Pipeline External Defect Detection Based on Magnetically Focused Eddy Current Testing System

Abstract

1. Introduction

2. Theoretical Analysis

3. Simulation Model

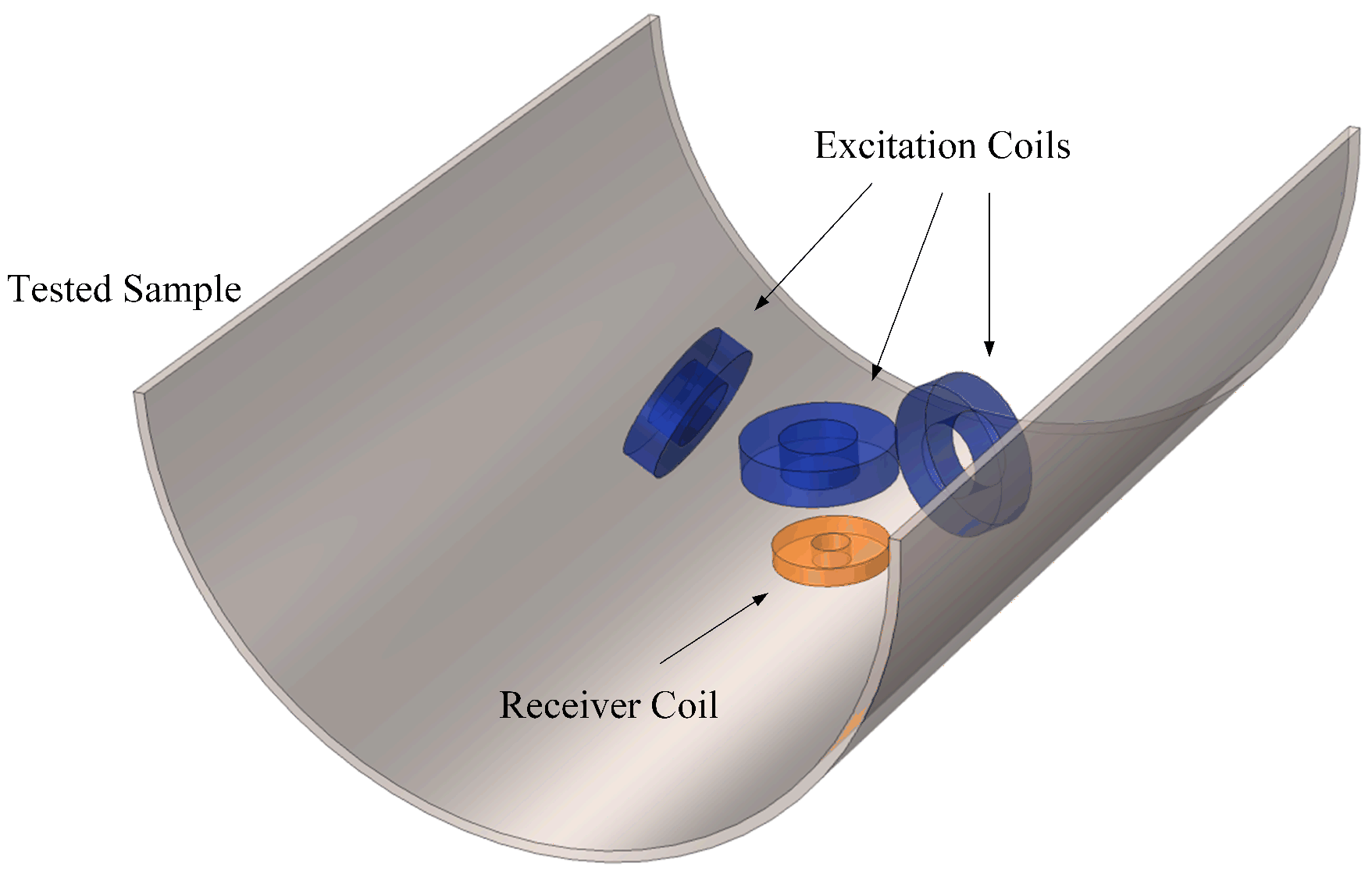

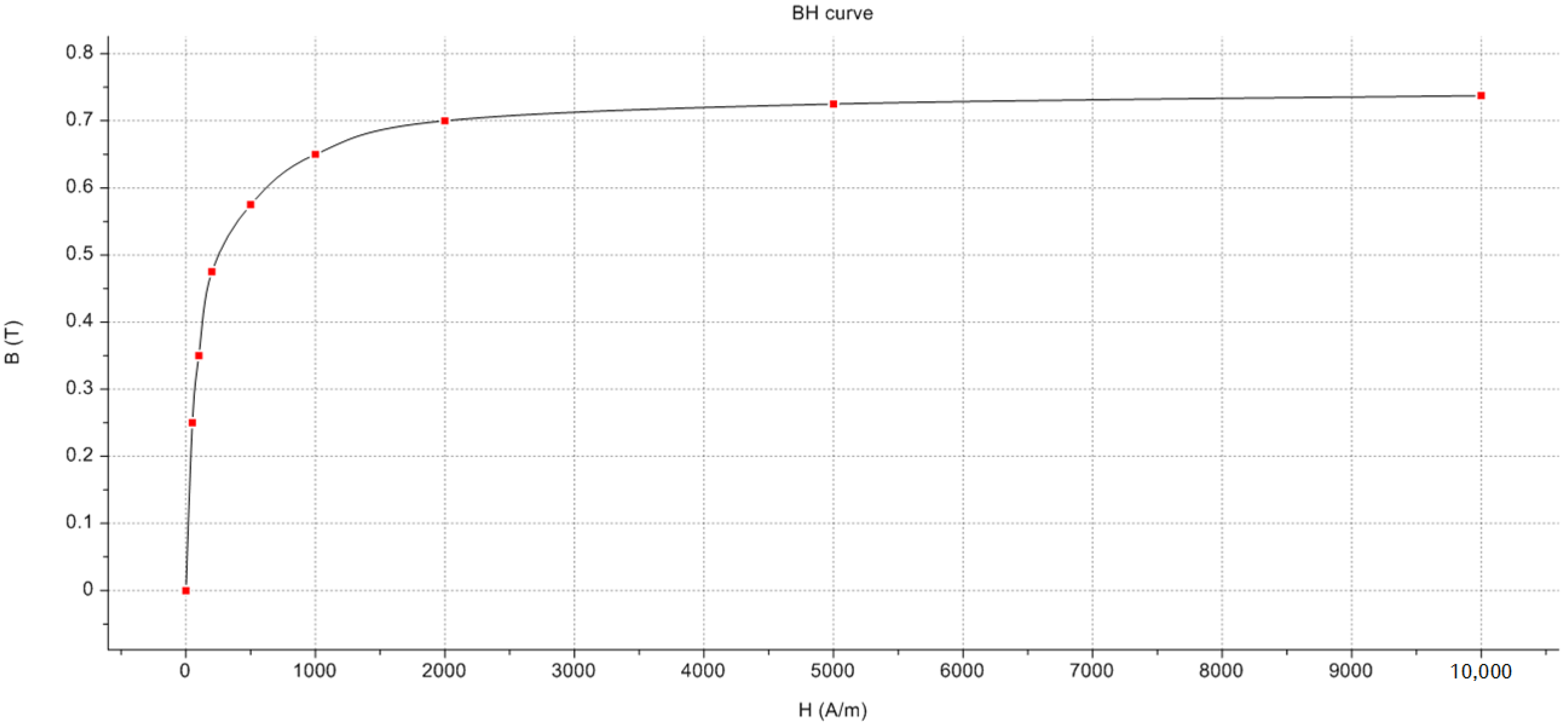

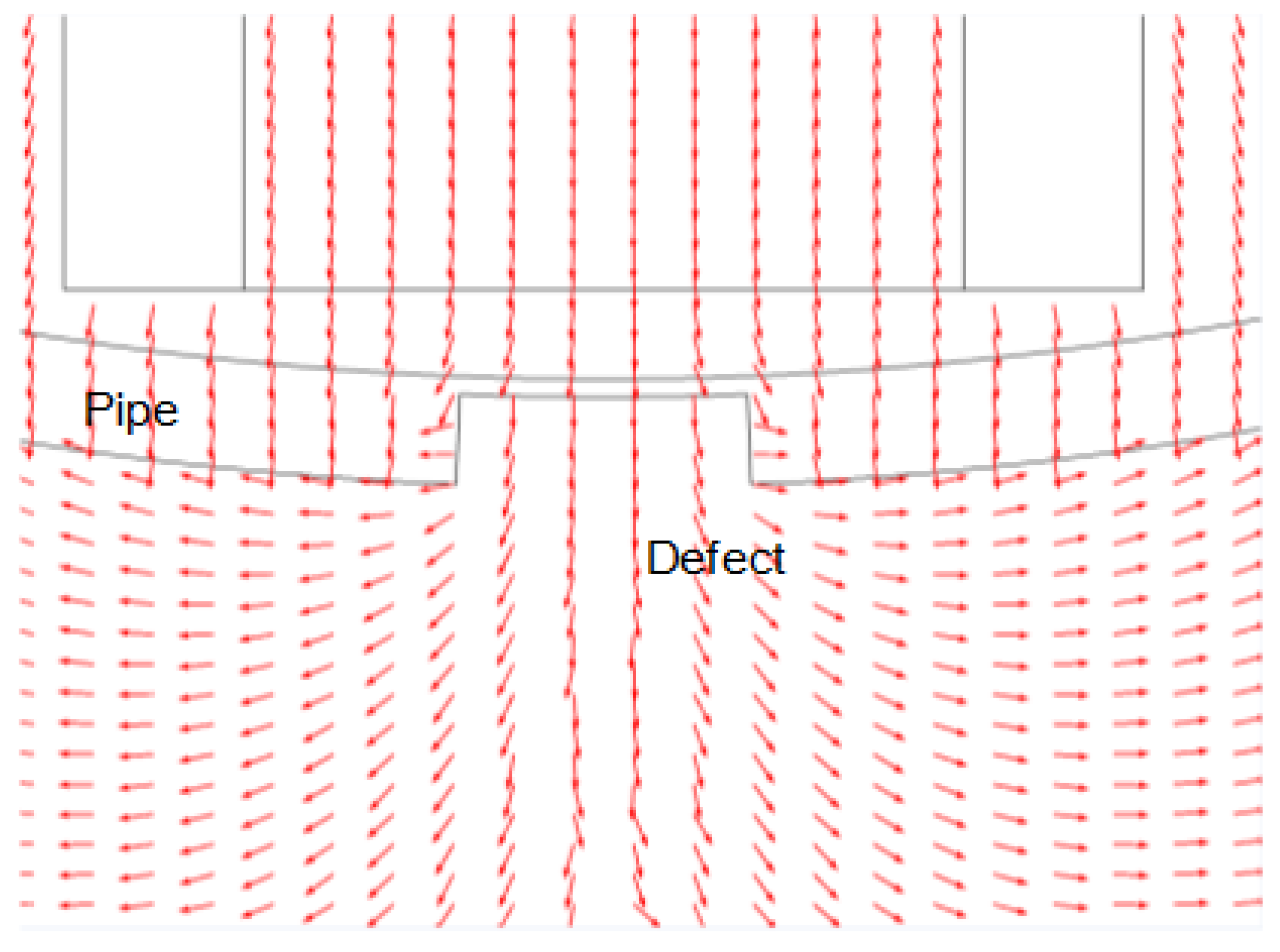

3.1. Finite Element Model

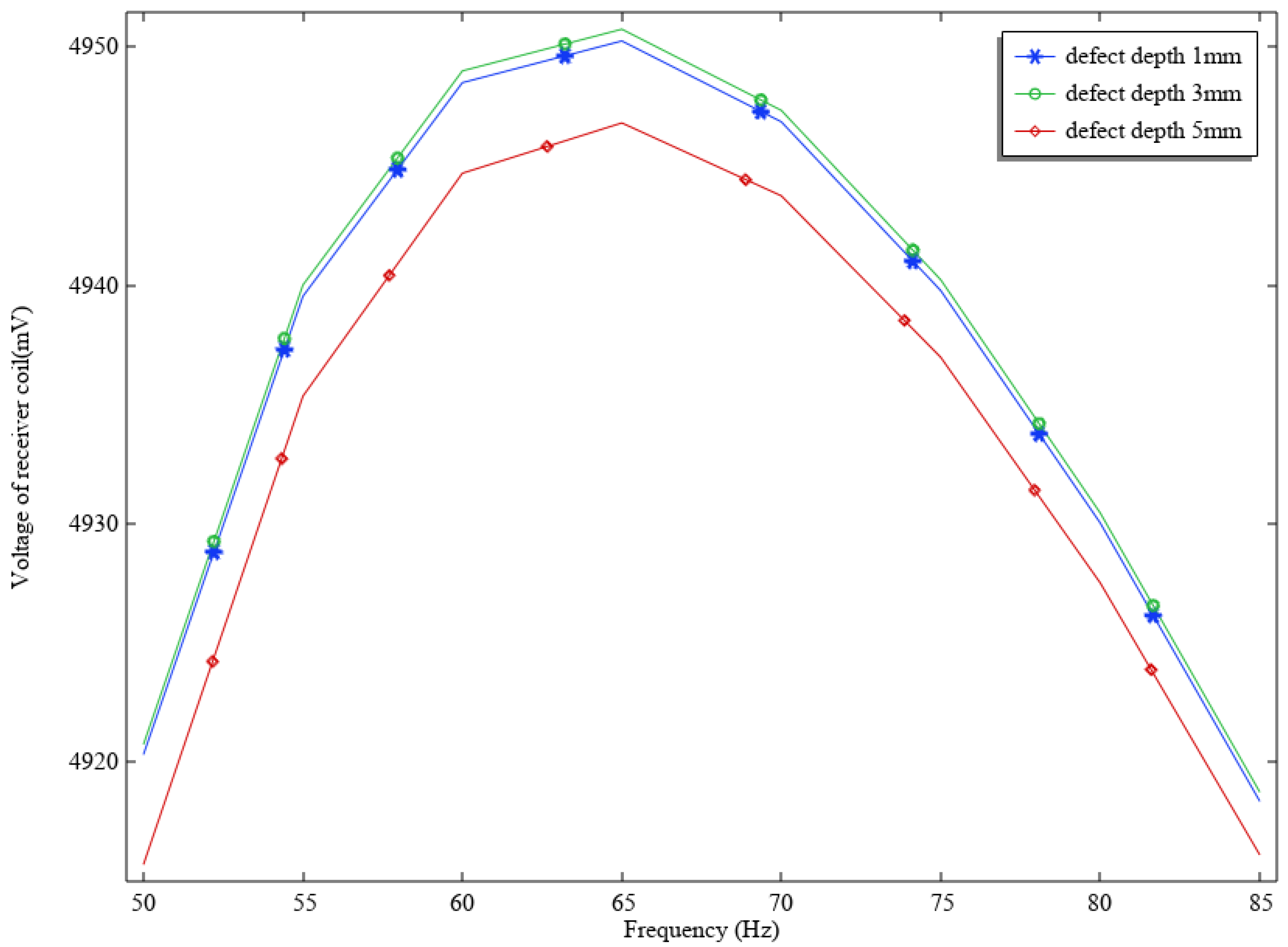

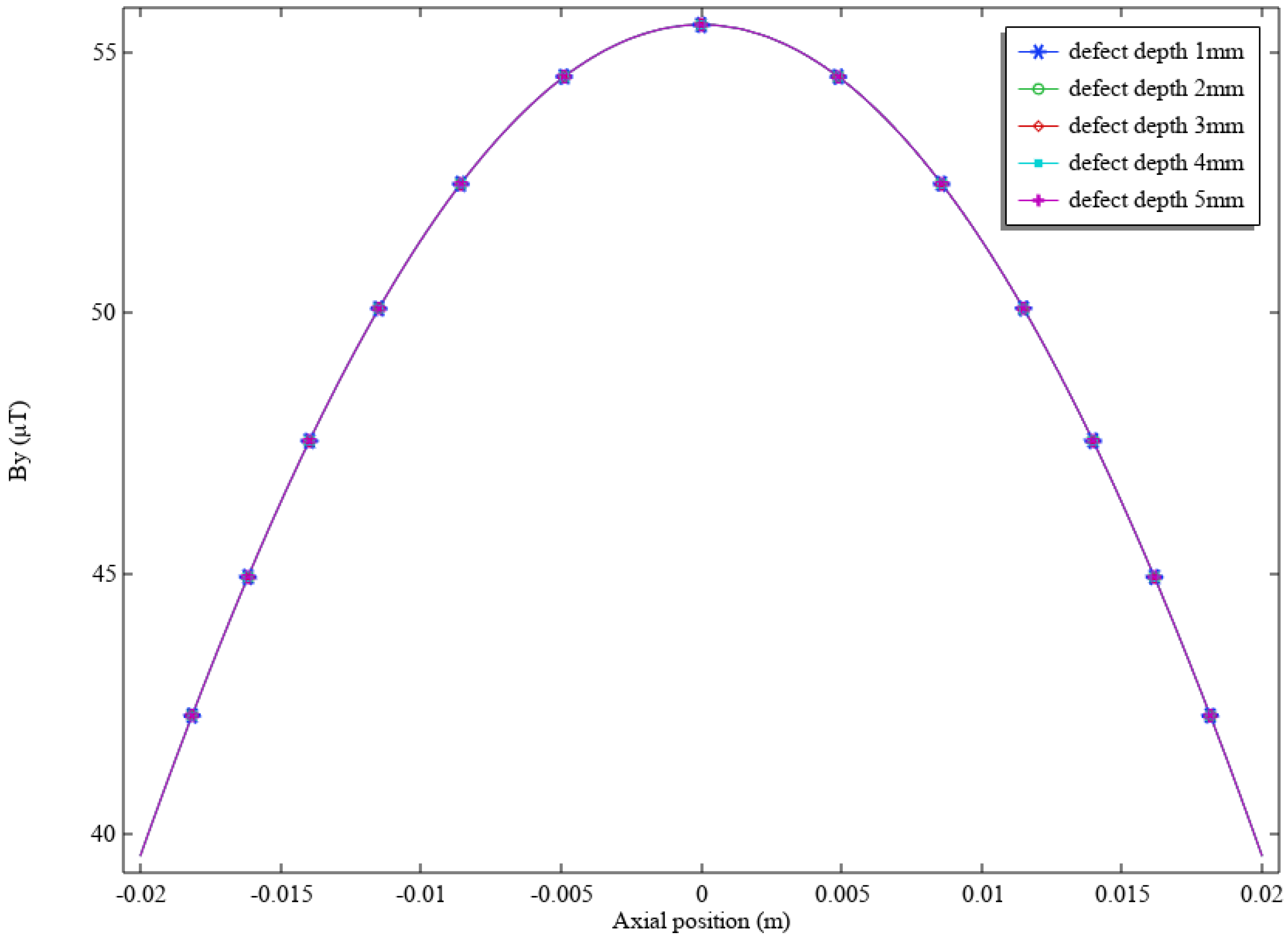

3.2. Optimal Frequency

4. Results and Discussion

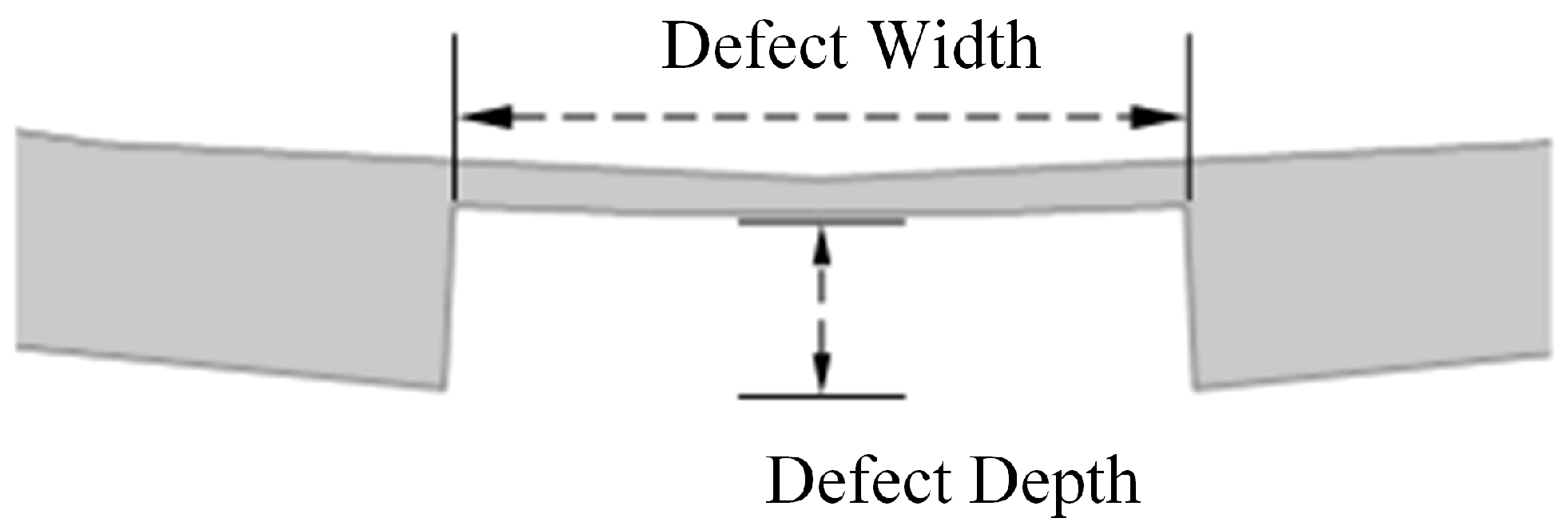

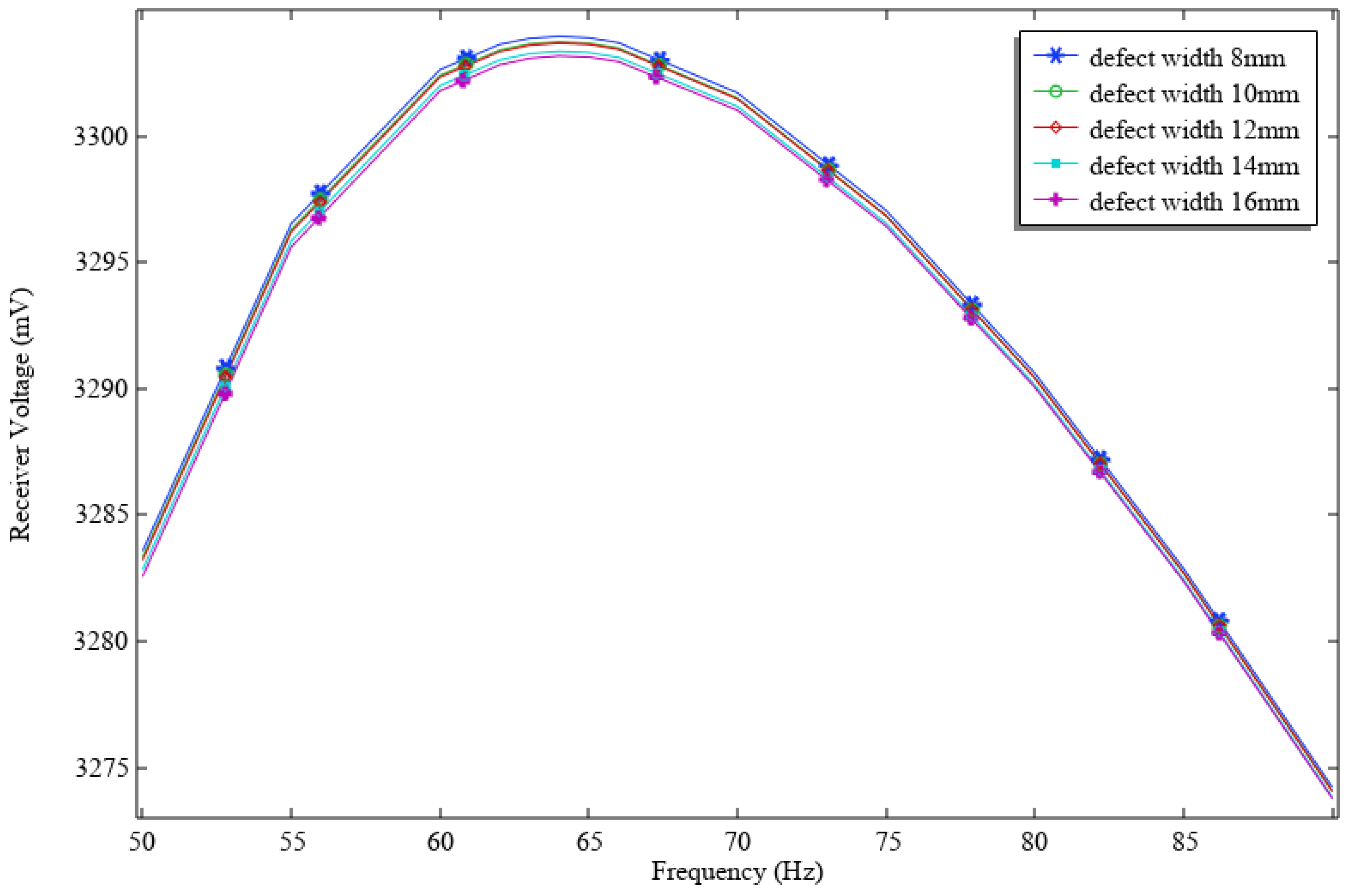

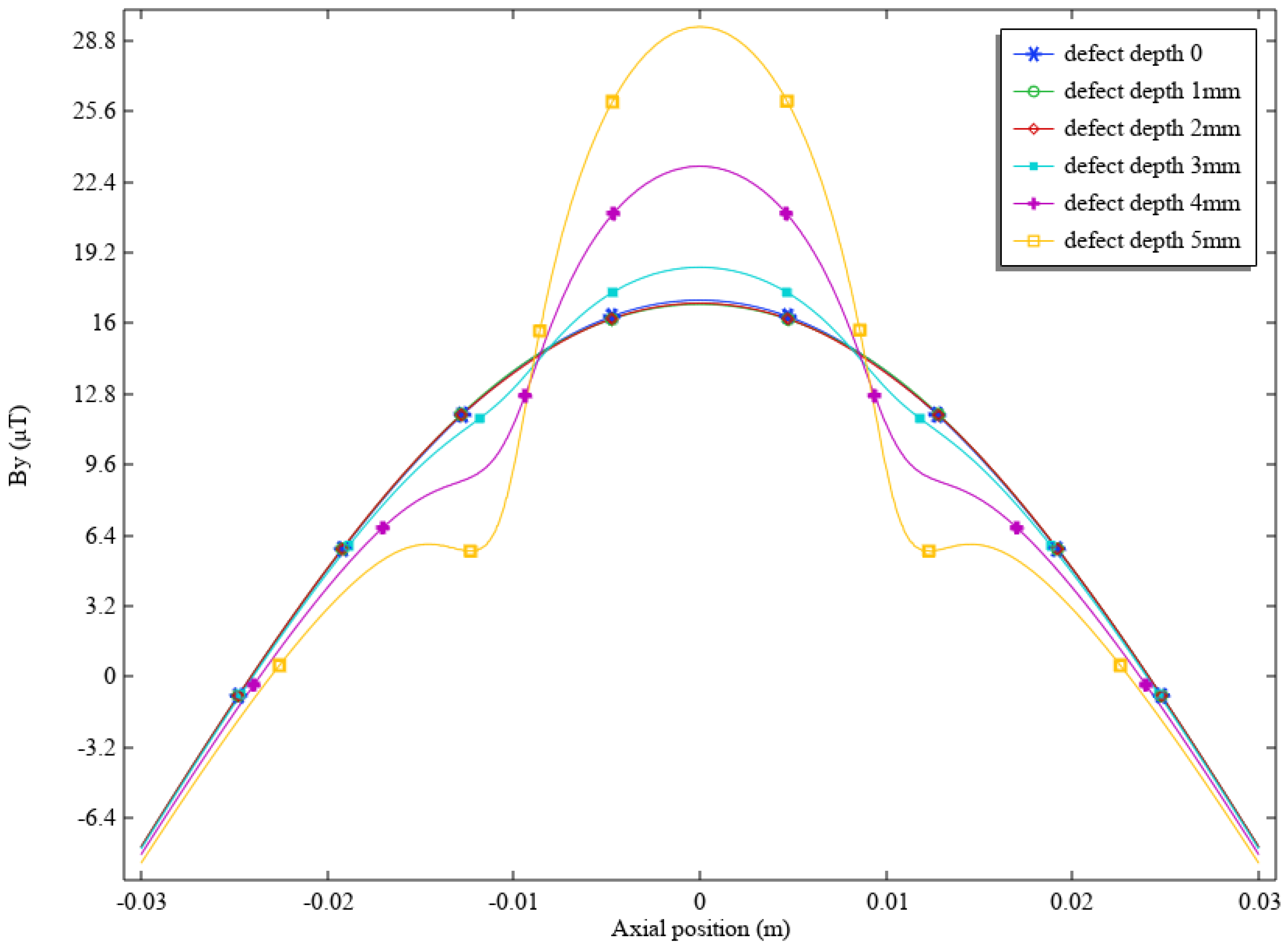

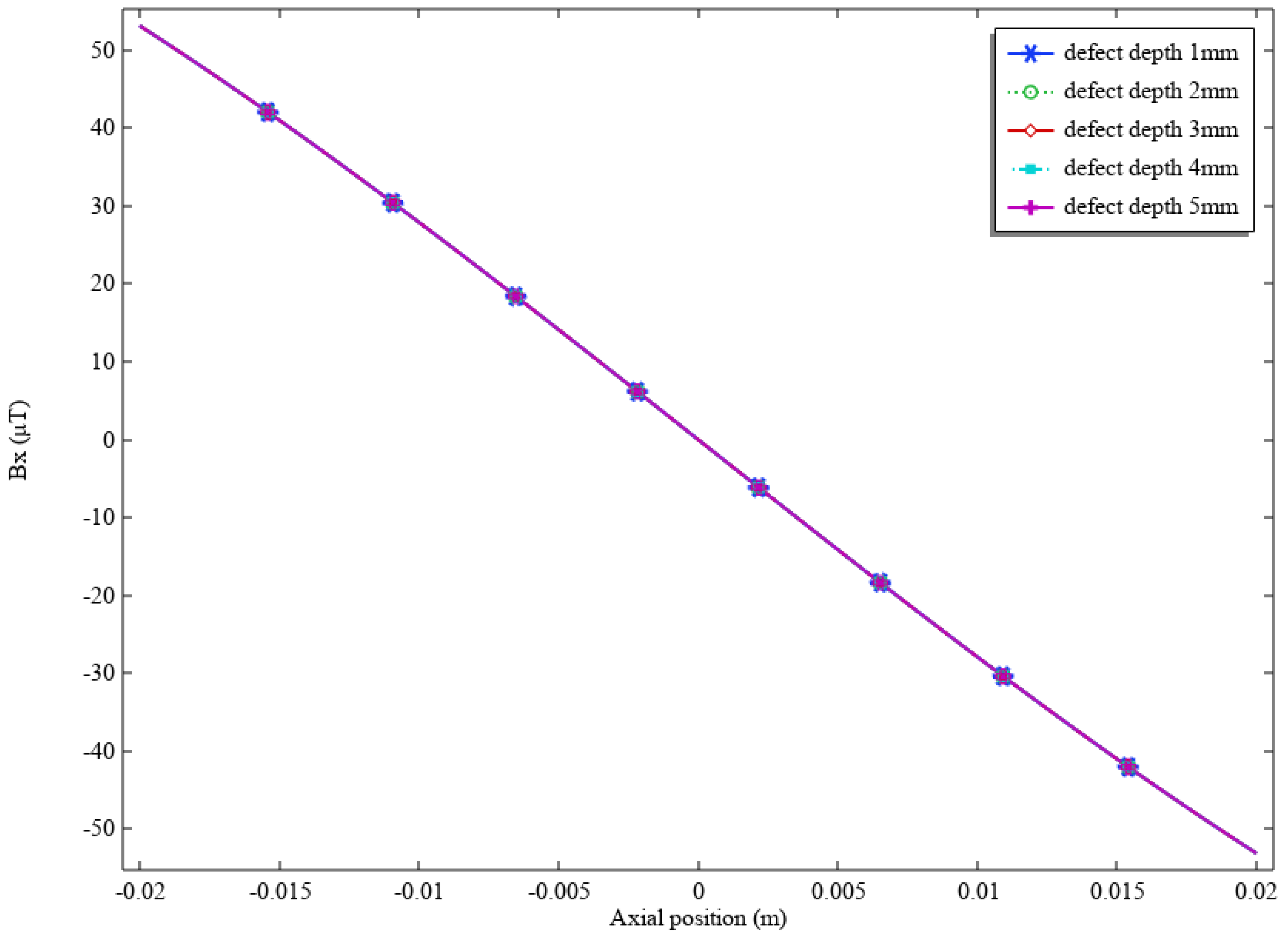

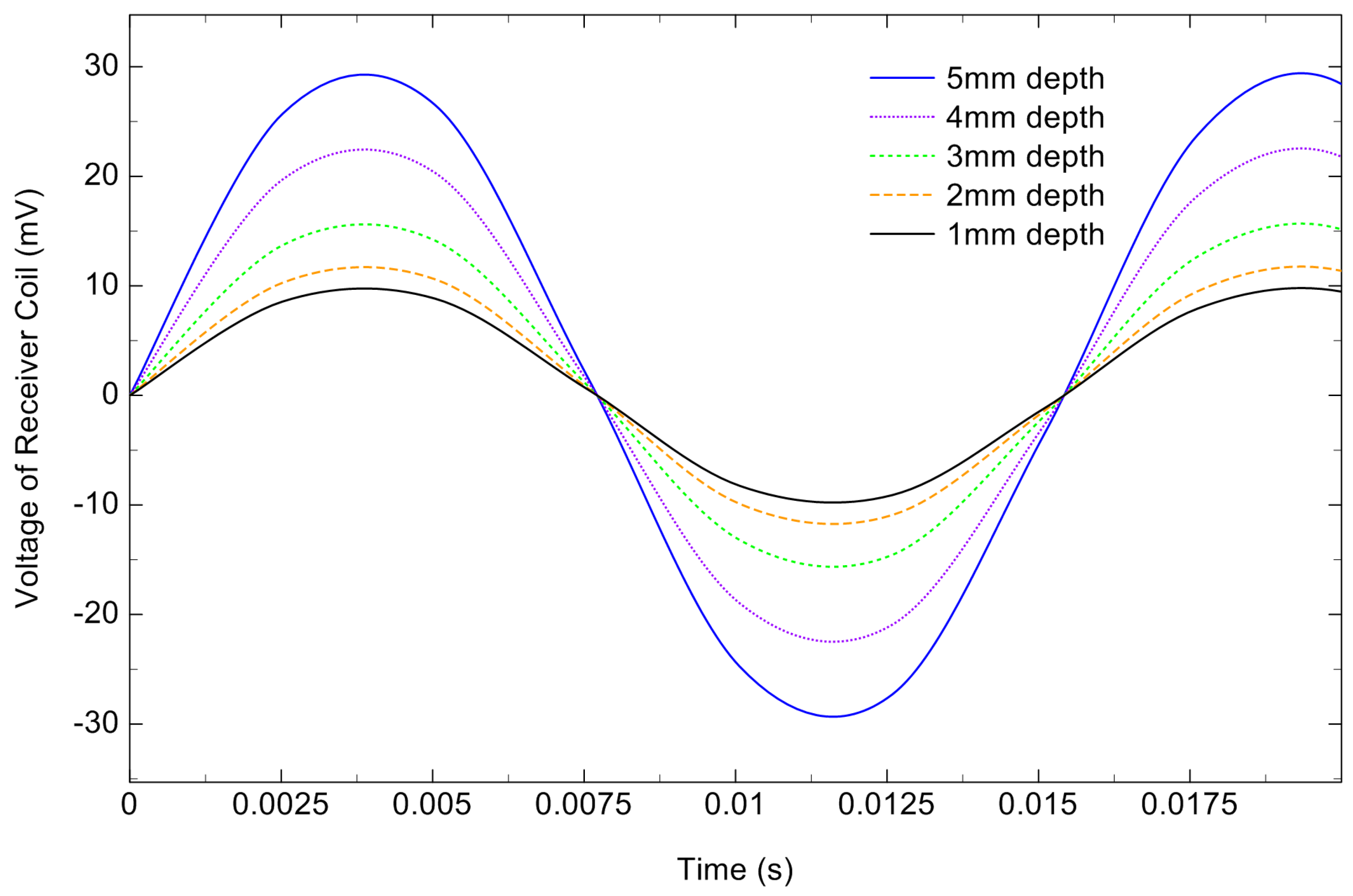

4.1. Defect Signal Analysis

4.2. Comparison with Non-MF ECT

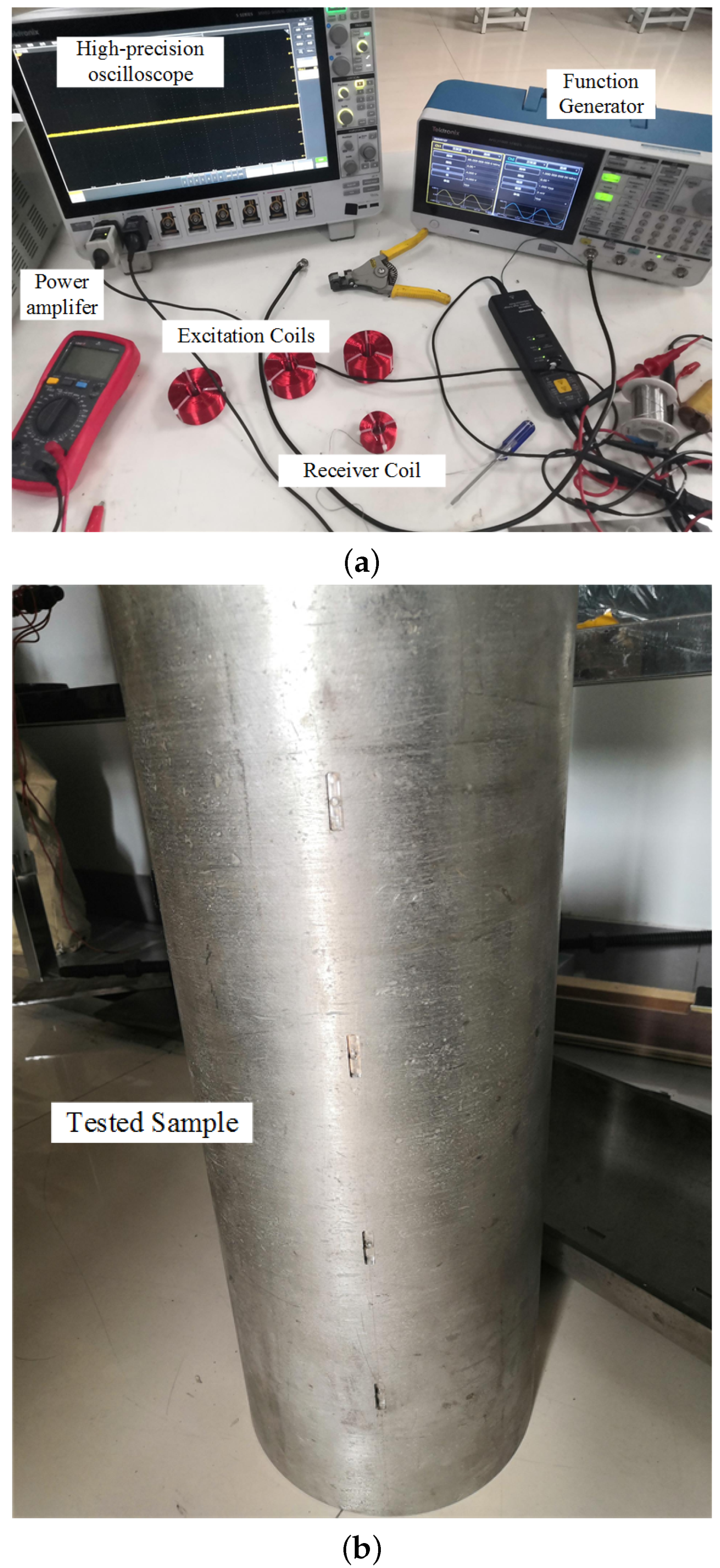

5. Experiment

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vanaei, H.; Eslami, A.; Egbewande, A. A review on pipeline corrosion, in-line inspection (ILI), and corrosion growth rate models. Int. J. Press. Vessels Pip. 2017, 149, 43–54. [Google Scholar] [CrossRef]

- Machado, M.A. Eddy currents probe design for NDT applications: A review. Sensors 2024, 24, 5819. [Google Scholar] [CrossRef]

- Ma, B.; Shuai, J.; Liu, D.; Xu, K. Assessment on failure pressure of high strength pipeline with corrosion defects. Eng. Fail. Anal. 2013, 32, 209–219. [Google Scholar] [CrossRef]

- Clough, M.; Fleming, M.; Dixon, S.M. Circumferential guided wave EMAT system for pipeline screening using shear horizontal ultrasound. NDT E Int. 2017, 86, 20–27. [Google Scholar] [CrossRef]

- Rossteutscher, I.; Blaschke, O.; Dötzer, F.; Uphues, T.; Drese, K.S. Improved EMAT sensor design for enhanced ultrasonic signal detection in steel wire ropes. Sensors 2024, 24, 7114. [Google Scholar] [CrossRef]

- He, Y.; Chen, S.; Zhou, D.; Huang, S.; Wang, P. Shared Excitation Based Nonlinear Ultrasound and Vibrothermography Testing for CFRP Barely Visible Impact Damage Inspection. IEEE Trans. Ind. Inform. 2018, 14, 5575–5584. [Google Scholar] [CrossRef]

- Meniconi, S.; Brunone, B.; Tirello, L.; Rubin, A.; Cifrodelli, M.; Capponi, C. Transient tests for checking the Trieste subsea pipeline: Toward field tests. J. Mar. Sci. Eng. 2024, 12, 374. [Google Scholar] [CrossRef]

- Meniconi, S.; Brunone, B.; Tirello, L.; Rubin, A.; Cifrodelli, M.; Capponi, C. Transient tests for checking the Trieste subsea pipeline: Diving into fault detection. J. Mar. Sci. Eng. 2024, 12, 391. [Google Scholar] [CrossRef]

- AbdAlla, A.N.; Faraj, M.A.; Samsuri, F.; Rifai, D.; Ali, K.; Al-Douri, Y. Challenges in improving the performance of eddy current testing: Review. Meas. Control 2019, 52, 46–64. [Google Scholar] [CrossRef]

- Dann, M.R.; Huyse, L. The effect of inspection sizing uncertainty on the maximum corrosion growth in pipelines. Struct. Saf. 2018, 70, 71–81. [Google Scholar] [CrossRef]

- Yan, C.; Bao, J.; Zheng, X. Conductivity Measurement for Non-Magnetic Materials Using Eddy Current Method with a Novel Simplified Model. Sensors 2025, 25, 3900. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; He, Y.; Dong, Z. Pulsed Eddy Current Nondestructive Testing for Defect Evaluation and Imaging of Automotive Lightweight Alloy Materials. J. Sens. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Ge, J.; Xu, F.; Yusa, N. Experimental investigation of low-frequency and pulsed eddy current testing in thickness measurement. Nondestruct. Test. Eval. 2024, in press. [Google Scholar] [CrossRef]

- Mihalache, O.; Yamaguchi, T.; Shirahama, T.; Ueda, M. Window multi-frequency ECT for multi-coils in a RFEC system for FBR SG tubes. Int. J. Appl. Electromagn. Mech. 2019, 59, 1161–1168. [Google Scholar] [CrossRef]

- Zou, X.; She, S.; Zheng, X.; Yu, K.; Shen, J.; Peyton, A.; Yin, W. Simultaneous Estimation of Conductivity and Radial Eccentricity of Metallic Cylinders Using Eddy Current Testing. IEEE Trans. Instrum. Meas. 2025, 74, 6011110. [Google Scholar] [CrossRef]

- Chen, W.; Wu, D.; Wang, X.; Wang, T. A self-frequency-conversion eddy current testing method. Measurement 2022, 195, 111129. [Google Scholar] [CrossRef]

- Shao, W.; Wu, X.; Lu, R.; Chen, J.; Ma, Y. A multi-frequency balanced electromagnetic field measurement for arbitrary angles of pipeline cracks with high sensitivity. Insight-Non Test. Cond. Monit. 2024, 66, 361–367. [Google Scholar] [CrossRef]

- Thirunavukkarasu, S.; Rao, B.; Jayakumar, T.; Raj, B. Techniques for processing remote field eddy current signals from bend regions of steam generator tubes of prototype fast breeder reactor. Ann. Nucl. Energy 2011, 38, 817–824. [Google Scholar] [CrossRef]

- Xu, Z.; Fan, S.; Song, T. Parameter identification of pulsed eddy current testing equivalent circuit model and its application to defect evaluation. Meas. Control 2021, 54, 1113–1121. [Google Scholar] [CrossRef]

- Komatsubara, K.; Gao, Y.; Gotoh, Y.; Guan, W.; Muramatsu, K. Frequency characteristics analysis of remote field eddy current testing on ferromagnetic pipes. IEEE Trans. Magn. 2023, 59, 6200605. [Google Scholar] [CrossRef]

- Mohammed, F.T.; Saffiudeen, M.F.; Syed, A.; Alamri, Y.A. Failure Analysis of Heat Exchanger Using Remote Field Eddy Current Testing (RFET). J. Fail. Anal. Prev. 2025, 25, 996–1002. [Google Scholar] [CrossRef]

- Mokros, S.G.; Underhill, P.R.; Morelli, J.E.; Krause, T.W. Pulsed Eddy Current Inspection of Wall Loss in Steam Generator Trefoil Broach Supports. IEEE Sens. J. 2017, 17, 444–449. [Google Scholar] [CrossRef]

- Mirzaei, M.; Ripka, P.; Chirtsov, A.; Grim, V. Eddy current speed sensor with magnetic shielding. J. Magn. Magn. Mater. 2020, 502, 166568. [Google Scholar] [CrossRef]

| Excitation Coils | Receiver Coil | Pipeline | |

|---|---|---|---|

| Thickness (mm) | 20 | 10 | 6 |

| Inner radius (mm) | 10 | 10 | 200 |

| Outer radius (mm) | 40 | 30 | 206 |

| Lift-off (mm) | 10 | 5 | / |

| Turns (N) | 400 | 200 | / |

| Excitation Coils | Receiver Coil | Pipeline | |

|---|---|---|---|

| Material | copper | copper | iron |

| Conductivity (S/m) | |||

| Relative permeability | 1 | 1 | BH curve |

| Item | Parameter | |

|---|---|---|

| Excitation Coil | Inner diameter | 10 mm |

| Outer diameter | 40 mm | |

| Height | 20 mm | |

| Turns | 400 | |

| Receiver Coil | Inner diameter | 10 mm |

| Outer diameter | 30 mm | |

| Height | 10 mm | |

| Turns | 700 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Zhang, H. Pipeline External Defect Detection Based on Magnetically Focused Eddy Current Testing System. Appl. Sci. 2025, 15, 11012. https://doi.org/10.3390/app152011012

Gao Z, Zhang H. Pipeline External Defect Detection Based on Magnetically Focused Eddy Current Testing System. Applied Sciences. 2025; 15(20):11012. https://doi.org/10.3390/app152011012

Chicago/Turabian StyleGao, Zihao, and Huaguang Zhang. 2025. "Pipeline External Defect Detection Based on Magnetically Focused Eddy Current Testing System" Applied Sciences 15, no. 20: 11012. https://doi.org/10.3390/app152011012

APA StyleGao, Z., & Zhang, H. (2025). Pipeline External Defect Detection Based on Magnetically Focused Eddy Current Testing System. Applied Sciences, 15(20), 11012. https://doi.org/10.3390/app152011012