temperature Titanium Alloy Deposited by Laser Direct Energy Deposition. Mater. Sci. Eng. A 2024, 908, 146757. [Google Scholar] [CrossRef]

- Wang, X.; Li, S.Q.; Liu, J.N. Study on Rotating Bending Fatigue Property of Ti65 Titanium Alloy. Mater. Sci. Forum 2016, 849, 347–352. [Google Scholar] [CrossRef]

- Yue, K.; Liu, J.; Zhu, S.; Wang, L.; Wang, Q.; Yang, R. Origins of Different Tensile Behaviors Induced by Cooling Rate in a near Alpha Titanium Alloy Ti65. Materialia 2018, 1, 128–138. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective Laser Melting of AlSi10Mg Alloy: Process Optimisation and Mechanical Properties Development. Mater. Des. (1980–2015) 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Xiong, Z.; Li, H.; Yang, H.; Yang, Y.; Liu, Y.; Cui, L.; Li, X.; Masseling, L.; Shen, L.; Hao, S. Micro Laser Powder Bed Fusion of NiTi Alloys with Superior Mechanical Property and Shape Recovery Function. Addit. Manuf. 2022, 57, 102960. [Google Scholar] [CrossRef]

- Dornelas, P.H.G.; Santos, T.G.; Oliveira, J.P. Micro-Metal Additive Manufacturing—State-of-Art and Perspectives. Int. J. Adv. Manuf. Technol. 2022, 122, 3547–3564. [Google Scholar] [CrossRef]

- Wei, P.; Wei, Z.; Chen, Z.; Du, J.; He, Y.; Li, J.; Zhou, Y. The AlSi10Mg Samples Produced by Selective Laser Melting: Single Track, Densification, Microstructure and Mechanical Behavior. Appl. Surf. Sci. 2017, 408, 38–50. [Google Scholar] [CrossRef]

- Patel, S.; Vlasea, M. Melting Modes in Laser Powder Bed Fusion. Materialia 2020, 9, 100591. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding Melt Pool Characteristics in Laser Powder Bed Fusion: An Overview of Single- and Multi-Track Melt Pools for Process Optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Guo, D.; Lambert-Garcia, R.; Hocine, S.; Fan, X.; Greenhalgh, H.; Shahani, R.; Majkut, M.; Rack, A.; Lee, P.D.; Alex Leung, C.L. Correlative Spatter and Vapour Depression Dynamics during Laser Powder Bed Fusion of an Al-Fe-Zr Alloy. Int. J. Extrem. Manuf. 2024, 6, 055601. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zhang, H.; Yin, J.; Ke, L.; Zeng, X. Selective Laser Melting of Al7050 Powder: Melting Mode Transition and Comparison of the Characteristics between the Keyhole and Conduction Mode. Mater. Des. 2017, 135, 257–266. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy Input Effect on Morphology and Microstructure of Selective Laser Melting Single Track from Metallic Powder. J. Mater. Process Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Gao, P.; Wang, Z.; Zeng, X. Effect of Process Parameters on Morphology, Sectional Characteristics and Crack Sensitivity of Ti-40Al-9V-0.5Y Alloy Single Tracks Produced by Selective Laser Melting. Int. J. Lightweight Mater. Manuf. 2019, 2, 355–361. [Google Scholar] [CrossRef]

- Wei, L.; Miao, B.; Liu, Z.; Su, H.; Ming, K.; Zheng, X.; Wang, F.; Zheng, S. The Dependence of Strength and Strain Hardening on Dislocation-Interface Interaction in Dual-Phase Titanium Alloys. Scr. Mater. 2024, 252, 116249. [Google Scholar] [CrossRef]

- Ezairi, S.; Elouafi, A.; Lmai, F.; Tizliouine, A. Structural, Magnetic and Magnetocaloric Effect of Pyrochlore Iridate Er2Ir2O7. Phys. Scr. 2023, 98, 065803. [Google Scholar] [CrossRef]

- Sun, J.; Lu, H.; Liang, Y.; Zhang, H.; Luo, K.; Lu, J. Evolution of Microstructure and Mechanical Properties of Ti65 High-Temperature Titanium Alloy after Additive Manufacturing and Annealing. Mater. Sci. Eng. A 2024, 913, 147002. [Google Scholar] [CrossRef]

- Sun, J.; Lu, H.; Liang, Y.; Luo, K.; Lu, J. Effects of Different Heat Treatment Temperatures on the Microstructure and Mechanical Properties of Additive Manufacturing Ti65 Alloys. Mater. Charact. 2025, 219, 114592. [Google Scholar] [CrossRef]

- Yin, J.; Li, X.; Guan, F.; Li, P.; Yang, G. Research on Microstructure and High-Temperature Performance of Novel Ti65 Titanium Alloy with V-Groove Connection in Laser Additive Manufacturing. Trans. Indian Inst. Met. 2024, 77, 3627–3639. [Google Scholar] [CrossRef]

- Li, J.; Jiang, W.; Xia, C.; Deng, Y.; Gao, Y.; Yang, C. Microstructural Evolution and Subsequent Mechanical Properties of Ti65 Titanium Alloy during Long-Term Thermal Exposure. Metals 2024, 14, 854. [Google Scholar] [CrossRef]

| Elements | Al | Sn | Zr | Ta | Mo | Si | Nb | W | C | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Powders (wt%) | 5.83 | 3.38 | 2.7 | 0.48 | 0.32 | 0.27 | 0.32 | 0.62 | 0.035 | Bal |

| P (W) | V (mm/s) | UTS (MPa) | YS (MPa) | Elongation (%) | Microhardness (HV) |

|---|---|---|---|---|---|

| 60 | 1000 | 1427 ± 8.1 | 1283 ± 10.4 | 3.3 ± 0.26 | 400.1 ± 6.1 |

| 100 | 1000 | 1489 ± 7.5 | 1278 ± 5.2 | 5.7 ± 0.15 | 446.7 ± 1.7 |

| 140 | 1000 | 1407 ± 11.1 | 1282 ± 3.2 | 4.7 ± 0.36 | 427.8 ± 2.2 |

| 100 | 600 | 1475 ± 8.8 | 1280 ± 13.1 | 3.8 ± 0.18 | 421.0 ± 3.7 |

| 100 | 1000 | 1489 ± 7.5 | 1278 ± 5.2 | 5.7 ± 0.15 | 446.7 ± 1.7 |

| 100 | 1400 | 1412 ± 10.6 | 1271 ± 25.7 | 6.0 ± 0.27 | 414.7 ± 1.5 |

| P (W) | V (mm/s) | Crystallite Size (nm) | Microstrain (ε × 10−3) |

|---|---|---|---|

| 60 | 1000 | 28.3 ± 1.9 | 5.11 ± 0.12 |

| 100 | 1000 | 39.7 ± 2.8 | 3.65 ± 0.14 |

| 140 | 1000 | 45.1 ± 3.2 | 3.21 ± 0.48 |

| 100 | 600 | 50.6 ± 2.2 | 2.86 ± 0.07 |

| 100 | 1400 | 32.5 ± 1.5 | 5.28 ± 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Y.; Wang, X.; Wu, J.; Wang, H.; Gan, P.; Lu, L.; Li, C.; Ma, T.; Niu, J.; Zhang, Z. On the Process Optimization, Microstructure Characterization and Mechanical Performance of Ti65 Titanium Alloy Produced by Laser Powder Bed Fusion. Appl. Sci. 2025, 15, 11717. https://doi.org/10.3390/app152111717

Meng Y, Wang X, Wu J, Wang H, Gan P, Lu L, Li C, Ma T, Niu J, Zhang Z. On the Process Optimization, Microstructure Characterization and Mechanical Performance of Ti65 Titanium Alloy Produced by Laser Powder Bed Fusion. Applied Sciences. 2025; 15(21):11717. https://doi.org/10.3390/app152111717

Chicago/Turabian StyleMeng, Yuan, Xianglong Wang, Jinjun Wu, Haojie Wang, Ping Gan, Lei Lu, Chengjie Li, Tongling Ma, Jun Niu, and Zhigang Zhang. 2025. "On the Process Optimization, Microstructure Characterization and Mechanical Performance of Ti65 Titanium Alloy Produced by Laser Powder Bed Fusion" Applied Sciences 15, no. 21: 11717. https://doi.org/10.3390/app152111717

APA StyleMeng, Y., Wang, X., Wu, J., Wang, H., Gan, P., Lu, L., Li, C., Ma, T., Niu, J., & Zhang, Z. (2025). On the Process Optimization, Microstructure Characterization and Mechanical Performance of Ti65 Titanium Alloy Produced by Laser Powder Bed Fusion. Applied Sciences, 15(21), 11717. https://doi.org/10.3390/app152111717