Analysis of the Possibilities of Using an Organic Bridging Material for Sealing the Borehole Wall

Abstract

1. Introduction

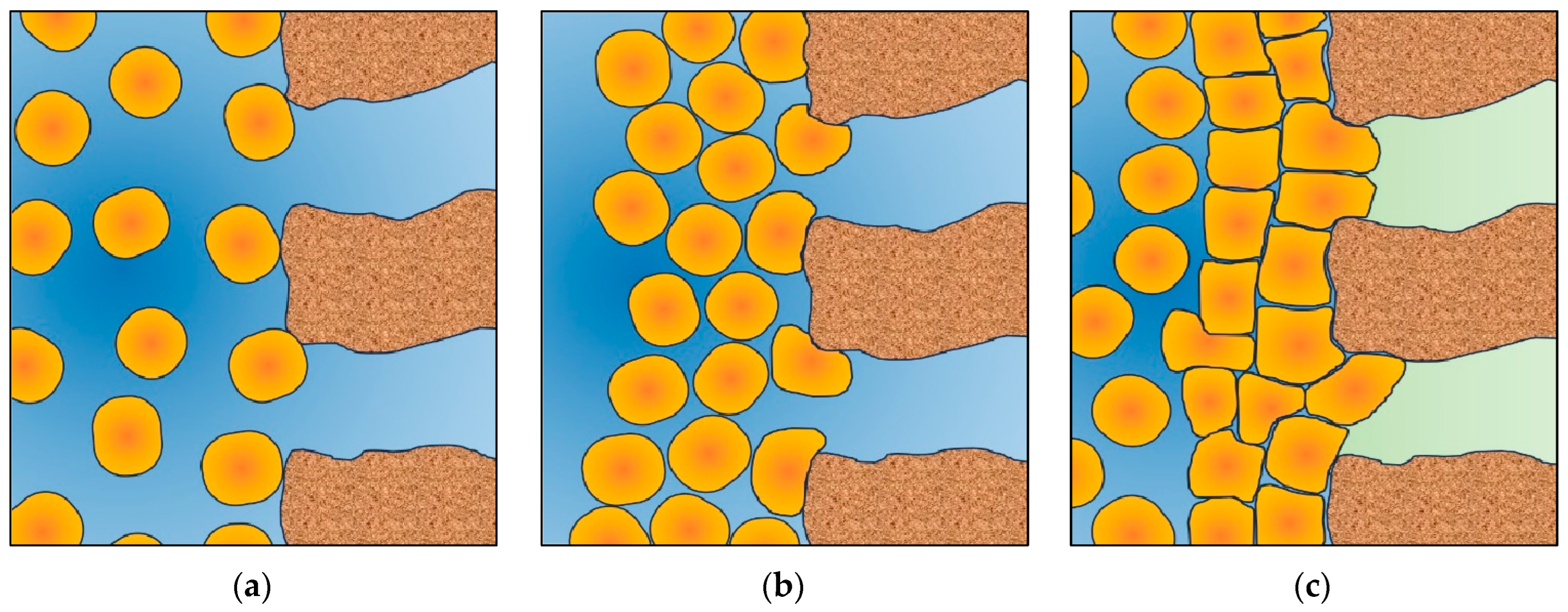

- Blocking of pore channels by solid phase particles from the drilling fluid;

- The effect of the aqueous phase on clay binders, causing their hydration and swelling or the dispersion of colloidal particles and pore clogging as they move with formation water;

- Blocking by the aqueous phase, due to the invasion of water into the formation during drilling (water blockage);

- Precipitation of insoluble deposits occurs when the alkaline filtrate from the drilling fluid comes into contact with mineralized formation water.

Research Aims

2. Materials and Methods

2.1. Methodology Overview

- A carbonate blocker;

- Organic blocker OB1;

- Organic blocker OB2;

- Organic blocker OB3.

- 4.0%/1.0%;

- 3.0%/2.0%;

- 2.0%/3.0%;

- 4.0%/1.0%.

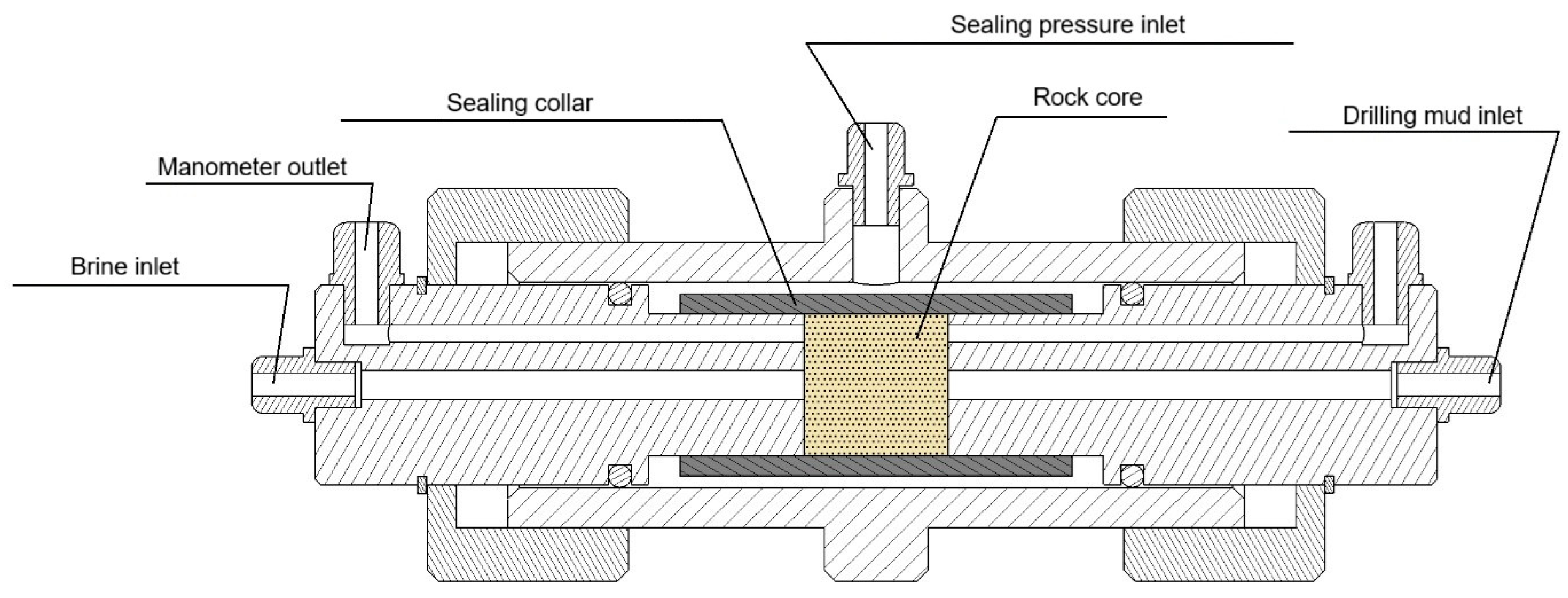

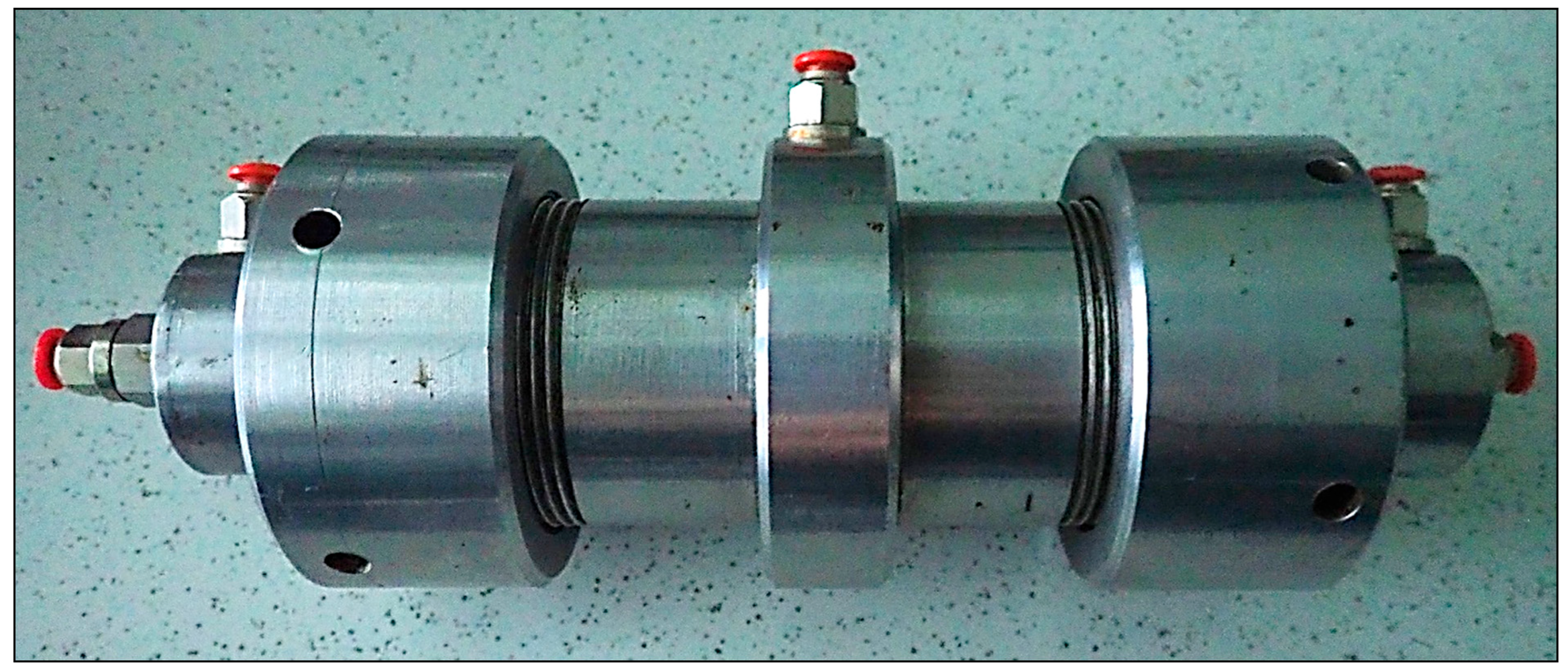

2.2. Tools and Methods

2.3. Raw Materials

- Modified carboxymethylcellulose (CMC) is obtained in the process of etherification of wood cellulose with monochloroacetic acid. It is used to reduce filtration and increase the viscosity of water-based drilling fluids.Polyanionic cellulose (PAC), described as highly purified carboxymethylcellulose, is primarily used to control the filtration and viscosity of drilling fluids and can be applied in the chemical treatment of all types of water-based dispersible drilling fluids. Two versions of the agent were used in the study: low-viscosity (LV) and medium-viscosity (R).

- The biopolymer XCD is obtained by the action of bacteria of the Xanthomonas campestris genus on glucose. Fermentation produces a polysaccharide known as xanthan gum. This agent dissolves easily in fresh water, seawater, as well as in solutions of various salts at any concentration. XCD can be dissolved in liquids with a pH range of 3 to 12 and primarily provides the required rheological properties to drilling fluids.

- Gelatinized starch. Natural starch does not dissolve in cold water and therefore undergoes chemical treatment. To make it water-soluble and capable of forming a colloidal solution, starch is modified through thermal gelatinization, usually in the presence of suitable chemicals. During gelatinization, the outer amylopectin layer breaks down, releasing the amylose contained inside.

- Potassium chloride—used as a clay-rock hydration inhibitor.

- Sodium hydroxide solution—used as a pH regulator for drilling fluids.

- Carbonate blocker—ground marble, used in drilling fluids both to reduce filtration and as a weighting material. Due to its high solubility in hydrochloric acid, it is mainly used for weighting drilling fluids intended for reservoir re-drilling, various working fluids, primarily brines, used in well completion and reconstruction, and for preparing packer fluids.

- Organic blocker—an innovative agent was used, with grains made of specially treated cellulose, giving them high strength and elasticity, enabling the formation of a tight and durable filter cake on the borehole wall. This agent comes in several types depending on grain size:

- -

- Grain diameter up to 150 µm—referred to as OB1 (Organic Blocker 1);

- -

- Grain diameter up to 250 µm—referred to as OB2 (Organic Blocker 2);

- -

- Grain diameter from 150 to 500 µm—referred to as OB3 (Organic Blocker 3).

3. Results

- Blocker M25;

- OB1;

- OB2.

- Base drilling fluid,

- Drilling fluid containing 5.0% of the M25 blocking agent;

- Drilling fluid containing 5.0% of the OB1 blocking agent;

- Drilling fluid containing 5.0% of the OB2 blocking agent;

- Drilling fluid with the 2.0% M25 + 3.0% OB1 set of blocking agents;

- Drilling fluid with the 2.0% M25 + 3.0% OB2 set of blocking agents.

4. Conclusions

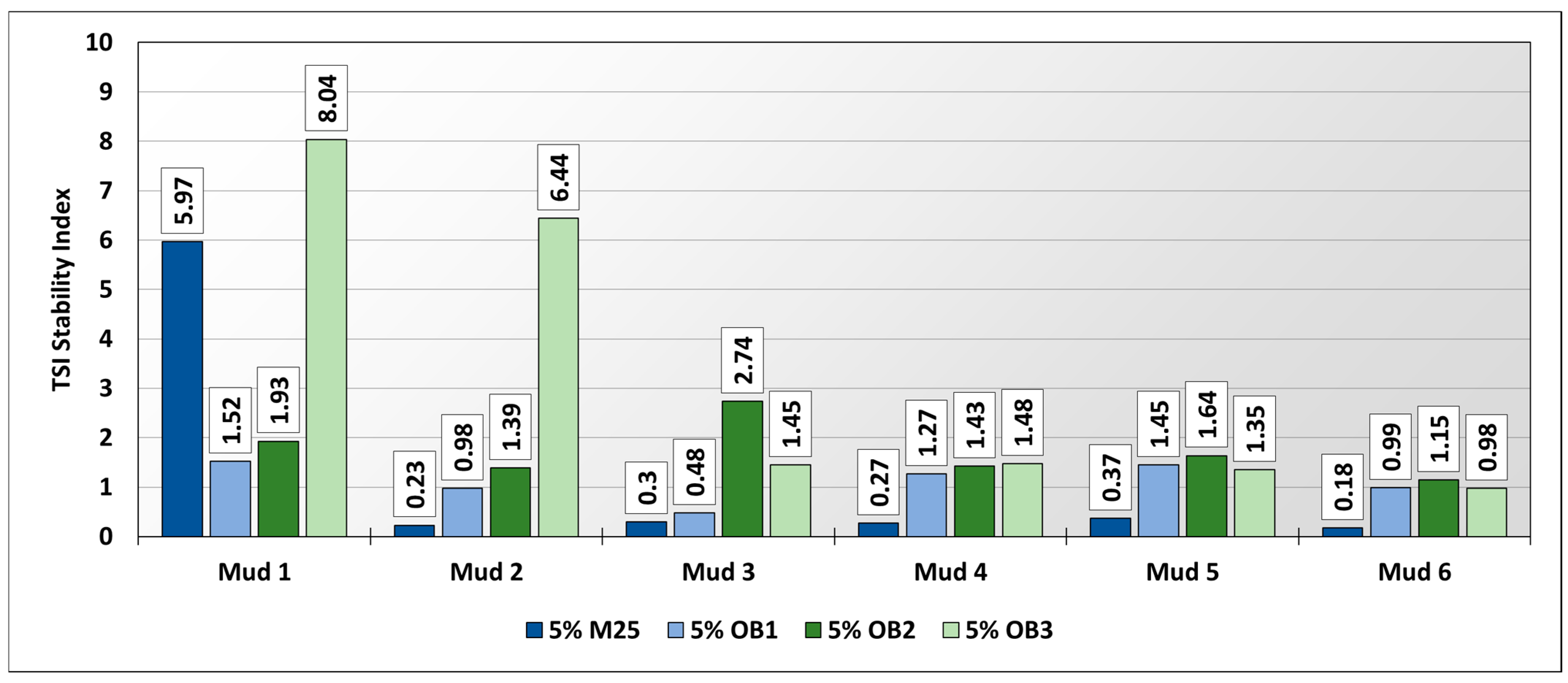

- Not all bridging materials selected in the first stage were suitable for use due to their inadequate physical properties. The organic blocker OB3 had significantly larger particle sizes than the other agents used (its grain diameter reached up to 0.5 mm), which resulted in filtration measurement values much higher than those of samples with other blockers. The large grain sizes of this material make it more suitable as a means of preventing losses rather than as a typical material limiting damage to the near-wellbore zone.

- The rheological and structural properties of the developed base fluid were sufficient to maintain structural stability after the addition of all types of blocking agents. The TSI coefficient was below 1 in three cases, while for one agent (OB2), it was slightly higher.

- The most effective agent in terms of limiting API filtration of the drilling fluid was OB1. At a concentration of 5.0% of this agent in the drilling fluid, the filtration value was 4.2 cm3. The highest filtration value among the drilling fluids treated with a single blocker was observed for the one modified with the OB3 agent.

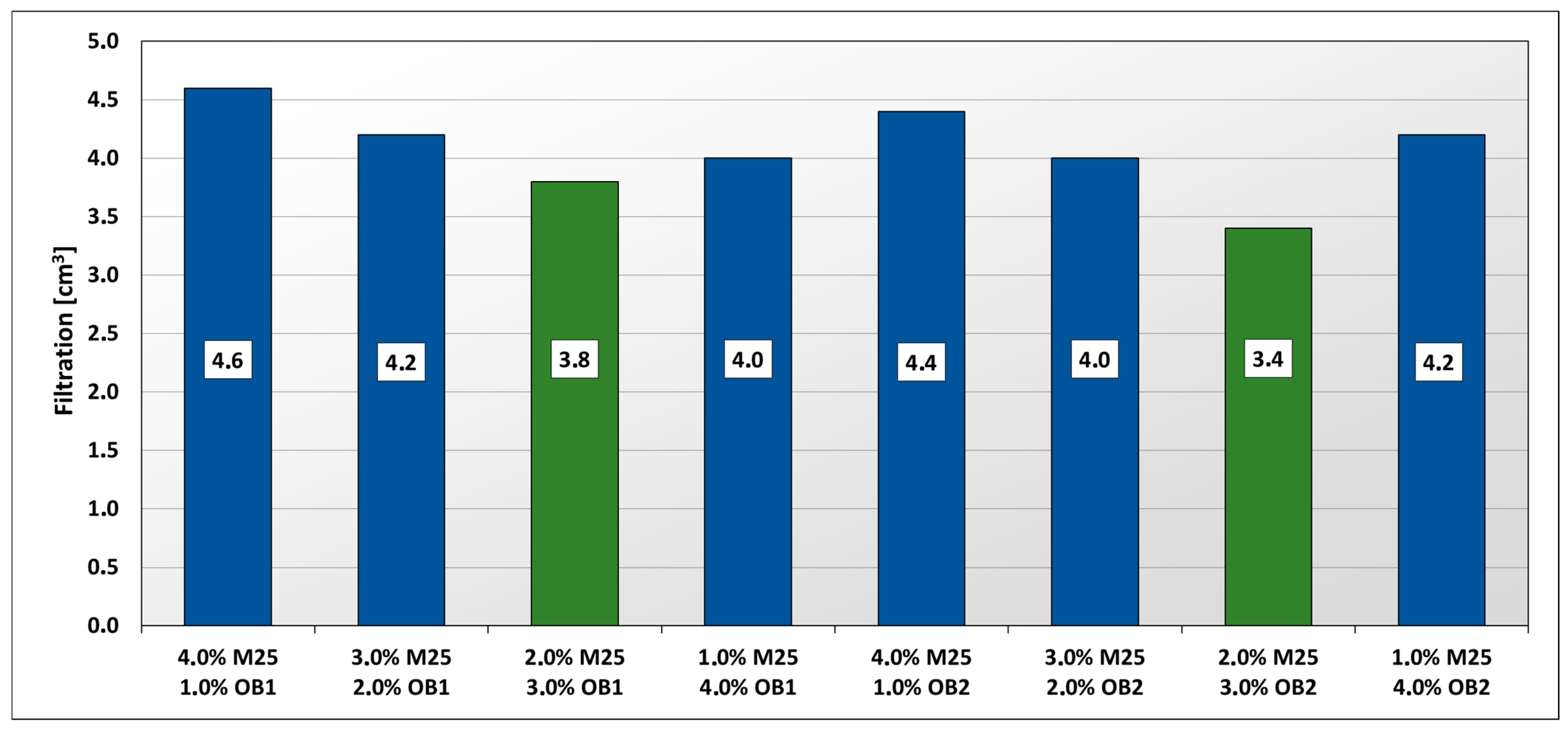

- Among the tested drilling fluids with a double set of blockers, the highest efficiency for reducing filtration values was shown by the following combinations: 2.0% M25 + 3.0% OB1 and 2.0% M25 + 3.0% OB2, with the obtained results being 3.8 cm3 and 3.4 cm3, respectively.

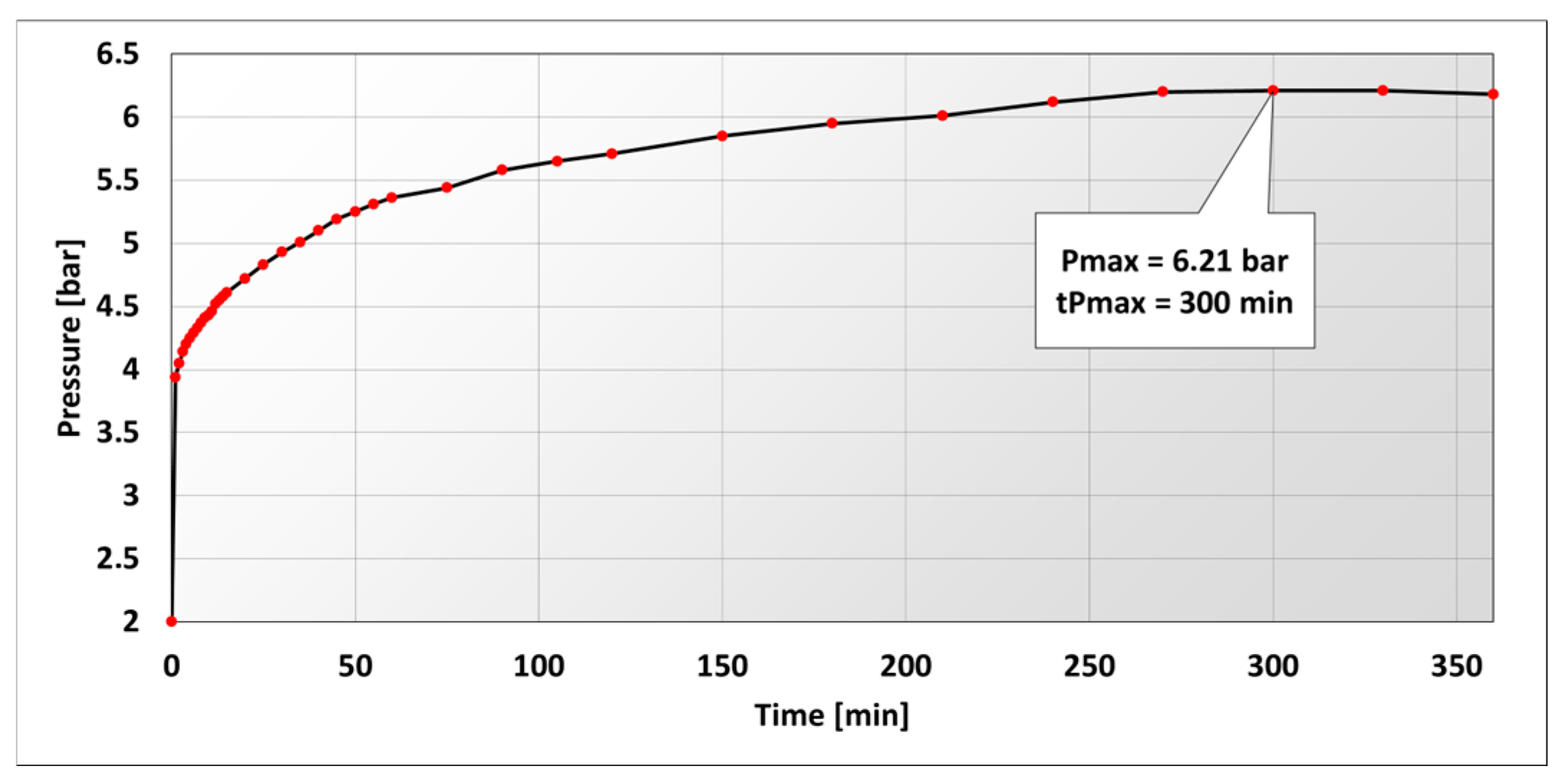

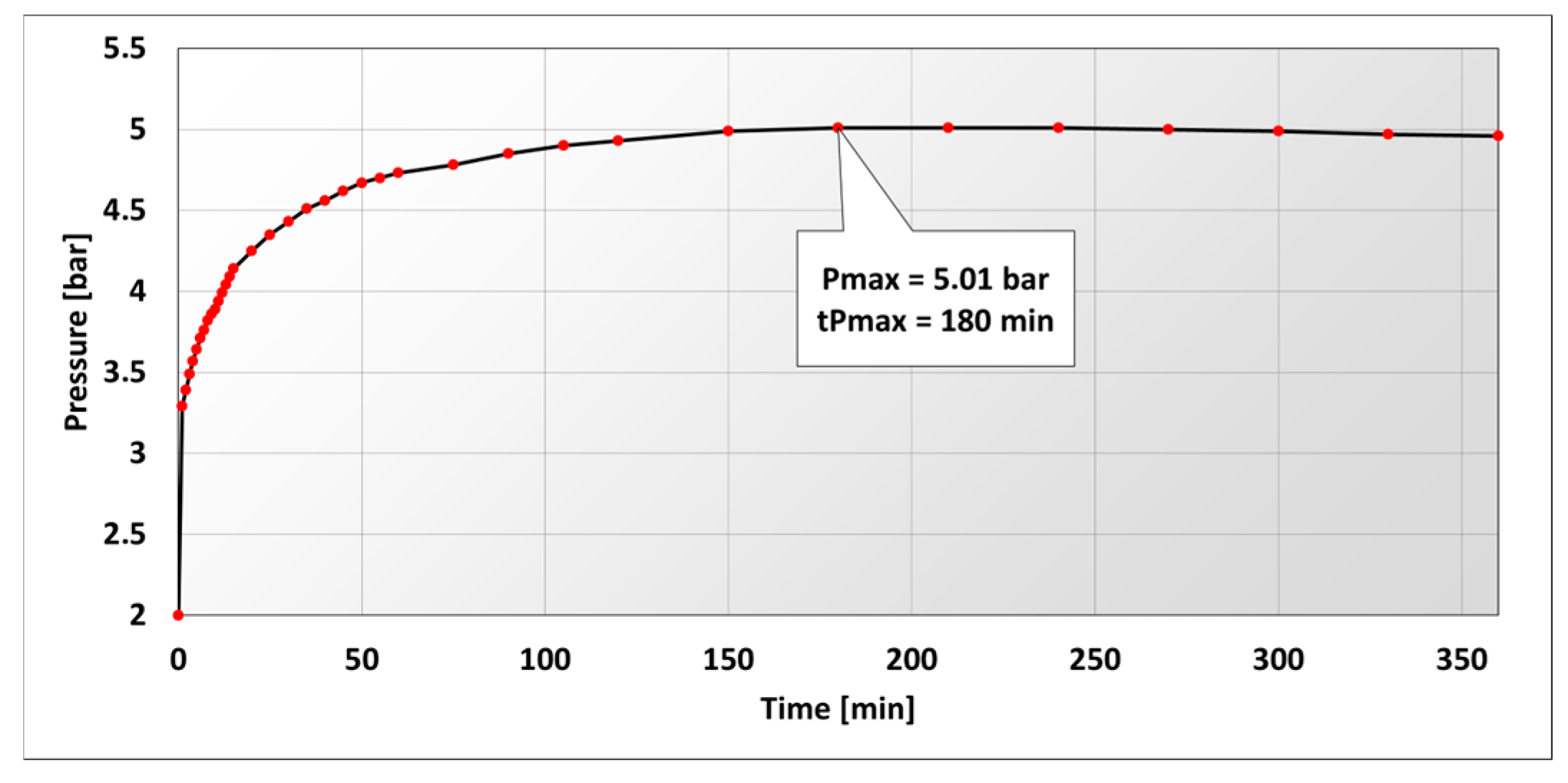

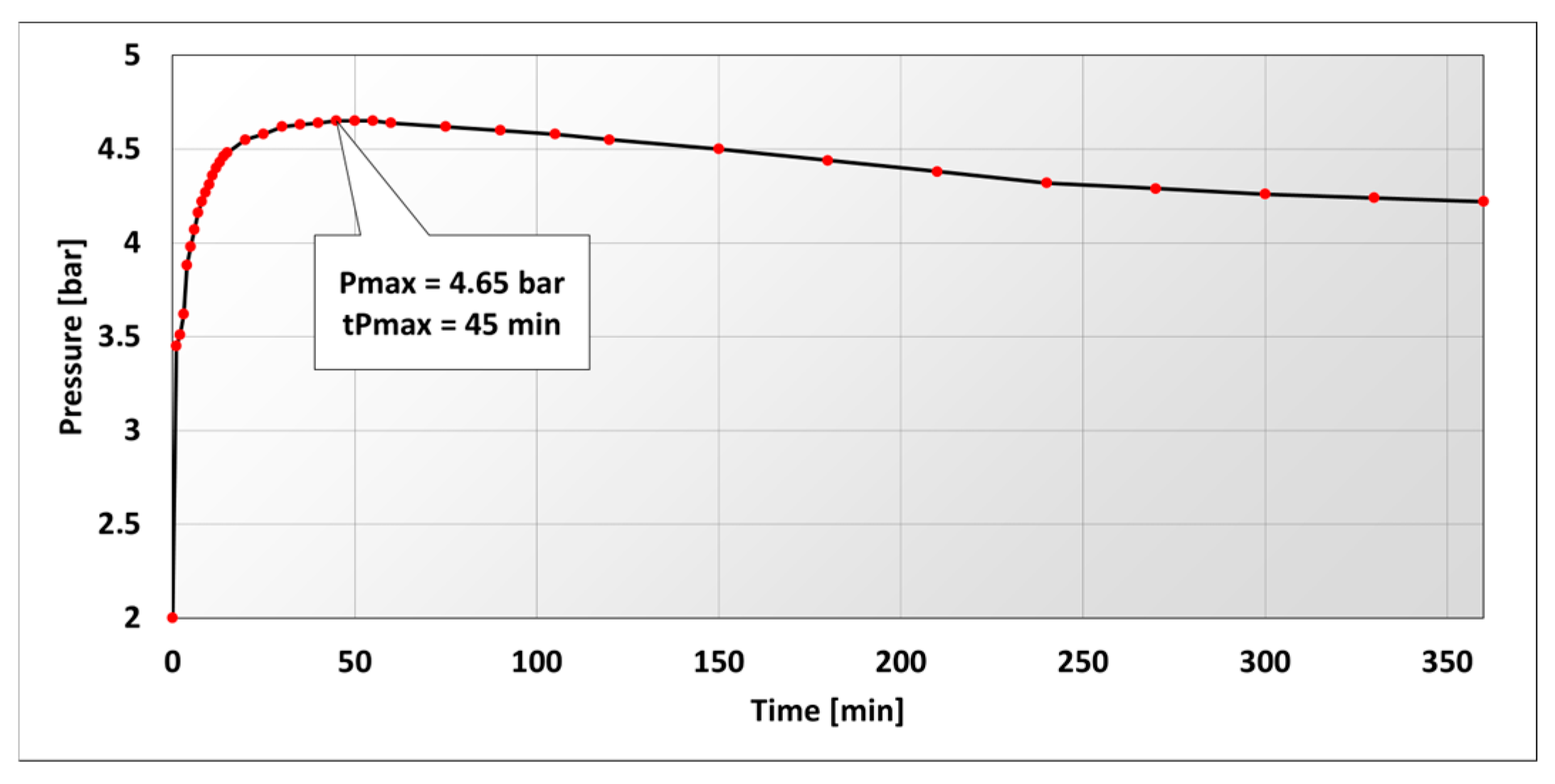

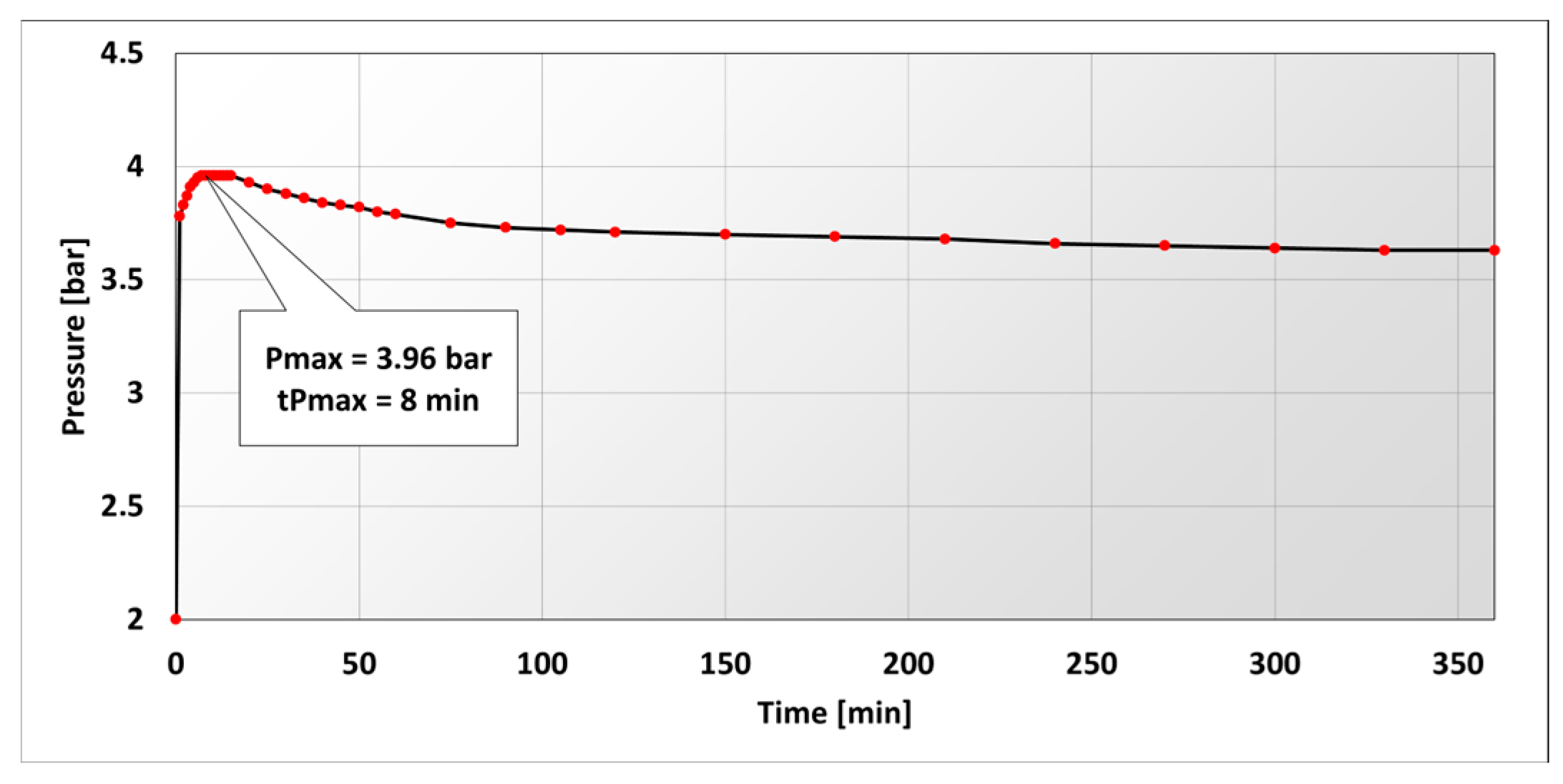

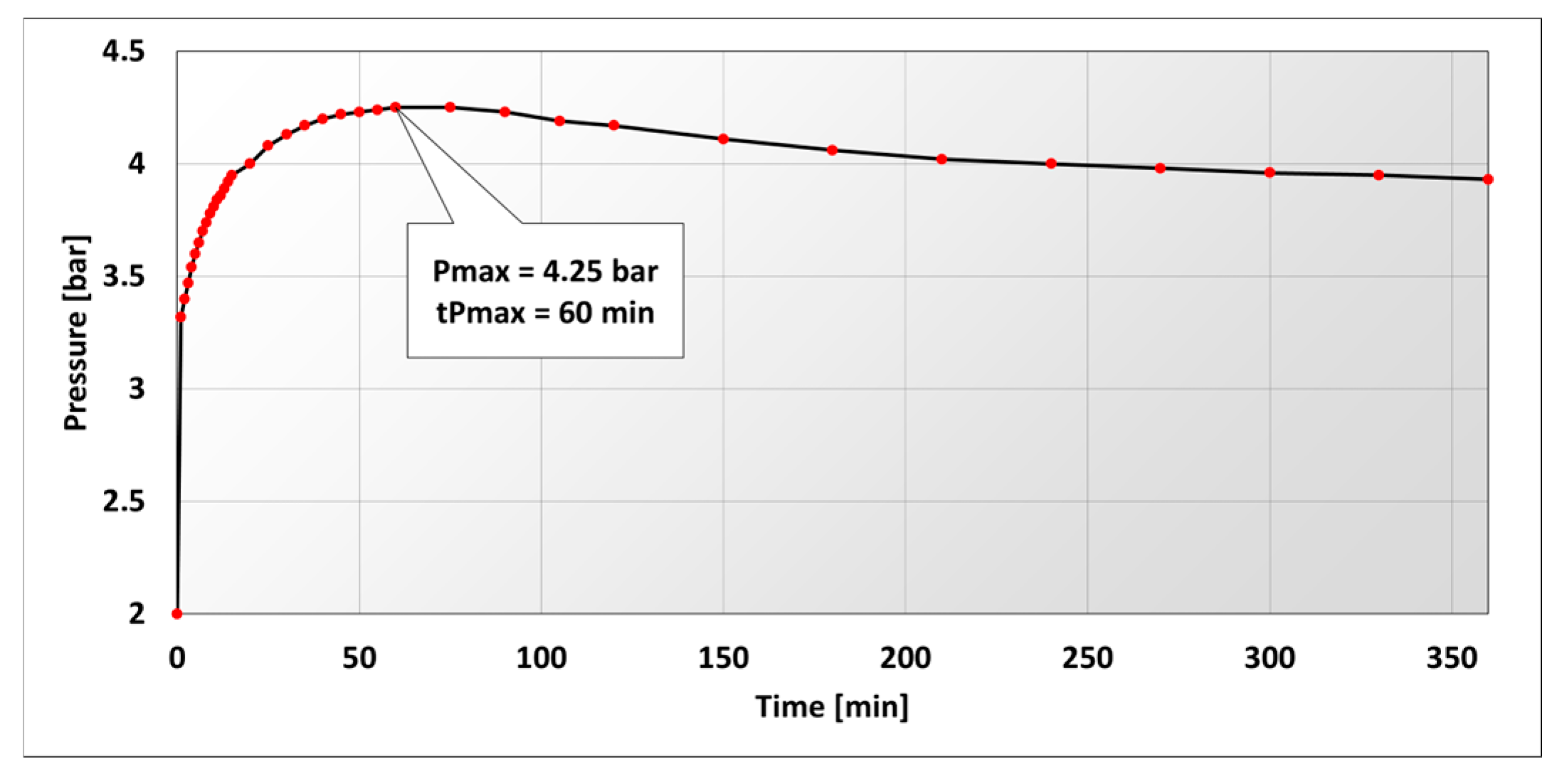

- The results obtained during the pore pressure transmission test confirmed the results achieved during the API filtration measurement. The base drilling fluid, which exhibited the highest filtration value (10.2 cm3), also had the highest maximum pore pressure (pmax = 6.21 bar) and the longest tpmax duration (300 s). In turn, the drilling fluids with a double set of blockers, which had the lowest filtration values, demonstrated the ability to quickly form a tight filter cake. For example, the fluid with the M25 + OB1 blocker set had a maximum pore pressure of 3.96 bar and a tpmax of 8 min, while the fluid with the M25 + OB2 set had pmax = 4.25 bar and tpmax = 45 min.

- The conducted tests allowed us to conclude that drilling fluids containing double sets of blocking materials with different particle sizes enabled the formation of a tighter filter cake that prevented filtrate invasion into the reservoir rock compared to fluids with a single bridging agent. This is exhibited both by the API filtration measurement results and the pore pressure transmission test. It also confirms the theory that to quickly create a filter cake sealing the rock, a wide range of blocker particle sizes should be used. Particularly good results were shown by the fluid containing the following combination: carbonate blocker M25 at a 2.0% concentration and organic blocker OB1 at a 3.0% concentration. It can be concluded that a fluid of such composition would effectively prevent the invasion of the solid phase and filtrate into the rock pore space.

Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elmgerbi, A.; Les, B.; Ashena, R.; Atkin, T. A Practical Decision Tool to Evaluate and Rank Potential Solutions for Expected Downhole Drilling Problems During the Well-planning Phase. J. Inst. Eng. India Ser. D 2022, 103, 25–36. [Google Scholar] [CrossRef]

- Gholami, R.; Elochukwu, H.; Fakhari, N.; Sarmadivaleh, M. A review on borehole instability in active shale formations: Interactions, mechanisms and inhibitors. Earth-Sci. Rev. 2018, 177, 2–13. [Google Scholar] [CrossRef]

- Plumb, R. Influence of Composition and Texture on the Failure Properties of Clastic Rocks. Eurock 1994, 94, 13–20. [Google Scholar] [CrossRef]

- Pedrosa, C.; Saasen, A.; Ytrehus, J.D. Hole cleaning and wet-granular rheology of rock cutting beds: Impact of drilling fluid composition. J. Pet. Sci. Eng. 2023, 220 Pt. B, 111267. [Google Scholar] [CrossRef]

- Panevnik, D.A.; Velichkovich, A.S. Assessment of the stressed state of the casing of the above-bit hydroelevator. Oil Ind. J. 2017, 1, 70–73. [Google Scholar]

- Velichkovich, A.S.; Panevnik, D.A. Study of the stress state of the downhole jet pump housing. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2017, 5, 50–55. [Google Scholar]

- Alvarez, L.A.; Cedeno, M.D.; Villon, P.V.; Pinoargote, R.C. Design of a fluid for workover operations in the Gustavo Galindo Oilfield, Ecuador. ARPN J. Eng. Appl. Sci. 2019, 14, 2118–2124. [Google Scholar]

- Caenn, R.; Darley, H.C.H.; Gray, G.R. Composition and Properties of Drilling and Completion Fluids, 6th ed.; Gulf Professional Publishing: Houston, TX, USA, 2011. [Google Scholar]

- Mungan, N. Permeability reduction through changes in pH and salinity. SPE-1283-PA. J. Pet. Technol. 1965, 17, 1449–1453. [Google Scholar] [CrossRef]

- Rahman, S.S.; Rahman, M.M.; Khan, F.A. Response of low-permeability, illitic sandstone to drilling and completion fluids. J. Petrol. Sci. Eng. 1995, 12, 309–322. [Google Scholar] [CrossRef]

- Stec, M. Opracowanie Nowych Receptur PłUczek Mrówczanowych W Aspekcie Ograniczenia Uszkodzenia Strefy Przyodwiertowej. Ph. D. Thesis, Rozprawa Doktorska, Akademia Górniczo-Hutnicza, Kraków, Poland, 2017. [Google Scholar]

- Uliasz, M. Ciecze Robocze—Ich Właściwości Technologiczne i Rola w Procesie Rekonstrukcji Odwiertów; Instytut Nafty i Gazu—Państwowy Instytut Badawczy: Kraków, Poland, 2021; p. 235. [Google Scholar] [CrossRef]

- van Oort, E. On the physical and chemical stability of shales. J. Petrol. Sci. Eng. 2003, 38, 213–235. [Google Scholar] [CrossRef]

- Fleming, N.; Moldrheim, E.; Teigland, E.; Mathisen, A.-M. Systematic Approach to Well Productivity Evaluation to Determine the Significance of Formation Damage for Wells Drilled in a Depleted Reservoir Without Bridging Particles: Oseberg Main Case History. SPE Prod. Oper. 2020, 35, 681–690. [Google Scholar] [CrossRef]

- Bageri, B.S.; Mahmoud, M.A.; Al-Mutairi, S.H.; Kuwait, C.; Abdulraheem, A. Filter Cake Porosity and Permeability Profile Along the Horizontal Well and Their Impact on Filter Cake Removal. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 6–9 December 2015. [Google Scholar] [CrossRef]

- Feng, Y.; Li, G.; Meng, Y.; Guo, B. A Novel Approach to Investigating Transport of Lost Circulation Materials in Rough Fracture. Energies 2018, 11, 2572. [Google Scholar] [CrossRef]

- Jinhua, H.; Xing, Z.; Yuanjun, C.; Baisong, Y.; Jian, Z.; Xuemin, W.; Wei, L.; Zhansheng, W.; Ruizhi, Z. Preparation, characterization and application of environment-friendly high density and low damage solid free completion fluids for completing HTHP oil and gas wells. Geoenergy Sci. Eng. 2023, 221, 211351. [Google Scholar] [CrossRef]

- Chen, L.; Huang, F.; Li, G.; Mao, Z.; Hu, Y.; Liu, L.; Zeng, H.; Xu, S. Experimental Study on Fiber Balls for Bridging in Fractured-Vuggy Reservoir. SPE J. 2023, 28, 1880–1894. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, Y.; Qu, L.; Wang, Y.; Zhang, S. A New Method for Designing the Bridging Particle Size Distribution for Fractured Carbonate Reservoirs. SPE J. 2023, 27, 2552–2562. [Google Scholar] [CrossRef]

- Rad, M.S.K.; Mohammadi, M.K.; Nowtarki, K.T. Bridging Agents Optimization Based on Predicting Induced Fracture Model for Deviated Wells—A Case Study. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference, Virtual, 8–9 June 2021. [Google Scholar] [CrossRef]

- Li, X.; Zheng, L.; Chen, Y.; Huang, X.; Zhai, X.; Wei, P.; Tao, X.; Nie, S. Fuzzy-Ball Fluids Enhance the Production of Oil and Gas Wells: A Historical Review. Energies 2023, 16, 6647. [Google Scholar] [CrossRef]

- Available online: http://bdc.com.pl (accessed on 14 August 2025).

- Available online: http://www.glossary.oilfield.slb.com (accessed on 20 August 2025).

- Available online: http://www.pspw-krosno.com.pl (accessed on 14 August 2025).

- Jasiński, B. Określenie dynamicznej filtracji płuczek wiertniczych w warunkach HPHT z użyciem nowatorskiej metody pomiarowej. Naft.-Gaz 2018, 2, 85–95. [Google Scholar] [CrossRef]

- Han, Y.; Luo, B.; Chang, F.; Li, W. Numerical Investigation of Particle Bridging Near Fracture Entrance. In Proceedings of the 56th U.S. Rock Mechanics/Geomechanics Symposium, Santa Fe, NM, USA, 26–29 June 2022. [Google Scholar] [CrossRef]

- Popov, S.V.; Nikitin, P.M.; Udaltsov, D.A.; Ryabtsev, P.L. Smart Bridging Agent—Prevents Formation Damage and Removed with Formation Fluid. In Proceedings of the SPE Russian Petroleum Technology Conference, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Uliasz, M.; Herman, Z. Wymagania i właściwości cieczy roboczych. In Proceedings of the Konferencja z okazji 20-lecia Instytutu Problemów Nafty i Gazu Rosyjskiej Akademii Nauk, Moscow, Russia, 24–26 April 2007. [Google Scholar]

- Uliasz, M.; Herman, Z. Wymagane parametry cieczy roboczych dla ochrony pierwotnych właściwości skał zbiornikowych. Wiert.-Naft.-Gaz 2008, 25, 753–764. [Google Scholar]

- Abiodun, S.; Vincent, J.M.; Schultz, K.; Rapp, E. Using Particle Size Theories to Optimize Bridging Solids for Post-Gravel-Pack Screens. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 12 February 2020. [Google Scholar] [CrossRef]

- Izyurov, V.; Kharitonov, A.; Semenikhin, I.; Korsunov, E.; Gassan, A.; Tikhonov, E.; Jadan, G.; Stashko, V.; Blagonadeshniy, I.; Manikhin, A.; et al. Selecting Bridging Agents’ Particle Size Distribution for Optimum Plugging While Drilling in Permeable Zones. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 22–24 October 2019. [Google Scholar] [CrossRef]

- Abdo, J.; Haneef, M.D. Nano-enhanced drilling fluids: Pioneering approach to overcome uncompromising drilling problems. J. Energy Resour. Technol. 2012, 134, 014501. [Google Scholar] [CrossRef]

- Abdo, J.; Haneef, M.D. Clay nanoparticles modified drilling fluids for drilling of deep hydrocarbon wells. Appl. Clay Sci. 2016, 86, 76–82. [Google Scholar] [CrossRef]

- Zima, G. Analiza wpływu nanomateriałów na właściwości osadu filtracyjnego. Naft.-Gaz 2017, 5, 312–320. [Google Scholar] [CrossRef]

- Mohamed, Y.A.; Ahmed, R.S.; El-Agamy, H.A.; Kheir, M.M.; Ahmed, S.S.; Hassan, S.H.; Hady, A.S.A.; Al-Zahry, A.A.E.; Salama, A.M.; Gaber, L.A.; et al. Innovative Polymeric Nanoparticles Associated with Engineered Bridging Particles Solve Depleted Reservoir Drilling Challenges (Case study: Gulf of Suez). In Proceedings of the Gas & Oil Technology Showcase and Conference, Dubai, United Arab Emirates, 13–15 March 2023. [Google Scholar] [CrossRef]

- Alia, U.; Latif, A.; Chong, Z.N.; Chong, K.I.; Belhaj, H.; Al Hameli, F. Smart Nano Clay to Reduce Water-Based Mud Filter Cake. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 31 October–3 November 2022. [Google Scholar] [CrossRef]

- Dębińska, E. Wpływ nanokrzemionki na parametry mechaniczne kamienia cementowego. Naft.-Gaz 2014, 4, 229–235. [Google Scholar]

- Dębińska, E. Niekonwencjonalne zaczyny cementowe z dodatkiem nanokrzemionki. Naft.-Gaz 2015, 5, 290–300. [Google Scholar]

- Jankiewicz, B.J.; Choma, J.; Jamioła, D.; Jaroniec, M. Nanostruktury krzemionkowo-metaliczne. Otrzymywanie i modyfikacja nanocząstek krzemionkowych. Wiadomości Chem. 2010, 64, 913–942. [Google Scholar]

- Alvi, M.A.A.; Belayneh, M.; Bandyopadhyay, S.; Minde, M.W. Effect of Iron Oxide Nanoparticles on the Properties of Water-Based Drilling Fluids. Energies 2020, 13, 6718. [Google Scholar] [CrossRef]

- Adel, M.; Ragab, S.; Noah, A. Reduction of formation damage and fluid loss using nano-sized silica drilling fluids. Pet. Technol. Dev. J. Int. J. 2014, 2, 75–88. [Google Scholar]

- Contreras, O.; Hareland, G.; Husein, M.; Nygaard, R.; Al-Saba, M. Application of in-house prepared nanoparticles as filtration control additive to reduce formation damage. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 18–20 February 2014. [Google Scholar] [CrossRef]

- Ponmani, S.; Nagarajan, R.; Sangwai, J.S. Effect of nanofluids of CuO and ZnO in polyethylene glycol and polyvinylpyrrolidone on the thermal, electrical, and filtration-loss properties of water-based drilling fluids. SPE-178919-PA. SPE J. 2016, 21, 405–415. [Google Scholar] [CrossRef]

- Salih, A.H.; Bilgesu, H. Investigation of rheological and filtration properties of water-based drilling fluids using various anionic nanoparticles. SPE-185638-MS. SPE J. 2017, 21, 405–415. [Google Scholar] [CrossRef]

- Salih, A.H.; Elshehabi, T.A.; Bilgesu, H.I. Impact of nanomaterials on the rheological and filtration properties of water-based drilling fluids. In Proceedings of the SPE Eastern Regional Meeting, Canton, OH, USA, 13–15 September 2016. [Google Scholar] [CrossRef]

- Raczkowski, J.; Półchłopek, T. Materiały i środki chemiczne do sporządzania płuczek wiertniczych. Prace INiG 1998, 95, 1–319. [Google Scholar]

- He, Z.; Fan, S.; Fang, J.; Yu, Y.; Zhang, J.; Li, S.; Xu, P. Research and Application of Fast Plugging Method for Fault Zone Formation in Tarim Basin, China. Energies 2023, 16, 4330. [Google Scholar] [CrossRef]

- Jia, H.; Chen, H.; Guo, S. Fluid loss control mechanism of using polymer gel pill based on multi-crosslinking during overbalanced well workover and completion. Fuel 2017, 210, 207–216. [Google Scholar] [CrossRef]

- Al-Delfi, A.K.; Al-Mahdawi, F.H. A comprehensive review of lost circulation: Principles and treatments. In Proceedings of the AIP Conference Proceeding, Sofia, Bulgaria, 10–16 June 2023; Volume 2839, p. 020026. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Jaafar, M.Z.; Yusof, M.A.M.; Idris, A.K. A review on the effect of nanoparticle in drilling fluid on filtration and formation damage. J. Pet. Sci. Eng. 2022, 217, 110922. [Google Scholar] [CrossRef]

- Idress, M.; Hasan, M.L. Investigation of different environmental-friendly waste materials as lost circulation additive in drilling fluids. J. Pet. Explor. Prod. Technol. 2020, 10, 233–242. [Google Scholar] [CrossRef]

- Shuvo, M.A.I.; Sultan, M.Z.B.; Ferdous, A.R.R. Applicability of sawdust as a green additive to improve the rheological and filtration properties of water-based drilling fluid: An experimental investigation. J. Pet. Explor. Prod. Technol. 2024, 14, 303–315. [Google Scholar] [CrossRef]

- Dike, H.N.; Chibueze, L.N.; Ipinsokan, S.; Adewumi, C.N.; Olabode, O.; Olaniyan, D.D.; Pius, I.E.; Oke, M.A. An Evaluation of the Rheological and Filtration Properties of Cow Bone Powder and Calcium Carbonate as Fluid-Loss Additives in Drilling Operations. Processes 2025, 13, 2205. [Google Scholar] [CrossRef]

| No | Mud Composition | Density | Viscosity | Yield Point | Structural Strength | Filtration | pH | ||

|---|---|---|---|---|---|---|---|---|---|

| ηpl | ηs | τy | I/II | ||||||

| [%] | [g/cm3] | [mPa·s] | [Pa] | [Pa] | [cm3] | ||||

| 1 | Biocide | 0.1 | 1.04 | 14 | 20.5 | 6.2 | 1.2/2.2 | total | 9.4 |

| XCD | 0.2 | ||||||||

| CMC LV | 1.0 | ||||||||

| PAC R | 0.2 | ||||||||

| KCl | 5.0 | ||||||||

| 2 | Biocide | 0.1 | 1.04 | 33 | 55.5 | 21.5 | 3.3/5.3 | 17.2 | 9.6 |

| XCD | 0.2 | ||||||||

| CMC LV | 1.0 | ||||||||

| PAC R | 0.2 | ||||||||

| Starch | 3.0 | ||||||||

| KCl | 5.0 | ||||||||

| 3 | Biocide | 0.1 | 1.04 | 33 | 50 | 16.3 | 2.7/4.0 | 16.0 | 9.6 |

| XCD | 0.2 | ||||||||

| CMC LV | 1.0 | ||||||||

| PAC LV | 0.2 | ||||||||

| Starch | 3.0 | ||||||||

| KCl | 5.0 | ||||||||

| 4 | Biocide | 0.1 | 1.04 | 42 | 65.5 | 22.5 | 4.1/5.9 | 14.8 | 9.7 |

| Defoamer | 0.1 | ||||||||

| XCD | 0.3 | ||||||||

| CMC LV | 1.0 | ||||||||

| PAC LV | 0.2 | ||||||||

| Starch | 3.0 | ||||||||

| KCl | 5.0 | ||||||||

| 5 | Biocide | 0.1 | 1.04 | 41 | 69 | 26.8 | 4.5/6.3 | 10.6 | 9.6 |

| Defoamer | 0.1 | ||||||||

| XCD | 0.3 | ||||||||

| CMC LV | 1.0 | ||||||||

| PAC R | 0.2 | ||||||||

| Starch | 3.0 | ||||||||

| KCl | 5.0 | ||||||||

| 6 | Biocide | 0.1 | 1.04 | 43 | 72.5 | 28.2 | 4.8/6.7 | 10.2 | 9.6 |

| Defoamer | 0.1 | ||||||||

| XCD | 0.35 | ||||||||

| CMC LV | 1.0 | ||||||||

| PAC R | 0.2 | ||||||||

| Starch | 3.0 | ||||||||

| KCl | 5.0 | ||||||||

| No | Mud Composition | Density | Viscosity | Yield Point | Structural Strength | Filtration | pH | ||

|---|---|---|---|---|---|---|---|---|---|

| ηpl | ηs | τy | I/II | ||||||

| [%] | [g/cm3] | [mPa·s] | [Pa] | [Pa] | [cm3] | ||||

| 1 | Base mud | 1.04 | 43 | 72.5 | 28.2 | 4.8/6.7 | 10.2 | 9.6 | |

| 2 | Base mud + OB1 + NaOH | 1.0 | 1.04 | 44 | 73.5 | 28.2 | 4.9/6.7 | 6.6 | 9.4 |

| 3 | Base mud + OB1 + NaOH | 3.0 | 1.05 | 46 | 75 | 27.8 | 4.8/6.6 | 5.8 | 9.3 |

| 4 | Base mud + OB1 + NaOH | 5.0 | 1.06 | 49 | 76.5 | 26.3 | 4.9/6.5 | 4.2 | 9.4 |

| 5 | Base mud + OB2 + NaOH | 1.0 | 1.04 | 45 | 73.5 | 27.3 | 4.8/6.4 | 7.4 | 9.5 |

| 6 | Base mud + OB2 + NaOH | 3.0 | 1.05 | 46 | 74.5 | 27.3 | 4.9/6.5 | 5.4 | 9.5 |

| 7 | Base mud + OB2 + NaOH | 5.0 | 1.06 | 45 | 75 | 28.7 | 4.8/6.4 | 4.8 | 9.4 |

| 8 | Base mud + OB3 + NaOH | 1.0 | 1.04 | 43 | 73.5 | 29.2 | 4.8/6.5 | 9.8 | 9.5 |

| 9 | Base mud + OB3 + NaOH | 3.0 | 1.05 | 44 | 74 | 28.7 | 4.7/6.4 | 8.0 | 9.5 |

| 10 | Base mud + OB3 + NaOH | 5.0 | 1.06 | 44 | 73 | 27.8 | 4.7/6.4 | 7.0 | 9.4 |

| No | Mud Composition | Density | Viscosity | Yield Point | Structural Strength | Filtration | pH | ||

|---|---|---|---|---|---|---|---|---|---|

| ηpl | ηs | τy | I/II | ||||||

| [%] | [g/cm3] | [mPa·s] | [Pa] | [Pa] | [cm3] | ||||

| 1 | Base mud | 1.04 | 43 | 72.5 | 28.2 | 4.8/6.7 | 10.2 | 9.6 | |

| 2 | Base mud + carbonate blocker + OB1 + NaOH | 4.0 1.0 | 1.07 | 45 | 76.5 | 30.2 | 5.2/6.8 | 4.6 | 9.3 |

| 3 | Base mud + carbonate blocker + OB1 + NaOH | 3.0 2.0 | 1.06 | 46 | 76.5 | 29.2 | 5.2/6.7 | 4.2 | 9.2 |

| 4 | Base mud + carbonate blocker + OB1 + NaOH | 2.0 3.0 | 1.06 | 45 | 76 | 29.7 | 4.9/6.6 | 3.8 | 9.2 |

| 5 | Base mud + carbonate blocker + OB1 + NaOH | 1.0 4.0 | 1.06 | 45 | 76 | 29.7 | 4.9/6.6 | 4.0 | 9.3 |

| No | Mud Composition | Density | Viscosity | Yield Point | Structural Strength | Filtration | pH | ||

|---|---|---|---|---|---|---|---|---|---|

| ηpl | ηs | τy | I/II | ||||||

| [%] | [g/cm3] | [mPa·s] | [Pa] | [Pa] | [cm3] | ||||

| 1 | Base mud | 1.04 | 43 | 72.5 | 28.2 | 4.8/6.7 | 10.2 | 9.6 | |

| 2 | Base mud + carbonate blocker + OB2 + NaOH | 4.0 1.0 | 1.07 | 47 | 74 | 25.9 | 4.7/6.4 | 4.4 | 9.3 |

| 3 | Base mud + carbonate blocker + OB2 + NaOH | 3.0 2.0 | 1.06 | 44 | 74.5 | 29.2 | 5.1/6.7 | 4.0 | 9.3 |

| 4 | Base mud + carbonate blocker + OB2 + NaOH | 2.0 3.0 | 1.06 | 48 | 75 | 25.9 | 4.8/6.5 | 3.4 | 9.4 |

| 5 | Base mud + carbonate blocker + OB2 + NaOH | 1.0 4.0 | 1.06 | 43 | 73 | 28.7 | 5.0/6.6 | 4.2 | 9.3 |

| No | Mud Composition | Maximum Pressure pmax | Time to Reach Pressure tpmax | |

|---|---|---|---|---|

| [%] | [bar] | [min] | ||

| 1 | Base mud | 6.21 | 300 | |

| 2 | Base mud + carbonate blocker | 5.0 | 5.25 | 150 |

| 3 | Base mud + OB1 | 5.0 | 5.01 | 180 |

| 4 | Base mud + OB2 | 5.0 | 4.65 | 45 |

| 5 | Base mud + carbonate blocker + OB1 | 2.0 3.0 | 3.96 | 8 |

| 6 | Base mud + carbonate blocker + OB2 | 2.0 3.0 | 4.25 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zima, G.; Błaż, S.; Jasiński, B. Analysis of the Possibilities of Using an Organic Bridging Material for Sealing the Borehole Wall. Appl. Sci. 2025, 15, 11601. https://doi.org/10.3390/app152111601

Zima G, Błaż S, Jasiński B. Analysis of the Possibilities of Using an Organic Bridging Material for Sealing the Borehole Wall. Applied Sciences. 2025; 15(21):11601. https://doi.org/10.3390/app152111601

Chicago/Turabian StyleZima, Grzegorz, Sławomir Błaż, and Bartłomiej Jasiński. 2025. "Analysis of the Possibilities of Using an Organic Bridging Material for Sealing the Borehole Wall" Applied Sciences 15, no. 21: 11601. https://doi.org/10.3390/app152111601

APA StyleZima, G., Błaż, S., & Jasiński, B. (2025). Analysis of the Possibilities of Using an Organic Bridging Material for Sealing the Borehole Wall. Applied Sciences, 15(21), 11601. https://doi.org/10.3390/app152111601