3D Reconstruction and Printing of Small, Morphometrically Complex Food Replicas and Comparison with Real Objects by Digital Image Analysis: The Case of Popcorn Flakes

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

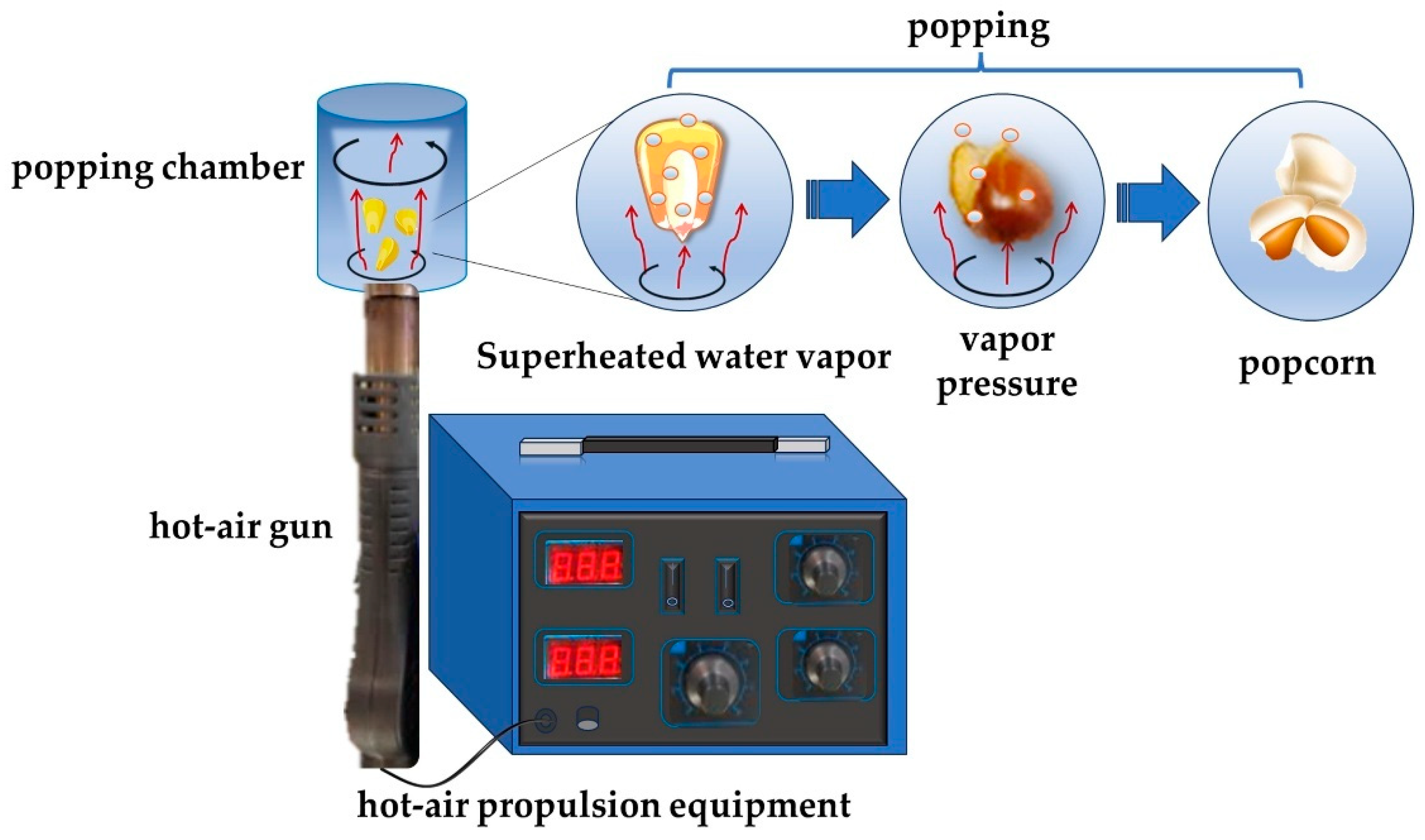

2.1. Preparation and Popping of Popcorn Kernels

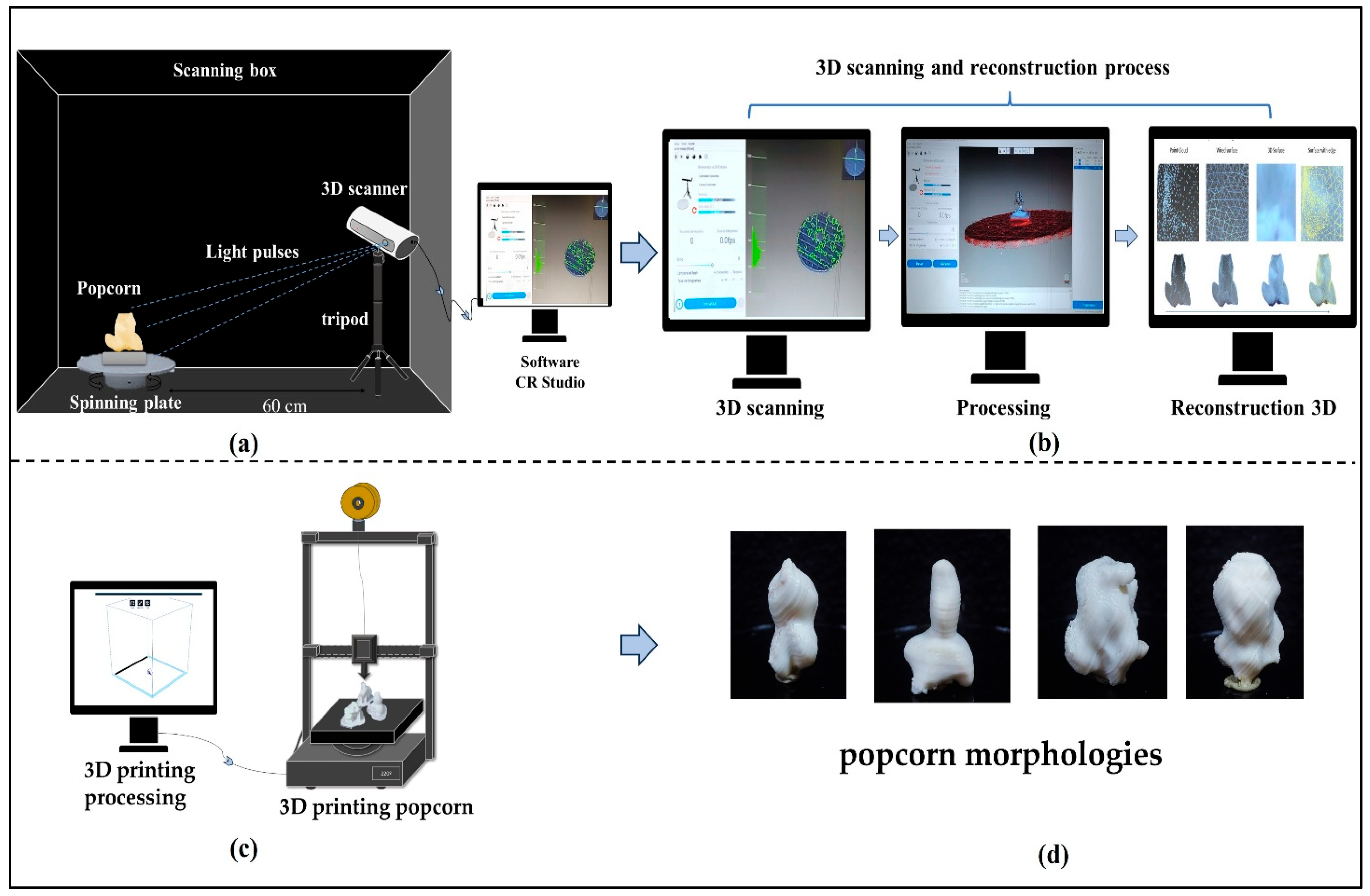

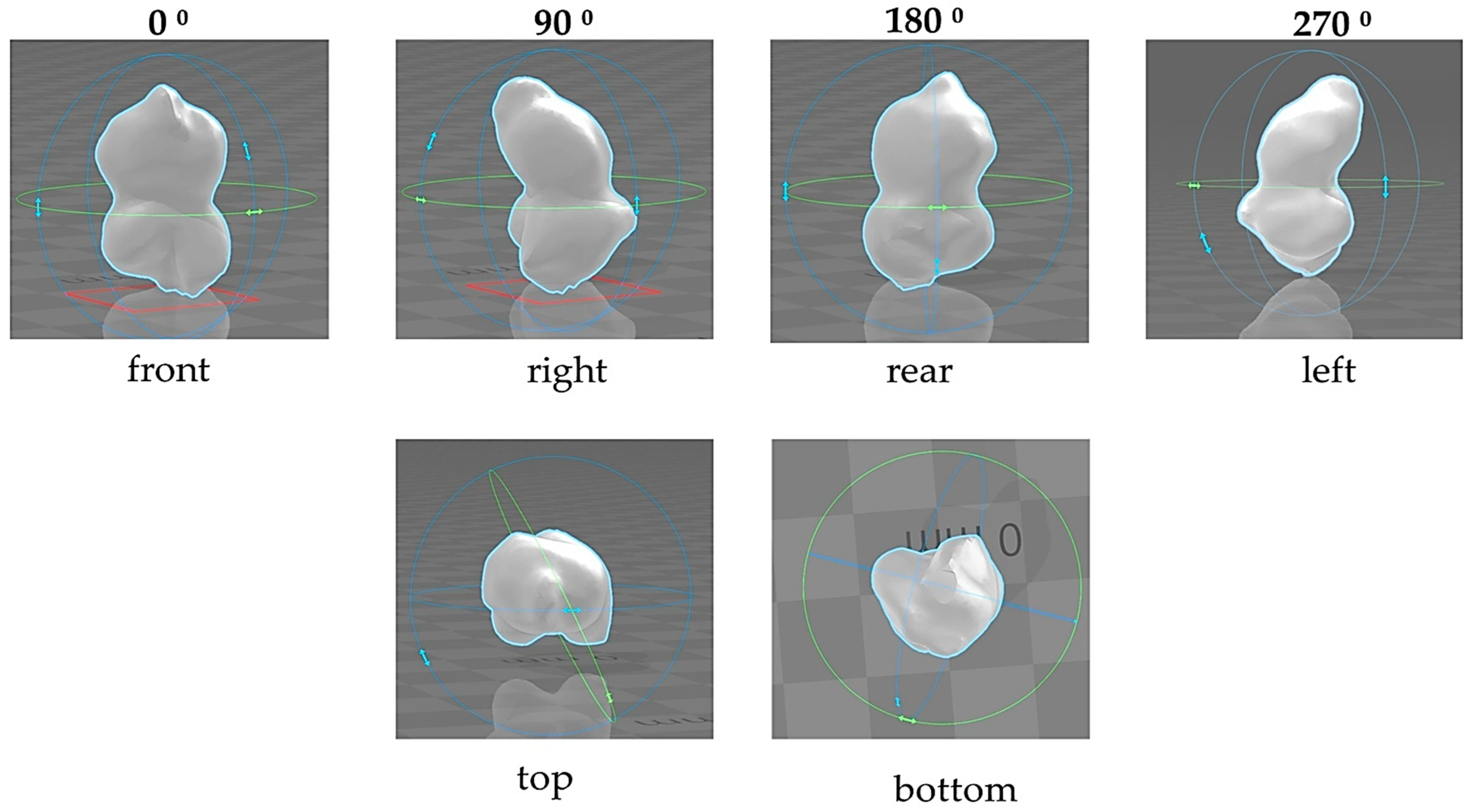

2.2. Three-Dimensional Scanning Reconstruction and Printing of Models

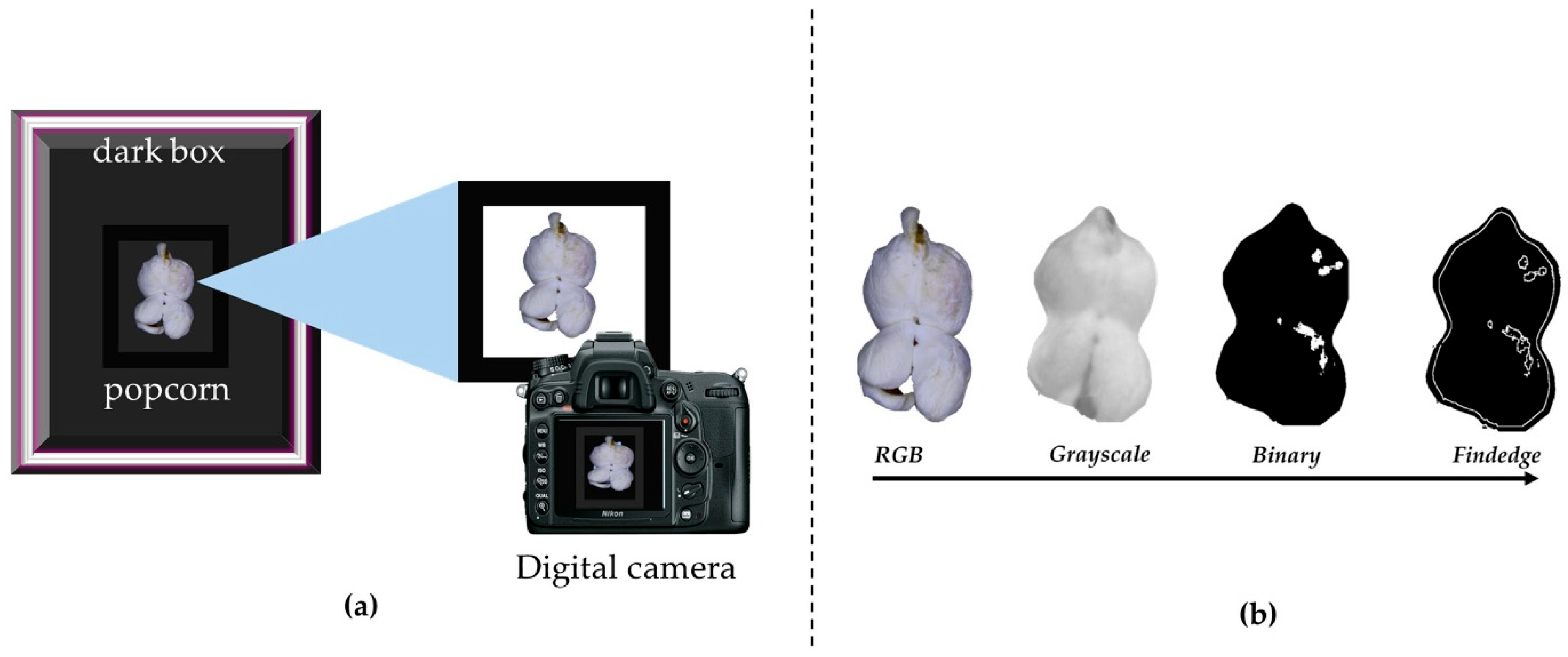

2.3. Popcorn Image Capture

2.4. Digital Image Analysis (DIA) of Real and Printed Popcorn Flakes

2.5. Statistical Analysis the Popcorn Morphology and 3D Reconstruction

3. Results and Discussion

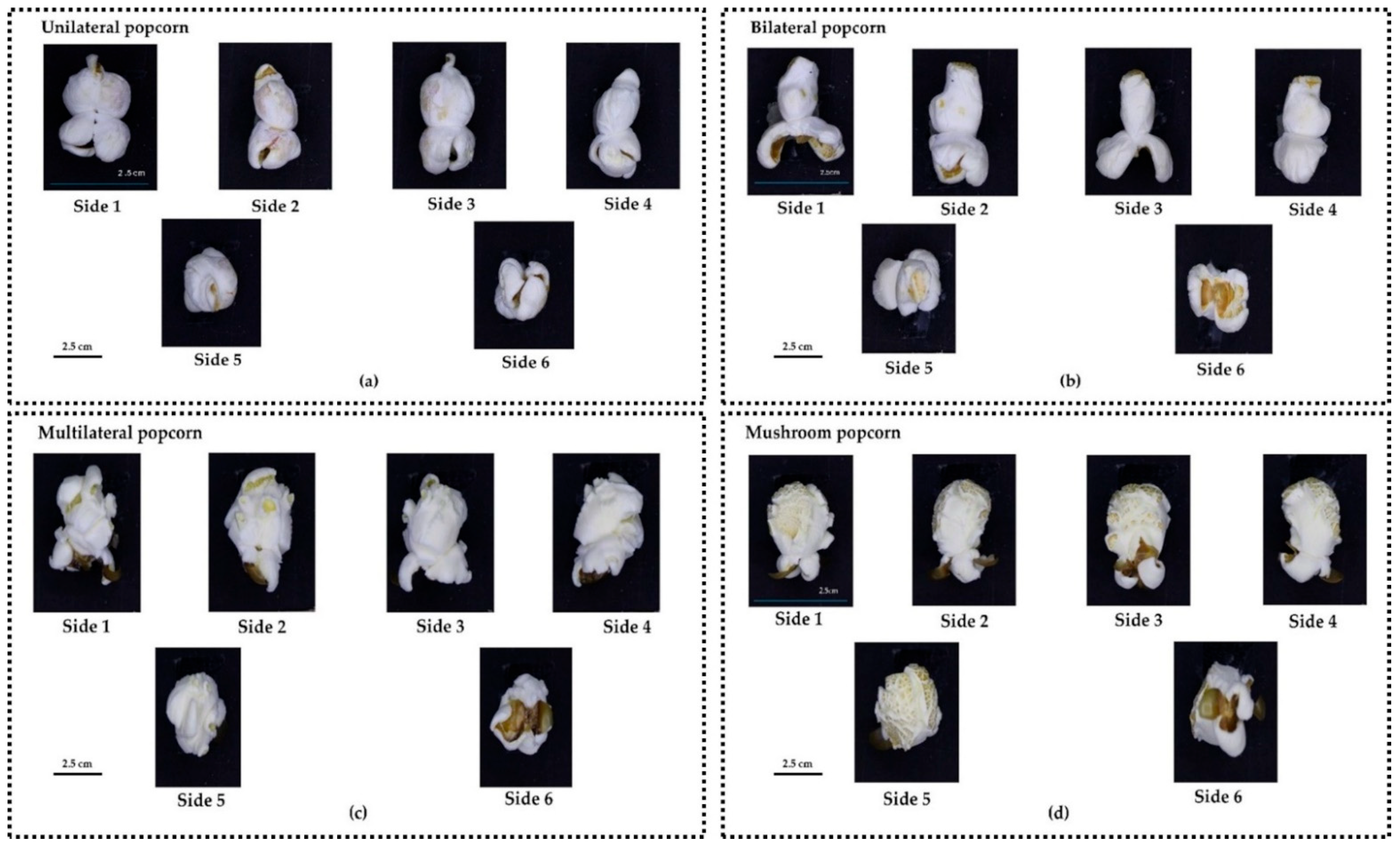

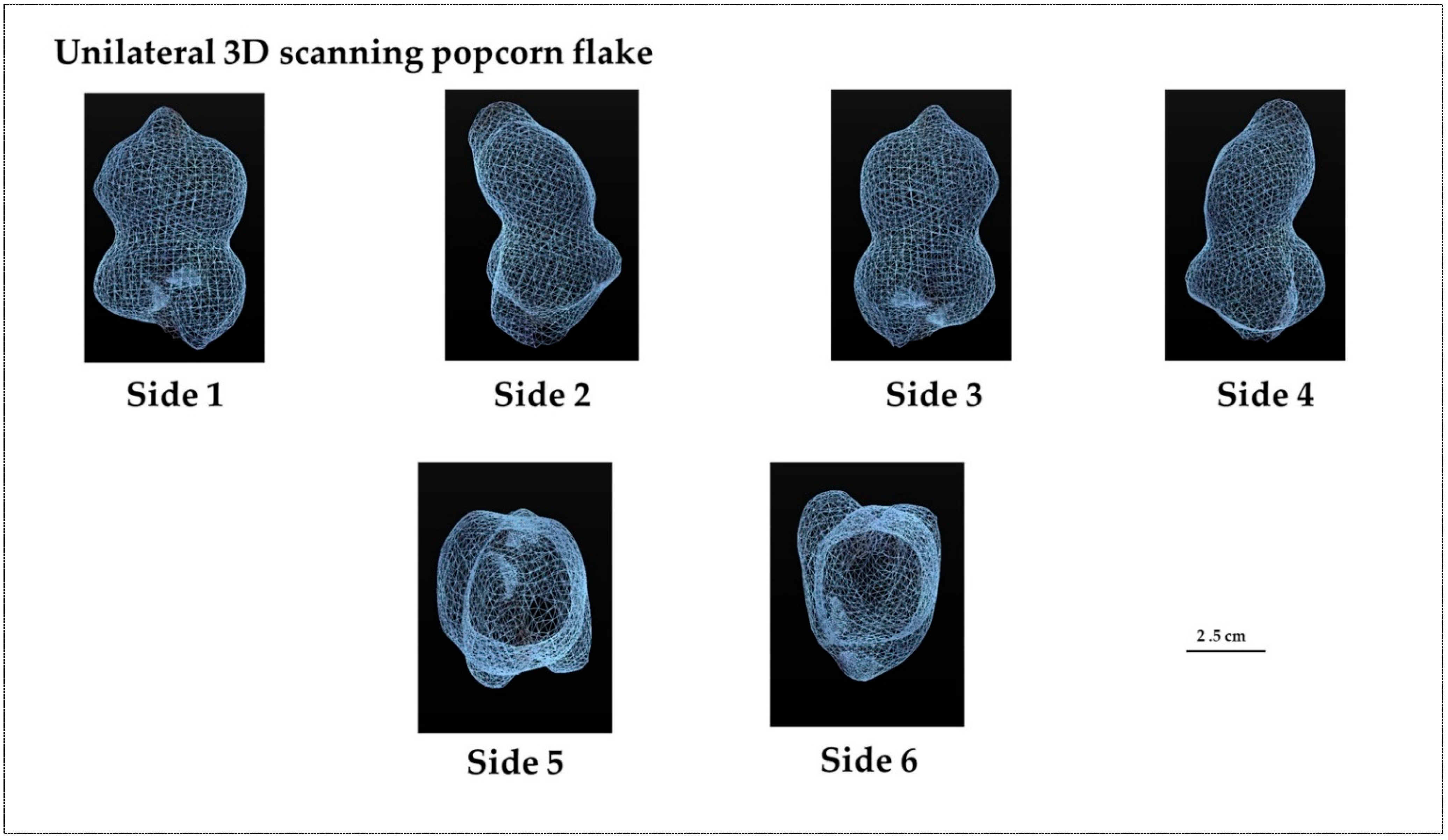

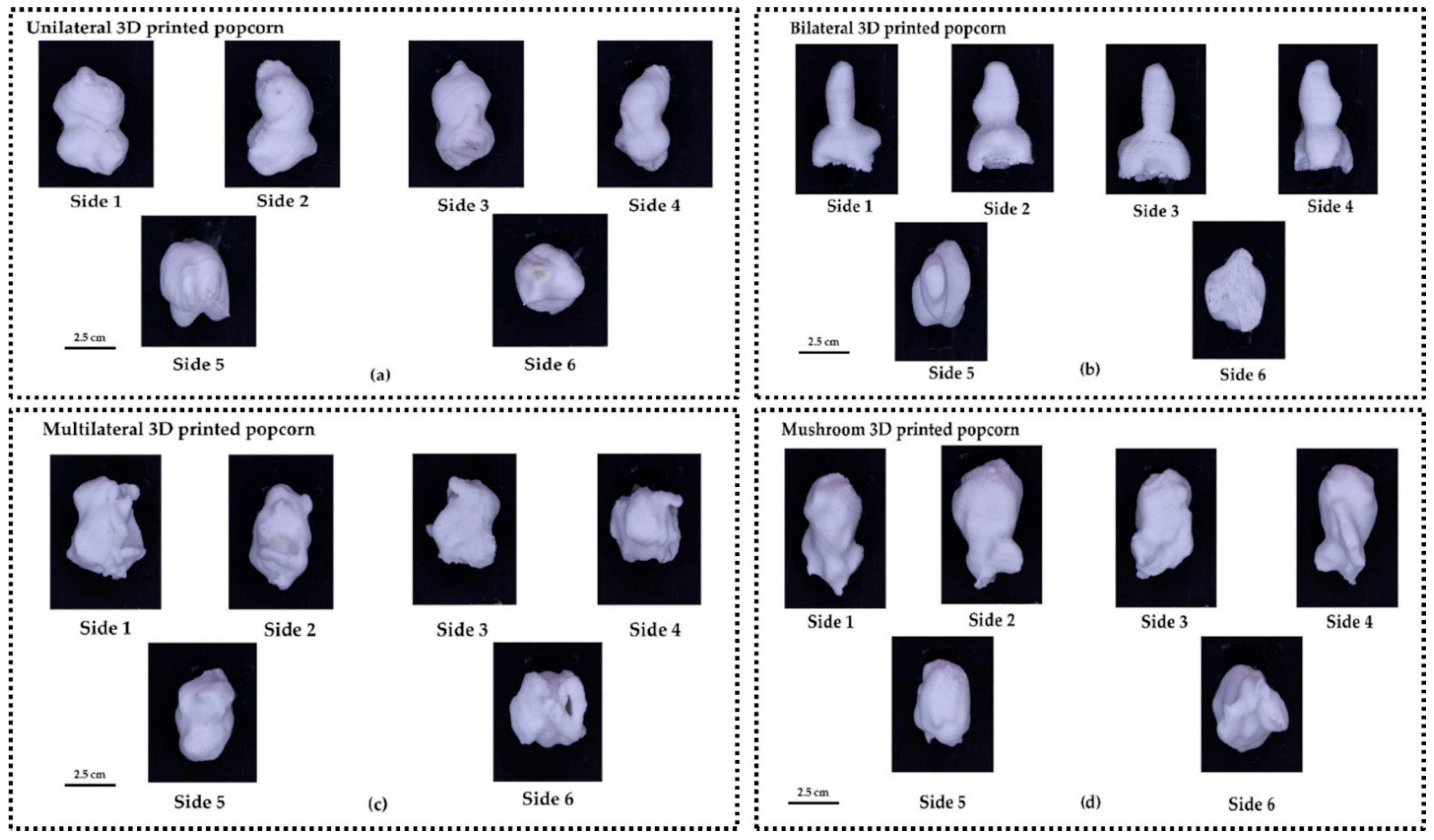

3.1. Three-Dimensional Scanning Reconstruction and 3D Printing

3.2. Digital Image Analysis

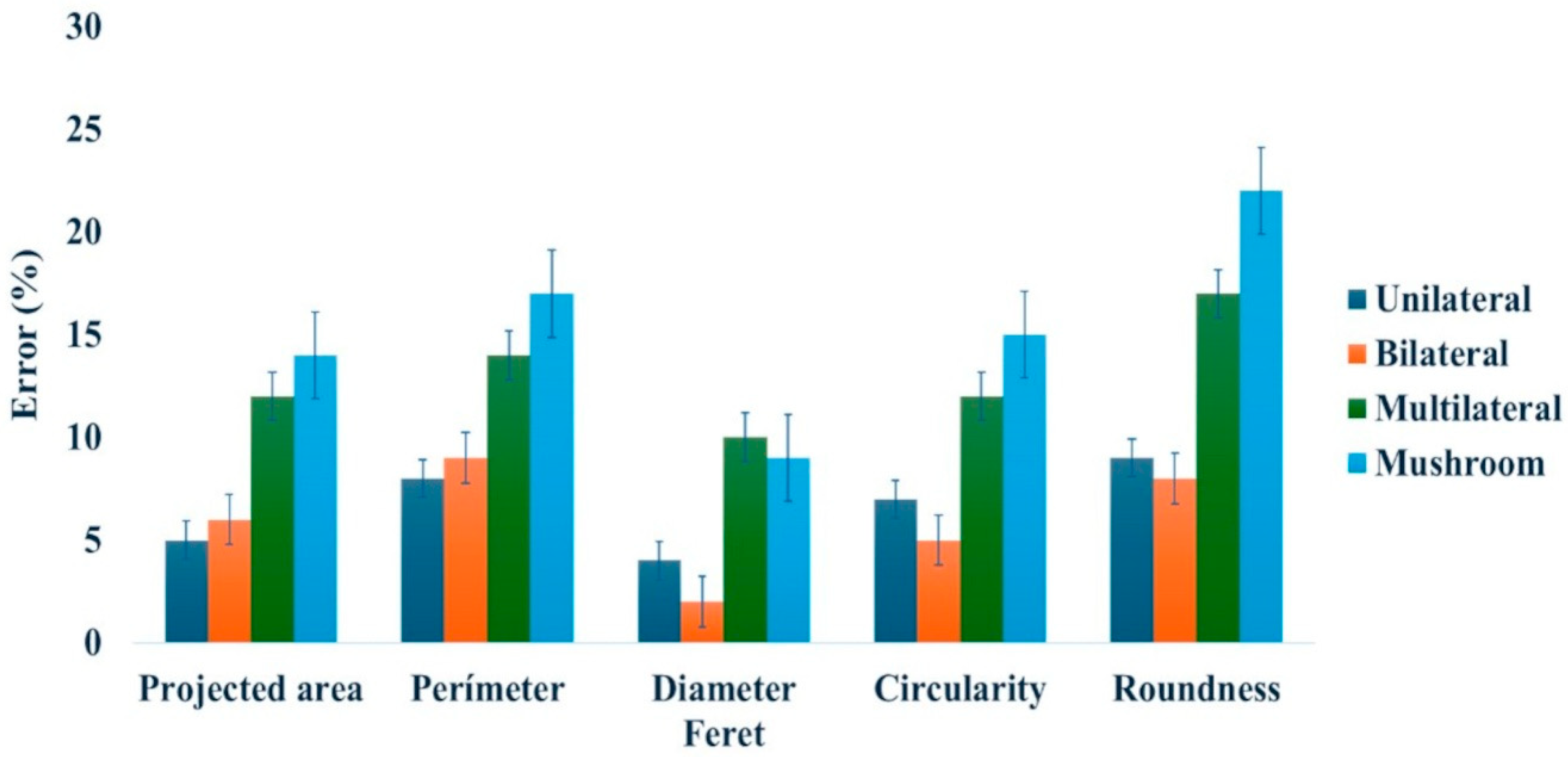

3.3. Error in Reconstruction and 3D Printing of Morphologies

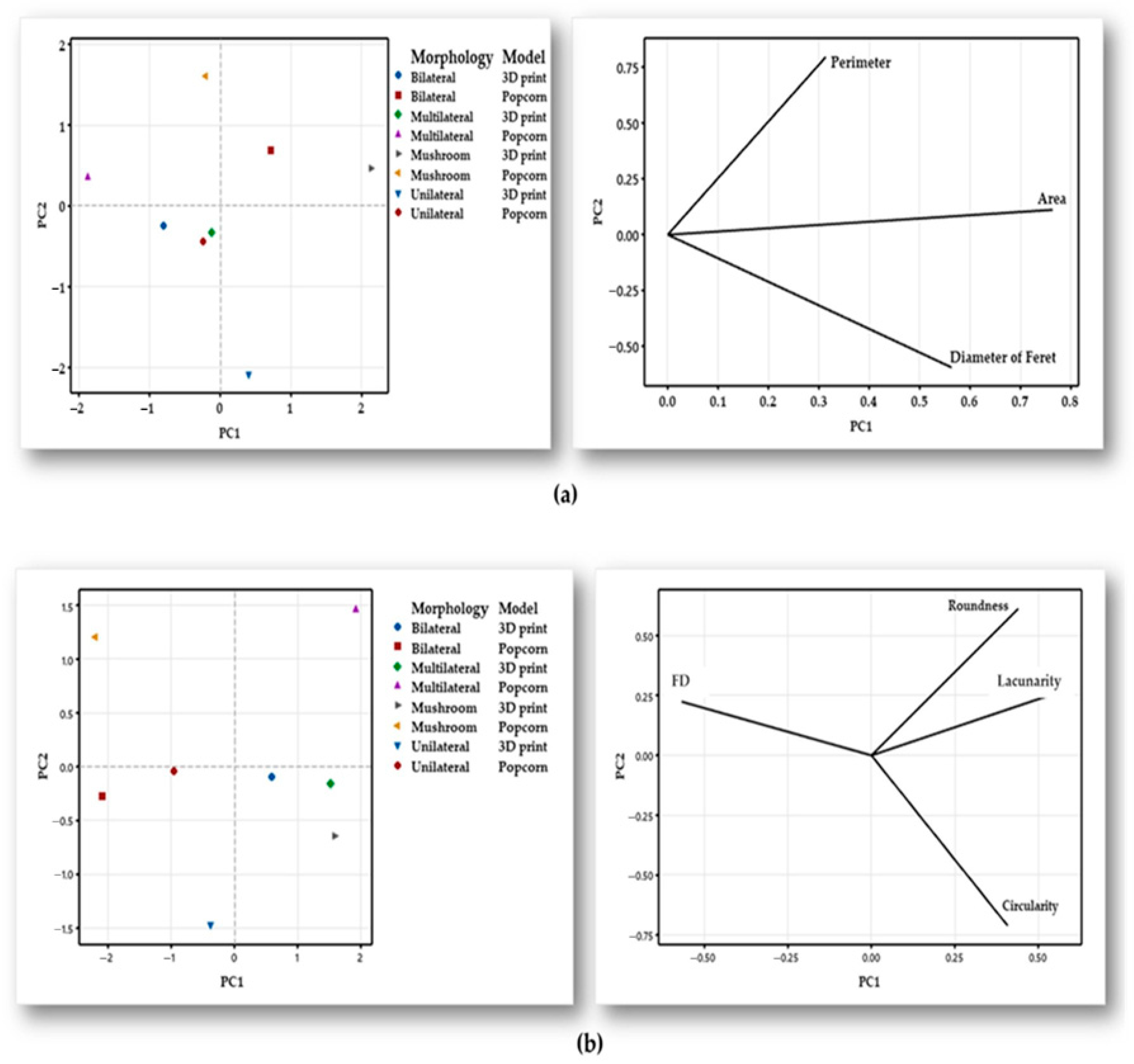

3.4. Contribution of DIA Parameters Towards Describing Morphometry of Popcorn Flakes as Estimated by Principal Component Analysis (PCA)

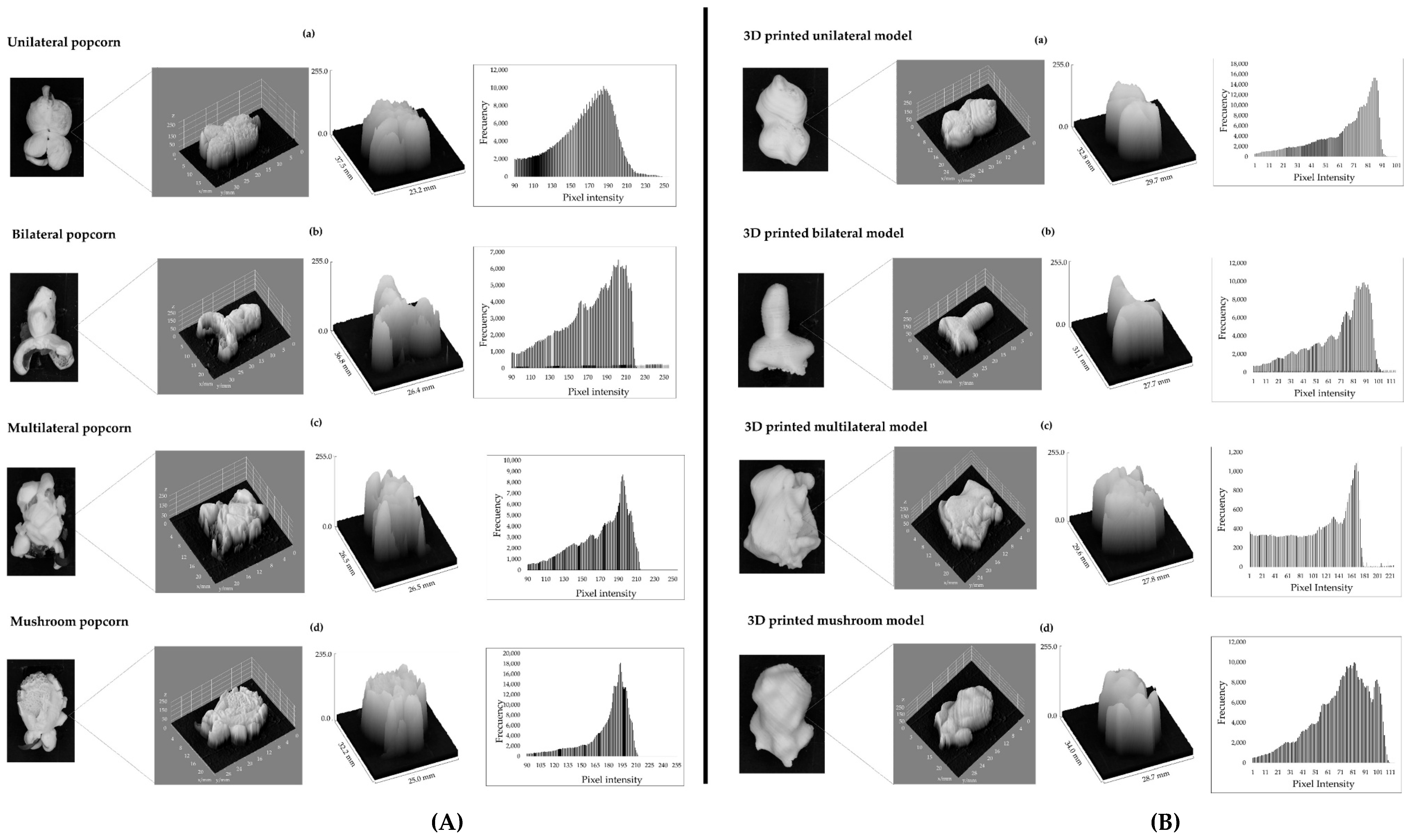

3.5. Three-Dimensional Texture Analysis of Popcorn Flakes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PLA | Polylactic Acid |

| 3D | Three-Dimensional |

| FD | Fractal Dimension |

| PCA | Principal Component Analysis |

| LED | Light Emitting Diode |

| DIA | Digital Image Analysis |

| FPS | Frames per Second |

| ROI | Region of Interest |

| P/R | Printed/Real |

References

- Pereira, T.; Barroso, S.; Gil, M.M. Food Texture Design by 3D Printing: A Review. Foods 2021, 10, 320. [Google Scholar] [CrossRef]

- Goñi, S.M.; Purlis, E.; Salvadori, V.O. Three-Dimensional Reconstruction of Irregular Foodstuffs. J. Food Eng. 2007, 82, 536–547. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, D. A Review of Three-Dimensional Vision Techniques in Food and Agriculture Applications. Smart Agric. Technol. 2023, 5, 100259. [Google Scholar] [CrossRef]

- Waseem, M.; Tahir, A.U.; Majeed, Y. Printing the Future of Food: The Physics Perspective on 3D Food Printing. Food Phys. 2024, 1, 100003. [Google Scholar] [CrossRef]

- Ma, Y.; Potappel, J.; Schutyser, M.A.I.; Boom, R.M.; Zhang, L. Quantitative Analysis of 3D Food Printing Layer Extrusion Accuracy: Contextualizing Automated Image Analysis with Human Evaluations. Curr. Res. Food Sci. 2023, 6, 100511. [Google Scholar] [CrossRef]

- Uyar, R.; Erdoğdu, F. Potential Use of 3-Dimensional Scanners for Food Process Modeling. J. Food Eng. 2009, 93, 337–343. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, Q.; Liu, Y.; Wei, S.; Han, Z.; Zheng, O.; Ji, H.; Zhang, B.; Liu, S. Investigation on 3D Printing of Shrimp Surimi Adding Three Edible Oils. Foods 2024, 13, 429. [Google Scholar] [CrossRef]

- De Salvo, M.I.; Palla, C.; Cotabarren, I.M. Development of an Operational Map for the 3D Printing of Phytosterol-Enriched Oleogels: Rheological Insights and Applications in Nutraceutical Design. Foods 2025, 14, 200. [Google Scholar] [CrossRef]

- Zhang, R.; Li, F.; Tang, J.; Koral, T.; Jiao, Y. Improved Accuracy of Radio Frequency (RF) Heating Simulations Using 3D Scanning Techniques for Irregular-Shape Food. LWT 2020, 121, 108951. [Google Scholar] [CrossRef]

- Siripon, K.; Tansakul, A.; Mittal, G.S. Heat Transfer Modeling of Chicken Cooking in Hot Water. Food Res. Int. 2007, 40, 923–930. [Google Scholar] [CrossRef]

- Mohamed, A.A.; Ashman, R.B.; Kirleis, A.W. Pericarp Thickness and Other Kernel Physical Characteristics Relate to Microwave Popping Quality of Popcorn. J. Food Sci. 1993, 58, 342–346. [Google Scholar] [CrossRef]

- Bucher, T.; Van Der Horst, K.; Siegrist, M. The Fake Food Buffet–a New Method in Nutrition Behaviour Research. Br. J. Nutr. 2012, 107, 1553–1560. [Google Scholar] [CrossRef] [PubMed]

- García-Pinilla, S.; Gutiérrez-López, G.F.; Hernández-Sánchez, H.; Cáez-Ramírez, G.; García-Armenta, E.; Alamilla-Beltrán, L. Quality Parameters and Morphometric Characterization of Hot-Air Popcorn as Related to Moisture Content. Dry. Technol. 2020, 39, 77–89. [Google Scholar] [CrossRef]

- Bucher, T.; Van Der Horst, K.; Siegrist, M. Fruit for Dessert. How People Compose Healthier Meals. Appetite 2013, 60, 74–80. [Google Scholar] [CrossRef]

- Pinilla, G.; Santiago, S. Estudio Del Reventado Por Aire Caliente de Palomitas de Maíz Caracterizadas Con Análisis Digital de Imágenes. Ph.D. Thesis, Instituto Politécnico Nacional, Ciudad de Mexico, Mexico, 2019. [Google Scholar]

- Kim, H.W.; Bae, H.; Park, H.J. Reprint of: Classification of the Printability of Selected Food for 3D Printing: Development of an Assessment Method Using Hydrocolloids as Reference Material. J. Food Eng. 2018, 220, 28–37. [Google Scholar] [CrossRef]

- Zhang, S. High-Speed 3D Shape Measurement with Structured Light Methods: A Review. Opt. Lasers Eng. 2018, 106, 119–131. [Google Scholar] [CrossRef]

- Cui, B.; Tao, W.; Zhao, H. High-Precision 3D Reconstruction for Small-to-Medium-Sized Objects Utilizing Line-Structured Light Scanning: A Review. Remote Sens. 2021, 13, 4457. [Google Scholar] [CrossRef]

- Ali, N.A.N.; Kamarudin, K.; Lam, C.K.; Azmi, M.S.M.; Ismail, A.H.; Rahim, N.A.; Yahya, W.M.N.W.; Sneah, G.K.; Seng, M.L.; Hai, T.P.; et al. 3D Reconstruction of Fruit Shape Based on Vision and Edge Sections. J. Electron. Inf. Syst. 2022, 4, 26–32. [Google Scholar] [CrossRef]

- Kaiser, J.; Dědič, M. Influence of Material on the Density of a Point Cloud Created Using a Structured-Light 3D Scanner. Appl. Sci. 2024, 14, 1476. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Rivera-López, F.; Pavón, M.M.L.; Correa, E.C.; Molina, M.H. Effects of Nozzle Temperature on Mechanical Properties of Polylactic Acid Specimens Fabricated by Fused Deposition Modeling. Polymers 2024, 16, 1867. [Google Scholar] [CrossRef]

- Acosta-Ramírez, C.; García-Armenta, E.; Calderón-Domínguez, G.; Cornejo-Mazón, M.; García, H.S.; Hernández-Sánchez, H.; Gutiérrez-López, G.F. Acoustic Signals Associated with the Multifractal Breakage Patterns of Brittle and Crispy Foods. J. Food Eng. 2024, 379, 112130. [Google Scholar] [CrossRef]

- Valdez-Miranda, J.I.; Robles-López, M.R.; Robles-de-la-Torre, R.R.; Alamilla-Beltrán, L.; Hernández-Sánchez, H.; Gutiérrez-López, G.F. Effect of High-Voltage Electrostatic Field Treatments on Bananas (Musa paradisiaca Var. sapientum) on Their Postharvest Quality, Enzymatic Activity and Morphological Changes. Food Bioprod. Process. 2024, 146, 135–146. [Google Scholar] [CrossRef]

- Meraz-Torres, L.S.; Quintanilla-Carvajal, M.X.; Téllez-Medina, D.I.; Hernández-Sánchez, H.; Alamilla-Beltrán, L.; Gutiérrez-López, G.F. Water Droplet Spreading and Recoiling upon Contact with Thick–Compact Maltodextrin Agglomerates. J. Sci. Food Agric. 2011, 91, 2594–2600. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Ho, C.; Wang, J. The Development of 3D Food Printer for Printing Fibrous Meat Materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 284, 012019. [Google Scholar] [CrossRef]

- García-Armenta, E.; Téllez-Medina, D.I.; Alamilla-Beltrán, L.; Arana-Errasquín, R.; Hernández-Sánchez, H.; Gutiérrez-López, G.F. Multifractal Breakage Patterns of Thick Maltodextrin Agglomerates. Powder Technol. 2014, 266, 440–446. [Google Scholar] [CrossRef]

- García-Armenta, E.; Téllez-Medina, D.I.; Sánchez-Segura, L.; Alamilla-Beltrán, L.; Hernández-Sánchez, H.; Gutiérrez-López, G.F. Multifractal Breakage Pattern of Tortilla Chips as Related to Moisture Content. J. Food Eng. 2016, 168, 96–104. [Google Scholar] [CrossRef]

- Barburiceanu, S.; Terebes, R.; Meza, S. 3D Texture Feature Extraction and Classification Using GLCM and LBP-Based Descriptors. Appl. Sci. 2021, 11, 2332. [Google Scholar] [CrossRef]

- Dong, P. Test of a New Lacunarity Estimation Method for Image Texture Analysis. Int. J. Remote Sens. 2000, 21, 3369–3373. [Google Scholar] [CrossRef]

- Valous, N.A.; Sun, D.-W.; Allen, P.; Mendoza, F. The Use of Lacunarity for Visual Texture Characterization of Pre-Sliced Cooked Pork Ham Surface Intensities. Food Res. Int. 2010, 43, 387–395. [Google Scholar] [CrossRef]

- Colın-Orozco, J.; Chanona-Perez, J.; Perea-Flores, M.d.J.; Pedroza-Islas, R. Changes in Large-Deformation Properties During Dough Fermentation by Lactobacillus Strains and Their Relationship with Microstructure. Revista Mexicana de Ingeniería Química 2014, 13, 457–471. [Google Scholar]

- Maldonado-Rosas, R.; Tejada-Ortigoza, V.; Cuan-Urquizo, E.; Mendoza-Cachú, D.; Morales-de La Peña, M.; Alvarado-Orozco, J.M.; Campanella, O.H. Evaluation of Rheology and Printability of 3D Printing Nutritious Food with Complex Formulations. Addit. Manuf. 2022, 58, 103030. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, X.; Vinod, G.; Raghavan, S.; He, J.; Zhu, F. MFP3D: Monocular Food Portion Estimation Leveraging 3D Point Clouds. In Proceedings of the International Conference on Pattern Recognition, Kolkata, India, 1 December 2024. [Google Scholar]

- Dehais, J.; Anthimopoulos, M.; Shevchik, S.; Mougiakakou, S. Two-View 3D Reconstruction for Food Volume Estimation. IEEE Trans. Multimed. 2017, 19, 1090–1099. [Google Scholar] [CrossRef]

- Masoudi, M.; Golzarian, M.R.; Lawson, S.S.; Rahimi, M.; Islam, S.M.S.; Khodabakhshian, R. Improving 3D Reconstruction for Accurate Measurement of Appearance Characteristics in Shiny Fruits Using Post-Harvest Particle Film: A Case Study on Tomatoes. Comput. Electron. Agric. 2024, 224, 109141. [Google Scholar] [CrossRef]

- Sweley, J.C.; Rose, D.J.; Jia, X.; Williams, R.A.; Jackson, D.S. Effect of Flake Shape on Packing Characteristics of Popped Popcorn. J. Food Eng. 2014, 127, 75–79. [Google Scholar] [CrossRef]

- Varvara, R.-A.; Szabo, K.; Vodnar, D.C. 3D Food Printing: Principles of Obtaining Digitally-Designed Nourishment. Nutrients 2021, 13, 3617. [Google Scholar] [CrossRef] [PubMed]

- Kewuyemi, Y.O.; Kesa, H.; Adebo, O.A. Trends in Functional Food Development with Three-Dimensional (3D) Food Printing Technology: Prospects for Value-Added Traditionally Processed Food Products. Crit. Rev. Food Sci. Nutr. 2022, 62, 7866–7904. [Google Scholar] [CrossRef]

- Johansson, M.; Nilsson, K.; Knab, F.; Langton, M. Faba Bean Fractions for 3D Printing of Protein-, Starch- and Fibre-Rich Foods. Processes 2022, 10, 466. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Prithviraj, V.; Díaz, L.P.; Lemus-Mondaca, R.; Ullah, A.; Roopesh, M.S. Emerging Advancements in 3D Food Printing. Front. Food Sci. Technol. 2025, 5, 1607449. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Sánchez-Casas, X.; Luis-Pérez, C.J. Analysis of AM Parameters on Surface Roughness Obtained in PLA Parts Printed with FFF Technology. Polymers 2021, 13, 2384. [Google Scholar] [CrossRef] [PubMed]

- Dhakal, N.; Wang, X.; Espejo, C.; Morina, A.; Emami, N. Impact of Processing Defects on Microstructure, Surface Quality, and Tribological Performance in 3D Printed Polymers. J. Mater. Res. Technol. 2023, 23, 1252–1272. [Google Scholar] [CrossRef]

- Rodríguez-Herrera, V.V.; Umeda, T.; Kozu, H.; Kobayashi, I. Formation and Texture Analysis of Extrusion-Based 3D Printed Foods Using Nixtamalized Corn and Chickpea Flours: Effect of Cooking Process. Appl. Sci. 2024, 14, 7315. [Google Scholar] [CrossRef]

- Chirico Scheele, S.; Hartmann, C.; Siegrist, M.; Binks, M.; Egan, P.F. Consumer Assessment of 3D-Printed Food Shape, Taste, and Fidelity Using Chocolate and Marzipan Materials. 3D Print. Addit. Manuf. 2022, 9, 473–482. [Google Scholar] [CrossRef]

- Zhu, W.; Iskandar, M.M.; Baeghbali, V.; Kubow, S. Three-Dimensional Printing of Foods: A Critical Review of the Present State in Healthcare Applications, and Potential Risks and Benefits. Foods 2023, 12, 3287. [Google Scholar] [CrossRef]

- Mateo, C.M.; Gil, P.; Torres, F. Visual Perception for the 3D Recognition of Geometric Pieces in Robotic Manipulation. Int. J. Adv. Manuf. Technol. 2016, 83, 1999–2013. [Google Scholar] [CrossRef]

- Habib, A.K.M.A.; Khalil, M.I.; Maleky, F.; Pal, R.; Egan, P.F. Print Fidelity Assessment for 3D Food Printed Designs Using Manual and Automated Approaches. Proc. Des. Soc. 2025, 5, 2641–2650. [Google Scholar] [CrossRef]

| Morphology | FPS | Faces | Vertices |

|---|---|---|---|

| Unilateral | 306.4 ± 0.5 | 6673.8 ± 4.1 | 9465 ± 3.4 * |

| Bilateral | 306.8 ± 0.8 | 6086.2 ± 3.7 | 6278 ± 6.3 |

| Multilateral | 309.1 ± 0.7 * | 10,718.8 ± 5.6 * | 5432 ± 4.3 |

| Mushroom | 305.8 ± 0.8 | 9442.2 ± 4.5 | 4704 ± 3.2 |

| Parameters | Popcorn Real (R) | 3D-Printed Flake (P) |

|---|---|---|

| Unilateral | ||

| Area (mm2) | 232.0 ± 4.01 * | 219 ± 1.97 |

| Perimeter (mm) | 71.4 ± 0.39 | 67.40 ± 0.77 * |

| Feret diameter (mm) | 22.72 ± 0.04 | 23.5 ± 1.01 |

| Fractal dimension | 1.23 ± 0.02 * | 1.16 ± 0.01 |

| Lacunarity | 9.67 ± 0.19 * | 5.75 ± 0.58 |

| Image entropy | 5.56 ± 0.11 | 5.14± 0.03 |

| Circularity | 0.58 ± 0.01 | 0.62 ± 0.01 * |

| Roundness | 0.62 ± 0.01 | 0.61± 0.02 |

| Bilateral | ||

| Area (mm2) | 226 ± 3.40 * | 205 ± 2.77 |

| Perimeter (mm) | 86.3 ± 1.47 * | 73.7 ± 2.10 |

| Feret diameter (mm) | 24.5 ± 0.33 * | 22.6 ± 0.74 |

| Fractal dimension | 1.39 ± 0.02 | 1.21 ± 0.01 |

| Lacunarity | 6.23 ± 0.08 * | 4.27 ± 0.35 |

| Image entropy | 5.55 ± 0.13 * | 4.84 ± 0.01 |

| Circularity | 0.75 ± 1.30 | 0.53± 0.01 |

| Roundness | 0.58 ± 0.01 | 0.64 ± 0.03 |

| Multilateral | ||

| Area (mm2) | 189 ± 2.09 | 244 ± 1.56 * |

| Perimeter (mm) | 73.5 ± 1.84 * | 70.8 ± 1.10 |

| Feret diameter (mm) | 20.67± 0.22 * | 5.21 ± 0.56 |

| Fractal dimension | 1.24 ± 0.05 | 1.26 ± 0.41 |

| Lacunarity | 21.6 ± 0.04 * | 6.01 ± 0.46 |

| Image entropy | 5.53 ± 0.05 | 5.12 ± 0.06 |

| Circularity | 0.51 ± 0.01 | 0.66 ± 0.01 * |

| Roundness | 0.80 ± 0.04 * | 0.75 ± 0.04 |

| Mushroom | ||

| Area (mm2) | 225 ± 2.57 | 299 ± 1.01 * |

| Perimeter (mm) | 86.11 ± 0.92 * | 81.44 ± 1.14 |

| Feret diameter (mm) | 21.98 ± 0.19 * | 4.26 ± 1.11 |

| Fractal dimension | 1.19 ± 0.03 | 1.23 ± 0.01 |

| Lacunarity | 3.63 ± 0.42 | 5.72 ±1.04 * |

| Image entropy | 5.78 ± 0.15 | 5.41 ± 0.78 |

| Circularity | 0.45 ± 0.02 | 0.63 ± 0.77 * |

| Roundness | 0.78 ± 0.07 | 0.77 ± 0.15 |

| Parameter (P/R) | Sides | |||||

|---|---|---|---|---|---|---|

| Side 1 | Side 2 | Side 3 | Side 4 | Side 5 | Side 6 | |

| Unilateral | ||||||

| Area | 0.91 ± 0.31 | 0.92 ± 0.14 | 0.92± 0.52 | 0.92 ± 0.22 | 1.31 ± 0.21 * | 1.02 ± 0.52 |

| Perimeter | 0.71 ± 0.22 | 0.82 ± 0.64 | 0.81 ± 0.22 | 0.96 ± 2.12 | 1.01 ± 0.82 | 1.35 ± 0.71 * |

| Feret diameter | 0.82 ± 0.12 | 1.0 1± 0.75 | 1.01 ± 0.13 | 0.92 ± 0.43 | 1.35 ± 0.54 * | 1.03 ± 0.73 |

| Fractal dimension | 0.81 ± 0.06 | 0.87 ± 0.27 | 1.02 ± 0.12 | 0.95 ± 0.23 | 1.13 ± 0.12 * | 1.15 ± 0.11 |

| Lacunarity | 1.02 ± 0.83 * | 0.74 ± 0.11 | 0.71 ± 0.67 | 0.43 ± 0.22 | 0.35 ± 0.59 | 0.87 ± 0.78 |

| Image entropy | 0.91 ± 0.15 | 0.71 ± 0.72 | 0.81 ± 0.17 | 0.82 ± 0.94 | 1.08 ± 0.93 * | 0.91 ± 0.34 |

| Circularity | 1.61 ± 0.41 | 1.12 ± 0.13 | 1.32 ± 0.42 | 1.11 ± 0.14 | 1.04 ± 0.57 | 2.61 ± 0.22 * |

| Roundness | 0.91 ± 0.62 | 0.92 ± 0.14 | 0.94 ± 0.17 | 1.22 ± 0.41 * | 0.91 ± 0.21 | 1.62 ± 0.48 |

| Bilateral | ||||||

| Area | 0.98 ± 2.51 * | 0.83 ± 8.11 | 0.93 ± 3.64 | 0.92 ± 1.21 | 0.97 ± 1.78 | 0.86 ± 1.34 |

| Perimeter | 0.74 ± 3.32 | 0.93 ± 1.92 | 0.71 ± 1.67 | 1.07 ± 1.72 * | 0.86 ± 2.38 | 0.98 ± 1.38 |

| Feret diameter | 0.97 ± 0.54 | 0.84 ± 0.24 | 0.96 ± 1.33 | 0.98 ± 0.56 | 1.18 ± 0.78 * | 1.13 ± 1.17 |

| Fractal dimension | 0.94 ± 0.11 | 0.81 ± 0.75 | 1.07 ± 0.27 | 1.07 ± 0.10 * | 0.98 ± 0.18 | 0.87 ± 0.57 |

| Lacunarity | 7.81 ± 0.82 * | 4.01 ± 0.54 | 0.68 ± 0.78 | 0.34 ± 0.24 | 4.67 ± 0.57 | 4.07 ± 0.21 |

| Image entropy | 0.88 ± 0.11 | 0.92± 0.14 | 0.97 ± 0.34 | 0.77± 0.46 | 0.93 ± 0.47 * | 0.77 ± 0.42 |

| Circularity | 1.01 ± 0.54 | 0.91 ± 0.97 | 0.82 ± 0.52 | 0.87 ± 0.16 | 1.07 ± 0.68 | 2.67 ± 0.25 * |

| Roundness | 0.93 ± 0.11 | 1.22 ± 0.37 | 0.97 ± 0.18 | 1.47 ± 0.47 * | 1.36 ± 0.57 | 1.35 ± 0.57 |

| Multilateral | ||||||

| Area | 1.60 ± 1.14 | 1.07 ± 0.37 | 1.33 ± 0.66 | 1.05 ± 0.52 | 1.19 ± 7.85 | 1.67 ± 0.17 * |

| Perimeter | 0.83 ± 4.64 | 0.90 ± 3.33 | 0.96 ± 2.78 | 0.81 ± 0.87 | 1.21 ± 1.07 | 1.21 ± 1.08 * |

| Feret diameter | 1.09 ± 0.41 | 1.09 ± 0.88 | 1.03 ± 1.18 | 1.09 ± 0.99 | 1.23 ± 0.52 * | 1.20 ± 0.53 |

| Fractal dimension | 0.97 ± 0.03 | 0.95 ± 0.08 | 1.00 ± 0.02 | 1.01 ± 0.01 | 1.12 ± 0.12 * | 0.99 ± 0.10 |

| Lacunarity | 3.05 ± 0.20 | 2.28 ± 1.44 | 1.21 ± 1.80 | 1.15 ± 4.20 | 0.59 ± 0.13 | 9.83 ± 0.70 * |

| Image entropy | 0.91 ± 0.16 | 0.91 ± 0.10 | 0.97 ± 0.11 | 0.91 ± 0.18 | 0.87 ± 0.19 | 0.94 ± 0.06 |

| Circularity | 2.22 ± 0.04 * | 1.45 ± 0.02 | 1.41 ± 0.01 | 1.76 ± 0.05 | 0.98 ± 0.01 | 0.82 ± 0.03 |

| Roundness | 1.07 ± 0.02 | 0.89 ± 0.02 | 1.10 ± 0.03 * | 0.86 ± 0.04 | 0.91 ± 0.06 | 0.76 ± 0.01 |

| Mushroom | ||||||

| Area | 1.07 ± 0.30 | 1.38 ± 0.02 | 1.07 ± 0.88 | 1.37 ± 0.03 | 1.60 ± 0.57 | 1.7 ± 0.27 * |

| Perimeter | 0.78 ± 0.71 | 0.83 ± 0.30 | 1.19 ± 0.16 | 0.87 ± 1.41 | 0.91 ± 1.90 | 1.2 ± 0.44 * |

| Feret diameter | 1.08 ± 0.60 | 1.11 ± 0.45 | 1.13 ± 1.40 | 1.11 ± 1.02 | 1.15 ± 1.10 | 1.3 ± 0.31 * |

| Fractal dimension | 0.86 ± 0.02 | 0.88 ± 0.03 | 0.86 ± 0.06 | 0.81 ± 0.09 | 0.98 ± 0.04 | 0.9 ± 0.5 * |

| Lacunarity | 4.17 ± 1.50 | 5.22 ± 2.18 | 4.93 ± 0.77 | 5.26 ± 1.77 | 7.43 ± 1.9 | 6.0 ± 0.5 * |

| Image entropy | 0.95 ± 0.87 | 1.02 ± 0.17 * | 0.22 ± 0.69 | 0.98 ± 0.12 | 0.96 ± 0.57 | 1.02 ± 0.88 |

| Circularity | 1.81 ± 0.17 | 2.94 ± 0.92 * | 0.85 ± 0.57 | 2.28 ± 0.27 | 1.42 ± 0.12 | 1.78 ± 0.61 |

| Roundness | 0.81 ± 0.66 | 1.18 ± 0.17 * | 0.93 ± 0.12 | 1.56 ± 0.58 | 1.07 ± 0.13 | 1.07 ± 0.33 |

| Morphology | Model | Fractal Dimension Texture | Lacunarity Texture |

|---|---|---|---|

| Mushroom | Real | 2.64 ± 0.01 Aa | 0.14 ± 0.00 Ba |

| 3D Print | 2.65 ± 0.01 Aa | 0.146 ± 0.01 Ba | |

| Unilateral | Real | 2.60 ± 0.01 Ba | 0.27 ± 0.02 a |

| 3D Print | 2.60 ± 0.01 Ba | 0.271 ± 0.02 a | |

| Multilateral | Real | 2.59 ± 0.01 Ba | 0.25 ± 0.02 Ba |

| 3D Print | 2.59 ± 0.01 a | 0.26 ± 0.02 Ba | |

| Bilateral | Real | 2.56 ± 0.01 a | 0.34 ± 0.02 Aa |

| 3D Print | 2.56 ± 0.01 a | 0.35 ± 0.02 Aa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrer-González, B.M.; Aguilar-Garay, R.; Acosta-Ramírez, C.I.; Alamilla-Beltrán, L.; Calderón-Domínguez, G.; Hernández-Sánchez, H.; Gutiérrez-López, G.F. 3D Reconstruction and Printing of Small, Morphometrically Complex Food Replicas and Comparison with Real Objects by Digital Image Analysis: The Case of Popcorn Flakes. Appl. Sci. 2025, 15, 11102. https://doi.org/10.3390/app152011102

Ferrer-González BM, Aguilar-Garay R, Acosta-Ramírez CI, Alamilla-Beltrán L, Calderón-Domínguez G, Hernández-Sánchez H, Gutiérrez-López GF. 3D Reconstruction and Printing of Small, Morphometrically Complex Food Replicas and Comparison with Real Objects by Digital Image Analysis: The Case of Popcorn Flakes. Applied Sciences. 2025; 15(20):11102. https://doi.org/10.3390/app152011102

Chicago/Turabian StyleFerrer-González, Beatriz M., Ricardo Aguilar-Garay, Carla I. Acosta-Ramírez, Liliana Alamilla-Beltrán, Georgina Calderón-Domínguez, Humberto Hernández-Sánchez, and Gustavo F. Gutiérrez-López. 2025. "3D Reconstruction and Printing of Small, Morphometrically Complex Food Replicas and Comparison with Real Objects by Digital Image Analysis: The Case of Popcorn Flakes" Applied Sciences 15, no. 20: 11102. https://doi.org/10.3390/app152011102

APA StyleFerrer-González, B. M., Aguilar-Garay, R., Acosta-Ramírez, C. I., Alamilla-Beltrán, L., Calderón-Domínguez, G., Hernández-Sánchez, H., & Gutiérrez-López, G. F. (2025). 3D Reconstruction and Printing of Small, Morphometrically Complex Food Replicas and Comparison with Real Objects by Digital Image Analysis: The Case of Popcorn Flakes. Applied Sciences, 15(20), 11102. https://doi.org/10.3390/app152011102