Engineering-Scale B-Spline Surface Reconstruction Using a Hungry Predation Algorithm, with Validation on Ship Hulls

Abstract

1. Introduction

2. Related Theories and Research

2.1. B-Spline Surface Fitting

2.2. Research Status

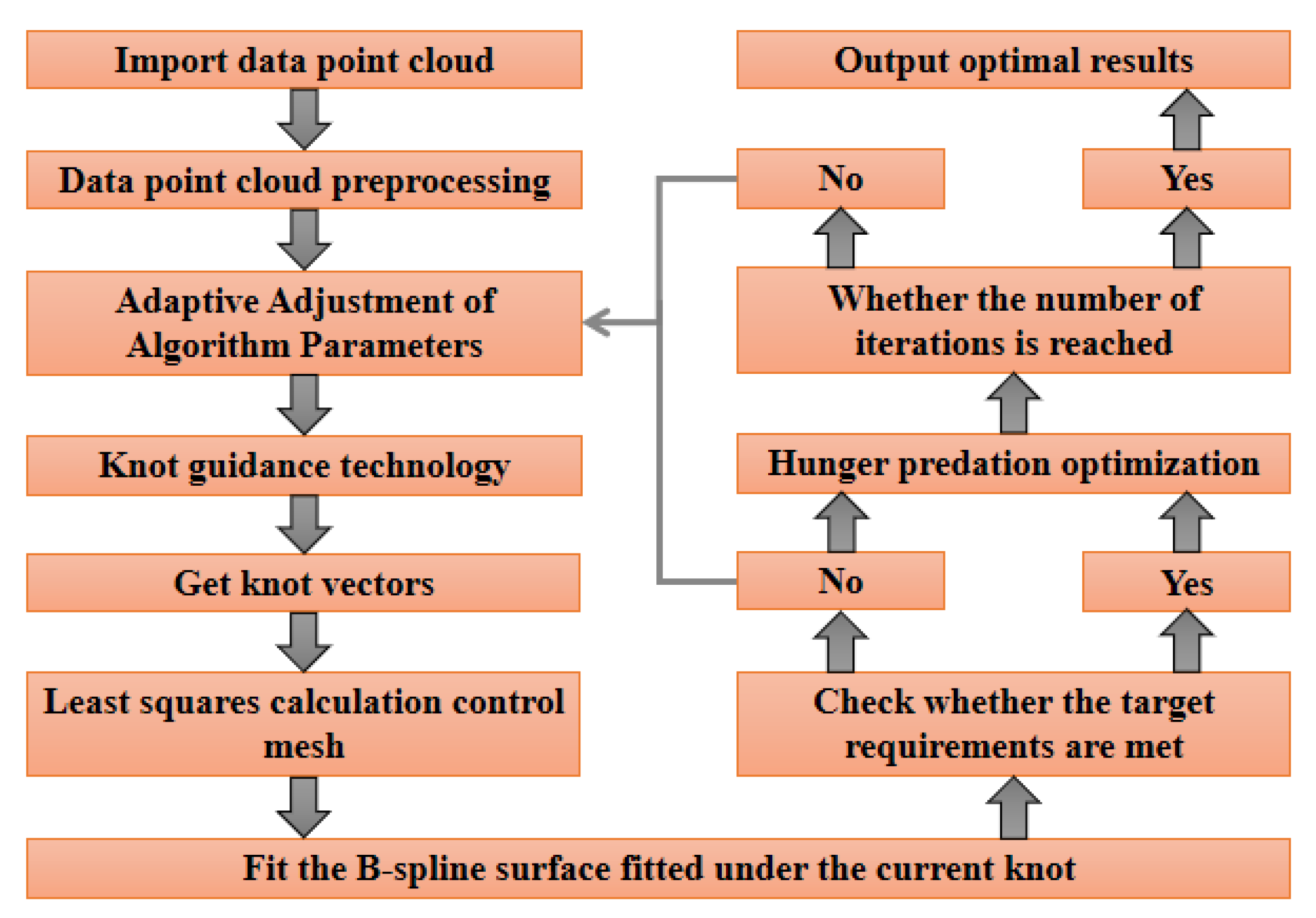

3. B-Spline Surface Fitting Based on HPA

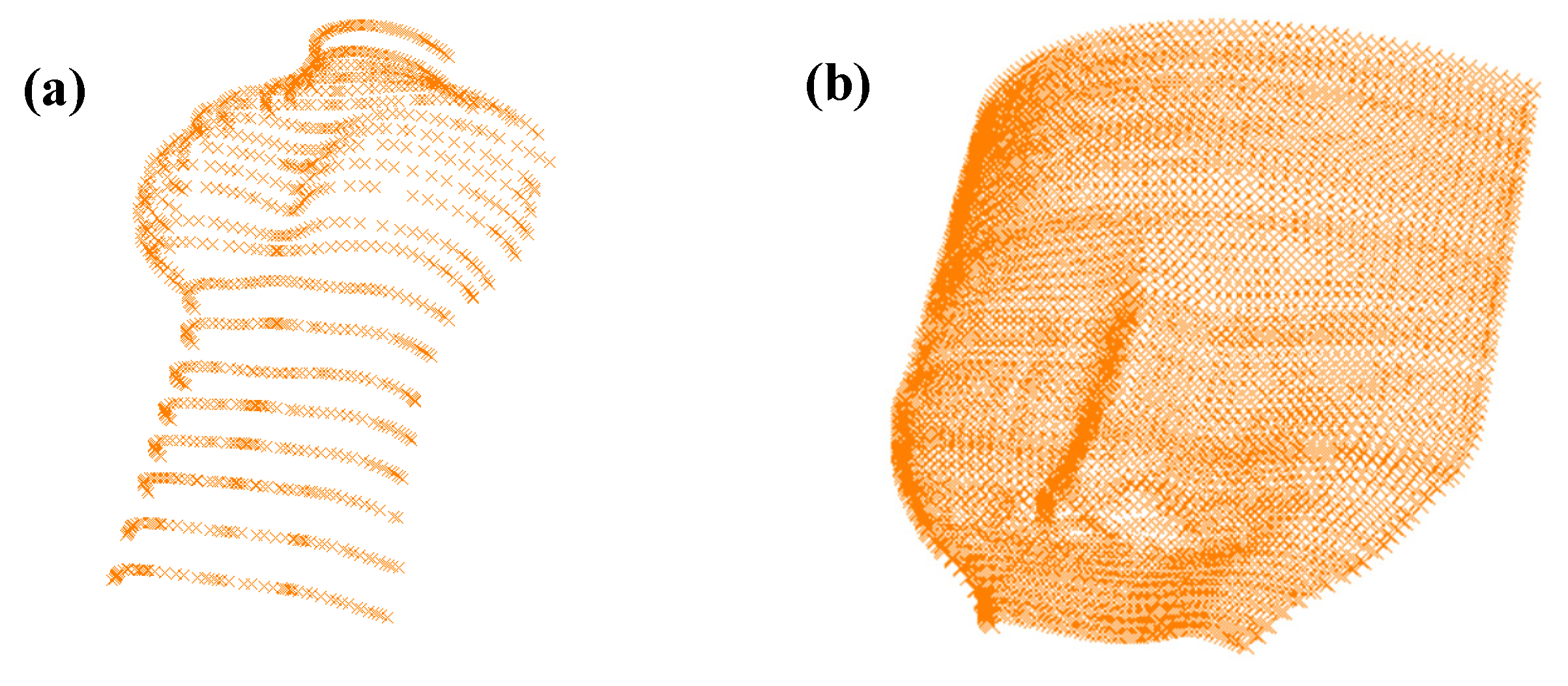

3.1. Hybrid Initial Knot Guidance Method Based on Multi-Strategy Integration

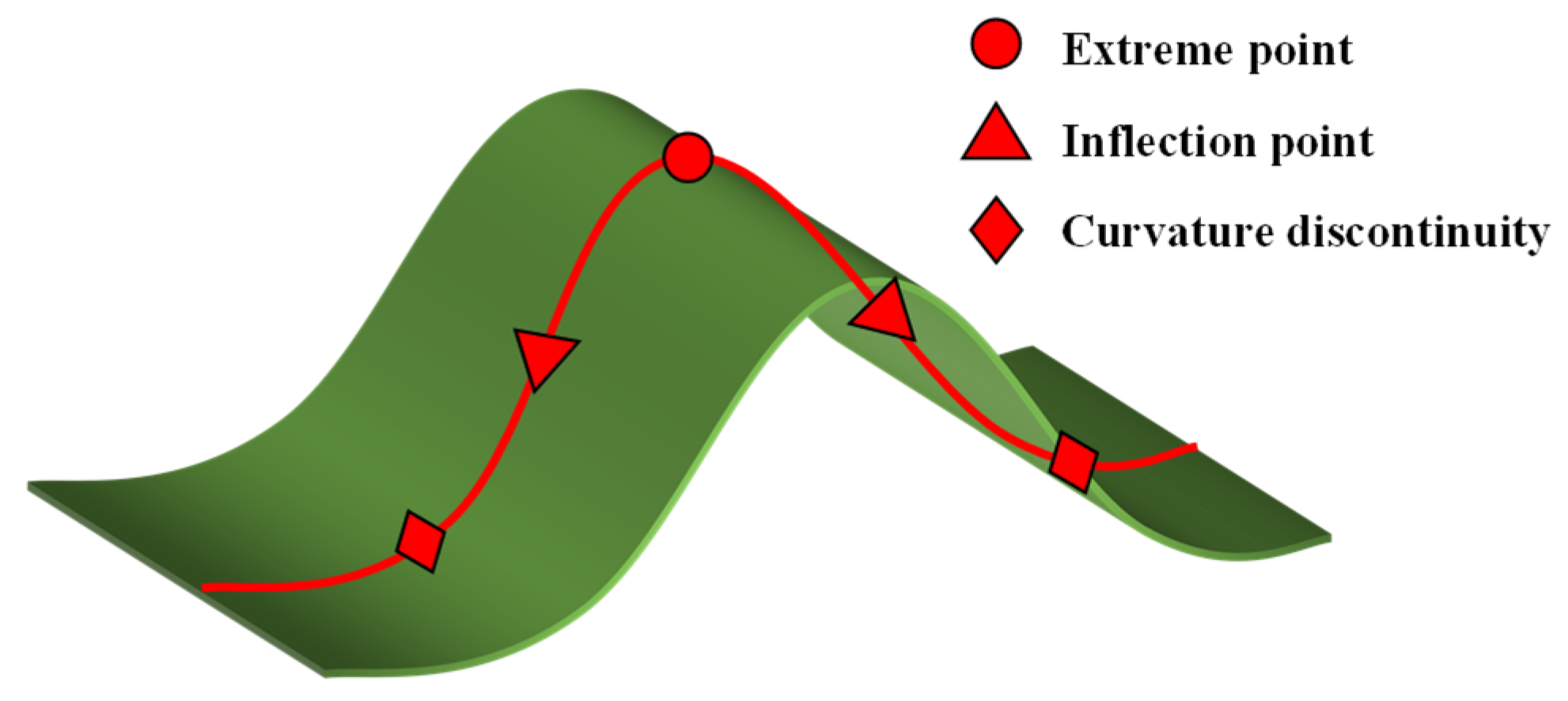

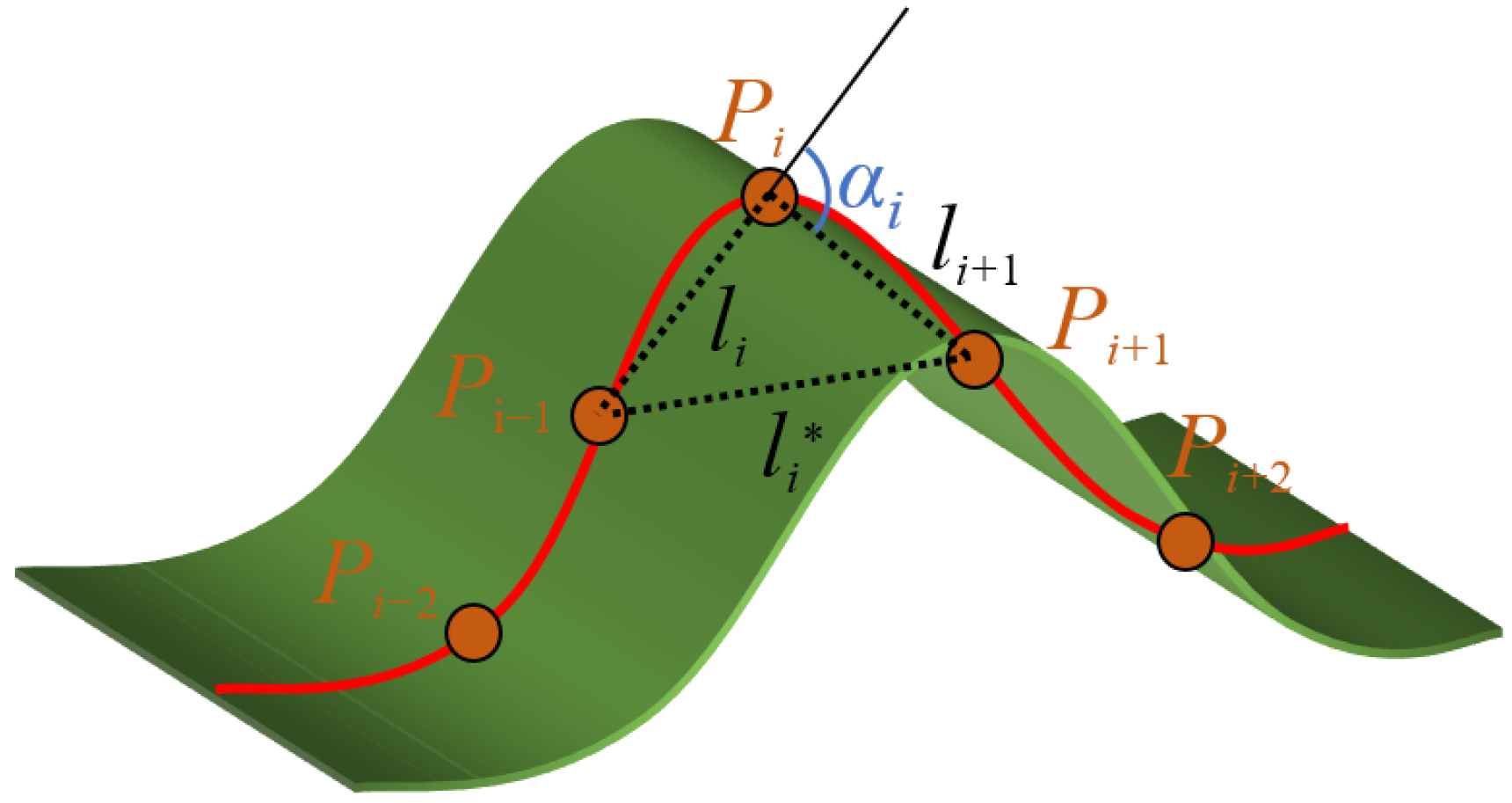

3.1.1. Geometry-Aware Knot Guidance

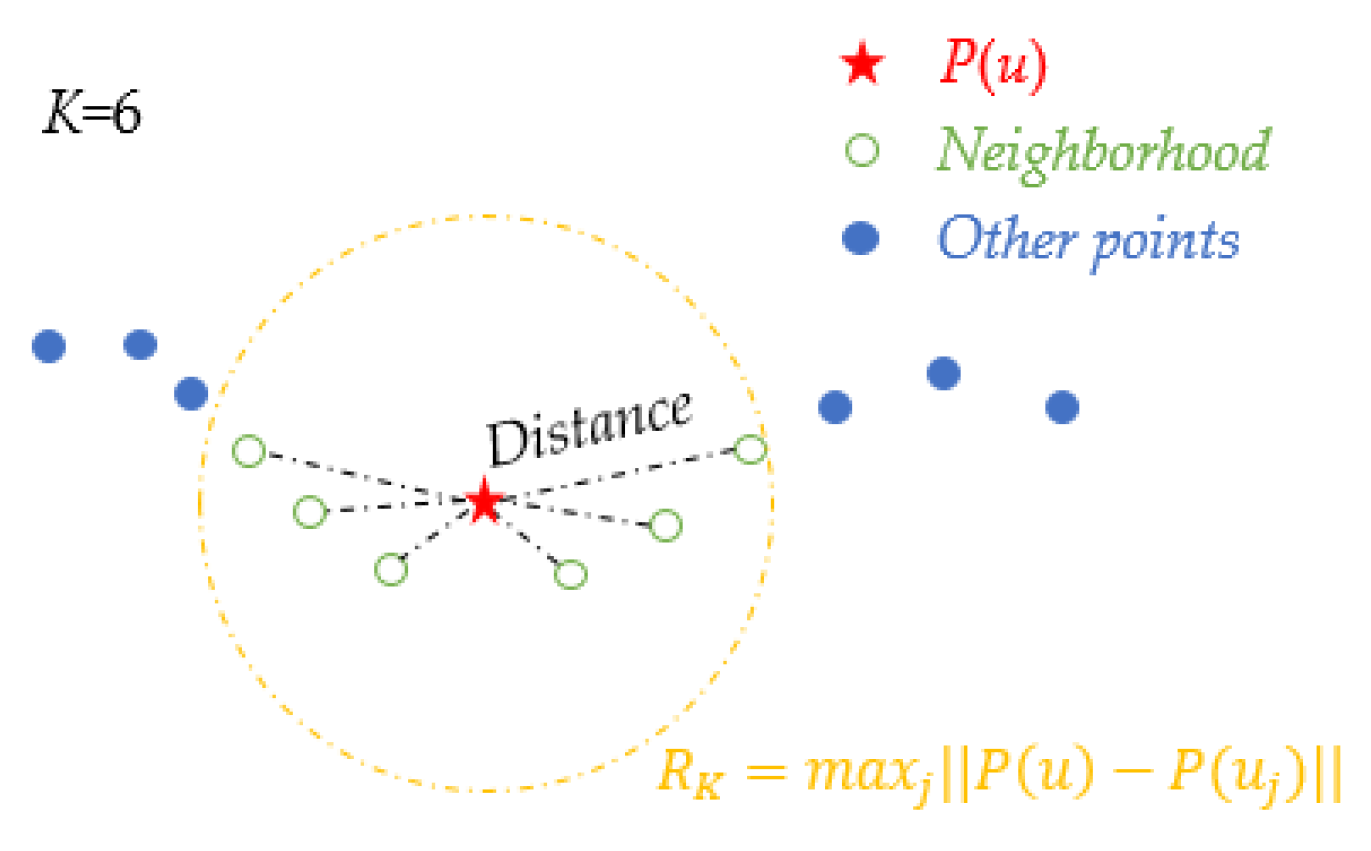

3.1.2. Complexity-Driven Probabilistic Guidance

- The identification of feature points is discrete in nature and can only guide knot placement around a limited number of critical locations, failing to capture the global geometric complexity of the surface.

- While local knot densification occurs near feature points, adjacent “semi-complex” regions may still suffer from insufficient knot density, leading to elevated local fitting errors.

- (1)

- Formulation of the Complexity Function

- (2)

- Implementation procedure for knot distribution

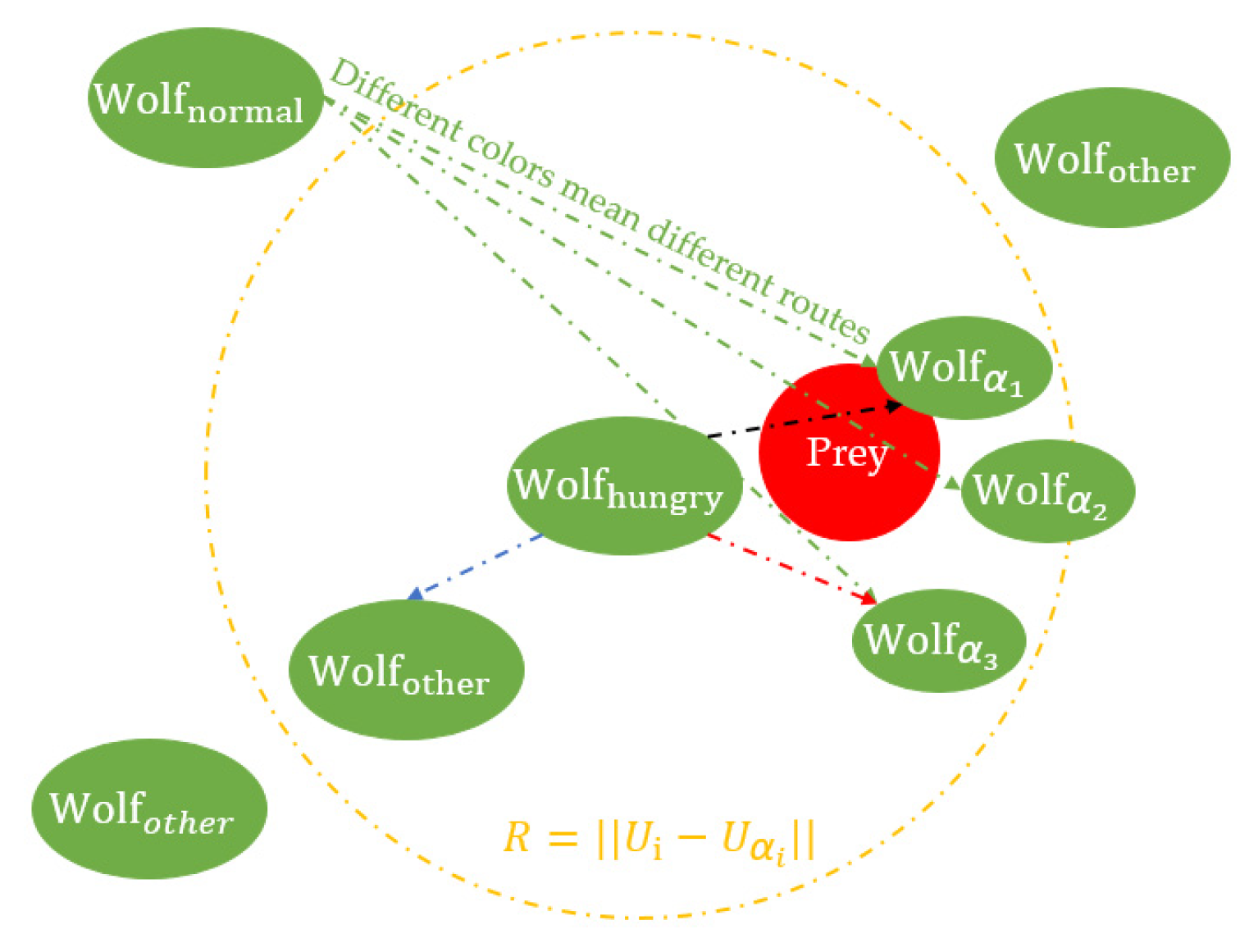

3.2. Hunger Predation Algorithm Optimization Technology

3.3. HPA Process

3.4. Adaptive Adjustment of Input Parameters

Internal Knots Number

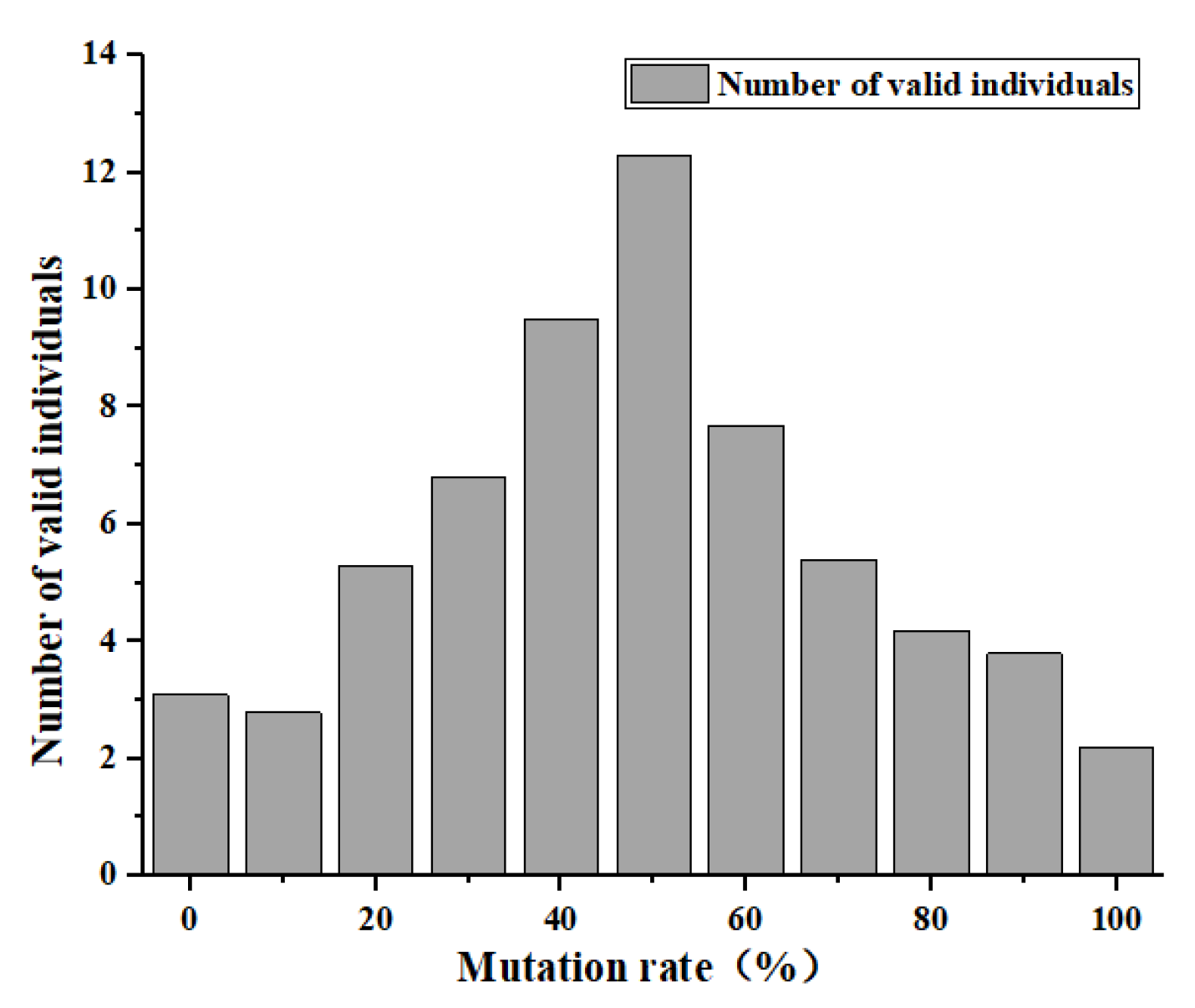

4. Surface Degree and Population Mutation Rate

Population Size and Iteration Number

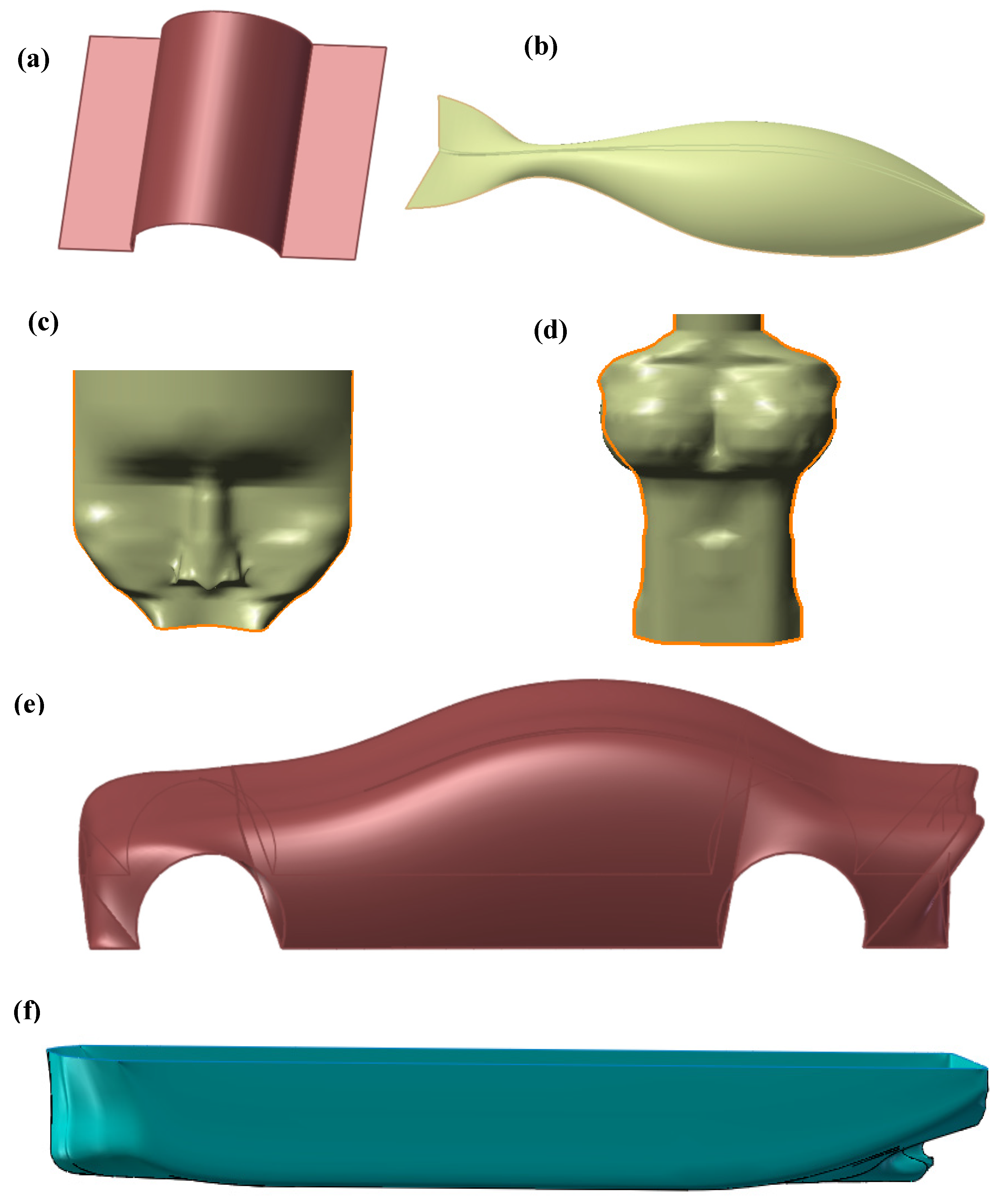

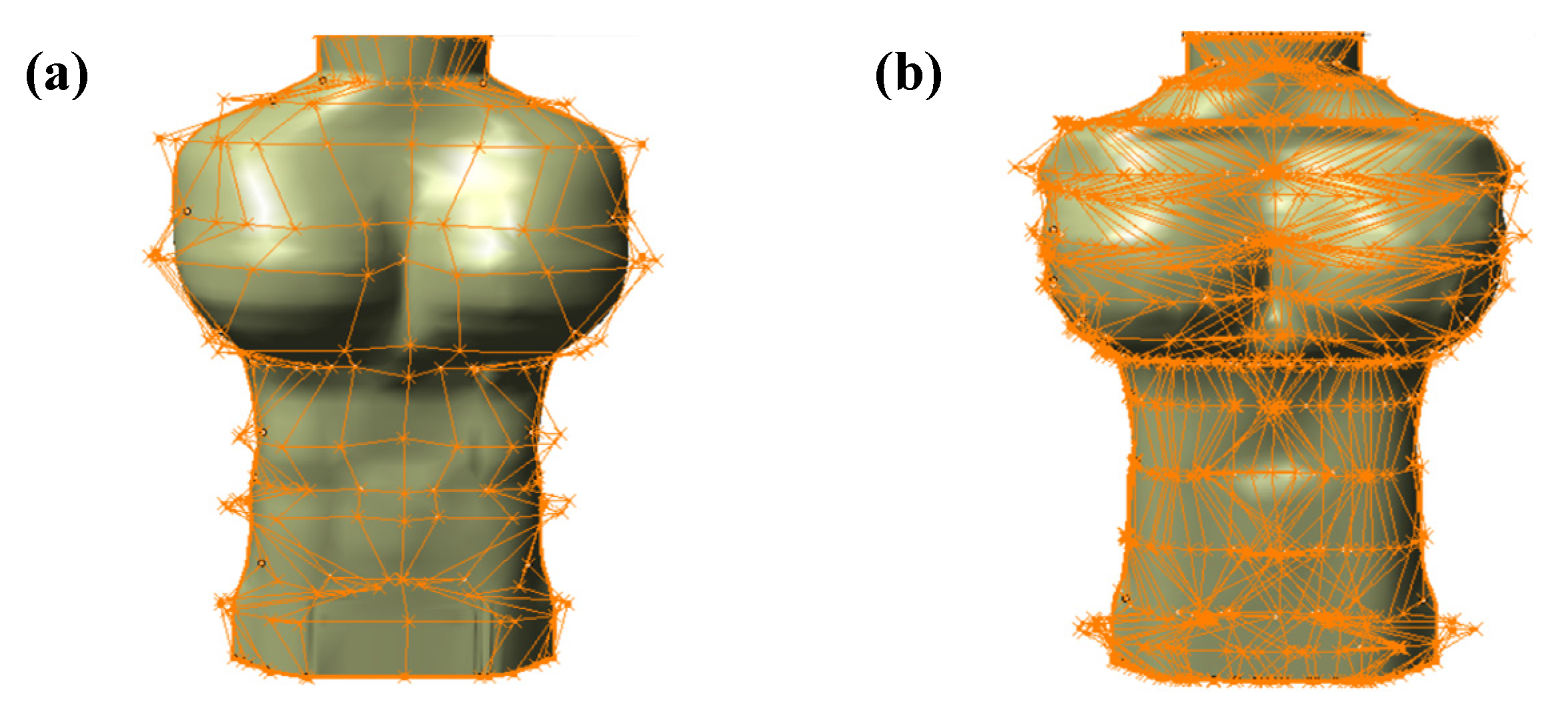

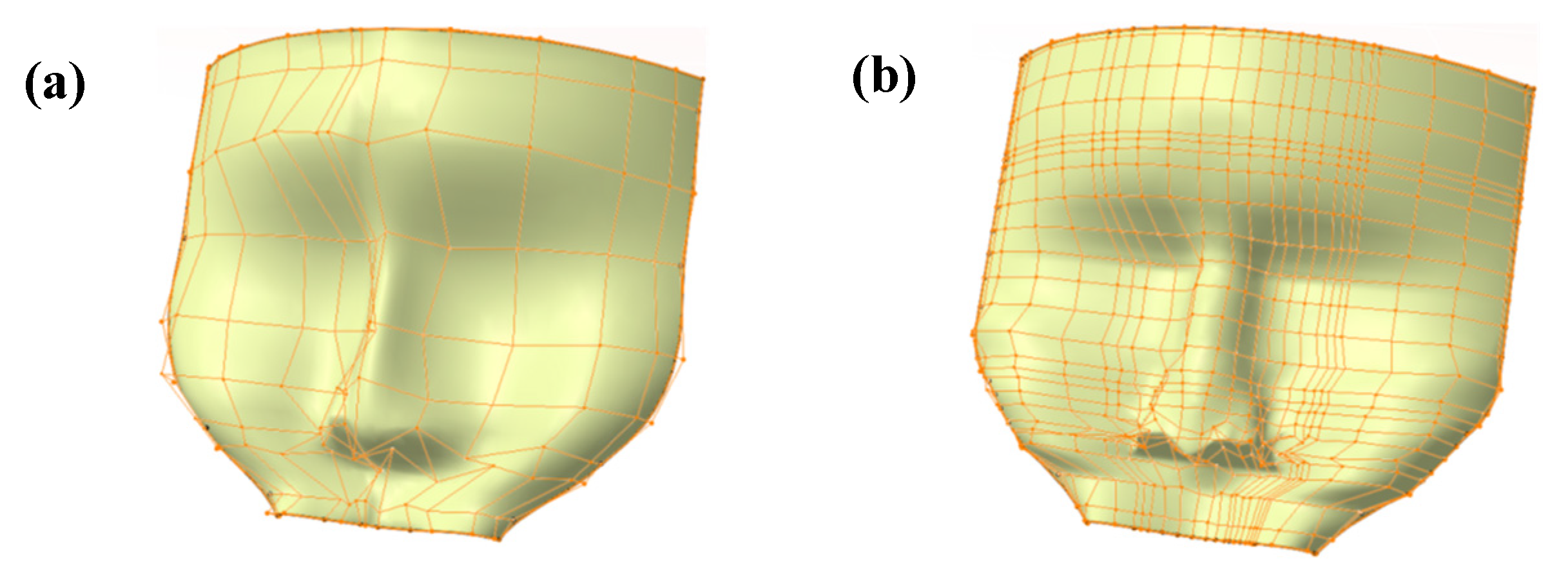

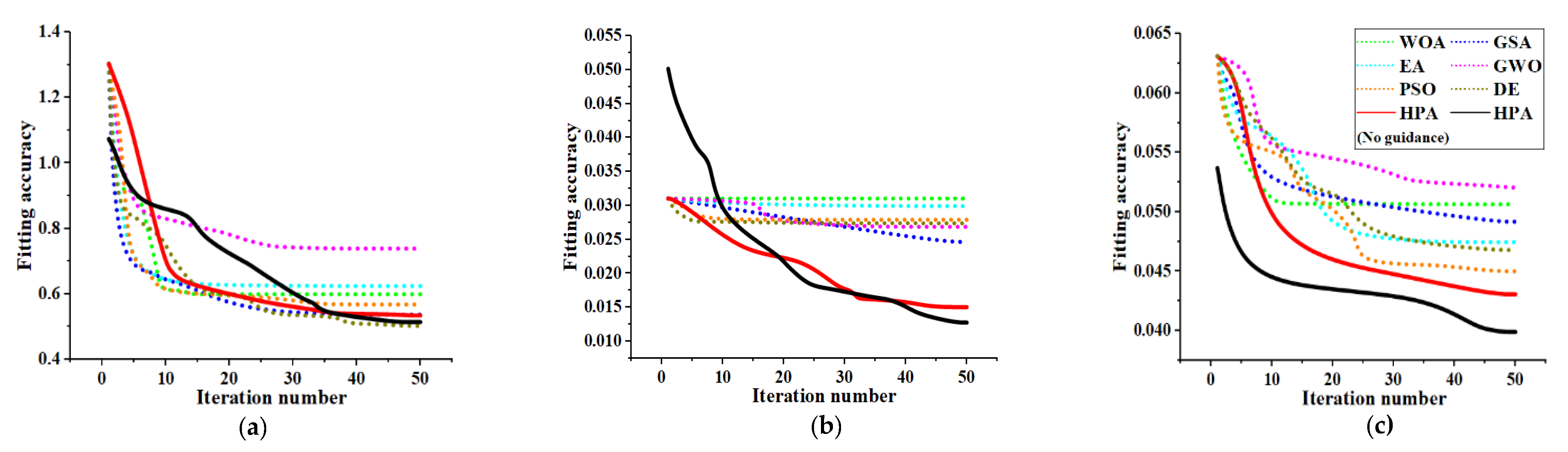

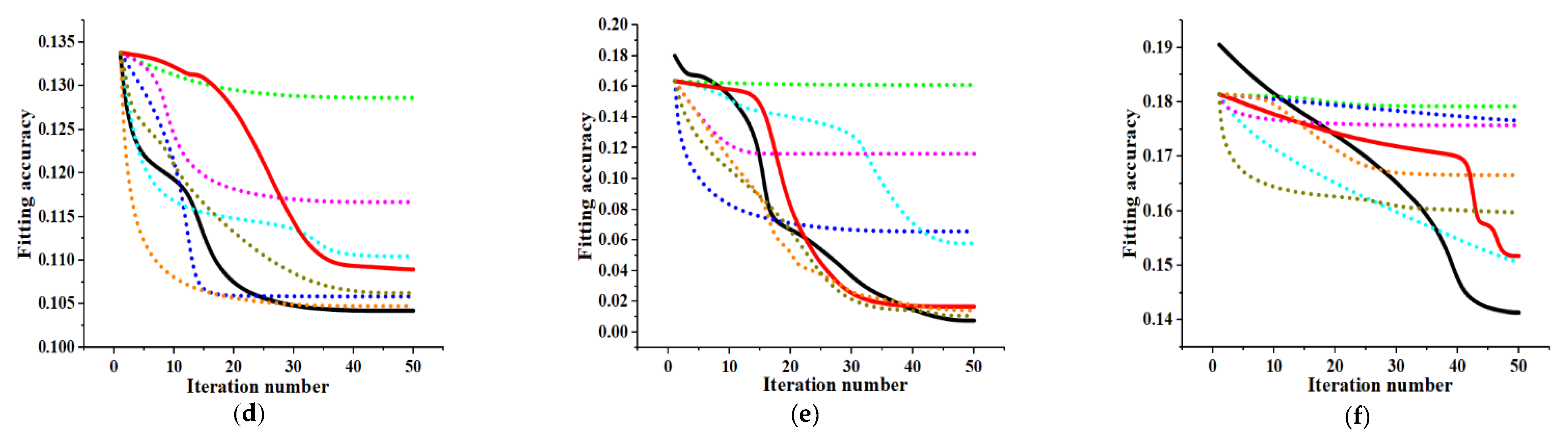

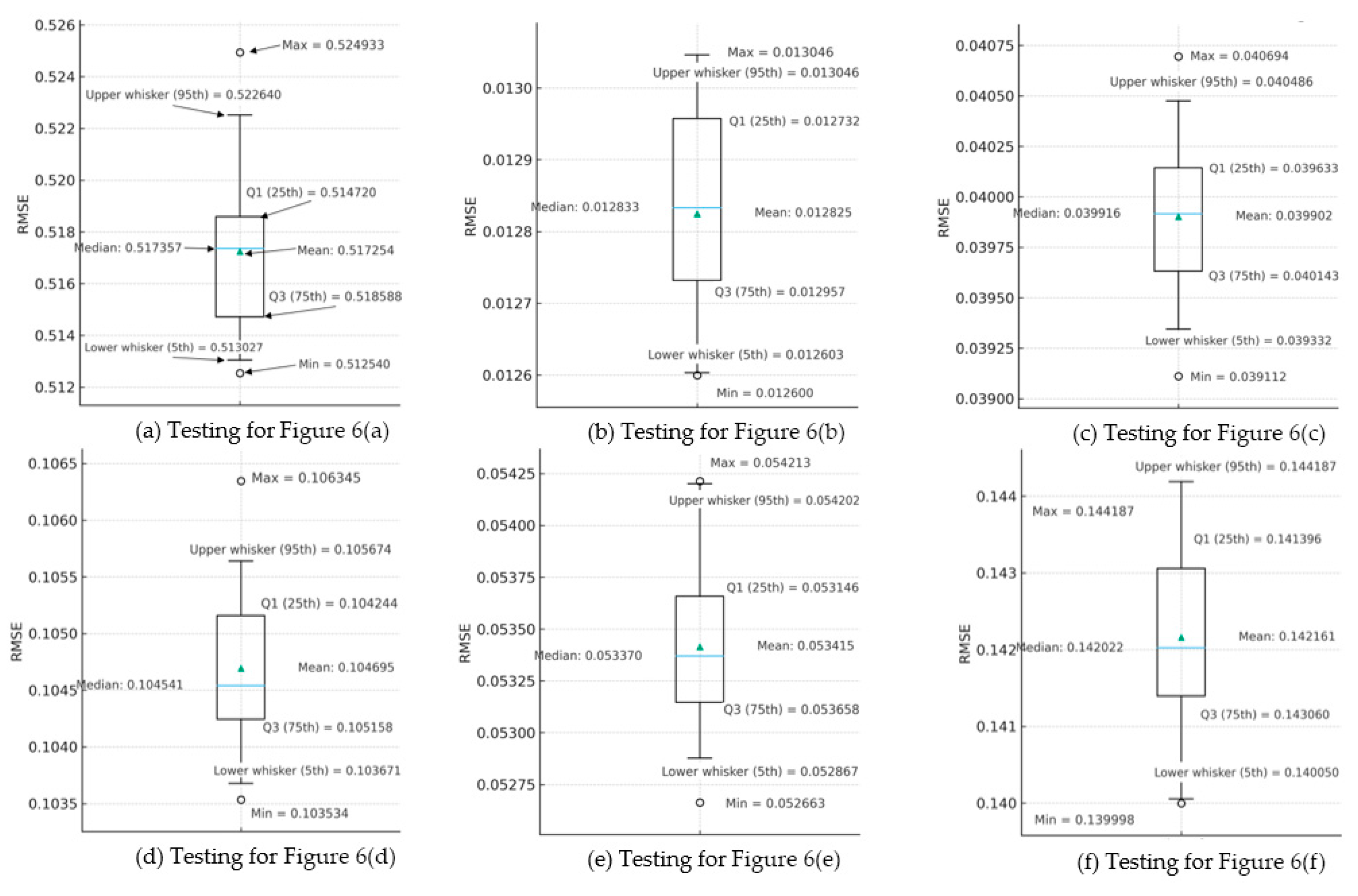

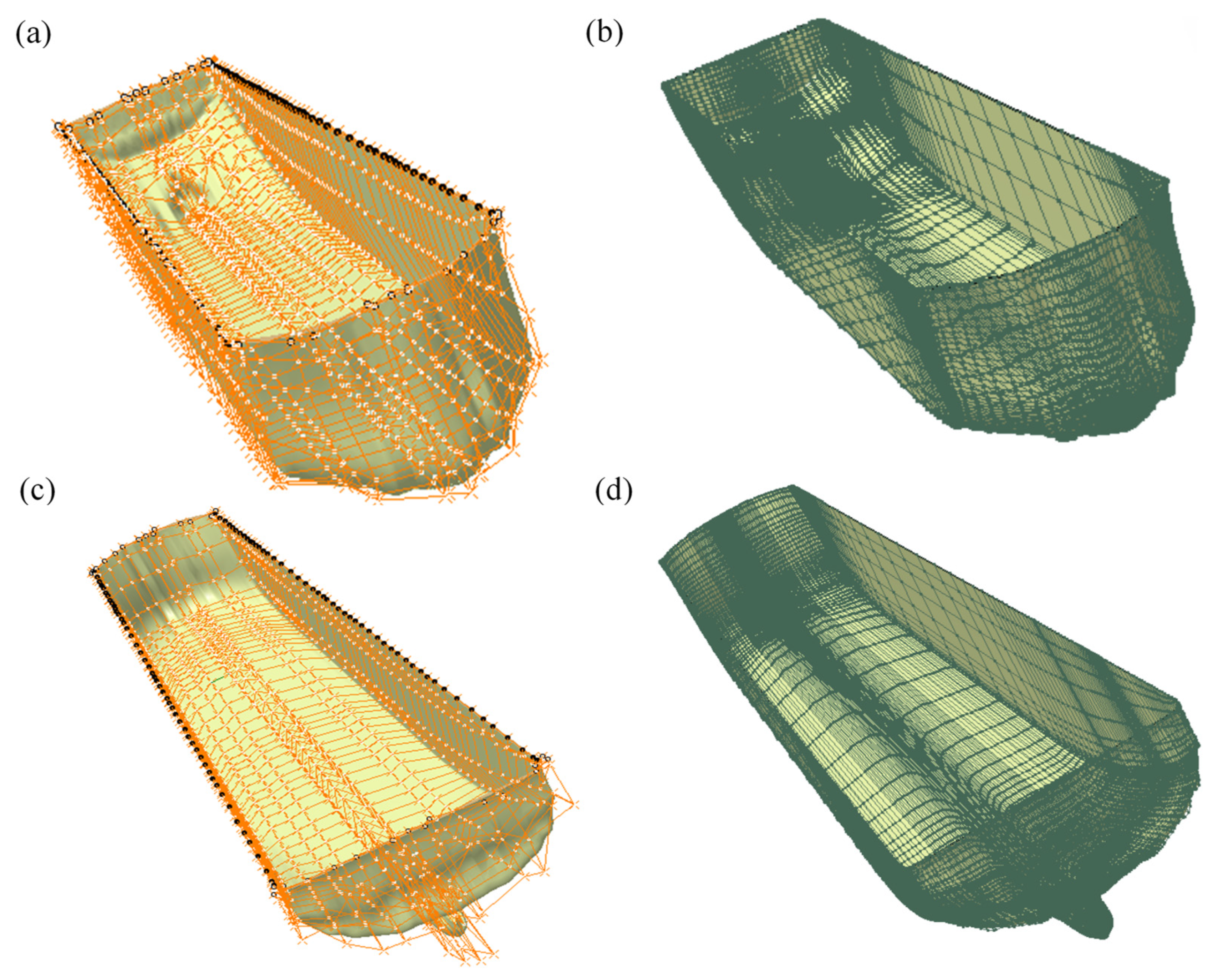

5. Experimental Comparisons

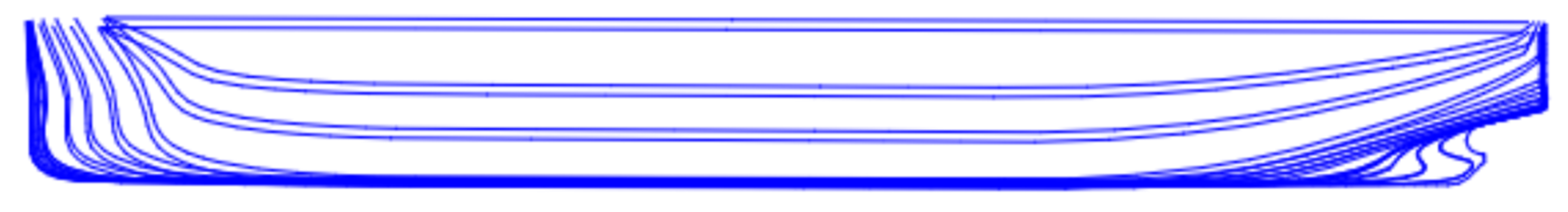

5.1. Comparison with Existing Research

5.2. Comparison with Commercial Software

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Park, H. B-spline surface fitting based on adaptive knot placement using dominant columns. CAD Comput. Aided Des. 2011, 43, 258–264. [Google Scholar] [CrossRef]

- Kawasaki, T.; Jayaraman, P.K.; Shida, K.; Zheng, J.; Maekawa, T. An image processing approach to feature-preserving B-spline surface fairing. CAD Comput. Aided Des. 2018, 99, 1–10. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, B.; Huo, G.; Su, C.; Yan, D.M.; Zheng, Z. Scattered Points Interpolation with Globally Smooth B-Spline Surface using Iterative Knot Insertion. CAD Comput. Aided Des. 2022, 148, 103244. [Google Scholar] [CrossRef]

- Piegl, L.; Tiller, W. The NURBS Book (Monographs in Visual Communication); Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Yang, L.; Ran, C.; Yu, Z.; Han, F.; Wu, W. Surface Reconstruction and Volume Calculation of Grain Pile Based on Point Cloud Information from Multiple Viewpoints. Agriculture 2025, 15, 1208. [Google Scholar] [CrossRef]

- Luo, Y.; Li, S.; Ruan, J.; Bai, J. A Space Discretization Method for Smooth Trajectory Planning of a 5PUS-RPUR Parallel Robot. Appl. Sci. 2025, 15, 9212. [Google Scholar] [CrossRef]

- Suzuki, S.; Ohtake, Y.; Suzuki, H. Curvature Gradient-estimation Using CT Sinogram and its Application to Reverse Engineering. CAD Comput. Aided Des. 2022, 148, 103240. [Google Scholar] [CrossRef]

- Albrecht, G.; Mainar, E.; Peña, J.M.; Rubio, B. A Shape Preserving Class of Two-Frequency Trigonometric B-Spline Curves. Symmetry 2023, 15, 2041. [Google Scholar] [CrossRef]

- Kovács, I.; Várady, T. Constrained fitting with free-form curves and surfaces. CAD Comput. Aided Des. 2020, 122, 102816. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Zhou, M.; Liu, L.; Liu, J.; Liu, Z.; Li, H.; Li, P. Research on 3D Modeling Method of Tunnel Surrounding Rock Structural Planes Based on B-Spline Interpolation. Appl. Sci. 2025, 15, 8142. [Google Scholar] [CrossRef]

- Dai, J.; Chai, Y.; Xiong, P. Path Planning of Underground Robots via Improved A* and Dynamic Window Approach. Appl. Sci. 2025, 15, 6953. [Google Scholar] [CrossRef]

- Zhou, H.; Shang, T.; Wang, Y.; Zuo, L. Salp Swarm Algorithm Optimized A* Algorithm and Improved B-Spline Interpolation in Path Planning. Appl. Sci. 2025, 15, 5583. [Google Scholar] [CrossRef]

- Sun, C.; Liu, M.; Ge, S. B-Spline Curve Fitting of Hungry Predation Optimization on Ship Line Design. Appl. Sci. 2022, 12, 9465. [Google Scholar] [CrossRef]

- Gálvez, A.; Iglesias, A. Particle swarm optimization for non-uniform rational B-spline surface reconstruction from clouds of 3D data points. Inf. Sci. 2012, 192, 174–192. [Google Scholar] [CrossRef]

- Gálvez, A.; Iglesias, A.; Puig-Pey, J. Iterative two-step genetic-algorithm-based method for efficient polynomial B-spline surface reconstruction. Inf. Sci. 2012, 182, 56–76. [Google Scholar] [CrossRef]

- Duan, Q.; Bao, F.; Du, S.; Twizell, E.H. Local control of interpolating rational cubic spline curves. CAD Comput. Aided Des. 2009, 41, 825–829. [Google Scholar] [CrossRef]

- Deng, C.; Lin, H. Progressive and iterative approximation for least squares B-spline curve and surface fitting. CAD Comput. Aided Des. 2014, 47, 32–44. [Google Scholar] [CrossRef]

- Crum, J.; Levine, J.A.; Gillette, A. Extending Discrete Exterior Calculus to a Fractional Derivative. CAD Comput. Aided Des. 2019, 114, 64–72. [Google Scholar] [CrossRef]

- Sánchez-Reyes, J.; Chacón, J.M. A polynomial Hermite interpolant for C 2 quasi arc-length approximation. CAD Comput. Aided Des. 2015, 62, 218–226. [Google Scholar] [CrossRef]

- Fauser, J.; Seelecke, S.; Werthschutzky, R.; Kupnik, M.; Mukhopadhyay, A.; Chadda, R.; Goergen, Y.; Hessinger, M.; Motzki, P.; Stenin, I.; et al. Planning for flexible surgical robots via bézier spline translation. IEEE Robot. Autom. Lett. 2019, 4, 3270–3277. [Google Scholar] [CrossRef]

- Lee, S.; Wolberg, G.; Shin, S.Y. Scattered data interpolation with multilevel b-splines. IEEE Trans. Vis. Comput. Graph. 1997, 3, 228–244. [Google Scholar] [CrossRef]

- Piegl, L.A.; Tiller, W. Least-squares B-spline curve approximation with arbitrary end derivatives. Eng. Comput. 2000, 16, 109–116. [Google Scholar] [CrossRef]

- Lyche, T.; Mørken, K. Knot removal for parametric B-spline curves and surfaces. Comput. Aided Geom. Des. 1987, 4, 217–230. [Google Scholar] [CrossRef]

- Razdan, A. Knot Placement for B-Spline Curve Approximation. Tech. Rep. Ariz. State Univ. 1999, 1, 8. [Google Scholar]

- Park, H.; Lee, J.H. B-spline curve fitting based on adaptive curve refinement using dominant points. CAD Comput. Aided Des. 2007, 39, 439–451. [Google Scholar] [CrossRef]

- Park, H.; Jung, H.B.; Kim, K. A new approach for lofted b-spline surface interpolation to serial contours. Int. J. Adv. Manuf. Technol. 2004, 23, 889–895. [Google Scholar] [CrossRef]

- Park, H. An approximate lofting approach for B-spline surface fitting to functional surfaces. Int. J. Adv. Manuf. Technol. 2001, 18, 474–482. [Google Scholar] [CrossRef]

- Lyche, T.; Morken, K. A date reduction strategy for splines. Ima J. Numer. Anal. 1988, 8, 185–208. [Google Scholar] [CrossRef]

- Jiang, B.; Han, J.; Tian, X.; Xia, L. B-spline surface fitting algorithm based on contour constraint points. China Mech. Eng. 2015, 26, 2016–2021. [Google Scholar]

- Yoshimoto, F.; Harada, T.; Yoshimoto, Y. Data fitting with a spline using a real-coded genetic algorithm. CAD Comput. Aided Des. 2003, 35, 751–760. [Google Scholar] [CrossRef]

- Sarfraz, M. Representing Shapes by Fitting Data using an Evolutionary Approach. Comput. Aided Des. Appl. 2004, 1, 179–185. [Google Scholar] [CrossRef]

- Gálvez, A.; Iglesias, A.; Avila, A.; Otero, C.; Arias, R.; Manchado, C. Elitist clonal selection algorithm for optimal choice of free knots in B-spline data fitting. Appl. Soft Comput. 2015, 26, 90–106. [Google Scholar] [CrossRef]

- Ülker, E.; Arslan, A. Automatic knot adjustment using an artificial immune system for B-spline curve approximation. Inf. Sci. 2009, 179, 1483–1494. [Google Scholar] [CrossRef]

- Ülker, E. B-Spline Curve Approximation Using Pareto Envelope-Based Selection, Algorithm—PESA. Int. J. Comput. Commun. Eng. 2013, 2, 60. [Google Scholar] [CrossRef]

- Valenzuela, O.; Delgado-Marquez, B.; Pasadas, M. Evolutionary computation for optimal knots allocation in smoothing splines. Appl. Math. Model. 2013, 37, 5851–5863. [Google Scholar] [CrossRef]

- Gálvez, A.; Iglesias, A. Firefly algorithm for explicit B-spline curve fitting to data points. Math. Probl. Eng. 2013, 2013, 528215. [Google Scholar] [CrossRef]

- Liu, G.; Wong, Y.; Zhang, Y.; Loh, H. Adaptive fairing of digitized point data with discrete curvature. CAD Comput. Aided Des. 2002, 34, 309–320. [Google Scholar] [CrossRef]

- Xu, S.; Guo, Y.; Qi, X.; Xia, W. Chaotic ant swarm optimization in solving curve fitting with free knot B-splines. Comput. Eng. Appl. 2014, 50, 177–182. [Google Scholar]

- Piegl, L.A.; Tiller, W. Surface approximation to scanned data. Vis. Comput. 2000, 16, 386–395. [Google Scholar] [CrossRef]

- Piegl, L.A.; Tiller, W. Reducing control points in surface interpolation. IEEE Comput. Graph. Appl. 2000, 20, 70–75. [Google Scholar] [CrossRef]

- KWeinert, T.; Surmann, J. Mehnen. Evolutionary Surface Reconstruction Using CSG-NURBS-Hybrids; University of Birmingham: Birmingham, AL, USA, 2001; pp. 1456–1463. [Google Scholar]

- Wagner, T.; Michelitsch, T.; Sacharow, A. On the Design of Optimisers for Surface Reconstruction. In Proceedings of the 9th Annual Conference on Genetic and Evolutionary Computation, London, UK, 7–11 July 2007. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Rashedi, E.; Nezamabadi-Pour, H.; Saryazdi, S. GSA: A Gravitational Search Algorithm. Inf. Sci. 2009, 179, 2232–2248. [Google Scholar] [CrossRef]

- Merino, D.I.; Reyes, E.N.; Steidley, C.W. Genetic algorithms: Theory and application. Comput. Educ. J. 2000, 10, 3–298. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential Evolution—A Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Son, M.J.; Kim, T.W. Implementation of an executable business process management model for the ship hull production design process. J. Mar. Sci. Technol. 2014, 19, 170–184. [Google Scholar] [CrossRef]

| Comparison 1 | Control Mesh | Comparison 2 | Control Mesh |

|---|---|---|---|

| Traditional approach | 1080 × 21 | NKTP [39] | 43 × 26 (tolerance rate = 0.01) |

| Piegl and Tiller’s approach [40] | 89 × 21 (per = 1.00) | 81×39 (tolerance rate = 0.001) | |

| 127 × 21 (per = 0.75) | |||

| 168 × 21 (per = 0.50) | DOM [1] | 23 × 22 (tolerance rate = 0.01) | |

| 292 × 21 (per = 0.25) | 37 × 35 (tolerance rate = 0.001) | ||

| A new approach [26] | 78 × 21 | ||

| HPA | 14 × 14 (tolerance rate = 0.01) | HPA | 14 × 10 (tolerance rate = 0.01) |

| 46 × 19 (tolerance rate = 0.001) | 25 × 25 (tolerance rate = 0.001) |

| Ref. | Method | Population | Data Points | Error | Runtime |

|---|---|---|---|---|---|

| [11] | Neural network SOM and PDE with gradient descent algorithm (GDA) | Not applicable | 104 | 10−1–10−2 | 3–6 h |

| [12] | Evolutionary algorithms (EA) | 30–50 | Not reported | Not reported | Tens of minutes to hours |

| [41] | Evolutionary search (ES) and genetic programming (GP) | 500 | 192 | 10−2 | 24 h |

| [42] | Multi-objective evolutionary and genetic algorithm (MOEA) | 20 | 823–17,307 | 10−2 | Tens of hours to days |

| [15] | Iterative two-steps genetic algorithm with SVD/LU mod LSQ fitting | 50–500 | 6000–14,400 | <10−4 | Tens of seconds to 3 h |

| Our method | HPA | 20 | 1260–10,000 | 10−1–10−3 | Tens of seconds to minutes |

| Optimization | Greedy Algorithm | Parameter Settings |

|---|---|---|

| WOA | × | Parameter of logarithmic spiral b = 1 |

| GSA | × | Initial value G0 = 100, Initial speed v0 = 0 |

| EA | × | Crossover rate = 0.8, Mutation rate = 0.05 |

| GWO | × | No parameters need to be set |

| HPA | × | Mutation rate of knots = 0.5, Hunger search rate = 0.6 |

| PSO | × | Inertial coefficient W = 0.4, Initial speed v0 = 0.1 |

| DE | √ | Scale factor F = 0.5, Crossover rate = 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Sun, C.; Ge, S. Engineering-Scale B-Spline Surface Reconstruction Using a Hungry Predation Algorithm, with Validation on Ship Hulls. Appl. Sci. 2025, 15, 11471. https://doi.org/10.3390/app152111471

Liu M, Sun C, Ge S. Engineering-Scale B-Spline Surface Reconstruction Using a Hungry Predation Algorithm, with Validation on Ship Hulls. Applied Sciences. 2025; 15(21):11471. https://doi.org/10.3390/app152111471

Chicago/Turabian StyleLiu, Mingzhi, Changle Sun, and Shihao Ge. 2025. "Engineering-Scale B-Spline Surface Reconstruction Using a Hungry Predation Algorithm, with Validation on Ship Hulls" Applied Sciences 15, no. 21: 11471. https://doi.org/10.3390/app152111471

APA StyleLiu, M., Sun, C., & Ge, S. (2025). Engineering-Scale B-Spline Surface Reconstruction Using a Hungry Predation Algorithm, with Validation on Ship Hulls. Applied Sciences, 15(21), 11471. https://doi.org/10.3390/app152111471