Featured Application

MUSM-VR enables immersive safety testing and operator training for forklift systems during warehouse design and process optimization stages.

Abstract

This article presents a novel methodology for evaluating the safety of forklift operations in intralogistics systems using a multi-user simulation model integrated with virtual reality (MUSM-VR). Set against the backdrop of persistent safety challenges in warehouse environments, particularly for inexperienced operators, the study addresses the need for proactive safety assessment tools. The authors develop a simulation framework within the FlexSim 24.2 environment, enhanced by proprietary VR and server integration libraries, enabling interactive, immersive testing of warehouse layouts and operational scenarios. Through literature review and analysis of risk factors, the methodology incorporates human, infrastructural, organizational, and technical dimensions of forklift safety. A case study involving inexperienced participants demonstrates the model’s capability to identify high-risk areas, assess operator behavior, and evaluate the impact of visibility and speed parameters on collision risk. Results highlight the effectiveness of MUSM-VR in pinpointing hazardous intersections and inform design recommendations such as optimal speed limits and layout modifications. The study concludes that MUSM-VR not only facilitates early-stage safety analysis but also supports ergonomic design, operator training, and iterative testing of preventive measures, aligning with Industry 4.0 and 5.0 paradigms. The integration of immersive simulation into design and safety workflows marks a significant advancement in intralogistics system development.

1. Introduction

The safety and efficiency of intralogistics systems have become inseparable concepts that must be studied and designed simultaneously to ensure continuous improvement in meeting user needs and expectations. Despite ongoing efforts to reduce accidents in systems where forklifts are used as a base equipment, such as warehouses and intralogistics facilities, incidents involving forklifts remain a serious threat and are responsible for numerous accidents (see [1,2,3,4]).

Forklifts, as essential components of warehouse infrastructure, enable handling and transportation of logistic units, and operate dynamically in confined spaces. This exposes operators and bystanders to the risk of injury and accidents, while also putting infrastructure and physical assets at risk of damage or destruction. The consequences of adverse events involving forklifts can be significant: socially (e.g., deterioration of working conditions, psychological stress), financially (e.g., material losses, production downtime, insurance and compensation costs), and operationally, as they may negatively affect the reliability of supply chains.

Analysis of forklift incidents indicates that new employees with limited experience are particularly vulnerable to accidents, especially when employed in small enterprises (up to 49 employees) where safety standards are often less stringent (see [3,4,5]). Research emphasizes that the most common causes of such incidents include improper forklift operation, insufficient hazard awareness, non-compliance with safety regulations, and inadequate workspace design (see [1,6]). According to data from the Central Statistical Office (GUS) (see [7]), workplace accidents involving forklifts in Poland represent a significant share of all incidents occurring in warehouses and logistics centers. This underscores the urgent need to develop effective methods for preventing these accidents and minimizing their consequences.

Factors influencing forklift safety can be categorized into operator-related factors (e.g., training, skills, fatigue), infrastructure-related factors (e.g., spatial layout, visibility, intersections of internal transport routes), organizational factors (e.g., speed limits, traffic regulations, workload), and technical factors, including both active and passive safety measures. Overall, safety results from the interaction of these factors under the specific workload conditions faced by forklift operators. Building safe warehouse systems therefore requires a comprehensive approach that integrates these considerations at every stage from design and concept testing to implementation and operational use.

These factors, particularly those related to the operator, can be effectively analyzed using immersive tools such as virtual reality (VR), which replicates real-world systems, as well as specialized stationary simulators. The application of modern simulation tools and VR in the design and safety assessment of intralogistics systems is becoming increasingly common due to the numerous advantages they offer. The ability to model various scenarios and evaluate safety during the design phase allows for the early identification of potential hazards, reducing the costs of later modifications and improving the overall efficiency of design processes (see [8,9,10]). When integrated into a flexible simulation environment that also functions as a design platform, VR enables rapid safety assessments at every stage of system development and operation.

Despite growing awareness of the benefits, comprehensive research on the use of VR for accident prevention and forklift operator training remains limited. Existing studies have primarily concentrated on specific aspects of VR technology, such as simulation or simple, single-scenario training applications, which do not fully capture the complexity of real-world intralogistics processes.

Because VR operates within a computer-generated simulation environment, the following section of this article addresses the development of flexible models specifically designed for testing forklift safety. These models can be constructed within an active, reconfigurable, and multifunctional simulation environment equipped with an advanced graphical interface, such as FlexSim, which aligns with the simulation paradigms of Industry 4.0 and 5.0. Such solutions enable comprehensive visualization and real-time analysis of logistics processes, facilitating faster hazard identification and reducing the risk of accidents [11].

The aim of this article is to present a proprietary methodology for evaluating safety in internal transport systems involving forklifts and to assess the potential benefits of using VR technology in forklift operator training. The selection of VR as a research tool is based on its distinctive capabilities: it allows the creation of immersive and safe training environments where critical operational scenarios can be simulated without endangering employees or generating additional costs. Furthermore, it supports the preliminary testing of architectural concepts from the perspective of forklift operator working conditions.

This article introduces a methodology for employing a multi-user simulation model integrated with a virtual reality layer (MUSM-VR), developed using proprietary libraries for the FlexSim simulation environment, to design and analyze the safety of intralogistics systems utilizing forklifts. The focus is placed on evaluating the influence of warehouse space configuration and work organization on occupational safety. The proposed approach demonstrates that, by leveraging widely available technical resources, it is possible to accelerate the design process while simultaneously enhancing the safety of future forklift operators.

The article explores the role of MUSM-VR in the design and evaluation of forklift systems and presents an algorithm for testing such systems using this method. To achieve this, it reviews the current state of research in the field, identifies critical factors affecting forklift operation, and discusses key aspects of simulation model construction and validation.

The remainder of the paper is structured as follows: Section 2 provides a literature review on VR applications for analyzing forklift safety; Section 3 outlines the factors that determine forklift safety; Section 4 introduces the proposed safety assessment methodology based on MUSM-VR; Section 5 presents experimental results; and finally, the paper concludes with a summary and discussion of the potential applications of MUSM-VR in the study of forklift-based internal transport systems in Section 6.

2. Application of Virtual Reality in Intralogistics Safety Research and Employee Training: A Literature Review

2.1. Using VR to Assess Forklift System Safety

Virtual reality (VR) is a promising tool for industry and logistics, particularly for early safety assessment and operational employee training [12,13]. In intralogistics, VR can be utilized to:

- test system configurations to ensure the passive safety of employees, equipment, and products [6,14,15];

- investigate new technological solutions aimed at enhancing safety [10,16,17,18,19,20];

- collect statistically significant data samples for studying the impact of technical solutions on safety and work comfort [21,22,23];

- train forklift operators and other personnel involved in material flow processes [24,25,26,27].

A practical example of VR use in the context of safety is the training system developed by Qiping, Tsoi, and Vázquez [28], which supports occupational risk assessment in industrial environments. The system allows users to explore a realistically recreated factory, identify hazards, and make decisions under time constraints and stress conditions. Research indicates that immersive VR environments facilitate better retention of procedures and the formation of safe work habits, ultimately contributing to improved occupational safety.

Yuen, Choi, and Yang [11] applied VR to the design of intralogistics systems, enabling the analysis of forklift maneuvering and operator behavior in controlled environments (CAVE). This approach facilitates training in responding to potential hazards. Similarly, research by Choi, Ahn, and Seo [29], which used VR to analyze forklift operation, demonstrates that increasing the difficulty of tasks such as loading and unloading pallets correlates with a higher risk of operator errors. The authors highlight the importance of complementing VR training with sensor systems and individualized training scenarios (cf. [19]).

Significant attention has also been directed toward analyzing human factors in VR-based forklift training. Experiments with novice operators revealed that as task complexity increased, so did cognitive load, as measured by both subjective scales (e.g., NASA-TLX) and objective physiological indicators (e.g., EEG). Notably, repeated training sessions did not consistently reduce stress levels, underscoring the need for adaptive, real-time support systems. Similar findings were reported by Zahabi et al. [24], who examined the cognitive load of forklift operators.

Research on operator ergonomics confirms that training conducted with advanced simulators replicating real-world conditions (e.g., steering wheels, pedals, physical levers) significantly improves maneuverability, vehicle control, and ergonomic posture. Participants trained in such environments made fewer errors, demonstrated greater confidence, and showed better spatial orientation. Importantly, these benefits persisted in follow-up tests conducted one week after training (Islam et al. [25]). However, the use of additional simulator hardware while enhancing sensory realism also increases workstation complexity, requiring careful consideration in system design.

VR is also extensively applied in occupational health and safety training. Wetzel et al. [12] developed a virtual environment aimed at preventing accidents caused by trips, slips, and missteps. Studies confirm that immersive VR scenarios improve employees’ understanding of workplace hazards and enhance motivation to follow safety procedures [30,31]. The authors emphasize the value of experiential learning in fostering long-term safety practices.

Although VR technology offers numerous advantages, it also presents significant technological and ergonomic limitations, particularly with respect to user adaptation. Some of these limitations are directly related to hardware properties, such as limited battery life, susceptibility to overheating, and the absence of automatic screen brightness adjustment. Others stem from the discomfort associated with prolonged use of VR equipment, including the relatively heavy headsets and controllers.

Even with advanced systems, users still face inherent constraints, such as the lack of realistic weight simulation when lifting objects and reduced precision in performing actions due to controller inaccuracies or data transmission delays. Image rendering delays can cause headaches, while displaying information in the upper part of the visual field can be visually fatiguing during extended sessions (Stolz et al. [13]; Bräuer and Mazarakis [32]; Reif et al. [33]).

Another significant issue is VR sickness, a condition characterized by dizziness, nausea, and disorientation caused by discrepancies between visual stimuli and the body’s sense of balance. Bräuer and Mazarakis [32] and Souchet et al. [34] identified several factors that increase the likelihood of VR sickness, including exposure duration, interface type, visual parameters (e.g., field of view), motion delays, and the nature of physical interactions. These findings suggest that while VR offers innovative opportunities for training and system design, it also introduces new ergonomic challenges that can translate into real-world strain on the body.

Reif et al. [33] note that among human-related barriers to VR adoption, privacy concerns and the required level of user competence are particularly significant. Some users may be apprehensive about the use of cameras and microphones in VR devices, fearing excessive data collection, including facial recognition, location tracking, or speech recording (Bhutta, Umm-e-Hani, Tariq [35]). Additionally, certain employees may face difficulties adapting to VR-based solutions, as effective implementation requires not only technical and digital competencies but also communication and teamwork skills (Oguz [36]).

Under specific circumstances, the cost of VR implementation can also be a major constraint, stemming from the price of VR devices (including high-performance graphics cards) and the required supporting infrastructure. Furthermore, the lack of physical obstacles and weight representation poses an additional challenge, as the absence of tactile resistance can result in unrealistic hand or body movements.

To address these challenges, the development of models such as MUSM-VR should integrate Virtual Human Factors (VHF) an interdisciplinary approach to studying human interactions with virtual systems, simulators, and digital models. VHF is commonly used to design work environments with distributed digital technologies (Escallada et al. [37]; Souchet et al. [38]; Tokatli [39]). It focuses on ensuring safety, comfort, and efficiency by accounting for users’ physical, cognitive, and emotional capabilities in digital environments.

As emphasized by Kobir et al. [40] and Kay et al. [41], applying VHF enables the evaluation of postures and biomechanical loads, analysis of decision-making processes and perception, interface usability testing, and the design of workstations in line with human-centered design principles. Key aspects include physical ergonomics, cognitive ergonomics, immersion, user safety and comfort, and adaptive design tailored to diverse user groups.

The publications discussed above demonstrate growing research interest in applying VR to the study of intralogistics systems, including forklift operation. The literature highlights several practical benefits of this approach, such as improving employee preparedness for real-world tasks, supporting workspace design, and enabling more precise analysis of human interactions with environmental elements. Despite these advantages, there are still few attempts to implement universal simulation environments for intralogistics system design. Solutions such as MUSM-VR, which can integrate a VR layer at the warehouse design stage and evaluate concepts from the user’s perspective, remain relatively rare.

The effectiveness of VR-based research depends largely on the quality of the simulated environment, the level of immersion, interface ergonomics, intuitive system operation, and the ability to adapt cognitive workloads to individual user characteristics. Findings from existing studies can serve as a foundation for developing personalized training programs and advanced decision support systems. Although challenges such as high implementation costs and the lack of standardized methodologies persist, VR is increasingly recognized as a crucial element in the digital transformation aimed at enhancing both the safety and efficiency of intralogistics systems.

2.2. Standard Methods for Testing Occupational Safety in Forklift Systems

This article focuses on proposing a methodological approach to assessing forklift system safety using MUSM-VR models. To establish the value of this approach, it is essential to compare traditional methods with VR-based solutions and position MUSM-VR within this context.

Conventional risk assessment methods for forklift operator safety rely primarily on quantitative and qualitative indicators. The most commonly applied techniques include accident and near-miss analyses (as cited by Fernández-Muñiz et al. [42]), reviews of occupational health and safety documentation, equipment condition audits, and evaluations of workstation ergonomics (see [27,43,44]). Standard indicators, such as the number of accidents, the incident frequency rate (IFR), the incident severity rate (ISR), and the number of sick leave days, are widely used to monitor overall workplace safety levels.

These methods are often complemented by behavioral observations, the use of checklists, and structured procedures for evaluating operator behavior in daily work conditions (Ryder [26]). To assess physical and mental strain, specialized questionnaires are employed, including the Cornell Musculoskeletal Discomfort Questionnaire (CMDQ) and subjective fatigue assessment scales such as NASA-TLX (e.g., [44]). Regular verification of operator skills, systematic analysis of hazardous events, and continuous training are also highlighted as critical components of safety management (Halusiak [15]; see also [27,43,44]).

In addition, standard risk assessment methodologies such as general risk analysis, the Risk Score method, and Failure Modes and Effects Analysis (FMEA) are used. These approaches typically rely on straightforward formulas that account for probability, potential effects, and exposure (Szaciłło [45]).

New methods are increasingly being integrated into traditional safety assessment approaches. One example is the use of brain activity monitoring (EEG), which enables the objective evaluation of employee engagement and concentration levels during real-world work conditions (Li et al. [46]; Nader et al. [47]). This technique allows for the detection of attention lapses and the development of early warning systems to prevent potentially hazardous situations. EEG-based assessment also holds potential for integration with MUSM-VR models.

Integrated monitoring systems that combine operator behavior analysis, physical workload measurement, and environmental condition tracking are gaining importance, providing more accurate tools for risk prediction (Jimenez et al. [21]). A practical example of this approach is the use of data from mobile devices to generate dynamic spaghetti charts. By analyzing the movement trajectories of forklifts and pedestrians within a warehouse, it becomes possible to identify high-risk collision zones (“hot zones”) and record near misses before actual incidents occur (Cantini et al. [20]). Notably, the MUSM-VR model can produce comparable results.

Another innovative technique is the dynamic warehouse risk assessment method based on the Decision-Making Trial and Evaluation Laboratory (DEMATEL), which allows for a more nuanced analysis of risk factors and their interdependencies (Esmaeili et al. [22]).

Forklift safety in warehouse facilities is influenced by a range of additional factors that must often be addressed at the design stage. Robotic systems, for example, incorporate autonomous technologies and sensing platforms that enhance operational safety and efficiency. At the same time, however, autonomous and automated devices may interact undesirably with employees if safe distances are not maintained or if passive protection systems fail (see Foumani et al. [48]). Other risks are associated with crisis situations, such as fires, and with the functioning of active protection systems, including sprinklers or fire curtains (see Ho et al. [49]). The occurrence of such hazards can be incorporated into VR simulation models both as random events and as structured scenarios for testing responses to emergency situations.

One limitation of several methods discussed above is that they primarily provide retrospective data based on past events, which does not always allow for effective hazard prediction in dynamic work environments (Halusiak [15]). In addition, approaches that rely heavily on quantitative indicators often overlook the influence of organizational and behavioral factors and fail to account for the variability of risk over time. Another challenge is that these methods typically depend on specific technical systems or require direct observations within the actual operating environment, which may introduce practical constraints.

Despite these limitations, the effectiveness and usefulness of these methods are well established. However, there is a clear need for complementary approaches that enable safety evaluation during the design and implementation stages of intralogistics systems while also supporting subsequent employee training. The methodology proposed in this article seeks to address this gap by providing a framework for proactive safety assessment and operator preparation using MUSM-VR.

Traditional risk assessment methods, particularly in the context of internal transport, provide a means of estimating the probability of undesirable events with forklift trucks. Their character, however, is predominantly indicative rather than evaluative, as they facilitate the assessment of risk within a defined technological system and the identification of areas of heightened vulnerability. The method proposed in this study is not positioned as a competitor to traditional approaches, but rather as a complementary tool. It enables the rapid examination of warehouse technological systems at the design stage and supports the evaluation of alternative concepts under varying operational conditions. Distinct advantages of the approach include its capacity for rapid reconfiguration, its ability to incorporate random and unpredictable phenomena within the simulation model, and its integration of interpersonal interaction.

The analysis of events in operational facilities requires either empirical data derived from existing sites or generalized knowledge based on the aggregation of numerous incidents across different facilities, which subsequently evolves into codified best practices. The simulation model of the forklift operating environment is developed with these best practices as a foundational element. Furthermore, by drawing upon insights from events observed in operational settings, the MUSM-VR framework facilitates the exploration of preventive strategies through systematic change analysis.

2.3. Research Implications

Despite its rapid development, the application of VR still shows clear limitations. These are particularly evident in the integration with real-world sensor systems, the full personalization of training based on physiological data, and the broader use of VR in analyzing organizational factors. The literature also lacks a coherent methodological framework and standardized criteria for evaluating the effectiveness of immersive environments in terms of both safety and operational efficiency.

While numerous studies confirm the positive effects of VR on situational awareness, stress reduction, decision accuracy, and postural ergonomics, relatively few have compared VR with alternative technologies such as augmented reality (AR), digital twins, or biomechanical monitoring systems. Conducting such comparative research could provide more definitive conclusions regarding the overall effectiveness and cost-efficiency of VR implementation across industrial sectors.

Although VR offers extensive possibilities for simulation, training, and process optimization, its adoption must account for both technological constraints and human factors. This calls for continued hardware development, including lighter and more ergonomic headsets and controllers as well as improved energy efficiency. At the same time, implementation procedures must address user privacy concerns and competency requirements to ensure safe and effective use.

Computer simulation in general, and virtual environments in particular, aligns closely with the principles of Industry 4.0 and 5.0. Such simulations are increasingly used for safety analyses and the design of warehouse and logistics processes. They enable the replication of complex event scenarios, the study of operator behavior under controlled conditions, and the evaluation of how organizational changes affect risk levels. Moreover, simulations make it possible to verify the effectiveness of preventive measures and to optimize spatial layouts and logistics workflows in warehouse environments (see Jurczyk and Cempel [50]).

3. Operational Safety of Forklift Systems—Factors Threatening Safety and the Possibility of Taking Them into Account in MUSM-VR

In intralogistics systems, forklifts operated by human operators, both pedestrians and drivers, create hazards primarily due to the dynamic movement of a heavy vehicle carrying loads within confined spaces where visibility is often limited and people are present. The factors influencing forklift safety, along with their specific manifestations, are summarized in Table 1. These factors also illustrate the potential for their integration into the MUSM-VR framework.

Table 1.

Factors influencing forklift safety in MUSM-VR.

Overall, the safety of intralogistics systems using forklift trucks results from the interaction of the factors listed above under specific workload conditions. The research methodology developed in this study, based on the use of MUSM-VR, incorporates these factors by introducing adjustable parameters into both the simulation model and the VR environment, as well as into the model construction process itself.

According to recent data on warehouse sector accidents (GUS [7]), the most common injuries sustained by employees working with forklifts include lower limb fractures, spinal injuries, and finger amputations. A significant proportion of these incidents are associated with improper forklift operation, insufficient operator training, and non-compliance with safety procedures [51]. On average, approximately 100 forklift-related accidents occur annually in the Polish warehouse sector, with up to 15 resulting in fatalities [15,52]. The operator fatality rate in such incidents ranges between 0.012 and 0.017 per accident, while the injury rate remains in the range of 0.37 to 0.41, indicating that nearly half of all incidents lead to serious injuries. Forklifts have long been identified as one of the leading causes of severe and fatal accidents in industry, logistics, and internal transport.

This situation is exacerbated not only by insufficient operator awareness but also by inadequate occupational safety management practices in many facilities. The most common causes of forklift accidents include:

- pedestrians being struck or crushed by a forklift [1,2,3,4,5,53];

- forklift collisions with other objects [2,51];

- crushing injuries caused by falling objects during loading and unloading [3];

- operators being crushed as a result of forklift tipping [4,5,6,52];

- forklifts falling off ramps or trucks [4];

- operators falling from forklifts [1,5];

- rear-end collisions involving forklifts [15,52].

Accidents involving pedestrians, collisions, falls from ramps, and rear-end impacts are strongly related to visibility, vehicle speed, and forklift trajectory. These variables can be effectively modeled and analyzed using MUSM-VR tools, making them a key focus of the proposed methodology.

It is important to note that forklift operating speed is one of the key determinants of internal transport efficiency, while reducing the width of working aisles remains one of the most critical strategies for improving warehouse space utilization (see [54,55]). Both factors, however, have a negative impact on operational safety and therefore must be carefully considered during the design and analysis of intralogistics systems.

To mitigate accident risks, a range of preventive measures is applied. Many of these can be directly implemented and tested within the MUSM-VR environment, including:

- forklift driving training (see [1,3,4,5,55]);

- training on the principles of safe operation and working in proximity to forklifts [1];

- awareness campaigns to increase employee understanding of hazards [2,3,4];

- improving operator visibility through reflective clothing [1];

- the use of forklift speed limiters [2];

- installation of proximity warning systems [2];

- designing safe workplaces, including routes and spatial layouts [4,5,55].

Other preventive measures can be indirectly incorporated into MUSM-VR, such as:

- establishing pedestrian-exclusion zones and safety barriers [2,3,5];

- using systems that reduce the risk of loads tipping during handling and transport [3];

- equipping forklifts with active safety systems [55];

- integrating passive safety systems into forklift design [6].

MUSM-VR also allows for evaluating the effectiveness of additional safety components commonly used in intralogistics environments (CIOP-PIB [56]), including spherical mirrors, floor markings, vertical warning signs, proximity sensors, audible and visual alarms, as well as pedestrian and vehicle detection systems installed on forklifts or within the surrounding infrastructure.

By enabling the adjustment and combination of these variables, MUSM-VR supports the creation of simulation models that not only identify key hazards but also test the effectiveness of individual preventive measures. This capability provides valuable support in the design of safe workspaces and the organization of forklift operations.

4. Safety Assessment Methodology Using MUSM-VR

4.1. Multi-User Simulation Model Integrated with a Virtual Reality Layer (MUSM-VR)

To create a universal tool for assessing the operational safety of forklift systems, a multi-user simulation model integrated with a virtual reality layer (MUSM-VR) was developed. The model was built on the FlexSim software platform, which is widely used for the design and analysis of intralogistics and production processes (Beaverstock, Greenwood, and Nordgren [57]; AutoDesk [58]).

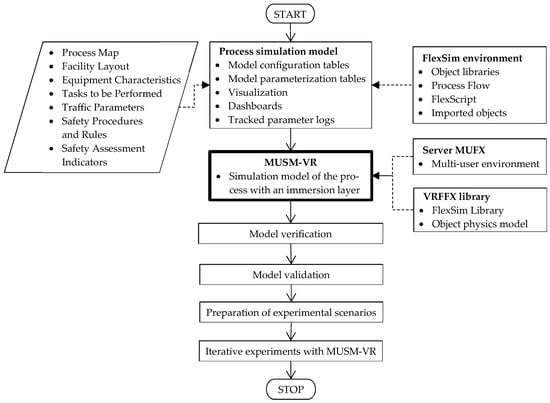

MUSM-VR represents a proprietary combination of the standard FlexSim environment with several dedicated components: physics mapping libraries (VRFFX), libraries for integrating VR with standard simulation models, and a multi-user server (MUFX) that enables simultaneous interaction by multiple participants within the same simulation environment (Figure 1).

Figure 1.

Schematic diagram of the structure and MUSM-VR.

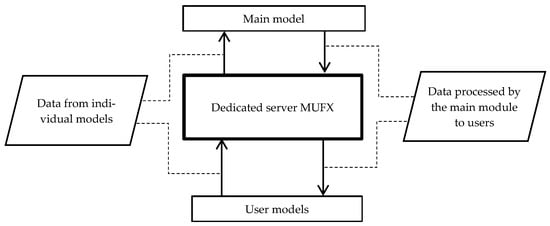

The MUFX multi-user server operates through the exchange of information between a master model and individual local user models. This communication is facilitated by a controlled data flow managed via a dedicated application. Data exchange between models is implemented using a socket-based mechanism built on Python’s 3.10 standard socket library, with the threading library providing support for handling multiple simultaneous connections.

Within this architecture, the master model collects and processes data transmitted by client models and subsequently distributes updated information to all connected user models. This ensures real-time synchronization of system states across the entire MUSM-VR environment (Figure 2).

Figure 2.

Schematic of the MUFX Multi-User Server.

The uniqueness of MUSM-VR lies in its versatility, derived from the FlexSim environment, combined with the integration of VR experiences into both the design and analysis processes. This approach enables work with a simulation model of the system, including digital twins or shadows, at an engineering level while simultaneously conducting analyses that require the participation of external users in virtual reality, such as forklift safety assessments.

Owing to its library-based architecture, MUSM-VR serves as a universal platform for studying interactions between real users within the VR layer and the simulation environment. Its application to forklift systems is particularly well aligned with the FlexSim environment’s established role in modeling intralogistics and production systems.

Thanks to the functional flexibility of FlexSim, MUSM-VR allows for relatively easy modification of scenarios and input parameters, enabling dynamic adaptation of the model to different conditions and research objectives. Integration with the VR layer provides interactive engagement with the virtual intralogistics system, enhancing immersion and realism during both training and testing. The connection to the MUFX server further extends these capabilities by facilitating multi-user interaction within the simulated environment.

4.2. Methodological Aspects of Safety Assessment Using MUSM-VR

The literature review presented in Section 2 and the analysis of factors influencing occupational safety discussed in Section 3 formed the basis for developing a methodological framework for applying MUSM-VR to the design and assessment of forklift system safety in warehouse and industrial environments.

The proposed methodology employs a proprietary MUSM-VR research tool built on simulation models that replicates the operations and logic of the systems under study, combined with VR technology and a multi-user simulation server. MUSM-VR supports multi-scenario analyses, including:

- simulation of real-world logistics operations and examination of operator and machine behavior in dynamic warehouse conditions;

- modeling of various forklift types, including their control panels and visibility limitations;

- simulation of diverse warehouse technological systems and working conditions;

- identification and analysis of critical hazards associated with forklift operation, such as collisions, inadequate route planning, and failure to account for “safety hazards” such as warehouse blind spots;

- consideration of human factors, including operator behavior under varying levels of training, fatigue, and stress, as well as interactions between multiple users;

- evaluation of the effects of planned changes to warehouse layouts or traffic procedures before their implementation in real environments.

Among all the identified hazards, the most significant for the effectiveness of the methodology are those related to warehouse layout design, detection of collision blind spots, and the assessment of operator behavior under realistic working conditions. These areas demonstrate the greatest added value of VR, as they allow the direct analysis of the risk factors summarized in Table 1.

A procedural algorithm for identifying and assessing hazards has been developed using MUSM-VR implemented within the FlexSim environment. An integral component of MUSM-VR is the proprietary MUFX server, which enables the integration of multiple users into a single simulation model. This capability facilitates interactions between simulation participants, including forklift operators and other warehouse personnel, creating a realistic representation of human interactions and allowing the analysis of group behavior impacts on intralogistics safety levels.

The proposed methodology is constructed as a four-stage algorithm:

- Identification of the technological system and threats:

- A.1.

- Identification of tasks performed with forklifts in existing or planned systems.

- A.2.

- Identification of factors that pose risks to forklift operations within the specific system configuration.

- A.3.

- Determination of the impact of human factors on forklift safety in the given system.

- A.4.

- Selection of appropriate safety assessment indicators.

- Construction and validation of the MUSM-VR simulation model:

- B.1.

- Development of a simulation model representing the technological system under study.

- B.2.

- Integration of the simulation model with the VR layer using proprietary FlexSim libraries.

- B.3.

- Integration of a multi-user server into the VR model using proprietary FlexSim libraries.

- B.4.

- Verification and validation of the model with respect to the defined safety assessment metrics.

- B.5.

- On-the-job user training to ensure realistic interaction with the simulation environment.

- Threat scenario analysis (Steps C.3–C.8 are performed iteratively):

- C.1.

- Analysis of technical concepts and projected changes.

- C.2.

- Selection of MUSM-VR users, including VR sickness risk assessment, VR training, and user surveys.

- C.3.

- Development of simulation scenarios based on technical concepts.

- C.4.

- Analysis of the human factor’s impact on technical concept parameters.

- C.5.

- Design of the MUSM-VR experiment.

- C.6.

- Execution of MUSM-VR experiments.

- C.7.

- Analysis of results from the perspective of the technical concept.

- C.8.

- Modification of the technical concept.

- C.9.

- Completion of the analysis or return to step C.2.

- Implementation and evaluation of results:

- D.1.

- Implementation of validated technical solutions in the real system.

- D.2.

- Evaluation of implementation results based on selected safety indicators.

- D.3.

- Modification and maintenance of the MUSM-VR model for future use.

The first step in the methodology is defining the assumptions for the intralogistics system under analysis. This includes reviewing existing solutions or establishing initial assumptions for new systems, as well as identifying key processes and functional requirements. At this stage, potential safety risk factors are determined, which may involve analyzing historical accident data, reviewing occupational health and safety documentation, and consulting experts and operators. Defining the human factor is equally important, requiring assessment of employee roles, levels of training and experience, and common operational errors. A thorough understanding of human behavior is essential for building a simulation model that accurately reflects the dynamics of warehouse operations.

The next step is to create a simulation model using the FlexSim environment (Figure 1). This model maps key elements of the intralogistics system, such as the warehouse layout, material flows, and forklift movement rules. Integration with the VR layer then takes place, allowing users to be transported to a virtual warehouse and data collected on their behavior in various situations. After building and integrating the model, verification and validation are necessary, as well as initial on-the-job training in the VR environment. This allows us to verify whether the virtual simulation adequately reflects reality and whether the tool is intuitive for users. After completing the model, simulation scenarios representing various technical concepts are developed. These may include changes to the rack layout, varying forklift movement parameters, or implementing innovative solutions (e.g., an RTLS system). Each scenario describes a hypothetical modification to the system and addresses the question of its impact on safety and efficiency. Considering the human factor is crucial. In practice, this means conducting VR experiments with forklift operators performing tasks in near-real-world conditions (e.g., with limited visibility or in crowded spaces). Thanks to a built-in server, users can also interact with each other. Data collected during the experiments allows for the identification of critical areas where the greatest risks occur.

Risk assessment within a given scenario can be enhanced through the use of a set of safety indicators, including:

- accident frequency rate over a specified time period;

- number of near misses;

- ergonomic assessment of workstations;

- frequency and effectiveness of occupational health and safety training;

- level of employee awareness regarding hazards;

- presence and visibility of safety signs and signals;

- degree of compliance with standard operating procedures;

- level of implementation and utilization of safety-enhancing technologies (e.g., operator assistance systems).

Combining these indicators enables a more precise comparison of safety levels across different design variants.

Following simulation and result analysis, if the outcomes of a particular concept do not meet expectations, the process can return to earlier stages, such as redefining scenarios and conducting additional iterations. This iterative approach allows for the progressive refinement of technical and organizational solutions to achieve optimal safety and efficiency. When VR experiment results are satisfactory, the validated improvements can be implemented in the actual warehouse or intralogistics facility. These may include modifications to the warehouse layout, the introduction of new safety procedures, or the deployment of additional operator assistance systems.

In the post-implementation phase, the impact of these actions should be systematically monitored using key safety indicators, such as accident frequency and incident rates, along with overall process efficiency metrics. Any emerging problems or unforeseen risks can be re-evaluated using the MUSM-VR model, which, with regular updates, becomes a permanent component of the enterprise’s safety management system.

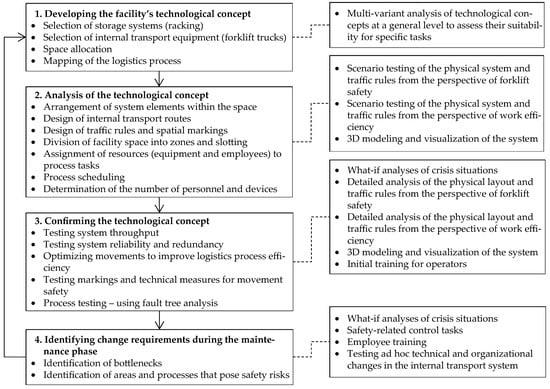

MUSM-VR is designed to be applied throughout the subsequent stages of a system’s lifecycle (Figure 3).

Figure 3.

Use of MUSM-VR in the life cycle of a forklift-based system.

The lifecycle of a forklift-based system typically follows an iterative loop, in which reengineering and redesign activities are periodically undertaken. Reengineering is most frequently carried out either during system scaling (i.e., expansion with the same technology) or in connection with traffic flow reorganization related to inventory placement.

In the phase of technological concept development (1), MUSM-VR can be applied at a general level to support concept evaluation, employing low-detail models primarily for hazard visualization.

In the technological concept analysis phase (2), the scope of MUSM-VR application becomes broader, as the design work emphasizes the comparison of detailed concept variants. At this stage, safety considerations are critical, and collaboration with architects is often necessary due to structural elements that may affect forklift operation.

In the phase of technological concept validation (3), high-fidelity simulation models are developed to enable detailed design analysis. This phase also involves cooperation with future users, such as facility managers, and provides opportunities to train operators under anticipated working conditions.

Finally, in the operational phase (4), issues associated with forklift systems, such as critical layout points, intersections, right-of-way conflicts, and recorded accidents or incidents are identified. These challenges can be analyzed using MUSM-VR, which, in this context, constitutes an updated version of the simulation model developed in phase (3).

Barriers to the use of VR in testing forklift systems should also be identified. Relying on headsets that are not integrated with 3D dynamic interaction systems disregards stress and distraction factors that can influence participant’s perception of the environment and, consequently, their interaction with objects in the model. The study, however, was designed to assess firstly speed, traffic rules, architectural barriers and visibility—factors that can be evaluated without dynamic interaction with the test subject. It should also be noted that experienced forklift operators often learn to disregard stressful and distracting stimuli in their work environment.

A valuable extension of the proposed system would be the implementation of a real forklift control panel and manipulators. This approach, however, would reduce the method’s universality and limit its broader applicability.

5. Case Study of Forklift Safety Assessment in a Pallet Warehouse

5.1. Experimental Parameters

To evaluate the effectiveness of MUSM-VR in analyzing occupational safety in forklift systems, a series of experimental studies were conducted. The MUSM-VR model was configured using actual design data, and multiple experiments were performed with external users who had little or no prior experience with forklift operations.

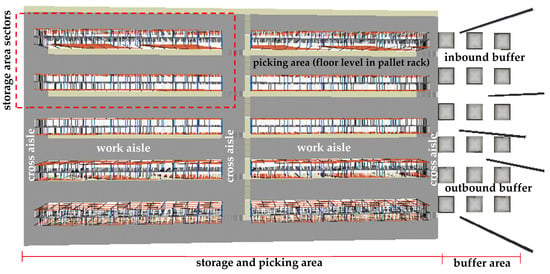

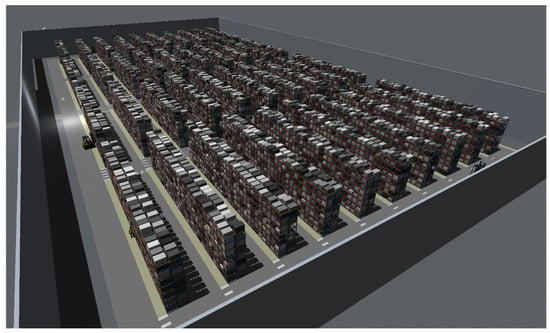

The experimental setup replicated a pallet warehouse with 8 m high steel pallet racks arranged in a system of six longitudinal aisles and three cross aisles, supplemented by a buffer storage zone (Figure 4). The model editor provided the capability to configure key parameters, including:

Figure 4.

Test warehouse layout in MUSM-VR—one of the layout versions.

- warehouse layout, such as rack height, the number and positioning of rack blocks, internal transport route widths, and pedestrian path placement and characteristics;

- rack occupancy levels and pallet unit density, which directly influence visibility;

- visual elements such as colors, shading, and lighting conditions;

- road markings and signage;

- the number of users and bots representing forklift operators and pedestrians;

- task structures in both rack and buffer zones;

- traffic parameters, including permissible forklift operating speeds;

- traffic rules, such as priority regulations and speed limits;

- dashboard appearance and interface elements of the forklift.

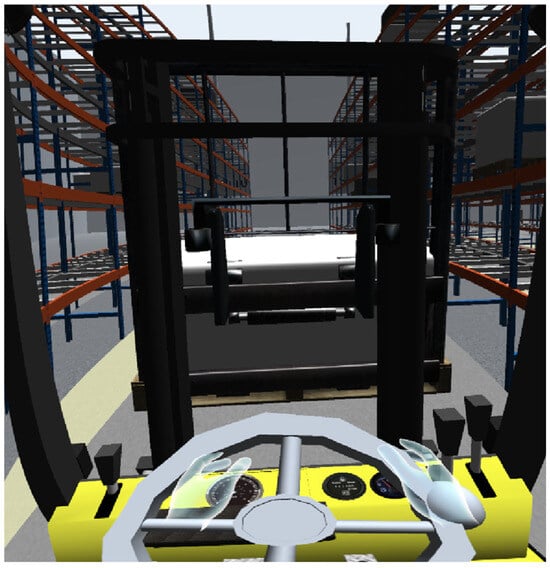

This flexible configuration enabled the creation of multiple test scenarios for evaluating the impact of spatial design, operational parameters, and user behavior on occupational safety. The model was verified to accurately reflect the technological concept of the analyzed warehouse and validated against the specified internal transport technologies, including forklift movement parameters. Figure 5 and Figure 6 present sample MUSM-VR visualizations based on the implemented design data.

Figure 5.

External view of MUSM-VR for experimental data.

Figure 6.

Operators view in MUSM-VR (driver’s cockpit view deactivated).

The primary objectives of the study were as follows:

- to identify areas within the warehouse layout that are particularly susceptible to forklift collisions, based on the configuration and parameters of internal transport routes;

- to determine safe operating speed ranges for forklifts in both working and cross aisles;

- to examine operator behavior in decision-making and traffic interaction scenarios;

- to assess the relative safety level as a function of visibility limitations caused by pallet rack occupancy;

- to evaluate storage area layouts in terms of operational efficiency and the number of potentially hazardous events for specific configurations and traffic parameters.

The experiment incorporated limited MUSM-VR features described in Section 4.2. The experiment incorporates human factors by having at least two participants (operators) in the model simultaneously interact with each other. It is potentially possible to introduce random events into the model, such as sudden turns and stops or unusual bot behavior, in case of specific analyses.

The analysis focused on the number, conditions, and spatial distribution of potentially hazardous situations. These were defined as unplanned events arising from traffic dynamics that create an imminent risk of collision and require immediate operator intervention, such as sudden steering maneuvers or abrupt braking in close proximity to other vehicles, pedestrians, or infrastructure elements.

The tasks assigned to participants involved transporting pallet units between designated locations within the warehouse according to a randomly generated task distribution. For each layout variant, ten test runs were performed with a total of twenty inexperienced operators. Two participants were engaged in each test run simultaneously. Each session lasted between 5 and 10 min, depending on the scenario variant, which was determined by the number of transport tasks and the individual predispositions of the participants. All test runs were preceded by a brief training session.

The study participants were recruited from individuals without prior forklift operation experience or certification, but who were familiar with warehouse processes and the nature of forklift operator tasks. Ten participants (X male, Y female), aged 20 to 24, took part in the study. Candidate selection was guided by a survey assessing any previous occurrence of VR-related symptoms. Pre- and post-experiment surveys confirmed that none of the participants exhibited sensitivity to VR sickness or reported symptoms following the experiment.

The study utilized commercial VR Oculus Meta Quest 2 128 GB headsets (resolution 3664 × 1920) with standard controllers with cable-connection. Setup included a suitably specified computer running FlexSim 24.2, handling the MUFX server. The test station was configured to ensure safe interaction with the MUSM-VR model without requiring participants to move outside the designated safety boundary for hand and head manipulation (Figure 7). MUSM-VR works with all commercially available headsets, which increases its versatility and range of applications.

Figure 7.

A seated test station for one participant—an application in an office setting for quick implementation.

Table 2 summarizes the parameter variability ranges applied to each experimental scenario.

Table 2.

Summary of scenario analysis parameters for experimental runs.

5.2. Experimental Procedure

The experimental procedure was conducted in accordance with the methodological framework outlined in Section 4.2 and included the following steps:

- Construction of MUSM-VR: Development of the simulation environment in line with the principles described in Section 4.1 and Section 4.2.

- Participant qualification: Selection of participants based on a voluntary survey assessing diagnosed VR-related disorders, neurological conditions, and other relevant limitations.

- User training: Introduction to the use of VR controllers and headsets.

- Test drives: Familiarization runs conducted using local models to allow participants to adapt to the environment and control mechanisms.

- Model integration: Connection of local participant models to the experimental MUSM-VR environment via the MUFX server, which recorded events and simulated additional operators (pedestrians and forklift drivers) generated automatically in FlexSim.

- Post-test survey: Voluntary assessment of participants’ well-being and subjective impressions following the experiment.

5.3. Experiment Results

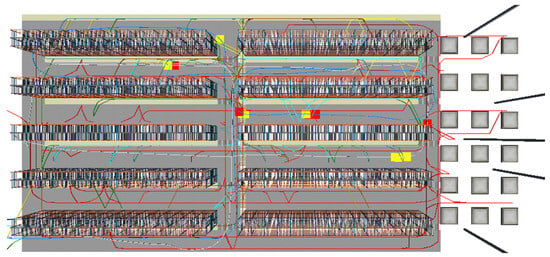

Following the completion of the experiment, the recorded locations of participants and video footage were analyzed to identify areas where potentially hazardous situations occurred most frequently. At the same time, the movement trajectories of individual operators were tracked to visualize traffic patterns and collision risk zones (Figure 8, Table 3). The analysis was based on the time-location convergence of positions, as well as the relative speeds and movement directions of objects in the model. On this basis, a gradient representation of high-risk locations was developed. Due to the small sample size, no statistical analysis was performed; instead, the focus was placed on examining recorded and potential events.

Figure 8.

Routes traveled by experiment participants and locations of potential hazardous situations for a given scenario (descriptions as in Figure 4).

Table 3.

Information on potentially hazardous situations.

Figure 8 highlights the points where the highest concentration of potentially hazardous events was recorded, marked in red. Based on this analysis, warehouse locations with particularly elevated accident risks were identified. The results showed that 87.5% of hazardous events involved interactions between forklifts and operators, with an average vehicle speed of approximately 0.72 m/s. Most incidents occurred near intersections and pedestrian crossings, underscoring the critical importance of effective traffic management in these areas.

5.4. Recommendations for Changes Based on Experiments

The experimental findings enabled conclusions to be drawn in relation to the research objectives outlined in Section 5.1:

- Identification of collision-prone areas: Areas with a high likelihood of forklift collisions were identified based on the layout and internal transport route parameters (Figure 8). To mitigate these risks, it is recommended to implement pedestrian and equipment detection systems (installed on forklifts and in the surrounding area) and to use spherical mirrors to enhance visibility at the intersections of working and cross aisles.

- Establishment of safe operating speeds: A safe forklift speed for working and cross aisles was determined, minimizing conflict situations while maintaining operational efficiency. The recommended value is v-safe = 0.6 m/s.

- Operator behavior and decision-making: Testing operator decision-making and movement behaviors highlighted the need to apply standard road traffic rules, as these are familiar to users and naturally recalled under pressure.

- Impact of limited visibility: No direct correlation was observed between the number of hazardous events and visibility restrictions caused by pallet rack contents. This may be due to inexperienced users focusing primarily on forklift operation and disregarding peripheral visual cues.

- Evaluation of storage zone layouts: Variants of the storage zone layout were analyzed in terms of both efficiency and the number of hazardous events under specific configurations and movement parameters, resulting in the identification of an optimal design variant.

The ability to easily modify storage zone layouts within MUSM-VR enables the repetition of experiments under different constraints and configurations. Since the model can be integrated into the design phase, it provides an opportunity for early alignment between system design and initial forklift safety assessment.

6. Conclusions

Virtual Reality is emerging as valuable tool for studying intralogistics systems, offering new opportunities for designing, testing, and analyzing occupational safety. VR can be particularly helpful in evaluating the risks associated with forklift operation, as it allows the assessment of spatial layouts, organizational principles, technical solutions, and human factors under simulated conditions. Applying VR eliminates investment costs associated with physical testing while providing high levels of user immersion.

The MUSM-VR enables multi-user research replicating real-world operating scenarios, operator interactions, and critical situations requiring immediate responses. It allows testing safety measures, human behavior, and organizational strategies in early stage of project realization for preliminary studies and in late stage for advanced and detailed studies. MUSM-VR serves as a practical tool for supporting the design of safe workspaces and the development of effective training programs.

Experiments conducted using MUSM-VR confirmed that critical system points such as intersections of transport routes, zones with limited visibility, and areas shared by pedestrians and vehicles can be effectively identified and subjected to detailed analysis within a virtual environment.

The following findings after the research can be formulated:

- Barriers to VR-based forklift testing include the use of headsets without dynamic interaction system, which neglect stress and distraction factors affecting perception.

- An extension of the system could include a real forklift control panel and manipulators, though this would reduce its universality and broader applicability.

- MUSM-VR can be integrated into all stages of forklift system implementation and maintenance. While its use requires operator training, its adaptability to standard office environments makes it a cost-effective organizational solution.

- Reducing the risk of forklift-related accidents requires a combination of organizational and technical interventions, many of which can be accurately replicated in MUSM-VR.

- MUSM-VR enables evaluation of the effectiveness of common safety solutions, such as pedestrian-only zones, safety barriers, systems reducing the risk of cargo tipping, active and passive vehicle safety systems.

- The Virtual Human Factors (VHF) approach is particularly relevant in MUSM-VR implementation, as it emphasizes designing with human capabilities and constraints in mind to reduce errors caused by perceptual limitations or excessive cognitive load.

Despite the identified challenges, the integration of MUSM-VR with intralogistics design, safety analysis, and training processes highlights the significant potential of this technology within the paradigms of Industry 4.0 and 5.0. Iterative risk scenario analysis and the examination of human–system interactions simulation settings provide valuable insights into the mechanisms of hazards and support the development of effective preventive measures.

Future research should refine MUSM-VR to support flexible warehouse layouts and forklift scenarios, expanding its use toward rapid prototyping. Equally important is the development of a standardized methodology for integrating MUSM-VR into the warehouse design process, particularly in early concept testing, in line with the growing use of digital twin and digital shadow models.

Author Contributions

Conceptualization, K.L. and P.Ż.; methodology, K.L.; software, P.Ż.; validation, P.Ż.; formal analysis, K.L.; investigation, P.Ż.; resources, P.Ż. and K.L.; data curation, P.Ż.; writing—original draft preparation, P.Ż.; writing—review and editing, K.L.; visualization, P.Ż.; supervision, K.L.; funding acquisition, K.L. All authors have read and agreed to the published version of the manuscript.

Funding

This paper was co-financed under the research grant of the Warsaw University of Technology supporting the scientific activity in the discipline of Civil Engineering, Geodesy and Transport.

Institutional Review Board Statement

The project meets the ethical standards of the Warsaw University of Technology, laid down in § 1 section 3 of Annex to Decision no. 314/2024 of the Warsaw University of Technology Rector of 2 December 2024 on the establishment of the Team for Ethics of Research Involving Human Beings and introduction of Regulation for the Team.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| VR | Virtual Reality |

| MUSM-VR | Multi-user simulation model integrated with a virtual reality layer |

References

- Michael, J.; Gorucu, S. Analysis of Forklift and Pallet Jack Injuries in Wood-Related Industries. For. Prod. J. 2020, 70, 403–408. [Google Scholar] [CrossRef]

- Saric, S.; McInnes, D.; Morello, R.; Jancey, J.; Howat, P. Analysis of Forklift Accident Trends within Victorian Industry (Australia). Saf. Sci. 2013, 60, 176–184. [Google Scholar] [CrossRef]

- Kim, K.W. Characteristics of Forklift Accidents in Korean Industrial Sites. Work 2021, 68, 679–687. [Google Scholar] [CrossRef] [PubMed]

- Lifschultz, B.D.; Donoghue, E.R. Deaths Due to Forklift Truck Accidents. Forensic Sci. Int. 1994, 65, 121–134. [Google Scholar] [CrossRef] [PubMed]

- Larsson, T.J.; Rechnitzer, G. Forklift Trucks—Analysis of Severe and Fatal Occupational Injuries, Critical Incidents and Priorities for Prevention. Saf. Sci. 1994, 17, 275–289. [Google Scholar] [CrossRef]

- Erel, F.; Ozturk, I.; Özkan, T. Safe Working with Forklifts: Investigating the Effect of Forklift Operators’ Behaviors, Skills and Effort-Reward Imbalance on Forklift Accidents. 2023. Available online: https://osf.io/preprints/psyarxiv/nj6dg_v1 (accessed on 13 September 2025).

- Główny Urząd Statystyczny (GUS). Wypadki Przy Pracy w 2023 r.; GUS: Warszawa, Poland, 2024. [Google Scholar]

- Simonetto, M.; Arena, S.; Peron, M. A Methodological Framework to Integrate Motion Capture System and Virtual Reality for Assembly System 4.0 Workplace Design. Saf. Sci. 2022, 146, 105561. [Google Scholar] [CrossRef]

- Menck, N.; Weidig, C.; Aurich, J.C.; Brieke, M.; Scheidel, W.; Schenk, M. Collaborative Factory Planning in Virtual Reality. Procedia CIRP 2012, 3, 317–322. [Google Scholar] [CrossRef]

- Lewczuk, K.; Żuchowicz, P. Virtual Reality Application for the Safety Improvement of Intralogistics Systems. Sustainability 2024, 16, 6024. [Google Scholar] [CrossRef]

- Yuen, K.K.; Choi, S.H.; Yang, X.B. A Full-Immersive CAVE-Based VR Simulation System of Forklift Truck Operations for Safety Training. Comput.-Aided Des. Appl. 2010, 7, 235–245. [Google Scholar] [CrossRef]

- Wetzel, C.; Lungfiel, A.; Nickel, P. BGHW Warehouse Simulation—Virtual Reality Supports Prevention of Slip, Trip and Fall (STF) Accidents. In Digital Human Modeling and Applications in Health, Safety, Ergonomics and Risk Management; Springer: Cham, Switzerland, 2023; pp. 276–289. [Google Scholar] [CrossRef]

- Stoltz, M.H.; Giannikas, V.; McFarlane, D.; Strachan, J.; Um, J.; Srinivasan, R. Augmented Reality in Warehouse Operations: Opportunities and Barriers. In Proceedings of the 20th IFAC World Congress, Toulouse, France, 9–14 July 2017; Volume 50, pp. 12979–12984. [Google Scholar] [CrossRef]

- Klačková, I.; Kuric, I.; Zajačko, I.; Tlach, V.; Wiecek, D. Virtual Reality in Industry. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1199, 012005. [Google Scholar] [CrossRef]

- Halusiak, S. Stan Bezpieczeństwa Pracy Operatorów Wózków Widłowych w Polsce. Bezpieczeństwo Pr. 2019, 9, 7–11. [Google Scholar]

- Coburn, J.Q.; Freeman, I.; Salmon, J.L. A Review of the Capabilities of Current Low-Cost Virtual Reality Technology and Its Potential to Enhance the Design Process. J. Comput. Inf. Sci. Eng. 2017, 17, 031013. [Google Scholar] [CrossRef]

- Bellalouna, F. New Approach for Digital Factory Using Virtual Reality Technology. Procedia CIRP 2020, 93, 256–261. [Google Scholar] [CrossRef]

- Lyu, Q.; Watanabe, K.; Umemura, H.; Murai, A. Design-Thinking Skill Enhancement in Virtual Reality: A Literature Study. Front. Virtual Real. 2023, 4, 1137293. [Google Scholar] [CrossRef]

- Machała, S.; Chamier-Gliszczyński, N.; Królikowski, T. Application of AR/VR Technology in Industry 4.0. Procedia Comput. Sci. 2022, 207, 2990–2998. [Google Scholar] [CrossRef]

- Cantini, A.; De Carlo, F.; Tucci, M. Towards Forklift Safety in a Warehouse: An Approach Based on the Automatic Analysis of Resource Flows. Sustainability 2020, 12, 8949. [Google Scholar] [CrossRef]

- Jimenez, J.; Sharotry, A.; Mendez Mediavilla, F.A. Forklift Operator Safety & Productivity: A Review of Current Research and Future Directions. In Proceedings of the 16th International Material Handling Research Colloquium (IMHRC), Dresden, Germany, 19–23 June 2023. [Google Scholar]

- Esmaeili, S.V.; Alboghobeish, A.; Yazdani, H.; Ghasemi Koozekonan, A.; Pouyakian, M. Optimizing In-Store Warehouse Safety: A DEMATEL Approach to Comprehensive Risk Assessment. PLoS ONE 2025, 20, e0317787. [Google Scholar] [CrossRef]

- Agudelo-Vélez, A.; Sarmiento-Ordosgoitia, I.; Córdoba-Maquilón, J. Virtual Reality as a New Tool for Transport Data Collection. Arch. Transp. 2021, 60, 23–38. [Google Scholar] [CrossRef]

- Zahabi, S.J.N.; Islam, M.S.; Kim, S.; Lau, N.; Nussbaum, M.A.; Lim, S. Cognitive Workload Assessment During VR Forklift Training. Int. J. Ind. Ergon. 2025, 107, 103718. [Google Scholar] [CrossRef]

- Islam, M.S.; Zahabi, S.J.N.; Kim, S.; Lau, N.; Nussbaum, M.A.; Lim, S. Changes in Forklift Driving Performance and Postures among Novices Resulting from Training Using a High-Fidelity Virtual Reality Simulator: An Exploratory Study. Int. J. Ind. Ergon. 2024, 104, 103648. [Google Scholar] [CrossRef]

- Occupational Health & Safety; Ryder, T. 7 Strategies for Improving Forklift Fleet Safety. 2024. Available online: https://ohsonline.com/articles/2024/11/29/7-strategies-for-improving-forklift-fleet-safety.aspx (accessed on 14 July 2025).

- Government of South Australia. High Risk Work: A Guide to Forklift Safety; SafeWork SA: Keswick, Australia, 2015. Available online: https://safework.sa.gov.au/__data/assets/pdf_file/0018/144513/A-guide-to-forklift-safety.pdf (accessed on 14 July 2025).

- Zhang, Q.; Tsoi, N.; Vázquez, M. SEAN-VR: An Immersive Virtual Reality Experience for Evaluating Social Robot Navigation. In Proceedings of the 2023 ACM/IEEE International Conference on Human-Robot Interaction, Stockholm, Sweden, 13–16 March 2023. [Google Scholar]

- Choi, M.; Ahn, S.; Seo, J. VR-Based Investigation of Forklift Operator Situation Awareness for Preventing Collision Accidents. Accid. Anal. Prev. 2020, 136, 105404. [Google Scholar] [CrossRef] [PubMed]

- Evangelista, A.; Manghisi, V.M.; Romano, S.; De Giglio, V.; Cipriani, L.; Uva, A.E. Advanced Visualization of Ergonomic Assessment Data through Industrial Augmented Reality. Procedia Comput. Sci. 2023, 217, 1470–1478. [Google Scholar] [CrossRef]

- Runji, J.M.; Lee, Y.-J.; Chu, C.-H. Systematic Literature Review on Augmented Reality-Based Maintenance Applications in Manufacturing Centered on Operator Needs. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 567–585. [Google Scholar] [CrossRef]

- Bräuer, P.; Mazarakis, A. AR in Order-Picking—Experimental Evidence with Microsoft HoloLens. In Mensch und Computer 2018-Workshopband; Gesellschaft für Informatik e.V.: Dresden, Germany, 2018. [Google Scholar] [CrossRef]

- Reif, R.; Gunthner, W.A.; Schwerdtfeger, B.; Klinker, G. Evaluation of an Augmented Reality Supported Picking System under Practical Conditions. Comput. Graph. Forum 2010, 29, 2–12. [Google Scholar] [CrossRef]

- Souchet, A.D.; Lourdeaux, D.; Pagani, A.; Rebenitsch, L. A Narrative Review of Immersive Virtual Reality’s Ergonomics and Risks at the Workplace: Cybersickness, Visual Fatigue, Muscular Fatigue, Acute Stress, and Mental Overload. Virtual Real. 2023, 27, 19–50. [Google Scholar] [CrossRef]

- Bhutta, Z.I.; Umm-e-Hani, S.; Tariq, I. The Next Problems to Solve in Augmented Reality. In Proceedings of the 2015 International Conference on Information and Communication Technologies (ICICT), Karachi, Pakistan, 12–13 December 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Oguz, D.A. Digital Skills, Organizational Behavior and Transformation of Human Resources: A Review. Eco-Forum J. 2019, 8. Available online: https://ecoforumjournal.ro/index.php/eco/article/view/1895 (accessed on 12 October 2025).

- Escallada, O.; Lasa, G.; Mazmela, M.; Apraiz, A.; Osa, N.; Nguyen Ngoc, H. Assessing Human Factors in Virtual Reality Environments for Industry 5.0: A Comprehensive Review of Factors, Metrics, Techniques, and Future Opportunities. Information 2025, 16, 35. [Google Scholar] [CrossRef]

- Souchet, A.D.; Lourdeaux, D.; Burkhardt, J.-M.; Hancock, P.A. Design Guidelines for Limiting and Eliminating Virtual Reality-Induced Symptoms and Effects at Work: A Comprehensive, Factor-Oriented Review. Front. Psychol. 2023, 14, 1161932. [Google Scholar] [CrossRef]

- Tokatli, A. A Multi-Criteria Framework for the Holistic Ergonomic Design Evaluation of VR Products. Front. Virtual Real. 2025, 6, 1549963. [Google Scholar] [CrossRef]

- Kobir, M.H.; Rahman, T.; Yang, Y.; Deb, S. A Human Factors Approach to Improve Layout Design for a Virtual Reality-Based Training Platform. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, Washington, DC, USA, 23–27 October 2023; Volume 67, pp. 1439–1444. [Google Scholar] [CrossRef]

- Kay, M.; Stanney, K.; Mourant, R.R.; Kennedy, R.S. Human Factors Issues in Virtual Environments: A Review of the Literature. Presence 1998, 7, 327–351. [Google Scholar]

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. The Role of Safety Leadership and Working Conditions in Safety Performance in Process Industries. J. Loss Prev. Process Ind. 2017, 50, 403–415. [Google Scholar] [CrossRef]

- Toyota Material Handling. 5 Ways to Improve Ergonomics for Your Forklift Drivers. Available online: https://toyota-forklifts.eu/about-toyota/news-and-editorials/5-ways-to-improve-ergonomics-for-your-forklift-drivers/ (accessed on 14 July 2025).

- Lu, M.-L.; Werren, D.M.; Ramsey, J.G.; Brueck, S.E. Evaluation of Forklift Operators’ Risk of Musculoskeletal Disorders at Two Manufacturing Plants; HHE Report No. 2012-0182-0208-3300; Health Hazard Evaluation: Washington, DC, USA, 2018. Available online: https://cdc.gov/niosh/hhe/reports/pdfs/2012-0182-0208-3300.pdf (accessed on 14 July 2025).

- Szaciłło, L. Model Oceny Ryzyka Realizacji Kolejowych Przewozów Towarowych; Politechnika Warszawska, Wydział Transportu: Warsaw, Poland, 2021. [Google Scholar]

- Li, X.; Kang, Y.; Chen, W.; Liu, F.; Jiao, Y.; Luo, Y. Recognizing the Situation Awareness of Forklift Operators Based on EEG Techniques in a Field Experiment. Front. Neurosci. 2024, 18, 1323190. [Google Scholar] [CrossRef]

- Nader, M.; Jacyna-Gołda, I.; Nader, S.; Nehring, K. Using BCI and EEG to Process and Analyze Driver’s Brain Activity Signals during VR Simulation. Arch. Transp. 2021, 60, 137–153. [Google Scholar] [CrossRef]

- Foumani, M.; Moeini, A.; Haythorpe, M.; Smith-Miles, K. A cross-entropy method for optimising robotic automated storage and retrieval systems. Int. J. Prod. Res. 2018, 56, 6450–6472. [Google Scholar] [CrossRef]

- Ho, H.-H.; Chen, C.-F.; Sung, M.-H.; Shen, T.-S.; Chen, Y.-J. Experimental investigation of in-rack sprinkler parameters for ASRS warehouse protection. J. Loss Prev. Process Ind. 2025, 98, 105760. [Google Scholar] [CrossRef]

- Jurczyk, K.; Cempel, W.A. Modelowanie i Symulacja Procesów Ewakuacji z Wykorzystaniem Oprogramowania FlexSim—Studium Przypadku. Syst. Logist. Wojsk. 2018, 48, 116–131. [Google Scholar] [CrossRef]

- Myrcha, K. Problemy Bezpieczeństwa i Higieny Pracy w Magazynach. Mechanik 2013, 7, 497–504. [Google Scholar]

- Milanowicz, M.; Budziszewski, P.; Kędzior, K. Numerical Analysis of Passive Safety Systems in Forklift Trucks. Saf. Sci. 2018, 101, 98–107. [Google Scholar] [CrossRef]

- Hong, C.C.; Nashi, N.; Kuan, W.S.; Teh, J.W.D.; Tan, K.J. Forklift-Related Crush Injuries of the Foot and Ankle. Foot Ankle Int. 2015, 36, 806–811. [Google Scholar] [CrossRef] [PubMed]

- Jacyna, M.; Lewczuk, K.; Kłodawski, M. Selected Aspects of Modelling Forklifts Velocity and Work Safety. In Proceedings of the 10th International Conference “Management of Technology Step to Sustainable Production”, Primošten, Croatia, 8–10 June 2022; Croatian Association for PLM: Zagreb, Croatia, 2018; pp. 1–9. [Google Scholar]

- Lewczuk, K.; Kłodawski, M.; Gepner, P. Energy Consumption in a Distributional Warehouse: A Practical Case Study for Different Warehouse Technologies. Energies 2021, 14, 2709. [Google Scholar] [CrossRef]

- CIOP-PIB. BHP Operatora Podnośnikowych Wózków Jezdniowych. Available online: https://www.ciop.pl/CIOPPortalWAR/appmanager/ciop/pl?_nfpb=true&_pageLabel=P30001831335539182278&html_tresc_root_id=29012&html_tresc_id=29012&html_klucz=19558&html_klucz_spis= (accessed on 14 July 2025).

- Beaverstock, M.; Greenwood, A.; Nordgren, W. Applied Simulation: Modeling and Analysis Using FlexSim, 5th ed.; Bookbaby: Pennsauken, NJ, USA, 2018; ISBN 978-0983231974. [Google Scholar]

- AutoDesk Company. FlexSim Technical Documentation. Available online: https://docs.flexsim.com/en/25.2/Introduction/Welcome/Welcome.html (accessed on 14 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).