1. Introduction

The food system is a significant contributor to anthropogenic greenhouse gas emissions, responsible for over one-third of global emissions [

1]. Of these, 18% are attributed to the supply chain and 6% to food transport, while a considerable proportion result from livestock farming, manure management, and the use of agricultural machinery [

2]. Approximately 63% of food-related greenhouse gas emissions originate from the production and consumption of animal-based products [

3]. Plant cultivation has a significantly lower environmental impact compared to the production of animal-based products, largely due to the complexity and resource intensity of animal agriculture; in fact, the carbon footprint of meat is several to dozens of times higher than that of most fruits and vegetables [

4]. Therefore, reducing the consumption of animal-based products appears environmentally beneficial, highlighting the need to develop combined food products in which animal ingredients are partially substituted with plant-based components. In parallel, growing concerns about the environmental and health impacts of the modern food system are driving the development of next-generation plant-based products to meet increasing consumer demand [

5].

The processing of animal and plant raw materials significantly impacts sustainability due to energy consumption, water use, and greenhouse gas emissions. In particular, it has been established that pasteurization and homogenization are the main contributors to the carbon footprint of ice cream production, regardless of the ingredients used or production scale [

6]. Therefore, optimizing these energy-intensive processes is essential for reducing environmental impact and promoting sustainable practices in the food industry.

Ice cream is a delicious frozen dessert that comes in a variety of flavors, colors, textures and ingredients. Its sensory appeal makes it a favorite with people of all ages [

7]. Ice cream has a unique texture that brings feelings of happiness and relaxation to consumers [

8]. There are many different types of ice cream on the market, including dairy ice cream, non-dairy ice cream, gelato, frozen yogurt, milk ice cream, sherbet, sorbet, water ice and fruit ice cream [

9].

Ice cream is a complex multi-phase food consisting of fat globules, air cells and ice crystals dispersed in a semi-frozen mixture [

10]. The main ingredients of ice cream are fat, milk solids (non-fat), sugar or sweeteners, flavorings (such as vanilla, cocoa or fruit extracts), stabilizers and emulsifiers [

11]. Ice cream is relatively high in fat and sugar, contributing to high intakes of these nutrients by consumers [

12]. As a result, manufacturers and researchers have attempted to modify the original recipes to develop functional ice cream and frozen desserts with lower fat and calorie content, while retaining the original taste, texture, and melting resistance [

11]. Reducing the fat and sugar content, replacing them or increasing protein content, and incorporating bioactive compounds can enhance the functional and nutritional properties of ice cream and frozen desserts [

13].

The ingredients used for ice cream fortification can be systematized into functional categories, including bioactive plant-based additives, dietary fibers, protein fortifiers, mineral and vitamin enrichment, prebiotic and probiotic components, synbiotic, natural antioxidants (e.g., polyphenols), functional pigments and microalgae, hydrocolloids, dairy by-products, and plant-based fat or milk alternatives [

14,

15,

16]. Specifically, for the fortification of ice cream and frozen desserts, ingredients such as turmeric and black pepper [

17], beet pectin and probiotic microorganisms [

18], green mate and lemon balm, ginger powder, dried grape, honey, and curcumin-loaded nanoemulsions [

19] are commonly used. Spices, including the aromatic parts of tropical plants such as dried fruits, seeds, roots or bark, are also used to fortify, flavor and color ice cream [

7]. Inulin, spirulina, or phycocyanin extract have made it possible to produce ice cream with physical characteristics similar to the original recipes [

13]. The physicochemical properties of ice cream can also be enhanced by incorporating various hydrocolloids [

19]. Whey permeate powder can be used in ice cream intended for extended storage, even at lactose levels previously considered too high for ice cream [

20]. Replacing dairy ingredients with plant-based alternatives like hempseed press cake supports sustainable food production by reducing environmental impact and utilizing nutritious by-products [

21]. Replacing milk with buttermilk and ricotta whey in ice cream promotes sustainability by reducing waste and adding value to a dairy by-product without compromising the quality of the ice cream [

22,

23]. Studies have shown that enriching ice cream with additives from processing by-products such as egg components and animal blood derivatives can improve quality while promoting waste valorization and sustainability [

24]. Mealworm powder fortification significantly enhances the nutritional, antioxidant, and physical properties of ice cream, demonstrating its potential as a sustainable ingredient for producing high-quality products [

25]. Previous studies have demonstrated that mango seed kernel and cheese whey waste possess valuable components that can be utilized to develop ice cream bases with superior physicochemical, functional, and sensory characteristics [

26]. Oleogel derived from strawberry seed oil has been used as a fat component in ice cream formulations, contributing to more sustainable production by utilizing plant-based, renewable resources [

27]. Almond drink has been proposed for vegan ice cream production as a sustainable alternative, offering the potential to minimize environmental impact, aligning with the priorities of environmentally conscious producers [

28].

Plant-based milk is a popular alternative to cow’s milk. The market for plant-based dairy products is expected to experience significant growth in the coming years [

29]. Although classified as ultra-processed foods, such products are widely perceived as safe, healthy, ethical, and environmentally sustainable [

30]. Soy milk, like other plant-based milk alternatives, is increasingly being used as a substitute for dairy milk in ice cream recipes. Their use makes it possible to create a product with similar physicochemical properties, textures and flavors to traditional dairy ice cream [

31]. Although plant-based ice cream provides functional benefits, it is more complicated to formulate and requires more ingredients to achieve the taste and texture that consumers demand.

Sustainability of food products is commonly assessed through their carbon and water footprints, with greenhouse gas emissions (CO

2-eq per kg of product) serving as a key indicator. Among plant-based alternatives, soy milk demonstrates a significantly lower environmental footprint compared to cow’s milk, making it a more sustainable option [

32]. Based on the current findings [

33], daily consumption of one glass (0.25 kg) of soy drink instead of conventional milk could reduce carbon emissions from 0.35 kg to 0.1 kg CO

2-eq per capita, saving approximately 0.25 kg CO

2-eq per day. Therefore, soy-based beverages represent a viable substitute for cow’s milk and contribute to the achievement of food security goals [

34]. Also, a cost-effective and optimized zero-waste soybean processing technology has been developed to minimize by-product waste and promote a sustainable food system [

35]. It should be noted that the area planted with genetically modified (GM) soybean has steadily increased, with a significant proportion of the total soybean cultivation now consisting of GM varieties [

36]. Nevertheless, products derived from genetically modified crops may elicit concerns among consumers.

Soy protein is regarded as a high-quality protein with a PDCAAS of 1.00, featuring a well-balanced profile of essential amino acids comparable to animal proteins such as meat and dairy, although it is somewhat limited in sulfur-containing amino acids like methionine [

37]. No notable differences were found in the amino acid profiles between soybeans and their derived products [

36]. The mean DIAAS value for soy-based products is approximately 84.5 ± 11.4%, which reflects generally good protein quality [

38]. Among these, soymilk exhibited the highest DIAAS, highlighting its comparatively better protein quality [

38]. Based on the amino acid requirements for children aged 0.5 to 3 years, soymilk demonstrated a DIAAS range of 78% to 88%, qualifying it as a protein source of “good” nutritional quality [

39]. Soy protein may trigger allergic reactions in susceptible individuals and is recognized as one of the eight major food allergens [

40]. Glycinin and

β-conglycinin are recognized as the main allergenic proteins present in soy [

40,

41].

Soy ice cream, characterized by a neutral pH, elevated total solids content, and the presence of prebiotic oligosaccharides, serves as an effective matrix for delivering probiotics [

42]. Substituting milk fat with soybean oil body increases apparent viscosity and droplet uniformity, reduces particle size in ice cream mixes, improves melting and textural properties, and enhances the content of unsaturated fatty acids with potential health benefits [

43]. Soy protein isolates contribute to the structural stability of ice cream, resulting in reduced melting rates and improved shape retention [

44]. Alongside the benefits of using soy milk in ice cream recipes, certain drawbacks also exist; notably, soy milk has a characteristic beany flavor that may be undesirable to some consumers. The addition of cinnamon extract improves the flavor of soy milk and increases the total phenolic content and antioxidant activity in the ice cream [

45]. Soy milk is essentially an aqueous extract of whole soybeans, which has become popular due to its high content of monounsaturated and polyunsaturated fatty acids and oils, high-quality protein, phosphatidylcholine, B vitamins, calcium, amino acids, and other components, including natural antioxidants such as isoflavones or phytoestrogens [

46]. Soy milk powder is a promising substitute for dairy products and can be used in ice cream recipes. It is an edible powder obtained by spray-drying soy milk, which is rich in iron, unsaturated fatty acids, and niacin [

47].

Developing frozen desserts in which part of the cow’s milk is replaced with soy milk can help address the environmental impacts and sensory challenges associated with using solely animal- or plant-based ingredients.

The aim of this study was to develop plant-based frozen dessert recipes containing soy milk and to investigate their physicochemical characteristics, air bubble structure, and sensory properties.

3. Results and Discussion

The results of the physicochemical analysis of the frozen dessert samples and their mixtures are presented in

Table 3. The pH values of the frozen dessert mixtures ranged from 6.2 to 6.9. The control sample (S1), which contained no plant-based milk, exhibited the lowest pH (6.2 ± 0.1). As the proportion of plant-based milk in the mixture increased, the pH value also increased. This can be attributed to the fact that the pH of pasteurized cow’s milk (6.73 ± 0.04) is lower than that of soy milk (8.27 ± 0.04) [

56]. The pH values of the melted dessert samples ranged from 7.1 to 7.5. The trend in pH variation was similar to that observed in the frozen dessert mixtures: as the proportion of soy milk increased, the pH also increased. The pH values obtained for the frozen dessert containing soy milk are in agreement with those reported by other researchers for soy milk-based ice cream, which ranged from 7.28 to 7.37 [

57]. Nevertheless, other research findings indicate that the pH of ice cream produced using soy milk ranges between 6.56 and 6.70 [

58]. The pH of ice cream varies depending on the type of plant-based milk used in its formulation. Specifically, ice cream made with almond milk has a pH of 6.1–6.2 [

59]; with hemp milk, 3.80–5.30 [

59]; with coconut milk, 5.90–5.95 [

60]; with cashew milk, 7.00–7.10 [

61]; and with hazelnut milk, 6.19–6.56 [

62].

The specific gravity of the unmelted frozen dessert samples ranged from 589.0 to 634.4 kg/m

3 (

Table 3). The sample without soy milk exhibited the lowest specific gravity—589.0 ± 6.4 kg/m

3. As the proportion of soy milk in the frozen dessert increased, the specific gravity also increased. This can be attributed to the higher specific gravity of soy milk (1037.6 ± 2.5 kg/m

3) compared to that of cow’s milk (1028.0 ± 1.3 kg/m

3). According to S. K. El-Samahy et al. [

50], the specific gravity of hard ice cream ranges from 710 to 860 kg/m

3. Therefore, frozen dessert has a lower specific gravity than hard ice cream.

The total solids content in the frozen dessert samples containing soy milk increased as the proportion of plant-based milk increased (

Table 3). The total solids content of the soy milk frozen dessert samples (24.59–28.99%) was higher than that of the control sample, which had 20.61 ± 0.12% (

Table 3). A. M. Asres et al. [

51] also reported that increasing the soy milk content in ice cream from 50% to 100% resulted in an increase in total solids from 31.07% to 34.13%, respectively. Similarly, S. Ahsan et al. [

57] found that the total solids content of soy milk-based ice cream ranged from 32.17% to 32.63%. Other studies reported that ice cream made with soy milk contains 33.67–34.23% total solids [

58]. The total solids content depends on the type of plant-based milk used in the formulation. Specifically, ice cream made with coconut milk contains 32.72–32.74% total solids [

60], while ice cream made with hazelnut milk contains 34.80–36.77% total solids [

62].

Currently, there are no established standards defining the required level of total solids in frozen desserts made with plant-based milk alternatives. The total solids content in the analyzed samples was determined by the specific combination and proportion of ingredients used in each formulation. The total solids content of the developed frozen desserts was generally lower than that found in traditional ice cream made with various types of milk.

The moisture content of the frozen dessert samples ranged from 71.01% to 79.39% (

Table 3). The highest moisture content was observed in the control sample S1, which contained no plant-based milk. As the proportion of plant-based milk in the frozen dessert increased, the moisture content decreased. These results align with those reported by A. M. Asres et al. [

51], who found that increasing the soy milk content in ice cream from 25% to 100% resulted in a decrease in moisture content from 69.0% to 65.87%.

The ash content of the control frozen dessert sample was 0.33 ± 0.01% (

Table 3). As the proportion of soy milk in the frozen dessert increased from 15% to 60%, the ash content also increased, rising from 0.58 to 0.98%. Previous studies have shown that the ash content of soy milk-based ice creams ranges from 0.90 to 1.77% [

57] and from 0.51 to 1.19% [

51]. For comparison, the ash content in ice cream made with coconut milk is 0.46–0.67% [

60], while in ice cream made with cashew nuts, it is 0.62–0.93% [

63].

The overrun of the frozen dessert samples containing soy milk ranged from 50.1 to 73.2% (

Table 3). The overrun decreased as the proportion of soy milk increased. The control sample (S1) exhibited the highest overrun value of 87.8 ± 3.5%. A. M. Asres et al. [

51] reported that when the soy milk content in ice cream increased from 25 to 100%, the overrun remained almost unchanged, maintaining a value close to 83%. However, S. Ahsan et al. [

57] found that the overrun of soy milk-based ice cream ranged from 39.42 to 60.85%. Other studies reported an overrun of soy-based ice cream ranging from 88.94% to 89.32% [

58].

The frozen dessert without soy milk exhibited the highest melting resistance, at 77.8 ± 1.2% (

Table 3). As the soy milk content in the frozen dessert samples increased from 15 to 60%, the melting resistance decreased from 72.8 ± 1.6% to 54.1 ± 1.2%, respectively. The values for this parameter in soy milk-based ice cream have been reported to vary widely in other studies, ranging from 10.41 to 15.54% in a 10 min test at 25 °C [

56] to 83.67–84.50% in a 15 min test at 24 °C [

51].

Notably, the overrun and melting resistance values exhibit a strong correlation. Sample S1, which has the highest overrun (87.8%), also demonstrates the greatest melting resistance (77.8%), suggesting that increased air incorporation enhances structural stability during melting. In contrast, sample S5, with the lowest overrun (50.1%), showed the poorest melting resistance (54.1%). According to K. Sakurai et al. [

64], ice cream with lower overrun tends to melt more quickly, whereas higher overrun results in slower melting and improved resistance. However, another study suggests that overrun may not be a significant factor influencing the melting rate of ice cream [

65].

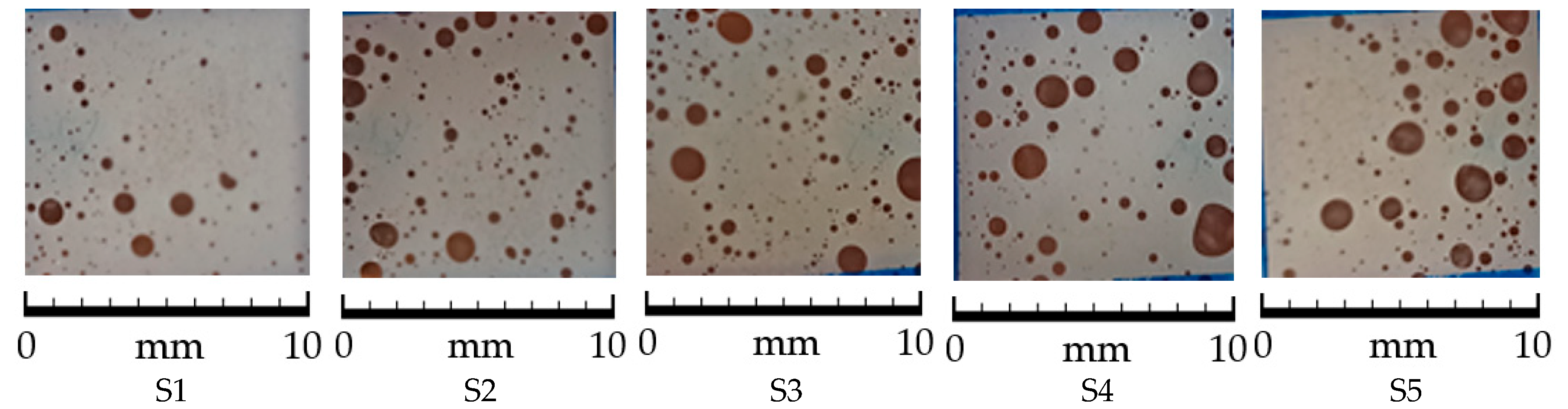

The results of the air cell size distribution analysis in the frozen dessert samples are presented in

Table 4. The majority of air cells in all samples had a diameter smaller than 0.1 mm. In the control sample, 86.2% of the air cells were smaller than 0.1 mm. As the proportion of soy milk in the frozen dessert increased from 15 to 60%, the proportion of air cells smaller than 0.1 mm decreased from 66.2 to 52.7%. The proportion of air cells measuring between 0.10 and 0.30 mm in the frozen dessert samples ranged from 6.5 to 23.8%. The control sample contained the fewest cells of this size (6.5%), while the S5 sample exhibited the highest proportion (23.8%). As a result, the addition of soy milk to the frozen dessert recipe led to an increase in the number of cells larger than 0.1 mm. Furthermore, increasing the soy milk content resulted in a higher proportion of air cells larger than 0.5 mm, rising from 9.0% in the S2 sample to 14.5% in the S5 sample. In contrast, although the number of air cells between 0.31 and 0.50 mm was higher in the frozen dessert samples made with soy milk compared to the control sample, the proportion of these cells decreased as the soy milk content increased, from 14.6% in the S2 sample to 9.0% in the S5 sample.

As shown in

Figure 1, the frozen dessert samples made with soy milk contained a greater proportion of larger air cells than the control sample, which contained a higher proportion of smaller air cells. Previous studies have shown that microstructural analysis of ice cream samples reveals air cell diameters ranging from 12.5 to 25.2 μm [

66]. Meanwhile, X. Liu et al. [

52] found that air cell sizes in ice cream samples ranged from 39 to 60 μm.

Enhancing the quality and consumer acceptance of plant-based ice cream involves minimizing off-flavors and optimizing sensory characteristics [

67].

Table 5 shows the results of the sensory evaluation of the frozen dessert samples. All the samples containing soy milk received an average appearance score of 4.86, while the control sample received the lowest score for this attribute (4.71). The appearance of the frozen dessert samples was typical of this type of dessert (

Figure 2), specifically, the homogeneity of the mass, the absence of ice crystals, and clear swirls immediately after extrusion.

The S4 frozen dessert sample received the highest average taste score (5.00) from the experts, while the S3 and S5 samples received slightly lower scores (4.57) (

Table 5). The lowest average score (4.14) was given to the S1 and S2 samples. All samples had a characteristic flavor typical of their respective type of frozen dessert and no off-flavors, including soy flavor. However, the S5 sample was considered overly sweet by the experts. The S3, S4, and S5 samples received the highest average aroma score (5.00) from the experts. The S1 and S2 samples received 4.86 and 4.71, respectively, for this attribute. All the samples had a pleasant aroma typical of the main ingredients, with no off-odors.

The control sample (S1) received the lowest average consistency score (4.00), while the S3, S4, and S5 samples received equally high average scores of 4.86 from the experts (

Table 5). The soy milk-based frozen dessert samples had a smooth, homogeneous consistency, free from lumps and wateriness. In contrast, the control sample S1 exhibited a grainy consistency. All frozen dessert samples received the highest average score of 5.00 for color. The color of the samples was uniform, white, with a creamy tint of varying intensity, which is characteristic of the ingredients used.

The panelists also evaluated the importance of each sensory attribute of the frozen dessert. The weighting coefficients assigned to each attribute were as follows: appearance—0.20, taste—0.33, flavor—0.07, consistency—0.26, and color—0.14. Using these coefficients, the quality index for each frozen dessert sample was calculated (

Table 5). The S4 sample received the highest quality index value (0.987), while the S1 sample had the lowest (0.878). The S2, S3, and S5 samples had quality index values of 0.919, 0.959, and 0.959, respectively. Therefore, the S4 sample was determined to be the best in terms of sensory attributes. According to F. Aboulfazli et al. [

68], ice cream containing 25% soy milk and 75% cow milk received higher sensory evaluation scores compared to the formulation with 75% soy milk and 25% cow milk.

Table 6 presents the nutritional value and caloric content of the frozen dessert mixtures. The protein content in mixtures containing soy milk ranged from 2.8 to 3.8 g/100 g, which was higher than in the control sample without soy milk (2.4 g/100 g) (

Table 6). Moreover, increasing the proportion of soy milk in the mixture led to a higher protein content. This is attributed to the fact that soy milk contains more protein (5.0 g/100 g) compared to cow’s milk (2.8 g/100 g). Previous studies have shown that the protein content of ice cream mixtures containing 25–100% soy milk ranges from 4.31 to 4.39% [

51]. Other studies have found that the protein content in ice cream made with soy milk ranges from 5.11% to 5.26% [

58]. The protein content in ice cream made with different types of milk varies as follows: almond milk—1.09–1.75% [

59], coconut milk—3.42–4.63% [

60], cashew milk—3.12–4.60% [

61,

63], and hazelnut milk—8.59–12.12% [

62].

At present, there are no standardized requirements regarding protein content in frozen desserts formulated with plant-based milk alternatives, such as soy milk. As a result, the protein levels in the analyzed samples reflect the combination of various ingredients with differing protein contents. The functional properties observed in the frozen dessert samples reflect the combined influence of the overall protein composition as well as other ingredient components, rather than being attributed solely to the specific functionality of soy protein.

In the frozen dessert mixtures containing soy milk, the fat content was slightly lower or comparable (5.6–5.8 g/100 g) to that of the mixture without soy milk (5.8 g/100 g) (

Table 6). The lowest fat content (5.6%) was observed in mixtures containing either 15% cow’s milk or none at all. This variation is due to the fact that cow’s milk has a higher fat content (3.2 g/100 g) than soy milk (2.8 g/100 g). A study by A. M. Asres et al. [

51] found that the fat content of ice cream mixtures made with soy milk ranges from 7.01% to 7.47%. In contrast, another study reported a lower fat content in soy milk-based ice cream, ranging from 2.99% to 3.40% [

58], likely due to differences in formulation or processing methods. Fat content in plant-based ice cream varies significantly depending on the type of milk used. Products made with coconut milk contain the highest fat levels (10.53–11.62%) [

60], followed by hazelnut milk (7.95–8.02%) [

62], and cashew milk (2.29–10.46%) [

61,

63]. Almond milk-based ice cream contains the least, ranging from 2.50% to 2.67% [

59].

The frozen dessert mixture without soy milk had the highest carbohydrate content (17.9 g/100 g) (

Table 6). Increasing the soy milk content in the mixtures led to a decrease in carbohydrate content. In mixtures containing 15%, 30%, 45% and 60% soy milk, the carbohydrate content was 17.6%, 17.2%, 16.9% and 16.6%, respectively. The carbohydrate content of the formulated ice cream mixtures with soy milk by A. M. Asres et al. [

51] ranged from 18.80% to 21.37%. Similarly, another study reported carbohydrate levels in soy milk-based ice cream ranging from 19.52% to 19.58% [

58], while ice cream made with cashew milk showed a wider variation—from 11.00% to 23.68% [

61,

63]. The calorie content of the frozen dessert mixtures ranged from 131.6 to 133.8 kcal/100 g, with the lowest content (131.6 kcal/100 g) found in the S4 mixture containing 45% soy milk (

Table 6).

In this study, Pearson correlation analysis was performed to assess the linear relationships between physicochemical parameters of frozen desserts and the nutritional composition of the dessert mixtures. Correlation analysis revealed strong and statistically significant relationships among all measured parameters of the frozen desserts (

Table 7). The pH of the melted frozen dessert showed strong positive correlations with specific gravity, ash content, protein content (

r = 0.99,

p < 0.01), and total solids (

r = 0.97,

p < 0.01), as well as strong negative correlations with overrun, melting resistance, carbohydrate content (

r = −0.99,

p < 0.01), and fat content (

r = −0.95,

p < 0.05).

Specific gravity of frozen desserts was positively correlated with protein content (r = 0.99, p < 0.01), ash content, and total solids (r = 0.97, p < 0.01), and negatively correlated with melting resistance (r = −0.99, p < 0.01), overrun (r = −0.97, p < 0.01), fat content (r = −0.90, p < 0.05), and carbohydrate content (r = −0.98, p < 0.01).

The total solids content of frozen desserts was positively correlated with protein content (

r = 0.98,

p < 0.01) and ash content (

r = 0.99,

p < 0.01). Negative correlations were observed with overrun (

r = −0.99,

p < 0.01), melting resistance (

r = −0.96,

p < 0.01), fat content (

r = −0.87,

p < 0.10), and carbohydrate content (

r = −0.97,

p < 0.01). Ash content of frozen desserts also showed a strong positive correlation with protein content (

r = 0.99,

p < 0.01), and negative correlations with overrun, melting resistance, fat content, and carbohydrate content (

Table 7).

Overrun of frozen desserts demonstrated strong negative correlation with protein content (r = −0.99, p < 0.01), while showing strong positive correlation with fat content (r = 0.92, p < 0.05), carbohydrate content (r = 0.99, p < 0.01), and melting resistance (r = 0.97, p < 0.01). Similarly, melting resistance was strongly and negatively related to protein (r = −0.99, p < 0.01), and positively to fat content (r = 0.93, p < 0.05) and carbohydrate levels (r = 0.99, p < 0.01).