Partitioning Early Warning in the Mining Process of Residual Ore Bodies via Microseismic Monitoring—Taking the Xianglushan Tungsten Mine as an Example

Abstract

1. Introduction

2. Ground Pressure Characteristics of Residual Ore Recovery in Goaf

2.1. Engineering Background

2.1.1. Project Overview

2.1.2. Residual Ore Recovery Analysis

2.2. Analysis of Ground Pressure Manifestation During Residual Mining and Filling Process

2.3. Relationship Between Microseismicity and Ground Pressure

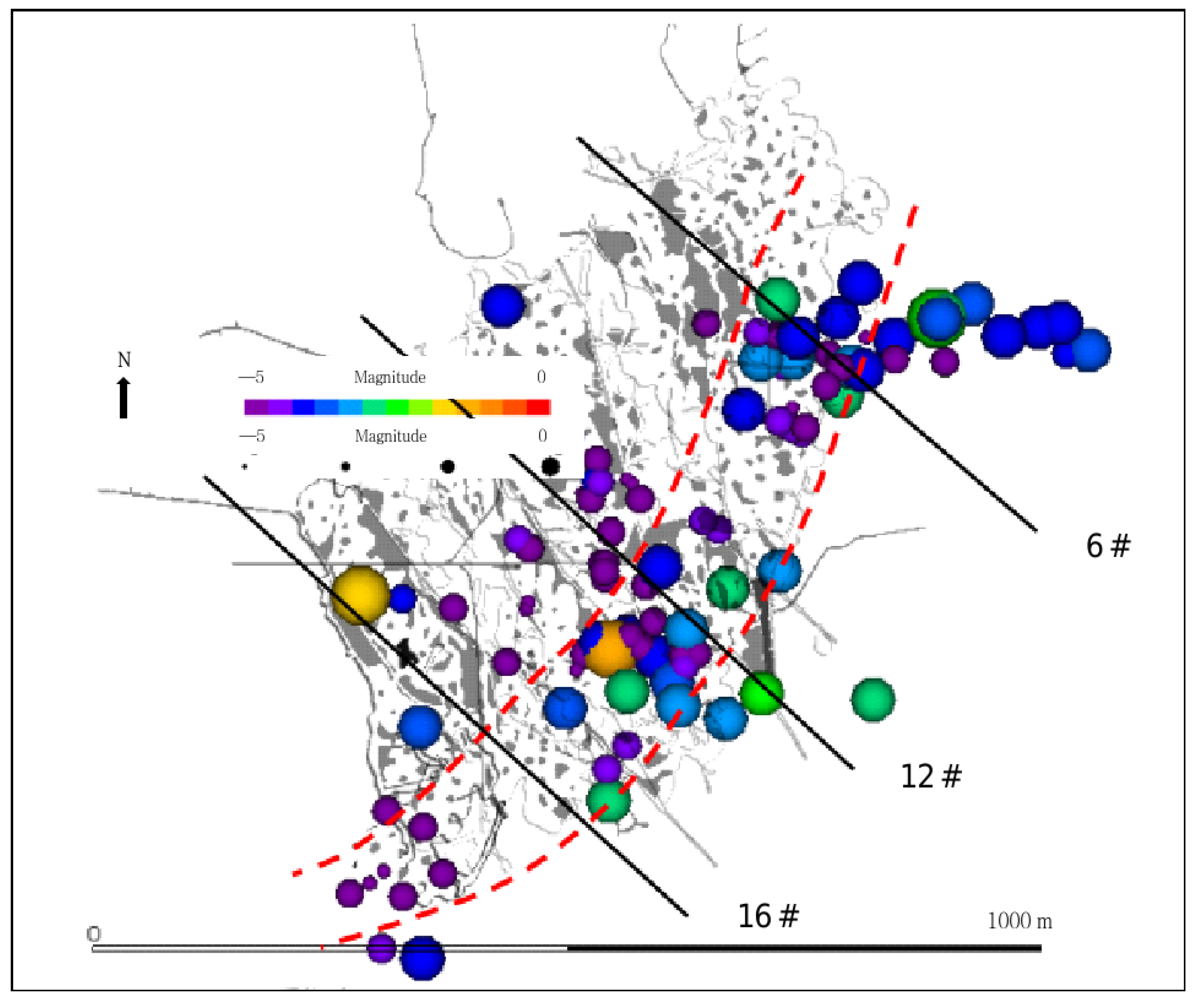

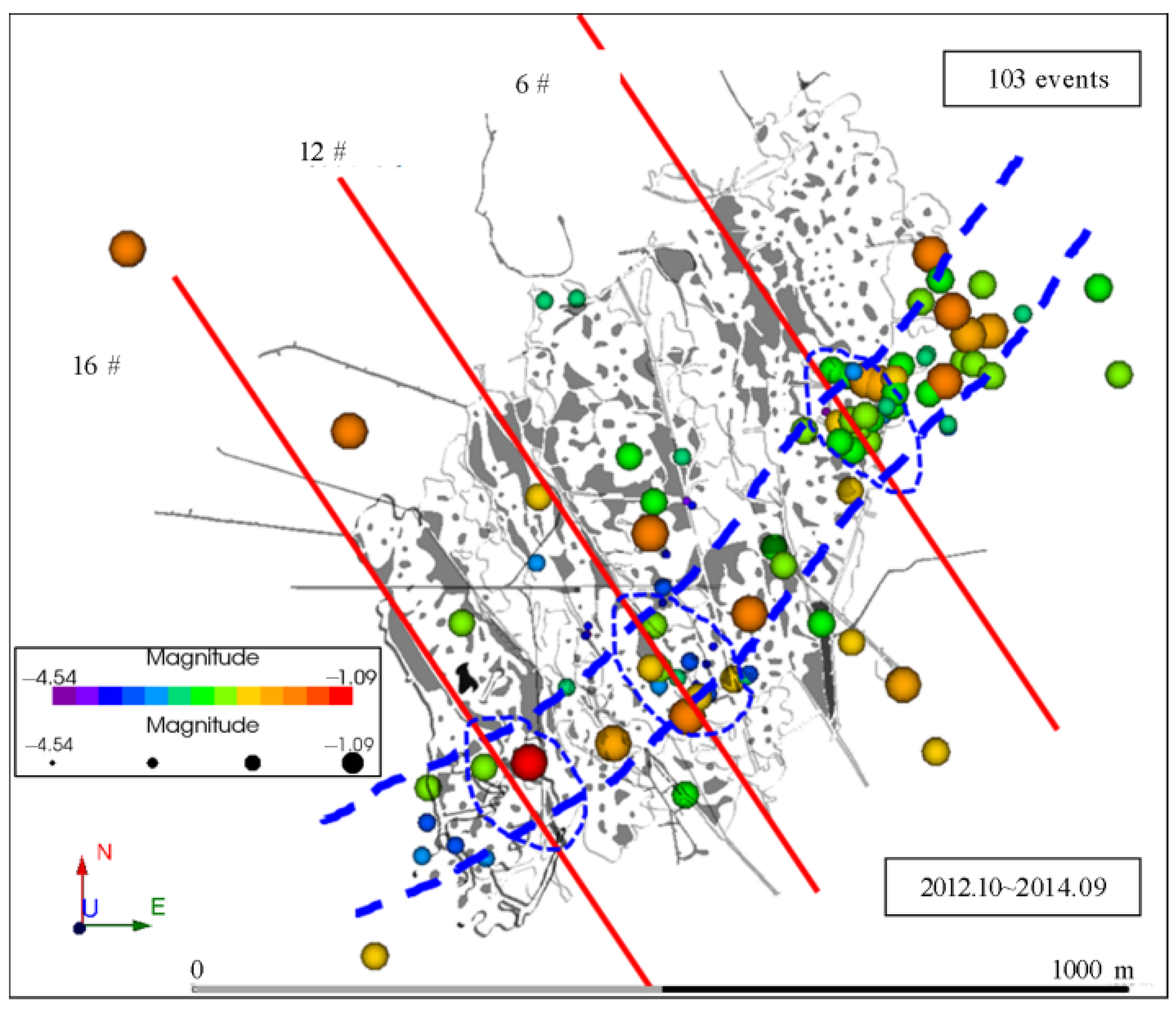

2.3.1. Microseismic Event Situation

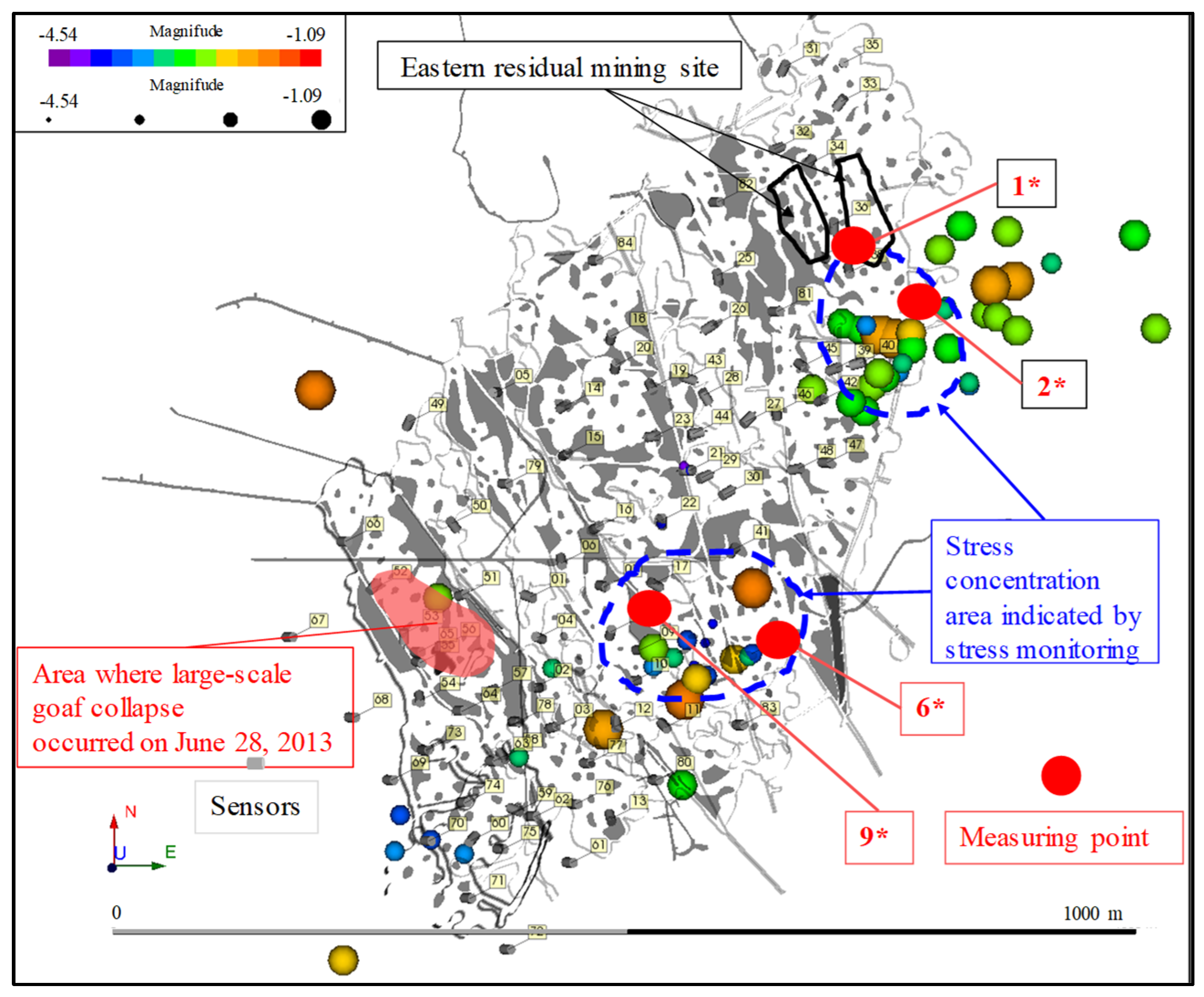

2.3.2. Distribution of Stress in Mines

- (1)

- Mining disturbance stress transfer

- (2)

- Overall stress transfer in the mine

2.4. Analysis of Typical Ground Pressure Manifestation Cases

3. Ground Pressure Zoning Warning and Management

3.1. Partition Warning Method

3.1.1. Seismic Warning Value Zoning Impact Indicators

- (1)

- Historical activity level of microseismic events

- (2)

- Stability of goaf roof

- (3)

- The degree of disturbance caused by production operations

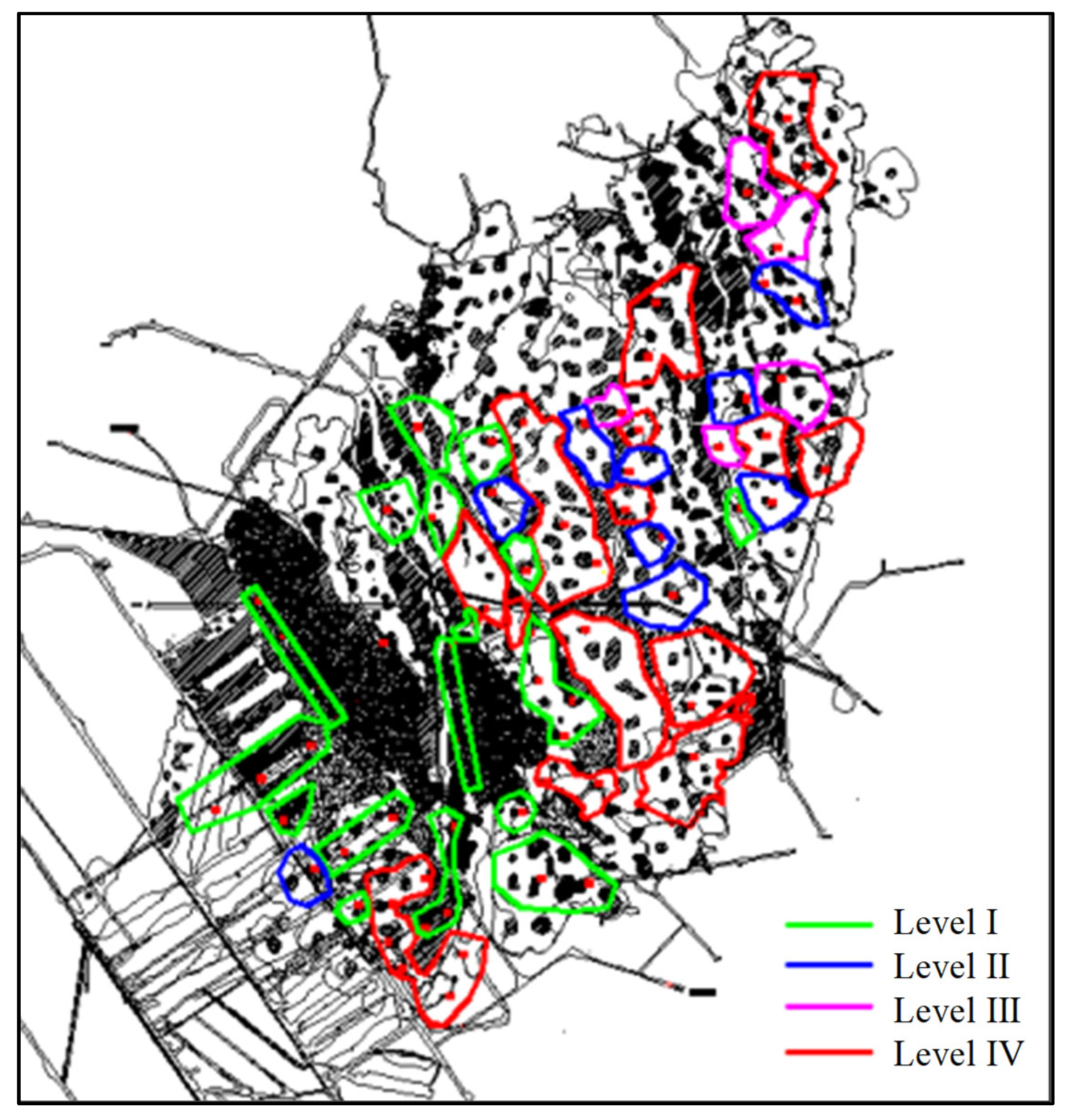

3.1.2. Establishment of Zoning Model for Microseismic Warning Values

3.1.3. Zoning Results of Underground Microseismic Warning Values

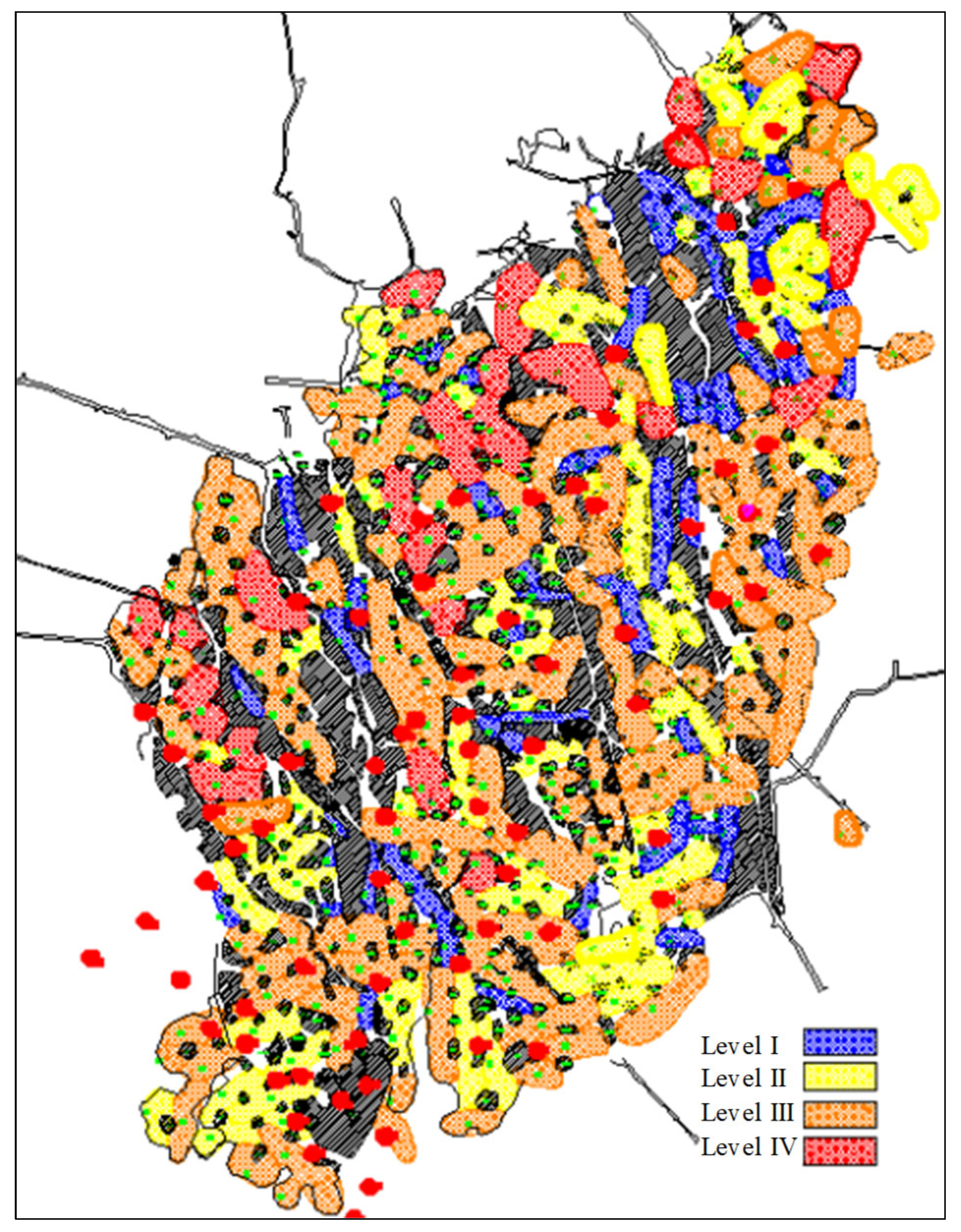

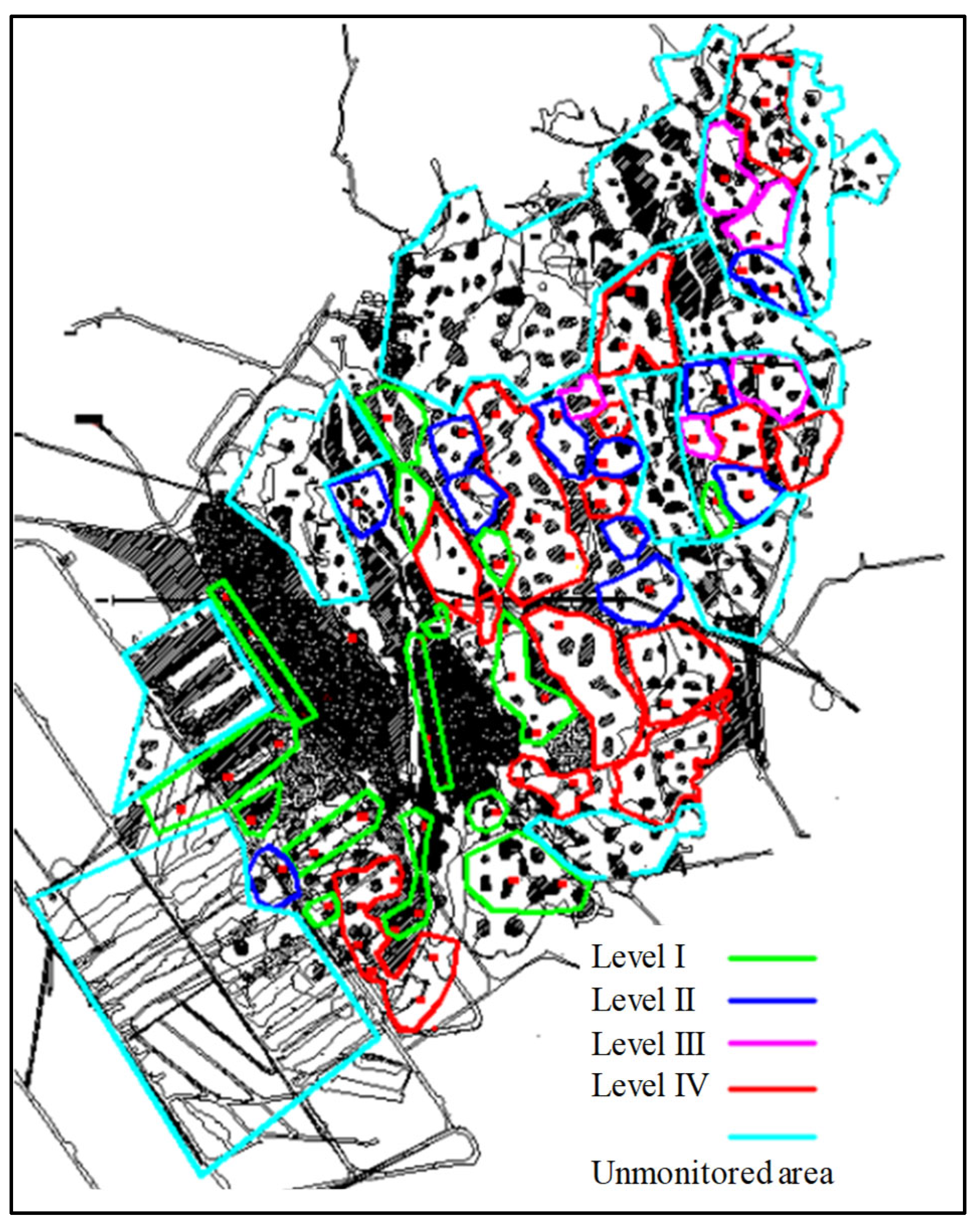

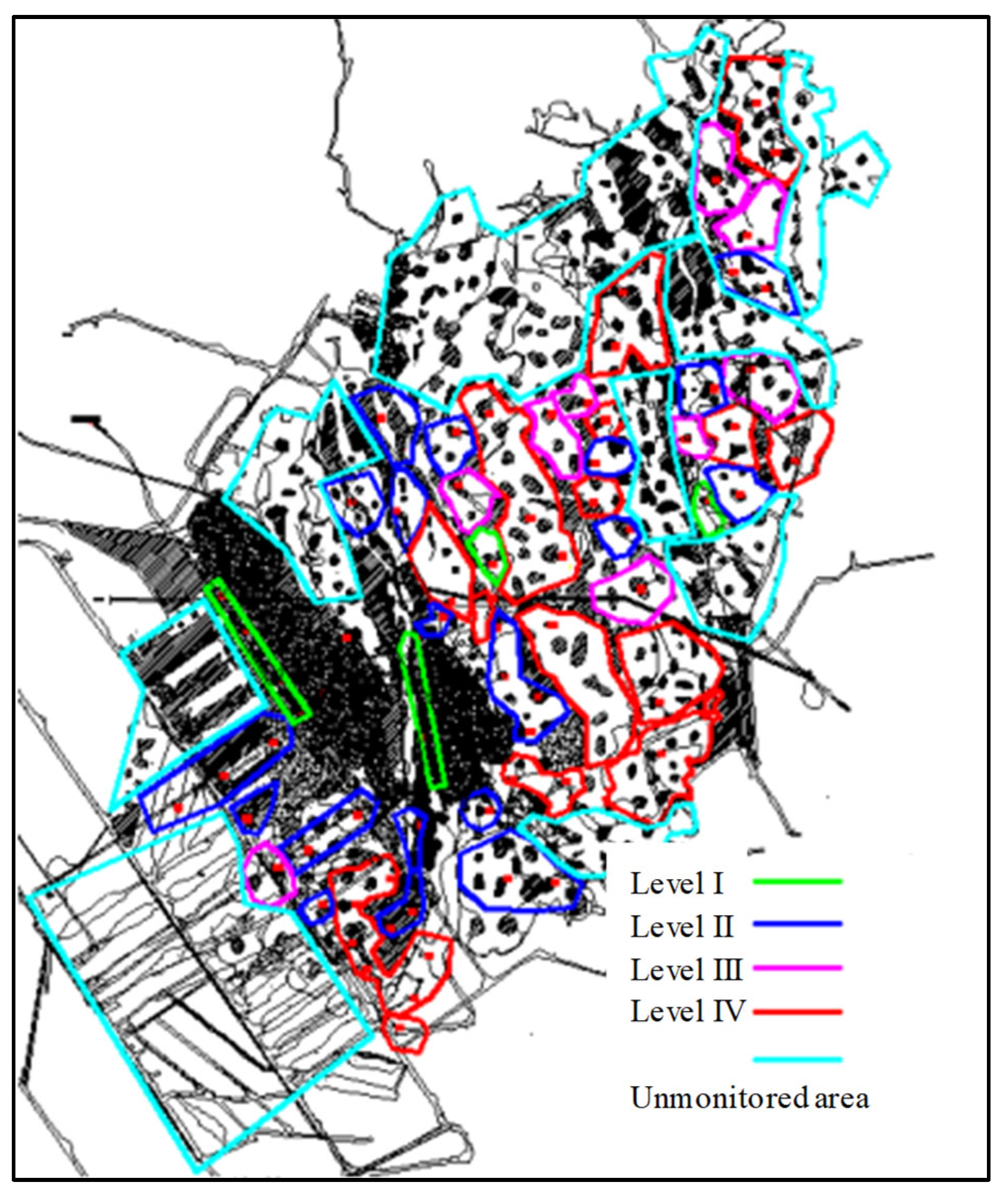

- (1)

- Zoning results of microseismic warning values without considering the impact of production operations

- (2)

- Considering the zoning results of microseismic warning values under the influence of production operations

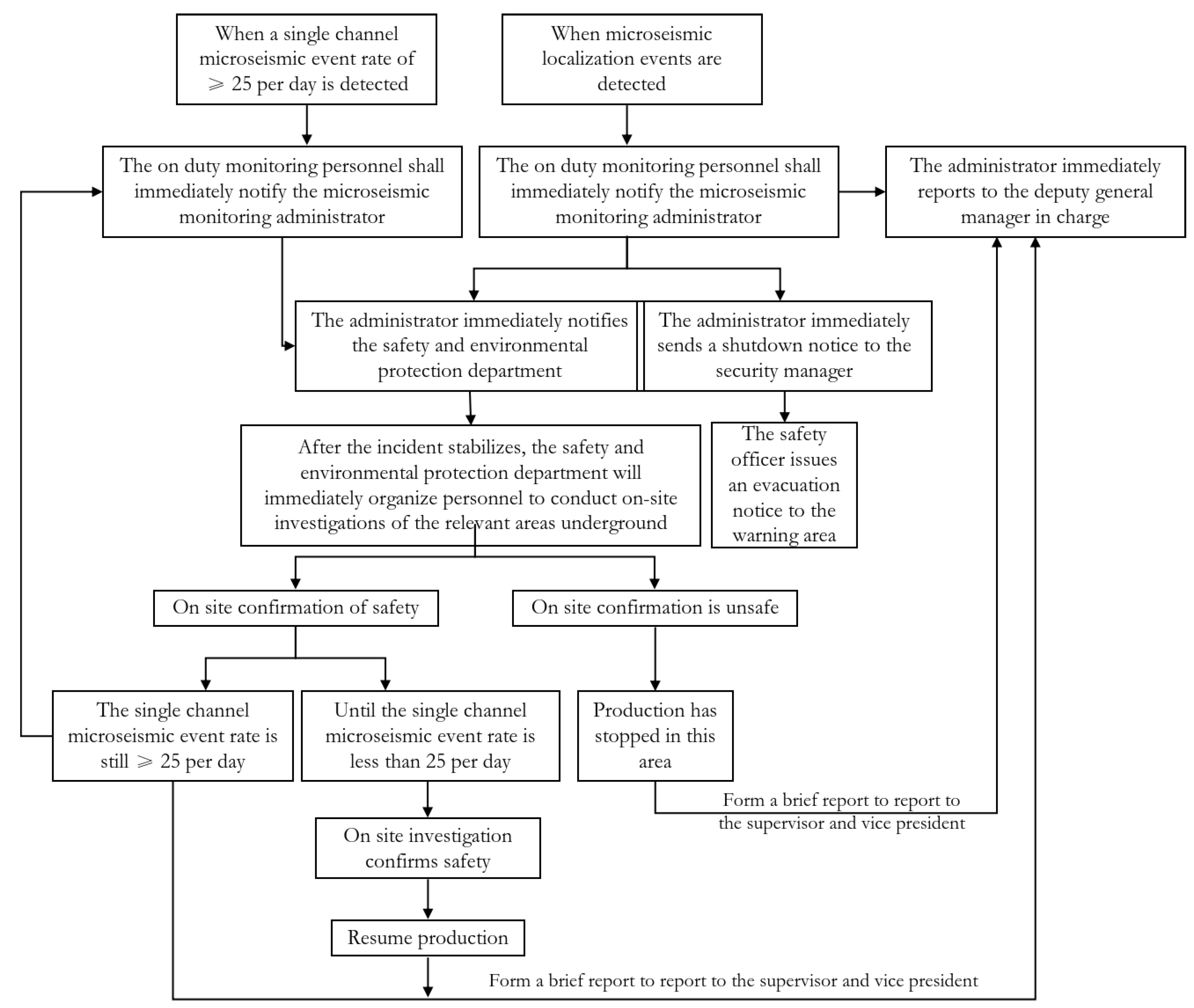

3.2. Warning of Ground Pressure Disasters

3.2.1. Issuance of Ground Pressure Disaster Warning Information

3.2.2. Case Analysis: Ground Pressure Warning (64 Pcs)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feng, X.-T.; Young, R.P.; Reyes-Montes, J.M.; Aydan, Ö.; Ishida, T.; Liu, J.-P.; Liu, H.-J. ISRM Suggested Method for In Situ Acoustic Emission Monitoring of the Fracturing Process in Rock Masses. Rock Mech. Rock Eng. 2019, 52, 1395–1414. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, L.; Cai, X.; Shen, B.; Zhou, J.; Du, K. Experimental Investigation of the Progressive Failure of Multiple Pillar-Roof System. Rock Mech. Rock Eng. 2018, 51, 1629–1636. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, Y.; Jiang, Y.; Zou, Y.; Cai, X.; Li, D. Dynamic behavior of rock during its post failure stage in SHPB tests. Trans. Nonferrous Met. Soc. China 2017, 27, 184–196. [Google Scholar] [CrossRef]

- Cai, X.; Zhou, Z.; Tan, L.; Zang, H.; Song, Z. Water Saturation Effects on Thermal Infrared Radiation Features of Rock Materials During Deformation and Fracturing. Rock Mech. Rock Eng. 2020, 53, 4839–4856. [Google Scholar] [CrossRef]

- Wang, F.; Ren, Q.; Jiang, X.; Jiang, A.; Zhao, C.; Liu, W. Engineering geology and subsidence mechanism of a mountain surface in the Daliang Lead-zinc Ore Mine in China. Bull. Eng. Geol. Environ. 2022, 81, 488. [Google Scholar] [CrossRef]

- Yuan, Z.; Ban, X.; Han, F.; Zhang, X.; Yin, S.; Wang, Y. Integrated three-dimensional visualization and soft-sensing system for underground paste backfilling. Tunn. Undergr. Space Technol. 2022, 127, 104578. [Google Scholar] [CrossRef]

- Bednarczyk, Z. Identification of flysch landslide triggers using conventional and ‘nearly real-time’ monitoring methods—An example from the Carpathian Mountains, Poland. Eng. Geol. 2018, 244, 41–56. [Google Scholar] [CrossRef]

- Fuxing, J.; Genxi, Y.E.; Cunwen, W.; Dangyu, Z.; Yongqiang, G. Application of High-Precision Microseismic Monitoring Technique to Water Inrush Monitoring in Coal Mine. Chin. J. Rock Mech. Eng. 2008, 27, 1932–1938. [Google Scholar]

- Li, D.; Zhang, J.-F.; Wang, C.-W.; Jiang, F.-X. Propagation patterns of microseismic waves in rock strata during mining: An experimental study. Int. J. Miner. Metall. Mater. 2019, 26, 531–537. [Google Scholar] [CrossRef]

- Ling-hai, K.; Fu-xing, J.; Jie, L.I.U.; Gen-xi, Y.E.; Cun-wen, W.; Guang-dong, S. High-precision microseismic monitoring system to reasonable width of segment coal pillar in extra-thick coal seam fully mechanized top-coal caving mining. J. China Coal Soc. 2009, 34, 871–874. [Google Scholar]

- Qiao, S.; Zhang, Q.; Zhang, Q. Mine Fracturing Monitoring Analysis Based on High-Precision Distributed Wireless Microseismic Acquisition Station. IEEE Access 2019, 7, 147215–147223. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, C.; Huang, Y. An Optimization Method for the Station Layout of a Microseismic Monitoring System in Underground Mine Engineering. Sensors 2022, 22, 4775. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, J.; Chen, Z.; Sun, F.; Zhu, X.; Fang, G. An Efficient Neural-Network-Based Microseismic Monitoring Platform for Hydraulic Fracture on an Edge Computing Architecture. Sensors 2018, 18, 1828. [Google Scholar] [CrossRef]

- Dip, A.C.; Giroux, B.; Gloaguen, E. Microseismic monitoring of rockbursts with the ensemble Kalman filter. Near Surf. Geophys. 2021, 19, 429–445. [Google Scholar] [CrossRef]

- Ma, K.; Tang, C.-A.; Xu, N.-W.; Liu, F.; Xu, J.-W. Failure precursor of surrounding rock mass around cross tunnel in high-steep rock slope. J. Cent. South Univ. 2013, 20, 207–217. [Google Scholar] [CrossRef]

- Xu, N.; Tang, C.a.; Zhou, Z.; Sha, C.; Liang, Z. Stability Analysis of Hydraulic Rock Slope Based on Three-Dimensional Numerical Simulation and Microseismic Monitoring. Chin. J. Rock Mech. Eng. 2013, 32, 1373–1381. [Google Scholar]

- Mercerat, E.D.; Driad-Lebeau, L.; Bernard, P. Induced Seismicity Monitoring of an Underground Salt Cavern Prone to Collapse. Pure Appl. Geophys. 2010, 167, 5–25. [Google Scholar] [CrossRef]

- Occhiena, C.; Coviello, V.; Arattano, M.; Chiarle, M.; di Cella, U.M.; Pirulli, M.; Pogliotti, P.; Scavia, C. Analysis of microseismic signals and temperature recordings for rock slope stability investigations in high mountain areas. Nat. Hazards Earth Syst. Sci. 2012, 12, 2283–2298. [Google Scholar] [CrossRef]

- Siddhamshetty, P.K. Modeling of Hydraulic Fracturing and Design of Online Optimal Pumping Schedule for Enhanced Productivity in Shale Formations. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2020. [Google Scholar]

- Zhai, J.; Wang, Q.; Yuan, D.; Zhang, W.; Wang, H.; Xie, X.; Shahrour, I. Clogging Risk Early Warning for Slurry Shield Tunneling in Mixed Mudstone-Gravel Ground: A Real-Time Self-Updating Machine Learning Approach. Sustainability 2022, 14, 1368. [Google Scholar] [CrossRef]

- Wang, X.Y.; Ma, Z.; Zhang, Y.T. Research on Safety Early Warning Standard of Large-Scale Underground Utility Tunnel in Ground Fissure Active Period. Front. Earth Sci. 2022, 10, 828477. [Google Scholar] [CrossRef]

- Kuldeev, E.I.; Rysbekov, K.B.; Donenbayeva, N.S.; Miletenko, N.A. Modern Methods of Geotechnic—Effective Way of Providing Industrial Safety in Mines. Eurasian Min. 2021, 2, 18–21. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, R.-P.; Wu, H.-N.; Liu, Y. Ground settlement induced by tunneling crossing interface of water-bearing mixed ground: A lesson from Changsha, China. Tunn. Undergr. Space Technol. 2020, 96, 103224. [Google Scholar] [CrossRef]

- Lebert, F.; Bernardie, S.; Mainsant, G. Hydroacoustic monitoring of a salt cavity: An analysis of precursory events of the collapse. Nat. Hazards Earth Syst. Sci. 2011, 11, 2663–2675. [Google Scholar] [CrossRef]

- Liu, J.-P.; Si, Y.-T.; Wei, D.-C.; Shi, H.-X.; Wang, R. Developments and prospects of microseismic monitoring technology in underground metal mines in China. J. Cent. South Univ. 2021, 28, 3074–3098. [Google Scholar] [CrossRef]

- He, M.; Wang, Q.; Wu, Q. Innovation and future of mining rock mechanics. J. Rock Mech. Geotech. Eng. 2021, 13, 1–21. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, G.; Wang, X. Development and application of a goaf-safety monitoring system using multi-sensor information fusion. Tunn. Undergr. Space Technol. 2019, 94, 103112. [Google Scholar] [CrossRef]

- Song, D.; He, X.; Qiu, L.; Zhao, Y.; Cheng, X.; Wang, A. Study on real time dynamic monitoring and early warning technology of regional and local outburst danger. Coal Sci. Technol. 2021, 49, 110–119. [Google Scholar]

- Dou, L.; Cai, W.; Cao, A.; Guo, W. Comprehensive early warning of rock burst utilizing microseismic multi-parameter indices. Int. J. Min. Sci. Technol. 2018, 28, 767–774. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhu, S.; Li, Z.; Wu, A.; Wang, M.; Su, Y.; Wang, S.; Qu, X.; Feng, M. Research on Real-Time Monitoring and Warning Technology for Multi-Parameter Underground Debris Flow. Sustainability 2023, 15, 15006. [Google Scholar] [CrossRef]

- He, S.; He, X.; Song, D.; Li, Z.; Chen, J.; Xue, Y.; Li, Y. Multi-parameter integrated early warning model and an intelligent identification cloud platform of rockburst. J. China Univ. Min. Technol. 2022, 51, 850–862. [Google Scholar]

- Indukala, P.K.; Gosh, U.G.; Ramesh, M.V. IoT-Driven Microseismic Sensing System and Monitoring Platform for Landslide Detection. IEEE Access 2024, 12, 97787–97805. [Google Scholar] [CrossRef]

- Li, J.; Stankovic, L.; Pytharouli, S.; Stankovic, V. Automated Platform for Microseismic Signal Analysis: Denoising, Detection, and Classification in Slope Stability Studies. IEEE Trans. Geosci. Remote Sens. 2021, 59, 7996–8006. [Google Scholar] [CrossRef]

- Li, T.; Xu, W.; Ma, C.; Zhang, H.; Zhang, Y.; Dai, K. Research of technology and system of tunnel microseismic monitoring and rockburst early warning based on deep learning. Chin. J. Rock Mech. Eng. 2024, 43, 1041–1063. [Google Scholar]

- Jiang, F.; Miao, X.; Wang, C.; Song, J.; Deng, J.; Meng, F. Predicting research and practice of tectonic-controlled coal burst by microseismic monitoring. J. China Coal Soc. 2010, 35, 900–903. [Google Scholar]

- Wei, Q.; Jiang, F.; Yao, S.; Wei, X.; Shu, C.; Hao, Q. Real-time monitoring and early warning of rock burst risk in dip coal pillar area of extra-thick coal seam. J. Min. Saf. Eng. 2015, 32, 530–536. [Google Scholar]

- Dou, L.; Feng, L.; Cai, W.; Wang, H.; He, H.; Jiao, B.; Zhang, M. Seismo-acoustic precursor identification and comprehensive warning model for the catastrophic failure process of coal and rock. J. Min. Saf. Eng. 2020, 37, 960–968. [Google Scholar]

- Qin, M.; Liu, C. Analysis of Early Warning Parameters for Ground Pressure Disaster Based on Microseismic Monitoring. Min. Metall. Eng. 2022, 42, 35–40. [Google Scholar]

- Zhou, Z.; Huang, Y.; Zhao, C. Microseismic Monitoring and Disaster Warning via Mining and Filling Processes of Residual Hazardous Ore Bodies. Minerals 2024, 14, 948. [Google Scholar] [CrossRef]

- Ayad, A.; Bakkali, S. Economic impact of derangements on mining process—Case study: Sidi Chennane. J. Min. Environ. 2022, 13, 989–996. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, Y.; Zhao, C. Distribution Law of Mine Ground Pressure via a Microseismic Sensor System. Minerals 2023, 13, 649. [Google Scholar] [CrossRef]

| No. | Time | Position | Type | Scale | Goaf Stability Level | Reason | Cause Sort | Location Relationship | Warning Precursor | Safety Accidents |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 4.14. | W3 mining site | pillar spalling rib | 1~2 m3 | III | The collapsed pillars are located on top of the filling material, and the surrounding rock mass stress is redistributed due to the filling of the mining area | Production site | Nearby | Yes | No |

| 2 | 5.15. | 407 mining site | Pillar explosion | / | IV | The mining operation in the mining site caused stress accumulation and release in the surrounding rock mass of sensor 44 # | Production site | Nearby | Yes | No |

| 3 | 5.18. | +597 m third mining site | Roof collapse | 3 m3 | III | The mining operation in the mining site caused stress accumulation and release in the surrounding rock mass of sensor 10 # | Production site | Nearby | Yes | No |

| 4 | 6.10. | W2 mining site | Roof collapse | 1 m3 | IV | Underground operations have caused stress accumulation and mild release in nearby rock masses | Production site | Nearby | Yes | No |

| 5 | 7.16. | +600 m W4 mining site | Pillar explosion | / | III | Underground operations cause stress redistribution and concentrated release in the surrounding rock mass | Production site | Nearby | No | No |

| 6 | 7.20. | 128 mining site | Roof collapse | 1 m3 | III | Production site | Nearby | No | No | |

| 7 | 8.2. | +600 m mining site | Roof collapse | 1 m3 | III | Production site | Nearby | Yes | No | |

| 8 | 8.8. | Shiyan ore pillar | Pillar explosion | / | III | Closed area | Faraway | No | No | |

| 9 | 8.20. | +610 m mining site | Roof collapse | 2 m3 | IV | Production site | Nearby | No | No | |

| 10 | 8.28. | Third mining site | Pillar spalling rib | / | III | Closed area | Faraway | No | No | |

| 11 | 9.28. | W9 mining site | Rock burst | Minor rock burst | III | Production site | Nearby | Yes | No | |

| 12 | 10.27. | +597 m mining site | Roof collapse | 10 m3 | IV | Filling area | Nearby | Yes | No |

| Activity Level of Microseismic Events | Inactive | More Active | Active | Abnormal Activity |

|---|---|---|---|---|

| Classification criteria | Accumulated single-channel events in the current month ≤ 30 | 30 < Accumulated single-channel events in the current month < 50 | Accumulated single-channel events in the current month ≥ 50 | Single-channel event exceeds warning value or location event occurs |

| Activity level | I | II | III | IV |

| Security Situation | Not meeting the conditions for roof collapse and local collapse, with no signs of deformation or damage | Only capable of generating local roof collapse conditions, with no obvious signs of deformation or damage | Own the conditions to form small-scale roof collapse and local collapse, with obvious signs of deformation and damage in some areas | Own the conditions for generating large-scale roof collapse and local collapse, with significant deformation and damage |

| Disposal and Management Requirements | Produced normally | Rectify within a limited time and eliminate potential safety hazards | Stop production, take measures, and eliminate dangerous situations within a specified time limit | Immediately cease production, eliminate potential risks, report to relevant departments, and activate emergency plans |

| Safety Level | Security | More secure | Less secure | Unsafe |

| Activity Level | I | II | III | IV |

| The Degree of Disturbance Caused by Production Operations | Minimal Impact | Less Impact | Significant Impact | More Significant Impact |

|---|---|---|---|---|

| Classification criteria | The distance between the sensor and the operating point is ≥ 150 m | 100 < Monthly cumulative single-channel events < 150 | 50 < Sensor distance from work point position ≤ 100 m | The distance between the sensor and the operating point is ≤ 50 m |

| Level | I | II | III | IV |

| Impact Indicators | Active Microseismic Events | Stability of Goaf Roof | The Degree of Disturbance Caused by Production Operations | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight Value | 0.6 | 0.2 | 0.2 | ||||||||||

| Warning value zoning scoring and standards | Subitem score | I | II | III | IV | I | II | III | IV | I | II | III | IV |

| 60 | 45 | 30 | 15 | 20 | 15 | 10 | 5 | 20 | 15 | 10 | 5 | ||

| Comprehensive score | Accumulate the scores of each subitem to obtain a comprehensive score | ||||||||||||

| Partition criteria | 100~86 | 85~71 | 70~51 | 50~25 | |||||||||

| Partition level | I | II | III | IV | |||||||||

| Ratio | 3.50 | 3.00 | 2.50 | 2.00 | |||||||||

| Partition warning value | Parameter benchmark value × ratio | ||||||||||||

| Location/Zone | Event Type | Risk Level | Number of Events | Typical Sensor Response | Typical Manifestation & Follow-Up Actions | Area Closure Rate | Warning Success Rate |

|---|---|---|---|---|---|---|---|

| Pit 4# 18# e6 | High activity | Very high | 12 | N/a (value-based) | Very high possibility of wall and roof collapse. Continuous monitoring. | 0% | 100% |

| Pit 2# 407 | High activity | Very high | 8 | N/a (value-based) | High possibility of wall and roof collapse. Area frequently evacuated and closed. | 100% | 87.5% |

| Pit 2# 407 | Positioning | Critical | 3 | Multi-sensor (13–23 triggers) | Confirmed rock fall after closure. Entry prohibited. | 100% | 100% |

| Pit 2# 597/600 | Positioning | High | 9 | Multi-sensor (7–23 triggers) | No personnel onsite. Roof caving found at 600. Area restricted; safety confirmation required before entry. | 100% | 100% |

| Pit 2# 585/603 | High activity | Medium | 5 | N/a (value-based) | High possibility of wall and roof collapse. | 0% | 40% |

| W18#/w16# w7 | Positioning | High | 8 | Multi-sensor (9–12 triggers) | Area designated as dangerous zone; personnel prohibited from passing. No operations. | 100% | 100% |

| W9/w20#/w22# | Positioning | High | 5 | Multi-sensor (12–15 triggers) | Included a confirmed rock burst event at w9. Dangerous zone established. “Knocking asking” System implemented. | 100% | 100% |

| Pit 5# | Positioning | Medium | 5 | Multi-sensor (3–15 triggers) | No personnel onsite. Recommended safety check before entry. One rock mass caving (1–2 m3) caused by backfilling stress. | 0% | 80% |

| Pit 5#/e pit 5# | High activity | Low | 3 | N/a (value-based) | High possibility of wall and roof collapse. | 0% | 66.7% |

| Total/average | 64 | / | 73.4% | 95.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Zhao, C.; Huang, Y.; Lyu, G. Partitioning Early Warning in the Mining Process of Residual Ore Bodies via Microseismic Monitoring—Taking the Xianglushan Tungsten Mine as an Example. Appl. Sci. 2025, 15, 11172. https://doi.org/10.3390/app152011172

Liu C, Zhao C, Huang Y, Lyu G. Partitioning Early Warning in the Mining Process of Residual Ore Bodies via Microseismic Monitoring—Taking the Xianglushan Tungsten Mine as an Example. Applied Sciences. 2025; 15(20):11172. https://doi.org/10.3390/app152011172

Chicago/Turabian StyleLiu, Chang, Congcong Zhao, Yinghua Huang, and Guanying Lyu. 2025. "Partitioning Early Warning in the Mining Process of Residual Ore Bodies via Microseismic Monitoring—Taking the Xianglushan Tungsten Mine as an Example" Applied Sciences 15, no. 20: 11172. https://doi.org/10.3390/app152011172

APA StyleLiu, C., Zhao, C., Huang, Y., & Lyu, G. (2025). Partitioning Early Warning in the Mining Process of Residual Ore Bodies via Microseismic Monitoring—Taking the Xianglushan Tungsten Mine as an Example. Applied Sciences, 15(20), 11172. https://doi.org/10.3390/app152011172