Development of Truss-Type Deployable Mesh Reflector Antenna, Part 1: 1.5 m-Scale Mesh Antenna

Abstract

1. Introduction

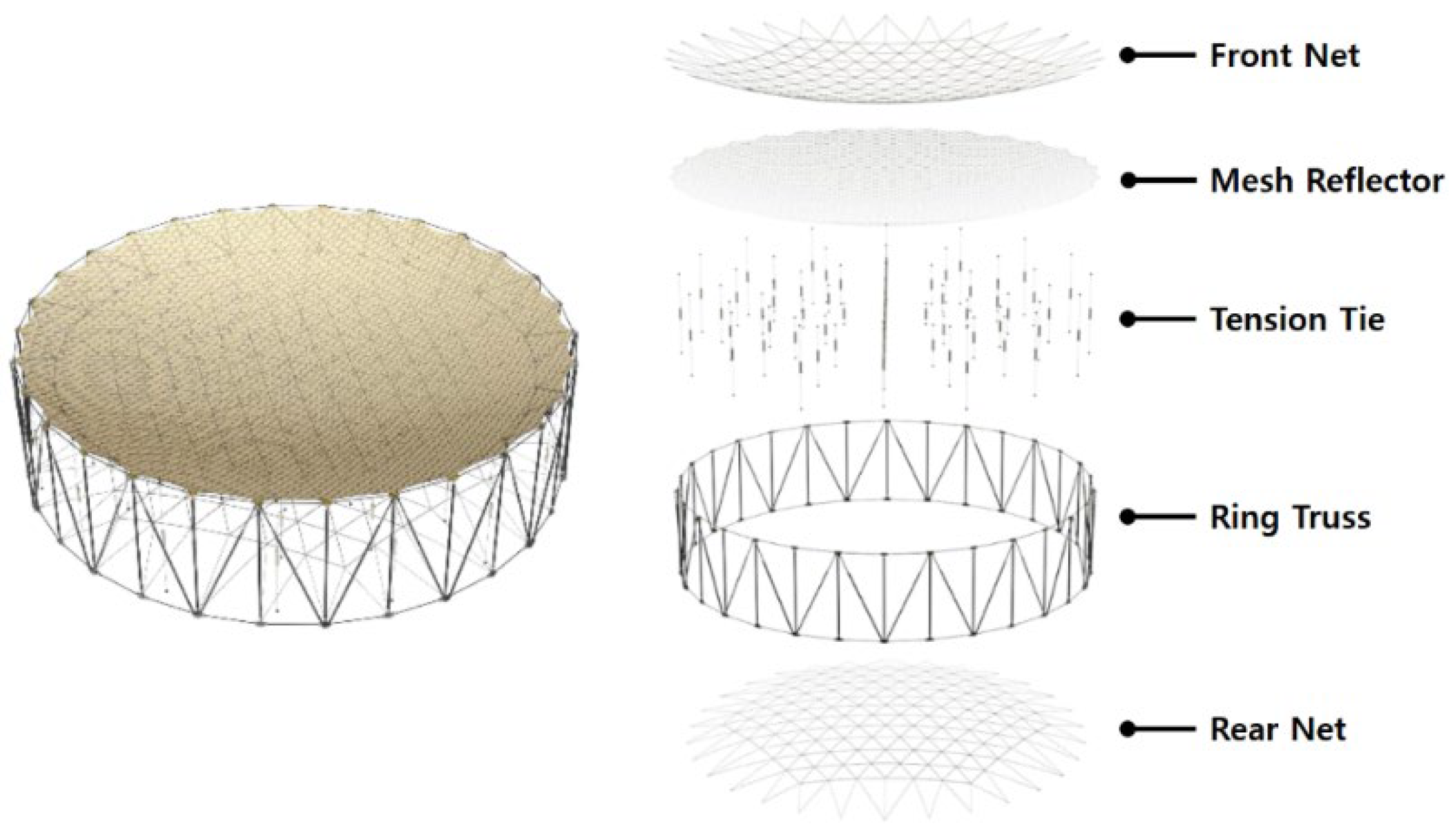

2. Design Approach of Deployable Mesh Reflector Antenna

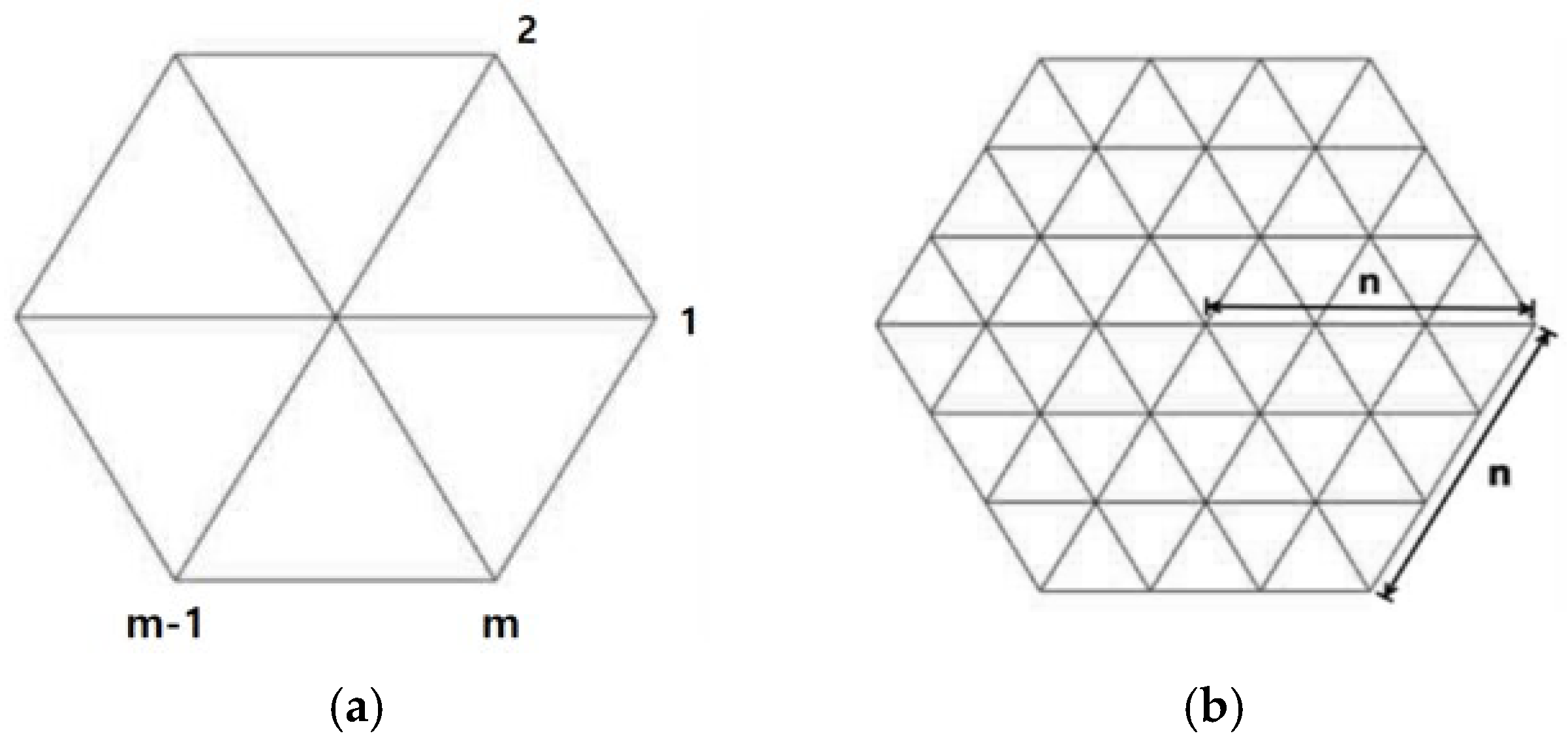

2.1. Initial Design of Mesh Reflector Antenna Net

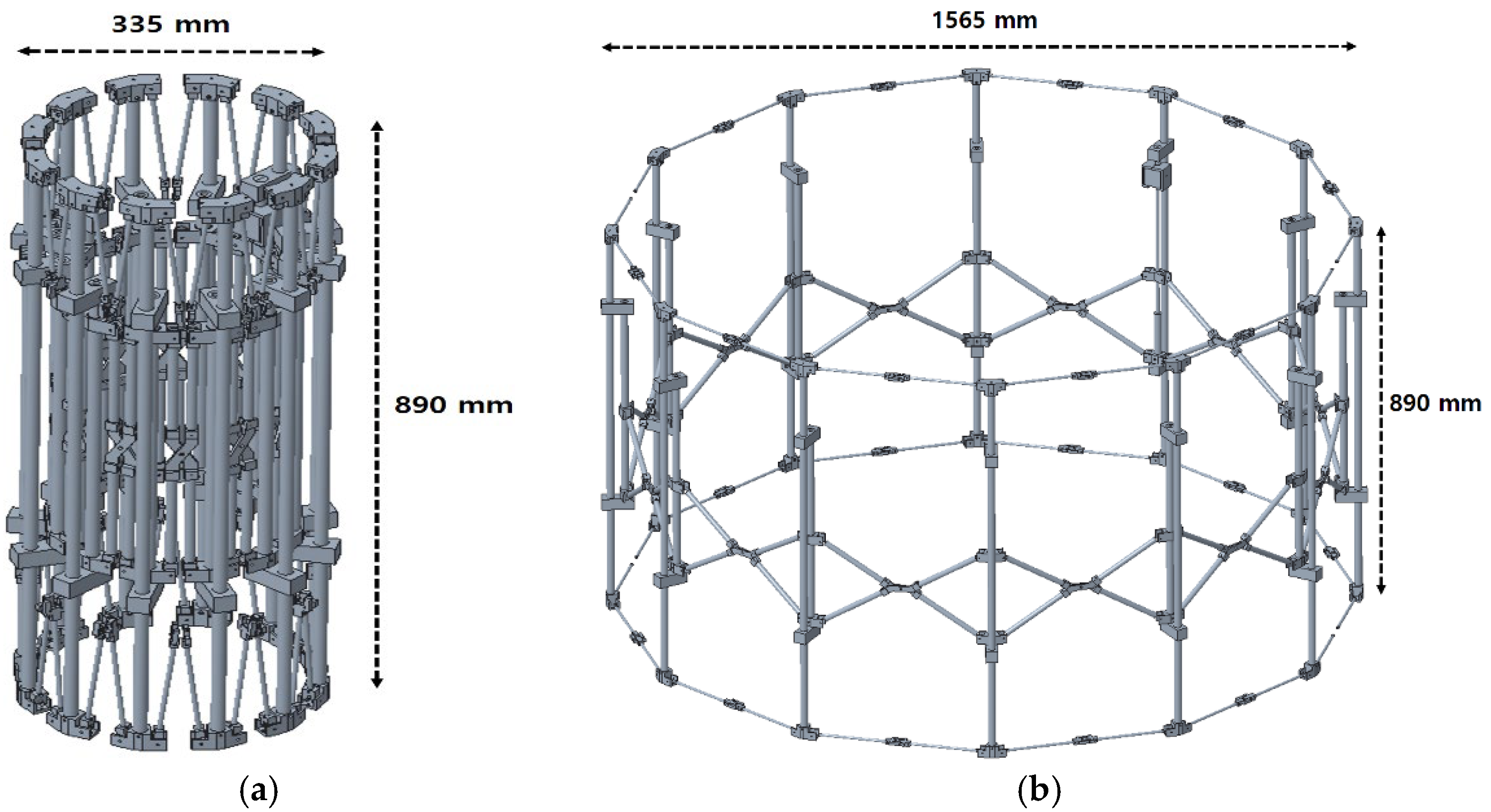

2.2. Design of Deployable Mesh Reflector Antenna

3. Development of Deployable Mesh Reflector Antenna

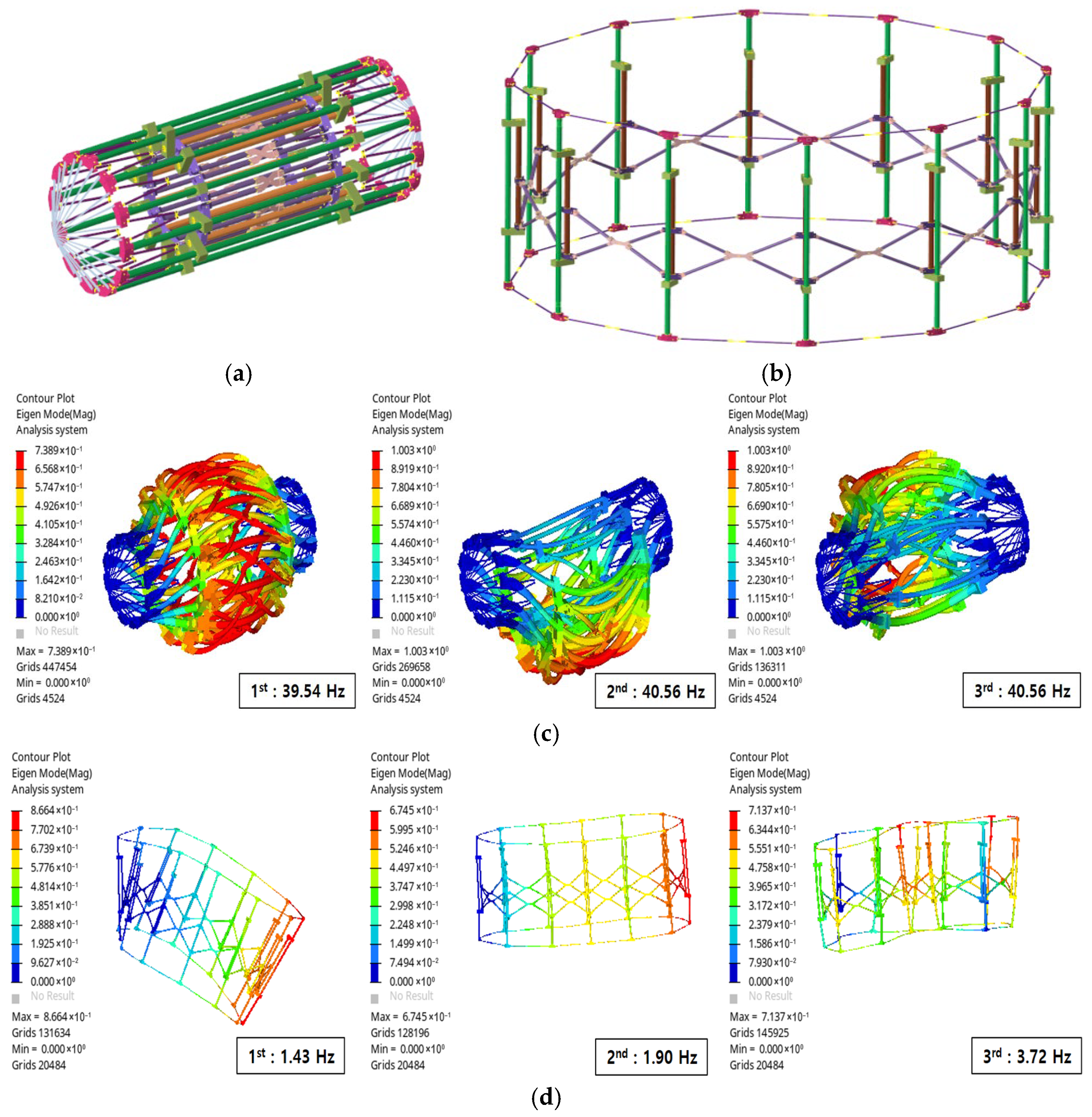

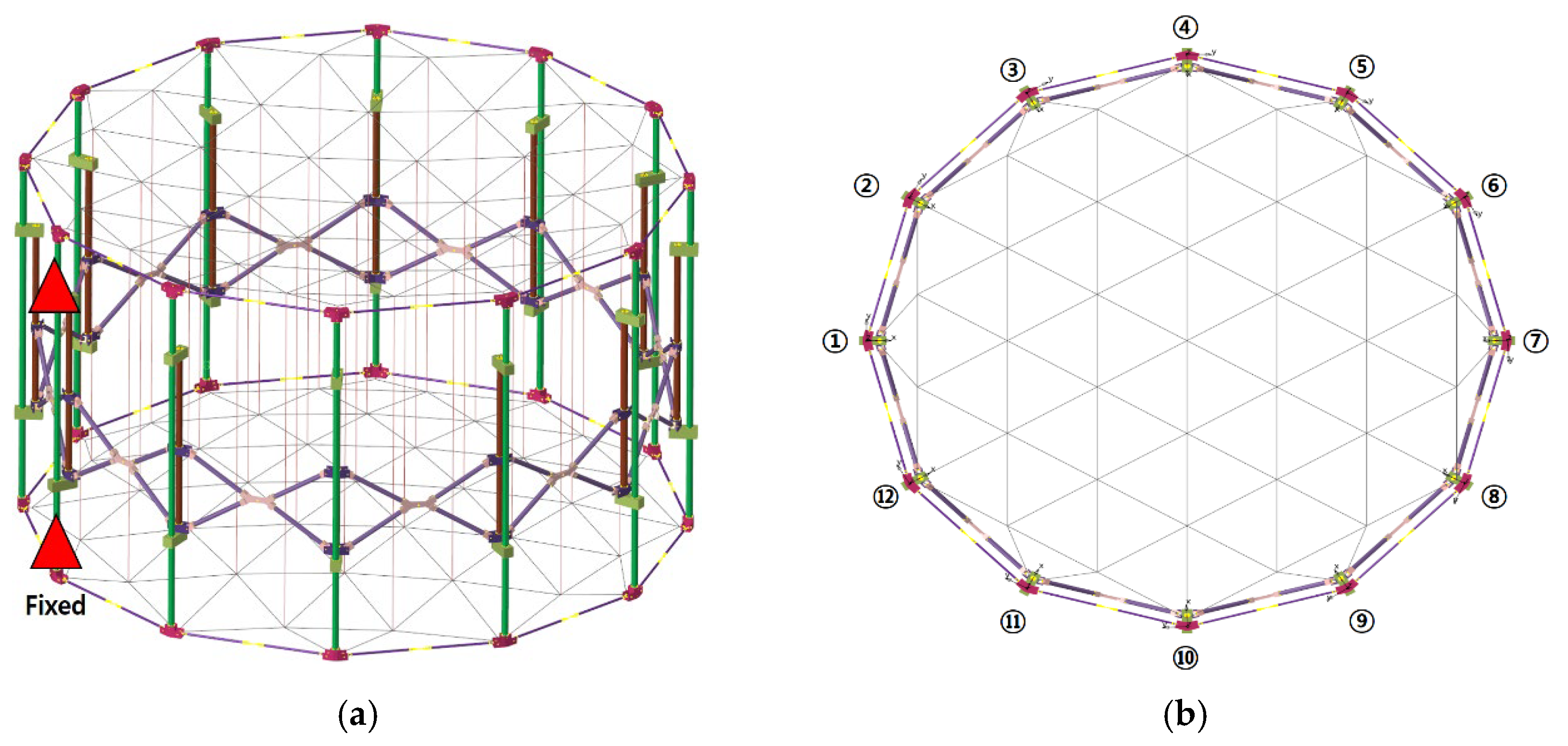

3.1. Analysis of Deployable Mesh Reflector Antenna

3.1.1. Modal Analysis of Deployable Mesh Reflector Antenna

3.1.2. Load Analysis of Deployable Mesh Reflector Antenna

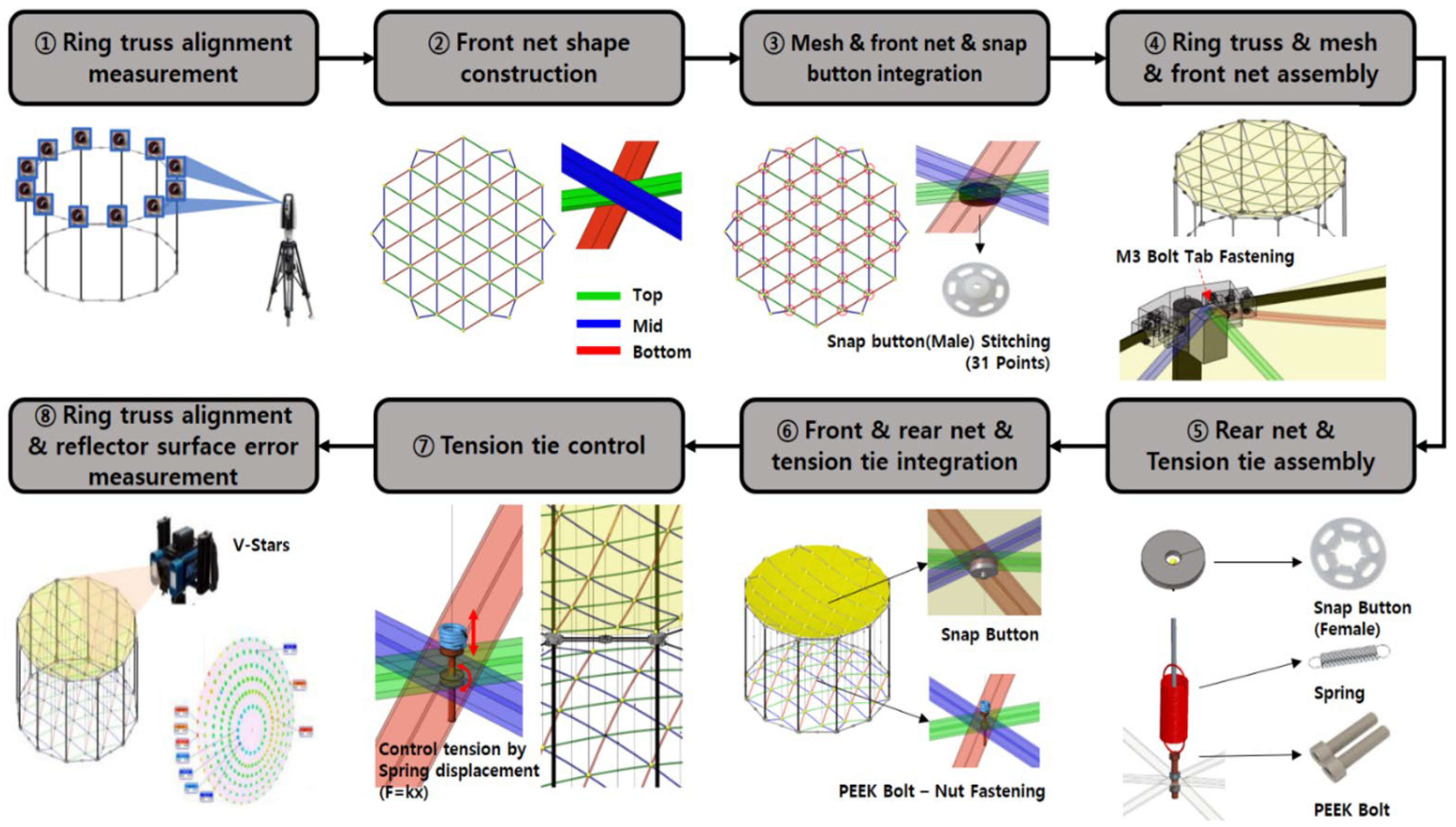

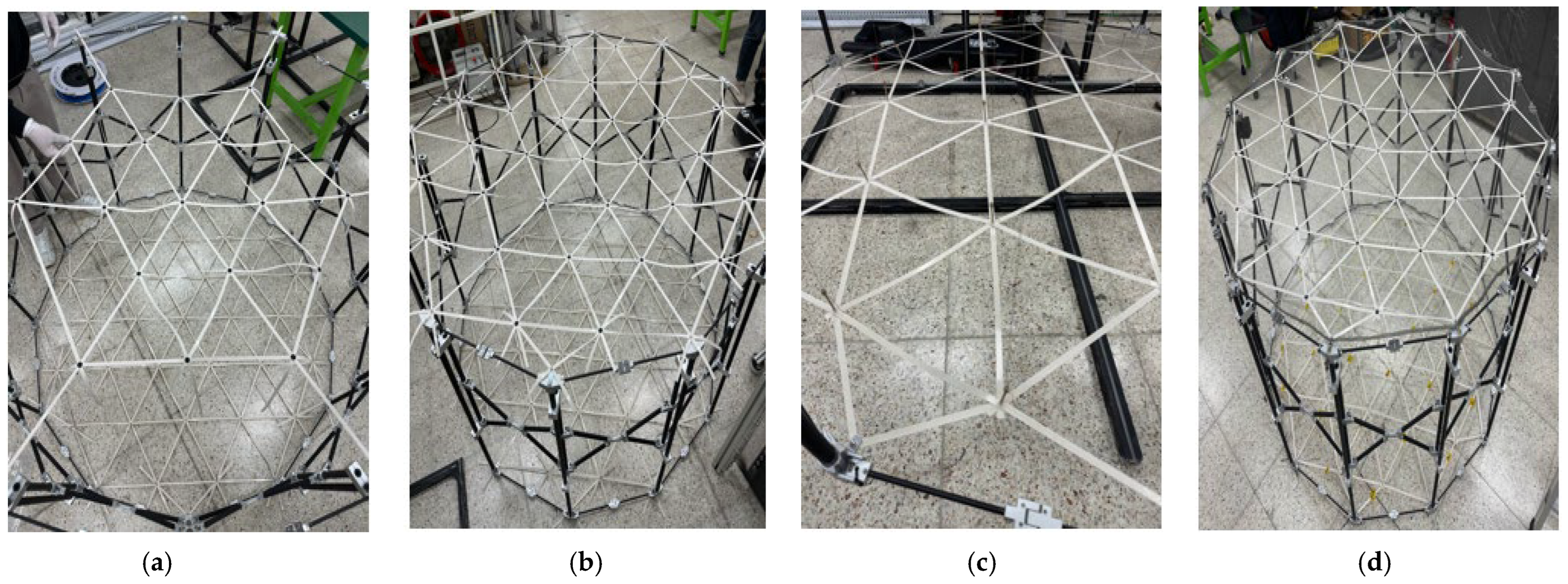

3.2. Assembly of Deployable Mesh Reflector Antenna

4. Experiment of Deployable Mesh Reflector Antenna

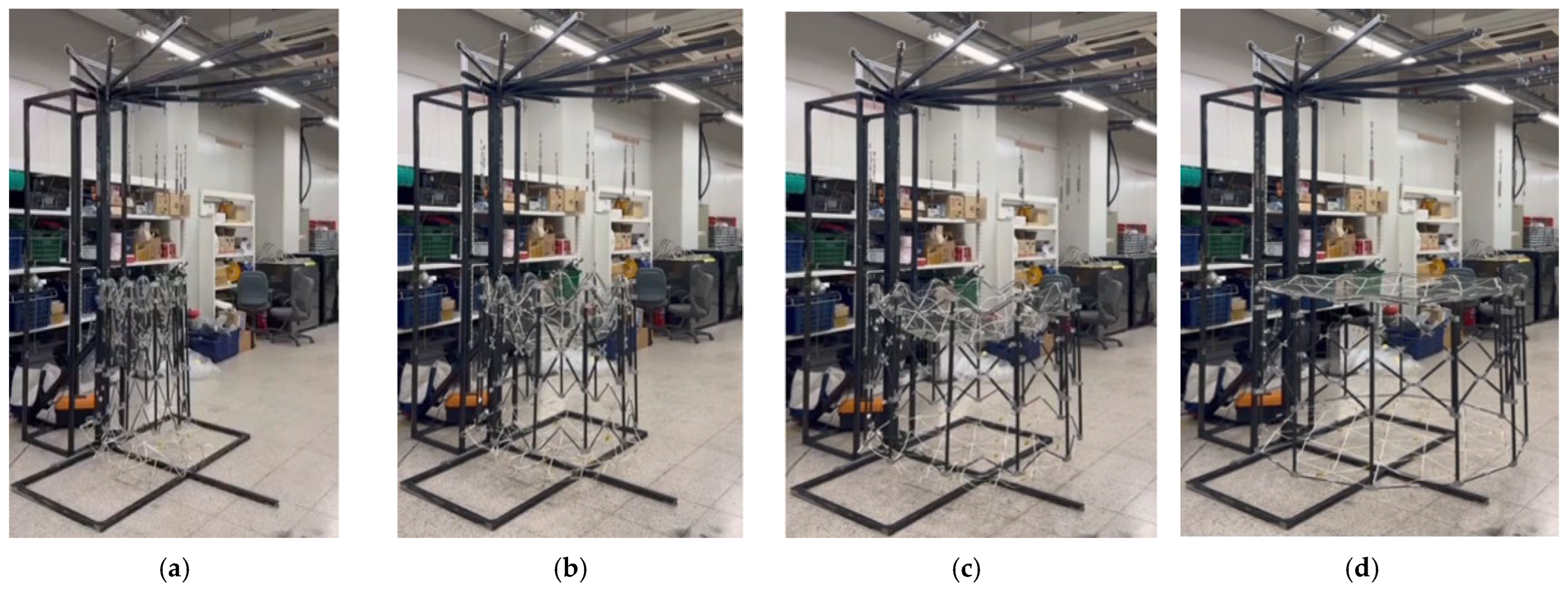

4.1. Deployment Test of Mesh Reflector Antenna

4.2. Thermal Vacuum Test of Deployable Mesh Reflector Antenna

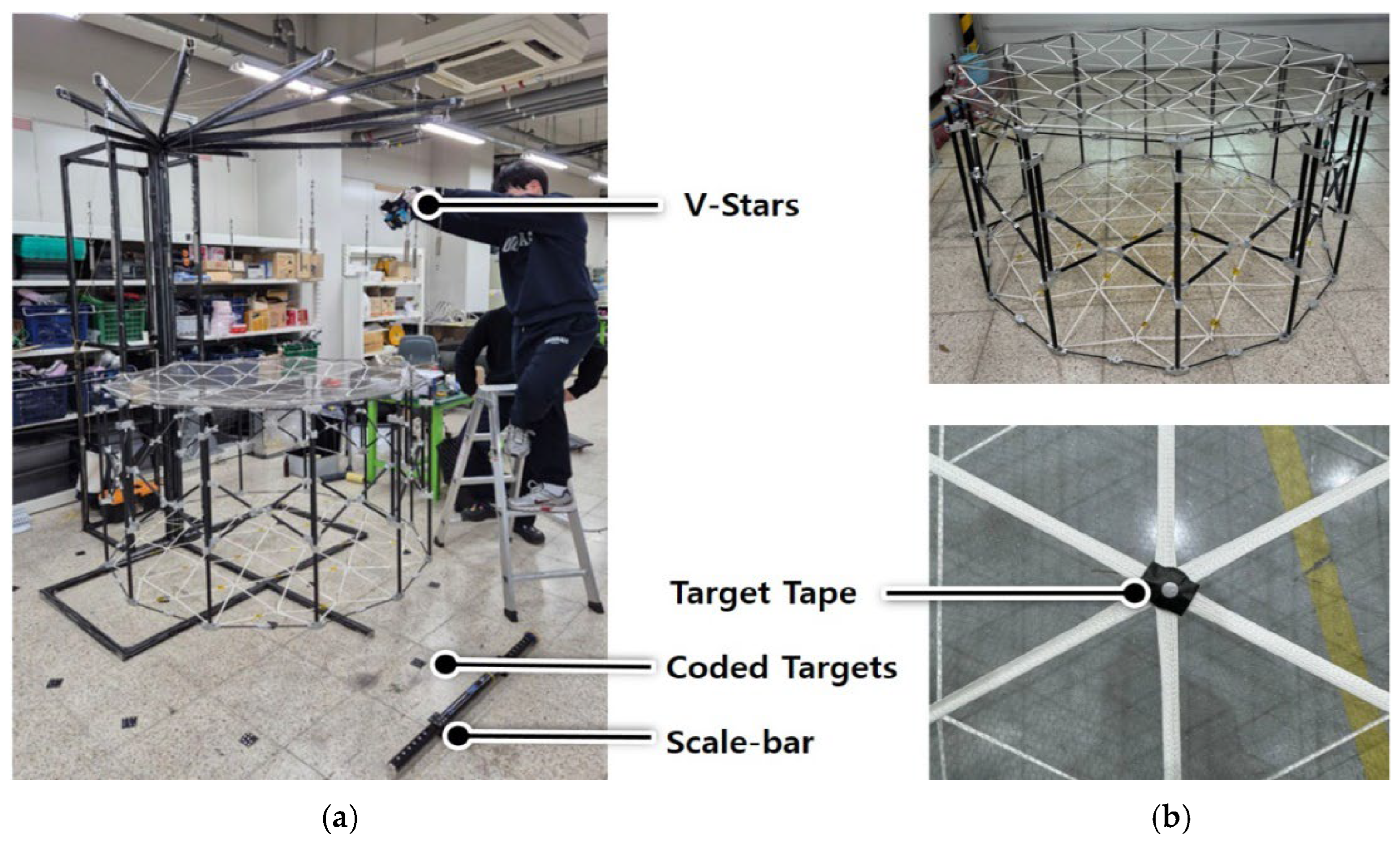

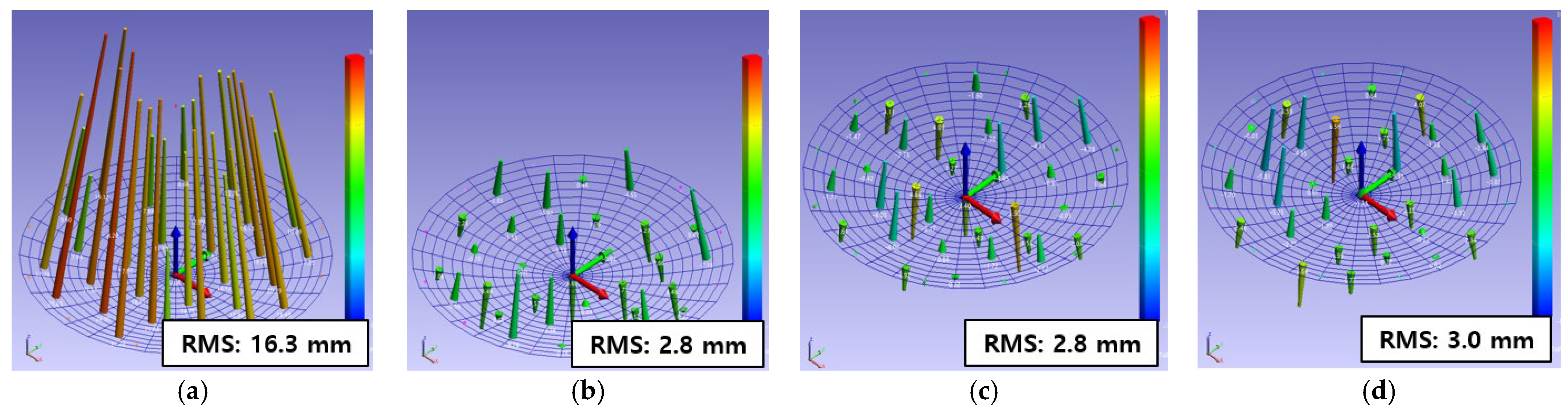

4.3. Reflector Surface RMS Error Measurement of Mesh Reflector Antenna

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ince, F. Nano and Micro satellites as the Pillar of the “new space” Paradigm. J. Aeronaut. Space Technol. 2020, 13, 235–250. [Google Scholar]

- Logue, T.J.; Pelton, J. Overview of Commercial Small Satellite systems in the “New Space” Age. In Handbook of Small Satellites; Springer Nature: Cham, Switzerland, 2019; pp. 69–86. [Google Scholar]

- Gao, S.; Clark, K.; Unwin, M.; Zackrisson, J.; Shiroma, W.; Akagi, J.; Maynard, K.; Garner, P.; Boccia, L.; Amendola, G. Antennas for Modern Small Satellites. IEEE Antennas Propag. Mag. 2009, 51, 40–56. [Google Scholar] [CrossRef]

- Rahmat-Samii, Y.; Densmore, A.C. Technology Trends and Challenges of Antennas for Satellite Communication Systems. IEEE Trans. Antennas Propag. 2014, 63, 1191–1204. [Google Scholar] [CrossRef]

- Bayer, H.; Krauss, A.; Zaiczek, T.; Stephan, R.; Enge-Rosenblatt, O.; Hein, M.A. Ka-Band User Terminal Antennas for Satellite Communications [Antenna Applications Corner]. IEEE Antennas Propag. Mag. 2016, 58, 76–88. [Google Scholar] [CrossRef]

- Miura, K.; Miyazaki, Y. Concept of the Tension Truss Antenna. AIAA J. 1990, 28, 1098–1104. [Google Scholar] [CrossRef]

- Thomson, M.W. The AstroMesh deployable reflector. IEEE Antenna Propag. Soc. Int. Symp. 1999, 3, 1516–1519. [Google Scholar]

- Thomson, M.W. AstroMesh Deployable Reflector for Ku and Ka Band Commercial Satellites. In Proceedings of the 20th AIAA International Communication Satellite Systems Conference Exhibit, Montreal, QC, Canada, 12–15 May 2002; p. 2032. [Google Scholar]

- Yang, G.; Zhang, Y.; Tang, A.; Li, Y. A design approach for AstroMesh-type contoured-beam reflector antennas. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 951–955. [Google Scholar] [CrossRef]

- Zhang, Y.; Ru, W.; Yang, G.; Li, N. Deployment analysis considering the cable-net tension effect for deployable antennas. Aerosp. Sci. Technol. 2016, 48, 193–202. [Google Scholar] [CrossRef]

- Liu, W.; Li, D.; Jiang, J. General Mesh Configuration Design Approach for Large Cable-Network Antenna Reflectors. J. Struct. Eng. 2013, 140, 04013051. [Google Scholar]

- Fu, K.; Du, J.; Li, J.; Zhao, Z. Robust Design of Tension Truss Antennas Against Variation in Tension Forces. AIAA J. 2018, 56, 3374–3381. [Google Scholar] [CrossRef]

- Gao, C.; Wang, H.; Yang, N.; Guo, J.; Liu, F.; Du, J. A Large-Span Ring Deployable Perimeter Truss for the Mesh Reflector Deployable Antenna. Symmetry 2025, 17, 1388. [Google Scholar] [CrossRef]

- Gao, C.; Kang, X.; Lei, H.; Xu, P.; Li, B. Design and analysis of a novel large-span two-fold deployable mechanism. Mech. Mach. Theory 2023, 186, 105352. [Google Scholar] [CrossRef]

- Du, X.; Du, J.; Bao, H.; Chen, X.; Wu, X. Dynamic analysis of the deployment for mesh reflector antennas driven with variable length cables. J. Comput. Nonlinear Dyn. 2019, 14, 111006. [Google Scholar] [CrossRef]

- Han, B.; Zhou, Y.; Zhao, Y. Kinematics and dynamics characteristics analysis of a double-ring truss deployable mechanism based on rectangular scissors unit. Eng. Struct. 2024, 307, 117900. [Google Scholar] [CrossRef]

- Han, B.; Xu, Y.; Yao, J.; Zheng, D.; Guo, L.; Zhao, Y. Type synthesis of deployable mechanism for ring truss antenna based on constraint-synthesis method. Chin. J. Aeronaut. 2020, 33, 2445–2460. [Google Scholar] [CrossRef]

- Li, B.; Qi, X.; Huang, H.; Xu, W. Modeling and analysis of deployment dynamics for a novel ring mechanism. Acta Astronaut. 2016, 120, 59–74. [Google Scholar] [CrossRef]

- Cao, W.; Xi, S.; Ding, H.; Chen, Z. Design and kinematics of a novel double-ring truss deployable antenna mechanism. J. Mech. Des. 2021, 143, 124502. [Google Scholar] [CrossRef]

- Shi, H.; Yuan, S.; Yang, B. New Methodology of Surface Mesh Geometry Design for Deployable Mesh Reflectors. J. Spacecr. Rocket. 2018, 55, 266–281. [Google Scholar] [CrossRef]

- Liu, R.; Guo, H.; Liu, R.; Tang, D.; Wang, H.; Deng, Z. Design and form finding of cable net for a large cable-rib tension antenna with flexible deployable structures. Eng. Struct. 2019, 199, 109662. [Google Scholar] [CrossRef]

- Yuan, S.; Yang, B.; Fang, H. The Projecting Surface Method for improvement of surface accuracy of large deployable mesh reflectors. Acta Astronaut. 2018, 151, 678–690. [Google Scholar] [CrossRef]

- Fanning, P.; Hollaway, L. The deployment analysis of large space antenna. Int. J. Space Struct. 1993, 8, 209–220. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, Z.; Zhou, M.; He, J. Flexible Multibody Model and the Dynamics of the Deployment of Mesh Antennas. J. Guid. Control. Dyn. 2017, 40, 1499–1506. [Google Scholar] [CrossRef]

| Requirement | Value | |

|---|---|---|

| Mass | Antenna assembly | ≤12 kg |

| Antenna diameter | Deployed condition | ≥1.5 m |

| Stowed condition | ≤0.5 m | |

| Antenna height | Deployed and stowed condition | ≤1.0 m |

| Fundamental frequency | Deployed condition | ≥1 Hz |

| Stowed condition | ≥33 Hz | |

| Node No. | Reaction X (N) | Reaction Y (N) | Reaction Z (N) | Total Load (N) |

|---|---|---|---|---|

| 1 | 15.30 | −0.09 | −2.92 | 15.57 |

| 2 | 14.53 | 2.50 | −2.54 | 14.96 |

| 3 | 13.28 | 0.69 | −2.88 | 13.61 |

| 4 | 13.05 | −0.56 | −2.53 | 13.30 |

| 5 | 13.18 | −1.75 | −2.88 | 13.61 |

| 6 | 14.34 | −3.42 | −2.54 | 14.96 |

| 7 | 15.29 | −0.56 | −2.92 | 15.58 |

| 8 | 14.53 | 2.43 | −2.53 | 14.95 |

| 9 | 13.24 | 0.99 | −2.88 | 13.59 |

| 10 | 13.09 | 0.00 | −2.53 | 13.34 |

| 11 | 13.24 | −1.07 | −2.88 | 13.60 |

| 12 | 14.48 | −2.74 | −2.54 | 14.96 |

| Contents | Number | Weight |

|---|---|---|

| Front net | 1 Set | 0.1 kg |

| Mesh reflector | 1 Set | 0.2 kg |

| Tension tie | 31 Sets | 0.4 kg |

| Rear net | 1 Set | 0.1 kg |

| Ring truss | 1 Set | 10.6 kg |

| Total assembly | 11.4 kg | |

| Test Classification | Specification |

|---|---|

| TRP temperature | ±60 °C |

| Test cycles | 8 Cycles |

| Test temperature tolerance | (Hot) 0/+4 °C (Cold) −4/0 °C |

| Temperature transition rate | 3 °C/min |

| Thermal balance criteria | 1 °C/4 h |

| Thermal dwell time | 1 h |

| Thermal vacuum pressure | torr |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.; Kim, D.; Do, R.; Kim, S.; Bae, G.; Koo, K.; Lee, Y.; Jung, I. Development of Truss-Type Deployable Mesh Reflector Antenna, Part 1: 1.5 m-Scale Mesh Antenna. Appl. Sci. 2025, 15, 11529. https://doi.org/10.3390/app152111529

Lee C, Kim D, Do R, Kim S, Bae G, Koo K, Lee Y, Jung I. Development of Truss-Type Deployable Mesh Reflector Antenna, Part 1: 1.5 m-Scale Mesh Antenna. Applied Sciences. 2025; 15(21):11529. https://doi.org/10.3390/app152111529

Chicago/Turabian StyleLee, ChulHyung, DongGeon Kim, RyoonHo Do, SeungHyun Kim, GyeongHun Bae, KyungRae Koo, YoonPyo Lee, and InO Jung. 2025. "Development of Truss-Type Deployable Mesh Reflector Antenna, Part 1: 1.5 m-Scale Mesh Antenna" Applied Sciences 15, no. 21: 11529. https://doi.org/10.3390/app152111529

APA StyleLee, C., Kim, D., Do, R., Kim, S., Bae, G., Koo, K., Lee, Y., & Jung, I. (2025). Development of Truss-Type Deployable Mesh Reflector Antenna, Part 1: 1.5 m-Scale Mesh Antenna. Applied Sciences, 15(21), 11529. https://doi.org/10.3390/app152111529