Development of Modified Gas Composition for Atmosphere Packaging of Sliced Apple Chips

Abstract

1. Introduction

2. Materials and Methods

2.1. Apple Dried Slice Preparation

2.2. Convective Drying

2.3. Modified Atmosphere Packaging

2.4. Measurement of Dry Basis, Reflation Index, and Acidity

2.5. Color Measurement and Browning Index

2.6. Textural Properties

2.7. Total Phenol Content

2.8. Vitamin C Content

2.9. Consumer Acceptance

2.10. Statistics

3. Results and Discussion

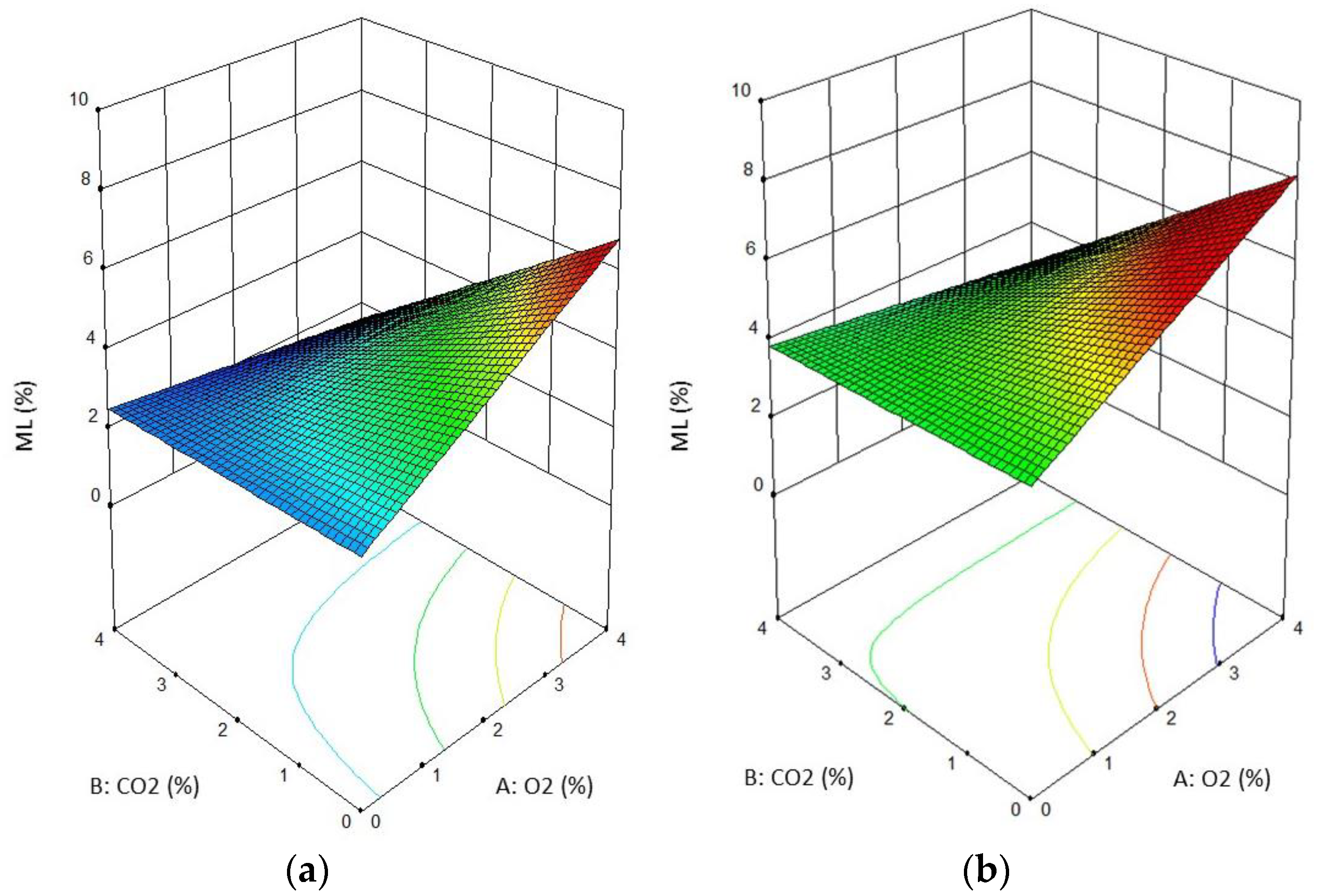

3.1. Mass Loss

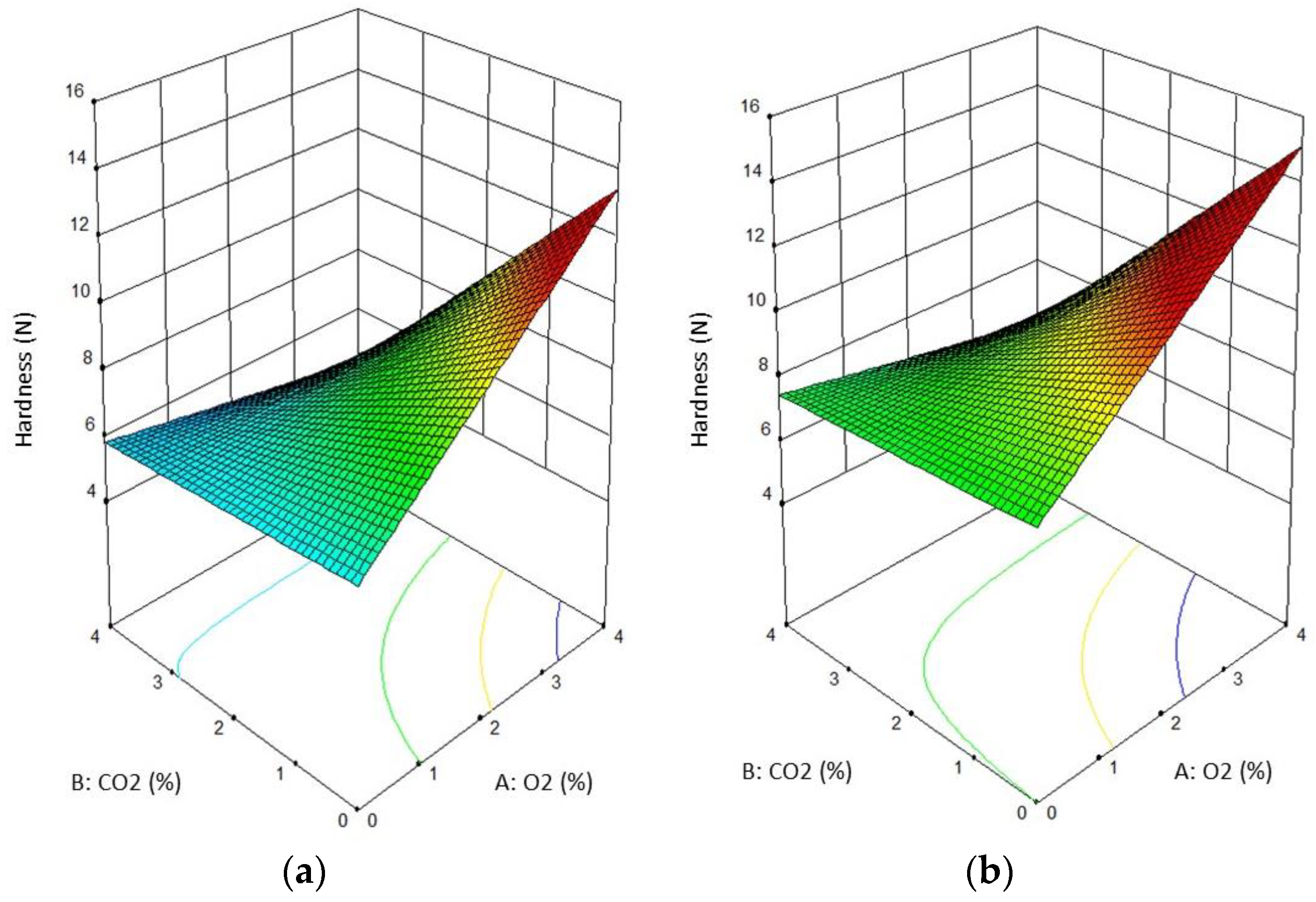

3.2. Hardness

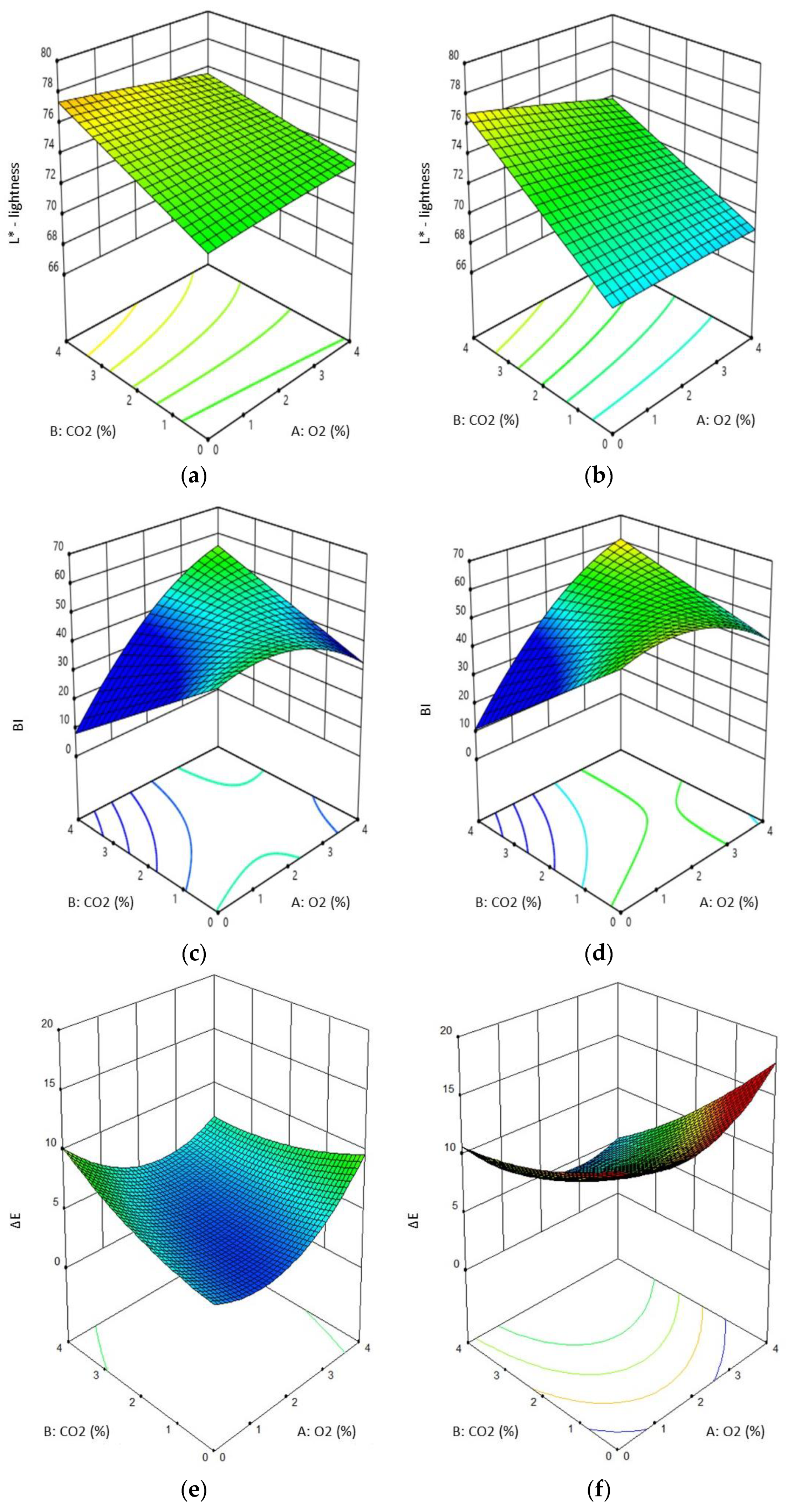

3.3. Color Attributes

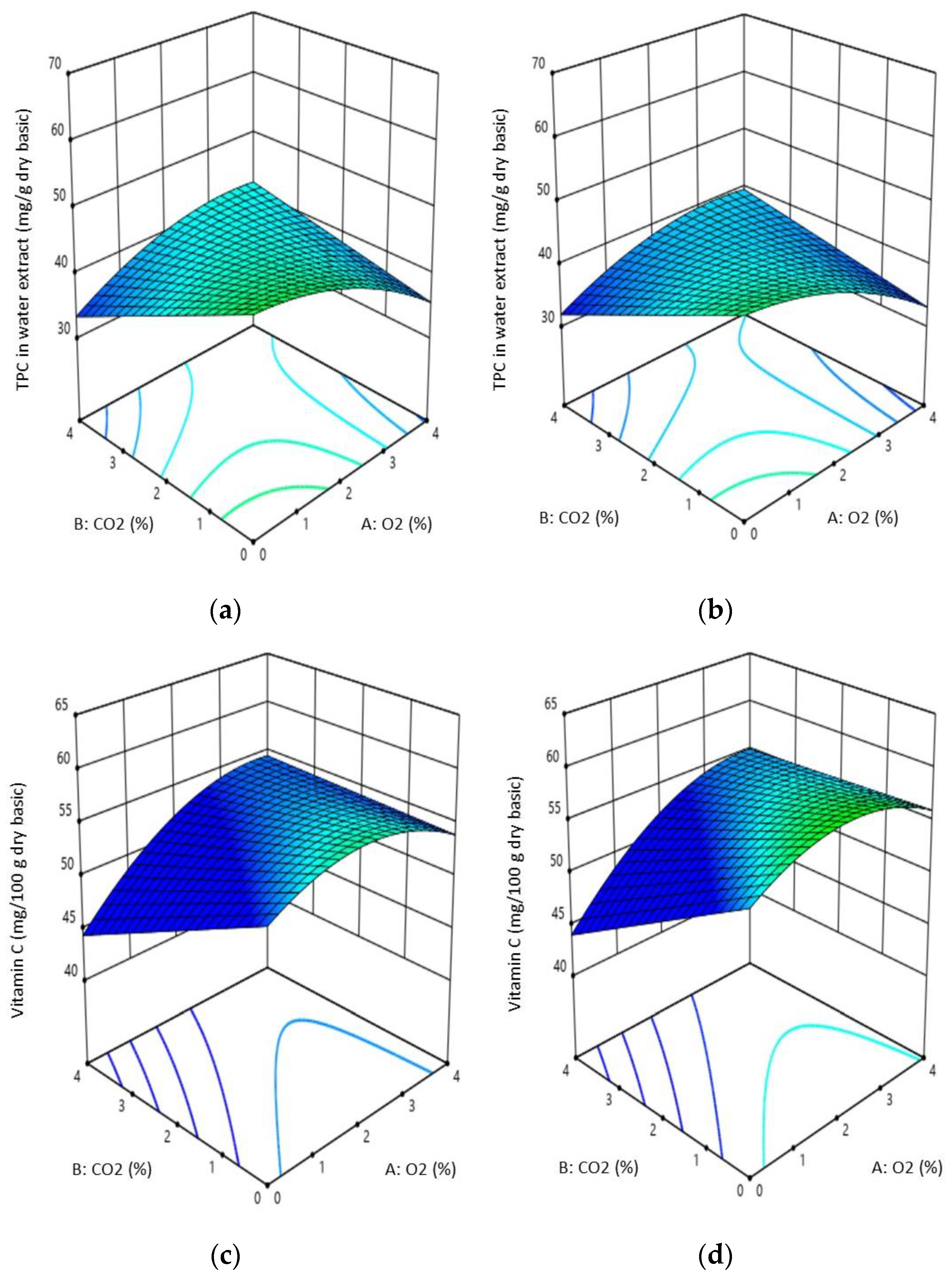

3.4. Chemical Composition

3.5. Overall Quality

3.6. The Optimization of the Gas Concentration

3.7. Verification of the Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rynek Owoców i Warzyw. Available online: https://kups.org.pl/wp-content/uploads/2024/01/Rynek-owocow-i-warzyw_63_2023_Poprawny.pdf (accessed on 30 January 2025).

- Statistical Yearbook of Agriculture 2024, Warsaw, Poland. Available online: https://stat.gov.pl/en/topics/statistical-yearbooks/statistical-yearbooks/statistical-yearbook-of-agriculture-2024,6,19.html (accessed on 31 January 2025).

- Lemmens, E.; Alós, E.; Rymenants, M.; De Storme, N.; Keulemans, W.J. Dynamics of ascorbic acid content in apple (Malus x domestica) during fruit development and storage. Plant Physiol. Biochem. 2020, 151, 47–59. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Int. J. Food Sci. Technol. 2010, 45, 891–898. [Google Scholar] [CrossRef]

- Apple Nutritional Composition. Public Health England. McCance and Widdowson’s The Composition of Foods Seventh Summary Edition. Royal Society of Chemistry. 2015. Available online: https://www.britishapplesandpears.co.uk/apple-nutritional-composition/ (accessed on 15 January 2025).

- Rothwell, J.A.; Pérez-Jiménez, J.; Neveu, V.; Medina-Ramon, A.; M’Hiri, N.; Garcia Lobato, P.; Manach, C.; Knox, K.; Eisner, R.; Wishart, D.; et al. Phenol-Explorer 3.0: A major update of the Phenol-Explorer database to incorporate data on the effects of food processing on polyphenol content. Database 2013, 2013, bat070. [Google Scholar] [CrossRef] [PubMed]

- Kschonsek, J.; Wolfram, T.; Stöckl, A.; Böhm, V. Polyphenolic Compounds Analysis of Old and New Apple Cultivars and Contribution of Polyphenolic Profile to the In Vitro Antioxidant Capacity. Antioxidants 2018, 7, 20. [Google Scholar] [CrossRef]

- Pissard, A.; Fernández Pierna, J.A.; Baeten, V.; Sinnaeve, G.; Lognay, G.; Mouteau, A.; Dupont, P.; Rondia, A.; Lateur, M. Non-destructive measurement of vitamin C, total polyphenol and sugar content in apples using near-infrared spectroscopy. J. Sci. Food Agric. 2013, 93, 238–244. [Google Scholar] [CrossRef]

- Soriano-Maldonado, A.; Hidalgo, M.; Arteaga, P.; de Pascual-Teresa, S.; Nova, E. Effects of regular consumption of vitamin C-rich or polyphenol-rich apple juice on cardiometabolic markers in healthy adults: A randomized crossover trial. Eur. J. Nutr. 2014, 53, 1645–1657. [Google Scholar] [CrossRef] [PubMed]

- Khanizadeh, S.; Tsao, R.; Rekika, D.; Yang, R.; Charles, M.R.; Rupasinghe, H.P.V. Journal of Food Composition and Analysis Polyphenol composition and total antioxidant capacity of selected apple genotypes for processing. J. Food Compos. Anal. 2008, 21, 396–401. [Google Scholar] [CrossRef]

- Hamid, A.A.; Aiyelaagbe, O.O.; Usman, L.A.; Ameen, O.M.; Lawal, A. Antioxidants. Its medicinal and pharmacological applications. J. Pure Appl. Chem. 2010, 4, 142–151. [Google Scholar]

- Leong, S.Y.; Oey, I. Effects of processing on anthocyanins, carotenoids and vitamin C in summer fruits and vegetables. Food Chem. 2012, 133, 1577–1587. [Google Scholar] [CrossRef]

- Rupasinghe, H.; Wang, L.; Huber, G.; Pitts, N. Effect of baking on dietary fibre and phenolics of muffins incorporated with apple skin powder. Food Chem. 2007, 107, 1217–1224. [Google Scholar] [CrossRef]

- Onyeaka, H.N.; Nwabor, O.F. Chapter 8—Green technology in food processing and preservation. In Food Preservation and Safety of Natural Products; Onyeaka, H.N., Nwabor, O.F., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 87–118. [Google Scholar] [CrossRef]

- Huang, L.; Zhang, M.; Mujumdar, A.S.; Lim, R. Comparison of four drying methods for re-structured mixed potato with apple chips. J. Food Eng. 2011, 103, 279–284. [Google Scholar] [CrossRef]

- Sturm, B.; Vega, A.N.; Hofacker, W.C. Influence of process control strategies on drying kinetics, colour and shrinkage of air dried apples. App. Therm. Eng. 2014, 62, 455–460. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Ah-Hen, K.; Chacana, M.; Vergara, J.; Martínez-Monzó, J.; García-Segovia, P.; Lemus-Mondaca, R.; Di Scala, K. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 2012, 132, 51–59. [Google Scholar] [CrossRef]

- Martynenko, A.; Janaszek, M. Texture Changes During Drying of Apple Slices. Dry Technol. 2014, 32, 567–577. [Google Scholar] [CrossRef]

- Mayor, L.; Sereno, A.M. Modelling shrinkage during convective drying of food materials: A review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Pedreschi, F.; León, J.; Mery, D.; Moyano, P. Development of a computer vision system to measure the color of potato chips. Food Res. Int. 2006, 39, 1092–1098. [Google Scholar] [CrossRef]

- Caleb, O.J.; Mahajan, P.V.; Al-Said, F.A.; Opara, U.L. Modified Atmosphere Packaging Technology of Fresh and Fresh-cut Produce and the Microbial Consequences-A Review. Food Bioprocess Technol. 2013, 6, 303–329. [Google Scholar] [CrossRef]

- Volpe, S.; Cavella, S.; Torrieri, E. Biopolymer Coatings as Alternative to Modified Atmosphere Packaging for Shelf Life Extension of Minimally Processed Apples. Coatings 2019, 9, 569. [Google Scholar] [CrossRef]

- Perez-Gago, M.B.; Serra, M.; del Río, M.A. Color change of fresh-cut apples coated with whey protein concentrate-based edible coatings. Postharvest Biol. Technol. 2006, 39, 84–92. [Google Scholar] [CrossRef]

- Kutyła-Olesiuk, A.; Nowacka, M.; Wesoły, M.; Ciosek, P. Evaluation of organoleptic and texture properties of dried apples by hybrid electronic tongue. Sens. Actuators B Chem. 2013, 187, 234–240. [Google Scholar] [CrossRef]

- Kumar, P.; Sethi, S. Influence of Modified Atmospheres on Shelf Life and Quality of Fresh-Cut Apples. J. Package Technol. Res. 2021, 5, 209–216. [Google Scholar] [CrossRef]

- Fang, Y.; Wakisaka, M.A. Review on the Modified Atmosphere Preservation of Fruits and Vegetables with Cutting-Edge Technologies. Agriculture 2021, 11, 992. [Google Scholar] [CrossRef]

- Cortellino, G.; Gobbi, S.; Bianchi, G.; Rizzolo, A. Modified atmosphere packaging for shelf life extension of fresh-cut apples. Trends Food Sci. Technol. 2015, 46, 320–330. [Google Scholar] [CrossRef]

- Fonseca, S.C.; Oliveira, F.A.R.; Brecht, J.K. Modelling respiration rate of fresh fruits and vegetables for modified atmosphere packages: A review. J. Food Eng. 2002, 52, 99–119. [Google Scholar] [CrossRef]

- Chung, H.; Moon, K. Browning characteristics of fresh-cut “Tsugaru” apples as affected by pre-slicing storage atmospheres. Food Chem. 2009, 114, 1433–1437. [Google Scholar] [CrossRef]

- Oliveira, M.; Abadias, M.; Usall, J.; Torres, R.; Teixidó, N.; Viñas, I. Application of modified atmosphere packaging as a safety approach to fresh-cut fruits and vegetables—A review. Trends Food Sci. Technol. 2015, 46, 13–26. [Google Scholar] [CrossRef]

- Mangaraj, S.; Goswami, T.K. Modified Atmosphere Packaging of Fruits and Vegetables for Extending Shelf-Life: A Review. Fresh Prod. 2009, 3, 1–31. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. [14] Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzym. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple pomace as a source of dietary fiber and polyphenols and its effect on the rheological characteristics and cake making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Odriozola-Serrano, I.; Hernandez-Jover, T.; Martin-Belloso, O. Comparative evaluation of UV-HPLC methods and reducing agents to determine vitamin C in fruits. Food Chem. 2007, 105, 1151–1158. [Google Scholar] [CrossRef]

- Velickova, E.; Winkelhausen, E.; Kuzmanova, S. Physical and sensory properties of ready to eat apple chips produced by osmo-convective drying. J. Food Sci. Technol. 2014, 51, 3691–3701. [Google Scholar] [CrossRef]

- PN-EN ISO 11136:2017-08; Analiza Sensoryczna. Metodyka. Ogólne Wytyczne Przeprowadzania Testów Hedonicznych z Konsumentami na Obszarze Kontrolowanym. Polish Committee for Standardization: Warszawa, Poland, 2017. (In Polish)

- PN-EN ISO 5492:2009; Analiza Sensoryczna. Terminologia. Polish Committee for Standardization: Warszawa, Poland, 2009. (In Polish)

- Doymaz, İ. Effect of citric acid and blanching pre-treatments on drying and rehydration of Amasya red apples. Food Bioprod. Process 2010, 88, 124–132. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; Porciuncula, B.D.A.; Laurindo, J.B. A convective multi-flash drying process for producing dehydrated crispy fruits. J. Food Eng. 2012, 108, 523–531. [Google Scholar] [CrossRef]

- Mabrouk, S.B.; Benali, E.; Oueslatia, H. Experimental study and numerical modelling of drying characteristics of apple slices. Food Bioprod. Process 2012, 90, 719–728. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Jakubczyk, E. Effect of hot air temperature on mechanical properties of dried apples. J. Food Eng. 2004, 64, 307–314. [Google Scholar] [CrossRef]

- Hatamipour, M.S.; Kazemi, H.H.; Nooralivand, A.; Nozarpoor, A. Drying characteristics of six varieties of sweet potatoes in different dryers. Food Bioprod. Process 2007, 85, 171–177. [Google Scholar] [CrossRef]

- Udomkun, P.; Nagle, M.; Argyropoulos, D.; Mahayothee, B.; Latif, S.; Müller, J. Compositional and functional dynamics of dried papaya as affected by storage time and packaging material. Food Chem. 2016, 196, 712–719. [Google Scholar] [CrossRef]

- Rocculi, P.; Romani, S.; Dalla Rosa, M. Evaluation of physicochemical parameters of minimally processed apples packed in non-conventional modified atmosphere. Food Res. Int. 2004, 37, 329–335. [Google Scholar] [CrossRef]

- Cocci, E.; Rocculi, P.; Romani, S.; Rosa, M.D. Changes in nutritional properties of minimally processed apples during storage. Postharvest Biol. Technol. 2006, 36, 265–271. [Google Scholar] [CrossRef]

- Farris, S.; Gobbi, S.; Torreggiani, D.; Piergiovanni, L. Assessment of two different rapid compression tests for the evaluation of texture differences in osmo-air-dried apple rings. J. Food Eng. 2008, 88, 484–491. [Google Scholar] [CrossRef]

- Rizzolo, A.; Vanolia, M.; Cortellino, G.; Spinelli, L.; Torricelli, A. Quality characteristics of air-dried apple rings: Influence of storage time and fruit maturity measured by time-resolved reflectance spectroscopy. Procedia Food Sci. 2011, 1, 216–223. [Google Scholar] [CrossRef][Green Version]

- Ward, G. Modified Atmosphere Packaging for Extending Storage Life of Fresh Fruits and Vegetables. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Moreno, J.; Simpson, R.; Pizarro, N.; Pavez, C.; Dorvil, F.; Petzold, G.; Bugueño, G. Influence of ohmic heating/osmotic dehydration treatments on polyphenoloxidase inactivation, physical properties and microbial stability of apples (cv. Granny Smith). Innov. Food Sci. Emerg. Technol. 2013, 20, 198–207. [Google Scholar] [CrossRef]

- Wang, S.Y. Fruits with high antioxidant activity as functional foods. In Functional Food Ingredients and Nutraceuticals: Processing Technologies; Shi, J., Ed.; Taylor & Francis Group: Boca Raton, FL, USA, 2007; pp. 371–413. [Google Scholar] [CrossRef]

- Lavelli, V.; Vantaggi, C. Rate of antioxidant degradation and color variations in dehydrated apples as related to water activity. J. Agric. Food Chem. 2009, 10, 4733–4738. [Google Scholar] [CrossRef] [PubMed]

- Bennett, L.E.; Jegasothy, H.; Konczak, I.; Frank, D.; Sudhamarajan, S.; Clingeleffer, P.R. Total phenolics and anti0oxidant properties of selected dried fruits and relationships to drying conditions. J. Funct. Foods 2011, 3, 115–124. [Google Scholar] [CrossRef]

- Leeratanarak, N.; Devahastin, S.; Chiewchan, N. Drying kinetics and quality of potato chips undergoing different drying technics. J. Food Eng. 2006, 77, 635–643. [Google Scholar] [CrossRef]

- Chang, S.K.; Alasalvar, C.; Shahidi, F. Review of dried fruits: Phytochemicals, antioxidant efficacies, and health benefits. J. Funct. Foods 2016, 21, 113–132. [Google Scholar] [CrossRef]

| Mean ± SD | |

|---|---|

| Dry Basis (%) | 16.03 ± 1.72 |

| Reflective index (°Brix) | 14.23 ± 1.16 |

| Acidity (mEq NaOH/100 g) | 10.54 ± 0.93 |

| Vitamin C content (mg/100 g dry basis) | 64.26 ± 1.45 |

| Total phenols content in water extract (mg/g dry basis) | 71.12 ± 2.02 |

| O2 (%) | CO2 (%) | Storage Period (d) | ML (%) | Hardness (N) | L* (%) | BI | ΔE | TPC (mg/g Dry Basis) | Vitamin C Content (mg/100 g Dry Basis) | Overall Quality | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.663 | 3.785 | 15 | C * | 2.08 | 5.18 | 75.49 | 40.46 | 5.18 | 41.22 | 53.78 | 7.64 a |

| M ** | 2.02 | 5.12 | 75.88 | 40.90 | 5.24 | 41.67 | 53.67 | 8.26 b | |||

| 30 | C | 3.59 | 6.32 | 74.68 | 42.88 | 4.46 | 41.02 | 53.42 | 5.86 a | ||

| M | 3.68 | 6.47 | 75.02 | 43.16 | 4.58 | 41.55 | 53.25 | 6.25 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wyrwisz, J.; Moczkowska-Wyrwisz, M.; Kurek, M.A. Development of Modified Gas Composition for Atmosphere Packaging of Sliced Apple Chips. Appl. Sci. 2025, 15, 2832. https://doi.org/10.3390/app15052832

Wyrwisz J, Moczkowska-Wyrwisz M, Kurek MA. Development of Modified Gas Composition for Atmosphere Packaging of Sliced Apple Chips. Applied Sciences. 2025; 15(5):2832. https://doi.org/10.3390/app15052832

Chicago/Turabian StyleWyrwisz, Jarosław, Małgorzata Moczkowska-Wyrwisz, and Marcin A. Kurek. 2025. "Development of Modified Gas Composition for Atmosphere Packaging of Sliced Apple Chips" Applied Sciences 15, no. 5: 2832. https://doi.org/10.3390/app15052832

APA StyleWyrwisz, J., Moczkowska-Wyrwisz, M., & Kurek, M. A. (2025). Development of Modified Gas Composition for Atmosphere Packaging of Sliced Apple Chips. Applied Sciences, 15(5), 2832. https://doi.org/10.3390/app15052832