Energy Dissipation and Damage Evolution of Water-Saturated Skarn Under Impact Loading

Abstract

1. Introduction

2. Test Method

2.1. Materials and Equipment

2.2. Test Equipment and Principle

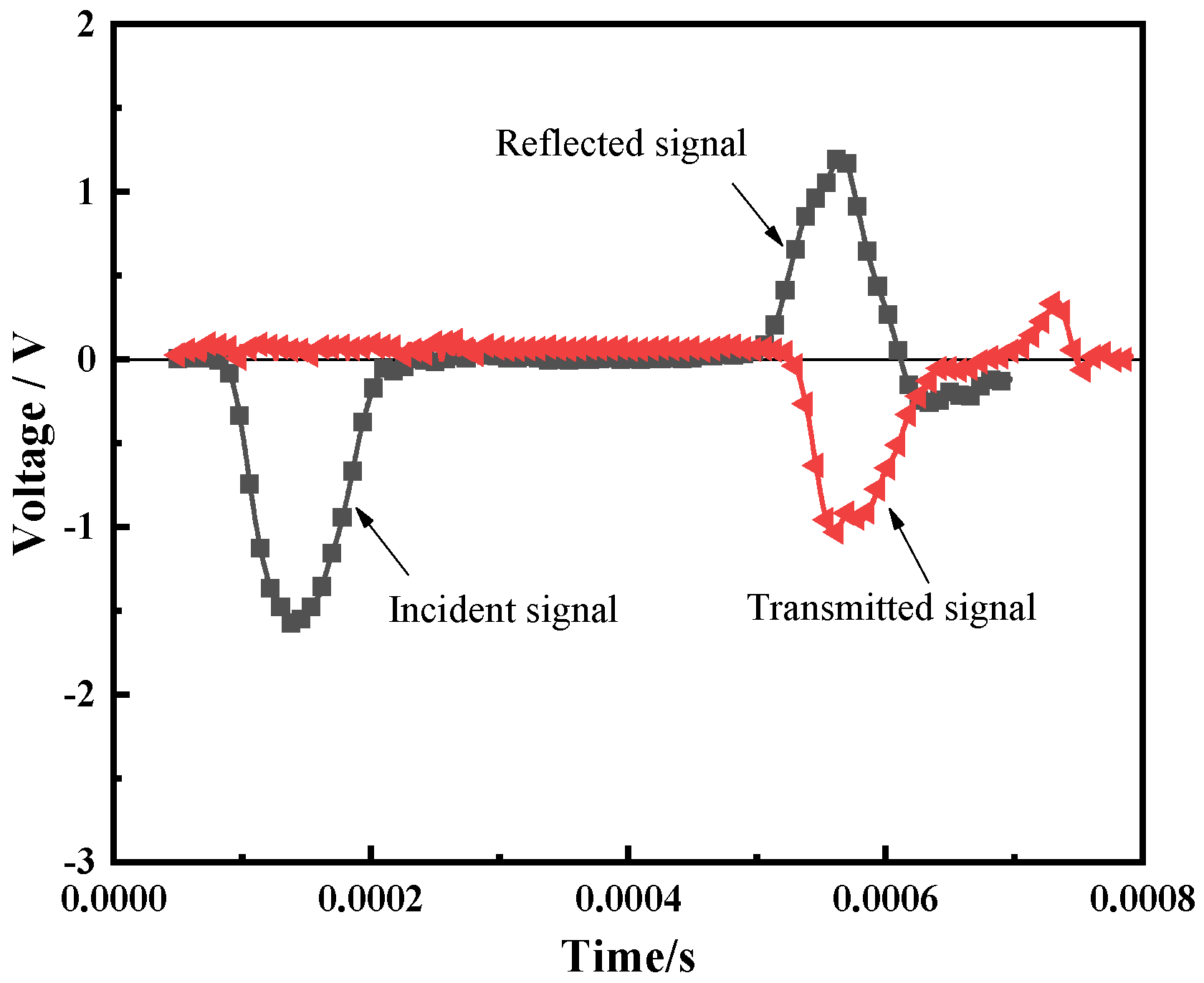

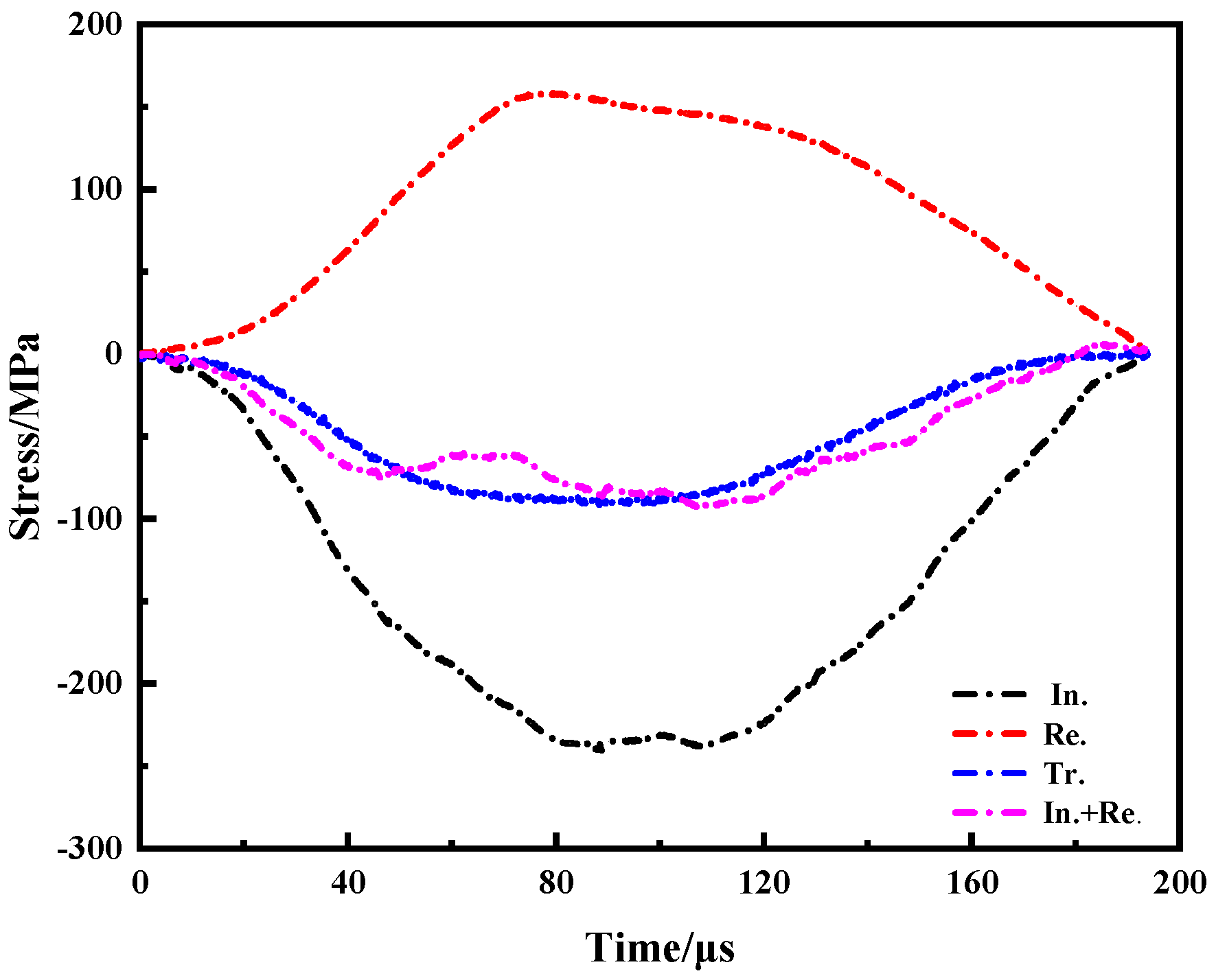

2.3. Stress Balance Verification

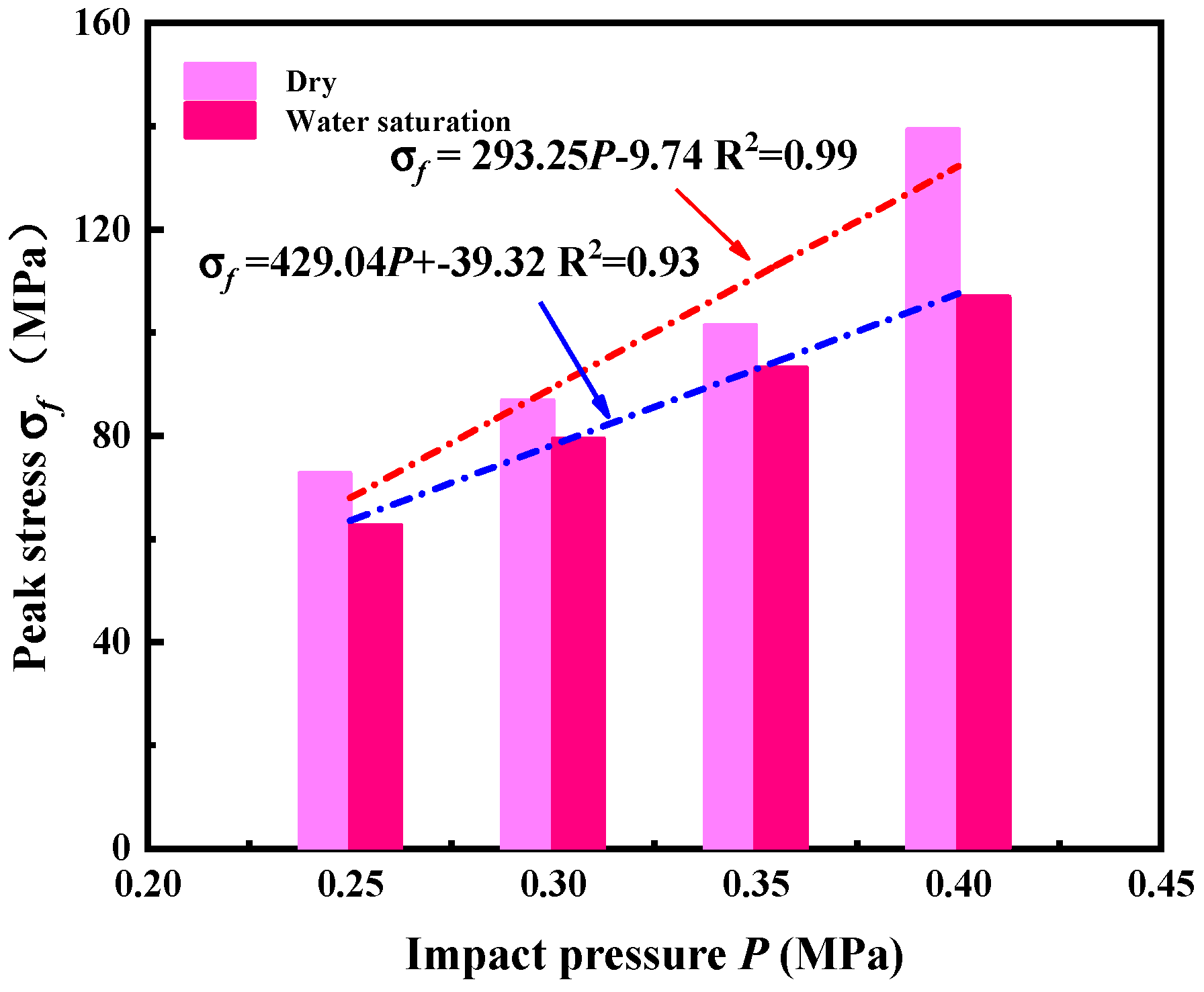

3. Analysis of SHPB Test Results

3.1. Analysis of Stress Wave Propagation Law

3.2. Stress–Strain Curve Analysis

3.3. Analysis of Specimen Failure Morphology

4. Analysis of Energy Evolution Characteristics

4.1. Evolution Characteristics of Energy with Strain

4.2. Damage Characteristics Based on Energy Evolution

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Tang, Y.; Wang, S. Influence of brittleness and confining stress on rock cuttability based on rock indentation tests. J. Cent. South Univ. 2021, 28, 2786–2800. [Google Scholar] [CrossRef]

- Xie, H.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar]

- Zhou, Z.; Liu, Y.; Cai, X.; Chang, Y.; Gao, S. Infrared radiation characteristics of sandstone under impact loading. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 2555–2562. [Google Scholar] [CrossRef]

- Chen, Q. Damage characteristics and dynamic response of sandstone in coal-fire area under impact loading. Ph.D. Thesis, Ningxia University, Yinchuan, China, 25 November 2022. [Google Scholar]

- Tang, L.; Wang, C.; Cheng, L.; Gao, L. Experimental study on mechanical properties of skarn under one-dimensional static loading and cyclic impact. J. Cent. South Univ. (Sci. Technol.) 2015, 46, 3898–3906. [Google Scholar] [CrossRef]

- Yang, R.; Xu, Y.; Liu, J.; Ding, J.; Xie, H. Comparative Analysis of Dynamic Mechanics and Failure Characteristics of Sandstone and Quasi-sandstone Material. Mater. Rep. 2023, 37, 22030265-11. [Google Scholar] [CrossRef]

- Tang, L.; Bu, S.; Wu, L.; Li, X. Dynamic characteristics of skarn under the combined action of high static stress and frequent dynamic disturbance. Chin. J. Eng. 2014, 36, 993–999. [Google Scholar] [CrossRef]

- Wang, L.; Zou, P.; Jiao, Z.; Liu, H.; Cheng, L.; Wang, J.; Wang, Z. Energy evolution and fractal characteristics of coal rock under two strain rate modes under shock load. J. Vib. Shock 2022, 41, 280–289. [Google Scholar] [CrossRef]

- Wen, S.; Zhao, X.; Chang, Y.; Li, B. Analysis of dynamic compression failure energy dissipation of composite rock samples based on SHPB. J. Basic Sci. Eng. 2021, 29, 483–492. [Google Scholar]

- Burshtein, L.S. Effect of moisture on the strength and deformability of sandstone. Sov. Min. Sci. 1969, 5, 573. [Google Scholar] [CrossRef]

- Xu, L.; Liu, S.; Li, Y. Experimental studies on rock softening properties in Danjiangkou Reservoir area. Rock Soil Mech. 2008, 29, 1430–1434. [Google Scholar]

- Lajtai, E.Z.; Schmidtke, R.H.; Bielus, L.P. The effect of water on the time-dependent deformation and fracture of a granite. Int. J. Rock Mech. Min. Sci. 1987, 24, 247. [Google Scholar] [CrossRef]

- Li, N.; Xu, H.; Hu, B. Shear creep characteristics of sandstone under dry and saturated states. Rock Soil Mech. 2012, 33, 439–443. [Google Scholar] [CrossRef]

- Hawkins, A.B.; McConnell, B.J. Sensitivity of sandstone strength and deformability to changes in moisture content. Q. J. Eng. Geol. Hydrogeol. 1992, 25, 115. [Google Scholar] [CrossRef]

- Zhu, Z.; Xing, F.; Wang, S.; Xu, W. Analysis on strength softening of argillite under groundwater by damage mechanics. Chin. J. Rock Mech. Eng. 2004, 23, 4739–4743. [Google Scholar]

- Deng, H.; Fang, J.; Li, J.; Xiao, Y.; Zhou, M. Mechanism of influence of water bearing state on mechanical properties of soft rock in red bed. J. China Coal Soc. 2017, 42, 1994–2002. [Google Scholar] [CrossRef]

- Yuan, P.; Ma, Q. Split Hopkinson pressure bar test on sandstone in coalmine under cyclic wetting and drying. Rock Soil Mech. 2013, 34, 2557–2562. (In Chinese) [Google Scholar] [CrossRef]

- Yuan, P.; Ma, R. Analysis on energy absorption of rock under various water absorption contents in SHPB test. Acta Armamentarii 2013, 34 (Suppl. S1), 328–332. (In Chinese) [Google Scholar]

- Lou, W. Dynamic fracture behavior of dry and waterlogged granite. Explos. Shock Waves 1994, 14, 249–254. [Google Scholar]

- Wang, B.; Li, X.; Yin, T.; Ma, C.; Yin, Z.; Li, Z. Split Hopkinson pressure bar (SHPB) experiments on dynamic strength of water-saturated sandstone. Chin. J. Rock Mech. Eng. 2010, 29, 1003–1009. [Google Scholar]

- Rubin, A.M.; Ahrens, T.J. Dynamic tensile-failure-induced velocity deficits in rock. Geophys. Res. Lett. 1991, 18, 219. [Google Scholar] [CrossRef]

- Jia, R.; Xu, H. Study on the dynamic characteristics of limestone of Jinshaxia hydropower station under different water cuts. Eng. Blasting Eng. 2022, 28, 34–43. [Google Scholar]

- Wang, C.; Li, J.; Cheng, L.; Li, X.; Zhang, P.; Hu, M. Damage and Failure Characteristics and Constitutive Model of Copper-Bearing Skarns Disturbed by Hierarchical Dynamic Loading After Loading And Unloading. Rock Mech. Rock Eng. 2022, 55, 6981–7004. [Google Scholar] [CrossRef]

- Lu, H.; Pan, Y.; He, K.; Wang, F.; Gao, L.; Pu, S.; Li, E. Dynamic Mechanical Properties and Damage Evolution Characteristics of Beishan Deep Granite under Medium and High Strain Rates. Materials 2023, 16, 5235. [Google Scholar] [CrossRef]

- Pi, Y.; Guo, Q.; Li, C.; Sun, C.; Li, L.; Zhong, W. Study on elastic modulus of skarn under uniaxial cyclic loading and unloading. China Min. Mag. 2023, 32, 173–181. [Google Scholar]

- Chu, F.; Liu, D.; Tao, M.; Peng, H. Dynamic response of sandstone in different aqueous states based on SHPB. Chin. J. Eng. 2017, 39, 1783–1790. [Google Scholar]

- Jin, J.; Yu, X.; Zhong, Y. Energy dissipation characteristics of red sandstone with different moisture cuts. Nonferrous Met. Sci. Eng. 2021, 12, 69–80. [Google Scholar]

- Tan, H.; Wu, X. Dynamic impact performance analysis of water-bearing sandstone and daliite. J. Hefei Univ. Technol. Nat. Sci. Ed. 2022, 45, 793–800. [Google Scholar]

- Zhou, Z.; Zhao, Y.; Jiang, Y.; Zou, Y.; Cai, X.; Li, D. Dynamic behavior of rock during its post failure stage in SHPB tests. Trans. Nonferrous Met. Soc. China 2017, 27, 184–196. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, X.; Ye, Z.; Liu, K. Obtaining Constitutive Relationship for Rate-Dependent Rock in SHPB Tests. Rock Mech. Rock Eng. 2010, 43, 697–706. [Google Scholar] [CrossRef]

- Gu, H.; Lai, X.; Tao, M.; Cao, W.; Yang, Z. The role of porosity in the dynamic disturbance resistance of water-saturated coal. Int. J. Rock Mech. Min. Sci. 2023, 166, 105388. [Google Scholar] [CrossRef]

- Xu, J.; Liu, S. Fractal characteristics analysis of marble crushing load test fragments. Rock Soil Mech. 2012, 33, 3225–3229. [Google Scholar]

- Zhang, Z.; Gao, F. Confining pressure effect on rock energy. Chin. J. Rock Mech. Eng. 2015, 34, 1–11. [Google Scholar]

- Wang, L.; Gao, Q. Prediction of rock mass mass distribution based on damage energy dissipation. Chin. J. Rock Mech. Eng. 2007, 26, 1202–1211. [Google Scholar]

- Huang, D.; Cen, D. Simulation of particle flow of mechanical response and energy dissipation mechanism of single fractured rock sample under uniaxial static-dynamic successive compression. Chin. J. Rock Mech. Eng. 2013, 32, 1926–1936. [Google Scholar]

- Kolsky, H. An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Society. Sect. B 1949, 62, 676–700. [Google Scholar] [CrossRef]

- Luo, H.; Jiang, J.; Zhao, K. Damage Characteristics of Basalt Fiber-Reinforced Recycled Concrete under Freeze-Thaw Cycles Based on Energy Dissipation. Compos. Sci. Eng. 2023, 5, 86–93. [Google Scholar]

- Hosseinzadehfard, E.; Mobaraki, B. Corrosion performance and strain behavior of reinforced concrete: Effect of natural pozzolan as partial substitute for microsilica in concrete mixtures. Structures 2025, 79, 109397. [Google Scholar] [CrossRef]

- Mobaraki, A.; Nikoofam, M.; Mobaraki, B. The Nexus of Morphology and Sustainable Urban Form Parameters as a Common Basis for Evaluating Sustainability in Urban Forms. Sustainability 2025, 17, 3967. [Google Scholar] [CrossRef]

- Zhang, Z.; Kou, S.; Jiang, L.; Lindqvist, P.-A. Effects of loading rate on rock fracture: Fracture characteristics and energy partitioning. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2000, 37, 745–762. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, S.; Wang, Z.; Yu, C. Analysis of marble failure energy evolution under loading and unloading conditions. Chin. J. Rock Mech. Eng. 2013, 23, 1572–1578. [Google Scholar]

- Dai, F.; Xia, K.; Tang, L. Rate dependence of the flexural tensile strength of Laurentian granite. Int. J. Rock Mech. Min. Sci. 2010, 47, 469–475. [Google Scholar] [CrossRef]

- Xie, H. A fractal model and energy dissipation for en echel on fractures. J. China Univ. Min. Technol. 1994, 4, 12–19. [Google Scholar]

- Liu, C.; Huang, D.; Wang, L.; Liu, Z.; Zhang, X. Microscopic Stage Characteristics of Rock Creep-Failure Experimental Curve. J. China Coal Soc. 2011, 36 (Suppl. S2), 219–223. [Google Scholar] [CrossRef]

- Li, J.; Rong, L.; Li, H.; Hong, S.N. An SHPB Test Study on Stress Wave Energy Attenuation in Jointed Rock Masses. Rock Mech. Rock Eng. 2019, 52, 403–420. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Q.; Qiao, L. Review of SHPB Dynamic Load Impact Test Characteristics and Energy Analysis Methods. Processes 2023, 11, 3029. [Google Scholar] [CrossRef]

- Wang, W.Y.; Deng, Y.J.; Liu, L.B.; Zhang, L.H.; Yao, Y. Dynamic mechanical properties and energy dissipation analysis of rubber-modified aggregate concrete based on SHPB tests. Constr. Build. Mater. 2024, 445, 137920. [Google Scholar] [CrossRef]

| Density/g·cm−3 | Elastic Modulus/GPa | Uniaxial Compressive Strength/MPa | Tensile Strength/MPa | Poisson’s Ratio | P-Wave Velocity/m·s−1 |

|---|---|---|---|---|---|

| 3.83 | 102.55 | 117.02 | 9.48 | 0.22 | 4465 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jian, X.; Zhao, P.; Li, X.; Wang, J.; Li, Y.; Yang, Y. Energy Dissipation and Damage Evolution of Water-Saturated Skarn Under Impact Loading. Appl. Sci. 2025, 15, 11040. https://doi.org/10.3390/app152011040

Jian X, Zhao P, Li X, Wang J, Li Y, Yang Y. Energy Dissipation and Damage Evolution of Water-Saturated Skarn Under Impact Loading. Applied Sciences. 2025; 15(20):11040. https://doi.org/10.3390/app152011040

Chicago/Turabian StyleJian, Ximing, Pinzhe Zhao, Xianglong Li, Jianguo Wang, Yaohong Li, and Yang Yang. 2025. "Energy Dissipation and Damage Evolution of Water-Saturated Skarn Under Impact Loading" Applied Sciences 15, no. 20: 11040. https://doi.org/10.3390/app152011040

APA StyleJian, X., Zhao, P., Li, X., Wang, J., Li, Y., & Yang, Y. (2025). Energy Dissipation and Damage Evolution of Water-Saturated Skarn Under Impact Loading. Applied Sciences, 15(20), 11040. https://doi.org/10.3390/app152011040