1. Introduction

The shearer drum is a key piece of equipment in underground fully mechanized coal mining, and its operational performance directly affects coal mine production efficiency. Owing to its continuous and efficient mining capability, it is widely used in coal mines. A core structure of the shearer, the drum, cuts coal from the coal wall via picks and conveys the cut coal into the scraper conveyor by means of helical vanes. Currently, shearer drums can be directly applied to mining coal seams with a thickness of 0.5–10 m; however, coal seams within this thickness range are often accompanied by complex geological conditions such as large dip angles, gangue inclusions, and faults [

1]. Under complex working conditions, an insufficient coal-loading performance of the drum will lead to an accumulation of ineffectively transported coal at the rear of the ranging arm, leaving loose coal on the machine road. This further hinders the shearer’s traction movement and working face advancement. Therefore, ensuring and improving the drum’s coal-loading performance is crucial for enhancing coal-mining efficiency.

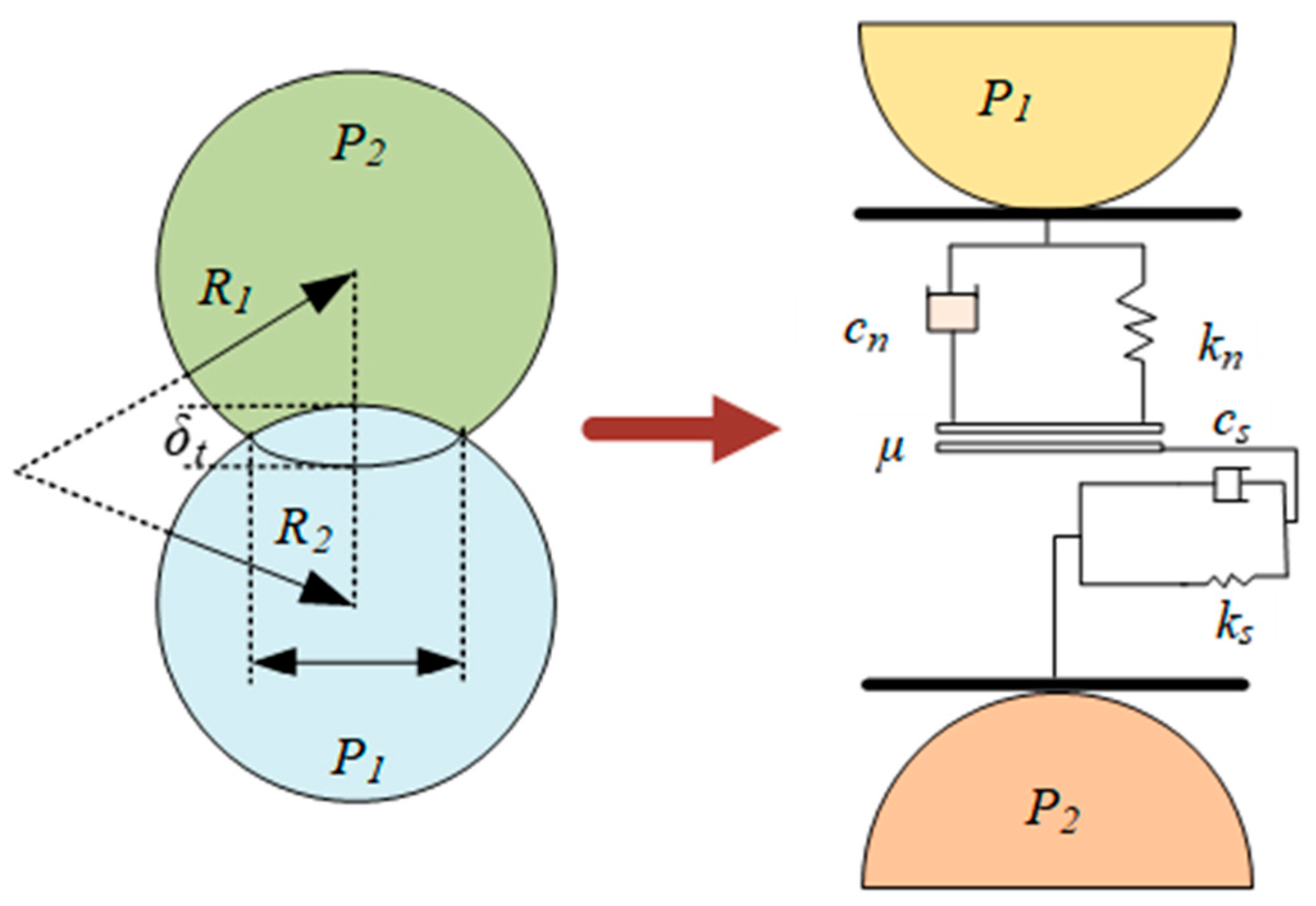

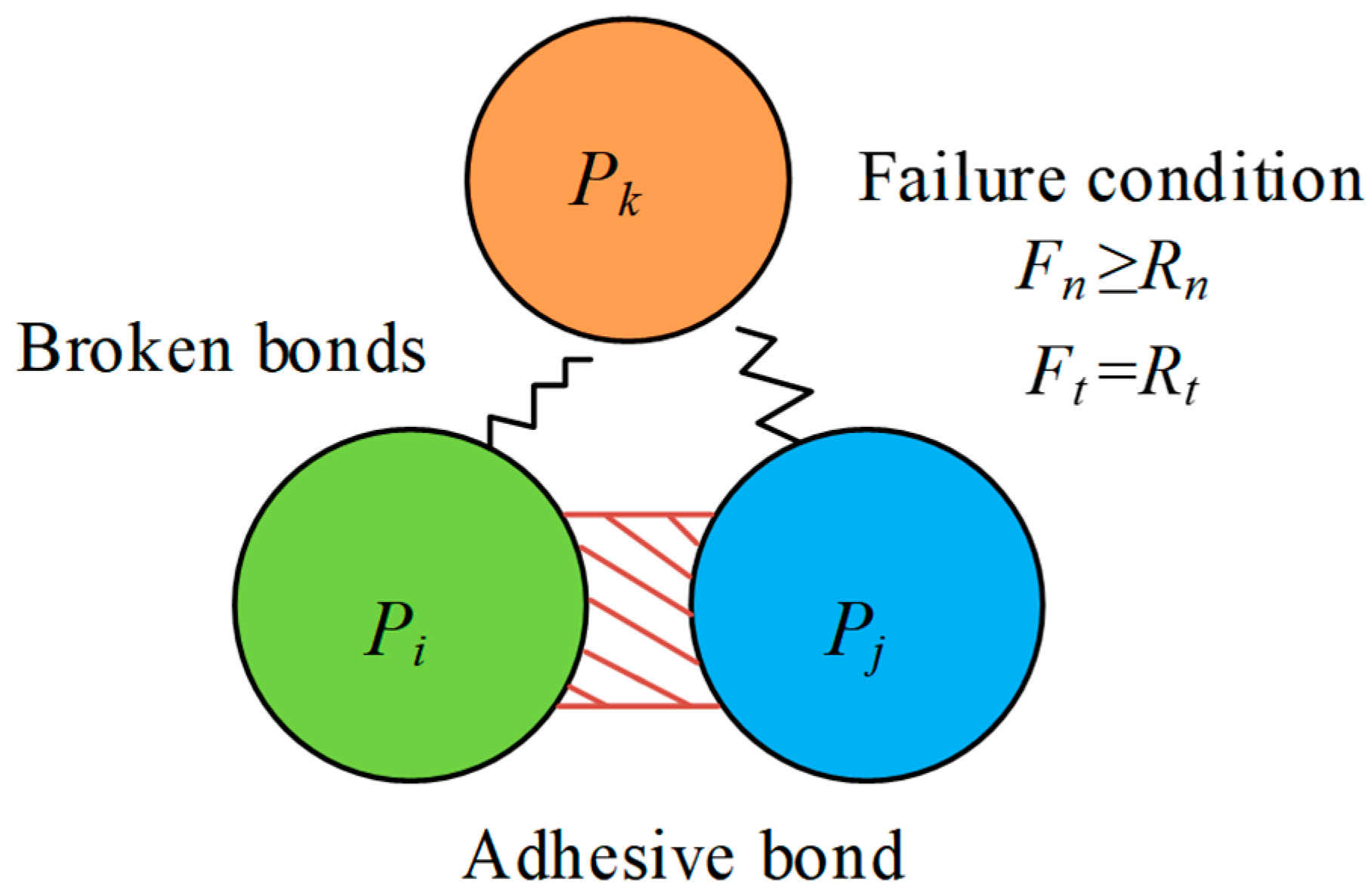

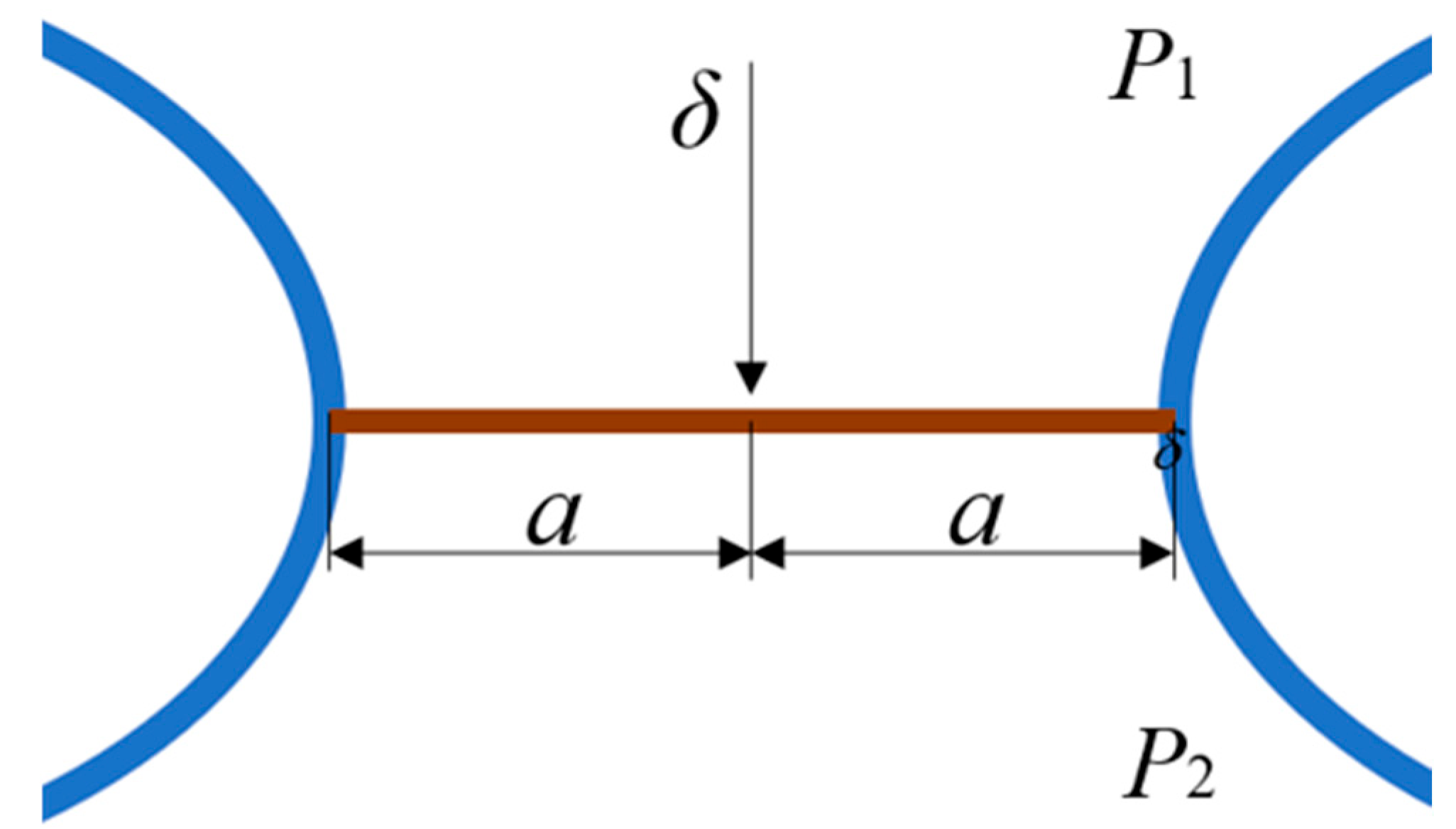

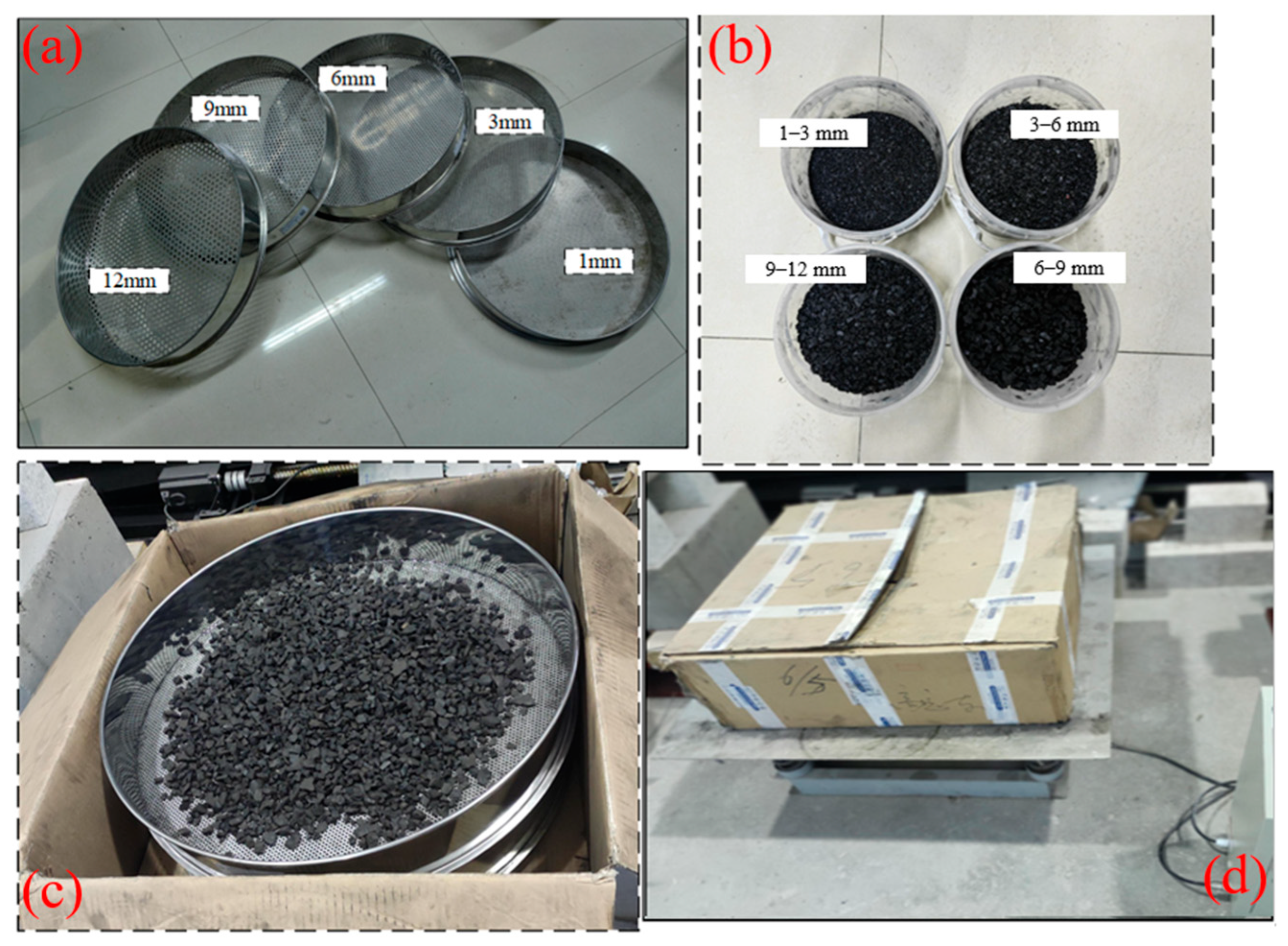

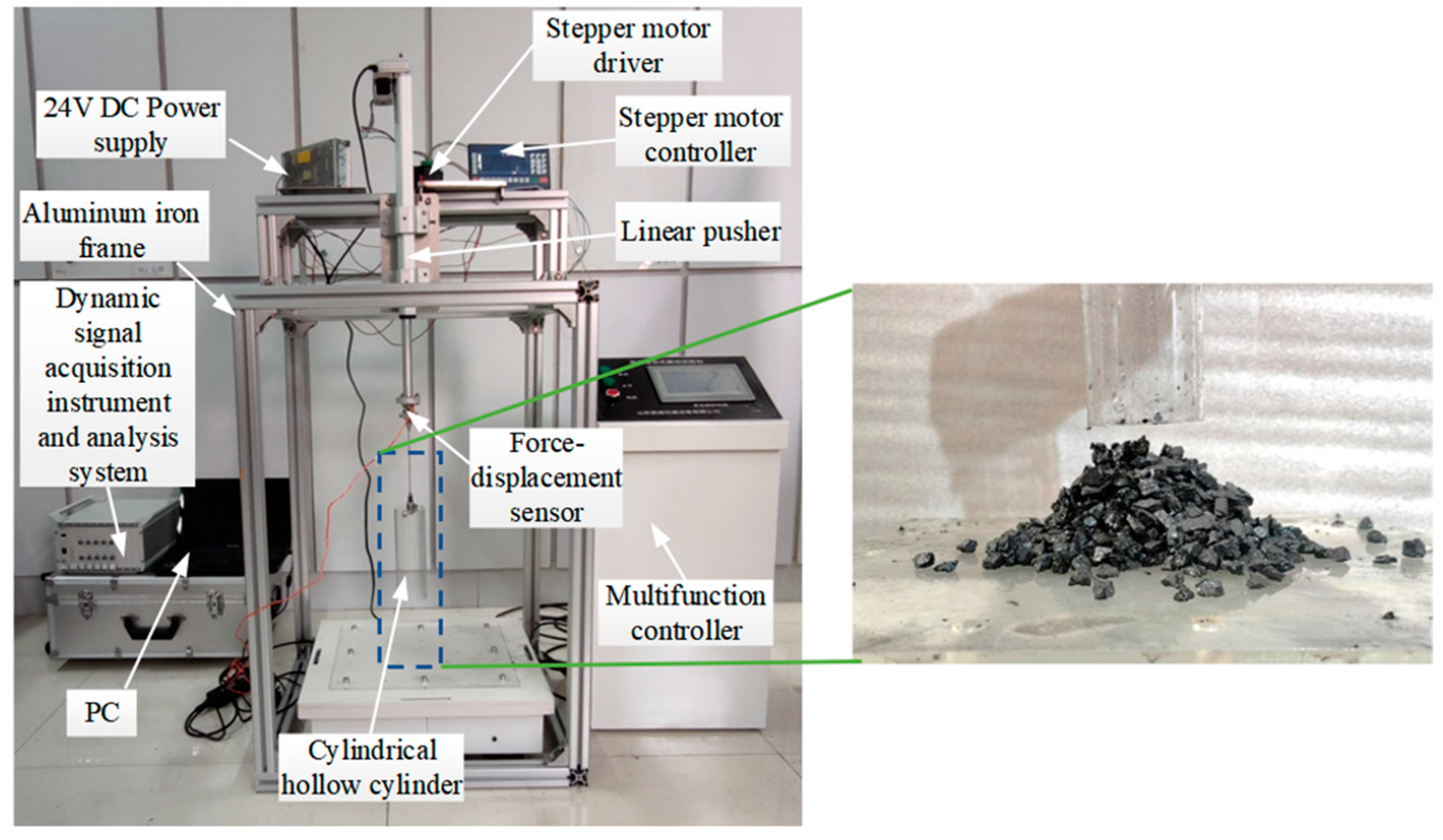

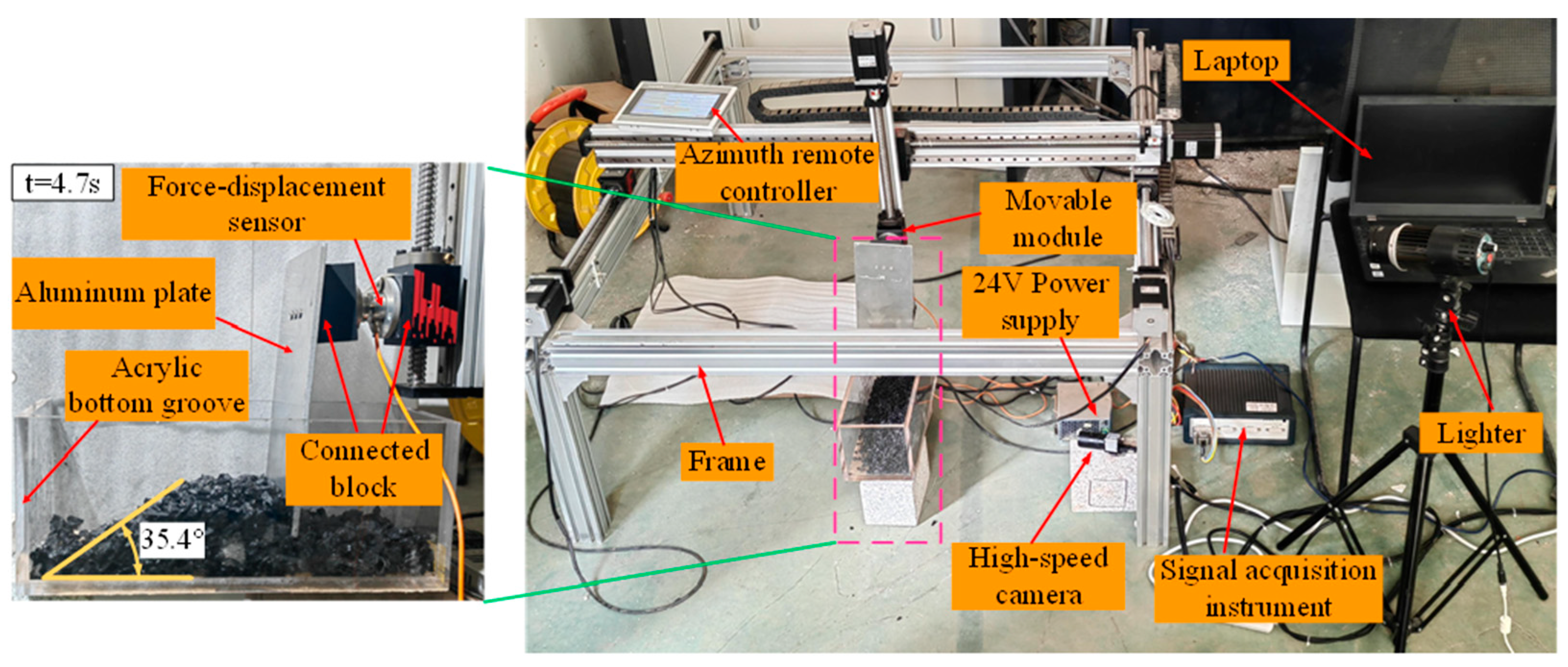

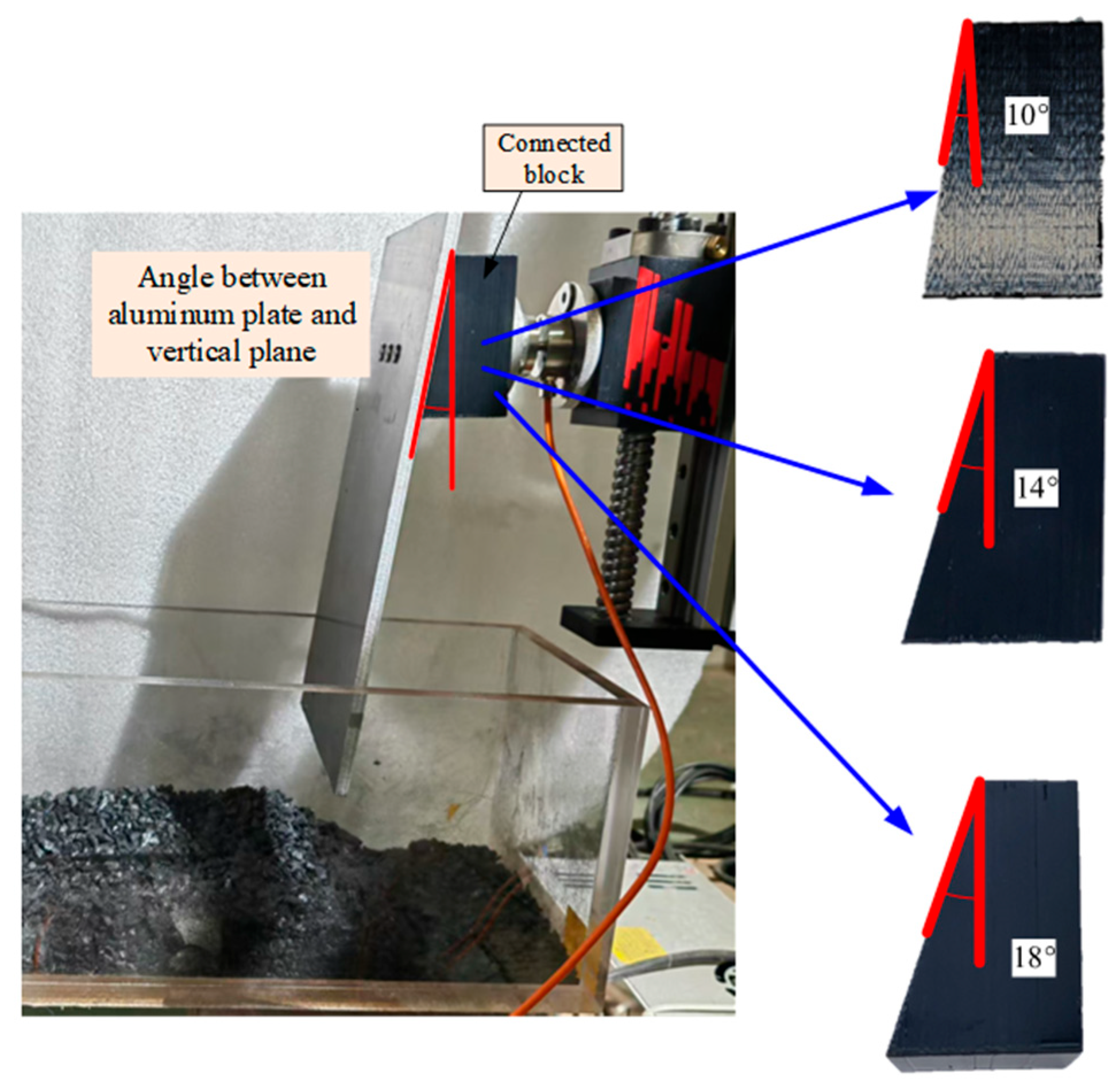

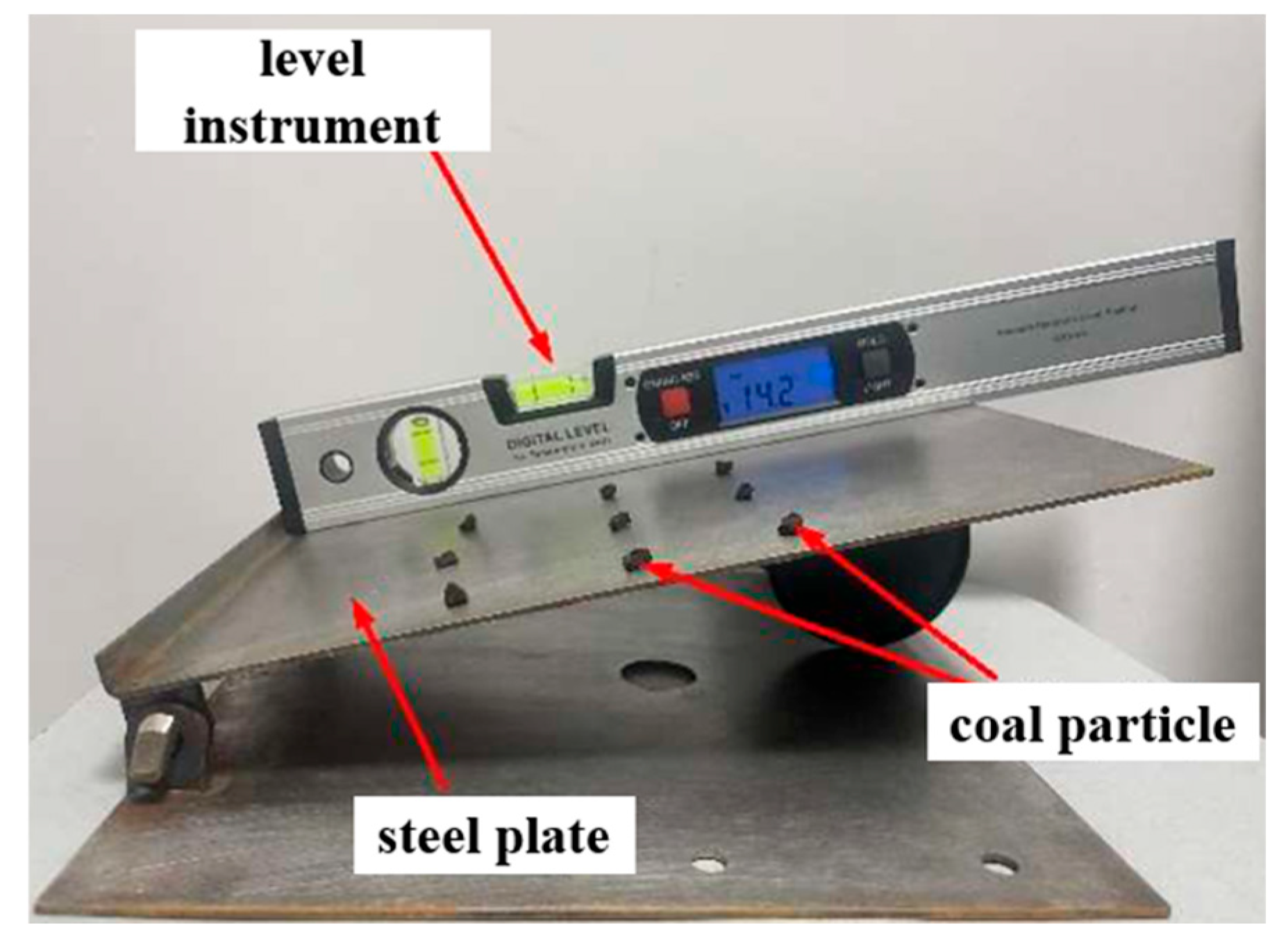

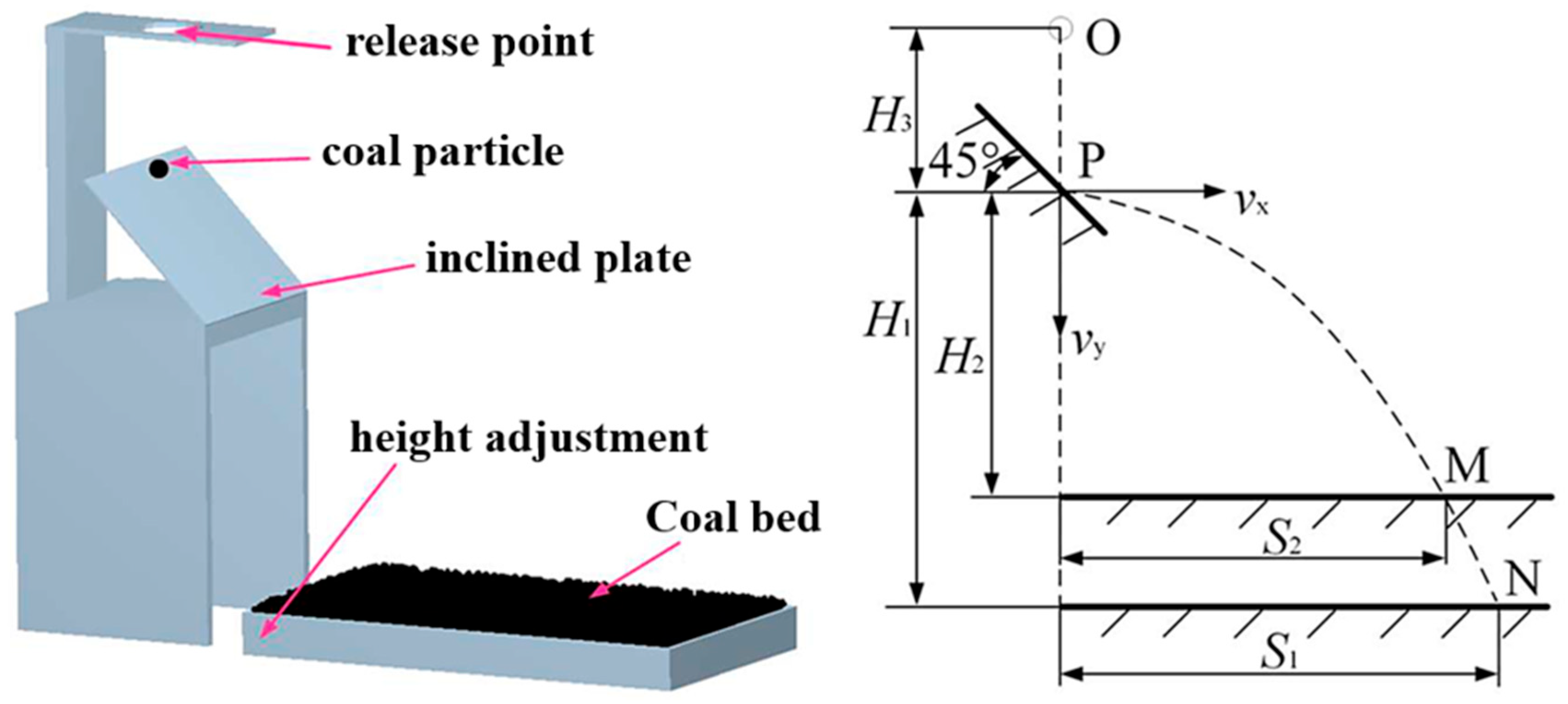

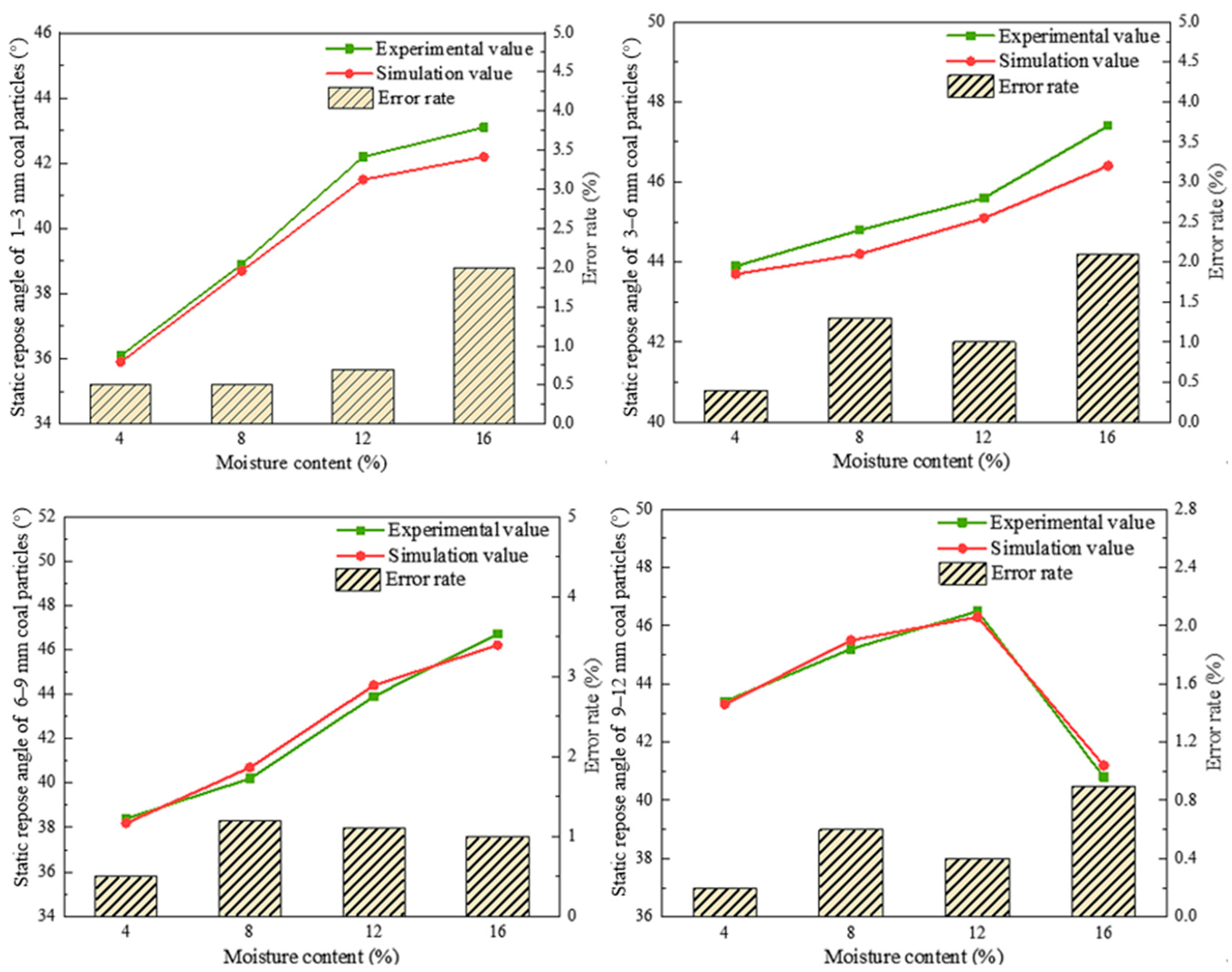

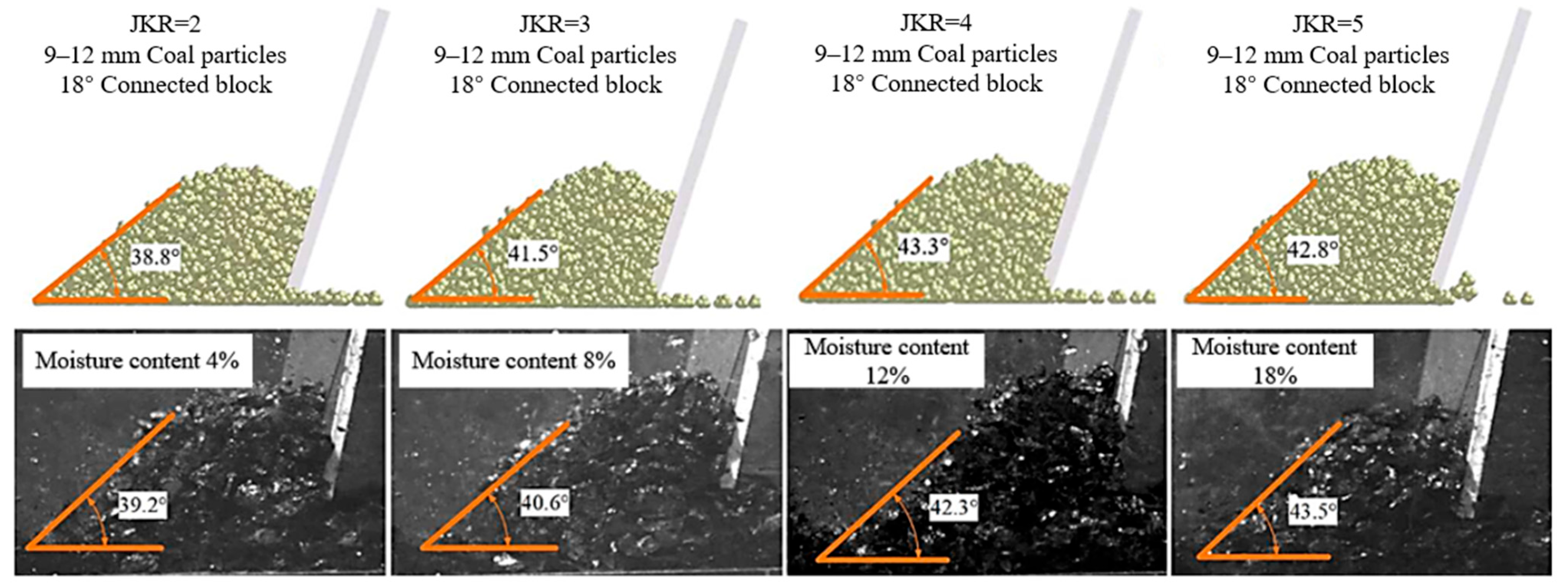

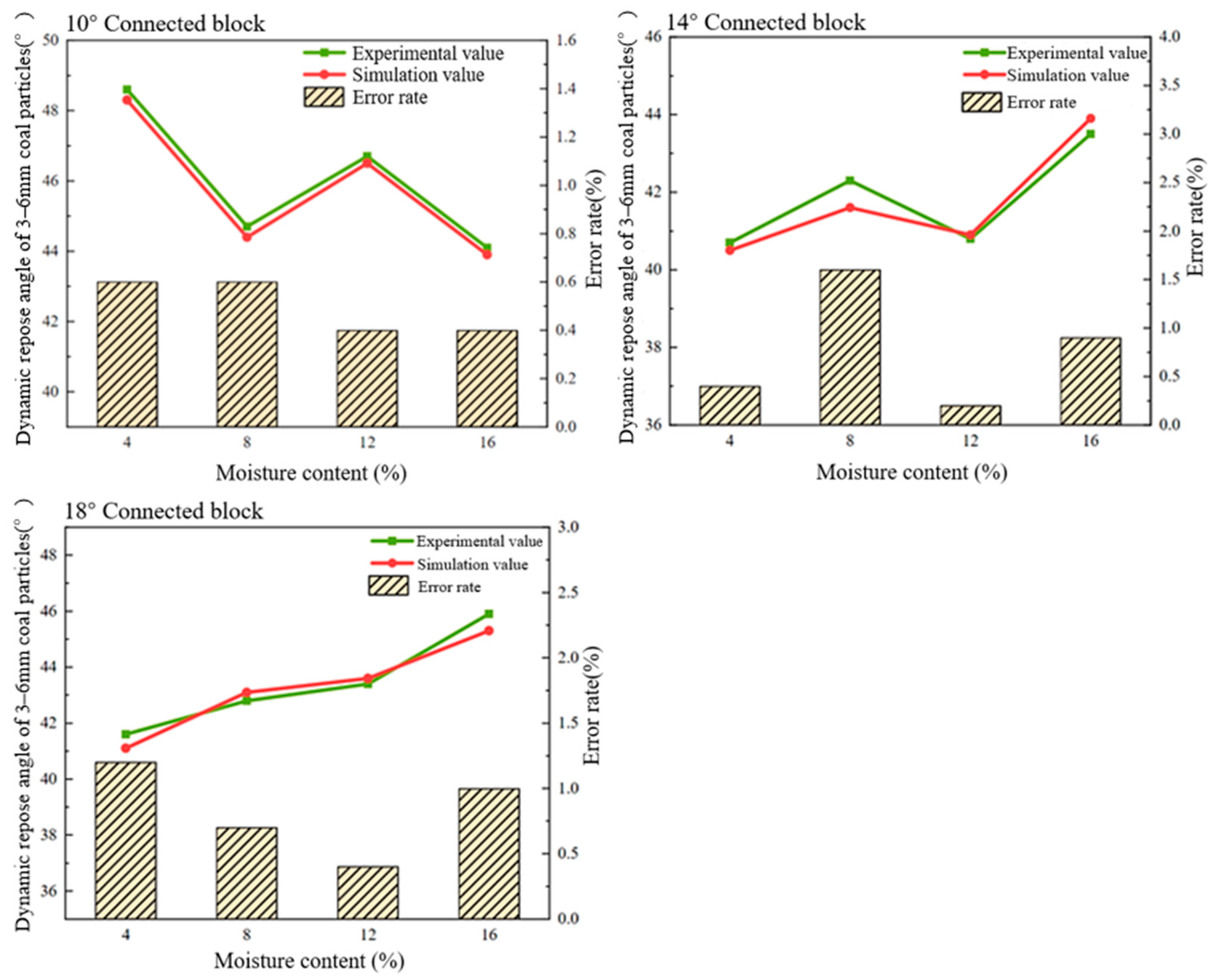

Against this backdrop, a series of exploratory studies have been conducted by researchers focusing on improving the drum coal-loading rate. However, restricted by factors such as complex on-site working conditions and high difficulty in collecting various types of data, relevant studies mostly focus on the discrete element method (DEM) for simulation analysis. To ensure the reliability of DEM simulation results, parameter calibration of DEM simulation software is usually performed by researchers through calibration tests such as the angle-of-repose test. Comparison and verification between simulation results and data measured on-site are carried out. This has laid an important research foundation for in-depth revelation of the drum coal-loading mechanism and optimization of coal-loading technical schemes.

Research on coal mine cutting and mining mainly focuses on optimizing cutting component performance, dynamic energy changes in coal seams, and coal mechanical properties. These explorations not only solve specific technical problems in mining but also lay a theoretical and experimental foundation for subsequent key tasks, such as improving the drum coal-loading rate and optimizing mining schemes. In 2020, to address core cutting component pain points, Lu et al. [

2] focused on conical picks’ “high wear, low efficiency” in roadway excavation. By combining numerical simulation and experiments, they revealed the pick–rock interaction mechanism, providing direct support for pick optimization and cutting parameter design. In the same year, Wang et al. [

3] used numerical simulation from a mining safety perspective. It was found that mining redistributes coal seam energy, with higher peak strain energy density near goafs, making the rock-burst risk there much higher than in coal pillars. This offers a key reference for regional cutting risk prediction. In 2022, research shifted to the influence of coal’s mechanical properties on cutting. Guo et al. [

4] experimentally confirmed that the axial compressive loading rate induces nonlinear growth of coal’s peak strength, logarithmic growth of the elastic strain energy conversion rate, and a brittle-to-ductile failure mode transition and clarified their correlations. In 2025, research was further deepened. Wang et al. [

5] noted that the loading rate reduces coal micro-cracks (concentrated around 90°), shifts the failure mode from shear to tensile, and accelerates elastic strain energy storage/release. Li et al. [

6] experimentally validated that the “loading rate correlates positively with coal parameters like fracture toughness,” together improving the impact mechanism of the loading rate on coal properties.

In the field of drum coal-loading rate optimization research, the influence of drum structural parameters on coal-loading efficiency is one of the core directions. Relevant studies mostly target coal-loading pain points in different coal seams (especially thin coal seams), with the discrete element method (DEM) the main analysis tool. The action mechanism of each drum structural parameter is systematically explored, providing key theoretical and technical support for the structural design optimization of shearer drums and improvement in coal-loading efficiency. In 2020, to address the common issue of a low coal-loading efficiency of shearer drums in thin coal seams, Xu et al. [

7] took the spherical envelope drum as the research object. Via the DEM, the influence of the drum cone half-angle on the coal-loading rate was systematically explored, and the correlation law between this parameter and coal-loading efficiency was clarified. In the same year, Gao et al. [

8] also focused on this issue: the influence mechanism of the hub shape, hub cone angle, and spiral blade angle on the coal-loading rate was analyzed in depth via the DEM, further improving the optimization basis for core structural parameters of thin coal seam drums. In 2021, Tian et al. [

9] focused on the shearer drum coal-loading process itself. The dynamic characteristics of drum coal loading were studied via DEM numerical simulation. The goal was to provide targeted solutions for improving drum coal-loading efficiency by analyzing the inherent laws of the coal-loading process. In 2022, Sun et al. [

10] found via the DEM that changes in drum blade angle directly affect the coal particle mass flow state and particle velocity. This conclusion was provided as a reference basis for drum blade angle design, clarifying the specific effect of blade angle adjustment on coal-loading performance. In 2024, relevant research further expanded the related dimensions of drum optimization. Biały et al. [

11] moved beyond single structural parameter research; based on three key indicators (coal extractability index, uniaxial compressive strength of coal, and theoretical energy consumption), a selection method for longwall shearers was established. Indirectly, this method achieved the goals of an improved mining concentration, increased output, and reduced equipment failure rate. In the same year, Xu et al. [

12] focused on coal hood parameters of thin coal seam shearers. Combining DEM and modeling analysis, the influence laws of coal hood parameters were revealed: coal hood offset showed a monotonic negative correlation with the coal-loading rate; the coal hood angle had a negative impact on the projectile coal-loading volume but a “first rise then fall” trend on the push coal-loading volume; the coal hood wrap angle had a weak influence; and the most significant parameters were the “angle (for projectile coal loading)” and “offset (for push coal loading),” providing a clear direction for the precise design of coal hoods.

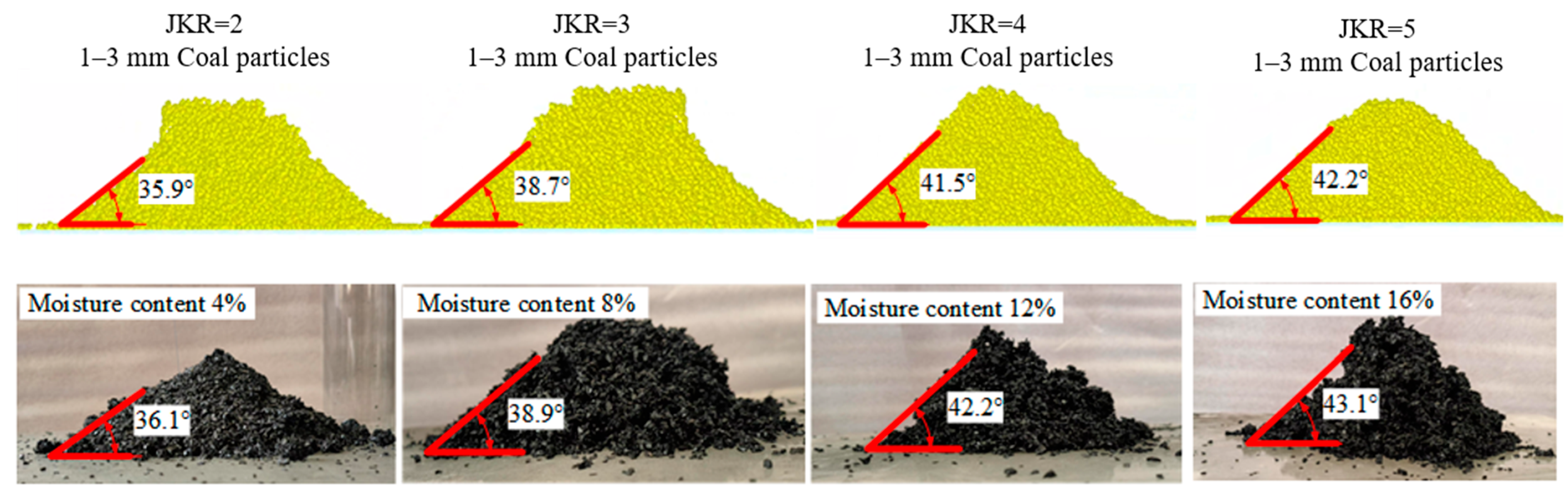

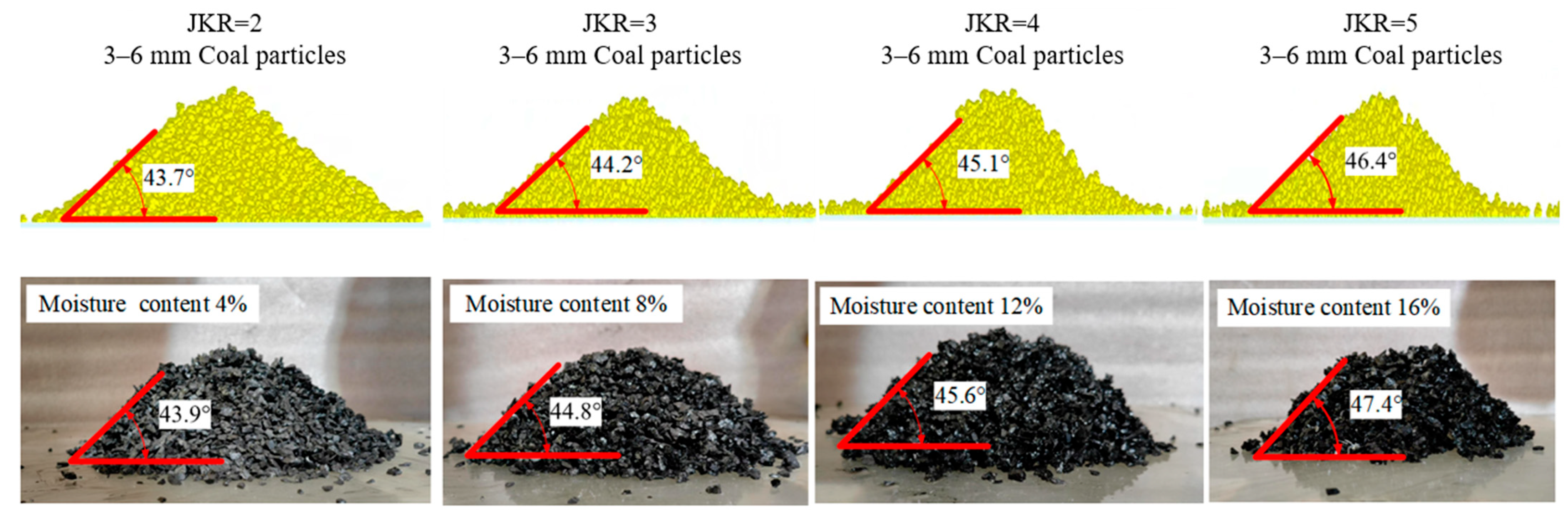

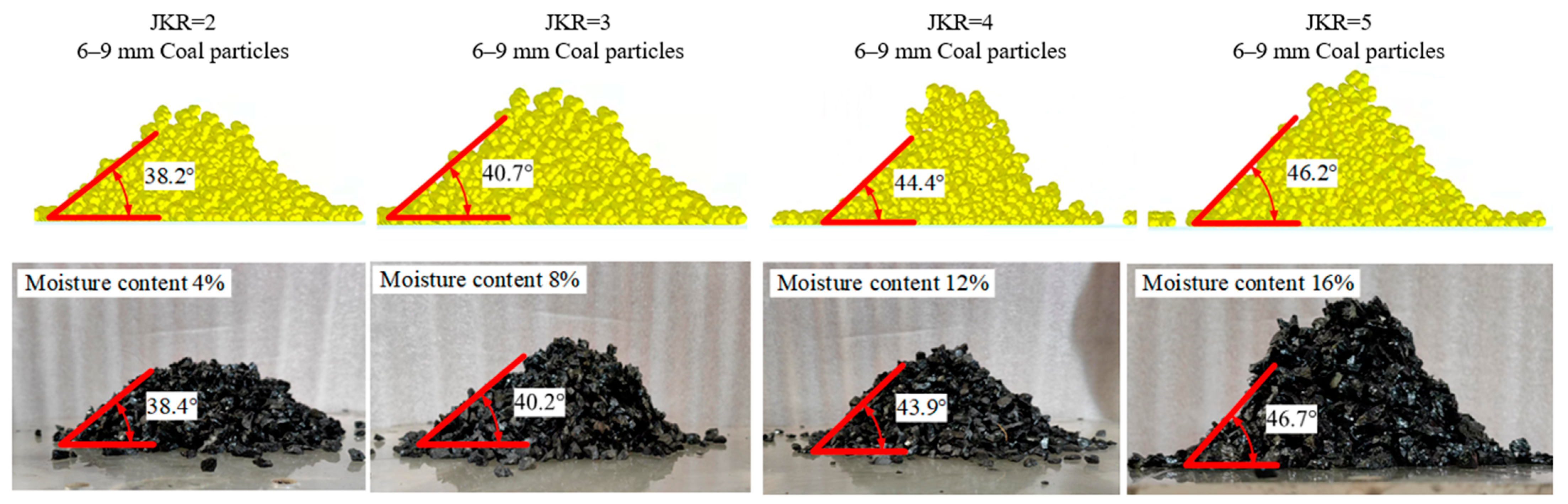

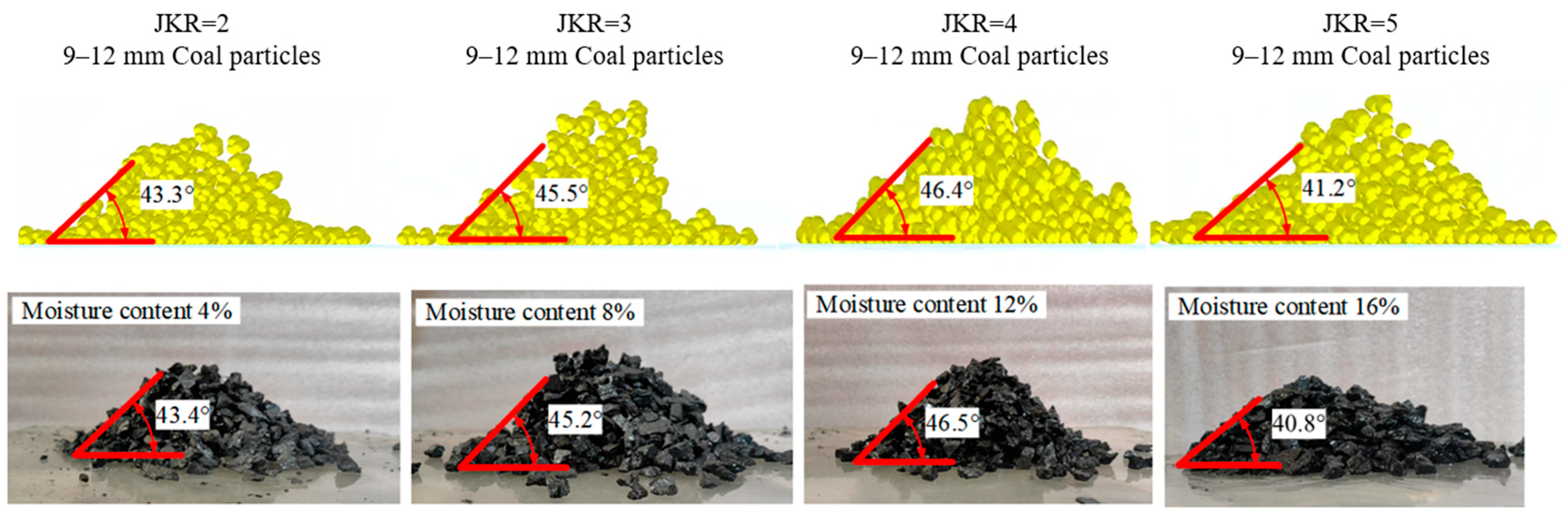

In the research on the influence of the moisture content on the drum coal-loading rate, the core direction is to explore how the moisture content indirectly affects coal-loading efficiency by changing the particle fluidity, adhesion, and mechanical properties of coal. Relevant studies are mostly carried out by combining experiments and the discrete element method (DEM). They provide theoretical support for coal-loading optimization under different moisture content conditions. In 2021, Wang et al. [

13] found through angle-of-repose measurement tests that within a certain range, increasing the coal moisture content increases the angle of repose. This directly reflects the influence law of the moisture content on coal particle fluidity. In 2025, Gao et al. [

14] confirmed by combining metal plate lifting tests and DEM analysis that the adhesion strength of wet coal increases with an increasing moisture content. Vibration can adjust adhesion friction: lower adhesion with a larger amplitude, and higher adhesion with a higher frequency. A new adhesion control method was thus proposed. In the same year, Zhang et al. [

15] conducted Mode I fracture tests on coal samples with different moisture contents in a low-temperature environment. It was found that the fracture toughness of coal is positively correlated with the moisture content at low temperatures, and the higher the moisture content, the more significant the toughness improvement.

In the research on the influence of the traction speed on the drum coal-loading rate, the core is to explore how the traction speed affects the coal-loading efficiency by changing coal particle flow characteristics, equipment operation resistance, and particles’ initial speed. Relevant studies are conducted by combining the discrete element method (DEM) and experiments. Some studies also improve the adaptability of the traction speed through equipment optimization, providing references for coal-loading efficiency regulation. In 2018, Wang et al. [

16] focused on the relationship between the speed and efficiency of scraper conveyors in coal transportation. The influence mechanism of the traction speed on coal particle flow behavior, the coal-loading rate, and energy consumption was revealed via the DEM. In 2021, Liu et al. [

17] adjusted the traction speed and calculated the coal-loading rate. It was found that the coal-loading rate decreases as the traction speed increases; when the speed reaches 4.23 m/min, the coal-loading rate drops to 41.65%. In 2024, Zhou et al. [

18] pointed out that an increased cutting depth increases the shearer’s traction resistance. This causes the full-load speed to decrease by 25% (from 8 m/min to 6 m/min), which adversely affects the balance of coal-loading efficiency. In the same year, Zhang et al. [

19] conducted single-factor and full-factor experiments. It was found that with a constant drum speed and cutting depth, the initial speed of coal–rock particles shows a “first increases then decreases” trend with traction speed. In 2025, Li et al. [

20] designed a tenon-mortise two-stage planetary reducer, deep-carburized traveling wheels, and high-wear-resistance sliding shoes. A high-power compact frequency converter was also developed. With these improvements, a traction speed of over 12 m/min was achieved, and the reliability and efficiency of the traction system were enhanced.

To adapt to coal mining in seams of different thicknesses, the diameter of shearer drums must be adjusted as needed, and the corresponding number of vanes must be matched to ensure the cutting and coal-loading performance. The number of vanes directly affects the coal-holding space and cutting efficiency of the drum, while the amount of coal discharged is jointly determined by the drum rotational speed and haulage speed; specifically, the reasonable matching of these three factors—vane number, drum rotational speed, and haulage speed—is the core of ensuring effective coal loading. In conventional configurations, drums with a diameter <1400 mm (for thin seams) mostly use two vanes; 1400 mm drums are designed with two or three vanes; those with a diameter of 1400~2240 mm (for medium-thickness seams) usually adopt three vanes; 2240 mm drums feature two designs (three or four vanes); and four vanes can be used for drums with diameters >2240 mm (for thick seams). When geological conditions are favorable, the coal-loading performance of drums is stable. However, under complex working conditions such as gangue inclusions, faults, and hard coal, cutting resistance increases sharply, resulting in a limited haulage speed. Meanwhile, the pick load and heat generation are increased, and wear is aggravated. To alleviate pick wear, the amount of spray cooling water must be increased. Yet excessive water changes the cohesion of coal and rock, which instead reduces the coal-loading efficiency. Existing studies have focused on the influence of the haulage speed, coal moisture content, and drum structure on the coal-loading rate. However, vane number selection for intermediate-sized drums remains largely empirical and based on production experience. For 1400 mm drums (used in thin-to-medium seam transitions) and 2240 mm drums (used in medium-to-thick seam transitions), the choice is still primarily determined by operational practice rather than systematic study.

This study focuses on shearer drums with diameters of 1400 mm and 2240 mm, investigating the influence of the vane number on the coal-loading rate. The analysis applies to transition coal seams, specifically thin-to-medium and medium-to-thick seam transitions, under different moisture content and haulage speed conditions. After completing parameter calibration via a series of calibration tests, DEM simulations were carried out with the Johnson–Kendall–Roberts (JKR) contact model. Simulation analyses were carried out under different haulage speeds and moisture contents for the two- and three-vane 1400 mm drums of Tiandi MG2X160/710-WD4 shearers in Shanghai, China, as well as the three- and four-vane 2240 mm drums of Tiandi MG500/1130-WD3 shearers in Shanghai, China. The simulation results were verified against field-collected data to ensure reliability. Based on these results, the applicable working conditions for two- and three-vane 1400 mm drums and three- and four-vane 2240 mm drums were clarified, providing a theoretical reference for vane number selection in transition coal seam mining.

4. Drum Coal-Loading Simulation Result Analysis

4.1. Establishment of Simulation Model

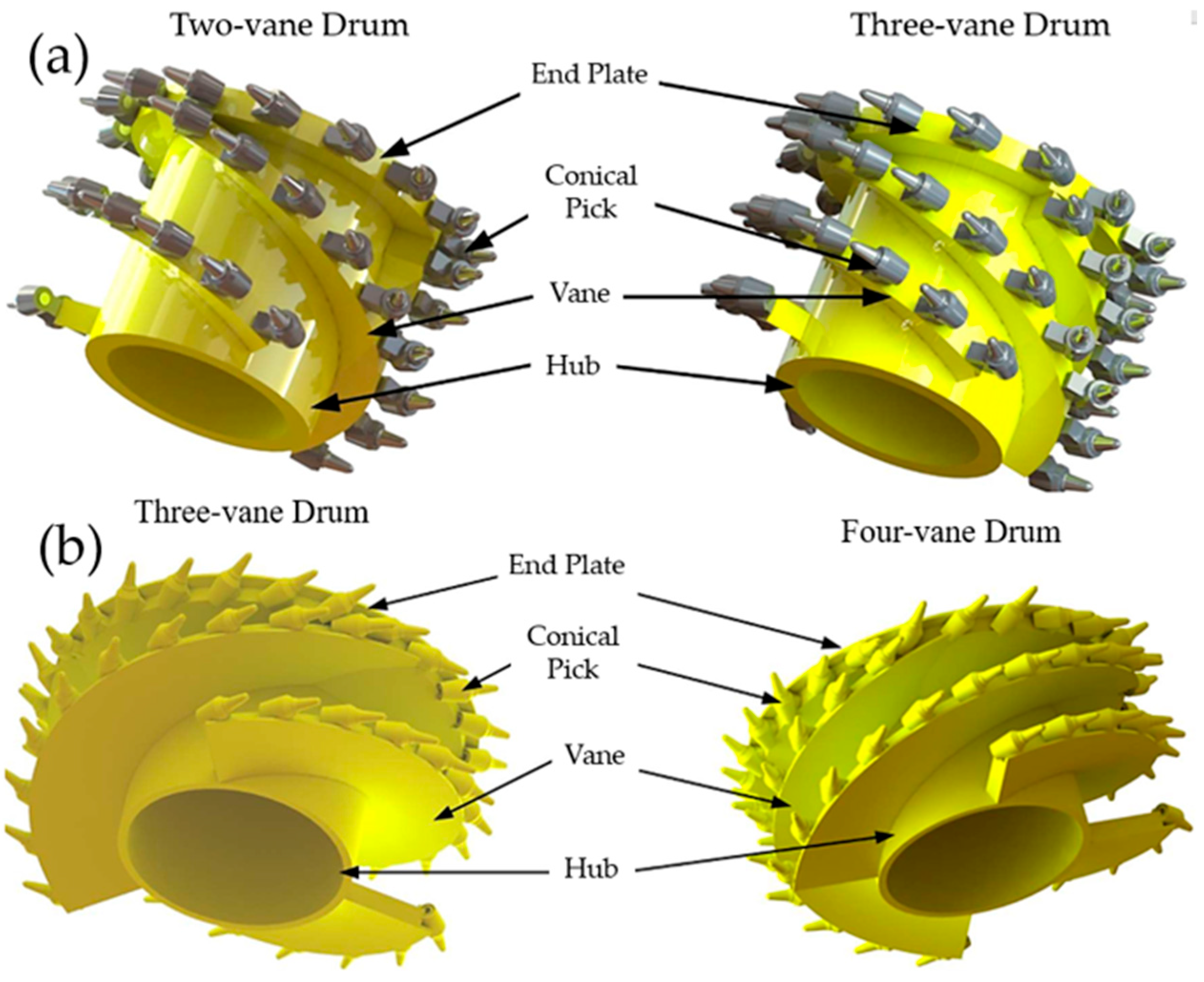

The coal-loading rate of shearers is affected by multiple factors, including geological conditions, coal–rock moisture content, number of vanes, helical angle, drum rotational speed, and drum diameter. Field tests are not only high in cost but also difficult for variable control; thus, it is challenging to conduct controlled-variable analysis relying solely on field-collected data. For this reason, calibrated simulation parameters are adopted to simulate the actual coal-mining environment under controlled-variable conditions, so as to obtain coal-loading rate data. The simulation results are verified using field-collected data, and finally, the analysis of factors influencing coal-loading rate is conducted based on the simulation data. The model adopted the three/four-vane drums with 2240 mm of the Tiandi MG500/1130-WD3 shearer and the two/three-vane drums with 1140 mm of the Tiandi MG2X160/710-WD4 shearer. Relevant parameters are shown in

Table 4 and models in

Figure 19.

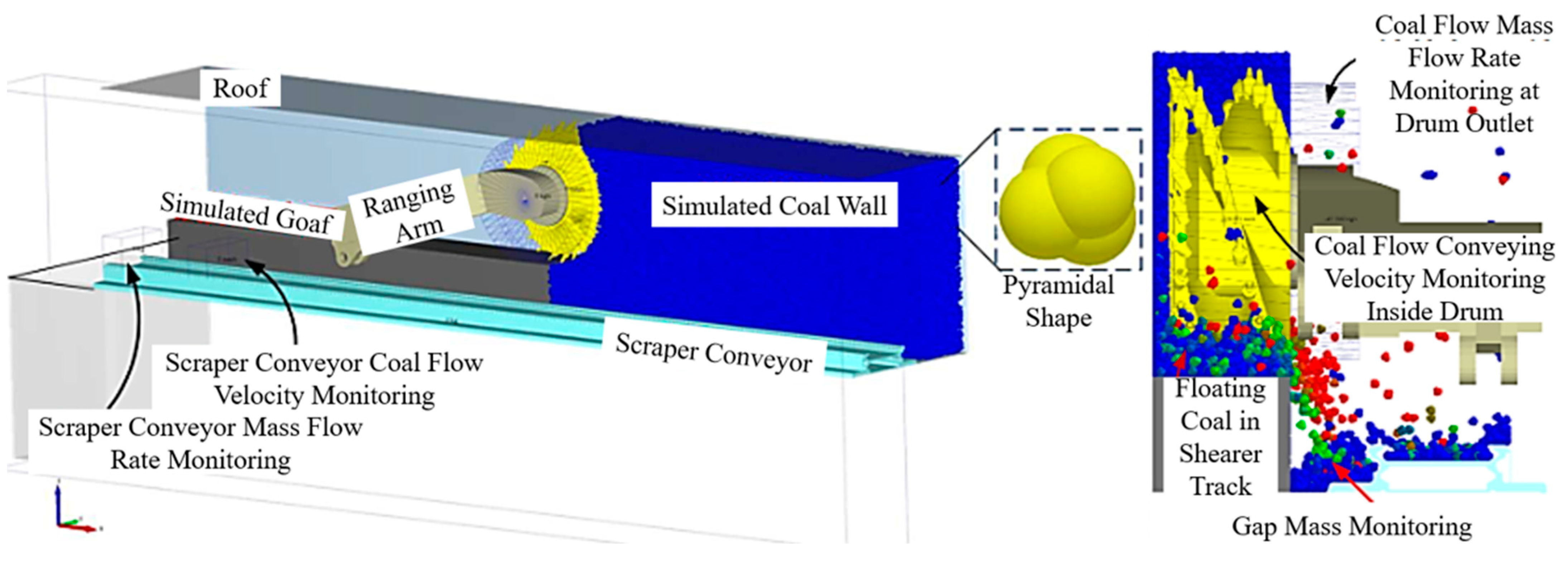

The structural stability of the coal wall is ensured through the bonding force of particles in the bonding particle (BP) contact model. After constructing the coal wall model based on the discrete element method, to achieve accurate calculation of the coal-loading rate, it is necessary to divide the coal particle distribution areas and calculate the coal-loading rate by counting the mass of coal particles in each area. The specific schematic diagram is shown in

Figure 20. In the figure, coal particles of different colors, respectively, indicate their different motion states.

When the shearer drum is cutting the coal wall, after coal particles are cut off, combined with the coal particle distribution characteristics, the coal particle statistical areas are divided into three parts: track goaf, the gap area between the coal wall and the scraper conveyor, and the effective loading area inside the scraper conveyor. The drum coal-loading rate is defined as the ratio of the mass of coal particles in the effective loading area to the total mined coal mass, and this ratio is calculated by Equation (11):

wherein

λ refers to the coal-loading rate with the unit of %;

Mloading refers to the mass of coal particles in the effective area with the unit of kg;

Mgoaf refers to the mass of coal particles in the goaf with the unit of kg; and

Mgap refers to the mass of coal particles in the gap area with the unit of kg.

4.2. Effect of Number of Vanes on Coal-Loading Rate Under Different Moisture Contents

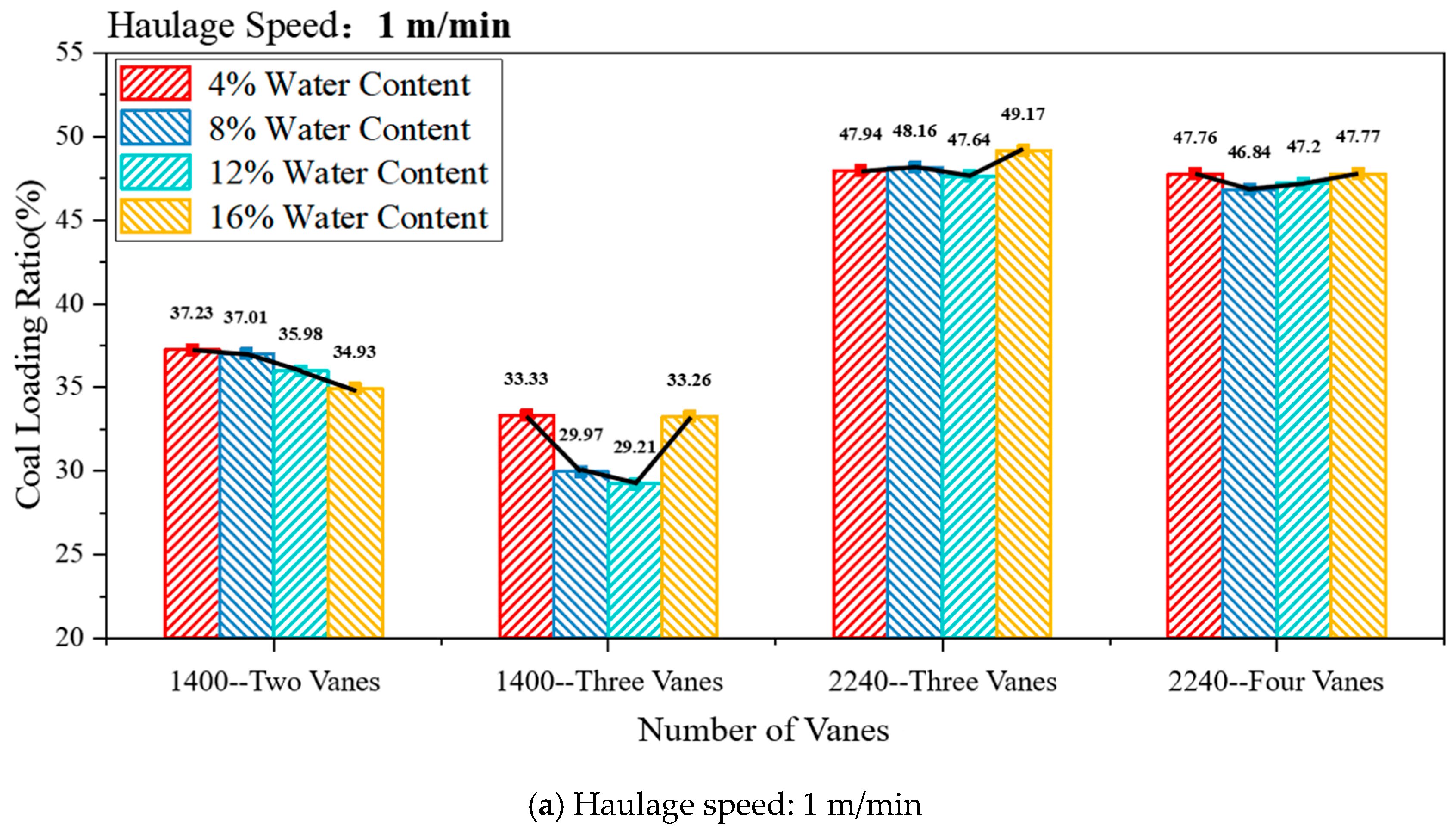

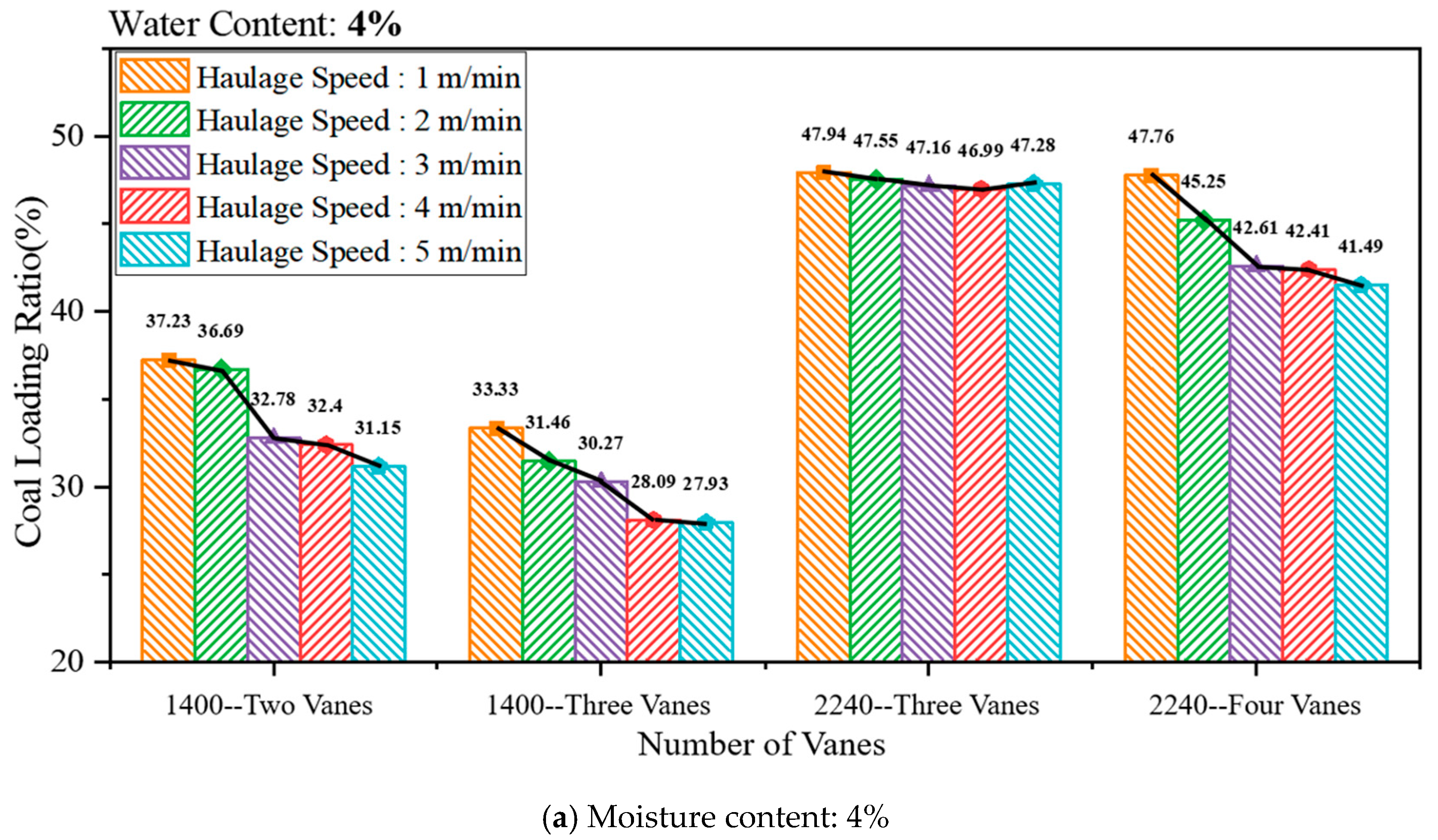

Under four moisture content conditions (4%, 8%, 12%, and 16%), significant regularity is exhibited in the influence of the vane number on the coal-loading rate of two drum sizes (1400 mm and 2240 mm). For the 1400 mm drum of the Tiandi MG2X160/710-WD4 shearer, results from comparisons between the two-vane and three-vane drums are shown as follows: under the same moisture content, the coal-loading rate of the two-vane drum is higher than that of the three-vane drum. At the same haulage speed, a steady downward trend is shown in the coal-loading rate of the two-vane drum as the moisture content increases. Meanwhile, a trend of first decreasing and then increasing is exhibited in the coal-loading rate of the three-vane drum. For the 2240 mm drum of the Tiandi MG500/1130-WD3 shearer, results from comparisons between the three-vane and four-vane drums are indicated as follows: under the same moisture content, the coal-loading rate of the three-vane drum is higher than that of the four-vane drum. At the same haulage speed, a “steady fluctuation” trend is mostly shown in the coal-loading rate of the three-vane drum. The variation trend of the four-vane drum’s coal-loading rate is similar to that of the 1400 mm three-vane drum (both first decreasing and then increasing), but with a smaller variation range. Specific results are shown in

Figure 21.

At the same haulage speed, the influence of the vane number on the coal-loading rate is essentially the result of the combined effect of different coal–rock particle sizes (caused by cutting thickness differences) and varying coal-holding spaces (determined by vane number and drum diameter). For the 1400 mm drum, the two-vane structure has fewer total picks due to having fewer vanes. According to the cutting thickness formula (Equation (9)), this increases the cutting thickness, resulting in coarser coal–rock particles formed by cutting. In contrast, the three-vane structure has more total picks due to an increased number of vanes. This reduces the cutting thickness and produces finer coal–rock particles. The difference in particle size, combined with the variation in coal-holding space, leads to distinctly different response trends. These trends refer to how the two drums’ coal-loading rates respond to moisture content: The two-vane drum has a larger coal-holding space, and the cohesion between coarse particles is weaker. The increase in particle cohesion caused by a higher moisture content has no significant interference with the coal-loading process; thus, the coal-loading rate only shows a steady downward trend. The fine particles of the three-vane drum are more sensitive to changes in moisture content, and the increased number of vanes limits the coal-holding space. At a low moisture content, the cohesion of coal–rock particles is low, and moisture content has little effect on their flowability. When the moisture content rises to a certain level, the cohesion of coal–rock particles increases—some particles adhere to the drum and rock wall surfaces, inter-particle adhesion is enhanced, and flowability decreases, leading to a drop in coal-loading rate. When the moisture content is further increased, cohesion promotes agglomerated transportation of particles, and the coal-loading rate rises accordingly. Eventually, a trend of first decreasing and then increasing is exhibited in the graph. When comparing the three-vane drums of 1400 mm and 2240 mm, although they have the same number of vanes, the 2240 mm drum has significantly more total picks and a larger coal-holding space due to its larger diameter, resulting in a much higher coal-loading rate than the 1400 mm drum. Additionally, the larger coal-holding space can effectively buffer the transportation resistance caused by particle cohesion, weakening the impact of coal–rock particle cohesion on the coal-loading rate—thus, the corresponding trend is not exhibited in the graph. For the three-vane and four-vane structures of the 2240 mm drum, the four-vane structure has more vanes and total picks. This reduces the cutting thickness and produces finer coal–rock particles, which enhances the cohesive response of particles to the moisture content, and the coal-loading rate curve also shows a “first decreasing and then increasing” trend. However, compared with the 1400 mm three-vane drum, the larger coal-holding space of the 2240 mm drum reduces the response sensitivity of coal–rock particle cohesion, making this trend relatively gentle in

Figure 21.

From the analysis results of the coal-loading rate of each type of drum at the same haulage speed, it can be concluded that for the 1400 mm drum shearer suitable for thin-to-medium-thickness transition coal seams, the two-vane structure is insensitive to the adhesion response of coal–rock particles and is suitable for working conditions with a large fluctuation range of coal–rock moisture content; and the three-vane structure, by contrast, is sensitive to the adhesion response of coal–rock particles and is suitable for working conditions where the coal–rock moisture content is too high or too low. For the 2240 mm drum shearer suitable for medium-to-thick transition coal seams, its large drum diameter ensures sufficient coal-holding space. Both structures (three-vane and four-vane) are insensitive to the adhesion response of coal–rock particles; thus, the coal-loading rate of the shearer mainly depends on the coal-holding space of the drum. Therefore, when selecting the number of drum vanes on-site, the requirement of geological conditions for coal-holding space must be mainly considered: the three-vane structure is preferred when the requirement for coal-holding space is high, while the four-vane structure is preferred when the requirement is low.

4.3. Effect of Number of Vanes on Coal-Loading Rate Under Different Haulage Speeds

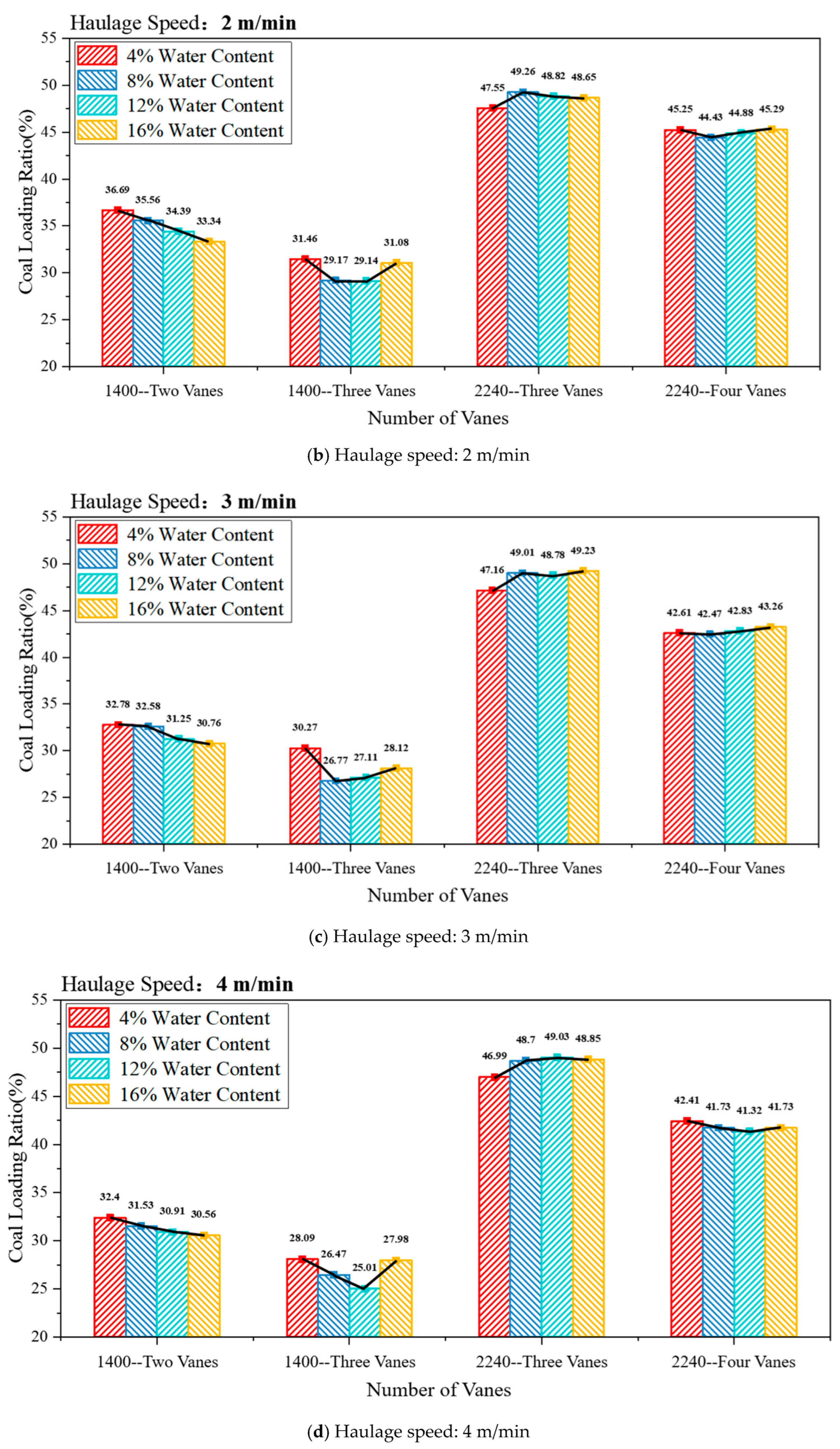

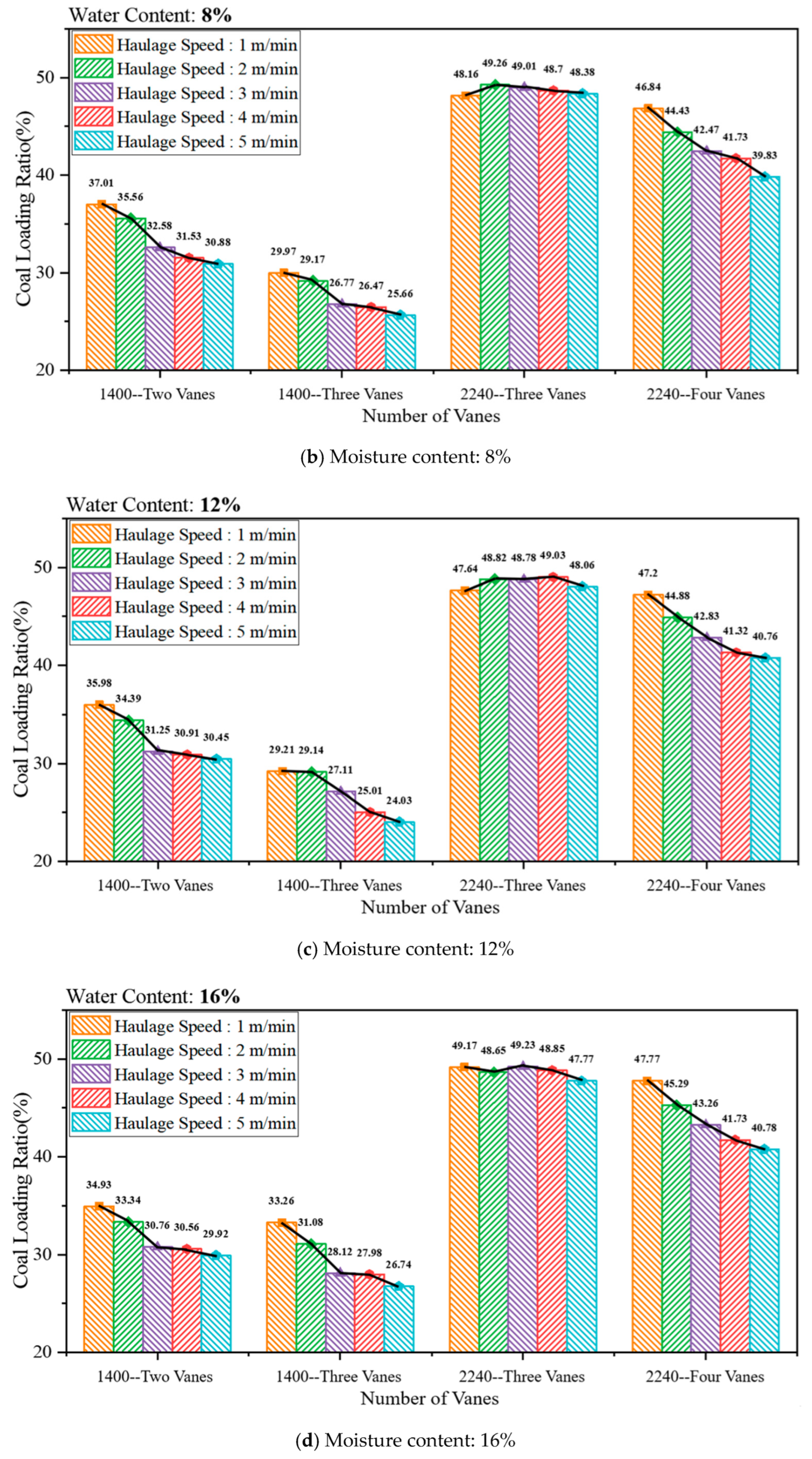

Under five haulage speed conditions (1 m/min, 2 m/min, 3 m/min, 4 m/min, 5 m/min), significant regularity is exhibited in the influence of the vane number on the coal-loading rate of two drum sizes (1400 mm and 2240 mm). For the 1400 mm drum of the Tiandi MG2X160/710-WD4 shearer, the comparison results between the two-vane and three-vane drums show that the coal-loading rates of both drums present a downward trend as the haulage speed increases. Generally, the coal-loading rate of the two-vane drum is slightly higher than that of the three-vane drum, and the difference in coal-loading rate between them first decreases and then increases with the rise in haulage speed. Meanwhile, when the moisture content is too high or too low, there is an overlapping part between the coal-loading rates of the two drums. For the 2240 mm drum of the Tiandi MG500/1130-WD3 shearer, the comparison between the three-vane and four-vane drums indicates that the coal-loading rate of the three-vane drum is relatively stable and shows no clear change with the increase in haulage speed. In contrast, the coal-loading rate of the four-vane drum presents a clear downward trend as the haulage speed increases. Different from the 1400 mm diameter drum, the difference in coal-loading rate between the three-vane and four-vane drums is the smallest at low haulage speeds, and it gradually increases as the haulage speed rises. Specific results are shown in

Figure 22.

Under the same moisture content, the influence of the vane number on the coal-loading rate is essentially determined by the degree of matching between the coal-cutting amount per unit time and the coal-conveying capacity of the drum. Due to its smaller diameter, the 1400 mm drum has limited coal-holding space and a correspondingly weak coal-conveying capacity. When the haulage speed is low, the coal-cutting amount per unit time does not exceed its coal-conveying capacity, resulting in a high coal-loading rate. As the haulage speed increases, the coal-cutting amount per unit time increases and exceeds the coal-conveying capacity, and the coal-loading rate decreases accordingly. This is reflected in the graph as a decrease in the coal-loading rate of the 1400 mm drum with the increase in haulage speed. Compared with the three-vane structure, the two-vane structure has fewer vanes and picks. This results in a lower coal-cutting amount per unit time and a larger coal-holding space, so its coal-loading rate is slightly higher than that of the three-vane structure. Theoretically, the difference in coal-loading rate between the two should decrease with the increase in haulage speed. However, under the coupling effect of coal–rock particle adhesion, the difference in coal-loading rate is finally reflected in the graph as first decreasing and then increasing. When comparing the 1400 mm and 2240 mm drums, the latter has a much larger coal-cutting amount per unit time and coal-holding space than the former; therefore, the coal-loading rate of the 2240 mm drum is significantly higher than that of the 1400 mm drum. When comparing the three-vane and four-vane structures of the 2240 mm drum, the four-vane structure has more vanes and picks, leading to a larger coal-cutting amount per unit time and a smaller coal-holding space than the three-vane structure; thus, as the haulage speed increases, the coal-cutting amount per unit time further increases and exceeds its coal-conveying capacity, resulting in a downward trend of coal-loading rate. The three-vane structure has fewer vanes and picks, resulting in a smaller coal-cutting amount per unit time and a larger coal-holding space than the four-vane structure; therefore, as the haulage speed increases, although the coal-cutting amount per unit time increases, it does not exceed its coal-conveying capacity. Hence, the coal-loading rate of the drum shows little fluctuation and no clear fluctuation in the graph.

From the analysis results of the coal-loading rate of each type of drum under the same moisture content, it can be concluded that for the 1400 mm drum shearer suitable for thin-to-medium-thickness transition coal seams, due to its limited coal-holding space, the two-vane structure is preferred if the drum’s coal-conveying capacity is mainly determined by the coal-holding space; if the coal-conveying capacity is jointly determined by multiple factors such as the vane structure, drum rotational speed, and coal-holding space, the three-vane structure—with a higher coal-cutting amount per unit time—should be considered for selection. For the 2240 mm drum shearer suitable for medium-to-thick transition coal seams, the three-vane structure is suitable for working conditions with a large fluctuation in haulage speed or where continuous adjustment of the haulage speed is required, as it is less affected by the haulage speed. The four-vane structure, by contrast, has a larger coal-cutting amount per unit time due to the increased number of vanes and picks; it is suitable for working conditions with a low haulage speed, stable haulage speed, or where the drum’s coal-conveying capacity can be improved through other means.

4.4. Field Data Verification

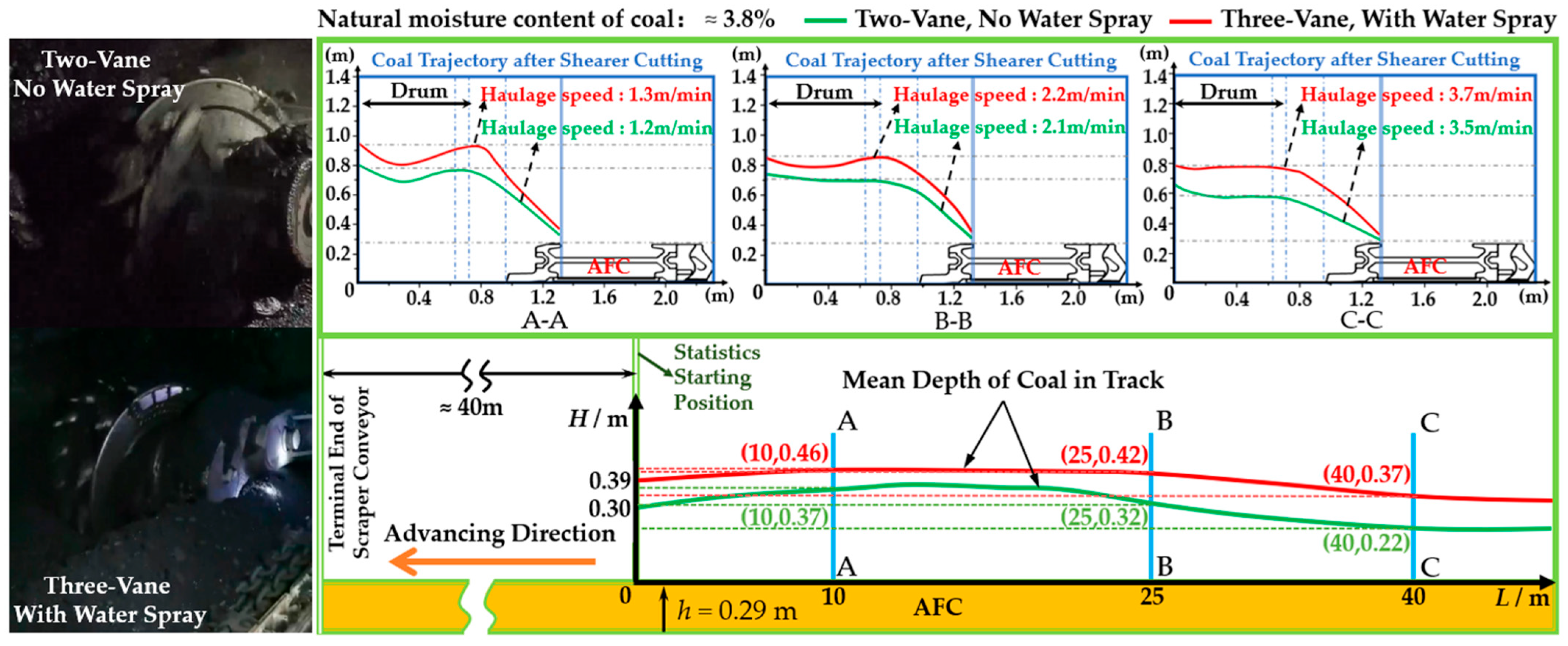

To verify the reliability of the simulation results, post-cutting floating coal trajectories were collected on-site at the coal mine for the Tiandi MG2X160/710-WD4 shearers (1400 mm two-vane without water spray, 1400 mm three-vane with water spray) and Tiandi MG500/1130-WD3 shearers (2240 mm three-vane without water spray, 2240 mm four-vane with water spray). The collected trajectories were visualized, and cross-sections perpendicular to the shearer’s advancing direction were established at positions A, B, and C. Subsequently, the floating coal trajectories in the track at each cross-section were graphically represented. Based on the characteristics of floating coal trajectories in the figures, the post-cutting coal accumulation state was determined, and the shearer’s coal-loading rate was further evaluated: the higher the floating coal accumulation height, the poorer the drum coal-loading rate, and the lower the actual coal-loading rate.

Figure 21 and

Figure 22 were compared and analyzed with

Figure 23. Through the comparison of on-site floating coal trajectories between the 1400 mm two-vane shearer without water spray and the 1400 mm three-vane shearer with water spray, it was found that the floating coal height of the two-vane drum under the condition of a low coal moisture content was slightly lower than that of the three-vane drum under the condition of a high coal moisture content, which was consistent with the simulation results in

Figure 21. Meanwhile, observation of the floating coal trajectory graph group in the track from

Figure 23 showed that with the increase in the shearer’s haulage speed, the amount of floating coal accumulated in the track gradually increased for both two-vane and three-vane drums, and the shearer’s coal-loading rate decreased accordingly, which was consistent with the simulation results in

Figure 22.

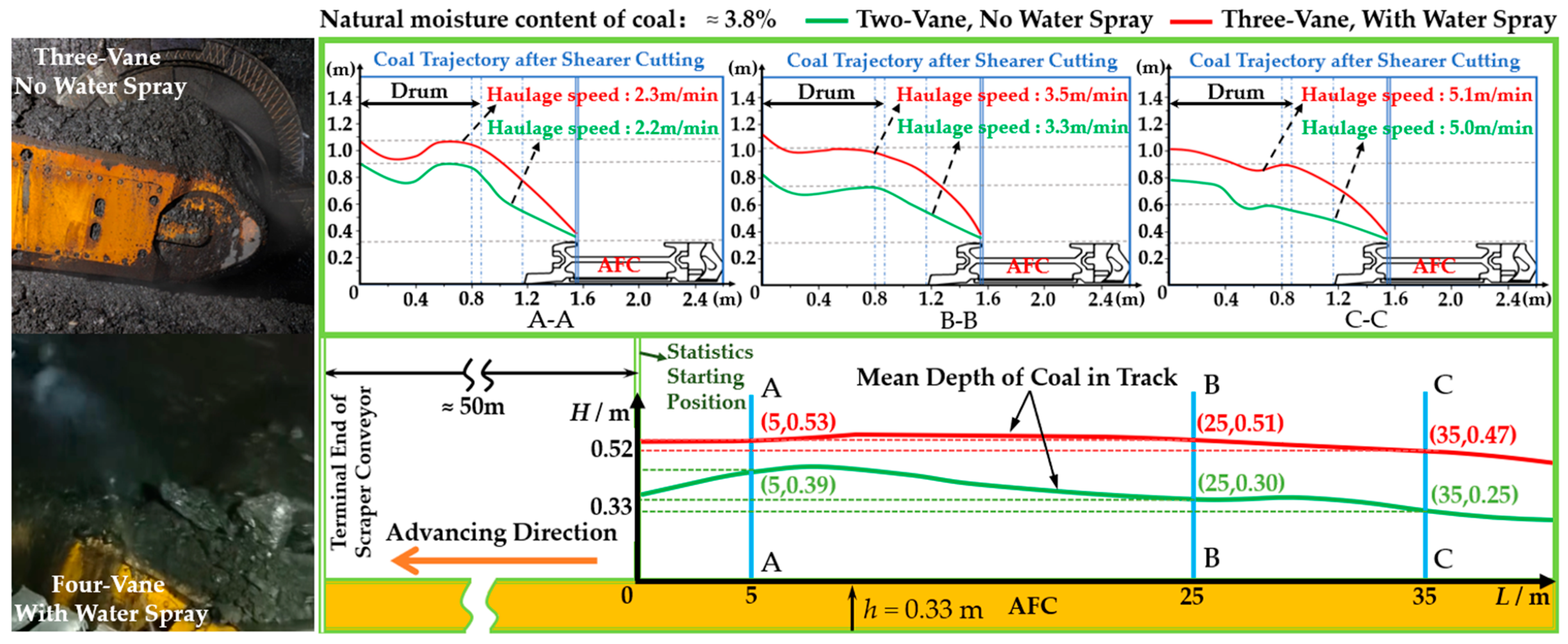

Figure 24 was compared and analyzed with

Figure 21 and

Figure 22, and it was found that the on-site floating coal trajectory characteristics of the 2240 mm three-vane shearer without water spray and the 2240 mm four-vane shearer with water spray were essentially consistent with those of the 1400 mm specification shearer, with only overlap in some areas. Meanwhile, from the on-site working pictures of the 2240 mm specification shearer, it could be seen that with the increase in haulage speed, the spalled coal was thrown out from the side of the ranging arm, which further confirmed the simulation-derived phenomenon that “the increase in haulage speed leads to the decrease in drum coal-loading rate.” All the above results verified the credibility of the simulation results.