Macroscopic Mechanical Properties and Mesoscopic Structure Evolution of Steel Slag–MSWIBA-Improved Soil Mixture

Abstract

1. Introduction

2. Materials and Methods

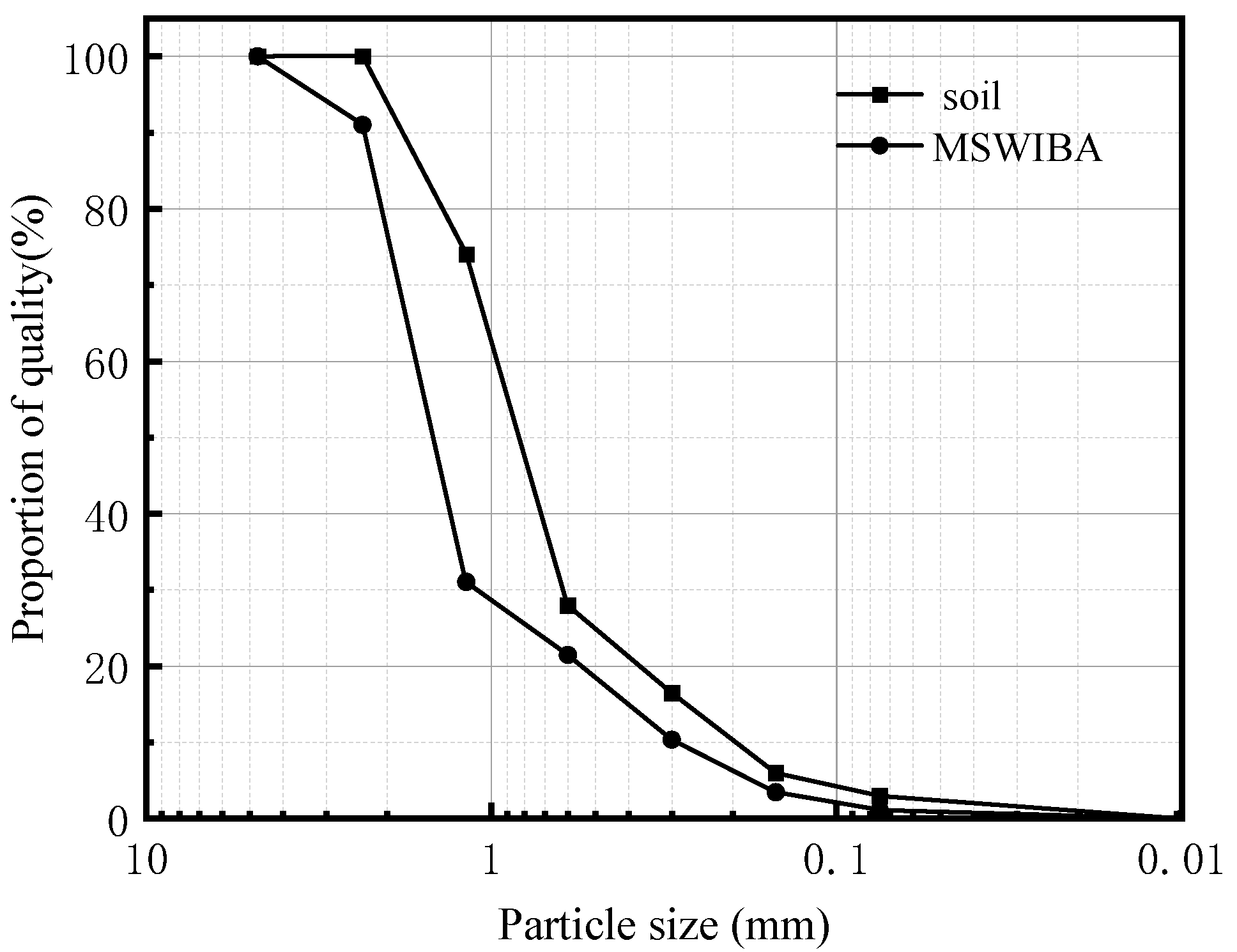

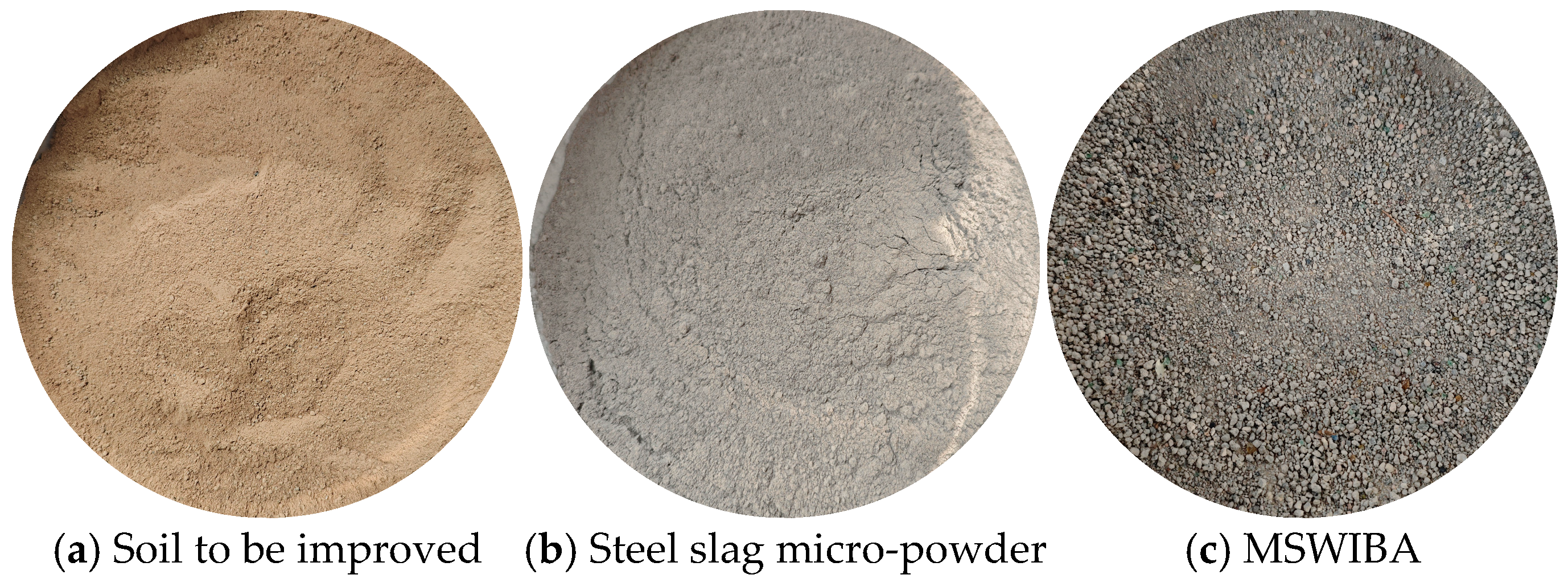

2.1. Experimental Materials

2.2. Test Methods

2.2.1. Sample Preparation

2.2.2. Unconfined Compressive Strength Test

2.2.3. Water Stability Test

2.2.4. California Bearing Ratio (CBR) Test

2.2.5. Freeze–Thaw Cycle Test

2.2.6. Microscopic Analysis

3. Results and Analysis of Macroscopic Performance Tests

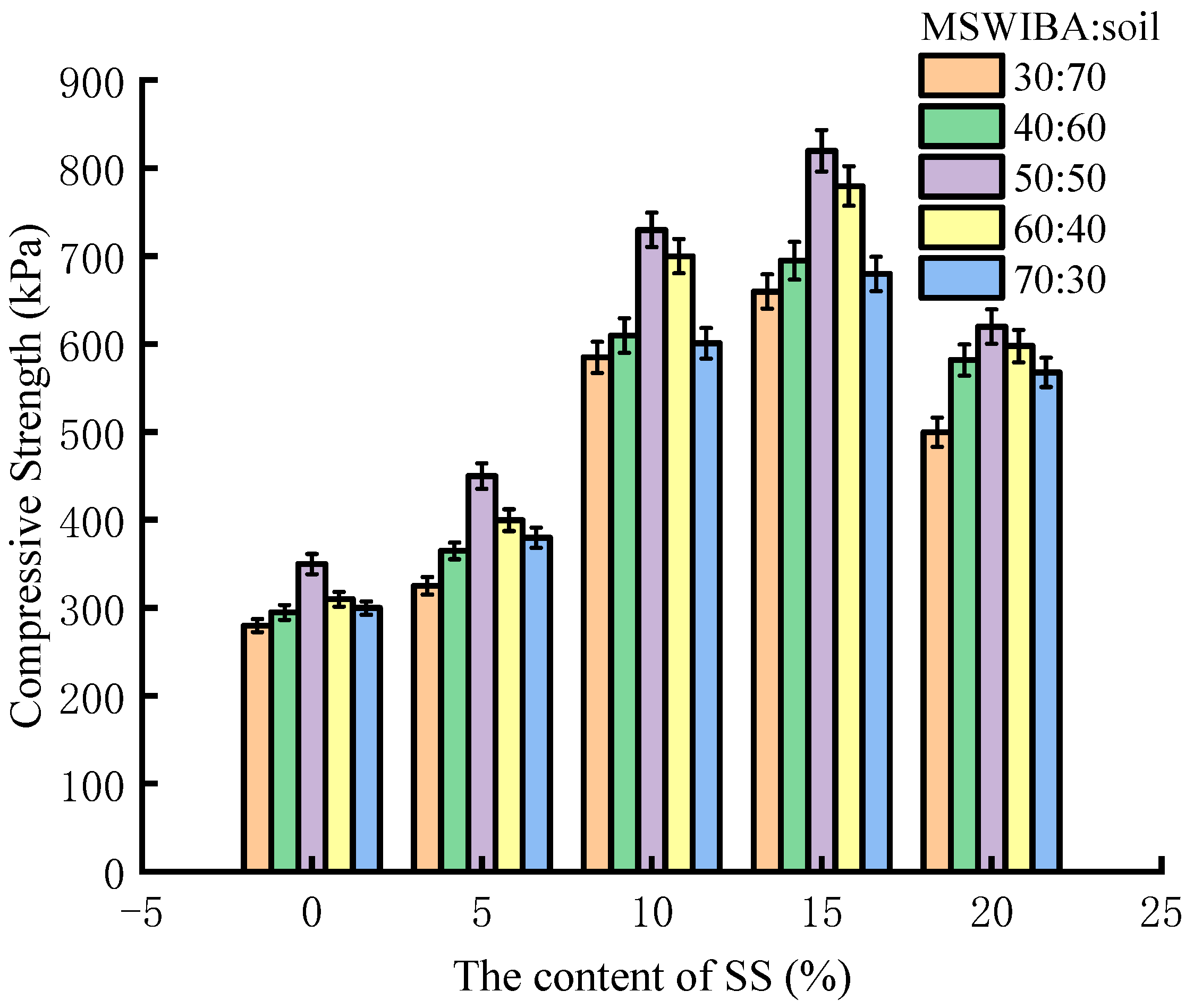

3.1. UCS

3.1.1. Influence of MSWIBA Content

3.1.2. Influence of Steel Slag Content

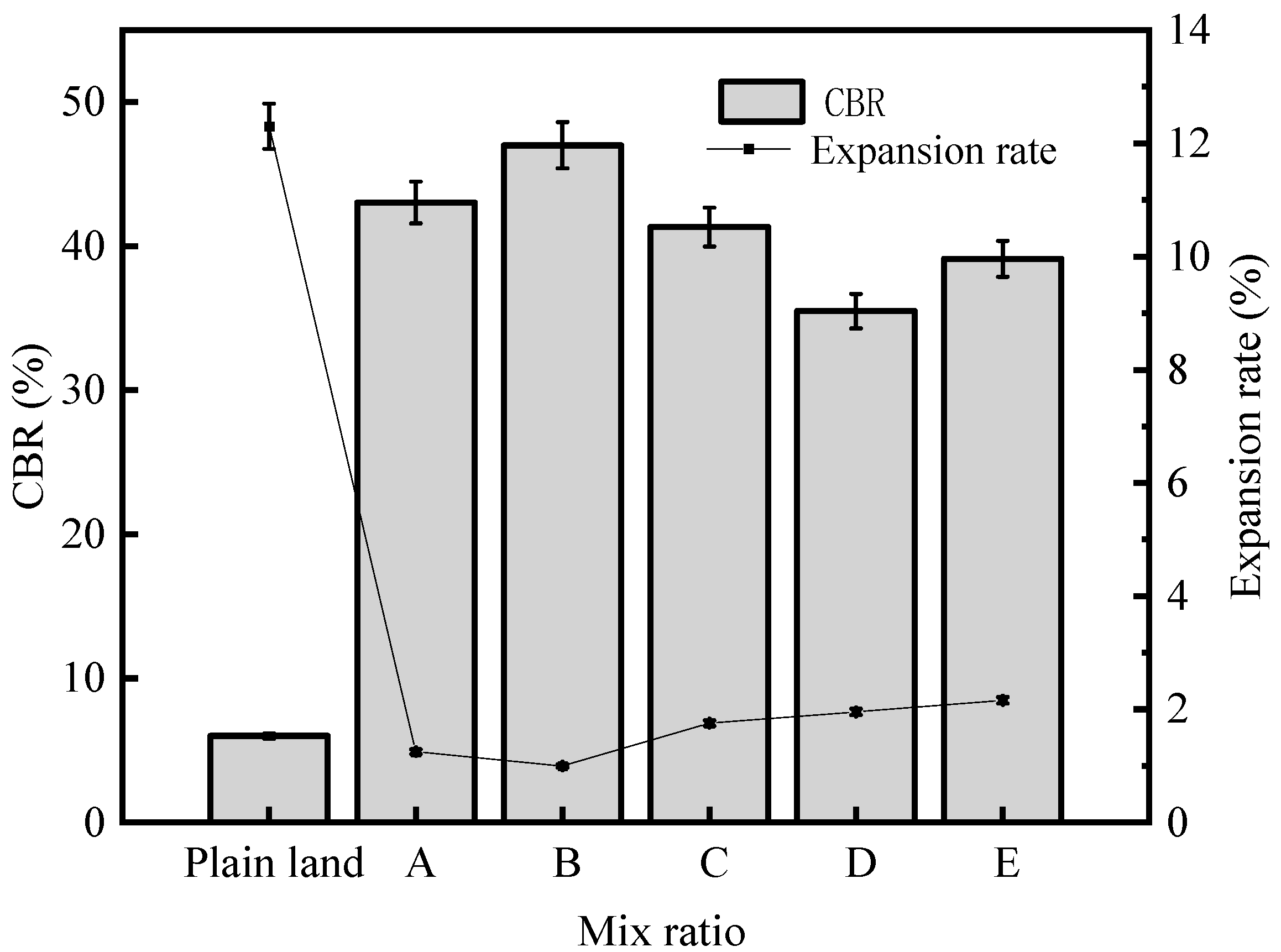

3.2. California Bearing Ratio (CBR)

3.3. Water Stability

3.4. Freeze–Thaw Resistance

3.5. Comparative Analysis with Traditional Base Materials

4. Microscopic Mechanism Analysis

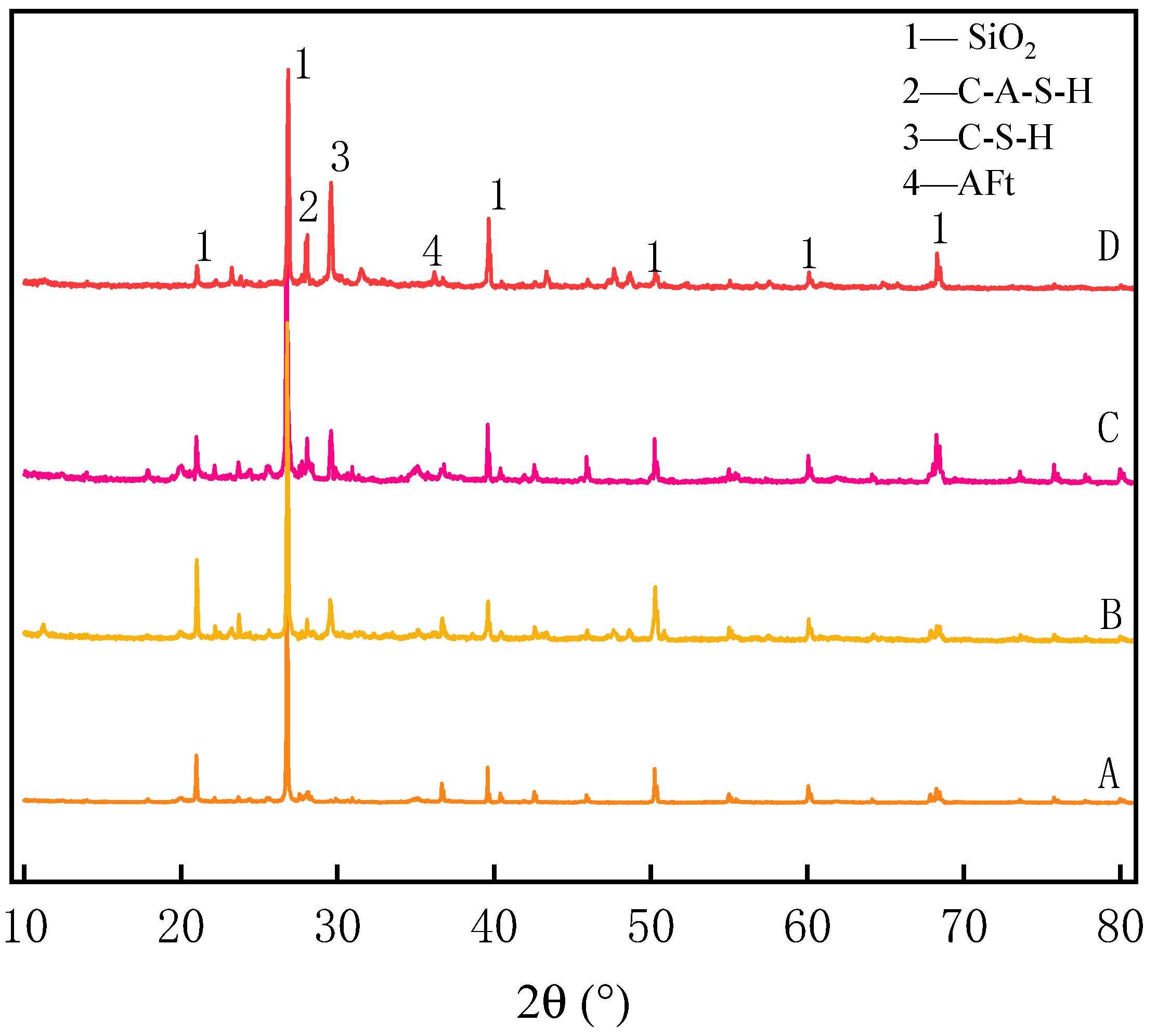

4.1. XRD

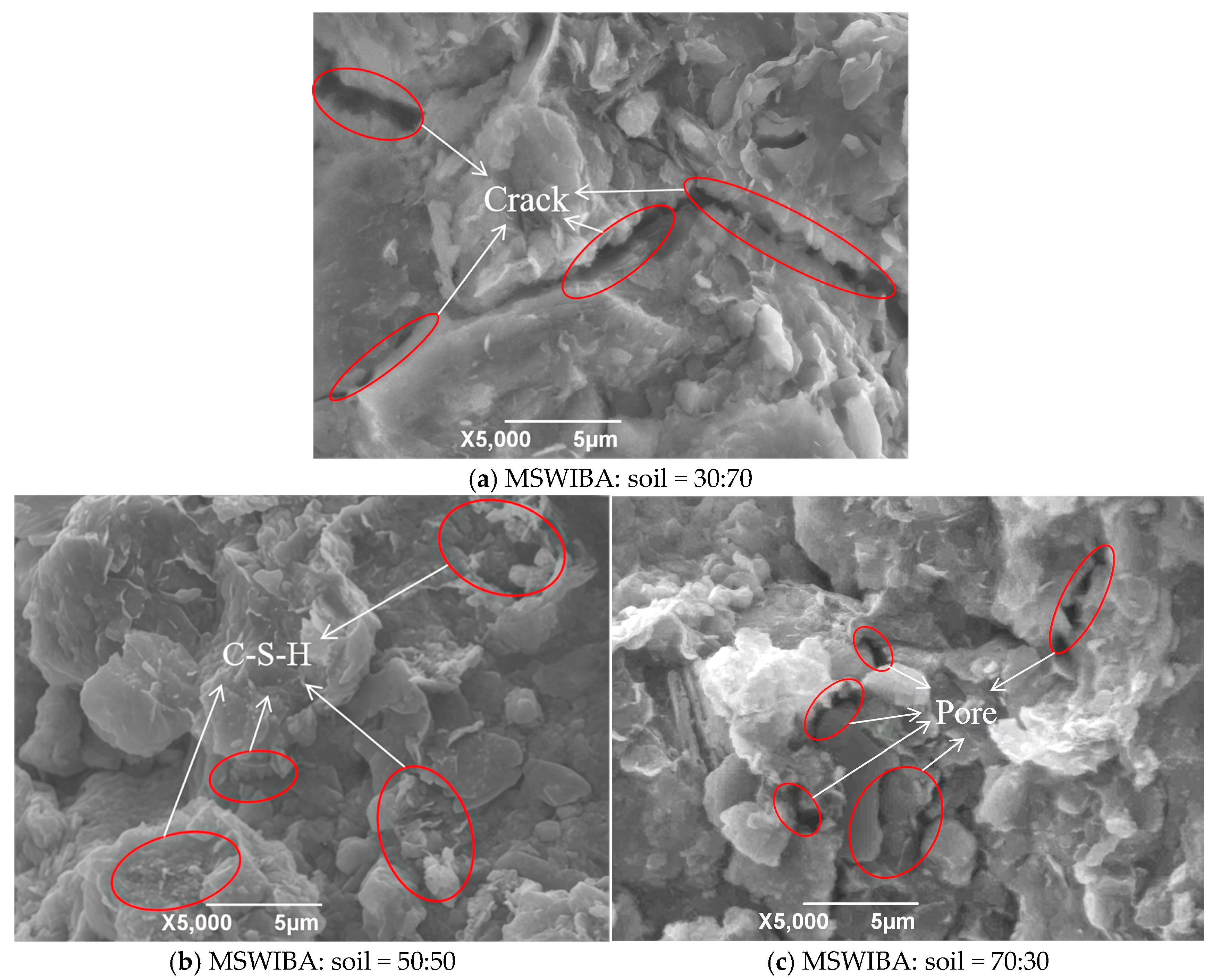

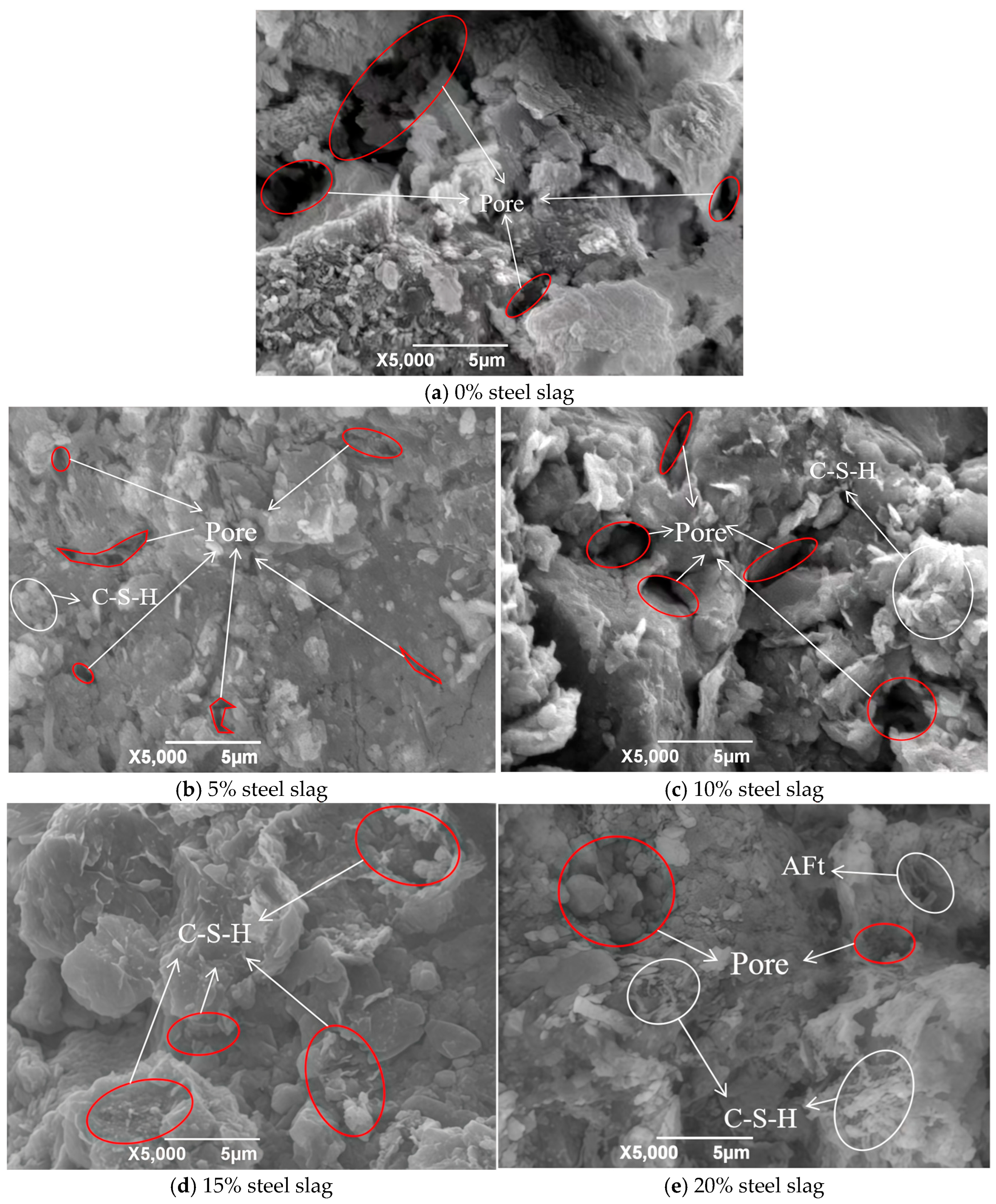

4.2. SEM

5. Discussion

5.1. Practical Viability and Regional Implementation Strategy

5.2. Limitations and Future Research Directions

6. Conclusions

- (1)

- Adding steel slag and MSWIBA can notably enhance the engineering properties of natural soil. As the steel slag content and MSWIBA proportion increase, the 7-day unconfined compressive strength (UCS) and California Bearing Ratio (CBR) of the mixed soil first rise and then decline, while the modified soil shows remarkable water stability.

- (2)

- The optimal mix proportion of steel slag–MSWIBA mixed soil is a 50:50 mass ratio of MSWIBA to natural soil, with an extra 15% steel slag relative to the total mass of MSWIBA and soil. Under this proportion, the 7-day UCS of the mixed soil reaches 0.82 MPa, the 5-day water stability coefficient is 0.91, the strength retention rate after 11 freeze–thaw cycles is 65.3%, the CBR value is 47.1%, and the expansion rate is 1.06%—all satisfying the technical criteria for subgrade fill stipulated in JTG/T F20-2015 Technical Specifications for Construction of Highway Pavement Base Courses and JTG D30-2015 Code for Design of Highway Subgrades.

- (3)

- The mechanism behind the improved performance of the modified soil was uncovered using microscopic testing techniques (XRD and SEM): Ca(OH)2 produced by steel slag hydration activates the pozzolanic activity of vitreous components in MSWIBA, facilitating the secondary formation of C-S-H, C-A-S-H gels, and AFt crystals. The total quantity of cementitious substances is considerably higher than that of soil modified solely with steel slag; the 50:50 MSWIBA-to-soil mass ratio allows for the most compact packing of MSWIBA and soil particles; the hydration products fill the pores and bind the particles together, reducing the expansion stress induced by water phase transition during freeze–thaw cycles, and establishing a dynamic balance of “early microcrack initiation–late cementitious product repair” to guarantee structural stability.

- (4)

- The findings of this study demonstrate the short-term viability of the steel slag–MSWIBA mixture. However, it is acknowledged that the conclusions have two key limitations: first, they are based on a specific material source and limited testing duration (e.g., 7-day UCS, 11 freeze–thaw cycles), and second, discussions on the long-term leaching behavior of heavy metals (a critical aspect of environmental impact) are only hypothetical and theoretical—in this study, long-term leaching experiments were not conducted, and relevant environmental risk assessments rely primarily on short-term TCLP data. This limitation must be addressed by subsequent long-term leaching monitoring experiments to fully validate the long-term environmental safety of the mixture. Beyond this, the long-term mechanical performance and in situ behavior under field traffic and environmental conditions also require further investigation through the research directions outlined in the discussion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bendixen, M.; Iversen, L.L.; Best, J.; Franks, D.M.; Hackney, C.R.; Latrubesse, E.M.; Tusting, L.S. Sand, Gravel, and UN Sustainable Development Goals: Conflicts, Synergies, and Pathways Forward. One Earth 2021, 4, 1095–1111. [Google Scholar] [CrossRef]

- Wu, Z.; Zhao, Z.; Duan, W.; Pu, S.; Chu, Y.; Liu, X.; Chen, R.; Li, T. Utilization of Tailings Sand in Sustainable Cement-Based Materials: A Comprehensive Review and Potential Challenges. Arab. J. Sci. Eng. 2025, 50, 16297–16332. [Google Scholar] [CrossRef]

- Yatoo, A.M.; Hamid, B.; Sheikh, T.A.; Ali, S.; Bhat, S.A.; Ramola, S.; Ali, M.N.; Baba, Z.A.; Kumar, S. Global Perspective of Municipal Solid Waste and Landfill Leachate: Generation, Composition, Eco-Toxicity, and Sustainable Management Strategies. Environ. Sci. Pollut. Res. 2024, 31, 23363–23392. [Google Scholar] [CrossRef] [PubMed]

- Trindade, A.B.; Palacio, J.C.E.; González, A.M.; Rúa Orozco, D.J.; Lora, E.E.S.; Renó, M.L.G.; Del Olmo, O.A. Advanced Exergy Analysis and Environmental Assesment of the Steam Cycle of an Incineration System of Municipal Solid Waste with Energy Recovery. Energy Convers. Manag. 2018, 157, 195–214. [Google Scholar] [CrossRef]

- Węgliński, S.; Martysz, G. Utilization of Municipal Solid Waste Incineration Bottom Ash in Cement-Bound Mixtures. Sustainability 2024, 16, 1865. [Google Scholar] [CrossRef]

- Bandarra, B.S.; Silva, S.; Pereira, J.L.; Martins, R.C.; Quina, M.J. A Study on the Classification of a Mirror Entry in the European List of Waste: Incineration Bottom Ash from Municipal Solid Waste. Sustainability 2022, 14, 10352. [Google Scholar] [CrossRef]

- Lan, T.; Meng, Y.; Ju, T.; Chen, Z.; Du, Y.; Deng, Y.; Song, M.; Han, S.; Jiang, J. Synthesis and Application of Geopolymers from Municipal Waste Incineration Fly Ash (MSWI FA) as Raw Ingredient—A Review. Resour. Conserv. Recycl. 2022, 182, 106308. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.; Chen, L.; Ma, B.; Zhang, Y.; Ni, W.; Tsang, D.C.W. Treatment of Municipal Solid Waste Incineration Fly Ash: State-of-the-Art Technologies and Future Perspectives. J. Hazard. Mater. 2021, 411, 125132. [Google Scholar] [CrossRef]

- Cheng, Y.; Gao, G.; Chen, L.; Du, W.; Mu, W.; Yan, Y.; Sun, H. Physical and Mechanical Study of Municipal Solid Waste Incineration (MSWI) Bottom Ash with Different Particle Size Distribution. Constr. Build. Mater. 2024, 416, 135137. [Google Scholar] [CrossRef]

- Xue, M.; Hu, W.; Huanyu, L.; Fu, Y. Beneficial Reuse of Municipal Solid Waste Incineration Bottom Slag in Civil Engineering. Eng. Technol. Appl. Sci. Res. 2022, 12, 8306–8310. [Google Scholar] [CrossRef]

- Quina, M.J.; Bordado, J.C.; Quinta-Ferreira, R.M. Treatment and Use of Air Pollution Control Residues from MSW Incineration: An Overview. Waste Manag. 2008, 28, 2097–2121. [Google Scholar] [CrossRef]

- Jike, N.; Xu, C.; Yang, R.; Qi, Y.; Dai, Y.; Peng, Y.; Wang, J.; Zhang, M.; Zeng, Q. Pervious Concrete with Secondarily Recycled Low-Quality Brick-Concrete Demolition Residue: Engineering Performances, Multi-Scale/Phase Structure and Sustainability. J. Clean. Prod. 2022, 341, 130929. [Google Scholar] [CrossRef]

- Bawab, J.; Khatib, J.; Kenai, S.; Sonebi, M. A Review on Cementitious Materials Including Municipal Solid Waste Incineration Bottom Ash (MSWI-BA) as Aggregates. Buildings 2021, 11, 179. [Google Scholar] [CrossRef]

- Arm, M. Variation in Mechanical Properties of MSW Incinerator Bottom Ash. In Waste Management Series; Elsevier: Amsterdam, The Netherlands, 2000; Volume 1, pp. 567–578. ISBN 978-0-08-043790-3. [Google Scholar]

- Hredoy, R.H.; Siddique, M.A.B.; Akbor, M.A.; Shaikh, M.A.A.; Rahman, M.M. Impacts of Landfill Leachate on the Surrounding Environment: A Case Study on Amin Bazar Landfill, Dhaka (Bangladesh). Soil Syst. 2022, 6, 90. [Google Scholar] [CrossRef]

- Wang, Q.; Ko, J.H.; Liu, F.; Xu, Q. Leaching Characteristics of Heavy Metals in MSW and Bottom Ash Co-Disposal Landfills. J. Hazard. Mater. 2021, 416, 126042. [Google Scholar] [CrossRef] [PubMed]

- Verbinnen, B.; Van Caneghem, J.; Billen, P.; Vandecasteele, C. Long Term Leaching Behavior of Antimony from MSWI Bottom Ash: Influence of Mineral Additives and of Organic Acids. Waste Biomass Valorization 2017, 8, 2545–2552. [Google Scholar] [CrossRef]

- Zhang, S.; Ghouleh, Z.; He, Z.; Hu, L.; Shao, Y. Use of Municipal Solid Waste Incineration Bottom Ash as a Supplementary Cementitious Material in Dry-Cast Concrete. Constr. Build. Mater. 2021, 266, 120890. [Google Scholar] [CrossRef]

- Xuan, D.; Tang, P.; Poon, C.S. MSWIBA-Based Cellular Alkali-Activated Concrete Incorporating Waste Glass Powder. Cem. Concr. Compos. 2019, 95, 128–136. [Google Scholar] [CrossRef]

- Chyan, J.M.; Lin, C.J.; Yu, M.J.; Shiu, R.-F.; Huang, D.J.; Lin, C.S.; Senoro, D.B. An Innovative Reuse of Bottom Ash from Municipal Solid Waste Incinerators as Substrates of Constructed Wetlands. Chemosphere 2022, 307, 135896. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Li, Z.; Zhang, W.; Jin, H.; Xing, F.; Tang, L. Novel Recycling Application of High Volume Municipal Solid Waste Incineration Bottom Ash (MSWIBA) into Sustainable Concrete. Sci. Total Environ. 2022, 838, 156124. [Google Scholar] [CrossRef]

- Shi, C.; Li, J.; Sun, S.; Han, H. Research on Pavement Performance of Cement-Stabilized Municipal Solid Waste Incineration Bottom Ash Base. Materials 2022, 15, 8614. [Google Scholar] [CrossRef]

- Vaitkus, A.; Gražulytė, J.; Šernas, O.; Vorobjovas, V.; Kleizienė, R. An Algorithm for the Use of MSWI Bottom Ash as a Building Material in Road Pavement Structural Layers. Constr. Build. Mater. 2019, 212, 456–466. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, F. Experimental Study on the Influence of Curing Conditions on the Mechanical Performance of Municipal Solid Waste Incinerated-Bottom Ash (MSWI-BA). Environ. Sci. Pollut. Res. 2023, 30, 89101–89113. [Google Scholar] [CrossRef] [PubMed]

- Sormunen, L.A.; Kolisoja, P. Construction of an Interim Storage Field Using Recovered Municipal Solid Waste Incineration Bottom Ash: Field Performance Study. Waste Manag. 2017, 64, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.; Kwon, E.E.; Lee, J. Upcycling Steel Slag into Construction Materials. Constr. Build. Mater. 2024, 444, 137882. [Google Scholar] [CrossRef]

- Li, L.L.; Zhao, F.Q.; Liu, S.J. The Activation of Steel Slag and Its Application in Construction and Building Materials. Adv. Mater. Res. 2014, 884–885, 702–705. [Google Scholar] [CrossRef]

- O’Connor, J.; Nguyen, T.B.T.; Honeyands, T.; Monaghan, B.; O’Dea, D.; Rinklebe, J.; Vinu, A.; Hoang, S.A.; Singh, G.; Kirkham, M.B.; et al. Production, Characterisation, Utilisation, and Beneficial Soil Application of Steel Slag: A Review. J. Hazard. Mater. 2021, 419, 126478. [Google Scholar] [CrossRef]

- Devnita, R.; Arifin, M. Utilization of Steel Slag in Improving Soil Characteristics. Int. J. Agric. Environ. Bioresearch 2024, 9, 125–136. [Google Scholar] [CrossRef]

- TozsiN, G.; Öztaş, T. Utilization of Steel Slag as a Soil Amendment and Mineral Fertilizer in Agriculture: A Review. Tarım Bilim. Derg. 2023, 29, 906–913. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Q.; Deng, Y.; Yu, X.; Feng, Q.; Yan, C. Expansive Soil Modified by Waste Steel Slag and Its Application in Subbase Layer of Highways. Soils Found. 2019, 59, 955–965. [Google Scholar] [CrossRef]

- Xu, W.; Zhu, Y.; Kang, H.; Xu, Q.; Han, Q.; Song, X.; Liu, Z. Study on the Cyclic Shear Performance of Waste Steel Slag Mixed Soil. Buildings 2023, 13, 3133. [Google Scholar] [CrossRef]

- Kumar, H.; Varma, S. A Review on Utilization of Steel Slag in Hot Mix Asphalt. Int. J. Pavement Res. Technol. 2021, 14, 232–242. [Google Scholar] [CrossRef]

- Kedar, H.N.; Patel, S.; Shirol, S.S. Bulk Utilization of Steel Slag–Fly Ash Composite: A Sustainable Alternative for Use as Road Construction Materials. Innov. Infrastruct. Solut. 2024, 9, 21. [Google Scholar] [CrossRef]

- Aziz, M.M.A.; Hainin, M.R.; Yaacob, H.; Ali, Z.; Chang, F.-L.; Adnan, A.M. Characterisation and Utilisation of Steel Slag for the Construction of Roads and Highways. Mater. Res. Innov. 2014, 18, S6-255–S6-259. [Google Scholar] [CrossRef]

- Song, Q.; Guo, M.-Z.; Wang, L.; Ling, T.-C. Use of Steel Slag as Sustainable Construction Materials: A Review of Accelerated Carbonation Treatment. Resour. Conserv. Recycl. 2021, 173, 105740. [Google Scholar] [CrossRef]

- Verbinnen, B.; Billen, P.; Van Caneghem, J.; Vandecasteele, C. Recycling of MSWI Bottom Ash: A Review of Chemical Barriers, Engineering Applications and Treatment Technologies. Waste Biomass Valorization 2017, 8, 1453–1466. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Li, X.; Jiang, Y. Leaching Behavior of Heavy Metals and PAHs from MSWI Bottom Ash in a Long-Term Static Immersing Experiment. Waste Manag. 2008, 28, 1126–1136. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhang, J.; Zhang, L. Accelerated Carbonation of Steel Slag: A Review of Methods, Mechanisms and Influencing Factors. Constr. Build. Mater. 2024, 411, 134603. [Google Scholar] [CrossRef]

- Sun, Y.; Zhong, Y.; Liao, J.; Gao, Y.; Huang, C. Life Cycle Assessment of Asphalt Pavement Containing MSWI Bottom Ash. Sci. Rep. 2025, 15, 12481. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P. Hydration Properties of Basic Oxygen Furnace Steel Slag. Constr. Build. Mater. 2010, 24, 1134–1140. [Google Scholar] [CrossRef]

- George, S.Z.; Ponniah, D.A.; Little, J.A. Effect of Temperature on Lime-Soil Stabilization. Constr. Build. Mater. 1992, 6, 247–252. [Google Scholar] [CrossRef]

- Amakye, S.Y.O.; Abbey, S.J.; Booth, C.A.; Oti, J. Performance of Sustainable Road Pavements Founded on Clay Subgrades Treated with Eco-Friendly Cementitious Materials. Sustainability 2022, 14, 12588. [Google Scholar] [CrossRef]

- 1999/31/EC; Council Directive 1999/31/EC on the Landfill of Waste. European Union: Brussels, Belgium, 1999.

- JTG E51-2019; Specification for Test Methods of Inorganic Binder Stabilized Materials for Highway Engineering. China Communications Press: Beijing, China, 2019.

- CJ/T 486-2015; Soil Stabilization Admixtures. Standardization Administration of China: Beijing, China, 2015.

- JTG D30-2015; Code for Design of Highway Subgrades. China Communications Press: Beijing, China, 2015.

- JTG/T F20-2015; Technical Specifications for Construction of Highway Pavement Base Courses. China Communications Press: Beijing, China, 2015.

| Component | SiO2 | Fe2O3 | Al2O3 | MgO | CaO | K2O | Na2O | P2O5 | Other |

|---|---|---|---|---|---|---|---|---|---|

| Content/% | 39.96 | 4.45 | 10.02 | 3.75 | 31.55 | 2.05 | 2.79 | 2.88 | 2.55 |

| Control Index | Ba | Cd | Cr | Cu | Pb | Zn |

|---|---|---|---|---|---|---|

| Measured Value | 0.459 | 0.021 | 0.4328 | 1.0035 | 0.034 | 8.5893 |

| Chinese Standard Limit (GB) | 100 | 1 | 5 | 100 | 5 | 100 |

| U.S. EPA TCLP Regulatory Limit | 100 | 1 | 5 | - | 5 | - |

| EU Landfill Directive (1999/31/EC) for Inert Waste | 20 | 0.04 | 0.5 | 2 | 0.5 | 4 |

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | MnO | P2O5 | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|---|

| Content/% | 58.85 | 12.80 | 5.21 | 14.39 | 2.63 | 2.20 | 1.51 | 0.92 | 0.31 |

| MSWIBA-to-Soil Mass Ratio (%) | Steel Slag Content 1 (%) |

|---|---|

| 30, 40, 50, 60, 70 | 0, 5, 10, 15, 20 |

| MSWIBA-to-Soil Mass Ratio | Steel Slag Content (%) | Soaking Days (d) Value (Mean ± SD) | ||

|---|---|---|---|---|

| 1 | 3 | 5 | ||

| 50:50 | 10 | 0.94 (±0.02) | 0.91 (±0.01) | 0.89 (±0.01) |

| 15 | 0.96 (±0.01) | 0.94 (±0.02) | 0.91 (±0.01) | |

| 20 | 0.93 (±0.02) | 0.91 (±0.02) | 0.88 (±0.01) | |

| 30:70 | 10 | 0.92 (±0.01) | 0.89 (±0.01) | 0.87 (±0.02) |

| 15 | 0.94 (±0.01) | 0.92 (±0.01) | 0.90 (±0.02) | |

| 20 | 0.92 (±0.02) | 0.90 (±0.01) | 0.87 (±0.01) | |

| 70:30 | 10 | 0.93 (±0.03) | 0.90 (±0.02) | 0.88 (±0.02) |

| 15 | 0.95 (±0.02) | 0.92 (±0.01) | 0.91 (±0.01) | |

| 20 | 0.94 (±0.01) | 0.91 (±0.02) | 0.89 (±0.01) | |

| 0:100 | Disintegration | |||

| Material Type | UCS (7-Day) | (CBR) % | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Natural Gravel | 0.5–1.0 MPa | 20–30 | Excellent drainage; Readily available. | High cost; Resource depletion. |

| Cement-Stabilized Soil | 1.0–2.0 MPa (with 5–10% cement) | 50–100 | High strength; Established practice. | High carbon footprint; Shrinkage cracks. |

| Proposed Mixture (Optimum) | 0.82 MPa | 47.1 | Waste utilization; Low cost; Eco-friendly. | Lower strength than cement-based materials. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, G.; Shao, F.; Zhang, H.; Bai, Y.; Li, Y. Macroscopic Mechanical Properties and Mesoscopic Structure Evolution of Steel Slag–MSWIBA-Improved Soil Mixture. Appl. Sci. 2025, 15, 11033. https://doi.org/10.3390/app152011033

Xiang G, Shao F, Zhang H, Bai Y, Li Y. Macroscopic Mechanical Properties and Mesoscopic Structure Evolution of Steel Slag–MSWIBA-Improved Soil Mixture. Applied Sciences. 2025; 15(20):11033. https://doi.org/10.3390/app152011033

Chicago/Turabian StyleXiang, Guosheng, Feiyang Shao, Hongri Zhang, Yunze Bai, and Youjun Li. 2025. "Macroscopic Mechanical Properties and Mesoscopic Structure Evolution of Steel Slag–MSWIBA-Improved Soil Mixture" Applied Sciences 15, no. 20: 11033. https://doi.org/10.3390/app152011033

APA StyleXiang, G., Shao, F., Zhang, H., Bai, Y., & Li, Y. (2025). Macroscopic Mechanical Properties and Mesoscopic Structure Evolution of Steel Slag–MSWIBA-Improved Soil Mixture. Applied Sciences, 15(20), 11033. https://doi.org/10.3390/app152011033