Shear Characteristics and Failure Evolution Process of the Cantilever Anti-Floating Ledge in Rock Strata: A Case Study of Guangzhou Metro Stations

Abstract

1. Introduction

2. Engineering Context

2.1. Project Overview

2.2. Lithological and Hydrogeological Conditions

2.3. The Cantilever Anti-Floating Ledge

3. Laboratory Shear Test of the Cantilever Anti-Floating Ledge

3.1. Test Design and Boundary Condition Determination

- (1)

- A comprehensive numerical model of the station was constructed in FLAC3D5.0 to simulate the entire anti-floating process.

- (2)

- The stress states near the cantilever anti-floating ledge were extracted from the simulation results.

- (3)

- These stresses were converted into specific boundary loads using the FISH programming language in FLAC3D5.0.

- (4)

- The corresponding boundary load conditions for the shear tests were derived using a dimensional similarity ratio.

3.2. Test Materials

3.3. Test Device and System

- (1)

- Test device

- (2)

- Test system

3.4. Test Process

4. Results of the Shear Test

4.1. Shear Mechanical Characteristics

4.2. Deformation Evolution Characteristics

4.3. Crack Development Characteristics

4.4. AE Results

5. PFC Numerical Simulation

5.1. Numerical Calculation Model

5.2. Calibration of Microscopic Parameters

- (1)

- Parameter calibration of the slightly weathered sandstone

- (2)

- Parameter calibration of the concrete

5.3. Comparison with the Test Results

5.4. Damage Evolution Law

5.5. Micro-Damage Crack Number and Micro-Damage Energy

6. Discussion

6.1. The Limitations of the Shear Test and Subsequent Work

6.2. Advancements over Classical Methods and Existing Limitations

7. Conclusions

- (1)

- The shear stress–shear displacement relationship curve of the cantilever anti-floating ledge can be divided into six stages: ① initial compression stage, ② approximate linear elastic compression–shear deformation stage, ③ initial microcrack initiation and propagation stage, ④ slow compression–shear nonlinear deformation stage, ⑤ stress brittle drop stage, and ⑥ plastic flow deformation stage.

- (2)

- During the initial loading phase, the sample remains compacted, with deformation primarily occurring as uniform overall deformation. Subsequently, the upper right corner of the sample begins to warp, and a diagonal crack extending to the ledge appears in the upper left corner, exhibiting typical deformation zonation. After failure, the total displacement field of the structure exhibits significant displacement on the right side of the upper plate and the entire lower plate region. The key displacement change regions are the region extending from the upper left corner to the edge of the cantilever beam (Region I), the left interface region (Region II), and the right interface region (Region III).

- (3)

- In the initial stage, the cantilever anti-floating ledge primarily exhibits localized microcracks. Subsequently, tensile shear cracks first form near the concrete–rock interface of the side walls, followed by localized failure of the rock mass near the ledge and interface debonding. This process is referred to as Stage I. Subsequently, the structure undergoes continuous cracking, expansion, and penetration; compressive shear cracks form from the base plate to the cantilever ledge; and the loading curve shows a small stress drop until the cracks connect, leading to structural failure. This process is referred to as Stage II. Thereafter, the structure continues to undergo severe damage under residual strength, referred to as Stage III. It is essential to avoid entering Stages II and III.

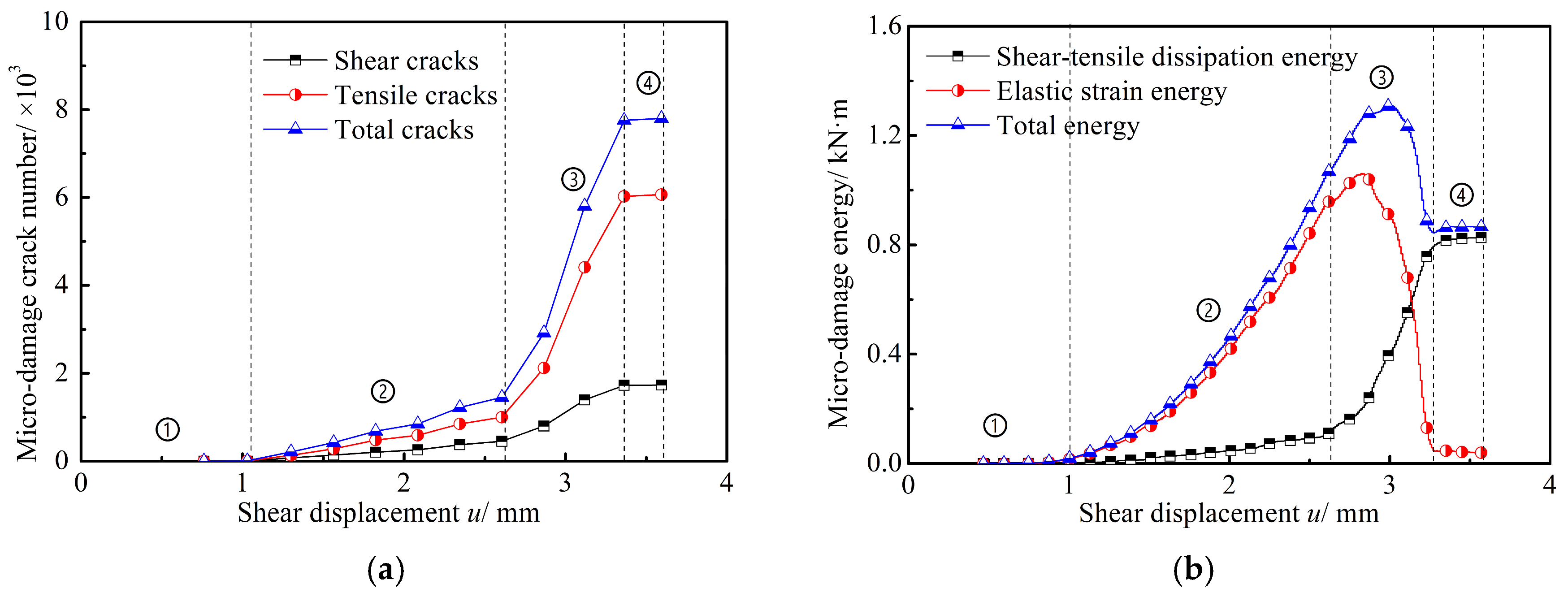

- (4)

- The micro-damage process of cantilever anti-floating ledge generally goes through four stages. Stage ①: With a few microcracks, the structure is compacted, and the shear–tensile dissipation energy and elastic strain energy are small. Stage ②: Crack growth accelerates, damage begins at ledge areas, and elastic strain energy increases rapidly. Stage ③: Rapid increase in crack growth, extensive crack propagation at ledge areas, decrease in elastic strain energy, and a sharp increase in shear–tensile dissipated energy, with total energy first increasing and then decreasing. Stage ④: Crack growth and energy remain constant, and the structure fails.

- (5)

- To fully utilize the performance of the cantilever anti-floating ledge, special attention should be paid to the stress and deformation conditions at the connection between the ledge and the side walls and bottom plate. The reinforcement ratio of the tensile reinforcing bars at the connection points between the ledge and the side walls, as well as at the protruding parts of the ledge, should be increased. The stirrups at the lower half of the ledge should be strengthened, and the bond strength between the ledge and the rock layer should be enhanced. If the rock layer has a high degree of weathering or well-developed joints, additional reinforcement of the rock layer should be carried out within the influence zone of the ledge.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Q.; Hu, Z.; Guo, Y.; Ji, Y.; Zhu, B.; Ma, J. Investigation on Uplift Behavior of Rock-Socketed Belled Piles in Horizontal and Inclined Ground Using 1-g Model Test and 3D Numerical Method. Rock Mech. Rock Eng. 2024, 57, 3371–3391. [Google Scholar] [CrossRef]

- Bai, Y.; Chao, Q.; Yuan, Y.; Feng, C.; Shan, Z. Field Test Study on Uplift Bearing Characteristics of Rock Socketed Piles in Sandstone Stratum. Soils Found. 2025, 65, 101598. [Google Scholar] [CrossRef]

- Bai, X.; Ma, H.; Yan, N.; Wang, F.; Hou, D.; Wang, P.; Sun, G.; Xu, F. Anchorage performance of BFRP anti-floating anchors: Field investigation and numerical simulation. Case Stud. Constr. Mater. 2025, 23, e04903. [Google Scholar] [CrossRef]

- Liu, Y.; Xia, K.; Wang, B.; Le, J.; Ma, Y.; Zhang, M. Experimental Investigation on the Anchorage Performance of a Tension–Compression-Dispersed Composite Anti-Floating Anchor. Appl. Sci. 2023, 13, 12016. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Liu, J.; Li, H. Study on the Uplift Bearing Capacity of Rock–Socketed Piles. Soil Mech. Found. Eng. 2021, 58, 203–208. [Google Scholar] [CrossRef]

- Bian, M.; Qin, S.; Peng, J.; Li, J.; Zhang, X. Exploration of the Slope Effect on the Uplift Capacity of Single Straight and Belled Piles Supporting Transmission Towers. Front. Mater. 2023, 10, 1171601. [Google Scholar] [CrossRef]

- Ma, H.; Ma, G.; Zhang, W. Prediction method of screw pile bearing capacity under uplift load. Soils Found. 2025, 65, 101662. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, R.; Gong, X.; Yu, J. Field Study on Uplift Bearing Capacity of Pre-bored Grouted Planted Pile and Bored Pile in Deep Soft Soil. Ocean Eng. 2025, 322, 120477. [Google Scholar] [CrossRef]

- Pu, S.; Zhu, Z.; Wei, W. A Method for Calculating the Ultimate Bearing Capacity of Uplift Piles in Combined Soil and Rock Mass. Eur. J. Environ. Civ. Eng. 2020, 26, 2158–2183. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, Q.; Li, S.; Li, L.; Zhang, S.; Wang, K. Nonlinear Analysis of the Response of a Single Pile Subjected to Tension Load Using a Hyperbolic Model. Eur. J. Environ. Civ. Eng. 2018, 22, 181–191. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Song, M.; Zhao, J.; Bai, J. Uplift Bearing Capacity of Squeezed Branch Pile Group. Geotech. Geol. Eng. 2023, 41, 283–293. [Google Scholar] [CrossRef]

- Wang, Q.; Ma, J.; Ji, Y.; Zhang, J.; Chen, W. Determination of Ultimate Bearing Capacity of Uplift Piles Using Intact and Non-intact Load–Displacement Curve. J. Cent. South. Univ. 2020, 29, 470–485. [Google Scholar] [CrossRef]

- Yang, M.; Wu, J.; Lu, Q.; Li, P. Optimization of Uplift Piles for a Base Plate Considering Local Anti-Floating Stability. Appl. Sci. 2024, 14, 5000. [Google Scholar] [CrossRef]

- Kou, H.; Guo, W.; Zhang, M. Pullout Performance of GFRP Anti-floating Anchor in Weathered Soil. Tunn. Undergr. Space Technol. 2015, 49, 408–416. [Google Scholar] [CrossRef]

- Hao, Z.; Liu, H.; Yan, N.; Wang, Z.; Bai, X.; Han, J.; Mi, C.; Jia, S.; Sun, G.; Zhu, L.; et al. In-Situ Test and Numerical Simulation of Anchoring Performance of Embedded Rock GFRP Anchor. Buildings 2023, 13, 2799. [Google Scholar] [CrossRef]

- Liu, G.; Jia, P.; Sun, J.; Jiang, Z.; Yang, F.; Yang, G.; Shao, G. Research and Application of New Anti-floating Anchor in Anti-floating Reinforcement of Existing Underground Structures. Front. Earth Sci. 2024, 12, 1364752. [Google Scholar] [CrossRef]

- Abedlgwad, A.; Nasr, A.; Azzam, W. Utilization of Enlarged Base to Improve the Uplift Capacity of Single Pile in Sand-model Study. Innov. Infrastruct. Solut. 2022, 7, 317. [Google Scholar] [CrossRef]

- Ibrahim, A.; Karkush, M. The Efficiency of Belled Piles in Multi-layers Soils Subjected to Axial Compression and Pullout Loads: Review. J. Eng. 2023, 29, 166–183. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, M. Experimental Study on the Uplift Bearing Capacity of Pre-drilled Planted Piles in Isolated Stone Strata Based on Transparent Soil Technology. Appl. Sci. 2024, 15, 304. [Google Scholar] [CrossRef]

- Schafer, M.; Madabhushi, S. Uplift Resistance of Enlarged Base Pile Foundations. Indian Geotech. J. 2020, 50, 426–441. [Google Scholar] [CrossRef]

- Yang, X.; Tang, L.; Mei, L.; Zhang, T.; Niu, S.; Sun, Z.; Wang, Z.; Feng, D.; Gui, F. Laboratory Investigation of the Uplift Resistance of a New Winged H-Pile Anchor Developed for Offshore Marine Aquaculture. J. Mar. Sci. Eng. 2024, 13, 342. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Zhang, J.; Xu, T.; Cao, G.; Xu, Y. Study on the Characteristics of Self-stabilizing Height Distribution for Deep Foundation Pit Vertical Sidewall in Binary Strata of Upper Soil and Lower Rock. Adv. Civ. Eng. 2021, 2021, 5411703. [Google Scholar] [CrossRef]

- Xu, Q.; Bao, Z.; Tu, L.; Gao, H.; Song, J. Numerical Simulation and Optimization Design of End-suspended Pile Support for Soil–Rock Composite Foundation Pit. Adv. Civ. Eng. 2021, 2021, 5593639. [Google Scholar] [CrossRef]

- Li, G.; Li, Q.; Wang, J.; Dong, J.; Sun, Q. The Deformation Characteristics of a 40-m-Deep Excavation Supported by a Suspended Diaphragm Wall in Rock and Soil Composite Ground. KSCE J. Civ. Eng. 2022, 26, 1040–1050. [Google Scholar] [CrossRef]

- Soltanianfard, M.; Toufigh, V.; Ghaemian, M. The Interface Behavior of Rock, Conventional Vibrated and Roller Compacted Concrete. Geotech. Geol. Eng. 2020, 38, 1949–1969. [Google Scholar] [CrossRef]

- Bista, D.; Sas, G.; Johansson, F.; Lia, L. Influence of Location of Large-scale Asperity on Shear Strength of Concrete–Rock Interface under Eccentric Load. J. Rock Mech. Geotech. Eng. 2020, 12, 449–460. [Google Scholar] [CrossRef]

- Stavropoulou, E.; Briffaut, M.; Dufour, F.; Camps, G. Time-dependent Behaviour of the Callovo-Oxfordian Claystone–Concrete Interface. J. Rock Mech. Geotech. Eng. 2020, 12, 89–101. [Google Scholar] [CrossRef]

- Zhang, M.; Sheng, Q.; Cui, Z. Experimental and Numerical Study on The Mechanical Properties of the Rock–Concrete Contact Surface for Consideration of Ground-liner Interaction in Rock Tunneling. Eur. J. Environ. Civ. Eng. 2022, 27, 339–355. [Google Scholar] [CrossRef]

- Wen, L.; Zhang, W.; Li, Y.; Huang, J.; Liu, Y. Shear Behavior of Asphalt Concrete Core and Transition Layer Interface under Original Gradation Condition. Constr. Build Mater. 2025, 490, 142419. [Google Scholar] [CrossRef]

- Ouyang, S.; Zhang, X.; Ma, Y.; Yao, C.; Yang, J.; Ye, Z.; Zhou, C. Shear Failure Behavior and a Shear Strength Prediction Model of Unbonded Rock–Cement Interface. Int. J. Geomech. 2025, 25, 04025082. [Google Scholar] [CrossRef]

- Liu, T.; Tang, M.; Cao, P.; Cui, M.; Dong, L. Shear Energy Evolution and Fracture Behavior of Rock–Concrete Interfaces Under Different Stress-level Conditions. Materials 2025, 18, 795. [Google Scholar] [CrossRef]

- Badika, M.; El, M.; Capdevielle, S.; Dufour, F.; Saletti, D.; Briffaut, M. Influence of Concrete–Rock Bonds and Roughness on the Shear Behavior of Concrete–Rock Interfaces under Low Normal Loading, Experimental and Numerical Analysis. Appl. Sci. 2022, 12, 5643. [Google Scholar] [CrossRef]

- Ren, J.; Xiao, M.; Liu, G. Rock Macro–Meso Parameter Calibration and Optimization Based on Improved BP Algorithm and Response Surface Method in PFC 3D. Energies 2022, 15, 6290. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, G.; Jiao, Y.; Yan, C.; Wang, X.; Shen, L.; Yang, L.; Liang, Z.; Li, W.; Zhou, X.; et al. A benchmark study of different numerical methods for predicting rock failure. Int. J. Rock Mech. Min. Sci. 2023, 166, 105381. [Google Scholar] [CrossRef]

- Tsang, M.; Clark, L.; Karlovsek, J. Automating the Calibration of Flat-Jointed Bonded Particle Model Microproperties for the Rewan Sandstone Case Study. Rock Mech. Rock Eng. 2023, 56, 6459–6480. [Google Scholar] [CrossRef]

- GB50487-2008; Code for Geological Investigation of Water Conservancy and Hydropower Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Wang, T.; Zhang, G. Failure behavior of soil-rock mixture slopes based on centrifuge model test. J. Mt. Sci. 2019, 16, 1928–1942. [Google Scholar] [CrossRef]

- Tan, W.; Huang, Q.; Chen, X. Physical Model Test on the Interface of Loess Fill Slope. Land 2022, 11, 1372. [Google Scholar] [CrossRef]

- GB50010-2010; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2024.

- Lin, H.; Zhang, X.; Li, S. Failure Mechanism and Control Mechanism of Intermittent Jointed Rock Bridge Based on Acoustic Emission (AE) and Digital Image Correlation (DIC). Materials 2024, 17, 3190. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Z.; Chen, Y.; Liu, Y.; Luo, X.; Dai, B. Experimental Investigation of Mechanical and Fracture Behavior of Parallel Double Flawed Granite Material under Impact with Digital Image Correlation. Materials 2023, 16, 2263. [Google Scholar] [CrossRef]

- Shan, P.; Lai, X. Mesoscopic Structure PFC Similar to 2D Model of Soil Rock Mixture Based on Digital Image. J. Vis. Commun. Image Represent. 2019, 58, 407–415. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, S.; Tian, W.; Wu, S. Experimental and Dem Study on Failure Behavior and Stress Distribution of Flawed Sandstone Specimens under Uniaxial Compression. Theor. Appl. Fract. Mech. 2022, 118, 103266. [Google Scholar] [CrossRef]

| Number | Layer | Thickness /m | Unit Gravity γ/(kN/m3) | Elastic Modulus E/MPa | Poisson’s Ratio μ/- | Cohesion c/kPa | Friction Angle φ/(°) | Void Ratio e/- | Permeability Coefficient k/(cm/s) |

|---|---|---|---|---|---|---|---|---|---|

| ① | Miscellaneous fill | 3.0 | 18.8 | 2 | 0.15 | 8.0 | 10.0 | 0.842 | 3.42 × 10−9 |

| ② | Mucky soil | 2.5 | 17.0 | 6 | 0.35 | 7.6 | - | 1.365 | 2.36 × 10−12 |

| ③ | Completely weathered sandstone | 3.5 | 20.2 | 1600 | 0.28 | 36.3 | 19.7 | 0.620 | 0.295 × 10−9 |

| ④ | Strongly weathered sandstone | 2.0 | 20.2 | 2000 | 0.25 | 41.6 | 24.3 | 0.547 | 0.496 × 10−9 |

| ⑤ | Medium weathered sandstone | 8.0 | 25.3 | 2300 | 0.22 | 120.0 | 36.0 | 0.340 | 0.649 × 10−9 |

| ⑥ | Slightly weathered sandstone | - | 25.6 | 6500 | 0.20 | 280.0 | 43.0 | 0.160 | 0.295 × 10−9 |

| Materials | Coarse Aggregate | Fine Aggregate | Cement | Fly Ash | Water | Water Reducer |

|---|---|---|---|---|---|---|

| Material ratio | 5.279 | 5.752 | 2 | 0.364 | 1 | 0.054 |

| Particle Density/(kg/m) | Minimum Particle Radius/m | Maximum Particle Radius/m | Particle Friction Factor/- | Particle Elastic Modulus/kPa | Particle Contact Stiffness Ratio/- |

| 2650 | 5 × 10−4 | 7.5 × 10−4 | 0.6 | 3 × 106 | 1.3 |

| Parallel bond radius factor/- | Parallel bond elastic modulus/kPa | Parallel bond stiffness ratio/- | Parallel bond normal stiffness/kPa | Parallel bond tangential stiffness/kPa | - |

| 0.22 | 2.17 × 105 | 1.3 | 1.55 × 104 | 1.55 × 104 | - |

| Particle Density/(kg/m) | Minimum Particle Radius/m | Maximum Particle Radius/m | Particle Friction Factor/- | Particle Elastic Modulus/kPa | Particle Contact Stiffness Ratio/- |

| 2650 | 5 × 10−4 | 7.5 × 10−4 | 0.5 | 3 × 106 | 1.3 |

| Parallel bond radius factor/- | Parallel bond elastic modulus/kPa | Parallel bond stiffness ratio/- | Parallel bond normal stiffness/kPa | Parallel bond tangential stiffness/kPa | - |

| 0.22 | 2 × 106 | 1.3 | 1.5 × 105 | 1.5 × 105 | - |

| Particle Density/(kg/m) | Minimum Particle Radius/m | Maximum Particle Radius/m | Particle Friction Factor/- | Particle Elastic Modulus/kPa | Particle Contact Stiffness Ratio/- |

| 2000 | 5 × 10−4 | 7.5 × 10−4 | 0.5 | 3 × 106 | 1.3 |

| Parallel bond radius factor/- | Parallel bond elastic modulus/kPa | Parallel bond stiffness ratio/- | Parallel bond normal stiffness/kPa | Parallel bond tangential stiffness/kPa | - |

| 0.22 | 2 × 105 | 1.3 | 8.5 × 104 | 8.5 × 104 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhou, X.; Liu, X.; Suliman, L.; Yu, W. Shear Characteristics and Failure Evolution Process of the Cantilever Anti-Floating Ledge in Rock Strata: A Case Study of Guangzhou Metro Stations. Appl. Sci. 2025, 15, 11009. https://doi.org/10.3390/app152011009

Wang L, Zhou X, Liu X, Suliman L, Yu W. Shear Characteristics and Failure Evolution Process of the Cantilever Anti-Floating Ledge in Rock Strata: A Case Study of Guangzhou Metro Stations. Applied Sciences. 2025; 15(20):11009. https://doi.org/10.3390/app152011009

Chicago/Turabian StyleWang, Linfeng, Xiaohan Zhou, Xinrong Liu, Lojain Suliman, and Wenbing Yu. 2025. "Shear Characteristics and Failure Evolution Process of the Cantilever Anti-Floating Ledge in Rock Strata: A Case Study of Guangzhou Metro Stations" Applied Sciences 15, no. 20: 11009. https://doi.org/10.3390/app152011009

APA StyleWang, L., Zhou, X., Liu, X., Suliman, L., & Yu, W. (2025). Shear Characteristics and Failure Evolution Process of the Cantilever Anti-Floating Ledge in Rock Strata: A Case Study of Guangzhou Metro Stations. Applied Sciences, 15(20), 11009. https://doi.org/10.3390/app152011009