Monte Carlo-Based Simulation of Reactivity and Transmutation in the CEFR Sodium-Cooled Fast Reactor

Abstract

1. Introduction

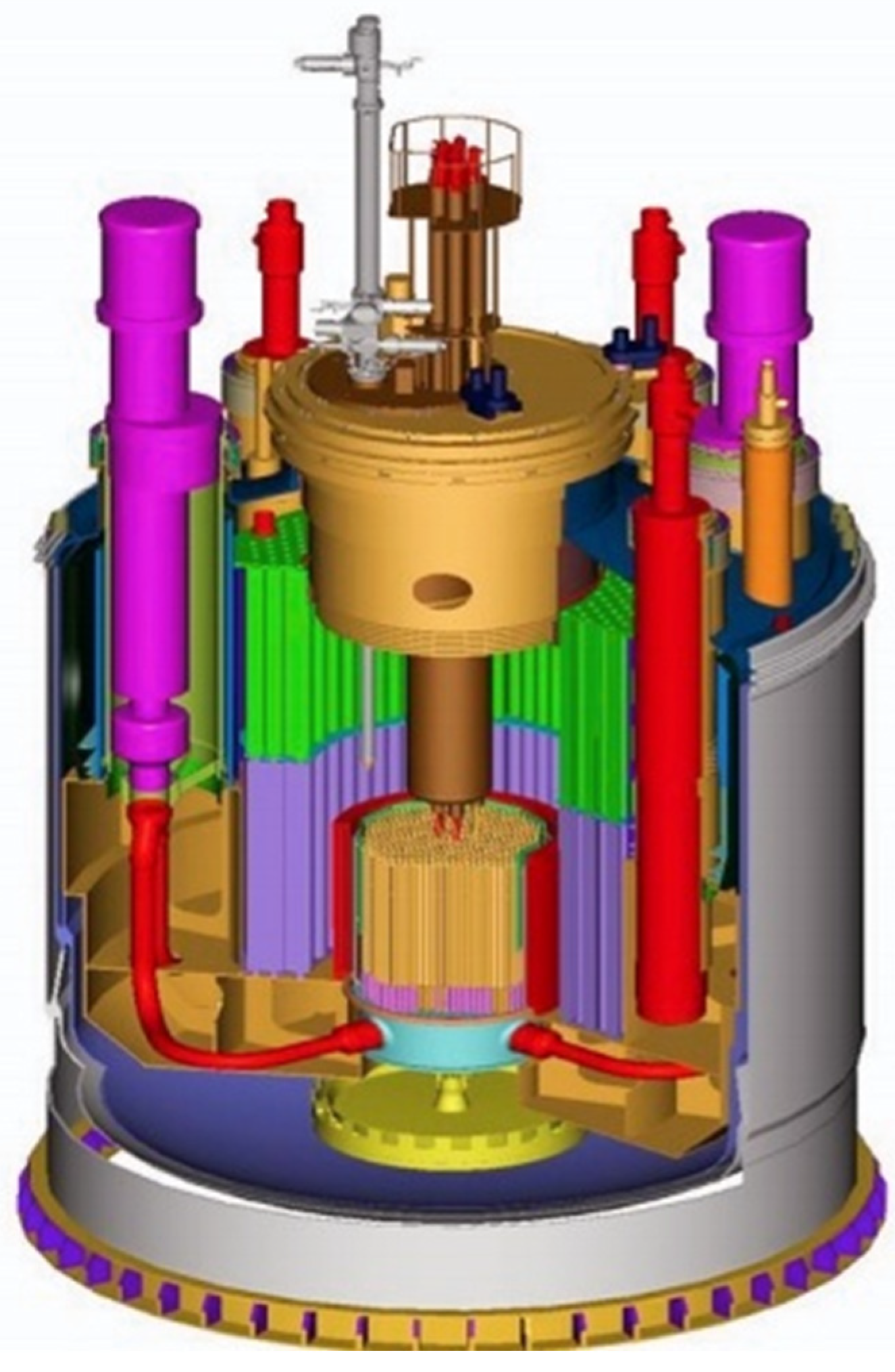

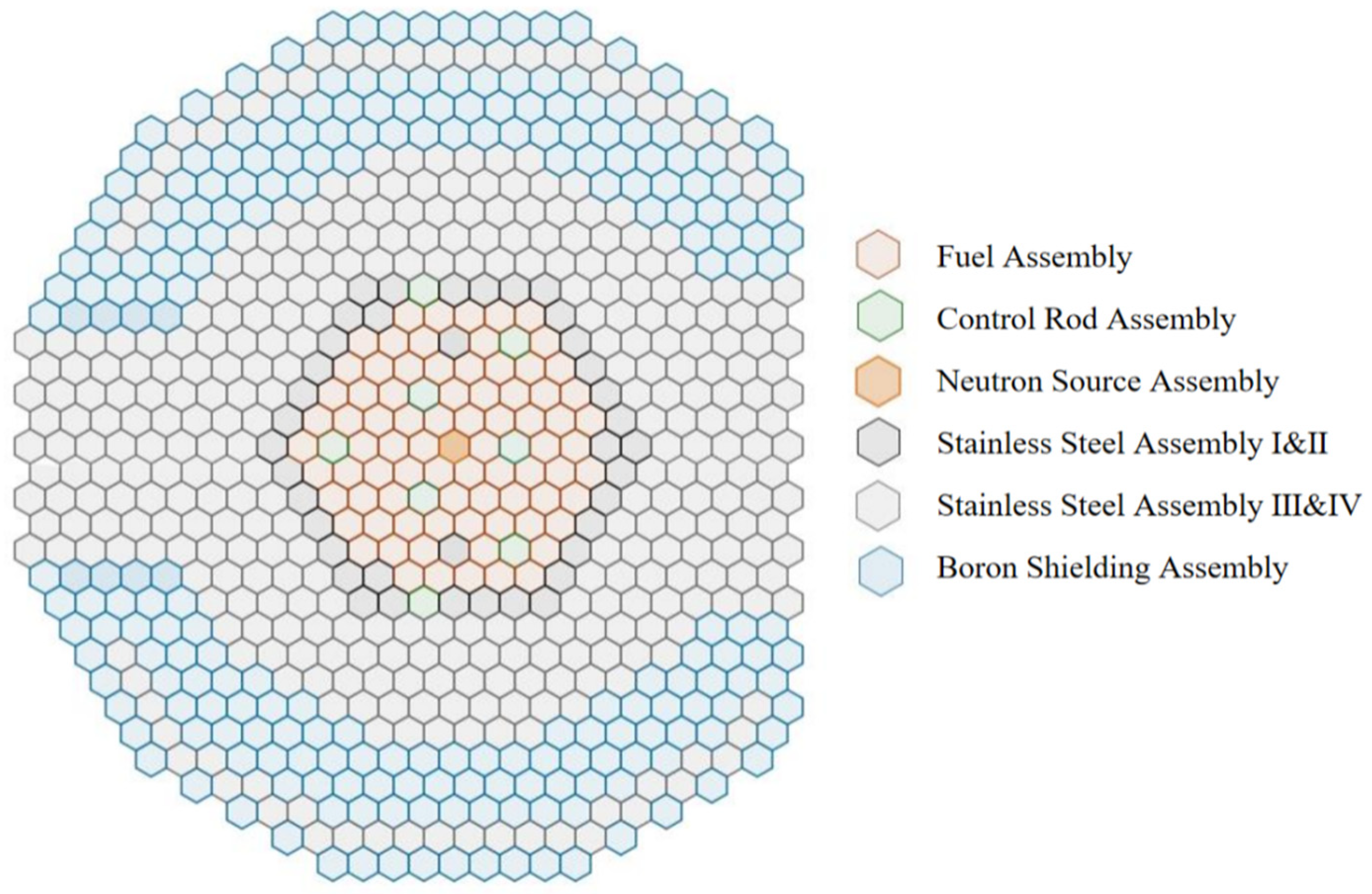

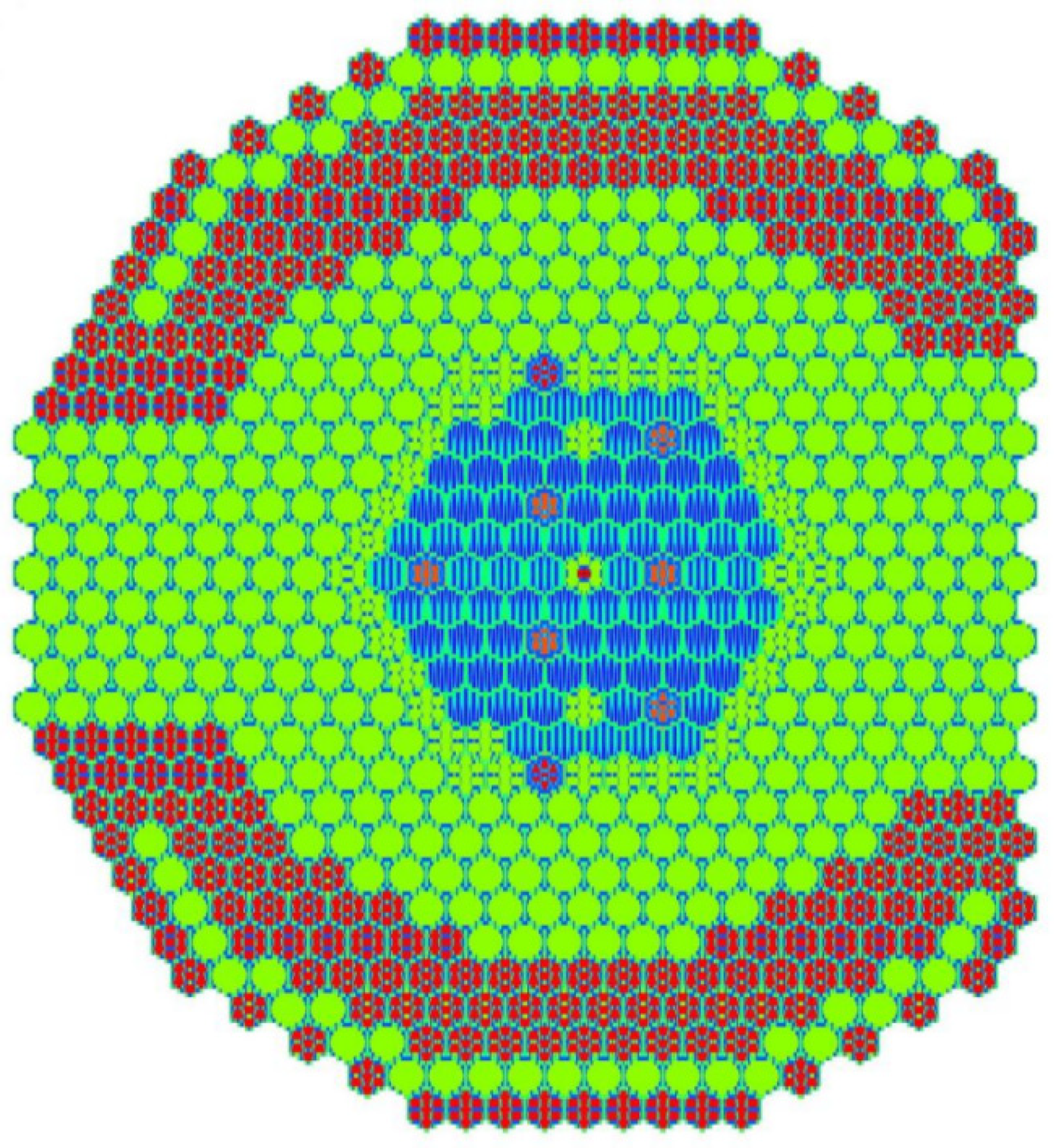

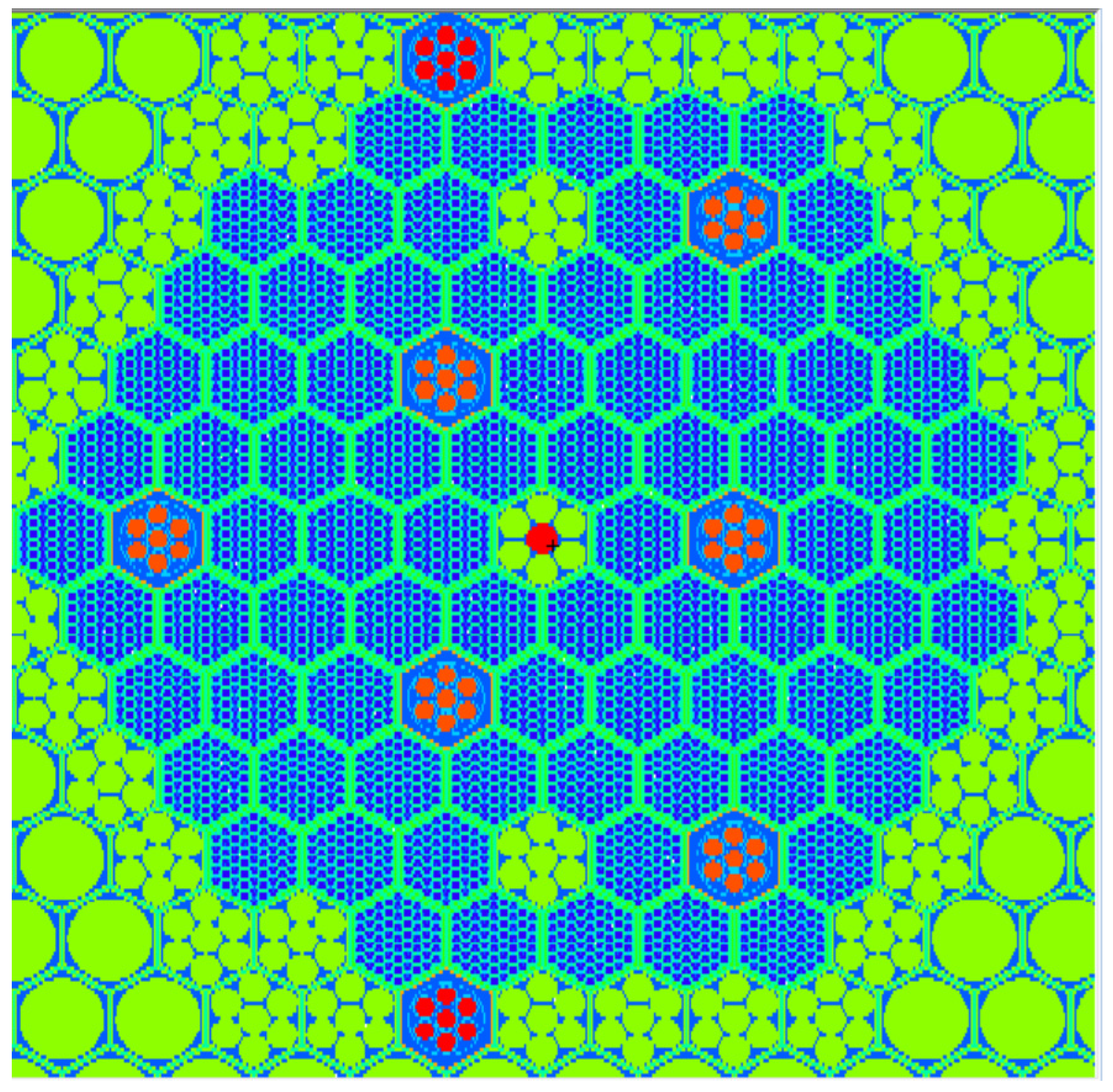

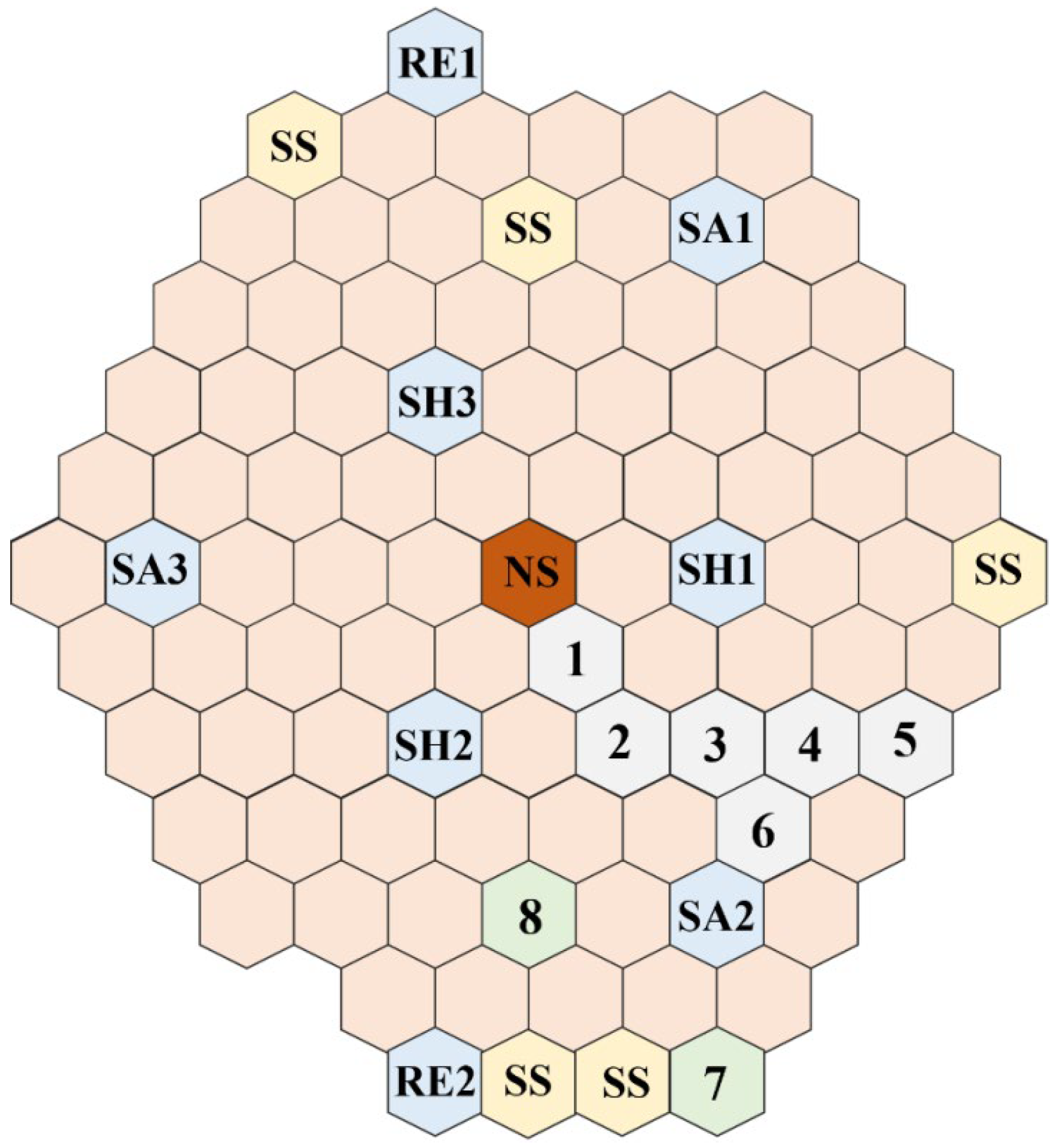

2. Core Modeling of the CEFR

2.1. Overview of the CEFR Core

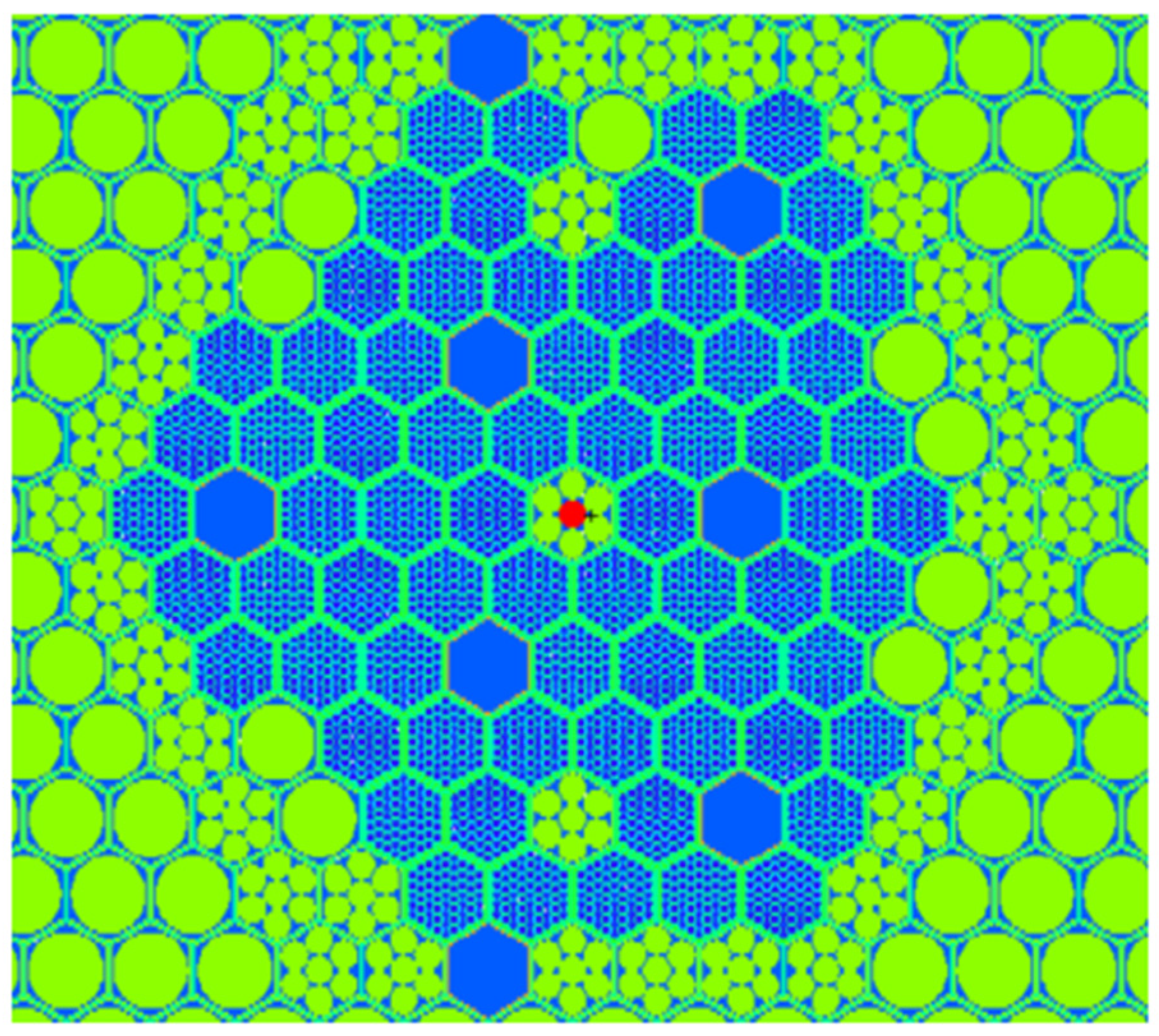

2.2. MCNP Modeling

3. MC Simulation and Transmutation Analysis of the CEFR

3.1. Neutronics Benchmark Simulation and Analysis for the CEFR

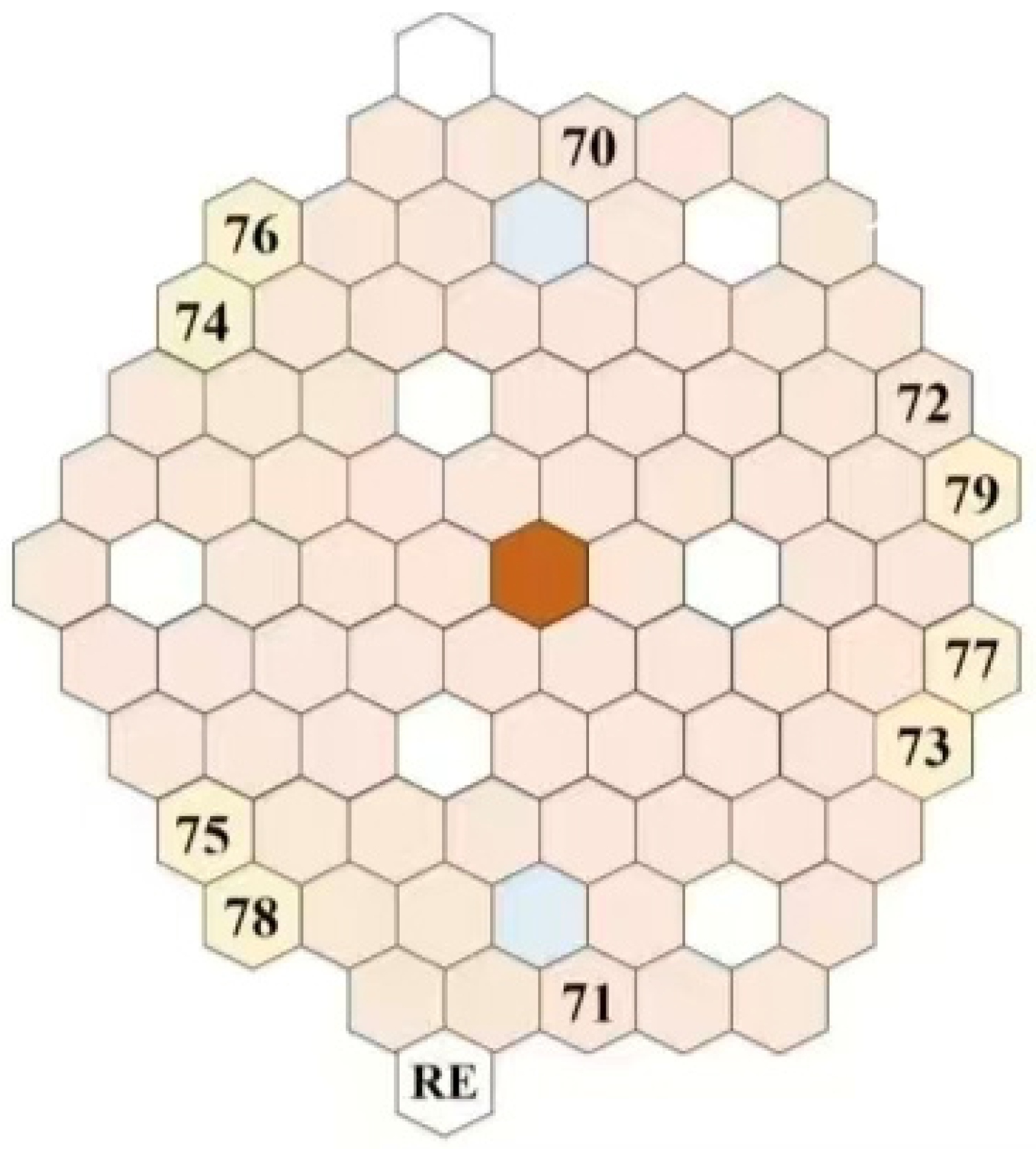

3.1.1. Critical Experiment Analysis

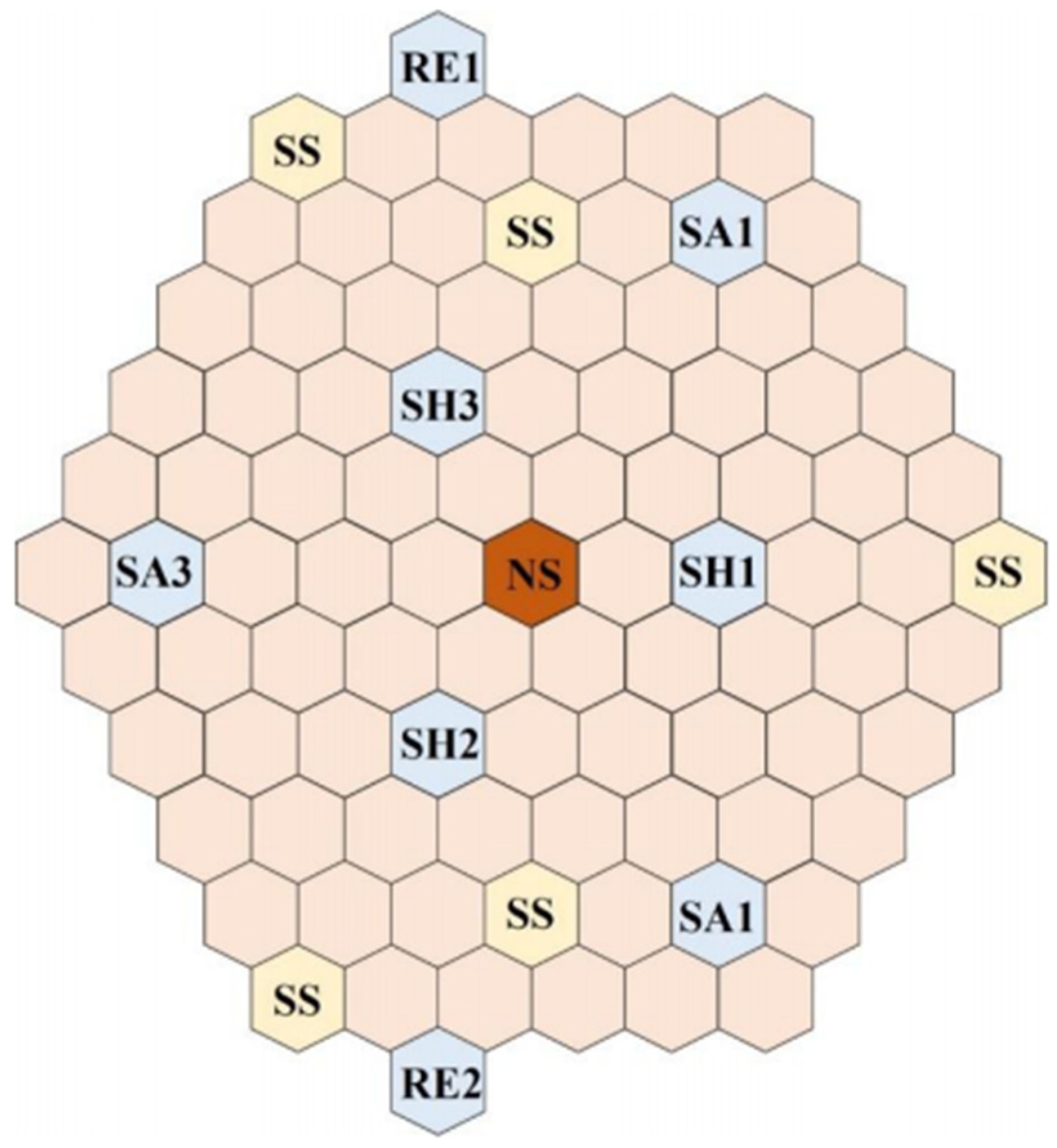

3.1.2. Control Rod Worth Calculation

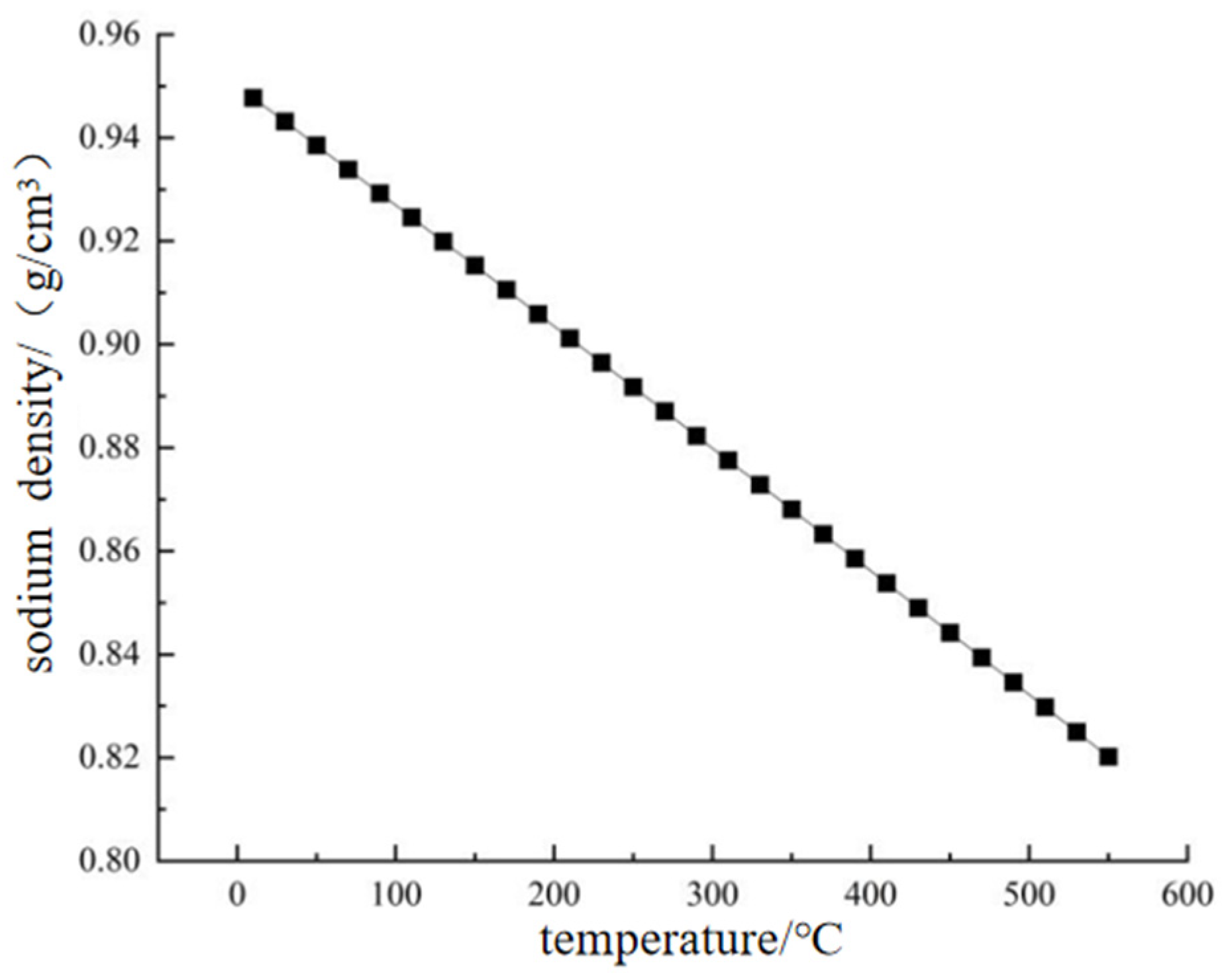

3.1.3. Sodium Void Reactivity Experiment Simulation

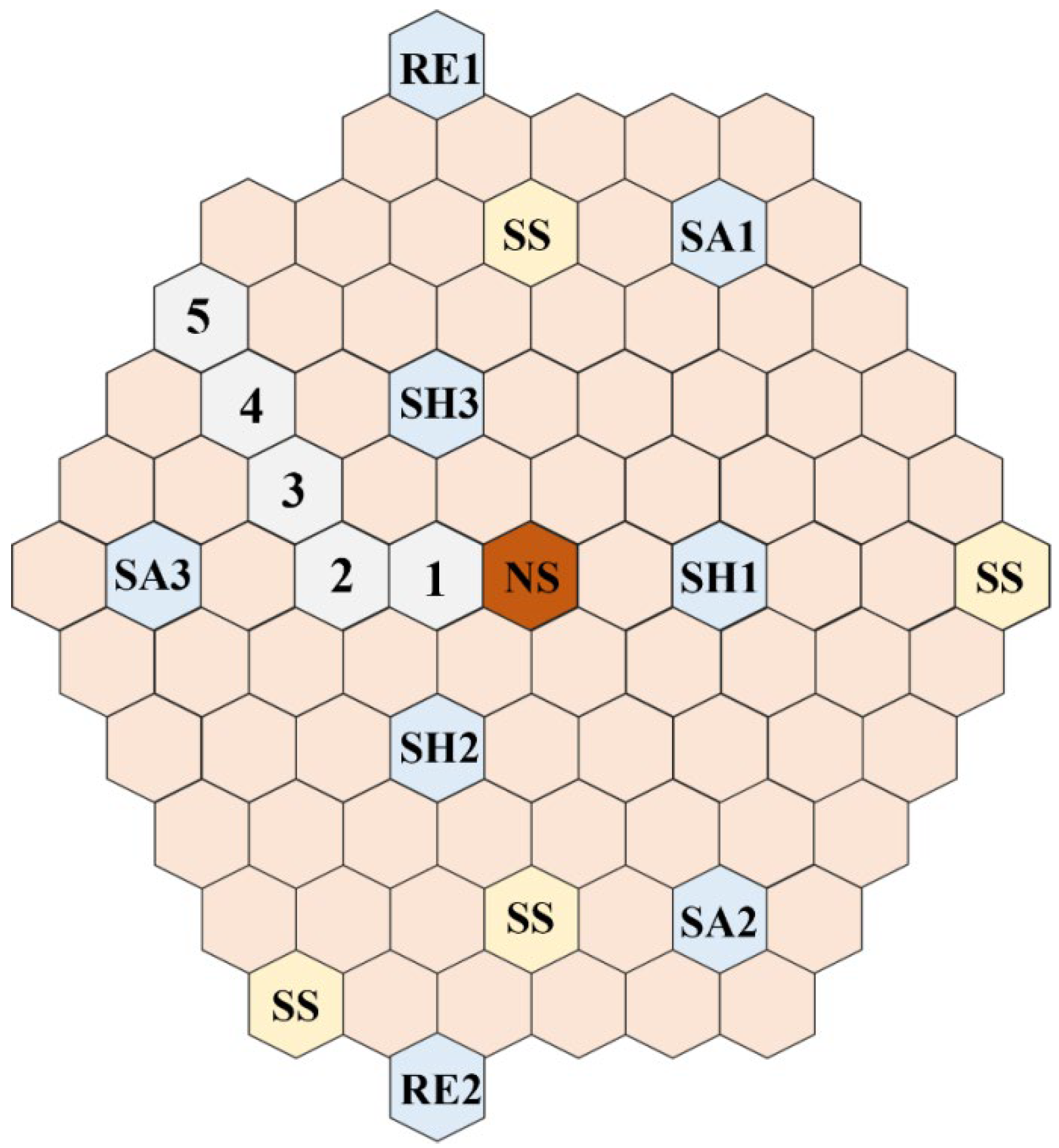

3.1.4. Reactivity Simulation for Assembly Substitution

3.1.5. Temperature Reactivity Coefficient Computation

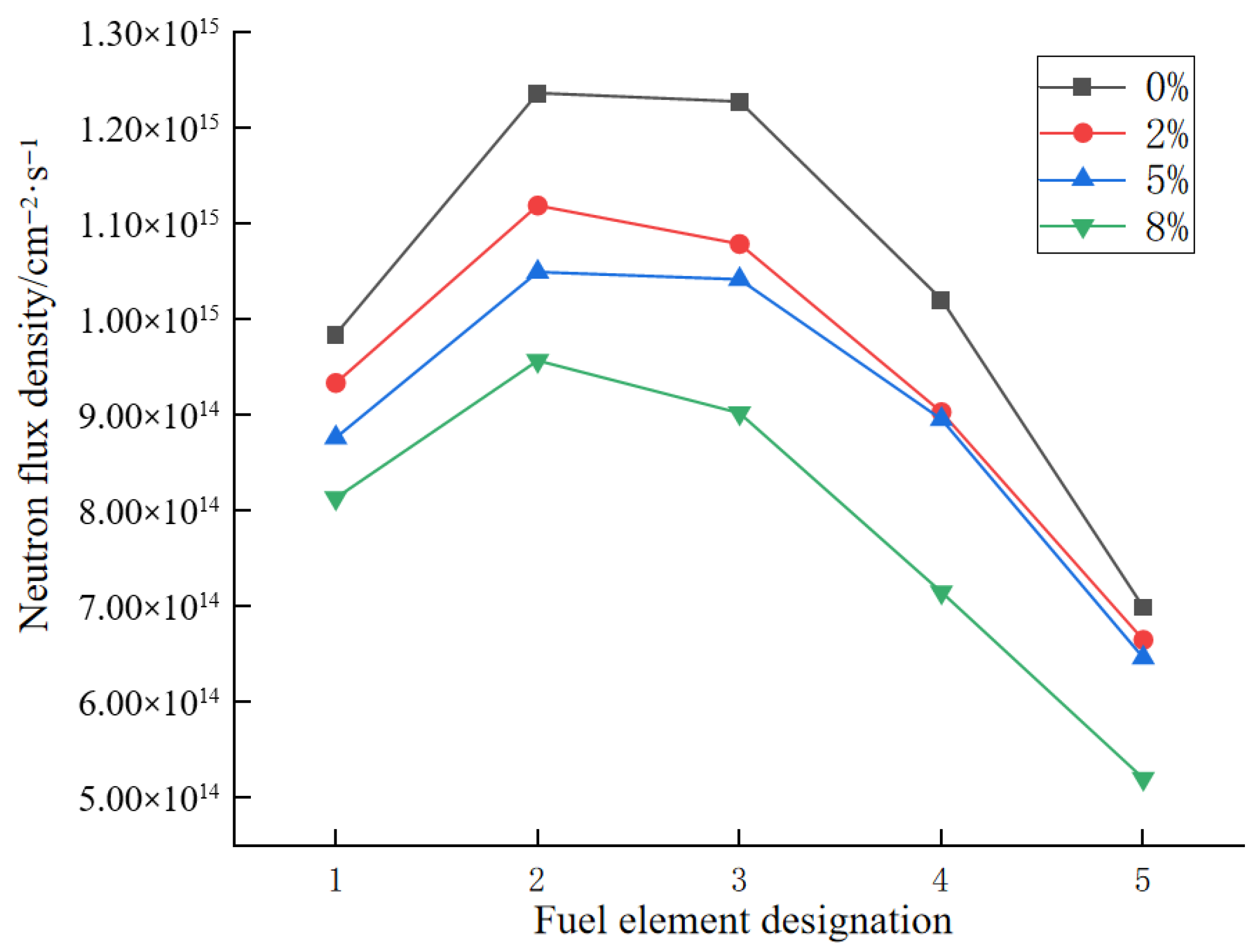

3.2. Study on Transmutation of MA in SFR

4. Conclusions

- Computational validation of the CEFR three-dimensional neutronics benchmark model confirms that its fundamental safety parameters and reactivity characteristics align with neutronics fundamentals. These findings provide substantial evidence for the reactor’s inherent safety features and demonstrate its rationally reliable design.

- The close agreement between MCNP5 computational outcomes and experimental measurements not only validates the program’s efficacy in neutronics calculations but also confirms the reliability of the developed three-dimensional neutronics model for CEFR.

- The transmutation of 237Np, 241Am, 243Am, and mixed MA reduces core Keff, whereas the transmutation of 244Cm and 245Cm enhances it. Notably, the reactivity increase induced by 245Cm far exceeds that attributable to all other nuclides.

- With the MA content increment from 0 wt% to 8 wt%, Keff undergoes substantial nonlinear attenuation (1.00033→0.95022). The reactivity variation coefficient progressively diminishes from −1242.5 pcm/wt% to −312.7 pcm/wt%, indicating neutron absorption saturation effects within the MA isotopes. Crucially, all operational scenarios maintain profoundly negative reactivity values, with even peak MA loading sustaining compliance within safety margin limits. These computational results empirically substantiate the inherent neutronics safety characteristics of the MA loading scheme.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Liu, P.; Li, R.; Feng, J.; Jiang, D.; Zhu, Z.; Wang, Q.; Qin, M. Research progress and prospects of advanced power generation technology under the goal of carbon emission peak and carbon neutrality. Therm. Power Gener. 2022, 51, 52–59. [Google Scholar]

- Fan, D.; Li, F.; Wang, Z.; Miao, Q.; Bai, Y.; Liu, Q. Development status and prospects of China’s energy minerals under the target of carbon peak and carbon neutral. China Min. Mag. 2021, 30, 1–8. [Google Scholar]

- Han, Z.; Chen, F.; Qin, X. Analysis on Nuclear Power and Renewable Energy Coordinated Development in Future. Shanghai Energy Conserv. 2020, 12, 1374–1380. [Google Scholar]

- Lin, B. China’s power sector milestones during the thirteenth five-year plan period and development trajectories toward the fourteenth five-year plan. China Electr. Power 2020, 12, 22–23. [Google Scholar]

- Zhang, X.P.; Lu, D.D.; Chen, M.X.; Gao, S.S.; Wu, A.P. Comprehensive analysis of world geography of nuclear power industry. Geogr. Res. 2021, 40, 673–688. [Google Scholar]

- Cheng, P. Three Interrogations for Fast Reactor. China Nucl. Ind. 2000, 4, 44–45. [Google Scholar]

- Koch, L. Status of Transmutation Use of Fast Reactors for Actinide Transmutation; IAEA: Vienna, Austria, 1996. [Google Scholar]

- Li, S. High-Level Radioactive Waste Transmutation and Advanced Nuclear Energy Systems Without Long-Lived Radioactive Waste Byproducts. Chin. J. Nucl. Sci. Eng. 1996, 269–283. [Google Scholar]

- Yang, H.; Guo, M. Design Innovation and Fulfillment of China Experimental Fast Reactor. At. Energy Sci. Technol. 2020, 54, 199–205. [Google Scholar]

- Gu, Z. Emerging Trajectories in Nuclear Energy and Advanced Fuel Cycle Technologies. Mod. Electr. Power 2006, 23, 89–94. [Google Scholar]

- Baetsle, L.H.; Wakahayashi, T.; Sakurai, S. Global’99 Proceedings of the International Conference on Future Nuclear System: Status and Assessment Report on Actinide and Fission Product Partitioning and Transmutation, an Oecd Nuclear Energy Agency Review; American Nuclear Society (ANS): Westmont, IL, USA, 1999. [Google Scholar]

- Zhou, P. Transmutation Performance Investigation in Modular Fast Reactors Utilizing MOX Fuel Assemblies. Ph.D. Thesis, China Institute of Atomic Energy, Beijing, China, 2001. [Google Scholar]

- Artisyuk, V.; Saito, M.; Stankovsky, A. Challenge of Transmutation of Long-lived Nuclides. Prog. Nucl. Energy 2005, 47, 327–338. [Google Scholar] [CrossRef]

- Tucek, K. Neutronic and Burnup Studies of Accelerator-Driven Systems Dedicated to Nuclear Waste Transmutation. Ph.D. Dissertation, KTH Royal Institute of Technology, Stockholm, Sweden, 2004. [Google Scholar]

- Steinberg, M. Neutron Burning of Long-Lived Fission Products for Waste Disposal; BNL: Upton, NY, USA, 1964.

- Luo, Z. Valorization of Radionuclides in Nuclear Waste. At. Energy Sci. Technol. 2004, 4, 334–338. [Google Scholar]

- Gu, Z.; Ye, G. Recent Developments in Studies of Advanced Nuclear Fuel Cycle System. At. Energy Sci. Technol. 2002, 36, 160–167. [Google Scholar]

- Liang, T.; Tang, C. Transmutation of long-lived nuclides. Nucl. Tech. 2003, 26, 935–939. [Google Scholar]

- Gu, M. Nuclear Waste Processing Technologies; Atomic Energy Press: Beijing, China, 2009. [Google Scholar]

- Sagara, H.; Matsumoto, K.; Yamauchi, I.; Nakao, K.; Han, C.Y.; Onishi, T.; Koyama, S.I.; Saito, M. Feasibility study of the fast breederreactor blanket as a target of plutonium denaturing and TRU transmutation forenhancement of the proliferation resistance and the actinide management in thefuture fuel cycle. Prog. Nucl. Energy 2014, 82, 92–97. [Google Scholar] [CrossRef]

- Zhang, Y.; Wallenius, J.; Jolkkonen, M. Transmutation of americium in a large sizedsodium-cooled fast reactor loaded with nitride fuel. Ann. Nucl. Energy 2013, 53, 26–34. [Google Scholar] [CrossRef]

- Allen, K.; Knight, T. Destruction rate analysis of transuranic targets in sodium-cooled fast reactor (SFR) assemblies using MCNPX and SCALE 6.0. Prog. Nucl. Energy 2010, 52, 387–394. [Google Scholar] [CrossRef]

- Vezzoni, B.; Gabrielli, F.; Rineiski, A.; Schwenk-Ferrero, A.; Romanello, V.; Maschek, W.; Fazio, C.; Salvatores, M. Plutonium and Minor Actinidesincineration options using innovative Na-cooled fast reactors: Mpacting onphasing-out and on-going fuel cycles. Prog. Nucl. Energy 2014, 82, 58–63. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, Y.; Zhao, J. Main Technical Innovation and Engineering Experience of China Experimental Fast Reactor. At. Energy Sci. Technol. 2020, 54, 194–198. [Google Scholar]

- Song, Y.; Hu, Y.; Zhang, C.; Shan, H.; Jia, X. Study on Heterogeneous Effect Correction Methods of Control Rod Assembly in Fast Reactor. At. Energy Sci. Technol. 2022, 56, 31–38. [Google Scholar]

- Guo, H.; Jin, X.; Huo, X.; Gu, H.; Wu, H. Influence of nuclear data library on neutronics benchmark of China experimental fast reactor start-up tests. Nucl. Eng. Technol. 2022, 54, 3888–3896. [Google Scholar] [CrossRef]

- Zwermann, W.; Berner, N.; Aures, A.; Velkov, K. Sensitivities of delayed neutron fractions in the framework of SCALE 6.2. Ann. Nucl. Energy 2021, 153, 108068. [Google Scholar] [CrossRef]

- Wang, Y. The Preliminary Analysis of Transmutation Characteristics of Long-Life High Level Radioactive Waste in Sodium-Cooled Fast Reactor. Master’s Thesis, North China Electric Power University, Beijing, China, 2011. [Google Scholar]

| Parametric | Parameter Value |

|---|---|

| Thermal power | 65 MW |

| Active zone equivalent diameter/height | 60 cm/45 cm |

| Fuel/First core fuel | (Pu, U) O2/UO2 |

| 235U enrichment | 42.6 kg (19.6%)/236.7 kg (64.4%) |

| Maximum linear heat rate | 430 W/cm |

| Neutron flux | 3.7 × 1015 n/cm2·s(MAX) |

| Average neutron flux | 1.76 × 1015 n/cm2·s |

| Target burnup | 100,000 MWd/t |

| Core inlet sodium temperature | 360 °C |

| Core outlet sodium temperature | 530 °C |

| Main vessel dimensions | 8.010 m |

| Materials | Linear Expansion Coefficient |

|---|---|

| Fuel pellet | 1.1 × 10−5/°C |

| Breeding blanket materials | 1.0 × 10−5/°C |

| B4C neutron absorber | 4.2 × 10−6/°C |

| Stainless steel materials | 1.8 × 10−5/°C |

| Fuel Assembly Loading Positions | RE Rod Positions (mm) | Keff (Measured Value) | Keff (MCNP) | Error (pcm) |

|---|---|---|---|---|

| 70 | 500 | - | 0.99300 | - |

| 71 | 500 | - | 0.99642 | - |

| 72 | 190 | 1.00040 | 0.99988 | −52 |

| 72 | 170 | 1.00034 | 0.99979 | −55 |

| 72 | 151 | 1.00025 | 0.99968 | −57 |

| 72 | 70 | 1.00000 | 0.99936 | −64 |

| Control Rod and Rod Banks | Control Rod Positions/mm | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Change | RE1 | RE2 | SH1 | SH2 | SH3 | SA1 | SA2 | SA3 | |

| RE1 | B | 501 | 106 | 240 | 240 | 239 | 498 | 500 | 500 |

| A | −1 | 106 | 240 | 240 | 239 | 498 | 500 | 500 | |

| RE2 | B | 106 | 499 | 240 | 240 | 239 | 498 | 500 | 500 |

| A | 106 | 5 | 240 | 240 | 239 | 498 | 500 | 500 | |

| SH1 | B | 240 | 240 | 501 | 141 | 141 | 498 | 499 | 499 |

| A | 240 | 240 | 4 | 141 | 141 | 498 | 499 | 499 | |

| SH2 | B | 239 | 240 | 151 | 498 | 151 | 498 | 500 | 500 |

| A | 239 | 240 | 151 | −1 | 151 | 498 | 500 | 500 | |

| SH3 | B | 240 | 239 | 148 | 150 | 498 | 498 | 500 | 500 |

| A | 240 | 239 | 148 | 150 | 7 | 498 | 500 | 500 | |

| SA1 | B | 240 | 239 | 240 | 240 | 241 | 498 | 499 | 499 |

| A | 240 | 239 | 240 | 240 | 241 | 498 | 499 | 499 | |

| SA2 | B | 240 | 240 | 240 | 240 | 240 | 498 | 499 | 499 |

| A | 240 | 239 | 240 | 240 | 240 | 498 | 55 | 499 | |

| SA3 | B | 240 | 239 | 240 | 240 | 240 | 498 | 499 | 499 |

| A | 240 | 239 | 240 | 240 | 240 | 498 | 499 | 40 | |

| 3SH + 2RE | B | 247 | 247 | 239 | 240 | 239 | 498 | 500 | 499 |

| A | 0 | 5 | 1 | −1 | 7 | 498 | 500 | 499 | |

| SH2 + SH3 + 2RE | B | 247 | 248 | 501 | 141 | 141 | 498 | 500 | 499 |

| A | −2 | 2 | 501 | −3 | 16 | 498 | 500 | 499 | |

| 3SA | B | 247 | 249 | 240 | 240 | 240 | 498 | 500 | 499 |

| A | 247 | 249 | 240 | 240 | 240 | 46 | 56 | 40 | |

| SA1 + SA2 | B | 247 | 248 | 240 | 240 | 240 | 498 | 500 | 500 |

| A | 247 | 248 | 240 | 240 | 240 | 45 | 54 | 500 | |

| 2RE + 3SH + 3SA | B | 247 | 248 | 240 | 240 | 240 | 499 | 500 | 500 |

| A | 0 | 3 | 2 | −2 | 0 | 45 | 56 | 40 | |

| 2RE + SH2 + SH3 +3SA | B | 248 | 248 | 500 | 141 | 141 | 498 | 500 | 499 |

| A | −2 | 2 | 500 | −3 | 7 | 45 | 55 | 40 | |

| Control Rod and Rod Banks | Measured Value | Error | MCNP Calculated Value | Deviation from Measured Value |

|---|---|---|---|---|

| RE1 | 150 | ±9 | 142 | −8 |

| RE2 | 149 | ±9 | 147 | −2 |

| SH1 | 2019 | ±250 | 1908 | −111 |

| SH2 | 1839 | ±225 | 1856 | 17 |

| SH3 | 1839 | ±226 | 1849 | 10 |

| SA1 | 945 | ±100 | 942 | −4 |

| SA2 | 911 | ±100 | 926 | 15 |

| SA3 | 946 | ±98 | 1000 | 54 |

| 3SH + 2RE | 2877 | ±355 | 3040 | 163 |

| SH2 + SH3 + 2RE | 881 | ±76 | 1029 | 148 |

| 3SA | 2981 | ±395 | 2854 | −128 |

| SA1 + SA2 | 1950 | ±226 | 1790 | −160 |

| 2RE + 3SH + 3SA | 6079 | ±989 | 6066 | −13 |

| 2RE + SH2 + SH3 + 3SA | 3899 | ±551 | 3940 | 41 |

| Control Rod and Rod Banks | Control Rod Positions | Keff | Control Rod Value (pcm) |

|---|---|---|---|

| 3SH+2RE+3SA | 3SH+2RE+3SA fully withdrawn | 1.02888 | |

| RE1 | RE1 fully inserted | 1.02737 | −151 |

| RE2 | RE2 fully inserted | 1.02739 | −149 |

| 2RE | 2RE fully inserted | 1.02581 | −307 |

| SH1 | SH1 fully inserted | 1.01015 | −1873 |

| SH2 | SH2 fully inserted | 1.01056 | −1832 |

| SH3 | SH2 fully inserted | 1.01054 | −1834 |

| 3SH3 | 3SH fully inserted | 0.97339 | −5549 |

| SA1 | SA1 fully inserted | 1.01891 | −997 |

| SA2 | SA2 fully inserted | 1.01892 | −996 |

| SA3 | SA3 fully inserted | 1.01854 | −1034 |

| 3SH + 2RE | 3SH + 2RE fully inserted | 0.97038 | −5850 |

| SH2 + SH3 + 2RE | SH2 + SH3 + 2RE fully inserted | 0.98919 | −3969 |

| 3SA | 3SA fully inserted | 0.99754 | −3134 |

| SA1 + SA2 | SA1 + SA2 fully inserted | 1.0086 | −2028 |

| 2RE + 3SH + 3SA | 2RE + 3SH + 3SA fully inserted | 0.93872 | −9016 |

| 2RE + SH2 + SH3 + 3SA | 2RE + SH2 + SH3 + 3SA fully inserted | 0.95932 | −6956 |

| Control Rod | Positions/mm |

|---|---|

| SH1 | 239.3 |

| SH2 | 239.2 |

| SH3 | 239.8 |

| SA1 | 498.3 |

| SA2 | 499.8 |

| SA3 | 499.1 |

| Simulated Assembly Positions | RE1 Positions | RE2 Positions | Measured Value (pcm) | Error | Calculated Value (pcm) |

|---|---|---|---|---|---|

| 1 | 277 mm | 277 mm | −39.2 | ±5.8 | −39.7 |

| 2 | 277 mm | 277 mm | −43.4 | ±5.9 | −39.9 |

| 3 | 277 mm | 277 mm | −40.5 | ±5.7 | −42.0 |

| 4 | 277 mm | 277 mm | −40.1 | ±5.5 | −44.3 |

| 5 | 277 mm | 277 mm | −32.9 | ±5.5 | −36.6 |

| Calculated Positions | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| 1 | SS | Fuel | Fuel | Fuel | Fuel | Fuel | SS | SS |

| 2 | Fuel | SS | Fuel | Fuel | Fuel | Fuel | SS | SS |

| 3 | Fuel | Fuel | SS | Fuel | Fuel | Fuel | SS | SS |

| 4 | Fuel | Fuel | Fuel | SS | Fuel | Fuel | SS | SS |

| S | Fuel | Fuel | Fuel | Fuel | SS | Fuel | SS | SS |

| 6 | Fuel | Fuel | Fuel | Fuel | Fuel | SS | SS | SS |

| 7 | Fuel | Fuel | Fuel | Fuel | SS | Fuel | Fuel | SS |

| 8 | Fuel | Fuel | Fuel | SS | Fuel | Fuel | SS | Fuel |

| Measurement Positions | Temperature (°C) | Keff (Before) | Keff (After) | Calculated Value (pcm) | Measured Value (pcm) | Error (pcm) |

|---|---|---|---|---|---|---|

| 1 | 250 | 1.00033 | 0.99056 | −984 | −977 | 7 |

| 2 | 250 | 1.00033 | 0.99177 | −875 | −856 | 19 |

| 3 | 250 | 1.00033 | 0.99340 | −772 | −693 | 79 |

| 4 | 250 | 1.00033 | 0.99355 | −639 | −678 | −39 |

| 5 | 250 | 1.00033 | 0.99660 | −476 | −373 | 103 |

| 6 | 250 | 1.00033 | 0.99492 | −586 | −541 | 45 |

| 7 | 250 | 0.9966 | 0.99954 | 210 | 294 | 84 |

| 8 | 250 | 0.99355 | 0.99992 | 582 | 637 | 55 |

| Temperature Variation | T (°C) | RE1 (mm) | RE2 (mm) | SH1 (mm) | SH2 (mm) | SH3 (mm) |

|---|---|---|---|---|---|---|

| Temperature increase | 250 | 207 | 208 | 248 | 248 | 248 |

| 274 | 212 | 213 | 254 | 253 | 254 | |

| 283 | 240 | 239 | 253 | 253 | 254 | |

| 293 | 283 | 283 | 253 | 253 | 254 | |

| 302 | 308 | 307 | 255 | 255 | 256 | |

| Temperature decrease | 300 | 408 | 409 | 502 | 162 | 162 |

| 290 | 283 | 284 | 254 | 254 | 254 | |

| 280 | 285 | 285 | 502 | 162 | 162 | |

| 270 | 232 | 232 | 502 | 162 | 162 | |

| 250 | 119 | 119 | 502 | 162 | 163 |

| Temperature (°C) | Measured Value (pcm/°C) | Calculated Value (pcm/°C) | Error |

|---|---|---|---|

| 274 | −3.78 ± 0.55 | −4.23 | −0.45 |

| 283 | −3.52 ± 0.49 | −3.78 | −0.26 |

| 293 | −3.54 ± 0.47 | −3.98 | −0.44 |

| 302 | −3.88 ± 0.52 | −4.30 | −0.42 |

| 290 | −4.46 ± 0.73 | −4.28 | 0.18 |

| 280 | −4.05 ± 0.58 | −3.92 | 0.13 |

| 270 | −4.31 ± 0.58 | −3.99 | 0.32 |

| 250 | −4.39 ± 0.58 | −4.16 | 0.23 |

| Nuclides | 237Np | 241Am | 243Am | 244Cm | 245Cm |

|---|---|---|---|---|---|

| Composition (%) | 56.2 | 26.4 | 12 | 5.12 | 0.28 |

| Nuclides | MA-Free | 237Np | 241Am | 243Am | 244Cm | 245Cm | Mixed MA |

|---|---|---|---|---|---|---|---|

| Keff | 1.00033 | 0.97454 | 0.97485 | 0.97487 | 1.00490 | 1.07034 | 0.97607 |

| Δkeff | - | −0.02579 | −0.02548 | −0.02546 | 0.00457 | 0.07001 | −0.02426 |

| Composition (%) | 0 | 2 | 5 | 8 |

|---|---|---|---|---|

| Keff | 1.00033 | 0.97607 | 0.95876 | 0.95022 |

| Δkeff | - | −0.02426 | −0.04157 | −0.05011 |

| Ρ (pcm) | 33 | −2452 | −4301 | −5239 |

| Δρ | - | −2485 | −1849 | −938 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Shang, R.; Tan, J.; Zhang, R.; Meng, Y.; Chen, Y.; Li, L. Monte Carlo-Based Simulation of Reactivity and Transmutation in the CEFR Sodium-Cooled Fast Reactor. Appl. Sci. 2025, 15, 11534. https://doi.org/10.3390/app152111534

Liu J, Shang R, Tan J, Zhang R, Meng Y, Chen Y, Li L. Monte Carlo-Based Simulation of Reactivity and Transmutation in the CEFR Sodium-Cooled Fast Reactor. Applied Sciences. 2025; 15(21):11534. https://doi.org/10.3390/app152111534

Chicago/Turabian StyleLiu, Jianquan, Rongbin Shang, Jie Tan, Rui Zhang, Yuqian Meng, Yubo Chen, and Lin Li. 2025. "Monte Carlo-Based Simulation of Reactivity and Transmutation in the CEFR Sodium-Cooled Fast Reactor" Applied Sciences 15, no. 21: 11534. https://doi.org/10.3390/app152111534

APA StyleLiu, J., Shang, R., Tan, J., Zhang, R., Meng, Y., Chen, Y., & Li, L. (2025). Monte Carlo-Based Simulation of Reactivity and Transmutation in the CEFR Sodium-Cooled Fast Reactor. Applied Sciences, 15(21), 11534. https://doi.org/10.3390/app152111534