Abstract

The study was conducted on 100 unsalted goat cheeses produced on a certified organic farm. From the 100 cheeses, 10 were selected, which constituted the so-called sample day 0 (before the start of cold storage) and were divided into three groups of 30 pieces each: A—unpackaged group; B—vacuum packed group; and C—vacuum packed group with MEGA CO2 absorbing insert. The cheeses were stored in a cold store at a temperature of 4 ± 1 °C and relative humidity of 85% for 5, 10, and 15 days. The greatest weight loss of the cheese was shown in group C (4.63%) and on the 10th day of storage (6.09%). The lowest pH value was recorded in groups B (6.31) and C (6.32) and on the 15th day of storage (5.48). The lowest titratable acidity was recorded in group C (14.90°SH) and in sample 0 (12.40 °SH). The highest value of shear force was in group B (3.89 N) and on the 10th day of storage (3.56 N). An analysis of the color parameters of the cheeses showed that the L* value on the surface and after cutting was the highest at p ≤ 0.01 and p ≤ 0.05 in group C and sample 0 and was, respectively: 94.30 and 94.97 and 95.31 and 96.17. The lowest values of the sensory evaluation were obtained in the case of cheeses from group A and on the 15th day of storage, where these values (points) were, respectively: 3.32 and 3.76—color; 2.79 and 3.32—aroma; 3.27 and 3.64—appearance; 4.07 and 4.18—structure and 2.80 and 2.91—taste.

1. Introduction

Goat milk accounts for around 2.4% of the global production of milk from different livestock species [1]. Poland is not a leading supplier of goat milk, and annual production is estimated at 45 million liters. However, the Polish market of goat dairy products continues to grow dynamically, and new products are introduced each year [2]. Around 85% of goat milk is processed into various types of cheese. Goat cheeses are manufactured in many countries and regions, but the largest selection of goat cheeses can be found in France. Goat milk is mainly processed into fresh cheeses (60%), which are produced predominantly in France; followed by semi-hard cheeses (30%), which are produced in the Netherlands, Italy, and Greece (Greek feta cheese is the most popular variety in this category); and cottage cheese (10%), which is produced in France, Spain, and the Netherlands [3]. In Europe, dairy products made from goat milk are regarded as regional and traditional foods [4].

The importance of artisanal cheeses is increasing both internationally and nationally due to changing consumer lifestyles [5]. The demand for goat cheese, especially its fresh milk varieties, has been steadily increasing among consumers of healthy and low-calorie foods over the past 20 years [6]. The goat cheeses manufactured and sold in Poland are mainly fresh cheeses, usually produced on a small scale by farmers using traditional techniques, but without packaging. The availability of manufactured cheese is limited due to the short shelf life of the product and the seasonality of production. Farmhouse cheeses are distinguished from industrially produced cheeses by their distinctive sensory qualities and are a showcase of their region or country of origin [7]. Producers of regional cheeses with unique characteristics want their efforts and determination to be reflected in consumer recognition through increased demand for their products [4]. Storage of unpackaged cheeses reduces their shelf life, decreases their quality, and hinders their potential sale in markets far from the production area. Packaging that can extend the shelf life of these types of cheeses may be a viable alternative for small producers [8]. Although the shelf life of unpackaged fresh cheese may vary depending on the type of cheese, storage temperature, and heat processing, it usually does not exceed 10–12 days at refrigerated temperatures because oxygen promotes microbial growth and affects sensory characteristics. The same applies to goat cheese [9]. Appropriate packaging also protects cheese from dehydration; exposure to light; and the degradation of proteins, fats, and vitamins, i.e., quality deterioration. Cheese stored under refrigerated conditions has a shelf life of 7 to 8 days (soft cheese) or up to 4 weeks (processed cheese). The shelf life of fresh white cheeses stored under aerobic conditions in active packaging can be extended by up to 3–4 weeks. Vacuum packaging (VAP) and modified atmosphere packaging (MAP) can also extend the shelf life of cheeses [10].

Today, several preservation techniques are available to extend the shelf life of food products, of which packaging is the most promising. The packaging process helps prevent microbial and chemical quality deterioration and facilitates the handling and marketing of packaged products. Today, food packaging is not only focused on convenience and protection, but also has many other applications [11]. Vacuum packaging is not suitable for all types of cheese because, although it delays the growth of some microorganisms, it may have undesirable effects on the color, taste, and texture of cheese or promote the accumulation of excess moisture on the surface due to the migration of water from the interior to the surface [12]. Therefore, the effect of VAP should be evaluated for each specific type of cheese [8]. Over the past three decades, MAP has attracted the attention of researchers as a practical technique for preserving the quality of various food products in addition to meeting the increased demand for fresh and preservative-free food. Two types of MAP are commonly applied, passive and active. Vacuum packaging is considered passive MAP for food containing viable microorganisms. A primary drawback of this MAP technique is that it may require a long storage period to achieve the optimum gas composition, which could be particularly disadvantageous for products with a relatively short shelf life. This disadvantage can be overcome by implementing active modification of the atmosphere. Active MAP is usually accomplished by first creating a vacuum and then injecting the desired gas mixture into the package; in this case, the desired atmosphere is achieved at the beginning of storage and remains unchanged, provided the right packaging material is used and there is no leakage. The disadvantage of active MAP, compared with passive MAP, is the higher cost of equipment and gases. The broader distribution of goat cheese also necessitates modifications in its packaging—rather than being sold by weight in local markets, it should be packaged individually [11,12,13].

Studies investigating different packaging systems, including the composition of gas atmosphere, and microbiological and physicochemical analyses, confirmed a significant drawback of the MAP system when compared with controlled atmosphere packaging (CAP), namely the inability to continuously control the composition of the atmosphere inside the package throughout storage and to increase the levels of gases (mainly CO2) to their initial levels. Modern cellulose sealed-edge absorbent pads such as MEGA CO2 help eliminate the above limitations of food packaging under a modified atmosphere and ensure the maintenance of a biostatic barrier throughout storage. Beyond their function of absorbing exudate from moist food products (meat, cold cuts, fish, and soft berries), MEGA CO2 absorbent pads slowly release bacteriostatic agents and maintain adequate levels of CO2 while reducing the levels of metabolic CO2 formed during the growth of pathogenic bacteria. Due to these properties, absorbent pads contribute to extending the shelf life of packaged foods and preserving their freshness. Furthermore, the released CO2 surrounds the product and acts as a natural protective barrier [14]. However, the packaging of goat cheeses under vacuum and with the use of MEGA CO2 absorbent pads has not been analyzed in the literature to date. Preserving the nutritional value of dairy products is contingent upon appropriate packaging and storage. At the time of purchase, packaging protects the contents against external factors and undesirable physicochemical and microbiological changes. The packaging of cheese is extremely important, and packaging methods may vary depending on the type of cheese, its anticipated shelf life, storage requirements, and consumer preferences. In addition, factors such as food safety, branding, environmental protection, and sustainability should be taken into account in the development of novel cheese packaging [10,15]. Optimal packaging methods and storage conditions of dairy products such as cheeses, which are classified as perishable foods, are constantly being sought, as these are important considerations for both small-scale producers and the dairy industry as a whole.

The aim of this study was to analyze changes in selected physicochemical parameters and sensory attributes of goat cheeses cold stored in different types of packaging for different periods of time.

2. Materials and Methods

2.1. Goat Cheese Production

Unsalted goat cheeses were purchased directly after production from an organic farm in the village of Złotna in Morąg municipality, Ostróda county, voivodeship of Warmia and Mazury. The farm has been registered as an entity conducting marginal, localized, and restricted activity, and it has received an organic farming certificate from AGRO BIO TEST (PL-EKO-07-10404).

The cheeses were produced from the milk of Polish White Improved goats. Raw milk was pasteurized at a temperature of around 75 °C for at least 30 min. The pasteurized milk was cooled to 30–35 °C, and liquid rennet was added at 2–4 mL per 10 L of milk. Around 60 min later, the formed curd was placed in a strainer lined with cheese cloth and left to drain for 30–50 min. The drained curd was transferred to plastic basket cheese molds and left for around 12 h to drain the whey according to the Organic Farming Handbook (Document 4a).

To eliminate potential differences between samples, all the analyzed cheeses were obtained from the same batch and had a cylindrical shape with a diameter of 8 cm, height of 2.5 cm, and average net weight of 150 g. Twelve hours after production, the cheese samples were transported in a self-powered isothermal container at a temperature of 4 ± 1 °C to the laboratory of the Department of Commodity Science and Animal Raw Material Processing of the University of Warmia and Mazury in Olsztyn, where they were packaged and subjected to quantitative and qualitative analyses.

The study was conducted on 100 goat cheeses produced using a traditional method. The samples were divided into three groups (A, B, and C). Immediately after transport to the laboratory, 10 representative cheeses were selected from a total of 100 cheeses; they constituted the day 0 sample (before cold storage) and were subjected to quantitative and qualitative analyses. The remaining cheeses, including unpackaged cheeses (group A—30 cheeses), vacuum-packaged cheeses without (group B—30 cheeses), and with (group C—30 cheeses) MEGA CO2 absorbent pads, were stored in a Frost refrigerated cabinet at a temperature of 4 ± 1 °C and relative humidity of 85% for 5, 10, and 15 days according to the experimental design (Table 1).

Table 1.

Experimental design.

2.2. Cheese Packaging with and Without Absorbent Pads

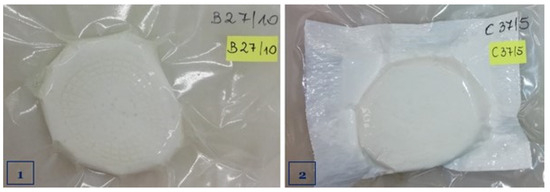

Group B and C cheeses (60 cheeses) were placed individually in heat-shrinkable packaging of the multilayer laminate type PET PVdC/CPP (PABEX, Poland; dimensions: 200 × 250 mm; thickness: 41 µm; thermal shrinkage temperature: 145–155 °C) made of high-barrier PET and non-oriented PP film (gas permeability: O2 = 8.73 cm3/m2/24 h/0, 1 MPa, 23 °C, 100% RH; CO2 = 23.89 cm3/m2/24 h/0, 1 MPa, 23 °C, <1% RH; H2O = 4.25 g/m2/24 h, 38 °C, 90% RH). Group C cheeses (30 cheeses) were vacuum-packaged with MEGA CO2 absorbent pads (POMONA, Żyrardów, Poland; dimensions: 120 × 80 mm; all side edges closed) (Figure 1). All the samples were sealed in a PP-15 Tepro Vacu Tronic 2000 single-chamber vacuum sealer (Tepro S.A., Koszalin, Poland) by removing 98% of the air.

Figure 1.

Goat cheeses vacuum packaged without (1) and with (2) MEGA CO2 absorbent pads.

2.3. Laboratory Analyses

2.3.1. Physicochemical Analysis

Cheese weight loss was determined by weighing the samples before and after refrigerated storage (at a temperature of 4 ± 1 °C) on a Radwag digital scale (Warsaw, Poland) to the nearest 0.01 g. The result was expressed as a percentage of the initial weight.

The moisture content of the examined cheeses was determined by drying in the presence of sand at a temperature of 130 °C according to Standard PN-A-86232 [16]. The vessel was filled with 30 g of sand, a glass rod was placed inside the vessel, and the vessel was placed in a drier set to a temperature of 130 ± 2 °C for 0.5 h. The vessel containing sand and the glass rod was cooled in a desiccator and weighed to the nearest 0.01 g. Three grams of cheese (weighed with an accuracy of 0.01 g) were placed in the vessel. The contents were thoroughly stirred and ground with the glass rod, and the vessel was placed in a drier set to a temperature of 130 ± 2 °C for 0.5 h. The vessel was cooled in a desiccator, the sample was weighed to the nearest 0.01 g, and the percentage of water was calculated using the following formula:

where

a—weight of the vessel containing sand, a glass rod, and cheese before drying (g);

b—weight of the vessel containing sand, a glass rod, and cheese after drying (g);

c—weight of the vessel containing sand and a glass rod (g).

The pH of the goat cheeses was measured with a pH meter in the cheese samples emulsified in water according to Standard PN-A-86232 [16]. For this purpose, 10 g cheese samples were weighed to the nearest 0.01 g and placed in a mortar. The samples were thoroughly ground by gradually adding distilled water (10 cm3) at a temperature of 40 °C until a smooth emulsion was obtained. The resulting emulsion was brought to a temperature of 20 °C, transferred to a pH meter probe, and the pH reading was recorded to the nearest 0.05 pH units. The analysis was conducted with the use of a 340i pH meter equipped with a TFK 150/E temperature sensor (WTW Wissenschaftlich-Technische Werkstätten, Weilheim, Germany) and a Hamilton Double Pore combination pH electrode (Bonaduz, Switzerland). The pH meter was calibrated with buffers with known pH prior to the measurements.

Titratable acidity was determined by titrating an aqueous cheese suspension with a solution of sodium hydroxide in the presence of phenolphthalein to Standard PN-A-86232 [16]. Cheese samples of 5 g each were weighted to the nearest 0.01 g, placed in a mortar, and thoroughly ground by adding small portions of distilled water (50 cm3) at a temperature of 40 °C. The obtained emulsion was combined with 2 cm3 of phenolphthalein and titrated with a solution of sodium hydroxide until the appearance of a faint pink color that persisted for 30 s. Cheese acidity was calculated in Soxhlet–Henkel degrees (°SH) using the formula below:

where a is the volume of 0.25 N sodium hydroxide solution used in titration (cm3).

x = a × 20

The shear force of the goat cheeses was determined according to the Warner–Bratzler method [17]. Three cubical samples measuring 2 × 2 × 2 cm were cut out from the cheeses across the grain. The specimens were placed in an Instron 5542 machine equipped (Canton, MA, USA) with a 500 N head moving at a speed of 100 mm/min and were cut with a knife with a triangular notch. The maximum shear force required to cut the specimens was recorded with the use of the Merlin program.

2.3.2. Color Analysis

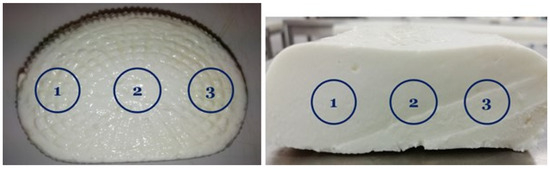

The color of the goat cheeses was determined based on the values of parameters L*, a*, and b* in the CIELAB color space [18], measured by the reflectance method with the HunterLab MiniScan XE Plus instrument (Hunter Associates Laboratory Inc., Reston, VA, USA), directly on the surface and at the cross-section of the cheese samples. Each measurement was conducted in triplicate, at the same points (Figure 2), with D65 standard illuminant, 10° observer, and aperture diameter of 2.54 cm. The measurements were performed immediately after removing the cheeses from refrigerated storage at a temperature of 4 ± 1 °C, before and after each analyzed storage period. The instrument was calibrated with the use of black and white tiles before each series of measurements.

Figure 2.

Color measurements points on the surface and at the cross-section of the cheese samples.

2.3.3. Sensory Analysis

The sensory analysis of the examined cheeses was conducted on a five-point scale according to Standard ISO 4121 [19]. The following quality attributes were considered in the analysis: overall appearance, color, aroma, consistency, and taste. The cheese samples were assessed by six panelists with validated sensory acuity (ISO 8586) [20]. The samples were lit uniformly from all directions with the use of fluorescent lamps (500 lx) that simulated natural daylight and were installed at a height of around 1 m above the table. Sensory analyses were conducted at a relative humidity of a minimum of 60% and a temperature of 21 °C. The cheeses were evaluated based on the reference standards for the sensory attributes of unripened rennet cheeses PN-A-86300 [21]. Each attribute was graded on a five-point scale, where 1 point denoted very poor quality; 2 points—unsatisfactory quality; 3 points—satisfactory quality; 4 points—high quality; and 5 points—excellent quality.

2.4. Statistical Analysis

The results were processed statistically by calculating the arithmetic mean () and standard deviation (±SD). The significance of differences between the mean values of the analyzed attributes in each group was determined by one-way and two-way analysis of variance and Duncan’s test. Statistical analyses were conducted in the Statistica v. 13.3 program [22].

3. Results

The study revealed a significant (p ≤ 0.001) interaction effect of both experimental factors (packaging method × cold storage time) on cheese weight loss, pH, titratable acidity (°SH), shear force values, the selected color parameters on the surface and at the cross-section of cheese samples, and the sensory attributes of the analyzed goat cheeses. The data presented in Table 2 indicate that the packaging method and cold storage time had a significant (p ≤ 0.01) effect on cheese weight loss. The B samples were characterized by the lowest weight loss (3.08% on average), which was 0.63% and 1.55% lower than in the unpackaged samples and C samples, respectively. A cold storage time of up to 15 days contributed to significant (p ≤ 0.01) weight loss relative to the initial values before storage. The greatest weight loss was noted on storage day 10 (6.09%), and the smallest weight loss was noted on storage day 5 (3.95%).

Table 2.

The effect of packaging method and cold storage time on the physicochemical parameters of the goat cheeses ( ± SD).

The moisture content of the analyzed goat cheeses was significantly (p ≤ 0.01) lower in the unpackaged group (A) (57.82%) relative to the experimental groups (B and C) (Table 2). This parameter was the highest in the vacuum-packaged samples (62.16%) and in the cheeses that were vacuum-packaged with MEGA CO2 absorbent pads (61.31%). A significant (p ≤ 0.01) decrease in moisture content was noted on storage days 10 and 15 (59.94% and 59.60%, respectively) in comparison with storage days 0 and 5 when the average moisture content of the examined goat cheeses was 60.82%.

The data presented in Table 2 indicate that the pH of the examined cheeses was affected by the packaging method, and it was significantly (p ≤ 0.01) lower in the vacuum-packaged samples (pH = 6.31) and in the samples that were vacuum-packaged with MEGA CO2 absorbent pads (pH = 6.32) than in the unpackaged group samples, which were characterized by the highest pH (6.55). Active acidity decreased significantly (p ≤ 0.01) on successive days of storage, from 6.52 on storage day 0 to 6.31 on day 5, 6.01 on day 10, and 5.48 on day 15.

Significant differences (p ≤ 0.01 and p ≤ 0.05) in titratable acidity (°SH) were observed between the cheese samples (Table 2). Total acidity was considerably lower in the cheeses that were vacuum-packaged without (16.50°SH) and with (14.90 °SH) MEGA CO2 absorbent pads, and it was highest in the unpackaged group cheeses (25.70 °SH). A significant increase (p ≤ 0.01) in titratable acidity was observed on successive days of refrigerated storage. Total acidity was the lowest on storage day 0 (12.40°SH) and highest on storage day 15 (26.60°SH). Titratable acidity increased gradually on storage days 5 and 10 (by 4.8 and 7.53°SH, respectively) relative to the initial values before storage.

The shear force analysis revealed significant differences (p ≤ 0.01) between the unpackaged group cheeses and packaged cheeses (Table 2). Group A cheeses were the most brittle, which was confirmed by a low value of shear force (2.08 N). The value of shear force was highest in the vacuum-packaged samples (3.89 N) and lower in the vacuum-packaged cheeses with absorbent pads (3.48 N). The shear force values of the examined cheeses were significantly (p ≤ 0.01) differentiated by cold storage time. The goat cheeses were most brittle on storage day 0 (2.27 N), and their shear force values decreased by 1.10, 1.29, and 0.94 N on storage days 5, 10, and 15, respectively.

An analysis of the color on the surface of the goat cheeses (Table 3) revealed that parameters L* and b* were significantly (p ≤ 0.01) influenced by the packaging method. The cheeses that were vacuum-packaged without and with MEGA CO2 absorbent pads were characterized by higher values of L* on the surface (94.26 and 94.30, respectively) than the unpackaged cheeses (92.81). Both packaging methods caused a significant (p ≤ 0.01) decrease in the contribution of yellowness on the surface of the cheese samples. Parameter b* was the highest in the unpackaged group (13.63), and it was lower (by 1.42 and 1.28, respectively) in the cheeses that were vacuum-packaged without and with MEGA CO2 absorbent pads. No significant changes were observed in the red component, and the values of parameter a* were fairly similar in all the samples (−0.90 on average). Parameter a* assumed negative values on all the storage days, which points to a shift toward green color. The data presented in Table 3 indicate that the values of parameter L* decreased significantly (p ≤ 0.01) by 1.66, 1.43, and 1.65 on storage days 5, 10, and 15, respectively, and the color on the surface of the stored cheeses was darker relative to the initial value before storage (94.97 on average). At the same time, cold storage for up to 15 days significantly (p ≤ 0.01) contributed to a decrease in redness (a*) and an increase in yellowness (b*) on the surface of the examined cheeses, which corresponds to lower values of L*. The greatest shift towards green color was observed on storage days 10 and 15 when parameter a* reached −1.07 and −1.10, respectively. The contribution of yellowness was the lowest before storage (b* = 11.32) and highest on storage days 5 and 15 (13.26 and 13.27, respectively).

Table 3.

The effect of the packaging method and cold storage time on the color parameters of the goat cheeses ( ± SD).

The influence of the packaging method and cold storage time on the color parameters at the cross-section of the examined cheeses was analyzed based on the data presented in Table 3. The packaging method exerted a significant (p ≤ 0.01 and p ≤ 0.05) effect on changes in lightness and the contribution of redness and yellowness in the analyzed cheese groups. The unpackaged group samples and C samples were characterized by higher and similar values of parameter L* at 95.20 on average. In turn, the value of L* was the lowest (94.97) in the vacuum-packaged cheeses without absorbent pads. An analysis of the red–green color spectrum revealed significant (p ≤ 0.01) differences in the contribution of redness at the cross-section of the unpackaged (control) cheeses and the samples that were vacuum-packaged without and with absorbent pads. The value of parameter a* at the cross-section of the unpackaged cheeses (−1.03) was 0.08 and 0.10 higher than in the experimental groups. Despite the absence of significant differences between the samples that were vacuum-packaged without and with absorbent pads, these cheeses were characterized by similar contributions of yellowness at the cross-section (10.30 on average). The lowest value of parameter b* (10.09) was noted at the cross-section of the unpackaged group samples relative to the vacuum-packaged samples (10.35), and the observed difference was statistically significant (p ≤ 0.05).

Significant (p ≤ 0.01) differences in color lightness at the cross-section of the cheese samples were observed before storage and after 5, 10, and 15 days of storage. No significant differences in lightness were observed between the cheeses stored for 5 and 15 days. The value of parameter L* was the highest at the cross-section of cheese samples on storage days 0 (96.17) and 10 (95.22). In turn, the color of the cheese cross-sections was clearly darker after 5 and 15 days of storage. The data presented in Table 3 indicate that the contribution of greenness at the cross-section of the cheese samples was significantly (p ≤ 0.01) highest on storage day 0 (a* = −1.20) and lowest on storage days 10 (−1.03) and 15 (−1.04). The above values differed significantly (p ≤ 0.01) from those noted on storage day 5 (a* = −1.10). These results indicate that cold storage time affected the contribution of yellowness at the cross-section of the cheese samples, and significant differences (p ≤ 0.01) in the values of parameter b* were noted between the groups. The contribution of yellowness increased with the cold storage time, and parameter b* was the highest on storage day 15 (10.77) and lowest on day 0 (9.41).

An analysis of the data in Table 4 revealed that the examined packaging methods significantly (p ≤ 0.01) affected the sensory quality of the goat cheeses. The cheeses that were vacuum-packaged with MEGA CO2 absorbent pads received the highest scores for color (4.82 points) and aroma (4.86 points), which testifies to the high quality of these products. The aroma of the studied cheeses was described as desirable and characteristic of goat dairy products, with a distinctive milky note. The color of the examined samples was described as bright white. The vacuum-packaged cheeses also received very high scores for color (4.52 points) and aroma (4.80 points). In terms of color and aroma, the panelists gave significantly (p ≤ 0.01) lowest scores to the unpackaged cheeses (3.32 and 2.79 points, respectively). The cheeses that were vacuum-packaged with absorbent pads received significantly (p ≤ 0.01) highest scores for taste (4.53 points on average), which was described as slightly sweet with a milky note characteristic of goat milk. The vacuum-packaged cheeses differed significantly (p ≤ 0.01) from the unpackaged samples which received the lowest scores for taste (2.80 points). The results presented in Table 4 indicate that the packaging method exerted a significant (p ≤ 0.01) effect on the appearance of the cross-section of the cheese samples, their structure, and their consistency. The goat cheeses that were vacuum-packaged without and with absorbent pads were characterized by a more desirable color at the cross-section (excellent quality) than the unpackaged samples which received the lowest score (3.27 points) in this respect (satisfactory quality). According to the panelists, the cheeses that were vacuum-packaged with absorbent pads had the most desirable structure and consistency, and these samples received a higher score (4.77 points) (excellent quality) than the unpackaged (4.07 points) and vacuum-packaged (4.25) cheeses (high quality). The cold storage time exerted a negative effect on cheese color, which was significantly (p ≤ 0.01) less desirable on storage days 10 and 15 than on days 0 and 5 (Table 4). The examined cheeses received the highest score for color on storage day 0 (4.86 points). Local discoloration and yellowing were observed on successive days of storage, and the evaluated cheeses received 4.43, 3.83, and 3.76 points on storage days 5, 10, and 15, respectively. These results point to the high (day 5) and satisfactory (days 10 and 15) quality of the analyzed cheeses. The aroma of the goat cheeses deteriorated significantly (p ≤ 0.01) during cold storage and was described as foreign, bitter, and acidic. The evaluated cheeses were characterized by the most desirable aroma on storage day 0 (4.94 points, excellent quality), but they received a lower score already on storage day 5 (4.40 points, high quality), as well as on days 10 (3.93 points) and 15 (3.32 points) (Table 4). Significant (p ≤ 0.01 and p ≤ 0.05) differences in the cross-sectional appearance of the cheeses were noted between storage day 0 and storage days 5, 10, and 15. The goat cheeses received the highest score on storage day 0 (4.88 points, excellent quality). Their quality was evaluated as high after 5 and 10 days of refrigerated storage (4.50 and 4.33 points, respectively). The cross-sectional appearance of the cheeses deteriorated after 15 days of storage, and these samples received only 3.64 points (satisfactory quality).

Table 4.

The effect of the packaging method and cold storage time on the sensory attributes of the goat cheeses ( ± SD).

The cold storage time significantly (p ≤ 0.01 and p ≤ 0.05) influenced the structure and consistency of cheeses, and the scores awarded for these sensory attributes decreased on successive days of storage, from 4.88 points on day 0 to 4.33 points on day 5 (high quality) (Table 4). The examined cheeses were characterized by the most acceptable, cohesive, and uniform structure and consistency on storage days 0 and 5. After 10 and 15 days of storage, the quality of the analyzed samples was still evaluated as high, but their consistency and structure were described as more gummy, with visible cracks and spaces between grains, and the corresponding scores decreased to 4.07 and 4.18 points, respectively. An analysis of the data presented in Table 4 indicates that cold storage time significantly (p ≤ 0.01) affected the taste of the goat cheeses across groups. The examined samples received the highest score for taste (4.88 points, excellent quality) on day 0. Their taste deteriorated after 5 and 10 days of storage, and the corresponding scores decreased to 3.80 and 3.60 points, respectively (satisfactory quality). After 15 days of storage, the taste of the analyzed samples underwent undesirable changes and was described as unacceptable (bland, fermented, acidic, and bitter), and these cheeses received only 2.91 points (unsatisfactory quality).

4. Discussion

Similar findings to those presented in Table 2 were reported by Mei et al. [23], who concluded that PET packaging minimizes weight loss and inhibits microbial growth in Mongolian cheese. Pluta et al. [24] and Mei et al. [23] found that MAP induced the greatest whey seepage, which was also observed in the present study.

In a study by Pluta et al. [24], the moisture content of tvorog cheeses decreased gradually during 21 days of storage, and the decrease was greater in samples packaged under a CO2-modified atmosphere and vacuum than in those packaged under a N2-modified atmosphere and refrigerated without VP. According to the cited authors, these differences resulted from whey syneresis inside the packaging. In turn, Paciorek and Bonczar [25] concluded that differences in the moisture content of fresh cheeses could be attributed to differences in milk acidity, drying time, size of cheese grains, and processing temperature. de Oliveira et al. [26] analyzed the quality of five goat cheese varieties containing different starter cultures and stored in VP for 21 days at a temperature of 10 °C. The moisture content of the cheeses studied by the authors ranged from 56.62 to 60.27% on storage day 1 to 54.39 to 59.46% on storage day 14. On the last day of refrigerated storage (day 21), the moisture content of the analyzed cheeses ranged from 54.20% to 59.97%.

Miloradovic et al. [13] investigated the effect of different NaCl concentrations in brine (3% and 6%) and different packaging methods on the physicochemical properties of brined white goat cheese and found that the pH of vacuum-packaged cheeses and cheeses packaged in a modified atmosphere (60% CO2 + 40% N2) decreased from the initial value of 5.29 to 4.60 and 4.40, respectively, after 40 days of storage. In the cited study, the pH of the goat cheeses reached 4.80 on storage day 10 regardless of the packaging method. Depending on CO2 concentration, MAP can increase the pH value by inhibiting the growth of lactic acid bacteria or decrease the pH value by promoting the formation of carbonic acid [9]. In the work of Miloradovic et al. [13] and Kirkin et al. [27], the pH of cheeses was not significantly affected by CO2, probably because CO2 was absorbed mainly on the surface rather than inside the stored samples. In a study by de Oliveira et al. [26], the average pH of five varieties of vacuum-packaged goat cheeses decreased from 6.98 on storage day 1 to 6.82 and 6.61 on storage days 14 and 21, respectively, and was higher than in the current experiment.

Acidity provides important information about the product’s freshness, the production process, potential adulterations, and the progression of undesirable biological and chemical changes [28]. According to Paciorek and Bonczar [25], considerable variations in the total acidity of “oscypek” cheese produced in the region of Podhale can be attributed to differences in production hygiene and storage methods.

Cheese hardness generally decreases with a reduction in dry matter content [29]. In a study by Miloradovic et al. [13], the dry matter content of cheeses stored in brine decreased during storage, but no significant differences in cheese hardness were noted past storage day 30. The cohesiveness of the examined cheeses decreased significantly only during ripening (days 1–10) when proteolysis processes were intensified. The cited authors did not report notable differences in the springiness or cohesiveness of the stored cheeses, which suggests that storage had no effect on the number and strength of protein bonds. The compared packaging methods (VP vs. MAP) did not cause significant changes in texture parameters such as hardness, cohesiveness, chewiness, and springiness. Regardless of the NaCl concentration in the brine and the packaging method, the average cheese hardness was 5 N on storage day 1, 25 N on day 10, and 35 N on day 20.

According to Chwastowska-Siwiecka et al. [30], color is one of the key parameters that affect consumer perceptions of food products. For this reason, the color of food products, including dairy products, provides vital information about the quality of ingredients or end products. Purchasing decisions are made based on the external appearance of cheese rather than its texture, taste, or aroma [31]. The surface color of regional and traditional products is regarded as the main indicator of their freshness and quality. According to Juric et al. [32], the color of cheese packaged in a modified atmosphere can be altered due to the drying effects of CO2. In addition, cheese color is also influenced by oxidation processes whose rate is determined by the composition of gases in MAP [33]. The color of cheeses can also be affected by their salt content [34].

In the work of de Oliveira et al. [26], the lightness of five varieties of goat cheese stored at a temperature of 10 °C approximated the values noted in the present study. In the cited research, parameter L* at cheese cross-sections was 92.50–93.50 on storage day 1 and 92.23–93.30 on storage day 7. The analyzed cheeses were darker at the end of storage (day 21), and parameter L* decreased to 91.36–92.73. Between storage days 1 and 21, parameter a* increased (from −3.18 to −2.88) in three cheese varieties, and parameter b* increased (from 9.17 to 11.6) in four cheese varieties. The samples examined by de Oliveira et al. [26] were characterized by high lightness (L*) with a predominance of yellow (b*) rather than green (−a*) color, which suggests that the color profile of the analyzed cheeses was influenced mainly by the yellow component. In turn, Rohm and Jaros [35] evaluated changes in the color of stored Emmental cheese and reported a decrease in the values of L* and an increase in the values of a* and b*. Miloradovic et al. [13] found no significant differences in the color parameters (L*, a*, and b*) of brined goat cheeses on storage day 10, regardless of NaCl concentration in the brine (3% and 6%). On storage day 10, the average values of L*, a*, and b* were 91.00, 1.00, and −0.35, respectively. On storage day 40, vacuum-packaged cheeses were still characterized by high lightness (L* = 90.5), whereas parameters a* and b* were close to zero at 1.00 and 0.00, respectively. In cheeses packaged in a modified atmosphere (60% CO2 + 40% N2), the average value of L* was 90.45, and the contribution of red and yellow components reached 1.00 and −0.45, respectively, on storage day 40. Cais-Sokolińska et al. [36] analyzed changes in the color of mozzarella cheese stored for four weeks at a temperature of 4 and 8 °C and observed higher values of lightness and lower values of color saturation on the surface than inside the examined samples regardless of the storage time or temperature. The cited authors reported that with a rise in storage temperature, time exerted a more significant effect on the increase in lightness and the decrease in saturation, both on the surface and inside cheese samples.

The sensory attributes of goat cheeses influence consumer perception, acceptance, and attractiveness of these dairy products. In cheeses, the values of most sensory and textural parameters tend to increase during ripening, mainly due to changes in moisture content, proteolysis, NaCl diffusion, Ca balance, and pH values [37,38]. According to Ribeiro and Ribeiro [39], consumers purchase cheeses at farmer’s markets due to the wide selection, freshness, and unique taste of the offered products. Pluta et al. [40] found that the high-CO2 MAP technology induced undesirable changes in the taste of rennet cheese. However, the taste of vacuum-packaged cheese did not deteriorate even after 60 days of refrigerated storage. Cakmakci et al. [41] demonstrated that prolonged storage can lead to the emergence of a bitter taste, which could be attributed to intense proteolysis processes. In turn, Bohdziewicz and Jasińska [42] found that a bitter aftertaste in Camembert cheese was intensified on successive days of ripening and storage. In a study by Pluta et al. [40], storage time affected only the external appearance of the packaging and the taste of sliced Swiss-type cheeses stored in CO2 and N2 MAP. de Oliveira et al. [26] found that the acidity of three cheese varieties increased during storage, potentially contributing to increased cheese hardness. Hardness is the most important textural attribute because cheeses with a brittle texture are usually regarded as unacceptable by consumers [43]. According to Miloradovic et al. [44], during ripening, the taste of cheeses produced from high heat-treated milk differs from the taste of traditionally manufactured cheeses. The cited authors examined the impact of various goat milk processing temperatures, ripening times (3, 10, and 40 days), and storage at a temperature of 13–15 °C on the sensory quality of brined cheeses and found that high-temperature processing of goat milk (80 and 90 °C for 5 min) significantly influenced taste and texture, but not the overall appearance, cross-sectional appearance, or aroma, and the analyzed cheeses received 5.00, 4.77, and 4.76 points on average on a five-point scale. In the early stage of ripening (day 3), cheeses produced from milk heated to 80 °C received a much higher score for texture (4.20 points) than control group cheeses (3.50 points). Cheeses made from milk heated to 90 °C received the highest scores for texture and taste (4.90 and 5.00 points, respectively). According to the panelists, cheeses produced from high heat-treated milk appeared to be ripe already in the early stage of ripening, whereas control group cheeses had a gummy texture and a bland taste. After 10 days of ripening, the experimental group cheeses received lower scores for their undesirable, brittle, and dry texture and predominantly salty taste.

de Oliveira et al. [26] examined five varieties of goat cheeses produced with the use of different starter cultures and stored in VP for up to 21 days at a temperature of 10 °C. The analyzed cheeses differed in color, aroma, taste, texture, and overall appearance on different days of storage, and these sensory attributes were evaluated on a nine-point scale. The overall appearance of the goat cheeses deteriorated between storage day 1 (6.66–7.86 points) and day 21 (5.93–7.26 points). The studied cheeses received very high scores for color on storage day 1 (7.54–8.06 points), but this attribute was evaluated as somewhat less desirable on storage day 21 (7.11–7.85 points). The goat cheeses received the highest scores for aroma on day 1 (5.88–7.22 points), but the first changes in this parameter were detected already on storage day 7, when the corresponding scores decreased to 5.69–6.49 points. According to the panelists, the examined cheeses were characterized by the most desirable taste on storage day 1 (5.26–7.28 points) and the least desirable taste on storage days 7 (4.93–7.10 points) and 14 (4.74–7.02 points).

Miloradovic et al. [13] analyzed the influence of NaCl concentration in brine (3% and 6%) and different packaging methods on the sensory attributes of brined white goat cheeses and found that vacuum-packaged cheeses stored in 6% brine were characterized by significantly more desirable taste (6.96 points) than cheeses stored in 3% brine (6.22 points). In turn, the taste of cheeses stored in MAP was not affected by NaCl concentration, and these samples were awarded 6.73 and 6.50 points. The vacuum-packaged cheeses stored in 6% brine received the highest scores for texture (7.50 points) relative to the cheeses stored in MAP (7.15 points). The vacuum-packaged cheeses stored in 3% brine also scored higher in terms of texture (6.88 points) than the MAP cheeses (6.73 points). The packaging method (VP and MAP) and NaCl concentration did not contribute to significant differences in the aroma (6.65–7.13 points) or the overall appearance (6.65–7.31 points) of the goat cheeses.

Miloradovic et al. [13] found that VP and MAP can be effectively used to store brined white goat cheeses produced from high heat-treated milk and stored in 6% brine. A decrease in NaCl concentration from 6% to 3% did not cause microbial spoilage or significant changes in the rate of proteolysis, but modified textural parameters, mainly by increasing cheese cohesiveness.

5. Conclusions

The study revealed a significant interaction effect of both experimental factors on all the analyzed physicochemical parameters, sensory attributes, and color parameters of goat cheeses (except for the contribution of redness on the surface of the cheese samples). Despite the higher moisture content of the vacuum-packaged cheeses in groups B and C, they were characterized by lower brittleness and higher weight loss during cold storage. In groups B and C, the packaging methods increased lightness and decreased the contribution of yellowness on the surface of the examined cheeses, whereas cold storage for 5 to 15 days decreased lightness and increased the contribution of yellowness both on the surface and at the cross-section of the cheese samples. Both packaging methods significantly improved the sensory attributes of the goat cheeses, and the samples stored in vacuum packaging with MEGA CO2 absorbent pads (group C) received the highest scores for all the sensory parameters. The color, aroma, structure, consistency, and taste of the cheeses deteriorated between storage days 0 and 10.

The results of the study indicate that vacuum combined with MEGA CO2 absorbent pads is the optimal packaging method for goat cheeses, whereas the optimal cold storage time is 5 and 10 days. Furthermore, the shelf life of goat cheeses can be extended through the use of brine in the production process.

Author Contributions

I.C.-S.—conceptualization, methodology, formal analysis, and data curation; S.S.—writing—original draft preparation; B.P.—writing—review and editing; J.M.—supervision. All authors have read and agreed to the published version of the manuscript.

Funding

Funded by the Minister of Science under the “Regional Initiative of Excellence Programme”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available from the authors upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- FAO Statistic Division. Food and Agriculture Organization of the United Nations. 2023, FAOSTAT. Available online: http://faostat.fao.org (accessed on 1 December 2024).

- Miciński, J. Polish goat farming—A current look at development opportunities. In Current Trends in Goat Breeding in Poland; Miciński, J., Ed.; Materials from the Goat Breeders Conference, Olsztyn; Wydawnictwo UWM: Olsztyn, Poland, 2024; Available online: http://wydawnictwo.uwm.edu.pl/uploads/documents/czytelnia/monografie/Konferencja-Micinski-red.pdf (accessed on 20 November 2014). (In Polish)

- Prosser, C.G. Compositional and functional characteristics of goat milk and relevance as a base for infant formula. J. Food Sci. 2021, 86, 257–265. [Google Scholar] [CrossRef] [PubMed]

- Barłowska, J.; Pastuszka, R.M.; Rysiak, A.; Król, J.; Brodziak, A.; Kędzierska-Matysek, M.; Wolanciuk, A.; Litwińczuk, Z. Physicochemical and sensory properties of goat cheeses and their fatty acid profile in relation to the geopraphic region of production. Int. J. Dairy Tech. 2018, 71, 699–708. [Google Scholar] [CrossRef]

- Cagri-Mehmetoglu, A. Food safety challenges associated with foods of Turkey. Food Sci. Technol. 2018, 38, 1–12. [Google Scholar] [CrossRef]

- Masotti, F.; Battelli, G.; De Noni, I. The evolution of chemical and microbiological properties of fresh goat milk cheese during its shelf life. J. Dairy Sci. 2012, 95, 4760–4767. [Google Scholar] [CrossRef]

- Kuźnicka, E.; Łapińska, A. Goat cheese on an organic farm in Grzybów as an example of organic products, direct sales and local markets. Wiad. Zoot. 2014, 52, 75–82. Available online: https://wz.iz.edu.pl/files/WZ_2014_2_art10.pdf (accessed on 15 November 2024).

- Frau, F.; Leguizamón Carate, J.N.; Salinas, F.; Pece, N. Effect of vacuum packaging on artisanal goat cheeses during refrigerated storage. Food Sci. Technol. 2021, 41, 295–303. [Google Scholar] [CrossRef]

- Dermiki, M.; Ntzimani, A.; Badeka, A.; Savvaidis, I.N.; Kontominas, M.G. Shelf-life extension and quality attributes of the whey cheese “Myzithra Kalathaki” using modified atmosphere packaging. LWT-Food Sci. Technol. 2008, 41, 284–294. [Google Scholar] [CrossRef]

- Kaczyński, Ł.K. Analysis of Water Activity and Gloss of Stored Goat Cheeses According to Consumer Preferences and Tastes. Foods 2024, 13, 3789. [Google Scholar] [CrossRef]

- Khoshgozaran, S.; Azizi, M.H. Evaluating the effect of modified atmosphere packaging on cheese characteristics: A review. Dairy Sci. Technol. 2012, 92, 1–24. [Google Scholar] [CrossRef]

- Pantaleão, I.; Pintado, M.; Pocas, F. Evaluation of two packaging systems for regional cheese. Food Chem. 2007, 102, 481–487. [Google Scholar] [CrossRef]

- Miloradovic, Z.; Smigic, N.; Djekic, I.; Tomasevic, I.; Kljajevic, N.; Nedeljkovic, A.; Miocinovic, J. The influence of NaCl concentration of brine and different packaging on goat white brined cheese characteristics. Int. Dairy J. 2018, 79, 24–32. [Google Scholar] [CrossRef]

- Chwastowska-Siwiecka, I.; Skiepko, N.; Kubiak, M.S. Food packages- exemplified solutions. Przem. Spoż. 2015, 1, 25–29. [Google Scholar] [CrossRef]

- El-Sayed, S.M.; Youssef, A.M. Emergence of cheese packaging by edible coatings for enhancing its shelf-life. J. Food Meas. Charact. 2024, 18, 5265–5280. [Google Scholar] [CrossRef]

- PN-A-86232:1973; Milk and Dairy Products-Cheeses-Methods of Analysis. Polish Committee for Standardization: Warsaw, Poland, 1973; pp. 1–12. (In Polish)

- Ishihara, Y.; Moreira, R.; de Souza, G.; Salviano, A.; Madruga, M. Study of the Warner-Bratzler Shear Force, Sensory Analysis and Sarcomere Length as Indicators of the Tenderness of Sun-Dried Beef. Molecules 2013, 18, 9432–9440. [Google Scholar] [CrossRef]

- CIE. Recommendations on Uniform Color Spaces, Color-Difference Equations, Psychometric Color Terms; Suppl. No. 2 to CIE publication No. 15 (E-1.3.1), 1971/(TC1-3); Commission Internationale de L’éclairage: Paris, France, 1978. [Google Scholar]

- ISO 4121:2003; Sensory Analysis—Guidelines for the Use of Quantitative Response Scales. International Organization for Standardization (ISO): Geneva, Switzerland, 2003.

- ISO 8586:2023; Sensory Analysis—Selection and Training of Sensory Assessors. International Organization for Standardization (ISO): Geneva, Switzerland, 2023.

- PN-A-86300:1991; Milk and Dairy Products—Unripened Curd Cheese. Polish Committee for Standardization: Warsaw, Poland, 1991; pp. 1–7. (In Polish)

- Statsoft Inc. Statistical Analysis System (SAS). In SAS/STAT: User’s Guide, Version 6, 12th ed.; SAS Institute Inc.: Cary, NC, USA, 2000. [Google Scholar]

- Mei, J.; Yuan, Y.; Wu, Y.; Li, Y. Characterization of edible starch-chitosan film and its application in the storage of Mongolian cheese. Inter. J. Biol. Macromol. 2013, 57, 17–21. [Google Scholar] [CrossRef]

- Pluta, A.; Wnuk, B.; Ziarno, M.; Berthold, A. Effects of packaging systems on the quality of tvorog cheeses. Żyw. Nauk. Techn. Jak. 2003, 4, 330–340. Available online: https://wydawnictwo.pttz.org/wp-content/uploads/2018/01/38_Pluta.pdf (accessed on 10 December 2024). (In Polish).

- Paciorek, A.; Bonczar, G. The Assessment of oszczypki cheeses quality and the evaluation of milk and whey properties. Żyw. Nauk. Techn. Jak. 2001, 1, 103–116. Available online: https://wydawnictwo.pttz.org/wp-content/uploads/2017/12/10_Paciorek.pdf (accessed on 10 December 2024). (In Polish).

- de Oliveira, M.E.G.; Garcia, E.F.; Queiroga, R.C.R.E.; Souza, E.L. Technological, physicochemical and sensory characteristics of a Brazilian semi-hard goat cheese (coalho) with added probiotic lactic acid bacteria. Scient. Agric. 2012, 69, 370–379. Available online: https://www.scielo.br/j/sa/a/FTwbzmsCVgztmy8SRCgycgK/?format=pdf&lang=en (accessed on 25 November 2024). [CrossRef]

- Kirkin, C.; Gunes, G.; Kilic-Akyilmaz, M. Preservation of precut white cheese by modified atmosphere packaging. Inter. J. Dairy Techn. 2013, 66, 576–586. [Google Scholar] [CrossRef]

- Kokotkiewicz, J.; Radzik-Rant, A.; Rant, W. Products of sheep origin in food quality systems. Wiad. Zoot. 2018, 2, 85–92. Available online: https://wz.iz.edu.pl/files/WZ_2018_2_art13.pdf (accessed on 14 December 2024).

- Bintsis, T. Quality of the Brine. In Brined Cheeses; Tamime, A., Ed.; Blackwell Publishing Ltd.: Oxford, UK, 2006; pp. 264–301. [Google Scholar]

- Chwastowska-Siwiecka, I.; Baryczka, M.J.; Dębczyńska, A. Chemical composition and physicochemical properties of Camembert cheeses available in retail shops. Aparat. Bad. Dyd. 2019, 1, 99–106. [Google Scholar]

- Tunick, M.H.; Malin, E.L.; Smith, P.W.; Shieh, J.J.; Sulivan, B.C.; Mackey, K.L.; Holsinger, V.H. Proteolysis and rheology of low fat and full fat Mouaretla Cheeses prepared from homogenized milk. J. Dairy Sci. 1993, 76, 3621–3628. [Google Scholar] [CrossRef]

- Juric, M.; Bertelsen, G.; Mortensen, G.; Petersen, M.A. Light-induced colour and aroma changes in sliced, modified atmosphere packaged semi-hard cheeses. Int. Dairy J. 2003, 13, 239–249. [Google Scholar] [CrossRef]

- Kristensen, D.; Orlien, V.; Mortensen, G.; Brockhoff, P.; Skibsted, L.H. Light-induced oxidation in sliced Havarti cheese packaged in modified atmosphere. Int. Dairy J. 2000, 10, 95–103. [Google Scholar] [CrossRef]

- Kaya, S. Effect of salt on hardness and whiteness of Gaziantep cheese during short-term brining. J. Food Engin. 2002, 52, 155–159. [Google Scholar] [CrossRef]

- Rohm, H.; Jaros, D. Colour of hard cheese. 1. Description of colour properties and effects of maturation. Zeit. Lebens. Unters. Forsch. 1996, 203, 241–244. [Google Scholar] [CrossRef]

- Cais-Sokolińska, D.; Danków, R.; Pikul, J. Stability and quality of colour of mozzarella cheese during storage. Nauka Przyr. Technol. 2009, 3, 1–7. Available online: https://www.npt.up-poznan.net/pub/art_3_112.pdf (accessed on 20 December 2024).

- Park, Y.W.; Drake, M.A. Effect of 3 months frozen-storage on organic acid contents and sensory properties, and their correlations in soft goat milk cheese. Small Rumin. Res. 2005, 58, 291–298. [Google Scholar] [CrossRef]

- Buňka, F.; Pachlová, V.; Pernická, L.; Burešová, I.; Kráčmar, S.; Lošák, T. The dependence of peleg’s coefficients on selected conditions of a relaxation test in model samples of edam cheese. J. Text. Stud. 2013, 44, 187–195. [Google Scholar] [CrossRef]

- Ribeiro, A.C.; Ribeiro, S.D.A. Specialty products made from goat milk. Small Rum. Res. 2010, 89, 225–233. [Google Scholar] [CrossRef]

- Pluta, A.; Ziarno, M.; Kruk, M. Impact of modified atmosphere packing on the quality of grated mozzarella cheese. Pol. J. Food Nutrit. Sci. 2005, 55, 117–122. [Google Scholar]

- Cakmakci, S.; Dagdemir, E.; Hayaloglu, A.A.; Gurses, M.; Cetin, B.; Tahmas-Kahyaoglu, D. Effect of Penicillum roqueforti and incorporation of whey cheese on volatile profiles and sensory characteristics of mould-ripened civil cheese. Inter. J. Dairy Techn. 2013, 66, 512–526. [Google Scholar] [CrossRef]

- Bohdziewicz, K.; Jasińska, A.M. The palatability profiling method as a tool for determining the nature of descriptor changes during storage of Camembert cheeses. In Innovative Solutions in Food Technology and Human Nutrition; Tarko, T., Drożdż, I., Najgebauer-Lejko, D., Duda-Chodak, A., Eds.; Polskie Towarzystwo Technologów Żywności: Kraków, Poland, 2016; pp. 295–303. ISBN 978-83-937001-8-9. Available online: https://pttzm.org/wp-content/uploads/2019/12/MONOGRAFIAt2.pdf (accessed on 15 November 2024). (In Polish)

- Souza, C.H.B.; Saad, S.M.I. Viability of Lactobacillus acidophilus La-5 added solely or in co-culture with a yoghurt starter culture and implications on physico-chemical and related properties of Minas fresh cheese during storage. LWT-Food Sci.Techn. 2009, 42, 633–640. [Google Scholar] [CrossRef]

- Miloradovic, Z.; Kljajevic, N.; Miocinovic, J.; Tomic, N.; Smiljanic, J.; Macej, O. High heat treatment of goat cheese milk. The effect on yield, composition, proteolysis, texture and sensory quality of cheese during ripening. Inter. Dairy J. 2017, 68, 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).