Trajectory Tracking Control Method via Simulation for Quadrotor UAVs Based on Hierarchical Decision Dual-Threshold Adaptive Switching

Abstract

1. Introduction

2. Theoretical Background

2.1. Quadrotor Dynamics Model

- -

- Inertial frame:

- -

- Body frame: (origin at center of mass).

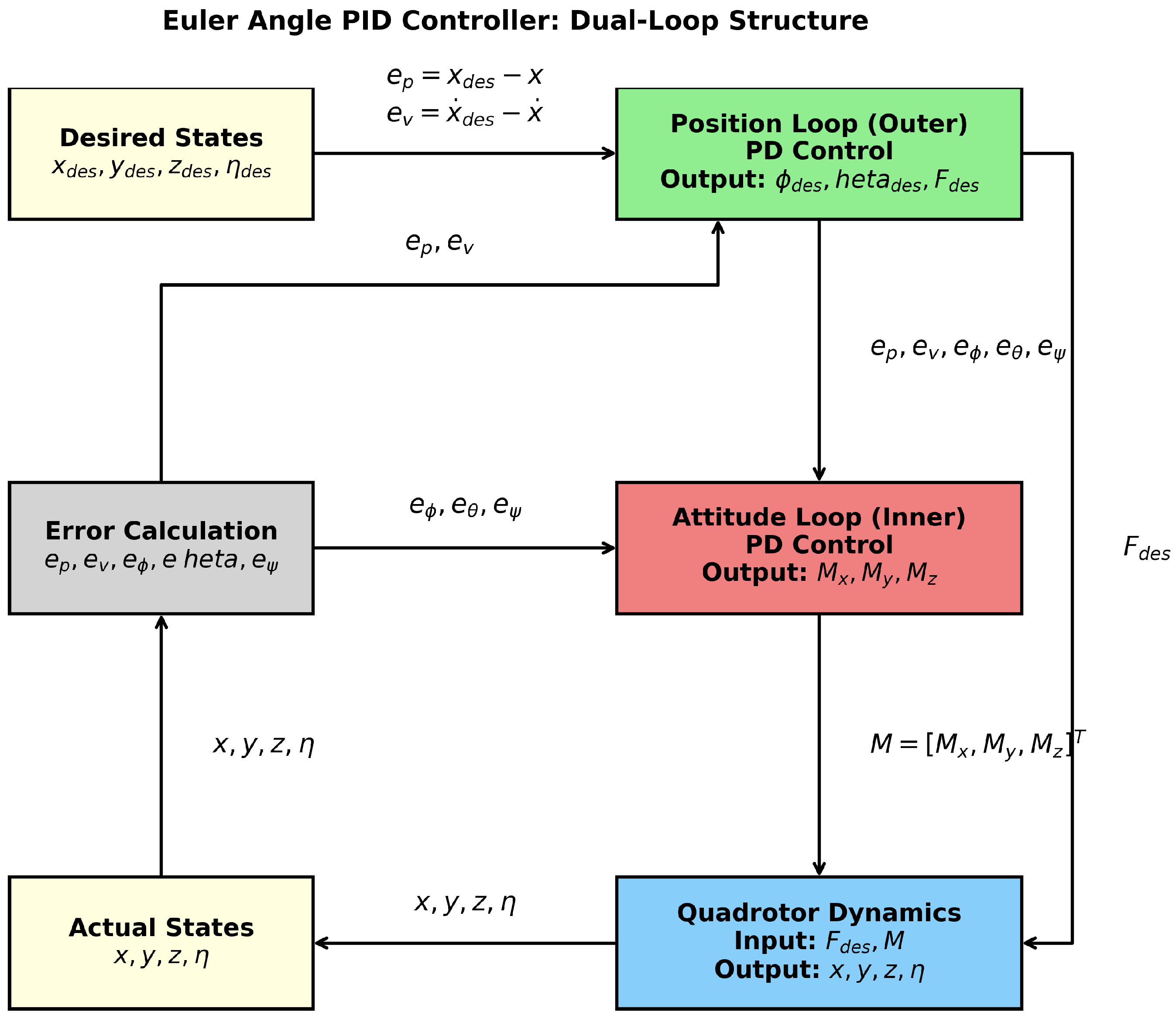

2.2. Euler Angle Controller Design

- Small-angle condition: , , , .

- Linearized angular velocity conversion between body and inertial frames.

- Position loop (outer): Computes desired attitude angles via PD control. For Z-axis control:where is total thrust, and are proportional/derivative gains.

- Attitude loop (inner): Computes torque via PD control. For roll angle,where is desired roll angle, and is moment of inertia.

- Integral windup prevention: During complex maneuvers (e.g., rapid turns in T1, wind disturbances in T3), error accumulation may cause actuator saturation and instability—conflicting with real-time stability requirements.

- Resource efficiency: Integral terms increase computational load by storing historical errors. For resource-constrained platforms (as stated in abstract), PD’s lightweight nature reduces CPU time to 266–285 ms (vs. 1297–1350 ms for geometric control).

- Synergy with switching mechanism: Euler control is applied in simple segments (e.g., straight-line phases) where steady-state errors are minimal. The PD structure (proportional term for current errors + derivative term for error rates) suffices. When error accumulation occurs (e.g., wind disturbances), the dual-threshold mechanism activates geometric control, eliminating need for integral compensation.

- Position loop: Computes desired angles and thrust:

- Attitude loop: Computes control torque:

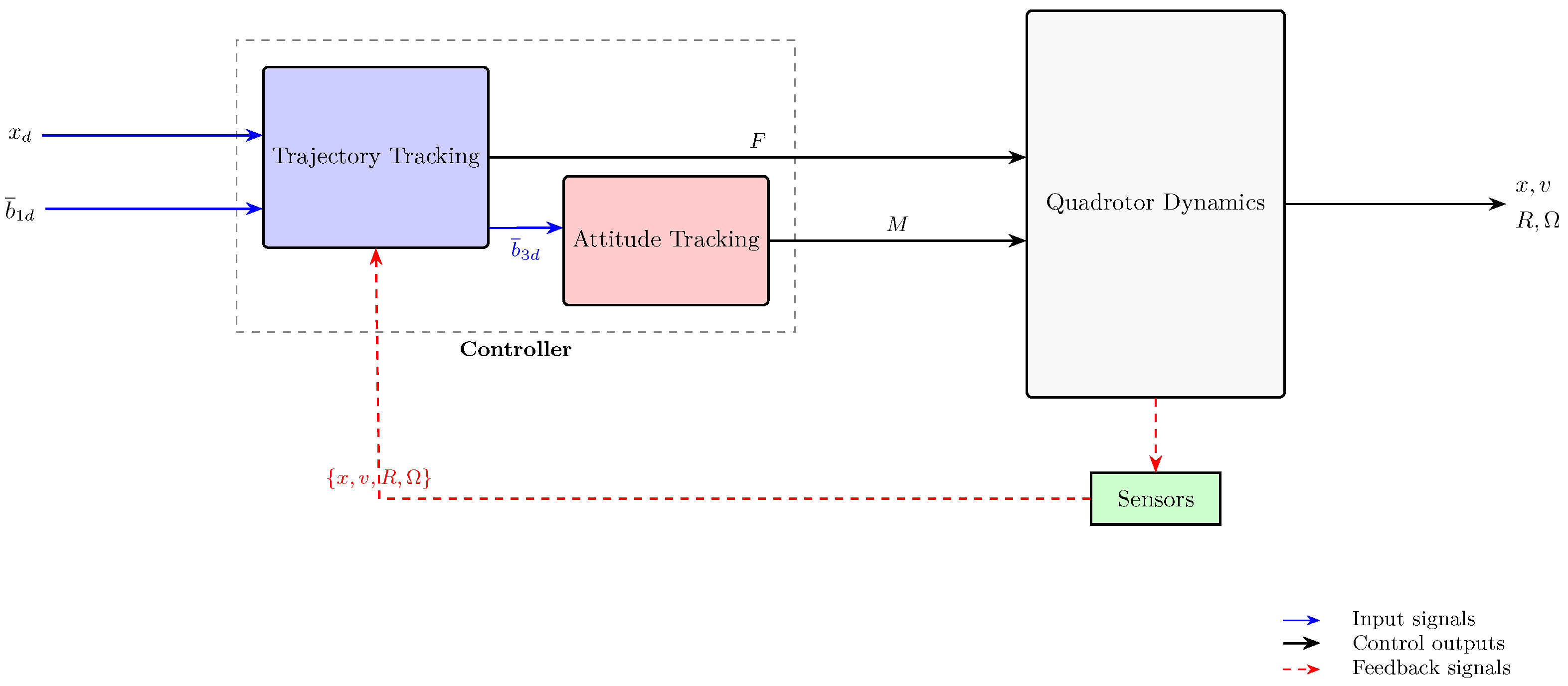

2.3. Geometric Controller Design

- No singularity: When the UAV performs maneuvers with a roll angle or continuous flips, the rotation matrix R always maintains smooth evolution.

- Global stability: Using the completeness of the Lie group manifold, a Lyapunov function covering the entire attitude space can be constructed [30].

- Physical consistency: The torque control input M acts directly on the rigid-body dynamic equations, avoiding model errors introduced by linearization [10].

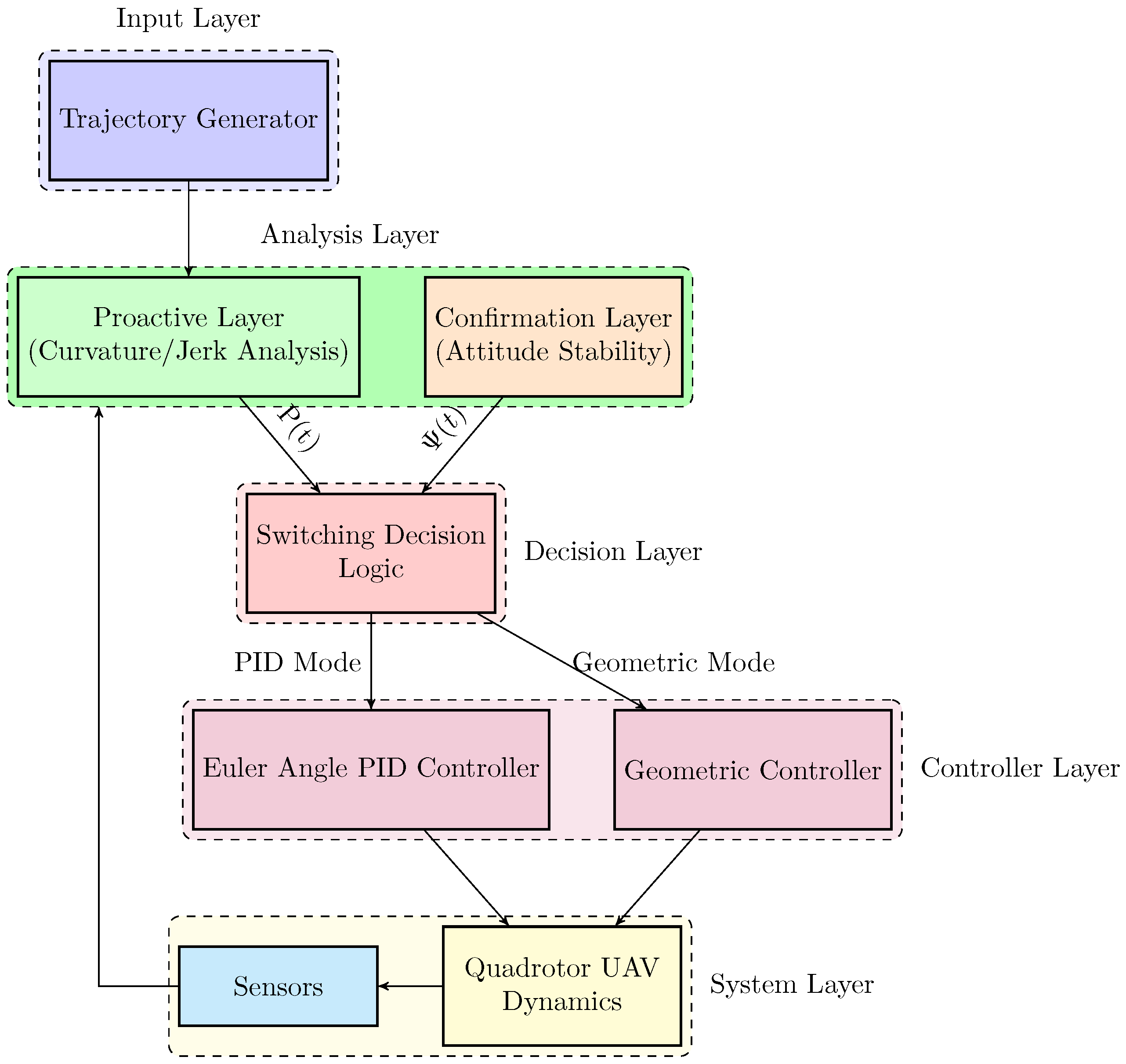

2.4. Hierarchical Dual-Threshold Cooperative Early Warning Switching Mechanism

2.4.1. Analysis of Existing Methods and Bio-Inspired Design

Limitations of Single-Controller Architecture

Bio-Inspired Architecture Design

- Confirmation Layer (Analogous to Vestibular System): Monitors real-time attitude stability using the composite index (Equation (30)), which integrates attitude deviation and angular velocity energy. This layer triggers switching only when actual instability risks are confirmed.

- Prospectiveness: Early warning prevents instability from delayed switching.

- Accuracy: Confirmation layer prevents false switching from transient fluctuations.

- Efficiency: Maintains low-energy control during simple flight segments.

2.4.2. Proactive Layer Design and Trajectory Complexity Quantification

Geometric Complexity Evaluation

Dynamic Impact Assessment

Risk Fusion Strategy

2.4.3. Confirmation Layer Design and Switching Mechanism

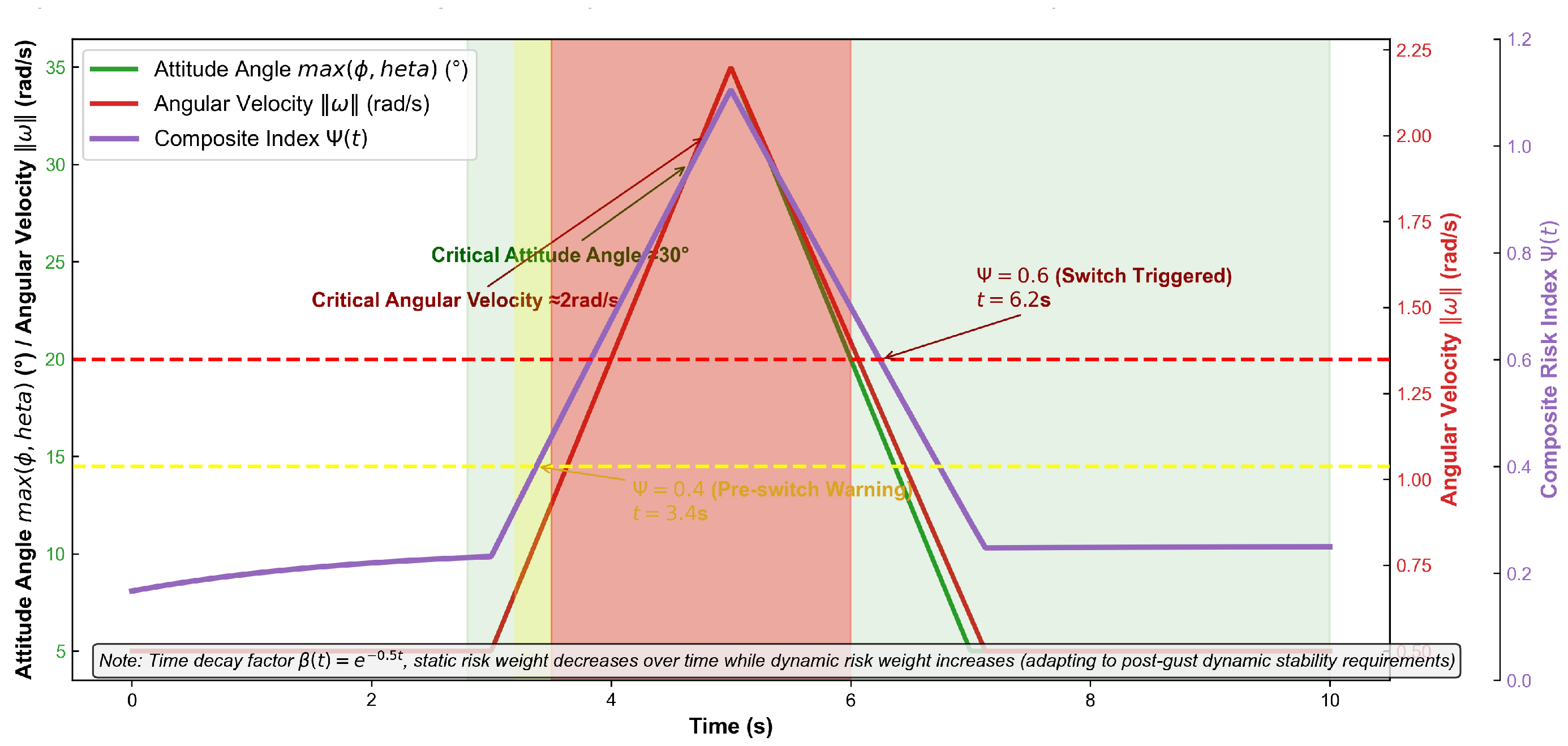

Composite Risk Index

Three-Tier Risk Strategy

Dual-Threshold Switching with Hysteresis Protection

Core Innovation Summary

- Collaborative Decision-Making: Controller switching requires simultaneous threshold exceedance in both layers (Equation (35)), eliminating response lag (single confirmation layer) and false switching (single proactive layer).

- Hysteresis Protection: Asymmetric switching conditions (Equation (34)) prevent oscillatory switching while maintaining noise robustness.

3. Research Methods

3.1. Implementation Process of the Control Algorithm

- Proactive Layer Indicator Calculation The proactive layer evaluates trajectory complexity using normalized curvature and window variance of jerk, with specific steps as follows: For a discrete desired trajectory (sampling time , for real-time performance), the following applies:

- Confirmation Layer Indicator Calculation

- -

- Low risk (): Maintain current controller (default: Euler angle PID).

- -

- Medium risk (): Trigger pre-switching warning (preload geometric control parameters).

- -

- High risk (): Confirm stability risk (corresponding to attitude angle or angular velocity ≥ 2 rad/s).

- Dual-Threshold Switching Logic

3.2. Simulation Experiment Design Method

- Experimental Platform and Parameter Configuration

- -

- Euler angle PID: , (proportional gains); , (derivative gains, tuned via Ziegler–Nichols method).

- -

- Geometric control: , (position gains); , (attitude gains, verified via Lyapunov function for global stability).

- Evaluation Indicator Quantification

- Typical Trajectory Generation Four trajectories are designed based on differential flatness theory (ensuring dynamic feasibility) to cover diverse complex scenarios:

4. Experimental Results

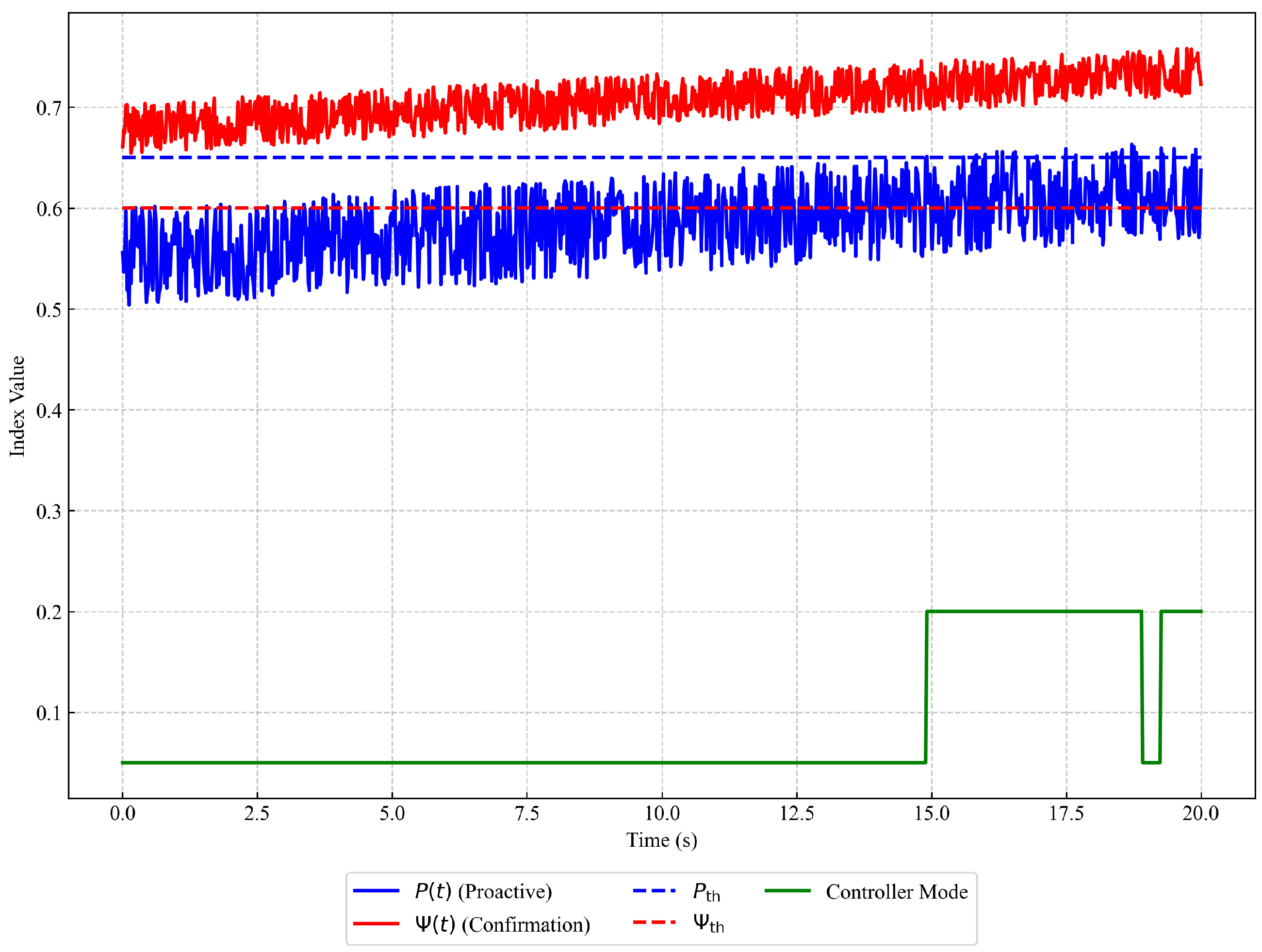

4.1. Calibration Results of Proactive Layer Threshold

- -

- Straight segment (0–5 s): ;

- -

- Maneuvering segment (5–10 s): .

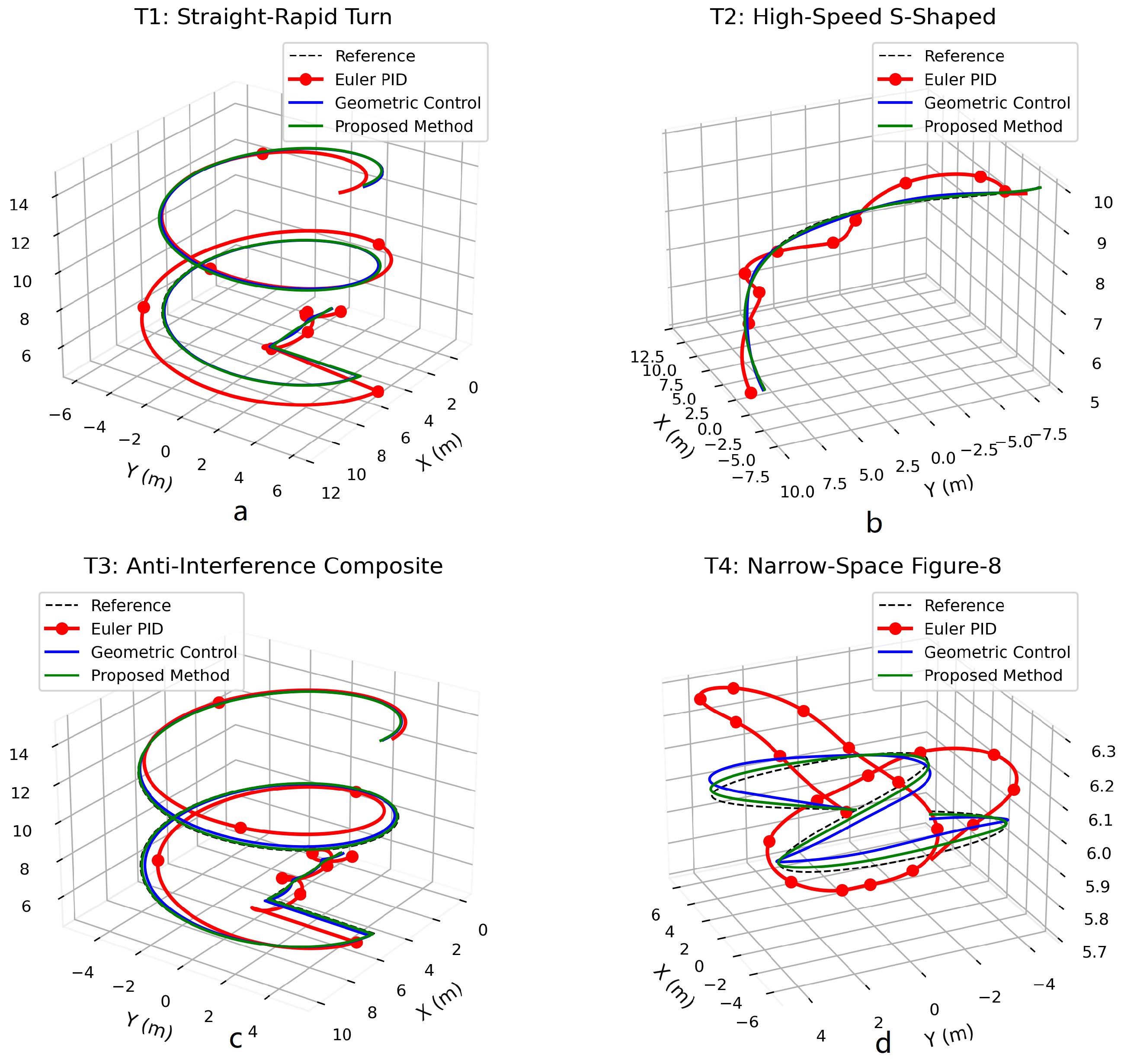

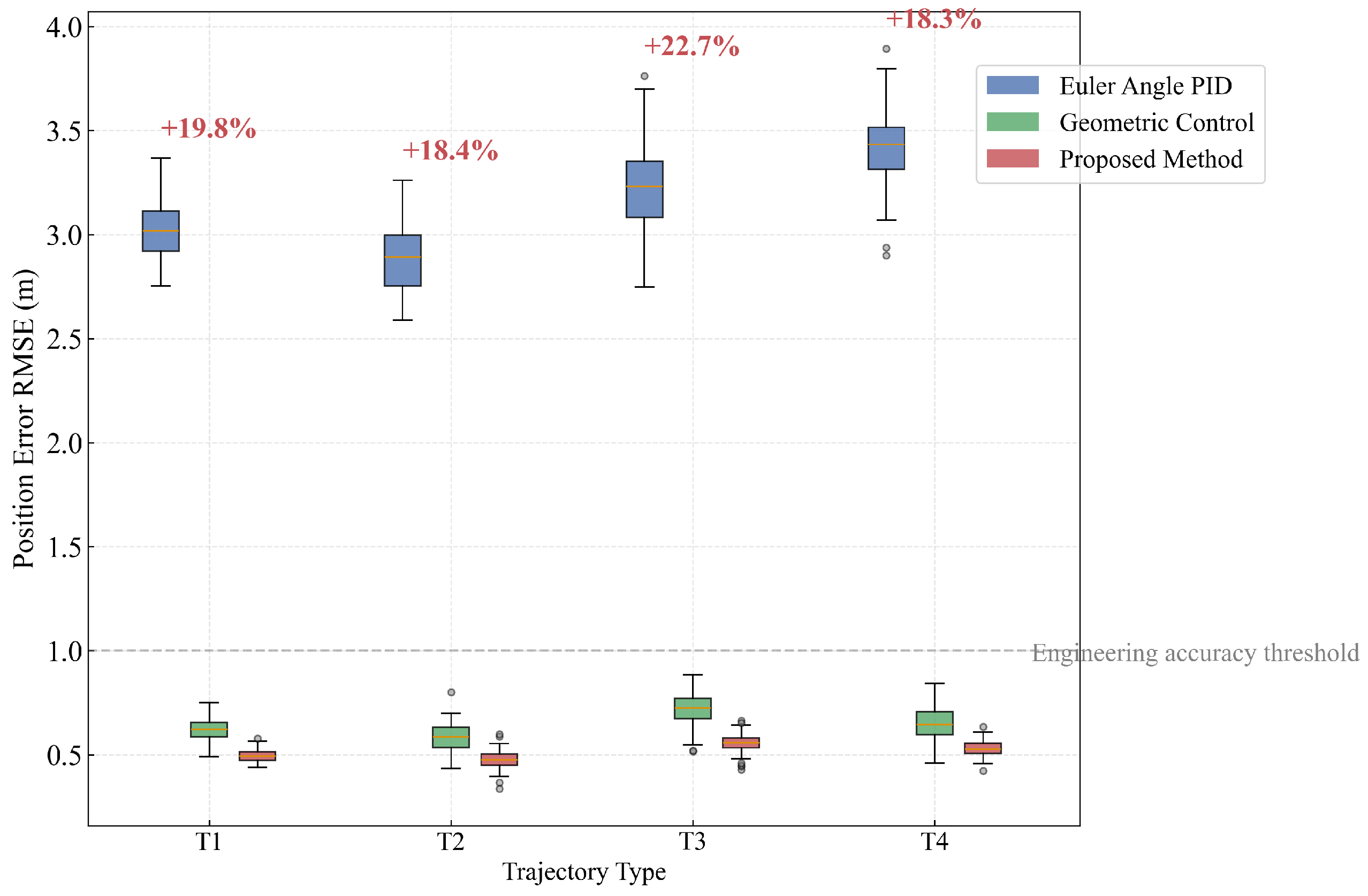

4.2. Performance Results on Typical Trajectories

4.2.1. Quantitative Performance Comparison

4.2.2. Visualized Performance Comparison

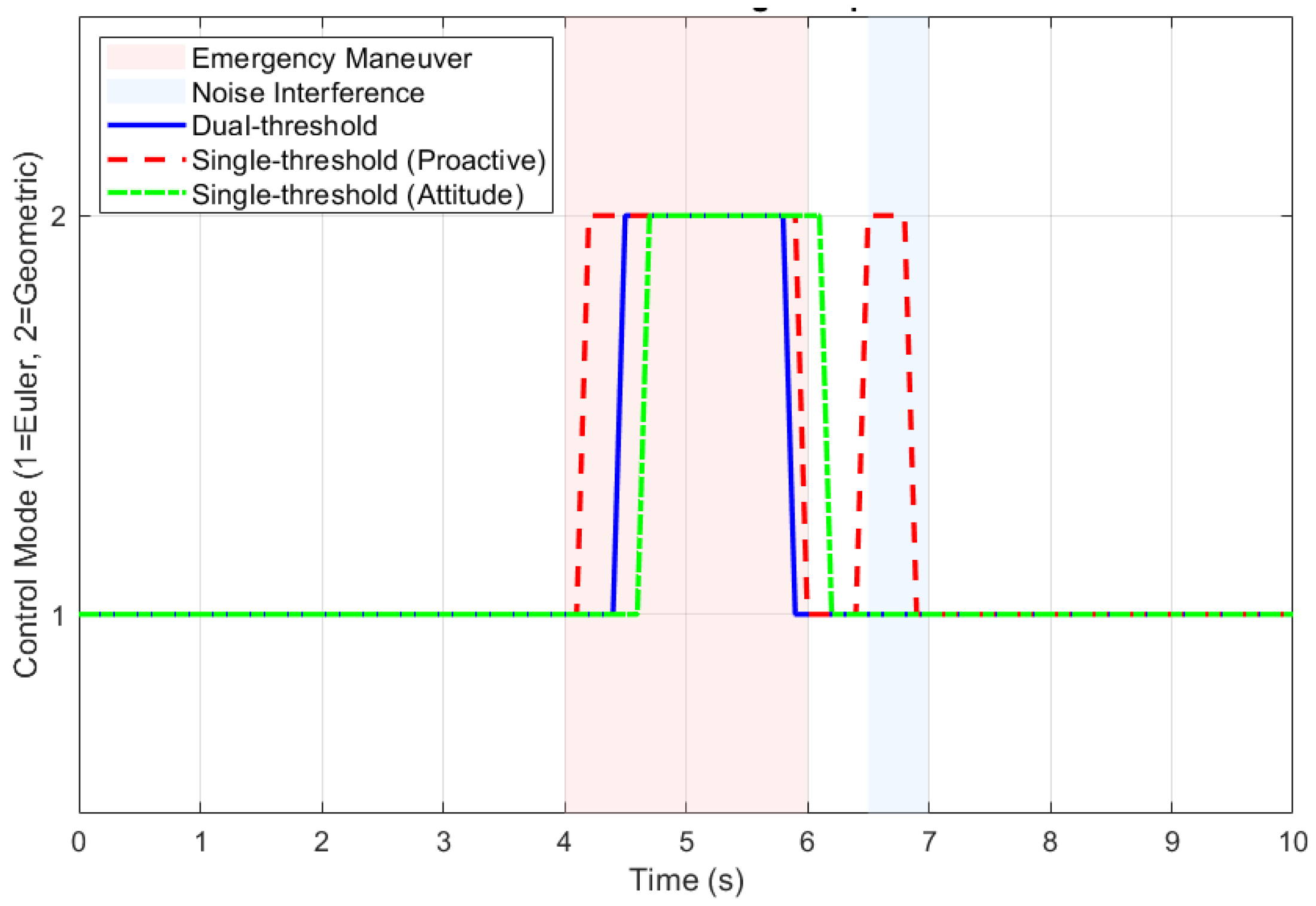

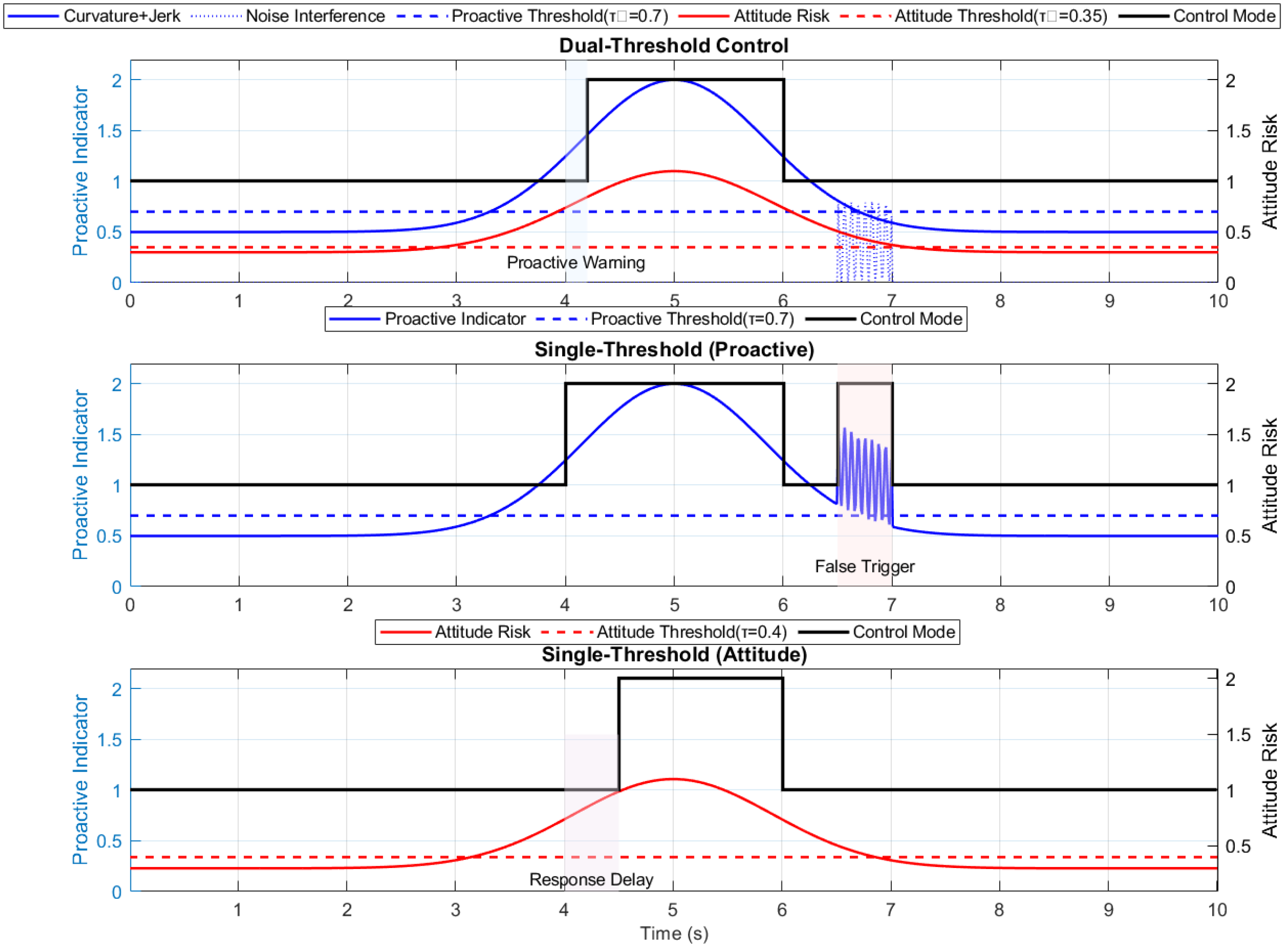

4.3. Comparative Results of Dual-Threshold and Single-Threshold Methods

5. Discussion

5.1. Analysis of Result Advantages

5.2. Core Value of the Proposed Method

- -

- The 45.9% reduction in energy consumption (Table 8) extends UAV endurance (e.g., from 29 min to 42 min for the DJI quadrotor), meeting long-duration tasks like infrastructure inspection;

- -

- The 28% reduction in CPU time (Table 8) adapts to embedded platforms (e.g., Raspberry Pi, Jetson Nano), avoiding computational delays in emergency scenarios like post-disaster rescue;

- -

5.3. Limitations of the Study

5.4. Future Research Directions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| UAV | Unmanned Aerial Vehicle |

| PID | Proportional–Integral–Derivative |

| SE(3) | Special Euclidean Group in 3D |

| SO(3) | Special Orthogonal Group in 3D |

| MIMO | Multi-Input Multi-Output |

| LQR | Linear Quadratic Regulator |

| RMSE | Root Mean Square Error |

| VTOL | Vertical Take-Off and Landing |

| LSTM | Long Short-Term Memory |

| PPO | Proximal Policy Optimization |

References

- Corbetta, M.; Banerjee, P.; Okolo, W.; Gorospe, G.; Luchinsky, D.G. Real-Time UAV Trajectory Prediction for Safety Monitoring in Low-Altitude Airspace. In Proceedings of the AIAA Aviation Forum 2019, Dallas, TX, USA, 14 June 2019; p. 3502. [Google Scholar]

- Annaswamy, A.M.; Guha, A.; Cui, Y.; Tang, S.; Fisher, P.A.; Gaudio, J.E. Integration of Adaptive Control and Reinforcement Learning for Real-Time Control and Learning. IEEE Trans. Autom. Control 2023, 68, 1786–1791. [Google Scholar] [CrossRef]

- Brunke, L.; Greeff, M.; Hall, A.W.; Yuan, Z.; Zhou, S.; Panerati, J.; Schoellig, A.P. Safe Learning in Robotics: From Learning-Based Control to Safe Reinforcement Learning. Annu. Rev. Control Robot. Auton. Syst. 2021, 5, 21–44. [Google Scholar] [CrossRef]

- Zeng, Q.; Chen, Z.; Li, C.; Chen, D.; Zhou, S.; Wei, G.; Bui, T. A Method for Maximizing UAV Deployment and Reducing Energy Consumption Based on Strong Weiszfeld and Steepest Descent with Goldstein Algorithms. Appl. Sci. 2025, 15, 9798. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Quyen, T.V.; Nguyen, C.V.; Le, A.M.; Tran, H.T.; Nguyen, M.T. Control Algorithms for UAVs: A Comprehensive Survey. EAI Endorsed Trans. Ind. Netw. Intell. Syst. 2020, 7, e5. [Google Scholar] [CrossRef]

- Sharma, M.; Kar, I. Nonlinear Disturbance Observer Based Geometric Control of Quadrotors. Asian J. Control 2021, 23, 1936–1951. [Google Scholar] [CrossRef]

- Pu, Z.; Yuan, R.; Yi, J.; Tan, X. A Class of Adaptive Extended State Observers for Nonlinear Disturbed Systems. IEEE Trans. Ind. Electron. 2015, 62, 5858–5869. [Google Scholar] [CrossRef]

- Dulac-Arnold, G.; Levine, N.; Mankowitz, D.J.; Li, J.; Paduraru, C.; Gowal, S.; Hester, T. Challenges of Real-World Reinforcement Learning. Mach. Learn. 2021, 110, 2419–2468. [Google Scholar] [CrossRef]

- Shen, Z.; Tan, L.; Yu, S.; Song, Y. Fault-Tolerant Adaptive Learning Control for Quadrotor UAVs With the Time-Varying CoG and Full-State Constraints. IEEE Trans. Neural Netw. Learn. Syst. 2021, 32, 5610–5622. [Google Scholar] [CrossRef]

- Goodarzi, F.A.; Lee, T. Global Formulation of an Extended Kalman Filter on SE(3) for Geometric Control of a Quadrotor UAV. J. Intell. Rob. Syst. 2017, 88, 395–413. [Google Scholar] [CrossRef]

- Hwangbo, J.; Lee, J.; Alexey; Bellicoso, D.; Tsounis, V.; Koltun, V.; Hutter, M. Learning Agile and Dynamic Motor Skills for Legged Robots. Sci. Robot. 2019, 4, eaau5872. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, S.; Chen, M.Z.Q. Composite Backstepping Consensus for Higher-Order Nonlinear Multi-Agent Systems. IEEE Trans. Cybern. 2018, 48, 1935–1946. [Google Scholar] [CrossRef]

- Wu, G.; Sreenath, K. Variation-Based Linearization of Nonlinear Systems Evolving on SO(3) and S2. IEEE Access 2015, 3, 1592–1604. [Google Scholar] [CrossRef]

- Wurman, P.R.; Barrett, S.; Kawamoto, K.; MacGlashan, J.; Subramanian, K.; Walsh, T.J.; Capobianco, R.; Devlic, A.; Eckert, F.; Fuchs, F.; et al. Outracing Champion Gran Turismo Drivers with Deep RL. Nature 2022, 602, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, Z.; Xiong, H.; Nian, X. Robust H∞ Attitude Tracking Control of a Quadrotor UAV on SO(3) via Variation-Based Linearization and Interval Matrix Approach. ISA Trans. 2019, 87, 10–16. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Chen, J.; Huang, Y.; Zhu, Y.; Pei, H. Geometric Attitude Tracking Control of Quadrotor UAVs with Adaptive Extended State Observers. ISA Trans. 2025, 160, 289–297. [Google Scholar] [CrossRef]

- Lotfi, B.; Goharimanesh, M.; Huang, L. Modelling and Control of Quadrotor Maneuvers with Variations of Center of Gravity (COG). In Proceedings of the IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Busan, Republic of Korea, 7–11 July 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1570–1574. [Google Scholar] [CrossRef]

- Palunko, I.; Fierro, R. Adaptive Control of a Quadrotor with Dynamic Changes in the Center of Gravity. IFAC Proc. Vol. 2011, 44, 2626–2631. [Google Scholar] [CrossRef]

- Coursey, A.; Hamadeh, H.; Johnson, E.N. Hybrid Control Framework of UAVs under Varying Wind and Payload Conditions. In Proceedings of the 2024 American Control Conference, Toronto, ON, Canada, 8–9 July 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1543–1549. [Google Scholar]

- Zhang, Y.; Sun, J.; Liang, H.; Li, H. Event-Triggered Adaptive Tracking Control for Multiagent Systems with Unknown Disturbances. IEEE Trans. Cybern. 2020, 50, 890–900. [Google Scholar] [CrossRef]

- Liu, J.; Hang, P.; Na, X.; Huang, C.; Sun, J. Cooperative Decision-Making for CAVs at Unsignalized Intersections: A MARL Approach With Attention and Hierarchical Game Priors. IEEE Trans. Intell. Transp. Syst. 2025, 26, 443–456. [Google Scholar] [CrossRef]

- Moali, O.; Mezghani, D.; Mami, A.; Oussar, A.; Nemra, A. UAV Trajectory Tracking Using Proportional-Integral-Derivative-Type-2 Fuzzy Logic Controller with Genetic Algorithm Parameter Tuning. Sensors 2024, 24, 6678. [Google Scholar] [CrossRef]

- Zhan, W.; Chen, Y.; He, B.; Miao, Z.; Zhang, H.; Wang, Y. Geometric-Based Prescribed Performance Control for Unmanned Aerial Manipulator System under Model Uncertainties and External Disturbances. ISA Trans. 2022, 128, 367–379. [Google Scholar] [CrossRef]

- Song, Y.; He, L.; Zhang, D.; Qian, J.; Fu, J. Neuroadaptive Fault-Tolerant Control of Quadrotor UAVs: A More Affordable Solution. IEEE Trans. Neural Netw. Learn. Syst. 2019, 30, 1975–1983. [Google Scholar] [CrossRef]

- Kayacan, E.; Maslim, R. Type-2 Fuzzy Logic Trajectory Tracking Control of Quadrotor VTOL Aircraft with Elliptic Membership Functions. IEEE/ASME Trans. Mechatron. 2017, 22, 339–348. [Google Scholar] [CrossRef]

- Ruggiero, F.; Lippiello, V.; Ollero, A. Aerial Manipulation: A Literature Review. IEEE Robot. Autom. Lett. 2018, 3, 1957–1964. [Google Scholar] [CrossRef]

- Lee, H.; Kim, H.J. Estimation, Control, and Planning for Autonomous Aerial Transportation. IEEE Trans. Ind. Electron. 2017, 64, 3369–3379. [Google Scholar] [CrossRef]

- Bechlioulis, C.P.; Karras, G.C.; Heshmati-Alamdari, S.; Kyriakopoulos, K.J. Trajectory Tracking with Prescribed Performance for Underactuated Underwater Vehicles under Model Uncertainties and External Disturbances. IEEE Trans. Control Syst. Technol. 2017, 25, 429–440. [Google Scholar] [CrossRef]

- Shen, Z.; Ma, Y.; Song, Y. Robust Adaptive Fault-Tolerant Control of Mobile Robots with Varying Center of Mass. IEEE Trans. Ind. Electron. 2018, 65, 2419–2428. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Yang, X.; Peng, Q. UAV–Ground Vehicle Collaborative Delivery in Emergency Response: A Review of Key Technologies and Future Trends. Appl. Sci. 2025, 15, 9803. [Google Scholar] [CrossRef]

- Mellinger, D.; Kumar, V. Minimum Snap Trajectory Generation and Control for Quadrotors. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011. [Google Scholar] [CrossRef]

- Lü, M.-L.; Ding, C.-B.; Han, H.-R.; Duan, H.-B. Autonomous Perception-Planning-Control Strategy Based on Deep Reinforcement Learning for Unmanned Aerial Vehicles. Acta Autom. Sin. 2025, 51, 1305–1319. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, Y.; Xu, M. Real-Time Path Planning for Gas Leak Monitoring Based on PPO Algorithm. In Proceedings of the 2025 IEEE 20th Conference on Industrial Electronics and Applications (ICIEA), Yantai, China, 3–6 August 2025; pp. 1–6. [Google Scholar] [CrossRef]

- Lee, T.; Dong, E.C.; Eun, Y. Attitude Control Strategies Overcoming the Topological Obstruction on SO(3). In Proceedings of the 2017 American Control Conference, Seattle, WA, USA, 24–26 May 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2225–2230. [Google Scholar]

- Wolpert, D.M.; Ghahramani, Z.; Jordan, M.I. An Internal Model For Sensorimotor Integration. Science 1995, 269, 1880–1882. [Google Scholar] [CrossRef]

| Research Framework | Literature Source | Core Research Gaps | Our Solutions |

|---|---|---|---|

| Euler angle PID/LQR | [10,11,12] | • Poor anti-wind disturbance (30% + position error); • Relies on small-angle assumption (invalid in large maneuvers) | 1. Dual-threshold switching activates high-precision control under wind; 2. Geometric control switching avoids small-angle limitations |

| Geometric control (SE(3)/SO(3)) | [12,13,14,15] | • High computational complexity (400–500% CPU time increase); • Low energy efficiency (redundant torque adjustments) | 1. Adaptive switching reduces CPU time by 28%; 2. Euler angle control in simple segments cuts energy by 45.9% |

| Geometric control + disturbance observer | [6,7,16] | • Fixed CoG assumption (fails in load swings); • No energy optimization | 1. Considers time-varying CoG impacts; 2. Dual-threshold decision balances anti-disturbance and energy efficiency |

| Hybrid control (RLDR/MA-PPO) | [19,21] | • Relies on extensive offline training; • Limited to 2D scenarios | 1. Lightweight online decision-making (no offline training); 2. Applicable to 3D complex trajectories (e.g., figure-eight) |

| Fault-tolerant control (BLFs) | [9] | • No optimization for “precision-energy-real-time” balance | Adaptive switching optimizes the triangular constraint |

| Symbol | Description | Unit |

|---|---|---|

| Total mass of the quadrotor | kg | |

| Moment of inertia of the quadrotor body | ||

| Rotation matrix from body to inertial frame | - | |

| Angular velocity in the body frame | rad/s | |

| Position of the center of mass in the inertial frame | m | |

| Velocity in the inertial frame | m/s | |

| Position of the i-th rotor relative to the center of mass | m | |

| Thrust of the i-th rotor along the body z-axis | N | |

| Torque of the i-th rotor along the body z-axis | N·m | |

| Total thrust () | N | |

| Total torque | N·m |

| Control Method | Core Limitations | Key Impacts | Triangular Constraints |

|---|---|---|---|

| Euler Angle Control | 1. Weak nonlinear handling | Oscillation in strong coupling; invalid in large maneuvers. | Accuracy ↓, Real-time ↑, Energy ↓ |

| 2. Poor disturbance rejection | >30% position error under wind [11]; integral saturation. | Accuracy ↓↓, Real-time ↑, Energy ↓ | |

| 3. Difficult parameter tuning | MIMO coupling; suboptimal trial-and-error tuning. | Accuracy ↓, Real-time ↑, Energy ↓ | |

| Geometric Control | 1. Insufficient robustness | Sensitive to model errors; attitude error accumulation. | Accuracy ↑, Real-time ↓, Energy ↑ |

| 2. High computational cost | Frequent Lie group operations cause delays. | Accuracy ↑, Real-time ↓↓, Energy ↑ | |

| 3. Energy inefficiency | Redundant high-frequency torque; shortened endurance. | Accuracy ↑, Real-time ↓, Energy ↑↑ |

| Risk Level | Condition | Control Action |

|---|---|---|

| Low | Maintain current controller | |

| Medium | Trigger pre-switching warning | |

| High | Execute immediate switching |

| Model Parameters | Values |

|---|---|

| m | |

| l |

| False Switching Rate (times/min) | Average Delay (ms) | Comprehensive Score S | |

|---|---|---|---|

| 0.5 | 3.2 | 520 | 0.60 |

| 0.65 | 0.8 | 220 | 0.67 |

| 0.7 | 0.3 | 380 | 0.88 |

| Trajectory Name | Num | Trajectory Equation | Core Challenge | Verification Target |

|---|---|---|---|---|

| Straight-rapid turn combined trajectory | T1 | Curvature mutation () | Geometric complexity response | |

| High-speed S-shaped trajectory | T2 | High-frequency jerk () [31] | Dynamic impact adaptability | |

| Anti-interference composite trajectory (T1 + wind gust) | T3 | T1 + lateral gust | Combined wind disturbance and maneuvering [4,6] | Anti-interference robustness |

| Narrow-space figure-8 trajectory | T4 | Continuous high curvature () | Long-term stability |

| Indicator | Trajectory | Euler Angle PID | Geometric Control | Proposed Method | Improvement Rate |

|---|---|---|---|---|---|

| Position Error RMSE (m) | T1 | ||||

| T2 | |||||

| T3 | |||||

| T4 | |||||

| Energy Consumption (kJ) | T1 | ||||

| T2 | |||||

| T3 | |||||

| T4 | |||||

| CPU Time (ms) | T1 | ||||

| T2 | |||||

| T3 | |||||

| T4 |

| Trajectory Phase | Characteristics |

|---|---|

| Straight flight (0–4 s) | - All methods maintain Euler angle control - Low attitude risk, low proactive index |

| Emergency maneuver (4–6 s) | - Rapid turn and climb - High curvature and jerk → elevated proactive index - Subsequent rise in attitude risk → confirmation layer trigger - Tests response delay of single-threshold (attitude) |

| Noise interference (6–10 s) | - High-frequency jerk noise added to straight flight (6.5–7.0 s) - Attitude risk remains low - Proactive index rises due to noise - Tests false switching of single-threshold (proactive) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, F.; Gao, Q.; Lu, H.; Bu, Z.; Jia, B.; Liu, G.; Tao, Z. Trajectory Tracking Control Method via Simulation for Quadrotor UAVs Based on Hierarchical Decision Dual-Threshold Adaptive Switching. Appl. Sci. 2025, 15, 11217. https://doi.org/10.3390/app152011217

Peng F, Gao Q, Lu H, Bu Z, Jia B, Liu G, Tao Z. Trajectory Tracking Control Method via Simulation for Quadrotor UAVs Based on Hierarchical Decision Dual-Threshold Adaptive Switching. Applied Sciences. 2025; 15(20):11217. https://doi.org/10.3390/app152011217

Chicago/Turabian StylePeng, Fei, Qiang Gao, Hongqiang Lu, Zhonghong Bu, Bobo Jia, Ganchao Liu, and Zhong Tao. 2025. "Trajectory Tracking Control Method via Simulation for Quadrotor UAVs Based on Hierarchical Decision Dual-Threshold Adaptive Switching" Applied Sciences 15, no. 20: 11217. https://doi.org/10.3390/app152011217

APA StylePeng, F., Gao, Q., Lu, H., Bu, Z., Jia, B., Liu, G., & Tao, Z. (2025). Trajectory Tracking Control Method via Simulation for Quadrotor UAVs Based on Hierarchical Decision Dual-Threshold Adaptive Switching. Applied Sciences, 15(20), 11217. https://doi.org/10.3390/app152011217