Analysis of the Structural Responses of Adjacent Components to the Operation of a Polymer-Based Explosive Fire Suppression System

Abstract

1. Introduction

2. Materials and Methods

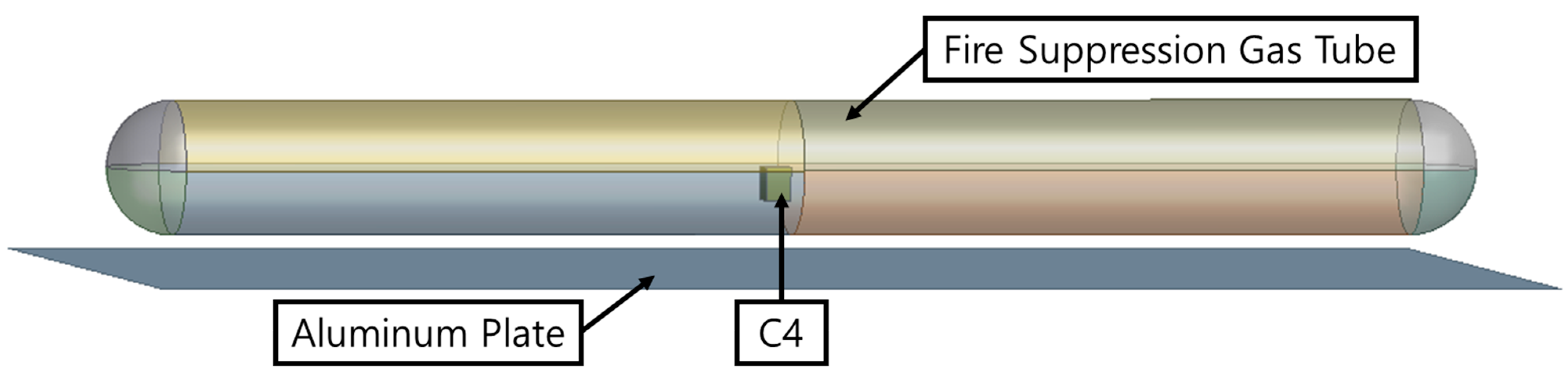

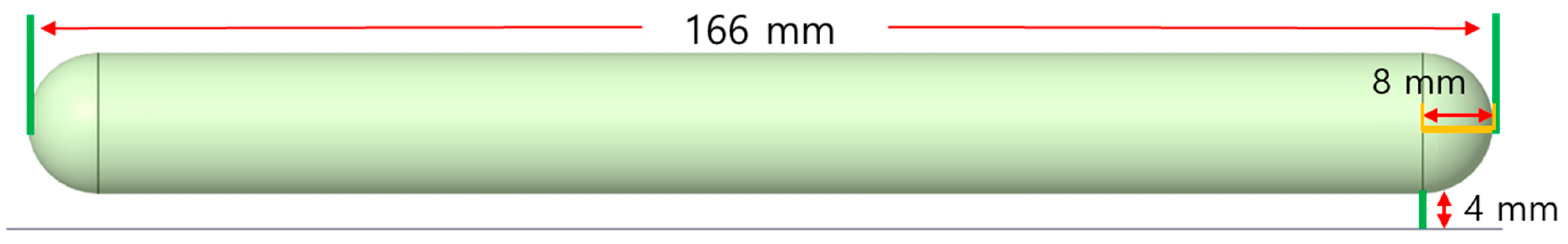

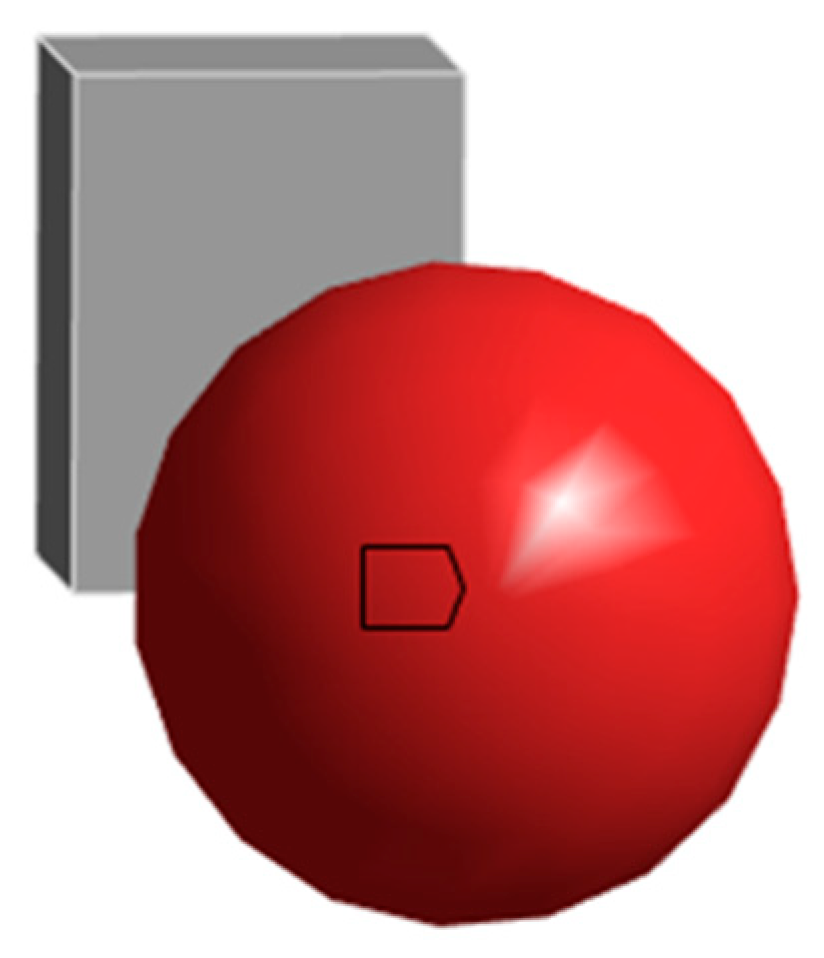

2.1. Model Geometry

2.2. Material Properties

2.3. Definition of Model Conditions and Analysis Settings

3. Results

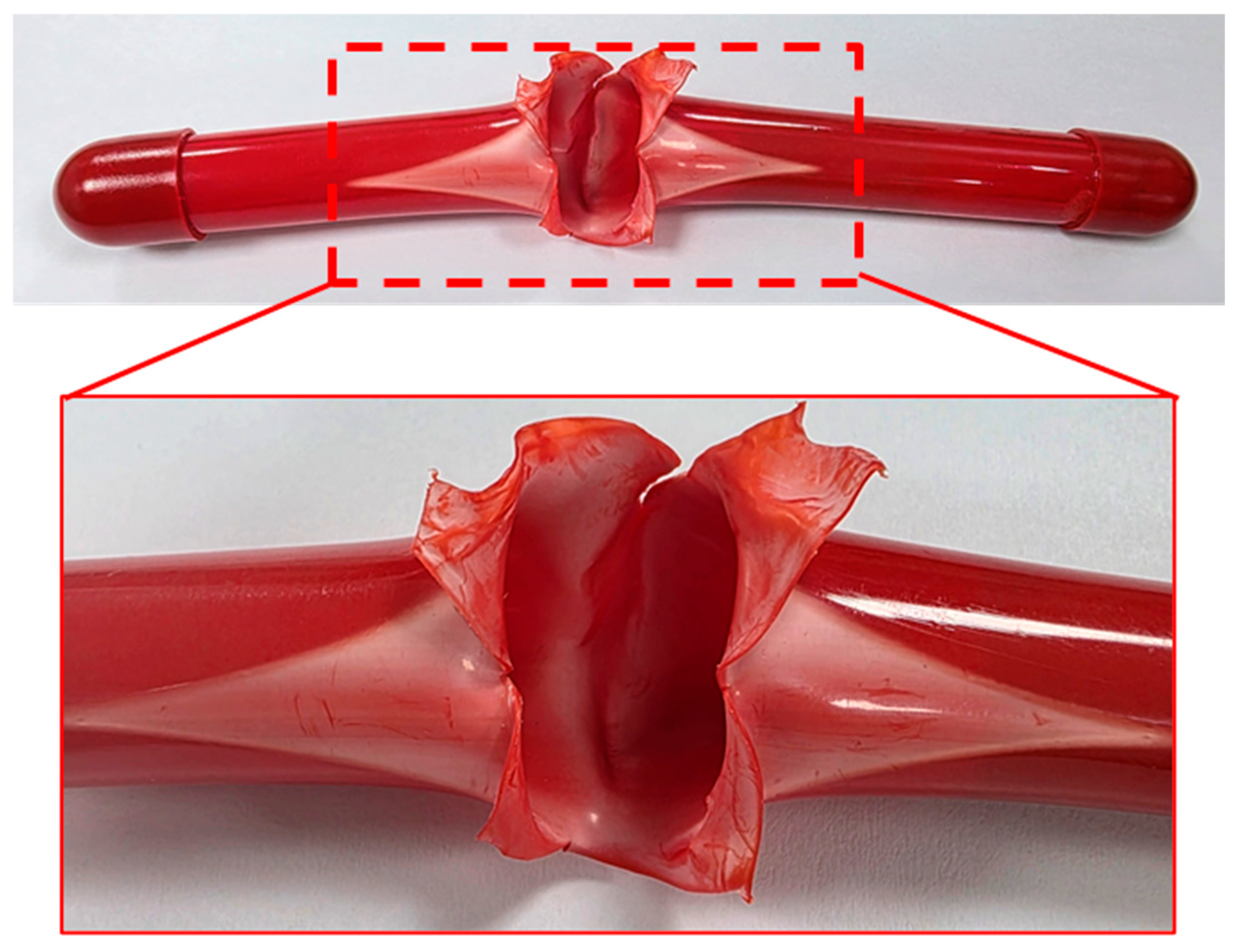

3.1. Observation of Actual Rupture Shape

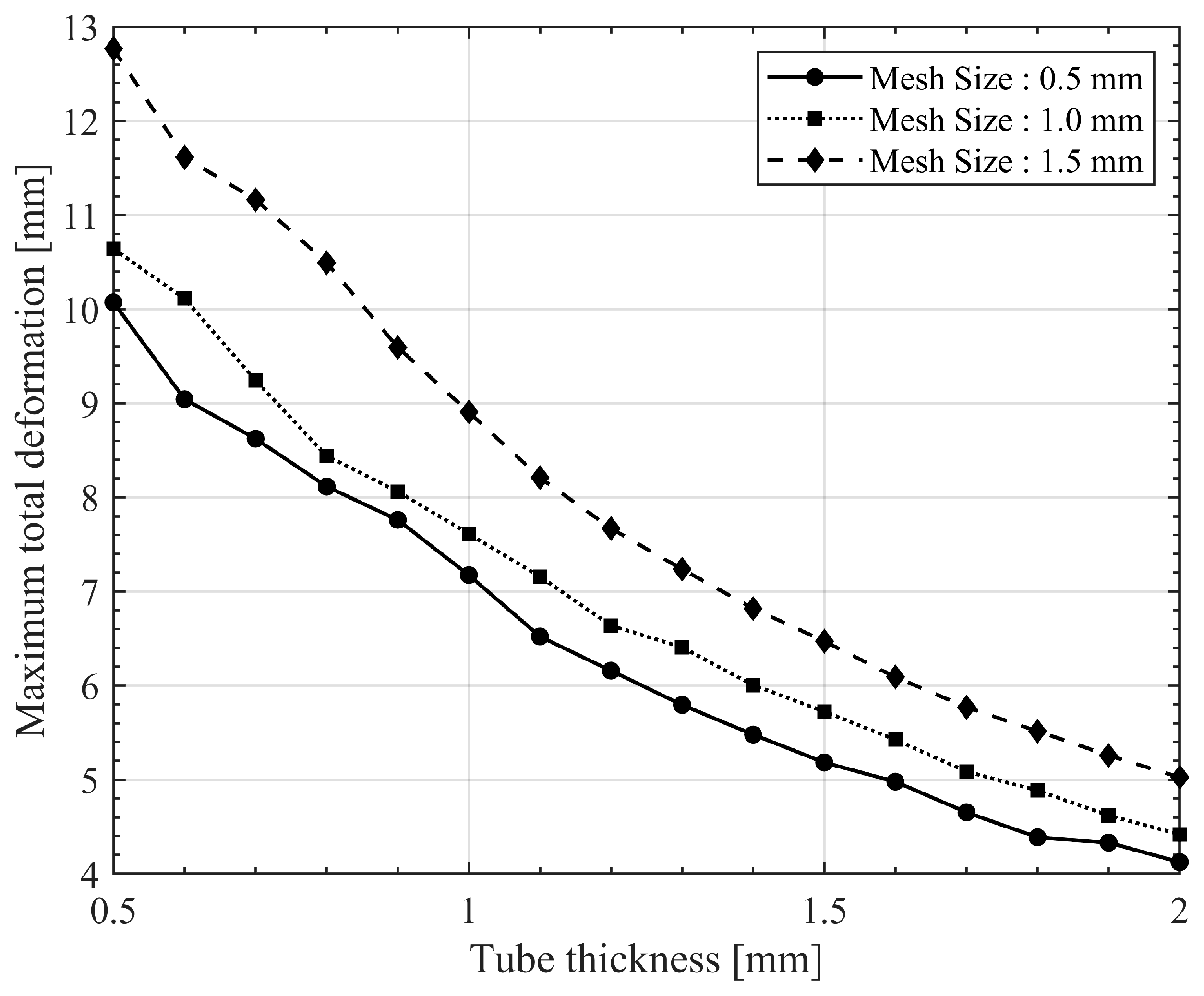

3.2. Mesh Independence Analysis

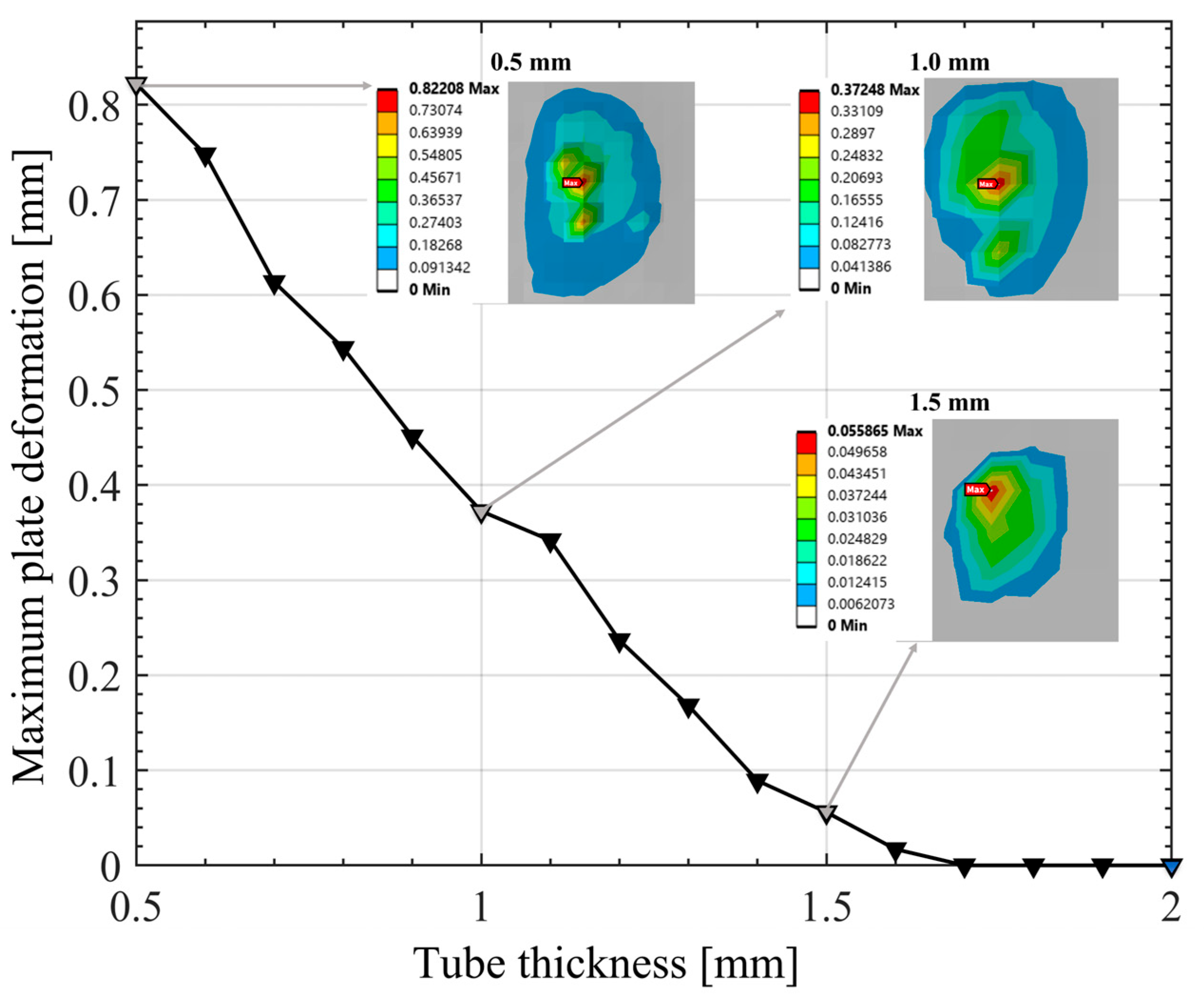

3.3. Structural Analysis Results

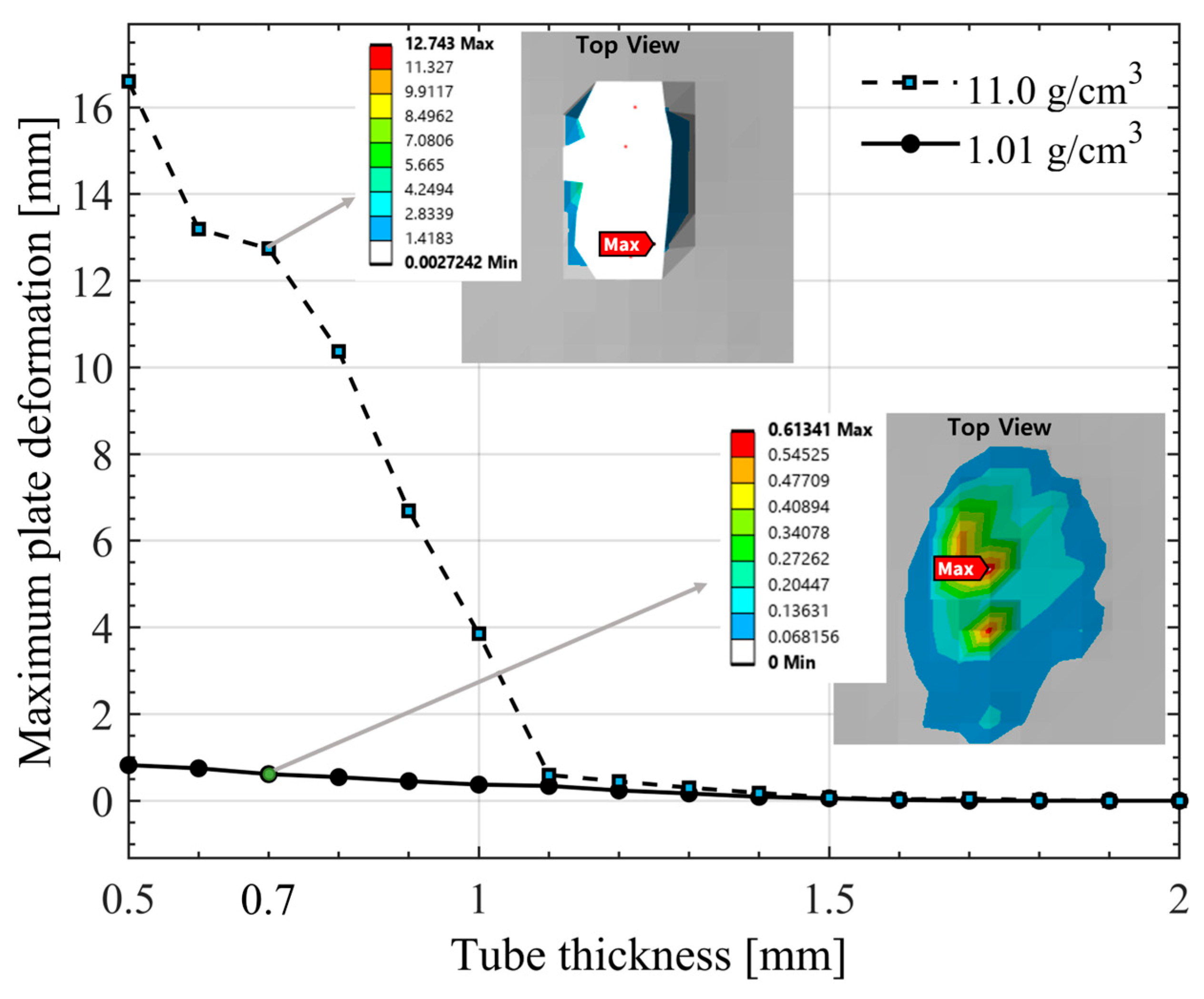

3.4. Effect of Material Density on Deformation Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Fire Safety Research Institute (FSRI). Fire Safety of Batteries and Electric Vehicles; UL Research Institutes Report: Northbrook, IL, USA, 2023. [Google Scholar]

- Tarascon, J.M.; Armand, M. Issues and Challenges Facing Rechargeable Lithium Batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Park, K.-S. The Li-Ion Rechargeable Battery: A Perspective. J. Am. Chem. Soc. 2013, 135, 1167–1176. [Google Scholar] [CrossRef] [PubMed]

- Goodenough, J.B.; Kim, Y.-S. Challenges for Rechargeable Li Batteries. Chem. Mater. 2010, 22, 587–603. [Google Scholar] [CrossRef]

- Armand, M.; Tarascon, J.M. Building Better Batteries. Nature 2008, 451, 652–657. [Google Scholar] [CrossRef]

- Finegan, D.P.; Scheel, M.; Robinson, J.B.; Tjaden, B.; Hunt, I.; Mason, T.J.; Millichamp, J.; DiMichiel, M.; Offer, G.J.; Hinds, G.; et al. In-Operando High-Speed Tomography of Lithium-Ion Batteries during Thermal Runaway. Nat. Commun. 2015, 6, 6924. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Shi, W.; Hu, F.; Wang, Y.; Hu, X.; Li, H. Over-Heating Triggered Thermal Runaway Behavior for Lithium-Ion Battery with High Nickel Content in Positive Electrode. Energy 2021, 224, 120072. [Google Scholar] [CrossRef]

- Rask, E.; Stutenberg, K.; Waller, T. Li-Ion Battery Pack Immersion Exploratory Investigation; Report No. DOT HS 813 136; United States Department of Transportation, National Highway Traffic Safety Administration: Washington, DC, USA, 2021. [Google Scholar] [CrossRef]

- Ineris. Summary of Work on Extinguishing Li-Ion Battery Fires of Electric Vehicles; Ineris Report: Verneuil-en-Halatte, France, 2023. [Google Scholar]

- Hong, J.; Wang, Z.; Zhang, X.; Wang, W.; Chen, Y.J.; Shan, T. Collision-Caused Thermal Runaway Investigation of Li-Ion Battery in Real-World Electric Vehicles. Appl. Therm. Eng. 2024, 236, 121901. [Google Scholar] [CrossRef]

- Lee, B.J.; Choi, G.J.; Lee, S.H.; Jeong, Y.M.; Park, Y.; Cho, D.U. A Study on Explosion and Fire Risk of Lithium-Ion and Lithium-Polymer Battery. J. Korean Inst. Commun. Inf. Sci. 2017, 42, 855–863. [Google Scholar] [CrossRef][Green Version]

- Li, Z.; Wang, Q. Experimental Study of Explosive Water Mist Extinguishing Fire. Procedia Eng. 2011, 11, 258–267. [Google Scholar] [CrossRef]

- Li, H.J.; Shen, C.J.; Lu, G.; Wang, Z.H. Response of Cylindrical Tubes Subjected to Internal Blast Loading. Eng. Struct. 2022, 272, 115004. [Google Scholar] [CrossRef]

- Aune, V.; Valsamos, G.; Casadei, F.; Langseth, M.; Børvik, T. On the Dynamic Response of Blast-Loaded Steel Plates with and without Pre-Formed Holes. Int. J. Impact Eng. 2017, 108, 27–46. [Google Scholar] [CrossRef]

- Sakong, J.; Woo, S.C.; Bae, Y.W.; Choi, Y.J.; Cha, J.P.; Ga, I.H.; Kim, T.W. Dispersion Pattern Simulation of Tungsten Impactors According to Mass and Shape of Explosives. J. Korean Soc. Mech. Eng. A 2014, 38, 1325–1333. [Google Scholar] [CrossRef][Green Version]

- Kuracina, R.; Szabová, Z.; Buranská, E.; Kosár, L.; Rantuch, P.; Blinová, L.; Měřínská, D.; Gogola, P.; Jurina, F. Study into the fire and explosion characteristics of polymer powders used in engineering production technologies. Polymers 2023, 15, 4203. [Google Scholar] [CrossRef]

- Hegde, G.; Verma, H.; Hegde, G.; Jagadeesh, G.; Asokan, S. Blast wave induced strain measurements in polymers using FBG sensor inside shock tube. Measurement 2024, 225, 114045. [Google Scholar] [CrossRef]

- Radermacher, L.; Mateescu, T. Study on the Behaviour of High-Density Polyethylene (HDPE) Pipes Buried, on the Explosion’s Effect. In Proceedings of the International Conference Building Services and Energy Efficiency, London, UK, 26–27 October 2020; pp. 268–275. [Google Scholar] [CrossRef]

- Michael, L.; Nikiforakis, N. A multi–physics methodology for the simulation of reactive flow and elastoplastic structural response. J. Comput. Phys. 2018, 367, 1–27. [Google Scholar] [CrossRef]

- Gu, M.; Wang, H.; Chen, G.; Yu, A.; Dang, W.; Ling, X. Experimental and numerical study on explosion resistance of polyurea-coated shelter in petrochemical industry. Sci. Rep. 2024, 14, 20643. [Google Scholar] [CrossRef] [PubMed]

- Nam, S.H.; Kim, J.Y.; Kim, E.S. Crash Safety Evaluation of LNG Fuel Containers for Vehicles Using ANSYS Explicit Dynamics. J. Korean Inst. Gas 2022, 26, 58–63. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, X.; Zhang, Q.; Bai, Z.; Cao, X. Numerical study on explosion risk and building structure dynamics of long-distance oil and gas tunnels. Fire 2024, 7, 302. [Google Scholar] [CrossRef]

- Kong, W.; Yang, S.; Wang, S.; Liu, Z.; Zhang, R.; Zhong, W.; Yao, X. On dynamic response and damage evaluation of bridge piers under far-field explosion loads. Structures 2023, 54, 1044–1059. [Google Scholar] [CrossRef]

- Wang, S.; Li, Z.; Fang, Q.; Yan, H.; Liu, Y. Numerical simulation of overpressure loads generated by gas explosions in utility tunnels. Process Saf. Environ. Prot. 2022, 161, 100–117. [Google Scholar] [CrossRef]

- Jeong, W.S.; Pyeon, Y.B. A Study on Analysis of Explosion Damage Reduction Effect on Protective Wall for Hydrogen Production Base via Explosion Simulation. J. Korea Soc. Nav. Sci. Technol. 2025, 8, 88–95. [Google Scholar] [CrossRef]

| Density | Young’s Modulus | Poisson’s Ratio |

|---|---|---|

| 1.01 [g/cm3] | 881 [MPa] | 0.4 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| P | 28 [GPa] | E | 5621 [kJ/m3] |

| A | 609.77 [GPa] | R1 | 4.5 |

| B | 12.95 [GPa] | R2 | 1.4 |

| Cd | 8193 [m/s] | ω | 0.25 |

| C4 Mass | 0.07685 [g] |

| Density | Specific Heat | Temperature |

|---|---|---|

| 2.77 [g/cm3] | 875 [J/kg·C] | 22 [°C] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, M.-S.; Yoon, T.-W.; Zhang, S.-U. Analysis of the Structural Responses of Adjacent Components to the Operation of a Polymer-Based Explosive Fire Suppression System. Appl. Sci. 2025, 15, 11718. https://doi.org/10.3390/app152111718

Kang M-S, Yoon T-W, Zhang S-U. Analysis of the Structural Responses of Adjacent Components to the Operation of a Polymer-Based Explosive Fire Suppression System. Applied Sciences. 2025; 15(21):11718. https://doi.org/10.3390/app152111718

Chicago/Turabian StyleKang, Min-Soo, Tae-Woon Yoon, and Sung-Uk Zhang. 2025. "Analysis of the Structural Responses of Adjacent Components to the Operation of a Polymer-Based Explosive Fire Suppression System" Applied Sciences 15, no. 21: 11718. https://doi.org/10.3390/app152111718

APA StyleKang, M.-S., Yoon, T.-W., & Zhang, S.-U. (2025). Analysis of the Structural Responses of Adjacent Components to the Operation of a Polymer-Based Explosive Fire Suppression System. Applied Sciences, 15(21), 11718. https://doi.org/10.3390/app152111718