Analysis of the Effects of Weld Melt Duration on Joint Integrity and Surface Quality During Profile Milling

Abstract

1. Introduction

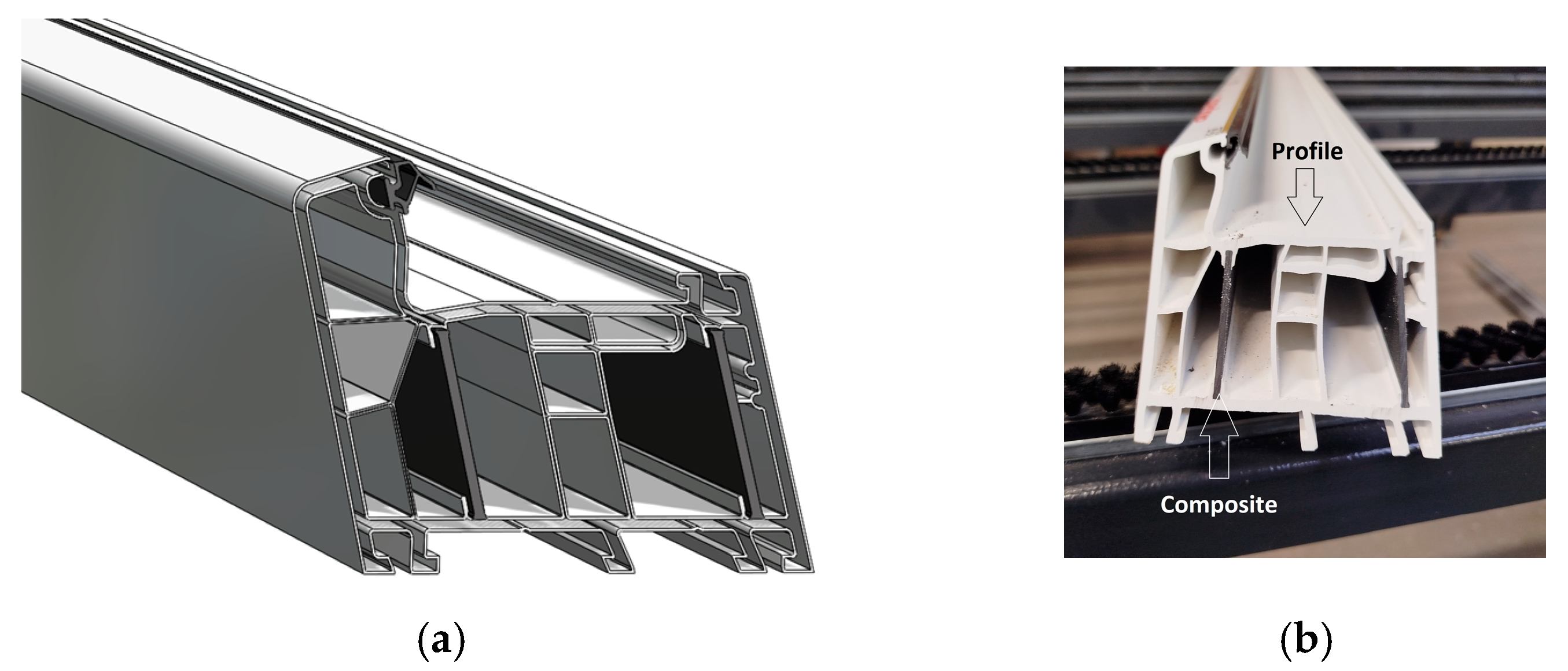

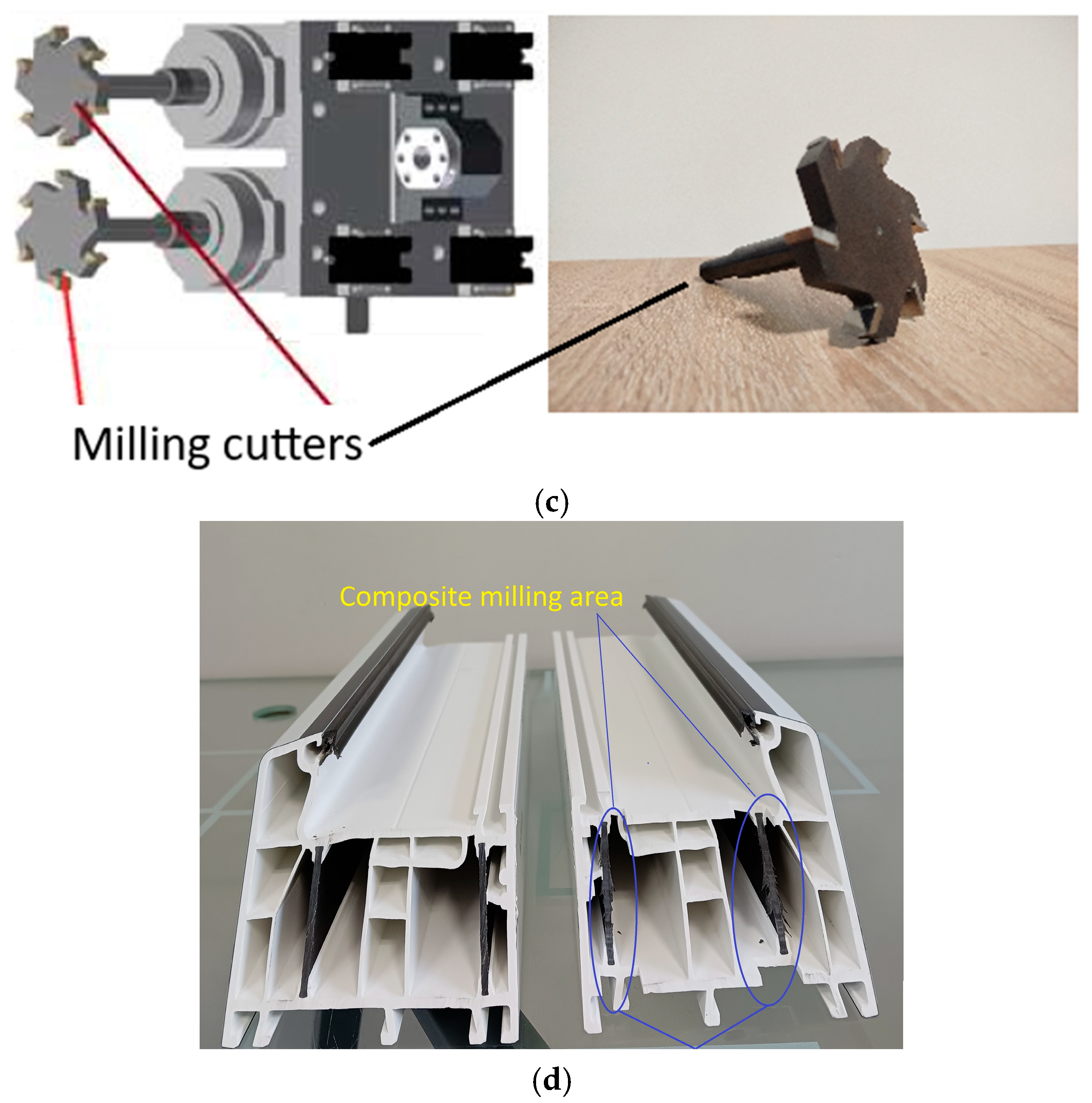

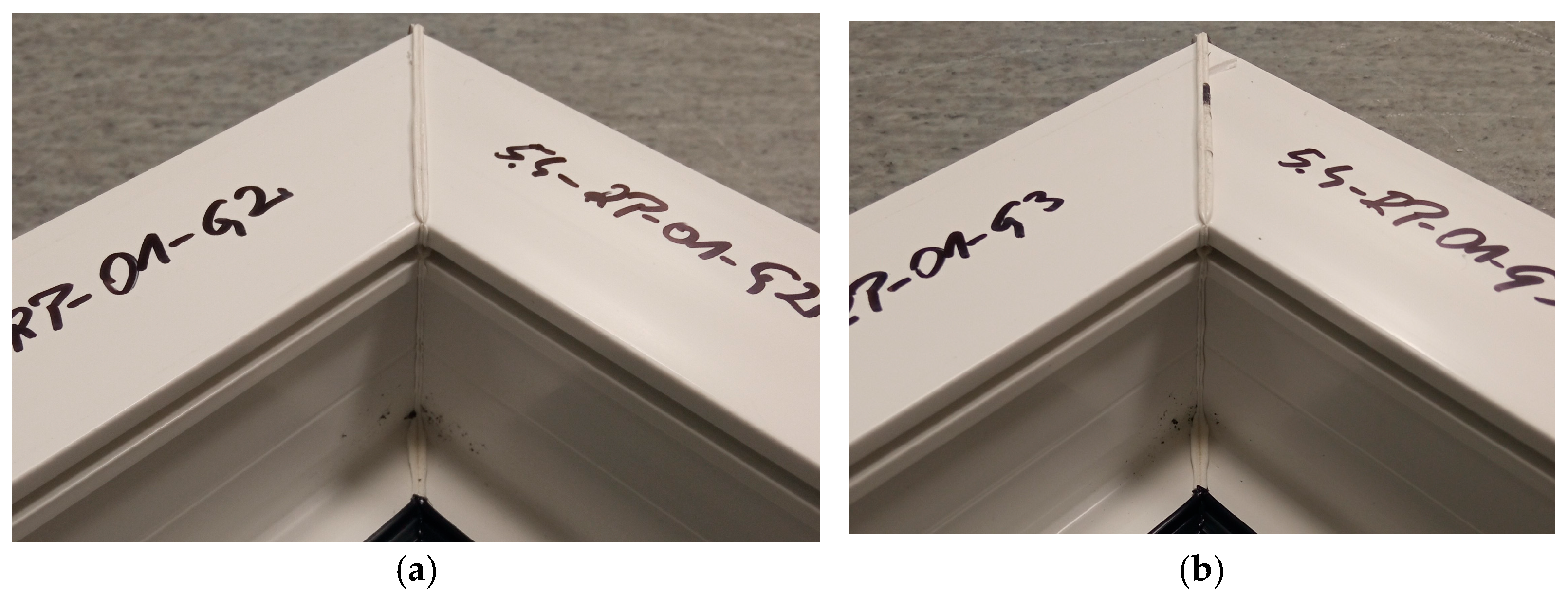

2. Materials and Methods

2.1. Research Plan

2.2. Materials and Test Benches

3. Analysis of Results and Discussion

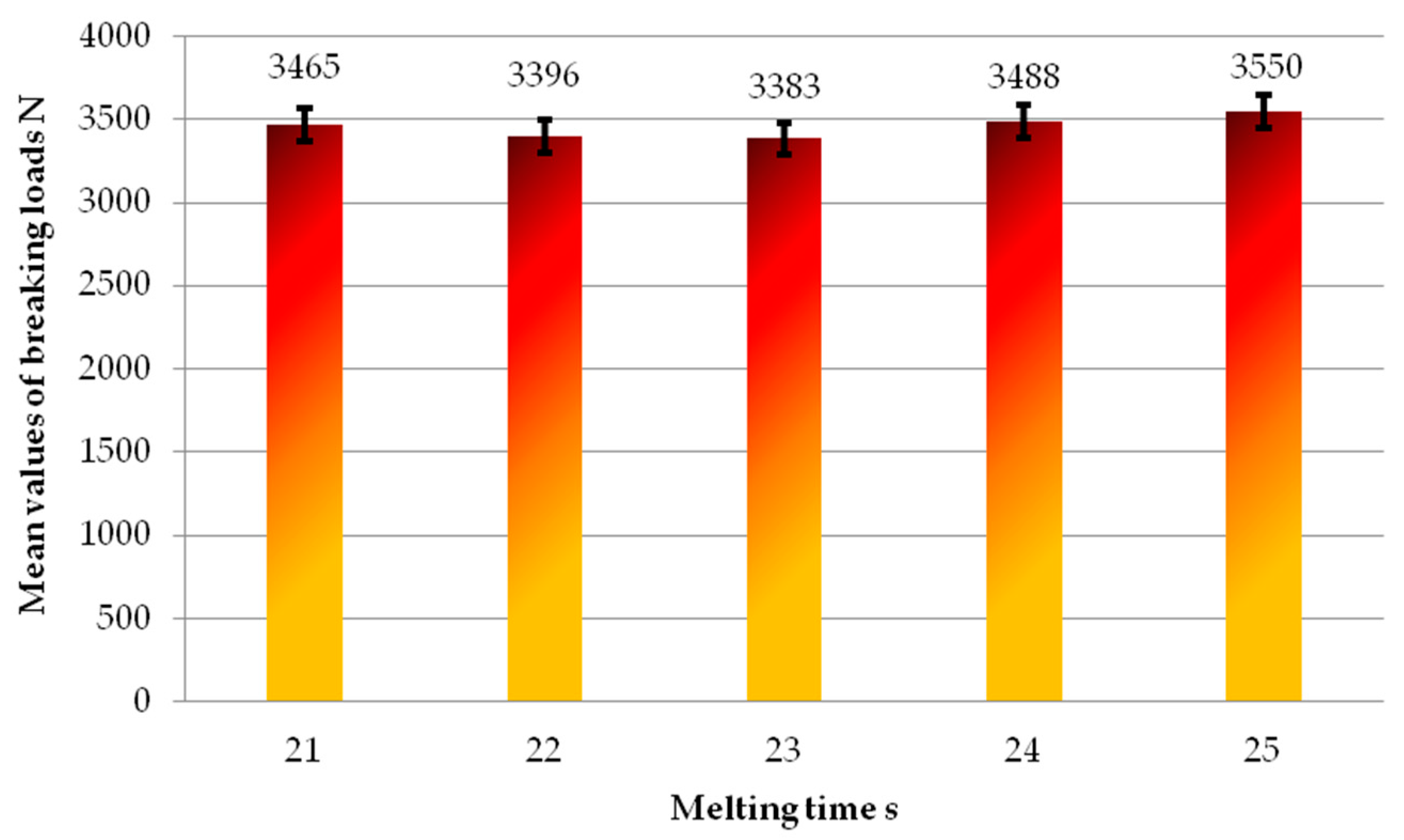

3.1. Comparison of the Average Failure Loads of Sets of Specimens, in the Context of a Given Melting Time, for a Milling Depth of 1 mm for the Glass Fibre-Reinforced Composite

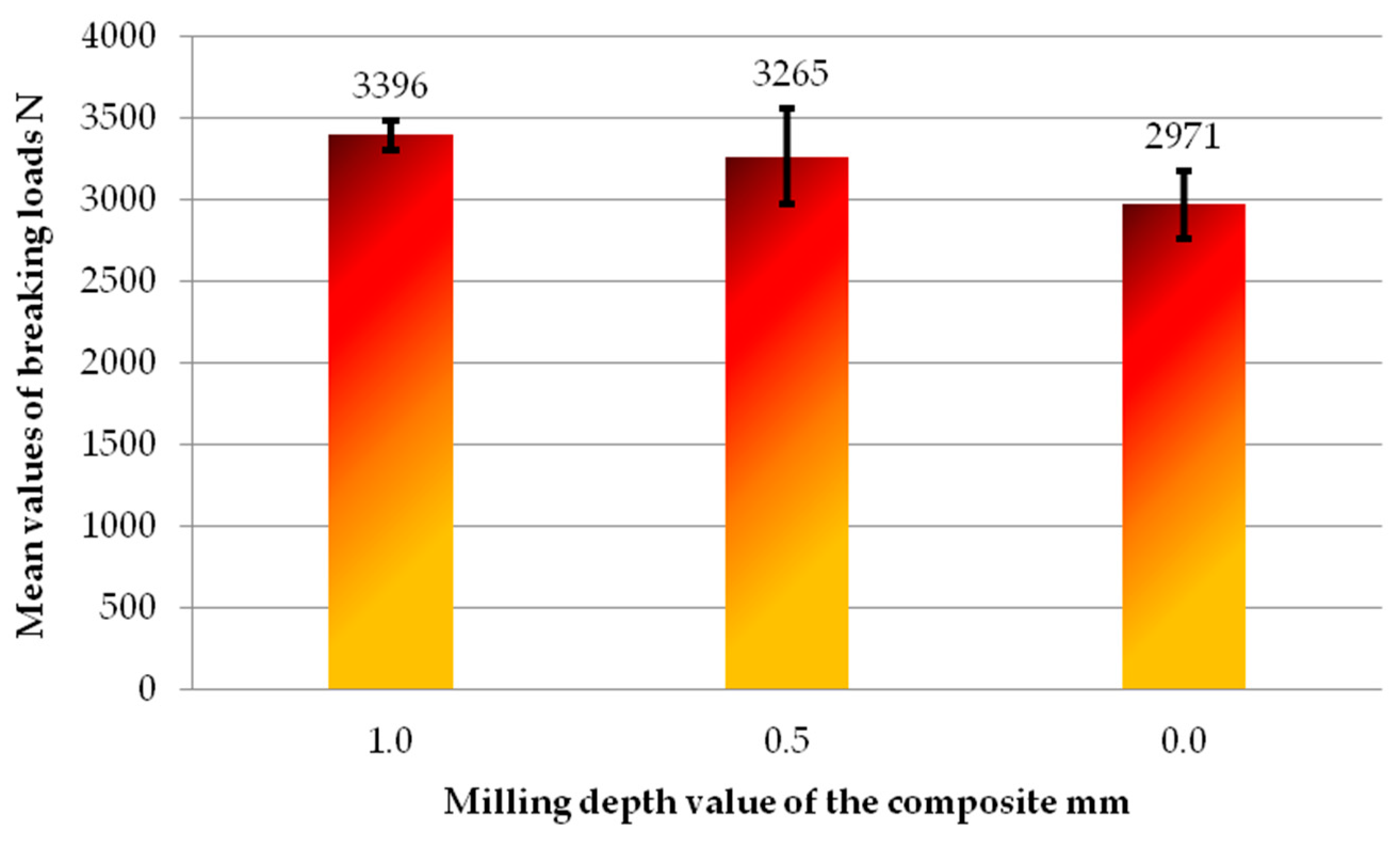

3.2. Comparison of the Average Failure Loads of Sets of Specimens, in the Context of a Given Melting Time of 22 s, for Different Milling Depths of the Glass Fibre Reinforced Composite

3.3. Comparison of the Dimensional Tolerances of Individual Sample Sets

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maria Obłój-Muzaj, M.; Świerz-Motysia, B. Polichlorek Winylu; WNT: Warsaw, Poland, 2016. [Google Scholar]

- Letcher, T. Plastic Waste and Recycling: Environmental Impact, Societal Issues, Prevention, and Solutions, 1st ed.; Academic Press: New York, NY, USA, 2020. [Google Scholar]

- Bhatia, S. Natural Polymers vs. Synthetic Polymer. In Natural Polymer Drug Delivery Systems; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, R.K. Fundamentals of Polymer Engineering, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar] [CrossRef]

- Shrivastava, A. Introduction to Plastics Engineering; William Andrew: New York, NY, USA, 2018. [Google Scholar]

- Carraher, C.E., Jr. Introduction to Polymer Chemistry, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Haque, M.S.; Siddiqui, M.A. Plastic Welding: Important Facts and Developments. Am. J. Mech. Ind. Eng. 2016, 1, 15–19. Available online: https://www.researchgate.net/publication/311544789_Plastic_Welding_Important_Facts_and_Developments (accessed on 15 March 2025).

- Konstantinov, A.; Aksenov, I. Engineering Method for Calculating Temperature Deformations of PVC Window Profiles with a Reinforcing Steel Core. Buildings 2023, 13, 1466. [Google Scholar] [CrossRef]

- Publications Office of the European Union. The Use of PVC (Poly Vinyl Chloride) in the Context of a Non-Toxic Environment; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Wygoda, M.; Paprocki, M.; Adamczyk, W. Influence of the Welding Process on the Quality of PVC Frames. Manuf. Technol. 2022, 22, 356–366. [Google Scholar] [CrossRef]

- Potente, H.; Schnieders, J. Influence of Process Parameters on the Phenomenon of Stress Cracking during Hot Plate Welding. J. Reinf. Plast. Compos. 2002, 21, 489–496. [Google Scholar] [CrossRef]

- PN-EN 514:2018; Plastics–Poly(Winyl Chloride) (PVC) Based Profiles–Determination of the Strength of Welded Corners and T-Joints. Polish Committee for Standardization: Warsaw, Poland, 2018.

- PN-EN 12608-1:2016+A1:2020; Unplasticized Poly(vinyl chloride) (PVC-U) Profiles for the Fabrication of Windows and Doors-Classification, Requirements and Test Methods-Part 1: Non-Coated PVC-U Profiles with Light Coloured Surfaces. Polish Committee for Standardization: Warsaw, Poland, 2021.

- Postawa, P.; Stachowiak, T.; Gnatowski, A. Strength Analysis of Welded Corners of PVC Window Profiles. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012003. [Google Scholar] [CrossRef]

- Villegas, I.F. In situ monitoring of ultrasonic welding of thermoplastic composites through power and displacement data. J. Thermoplast. Compos. Mater. 2015, 28, 66–85. [Google Scholar] [CrossRef]

- Sánchez, H.; Sánchez, P.; Estrems, M. SCADA System Improvement in PVC High-Frequency Plastic Welding. Int. J. Adv. Manuf. Technol. 2009, 40, 84–94. [Google Scholar] [CrossRef]

- Tsujino, J.; Tanaka, R.; Ueoka, T.; Hongoh, M.; Onoguchi, R. Ultrasonic Plastic Welding Using Fundamental and Higher Resonance Frequencies. Ultrasonics 2002, 40, 375–378. [Google Scholar] [CrossRef]

- Hou, M.; Friedrich, K. Resistance Welding of Continuous Glass Fibre-Reinforced Polypropylene Composites. Compos. Manuf. 1992, 3, 153–163. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L. Resistance Welding of Thermosetting Composite/Thermoplastic Composite Joints. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1603–1612. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L.; Hou, M. Experimental Investigation of the Resistance Welding for Thermoplastic-Matrix Composites. Part I: heating element and heat transfer. Compos. Sci. Technol. 2000, 60, 1027–1039. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L.; Hou, M.; Mai, Y. Characteristics of Resistance Welding of Lap Shear Coupons. Part I: Heat transfer. Compos. Part A Appl. Sci. Manuf. 1998, 29, 899–909. [Google Scholar] [CrossRef]

- Dashatan, S.; Azdast, T.; Rash-Ahmadi, S.; Bagheri, A. Friction Stir Spot Welding of Dissimilar Polymethyl Methacrylate and Acrylonitrile Butadiene Styrene Sheets. Mater. Des. 2013, 45, 135–141. [Google Scholar] [CrossRef]

- Hou, M.; Beehag, A.; Mai, Y.; Yang, M. Resistance Welding of Carbon Fibre Reinforced Thermoplastic Composite Using Alternative Heating Element. Compos. Struct. 1999, 47, 667–672. [Google Scholar] [CrossRef]

- Rejman, E.; Kiełbasa, B.; Smusz, R. Influence of the Shape of Reinforcing Window Profiles on the Strength and Torsional Stiffness of Windows. Mechanik 2022, 95, 46–51. [Google Scholar] [CrossRef]

- Iliev, V.; Geshkova, Z.Y.; Ivanov, R.; Samichkov, V. Constitutive Model of Unplasticized Polyvinyl Chloride for Numerical Stress-Strain Analysis. Sci. Eng. Educ. 2020, 5, 3–8. Available online: https://www.researchgate.net/publication/347257058_Constitutive_Model_of_Unplasticized_Polyvinyl_Chloride_for_Numerical_Stress-Strain_Analysis (accessed on 15 March 2025). [CrossRef]

- Smusz, R.; Bałon, P.; Kiełbasa, B.; Rejman, E.; Bembenek, M.; Kowalski, Ł. Experimental and Numerical Characterization of Thermal Bridges in Windows. Adv. Sci. Technol. Res. J. 2023, 17, 315–331. [Google Scholar] [CrossRef]

- PN-EN 12519:2018-10; Windows and Doors—Terminology. Polish Committee for Standardization: Warsaw, Poland, 2018.

- Moumtzakis, A.; Zoras, S.; Evagelopoulos, V.; Dimoudi, A. Experimental Investigation of Thermal Bridges and Heat Transfer through Window Frame Elements at Achieving Energy Saving. Energies 2022, 15, 5055. [Google Scholar] [CrossRef]

- Aksenov, I.; Konstantinov, A.; Verkhovsky, A. Numerical Analytic Method for Calculation of PVC Window Profiles Temperature Deformation. Build. Reconstr. 2022, 102, 3–14. Available online: https://www.researchgate.net/publication/363814389_NUMERICAL_ANALYTIC_METHOD_FOR_CALCULATION_OF_PVC_WINDOW_PROFILES_TEMPERATURE_DEFORMATION (accessed on 15 March 2025). [CrossRef]

- Feng, F.; Kunwar, N.; Cetin, K.; O’Neill, Z. A Critical Review of Fenestration/Window System Design Methods for High-Performance Buildings. Energy Build. 2021, 248, 111184. [Google Scholar] [CrossRef]

- Aksenov, I.; Konstantinov, A. Temperature Deformations of PVC Window Profiles with Reinforcement. Int. J. Comput. Civ. Struct. Eng. 2022, 18, 98–111. [Google Scholar] [CrossRef]

- Saadatian, S.; Freire, F.; Simões, N. Embodied Impacts of Window Systems: A Comparative Assessment of Framing and Glazing Alternatives. J. Build. Eng. 2021, 35, 102042. [Google Scholar] [CrossRef]

- Kozielczyk, M.; Mencel, K.; Kowalczyk, J.; Paczkowska, M. Selection of Processing Methods and Parameters for Composite Inserts in Window Profiles with Regard to the Strength of Their Welds. Materials 2025, 18, 44. [Google Scholar] [CrossRef]

- Kozielczyk, M.; Mencel, K.; Kowalczyk, J.; Paczkowska, M. Analysis of the Strength and Quality Properties of Welded PVC Profiles with Glass Fiber Composite Reinforcement in the Context of Milling and Weld Head Feed. Materials 2025, 18, 1297. [Google Scholar] [CrossRef]

- IDEAL 7000; Aluplast GmbH Kunststoff-Fenstersysteme. Aluplast GmbH: Karlsruhe, Germany, 2020.

| Set Melting Time s | ||||||

|---|---|---|---|---|---|---|

| 21 | 22 | 23 | 24 | 25 | ||

| Milling depth of the composite mm | 0.0 | X | ||||

| 0.5 | X | |||||

| 1.0 | X | X | X | X | X | |

| Melting Time [s] | 25 | 24 | 23 | 22 | 21 |

|---|---|---|---|---|---|

| Compliance with the expected value of minimum fracture loads on individual welds | Yes | Yes | Yes | Yes | Yes |

| Dimensional conformity | Yes | Yes | Yes | Yes | No |

| Milling Depth of Composite Reinforcement [mm] | 1.0 | 0.5 | 0.0 |

|---|---|---|---|

| Compliance with the expected value of minimum fracture loads on individual welds | Yes | No | No |

| Dimensional conformity | Yes | No | No |

| Welding Process Conditions [Melting Time; Milling Depth] | Sample No. | |||||

|---|---|---|---|---|---|---|

| Dimensional Deviations from Nominal Size in the X; Y Axes [mm] | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 25 s; 1 mm | 1; 1 | 0; 1 | 1; 1 | 1; 1 | 1; 1 | 1; 1 |

| 24 s; 1 mm | 1; 1 | 1; 1 | 1; 1 | 1; 1 | 1; 1 | 1; 1 |

| 23 s; 1 mm | 1; 1 | 0; 1 | 1; 1 | 1; 1 | 1; 1 | 0; 1 |

| 22 s; 1 mm | 1; 1 | 1; 1 | 1; 1 | 1; 1 | 1; 1 | 0; 1 |

| 21 s; 1 mm | 2; 2 | 2; 2 | 2; 2 | 2; 2 | 2; 2 | 2; 2 |

| 22 s; 0.5 mm | 2; 2 | 1; 2 | 1; 2 | |||

| 22 s; 0 mm | 2; 2 | 2; 2 | 2; 2 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozielczyk, M.; Kowalczyk, J.; Paczkowska, M. Analysis of the Effects of Weld Melt Duration on Joint Integrity and Surface Quality During Profile Milling. Appl. Sci. 2025, 15, 11024. https://doi.org/10.3390/app152011024

Kozielczyk M, Kowalczyk J, Paczkowska M. Analysis of the Effects of Weld Melt Duration on Joint Integrity and Surface Quality During Profile Milling. Applied Sciences. 2025; 15(20):11024. https://doi.org/10.3390/app152011024

Chicago/Turabian StyleKozielczyk, Marek, Jakub Kowalczyk, and Marta Paczkowska. 2025. "Analysis of the Effects of Weld Melt Duration on Joint Integrity and Surface Quality During Profile Milling" Applied Sciences 15, no. 20: 11024. https://doi.org/10.3390/app152011024

APA StyleKozielczyk, M., Kowalczyk, J., & Paczkowska, M. (2025). Analysis of the Effects of Weld Melt Duration on Joint Integrity and Surface Quality During Profile Milling. Applied Sciences, 15(20), 11024. https://doi.org/10.3390/app152011024