Femtosecond Laser-Textured Titanium Alloys: Effects of Circular, Elliptical, and Grooved Morphologies on Tribological Performance in Artificial Joints

Abstract

1. Introduction

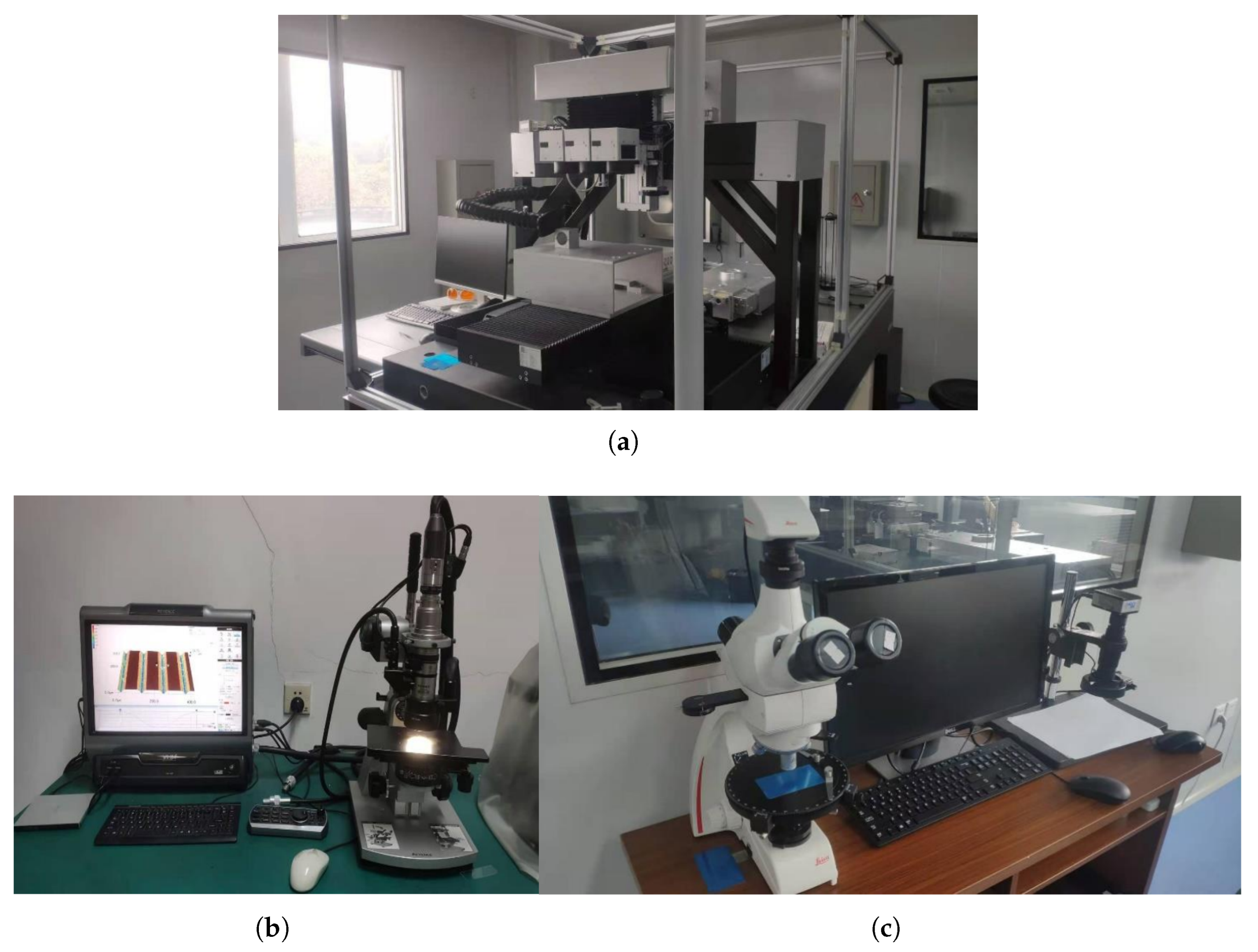

2. Experiment

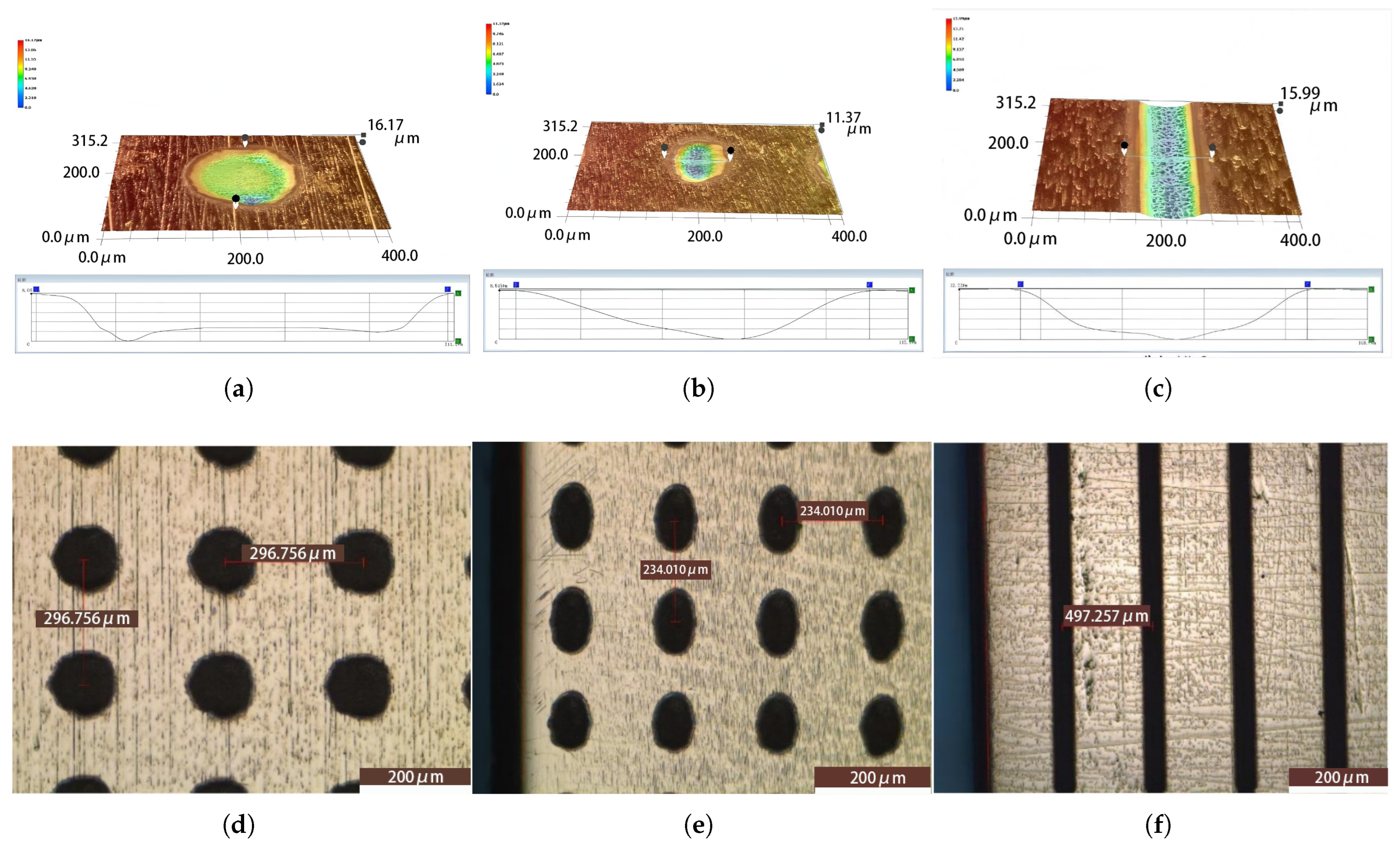

2.1. Sample Preparation and Femtosecond Laser Texturing Process

2.2. Friction and Wear Experiment Design

3. Results and Discussion

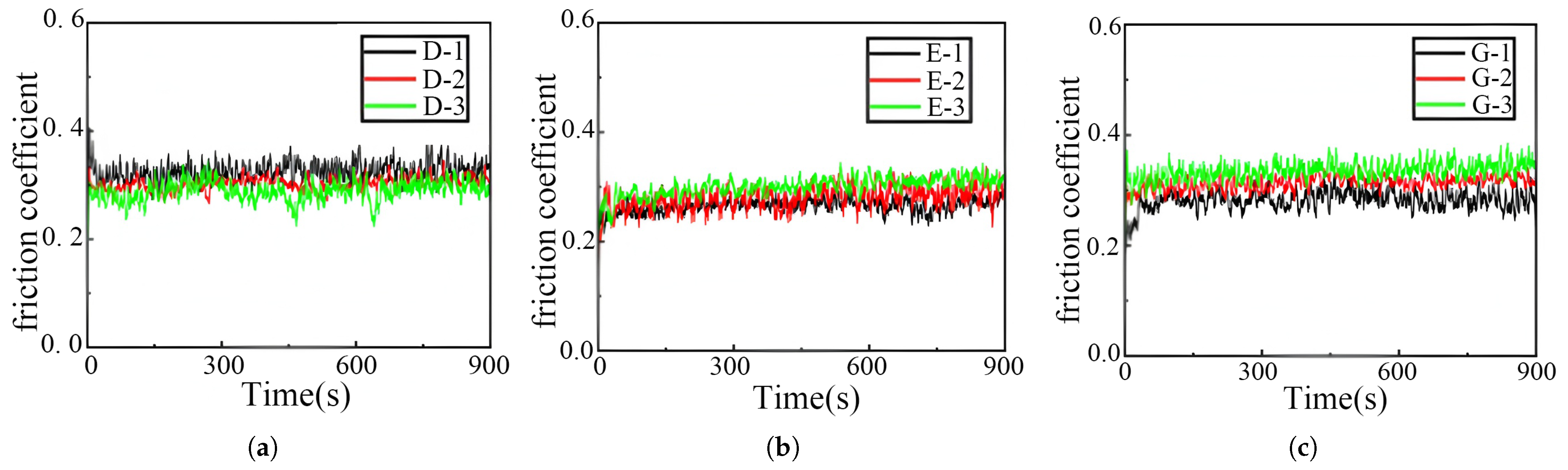

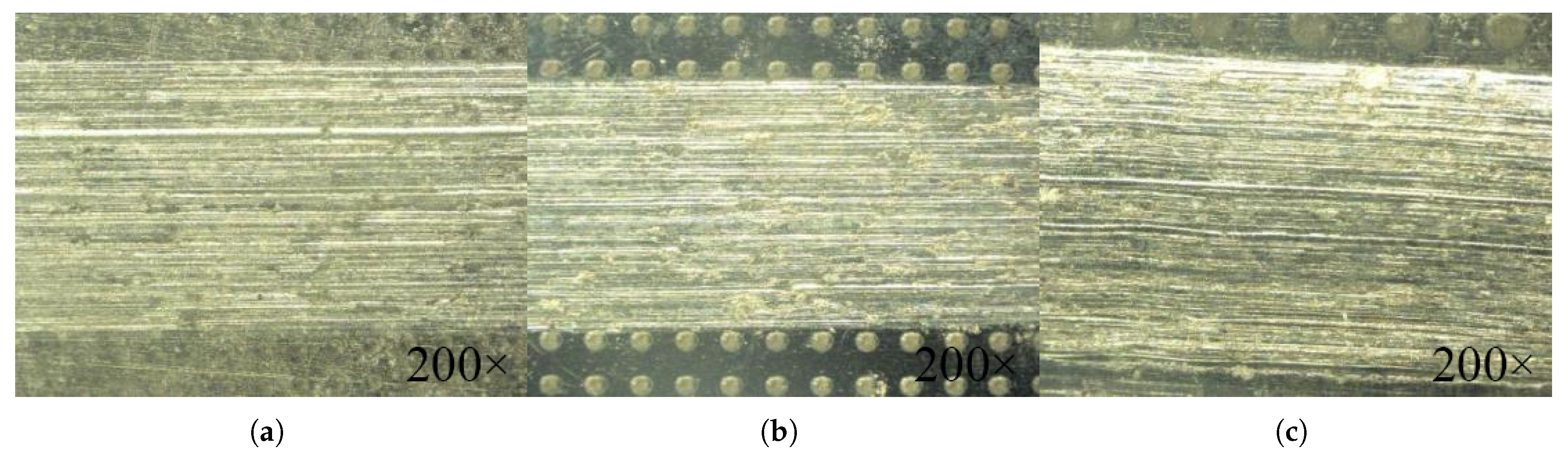

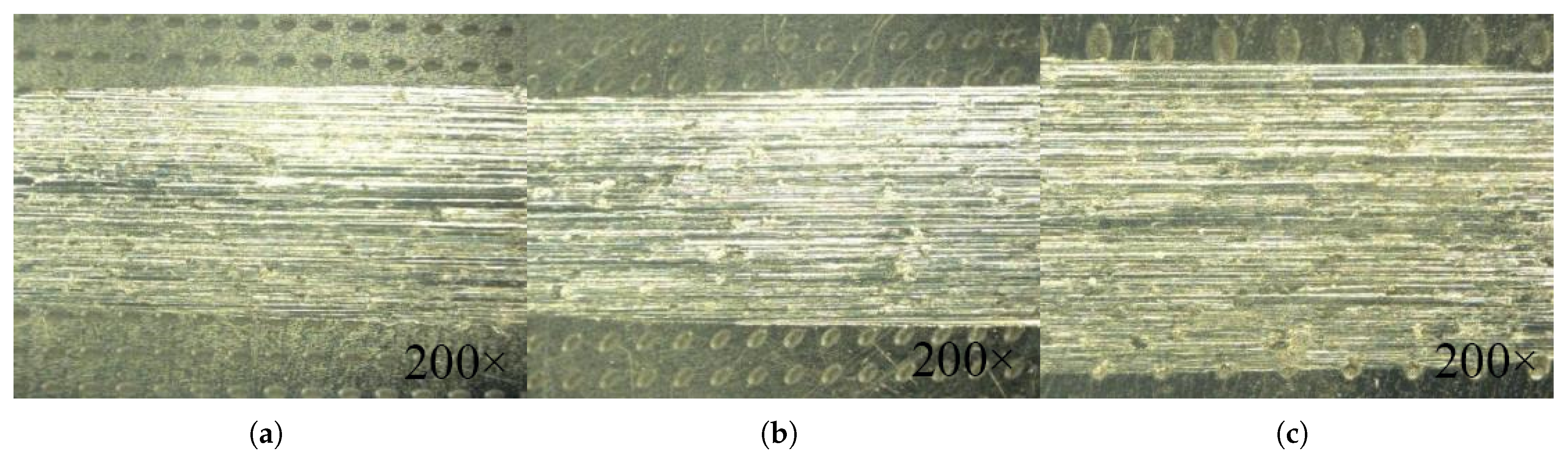

3.1. Analysis of Friction and Wear Experiment Results

3.2. Impact of Texture Morphology on Tribological Performance of Joint Interfaces

4. Discussion

- Mechanistic Insights into Texture Performance

- Circular texture (D-3): Large-diameter pits reduce friction through the dual effect of “oil storage + chip storage”, storing more albumin solution (under oil lubrication conditions) while capturing titanium alloy debris (size∼50 m) to avoid scratching ceramic balls.

- Elliptical texture (E-1): When the long axis is parallel to the direction of motion, a “convergent wedge” structure is formed, which conforms to the law that “lubricating film pressure increases with the decrease of clearance” in the Reynolds equation, enhancing the fluid dynamic pressure effect, and the oil film thickness is 2–3 times higher than that in the control group.

- Groove-shaped texture (G-1): Narrow grooves form dense channels, guiding the even distribution of the lubricant while discharging debris, reducing adhesive wear caused by “debris embedding”.

- Quantifying the Impact of Performance Improvements on Prosthesis Lifespan

- Clinical Relevance: The primary cause of artificial joint failure is wear debris-induced osteolysis. A 50% reduction in wear volume can decrease the risk of prosthesis revision by approximately 40% (based on the positive correlation between wear volume and revision rate in the literature). In this study, the elliptical texture reduced wear volume by 52.94%, which theoretically could extend the average lifespan of a prosthesis from 15–20 years to 25–30 years (assuming a linear reduction in wear rate).

- Significance of Reduced Friction Coefficient: A 20.51% reduction in the average friction coefficient can decrease energy loss during joint movement and reduce the stress at the prosthesis–bone interface (for example, the maximum stress during the gait cycle in the hip joint can be reduced by about 15%), thereby delaying loosening.

- Adapting Optimal Parameters to Different Joint Types

- Knee Joint: Primarily characterized by flexion–extension movements (reciprocating linear motion), it is recommended to use elliptical textures with the long axis parallel to the direction of motion (with a long-to-short axis ratio of 2:1), and the width of grooved textures can be increased to 150 m (to accommodate a larger contact area).

- Hip Joint: Characterized by compound rotational and swinging movements, a combination of elliptical textures (with a long axis angle of 45°) and circular textures (with a diameter of 500 m) is recommended to balance the lubrication needs in multiple directions.

- Shoulder Joint: With the largest range of motion, it is suggested to use small-sized grooved textures (with a width of 80 m) to enhance debris removal and avoid additional friction between the prosthesis and the surrounding rotator cuff tissues.

5. Conclusions

- As the diameter of circular dimples increases, there is a decrease in wear amount and wear depth, as well as a lower degree of morphological wear.

- When the long axis of elliptical textures is aligned parallel to the direction of motion, the friction coefficient is minimized, offering the best friction reduction performance, and the morphology remains well-preserved after testing.

- Under the same coverage area, narrower grooves in grooved textures lead to denser texture patterns, resulting in a lower friction coefficient, superior friction reduction performance, and a more intact texture morphology.

- A comparative analysis of the optimal parameters among the three different texture morphologies was conducted under the same coverage area and dimple depth. The elliptical texture (E-1) demonstrated superior anti-wear and friction-reducing performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Charnley, J. The long-term results of low-friction arthroplasty of the hip performed as a primary intervention. J. Bone Joint Surg. Br. 1972, 54, 61–76. [Google Scholar] [CrossRef]

- Batailler, C.; Fary, C.; Verdier, R.; Aslanian, T.; Caton, J.; Lustig, S. The evolution of outcomes and indications for the dual-mobility cup: A systematic review. Int. Orthop. 2017, 41, 645–659. [Google Scholar] [CrossRef]

- Bertagnoli, R.; Yue, J.; Fenk-Mayer, A.; Eerulkar, J.; Emerson, J. Treatment of symptomatic adjacent-segment degeneration after lumbar fusion with total disc arthroplasty by using the prodisc prosthesis: A prospective study with 2-year minimum follow up. J. Neurosurg. Spine 2006, 4, 91–97. [Google Scholar] [CrossRef]

- Zhang, D.M.; Liu, H.T.; Wang, J.M.; Sheng, C.X.; Li, Z.X. Wear mechanism of artificial joint failure using wear debris analysis. J. Nanosci. Nanotechnol. 2018, 18, 6805–6814. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, Y.; Su, Y.J.; Qiao, L.J. Release of metal ions from nano CoCrMo wear debris generated from tribo-corrosion processes in artificial hip implants. J. Mech. Behav. Biomed. Mater. 2017, 68, 124–133. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Qin, Y.G.; Qing, Y.A.; Deng, R.P.; Jin, H.; Li, R.Y.; Rehman, J.; Wen, M.; Zhang, K. TiCuN solid solution coating: Excellent wear-resistant biocompatible material to protect artificial joint. Mater. Lett. 2018, 227, 145–148. [Google Scholar] [CrossRef]

- Šugár, P.; Antala, R.; Šugárová, J.; Kováčik, J.; Pata, V. Study on surface roughness, morphology, and wettability of laser-modified powder metallurgy-processed Ti-graphite composite intended for dental application. Bioengineering 2023, 10, 1406. [Google Scholar] [CrossRef]

- David, N.; Hatsuhiko, U.; Tatsuya, N.; Sawae, Y.; Křupka, I.; Martin, H. Running-in friction of hip joint replacements can be significantly reduced: The effect of surface-textured acetabular cup. Friction 2020, 8, 1137–1152. [Google Scholar]

- Borjali, A.; Langhorn, J.; Monson, K.; Raeymaekers, B. Using a patterned microtexture to reduce polyethylene wear in metal-on-polyethylene prosthetic bearing couples. Wear 2017, 392–393, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Philipp, D.; Paul, O.; Tim, D.; Rigo, P.; Hermann, S. Modification of joint prosthesis surfaces by ultrashort pulse laser treatment for improved joint lubrication. Curr. Dir. Biomed. Eng. 2019, 5, 57–60. [Google Scholar] [CrossRef][Green Version]

- Ji, Z.; Wan, Y.; Wang, H.; Song, W.; Zou, Y.; Zhou, L. Polydopamine-assisted loading of bioactive ions onto the multi-scale composite-structured surface of 3D-printed porous Ti-6Al-4V implant to enhance its osteogenic and antibacterial properties. Surf. Interfaces 2025, 67, 106624. [Google Scholar] [CrossRef]

- Wang, C.; Hu, H.; Li, Z.; Shen, Y.; Xu, Y.; Zhang, G.; Zeng, X.; Deng, J.; Zhao, S.; Ren, T.; et al. Enhanced Osseointegration of Titanium Alloy Implants with Laser Microgrooved Surfaces and Graphene Oxide Coating. ACS Appl. Mater. Interfaces 2019, 11, 39470–39483. [Google Scholar] [CrossRef]

- Allen, Q.; Raeymaekers, B. Surface texturing of prosthetic hip implant bearing surfaces: A review. J. Tribol. 2021, 143, 040801. [Google Scholar] [CrossRef]

- Vishnoi, M.; Kumar, P.; Murtaza, Q. Surface texturing techniques to enhance tribological performance: A review. Surf. Interfaces 2021, 27, 101463. [Google Scholar] [CrossRef]

- Gao, L.; Yang, P.; Dymond, I.; Fisher, J.; Jin, Z. Effect of surface texturing on the elastohydrodynamic lubrication analysis of metal-on-metal hip implants. Tribol. Int. 2010, 43, 1851–1860. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Zhu, Q.; Wang, C.Y.; Li, J.Q. Tribological behavior of CoCrMo artificial knee joint with symmetrically biomimetic textured surfaces on PEEK. Opt. Laser Technol. 2023, 157, 108774. [Google Scholar] [CrossRef]

- Dipankar, C.; David, R.; Shinya, S.; Pavel, H.; Martin, V.; Min, Z. Enhanced lubricant film formation through micro-dimpled hard-on-hard artificial hip joint: An in-situ observation of dimple shape effects. J. Mech. Behav. Biomed. Mater. 2018, 81, 120–129. [Google Scholar]

- Dipankar, C.; Martin, V.; Azuddin, B.M.; Ian, S.; Chanchal, K.R.; Rajshree, M.; Ivan, K. The impact of surface and geometry on coefficient of friction of artificial hip joints. J. Mech. Behav. Biomed. Mater. 2017, 72, 192–199. [Google Scholar] [CrossRef] [PubMed]

- Bao, Y.M.; Wu, X.; Wang, C.W. Effect of texture on the friction and wear properties under mixed lubrication conditions for artificial joint materials. J. Zhejiang Univ. Technol. 2019, 47, 375–381. [Google Scholar]

- Saikko, V.; Ahlroos, T.; Calonius, O. A three-axis knee wear simulator with ball-on-flat contact. Wear 2001, 249, 310–315. [Google Scholar]

- Wang, S.; Fu, S.Q.; Tian, X.Y.; Li, J.H.; Xu, J.; Liu, W.Q. Friction, wear and debris characteristics of artificial joint CoCrMo-UHMWPE pair under different contact stresses. Mater. Prot. 2022, 55, 33–39. [Google Scholar]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- García-Fernández, J.; Salguero, J.; Vázquez-Martínez, J.M.; del Sol, I.; Batista, M. Influence of laser surface texture orientation on the tribological behavior of the WC-Co/Ti6Al4V pair in dry and lubricated conditions. Wear 2025, 571, 205852. [Google Scholar] [CrossRef]

| Texture Type | Key Parameters | Parameter Range |

|---|---|---|

| Circular texture | Diameter | 300 m, 500 m, 700 m |

| Elliptical texture | Long axis/Short axis/Angle | 500 m/250 m, 700 m/350 m; 0°, 45°, 90° |

| Grooved texture | Width | 100 m, 200 m, 300 m |

| Experimental Parameters | Value/Condition |

|---|---|

| Contact stress | 30 N |

| Velocity | 0.1 m/s |

| Temperature | 37 °C |

| Lubricant | 3 mg/mL bovine serum albumin (BSA) |

| Lubricant supply | 0.5 mL/15 min |

| Specimen | Control Group | Circular Texture | Elliptical Texture | Grooved Texture | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T-0 | D-1 | D-2 | D-3 | E-1 | E-2 | E-3 | G-1 | G-2 | G-3 | |

| Wear amount (g) | 0.0017 | 0.0015 | 0.0013 | 0.0012 | 0.0008 | 0.0010 | 0.0011 | 0.0011 | 0.0012 | 0.0014 |

| Wear scar depth (m) | 158.1 | 54.19 | 51.47 | 48.59 | 39.37 | 43.60 | 47.83 | 40.21 | 46.23 | 53.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; Zhao, Y.; Yu, X.; Cao, S. Femtosecond Laser-Textured Titanium Alloys: Effects of Circular, Elliptical, and Grooved Morphologies on Tribological Performance in Artificial Joints. Appl. Sci. 2025, 15, 11450. https://doi.org/10.3390/app152111450

Zhu C, Zhao Y, Yu X, Cao S. Femtosecond Laser-Textured Titanium Alloys: Effects of Circular, Elliptical, and Grooved Morphologies on Tribological Performance in Artificial Joints. Applied Sciences. 2025; 15(21):11450. https://doi.org/10.3390/app152111450

Chicago/Turabian StyleZhu, Chunxia, Yuan Zhao, Xueliang Yu, and Shunyu Cao. 2025. "Femtosecond Laser-Textured Titanium Alloys: Effects of Circular, Elliptical, and Grooved Morphologies on Tribological Performance in Artificial Joints" Applied Sciences 15, no. 21: 11450. https://doi.org/10.3390/app152111450

APA StyleZhu, C., Zhao, Y., Yu, X., & Cao, S. (2025). Femtosecond Laser-Textured Titanium Alloys: Effects of Circular, Elliptical, and Grooved Morphologies on Tribological Performance in Artificial Joints. Applied Sciences, 15(21), 11450. https://doi.org/10.3390/app152111450