Study on the Evolution Patterns of Cavitation Clouds in Friction-Shear Cavitating Water Jets

Abstract

1. Introduction

2. Materials and Methods

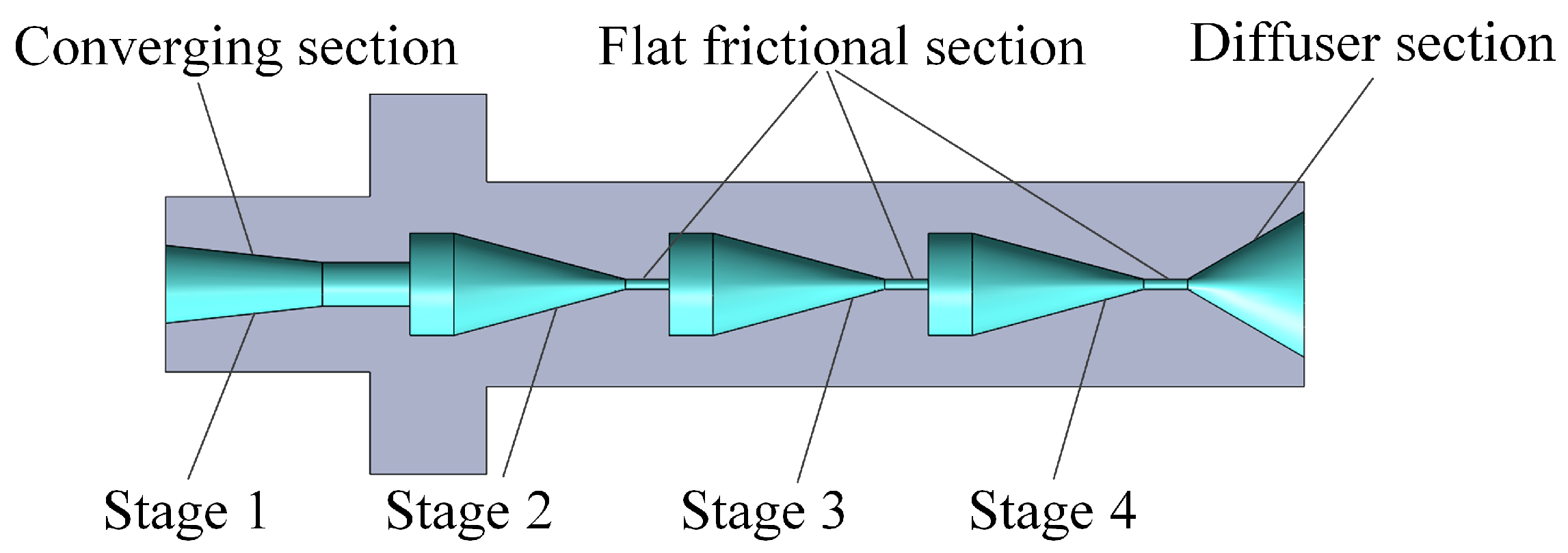

2.1. Cavitating Jet Nozzle with Friction-Shear Effects

- (1)

- Fluid acceleration and kinetic energy impartment. According to the continuity equation for incompressible flow:where Q is the volumetric flow rate, Ai is the inlet cross-sectional area of the converging section, Ao is the outlet cross-sectional area of the converging section, vi is the average flow velocity at the inlet, and vo is the average flow velocity at the outlet. The first nozzle stage, featuring a converging section, induces a significant reduction in the flow path cross-sectional area along the flow direction (Ao < Ai). According to Equation (1), this results in the outlet average velocity vo significantly exceeding the inlet velocity vi under a constant flow rate Q, thereby conferring high initial kinetic energy to the fluid.

- (2)

- Intensification of shear stress within the fluid, enhancing friction-shear coupling effects. Stages 2 to 4 each incorporate flat frictional sections within their internal flow paths. For a Newtonian fluid (assuming no-slip boundary conditions), the shear stress τ within the fluid satisfies Equation [33]:where μ is the dynamic viscosity of the fluid and γ represents the velocity gradient. The confined channel height (700–600 μm) in these flat frictional sections induces a significant velocity gradient, yielding high shear stress. This intensified shear stress constitutes the core driving force of the friction-shear coupling effects. Consequently, as layered mineral particles traverse these regions, they undergo intense friction and shear, promoting effective interlayer delamination.

- (3)

- Active induction of cavitation. Stage 4 incorporates a diffuser section. The geometric expansion of this diffuser is designed to generate a substantial pressure drop in the flow field, creating the low-pressure conditions required for cavitation inception. The propensity for cavitation is characterized by the cavitation number, σ [34,35,36]:where p1 is the jet pressure (at the nozzle inlet), p2 is the ambient pressure (the static water pressure inside the cavitation tank at the nozzle outlet), and pv is the saturated vapor pressure of water at room temperature. Cavitation occurs when σ falls below a critical value σc. The diffuser section is designed to reduce the ambient pressure p2. This decrease in p2 lowers the cavitation number σ, thereby inducing cavitation. Studies indicate [31,37] that optimal cavitation effects are achieved with divergence angles within 40–60°. The divergence angle θ of conventional nozzles is defined by:where ro is the equivalent outlet radius, ri is the equivalent inlet radius, and Lk is the diffuser length. Based on Equation (4), the equivalent divergence angles for the present nozzle were calculated to be 60° in the height direction and 47.27° in the width direction, both of which fall within the recommended effective range.

2.2. Test System and Experimental Setup

2.3. Test Procedure

3. Results

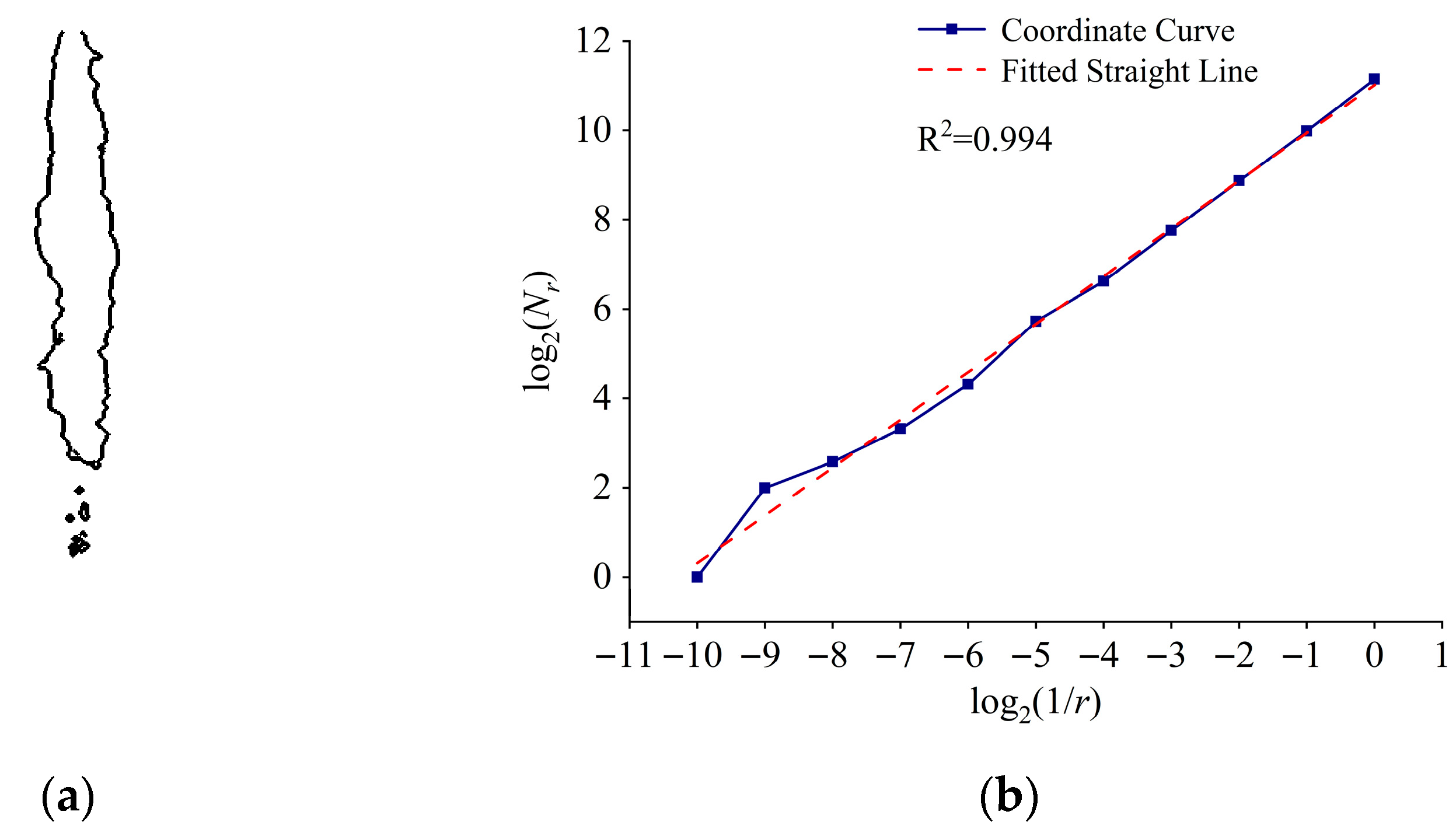

3.1. Image Processing Methods and Procedure

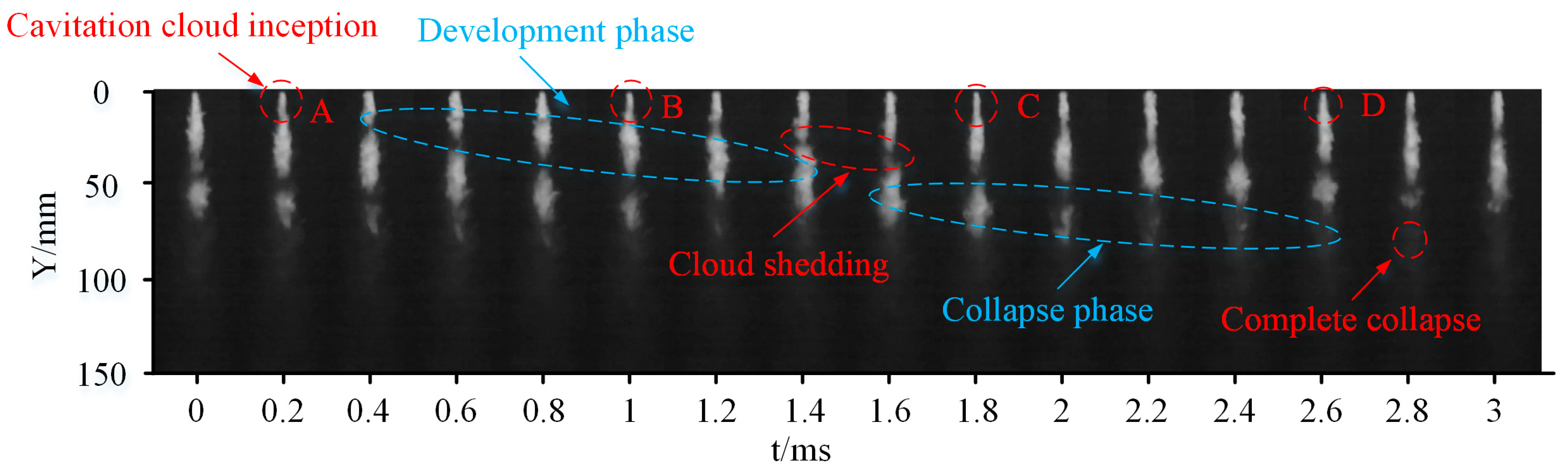

3.2. Dynamic Behavior of Cavitation Clouds Under Constant Jet Pressure

3.3. Characteristics of Cavitation Clouds Under Varying Jet Pressures

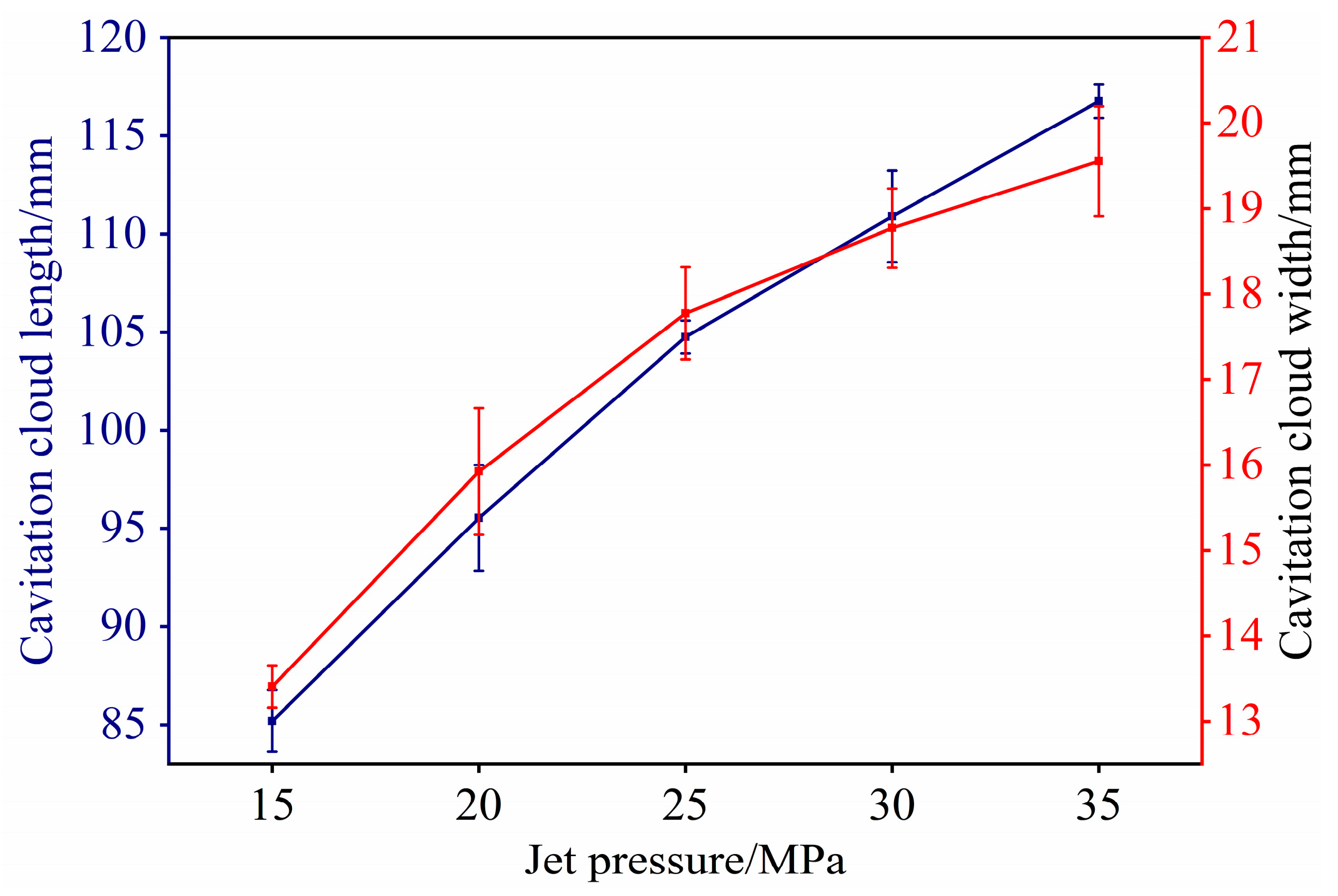

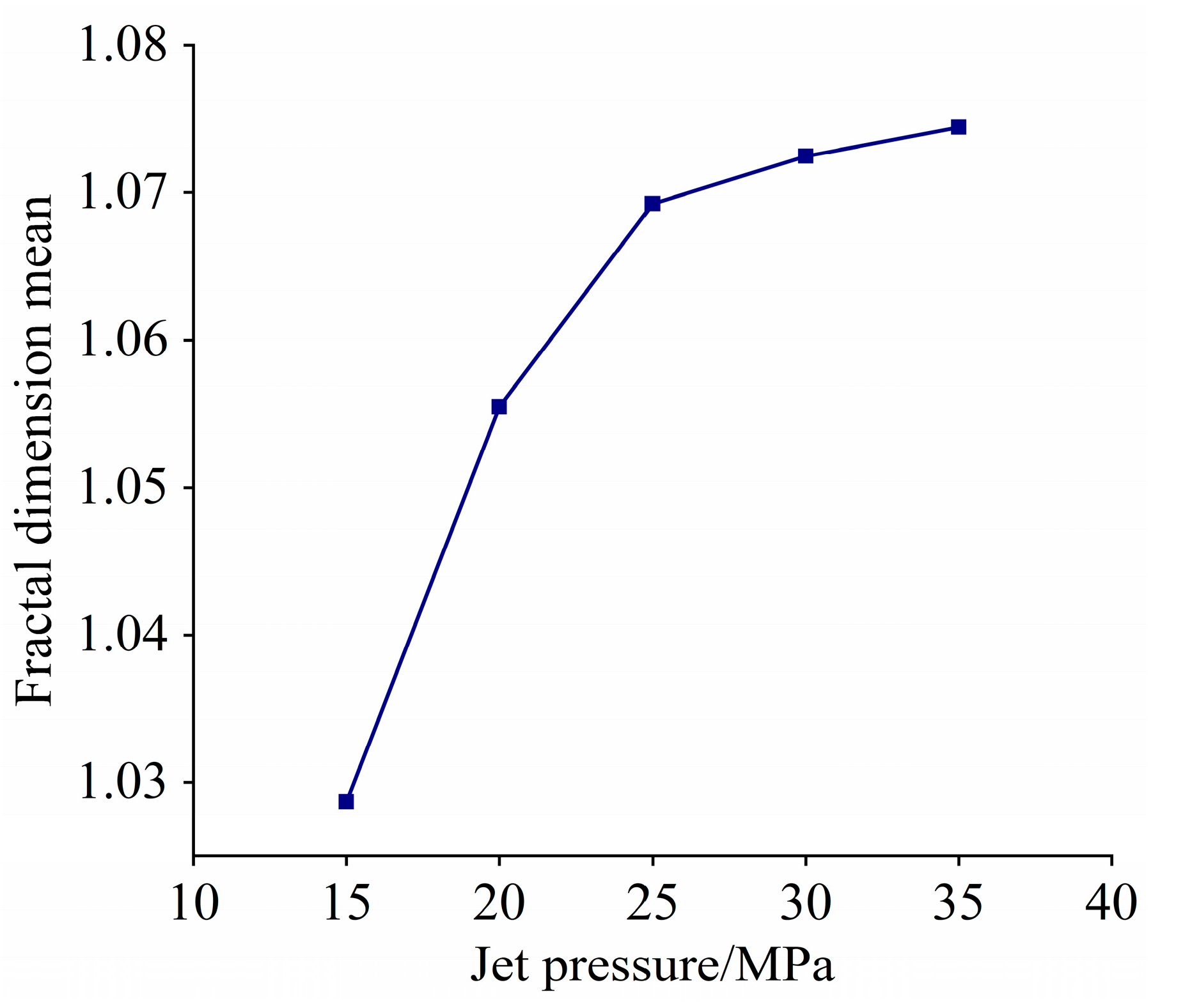

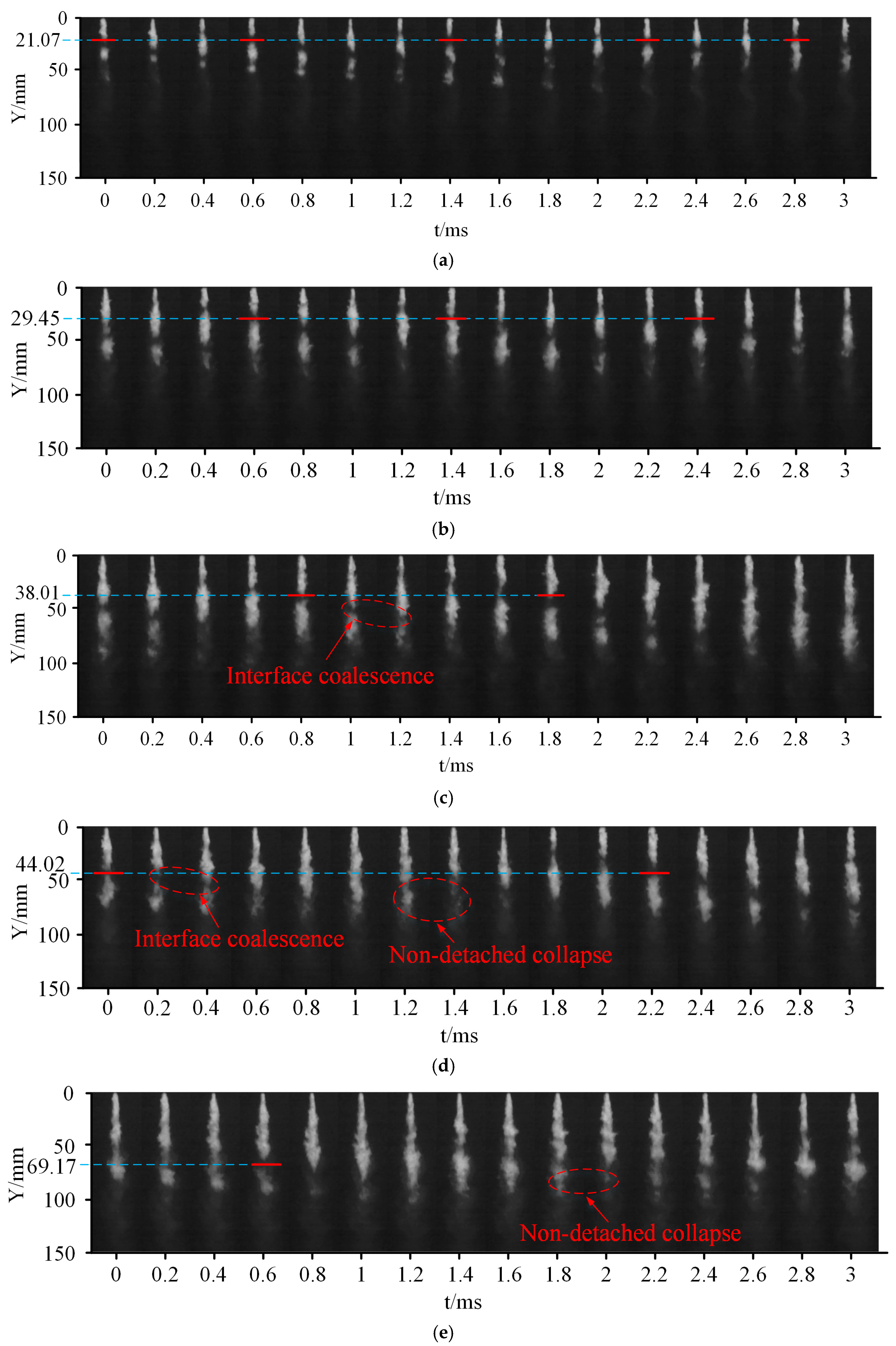

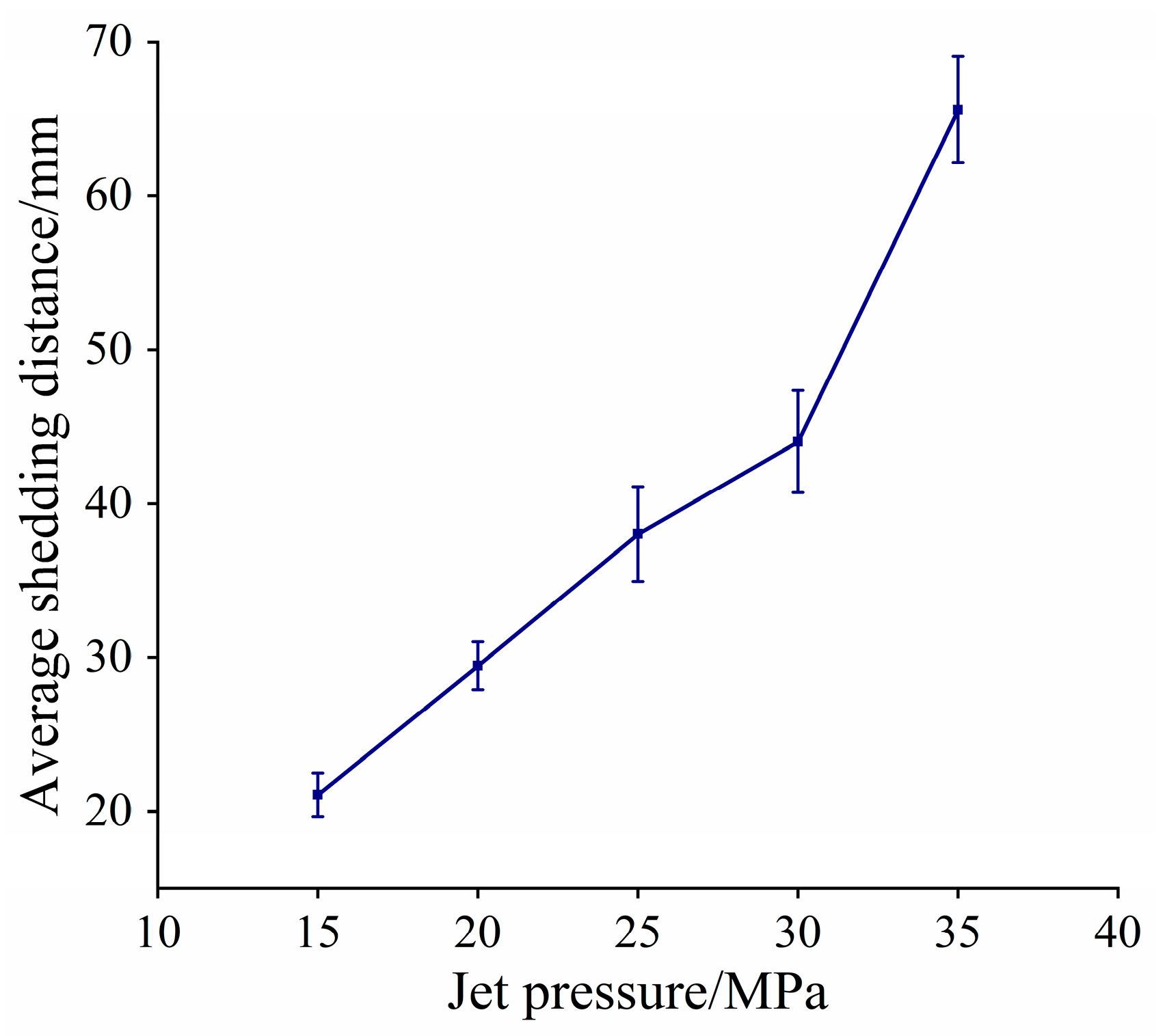

3.3.1. Morphological Features of Cavitation Clouds

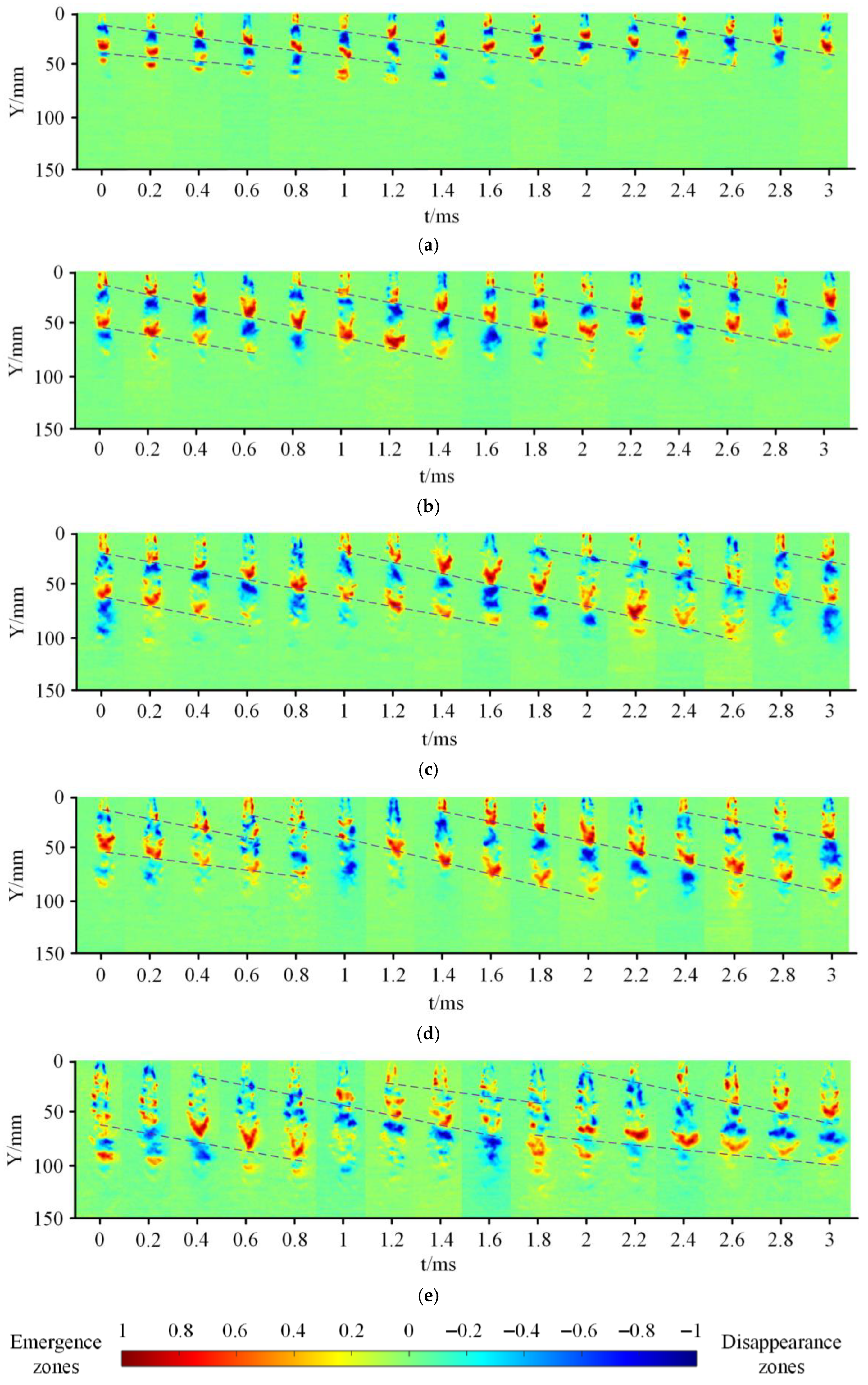

3.3.2. Dynamic Evolution of Cavitation Clouds Under Varying Jet Pressures

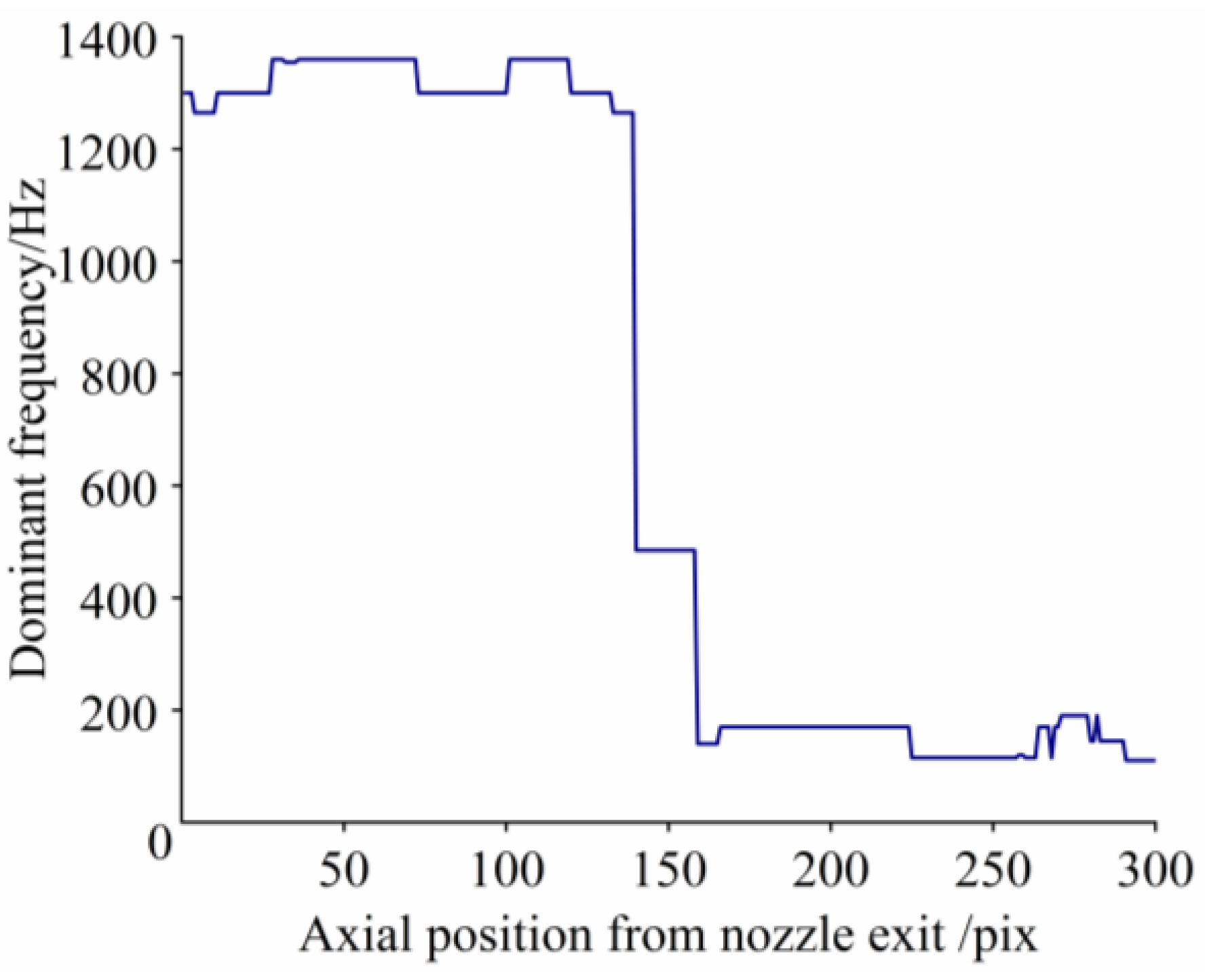

3.3.3. Shedding Frequency of Cavitation Clouds Under Varying Jet Pressures

4. Discussion

5. Conclusions

- (1)

- For a novel nozzle with a multi-stage flow path structure (converging section, flat frictional section, diffuser section), a friction-shear cavitating water jet intended for layered mineral liberation and characterized by a “friction-shear” coupling effect was proposed.

- (2)

- The regulatory effect of jet pressure on the cavitation cloud evolution behavior of the CJN-FSE was investigated. Within the 15–25 MPa range, the cavitation clouds exhibit stable periodic evolution (inception, development, shedding, collapse). When the pressure exceeds 30 MPa, excessive flow field kinetic energy leads to mutual interference between clouds, resulting in a transition to an unsteady shedding mode. The geometric dimensions (length, width) and morphological complexity (box-counting dimension) of the cavitation clouds increase monotonically with pressure, while the shedding frequency decreases.

- (3)

- Based on the clear correlation between cavitation stability and jet pressure, we recommend maintaining the operational pressure at or below 30 MPa for mineral liberation applications. This pressure threshold is identified as the upper limit for preserving stable and controllable cavitation, which is a critical prerequisite for achieving uniform and efficient liberation performance. This finding provides a crucial operational guideline for the future application of the CJN-FSE.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hutli, E.; Nedeljkovic, M.; Bonyár, A. Dynamic behaviour of cavitation clouds: Visualization and statistical analysis. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 281. [Google Scholar] [CrossRef]

- Soyama, H. Cavitating Jet: A Review. Appl. Sci. 2020, 10, 7280. [Google Scholar] [CrossRef]

- Yang, Y.F.; Wang, G.W.; Shi, W.D.; Li, W.; Ji, L.L.; Wang, H.L. Turbulence Characteristics in the Mixing Layer of a Submerged Cavitating Jet at High Reynolds Numbers. Sustainability 2022, 14, 11963. [Google Scholar] [CrossRef]

- Han, L.; Zhang, M.D.; Huang, G.H.; Huang, B. Energy transformation mechanism of a gas bubble collapse in the free-field. Chin. J. Theor. Appl. Mech. 2021, 53, 1288–1301. [Google Scholar] [CrossRef]

- Schenke, S.; van Terwisga, T.J.C. An energy conservative method to predict the erosive aggressiveness of collapsing cavitating structures and cavitating flows from numerical simulations. Int. J. Multiph. Flow 2019, 111, 200–218. [Google Scholar] [CrossRef]

- Peng, C.; Tian, S.C.; Li, G.S. Joint experiments of cavitation jet: High-speed visualization and erosion test. Ocean Eng. 2018, 149, 1–13. [Google Scholar] [CrossRef]

- Li, X.F.; Duan, Y.X.; Zhang, Y.N.; Tang, N.N. Retardant Effects of Collapsing Dynamics of a Laser-Induced Cavitation Bubble Near a Solid Wall. Symmetry 2019, 11, 1051. [Google Scholar] [CrossRef]

- Bukharin, N.; El Hassan, M.; Omelyanyuk, M.; Nobes, D. Applications of cavitating jets to radioactive scale cleaning in pipes. Energy Rep. 2020, 6, 1237–1243. [Google Scholar] [CrossRef]

- Gu, J.Y.; Luo, C.H.; Lu, Z.B.; Ma, P.C.; Xu, X.C.; Ren, X.D. Bubble dynamic evolution, material strengthening and chemical effect induced by laser cavitation peening. Ultrason. Sonochem. 2021, 72, 105441. [Google Scholar] [CrossRef]

- Soyama, H. Cavitation Peening: A Review. Metals 2020, 10, 270. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Tech. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- El Hassan, M.; Bukharin, N.; Al-Kouz, W.; Zhang, J.W.; Li, W.F. A Review on the Erosion Mechanism in Cavitating Jets and Their Industrial Applications. Appl. Sci. 2021, 11, 3166. [Google Scholar] [CrossRef]

- Li, G.S.; Shen, Z.H. Theory and Application of Self-Resonating Cavitating Water Jet, 1st ed.; China University of Petroleum Press: Dongying, China, 2008; p. 4. ISBN 978-7-5636-2146-0. [Google Scholar]

- Guo, C.W.; Dong, L. Energy Consumption in Comminution of Mica with Cavitation Abrasive Water Jet. J. Chin. Univ. Min. Technol. 2007, 17, 251–254. [Google Scholar] [CrossRef]

- Dvorsky, R.; Lunacek, J.; Sliva, A. Dynamics analysis of cavitation disintegration of microparticles during nanopowder preparation in a new Water Jet Mill (WJM) device. Adv. Powder Technol. 2011, 22, 639–643. [Google Scholar] [CrossRef]

- Sen, S. Grinding of magnetite using a waterjet driven cavitation cell. Powder Technol. 2016, 297, 34–43. [Google Scholar] [CrossRef]

- Galecki, G.; Akar, G.; Sen, S.; Li, Y. Advanced studies on coal injection into a cavitation cell for the purpose of comminution. Arch. Min. Sci. 2012, 57, 769–778. [Google Scholar] [CrossRef]

- Galecki, G.; Sen, S.; Akar, G.; Li, Y. Parametric evaluation of coal comminution by waterjets. Int. J. Coal Prep. Util. 2013, 33, 36–46. [Google Scholar] [CrossRef]

- Dong, X.; Jiang, Y.; Guo, C.H. Mechanical mechanism of shear cavitating water jet dissociation of flake graphite. In Proceedings of the 2024 7th International Conference on Mechanical, Electrical and Material Application, Changsha, China, 23–25 February 2024. [Google Scholar]

- Soyama, H. Enhancing the aggressive intensity of a cavitating jet by means of the nozzle outlet geometry. J. Fluids Eng. 2011, 133, 101301. [Google Scholar] [CrossRef]

- Dong, W.Q.; Yao, L.G.; Luo, W.L. Numerical Simulation of Flow Field of Submerged Angular Cavitation Nozzle. Appl. Sci. 2023, 13, 613. [Google Scholar] [CrossRef]

- Huang, S.W.; Huang, J.P.; He, K. Research on erosion effect of various submerged cavitating jet nozzles and design of self-rotating cleaning device. Appl. Sci. 2024, 14, 1433. [Google Scholar] [CrossRef]

- Hutli, E.; Nedeljkovic, M.S.; Czifrus, S. Study and Analysis of the Cavitating and Non-Cavitating Jets Part Two Parameters Controlling the Jet Action and a New Formula for Cavitation Number Calculation. Therm. Sci. 2020, 24, 407–419. [Google Scholar] [CrossRef]

- Liu, H.S.; Xu, Y.; Wang, Z.C.; Zhang, J.L.; Wang, J.X. Experimental and numerical simulations to examine the mechanism of nozzle geometry affecting cavitation water jets. Geoenergy Sci. Eng. 2024, 233, 212511. [Google Scholar] [CrossRef]

- Kamisaka, H.; Soyama, H. Enhancing the Aggressive Intensity of a Cavitating Jet by Introducing Water Flow Holes and a Long Guide Pipe. J. Fluids Eng. 2021, 143, 031201. [Google Scholar] [CrossRef]

- Cai, T.F.; Chamorro, L.P.; Ma, F.; Han, J. Impact of nozzle lip on the cavitation cloud characteristics of self-excited cavitating waterjets. Ocean Eng. 2023, 285, 115329. [Google Scholar] [CrossRef]

- Prasetya, R.; Sou, A.; Moon, S.; Pratama, R.H.; Wada, Y.; Yokohata, H. X-ray Phase Contrast Imaging of Cavitation and Discharged Liquid Jet in Nozzles with Various Sizes. At. Sprays 2019, 29, 59–78. [Google Scholar] [CrossRef]

- Wang, G.W.; Yang, Y.F.; Wang, C.; Shi, W.D.; Li, W.; Pan, B. Effect of Nozzle Outlet Shape on Cavitation Behavior of Submerged High-Pressure Jet. Machines 2022, 10, 4. [Google Scholar] [CrossRef]

- Guo, C.H.; Dong, X.; Song, H.R.; Jiang, Y. Features of Structure and Flow Field in Homemade Co-Current Cavitation Water Jet Nozzle. Materials 2025, 18, 146. [Google Scholar] [CrossRef] [PubMed]

- Ullas, P.K.; Chatterjee, D.; Vengadesan, S. Experimental study on the effect of throat length in the dynamics of internal unsteady cavitating flow. Phys. Fluids 2023, 35, 023332. [Google Scholar] [CrossRef]

- Yang, Y.F.; Li, W.; Shi, W.D.; Zhou, L.; Zhang, W.Q. Experimental Study on the Unsteady Characteristics and the Impact Performance of a High-Pressure Submerged Cavitation Jet. Shock Vib. 2020, 2020, 1701843. [Google Scholar] [CrossRef]

- Vidvans, A.N.; Melkote, S.N.; Sanders, D.G. Enhancing Cavitation Intensity in Co-Flow Water Cavitation Peening with Organ Pipe Nozzles. J. Manuf. Sci. Eng. ASME 2021, 143, 071010. [Google Scholar] [CrossRef]

- Yin, S.H.; Hao, S.; Zhang, H.S.; Hu, S.; Cao, D.Y. The calculation medel of conveying resistance of waste rock-unclassified pastes slurry mixed with water-reducing agent. J. Harbin Eng. Univ. 2022, 43, 212–220. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, H.S.; Wang, Z.C.; Zhang, J.L.; Wang, J.X. Analysis of the Effects of Nozzle Geometry on the Cavitation Water Jet Flow Field Using Orthogonal Decomposition. Iran. J. Sci. Technol. Trans. Mech. Eng. 2024, 48, 119–132. [Google Scholar] [CrossRef]

- Zhu, R.Y.; Zhu, H.T.; Zhang, X.H.; Pan, S.Z.; Zhang, C.; Xie, B. Experimental study on the unsteady behavior and frequency characteristics of high-speed submerged cavitating water jets. Phys. Fluids 2024, 36, 103336. [Google Scholar] [CrossRef]

- Nishimura, S.; Takakuwa, O.; Soyama, H. Similarity Law on Shedding Frequency of Cavitation Cloud Induced by a Cavitating Jet. J. Fluid Sci. Technol. 2012, 7, 405–420. [Google Scholar] [CrossRef]

- Yang, Y.F.; Li, W.; Shi, W.D.; Zhang, W.Q.; El-Emam, M.A. Numerical Investigation of a High-Pressure Submerged Jet Using a Cavitation Model Considering Effects of Shear Stress. Processes 2019, 7, 541. [Google Scholar] [CrossRef]

- Lu, Y.P.; Wang, J.; Yu, H.L. 3D image processing and analyzing system for industrial computed tomography. Chin. J. Sci. Instrum. 2009, 30, 444–448. [Google Scholar] [CrossRef]

- Dong, J.M.; Li, S.; Meng, R.X.; Zhong, X.; Pan, X.X. Research on Cavitation Characteristics of Two-Throat Nozzle Submerged Jet. Appl. Sci. 2022, 12, 536. [Google Scholar] [CrossRef]

- Cui, Y.Y.; Zhao, M.J.; Ding, Q.M.; Cheng, B. Study on Dynamic Evolution and Erosion Characteristics of Cavitation Clouds in Submerged Cavitating Water Jets. J. Mar. Sci. Eng. 2024, 12, 641. [Google Scholar] [CrossRef]

- Peng, G.Y.; Wakui, A.; Oguma, Y.; Shimizu, S.; Ji, H. Periodic Behavior of Cavitation Cloud Shedding in Submerged Water Jets Issuing from a Sheathed Pipe Nozzle. J. Flow Control Meas. Vis. 2018, 6, 15–26. [Google Scholar] [CrossRef]

- Hutli, E.; Nedeljkovic, M.S.; Radovic, N.A.; Bonyár, A. The relation between the high speed submerged cavitating jet behaviour and the cavitation erosion process. Int. J. Multiph. Flow 2016, 83, 27–38. [Google Scholar] [CrossRef]

- Zhu, R.Y.; Zhang, X.H.; Zhu, H.T.; Zhang, C.; Pan, S.Z. On unsteady cavitation flow of a high-speed submerged water jet based on data-driven modal decomposition. Ocean Eng. 2024, 295, 116916. [Google Scholar] [CrossRef]

- Datseris, G.; Kottlarz, I.; Braun, A.P.; Parlitz, U. Estimating fractal dimensions: A comparative review and open source implementations. Chaos Interdiscip. J. Nonlinear Sci. 2023, 33, 102101. [Google Scholar] [CrossRef] [PubMed]

- Sajid, M.; Husain, A.; Reddy, J.; Alresheedi, M.T.; Al Yahya, S.A.; Al-Rajy, A. Box dimension of the border of Kingdom of Saudi Arabia. Heliyon 2023, 9, e14846. [Google Scholar] [CrossRef] [PubMed]

- Patiño-Ortiz, M.; Patiño-Ortiz, J.; Martínez-Cruz, M.; Esquivel-Patiño, F.; Balankin, A.S. Morphological Features of Mathematical and Real-World Fractals: A Survey. Fractal Fract. 2024, 8, 440. [Google Scholar] [CrossRef]

- Hutli, E.A.F.; Nedeljkovic, M.S. Frequency in Shedding/Discharging Cavitation Clouds Determined by Visualization of a Submerged Cavitating Jet. J. Fluids Eng. 2008, 130, 021304. [Google Scholar] [CrossRef]

- Li, F.Z.; Tan, Z.R.; Chen, L.Y.; Li, R.T.; Xu, Z.Y.; Wang, Y. Study on Dynamic Evolution of Cavitation Clouds and Optimization of Standoff Distance in Water Cavitation Peening. J. Mech. Eng. 2019, 55, 120–126. [Google Scholar] [CrossRef]

- Wright, M.M.; Epps, B.; Dropkin, A.; Truscott, T.T. Cavitation of a submerged jet. Exp. Fluids 2013, 54, 1541. [Google Scholar] [CrossRef]

- Peng, C.; Tian, S.C.; Li, G.S. Determination of the shedding frequency of cavitation cloud in a submerged cavitation jet based on high-speed photography images. J. Hydrodyn. 2021, 33, 127–139. [Google Scholar] [CrossRef]

- Peng, C.; Li, G.S.; Tian, S.C. Dynamics of cavitation cloud in submerged cavitation water jet. Pet. Sci. Bull. 2017, 2, 228–239. [Google Scholar] [CrossRef]

| pj (MPa) | Q (L/s) | Re | σ |

|---|---|---|---|

| 15 | 0.158 | 1.860 × 105 | 0.333 × 10−3 |

| 20 | 0.182 | 2.143 × 105 | 0.250 × 10−3 |

| 25 | 0.204 | 2.402 × 105 | 0.200 × 10−3 |

| 30 | 0.223 | 2.626 × 105 | 0.167 × 10−3 |

| 35 | 0.241 | 2.838 × 105 | 0.143 × 10−3 |

| pj (MPa) | DFmean | SD | R2mean | n |

|---|---|---|---|---|

| 15 | 1.0287 | 0.0243 | 0.9954 | 1000 |

| 20 | 1.0555 | 0.0258 | 0.9975 | 1000 |

| 25 | 1.0692 | 0.0202 | 0.9983 | 1000 |

| 30 | 1.0725 | 0.0208 | 0.9980 | 1000 |

| 35 | 1.0744 | 0.0196 | 0.9967 | 1000 |

| pj (MPa) | Dominant Frequency (Hz) | 95% Confidence Interval (Hz) |

|---|---|---|

| 15 | 1360 | 1359.02–1360.98 |

| 20 | 1300 | 1299.02–1300.98 |

| 25 | 1285 | 1283.88–1286.12 |

| 30 | 1165 | 1163.68–1166.32 |

| 35 | 640 | 638.92–641.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Jiang, Y.; Guo, C.; Chang, L. Study on the Evolution Patterns of Cavitation Clouds in Friction-Shear Cavitating Water Jets. Appl. Sci. 2025, 15, 10992. https://doi.org/10.3390/app152010992

Dong X, Jiang Y, Guo C, Chang L. Study on the Evolution Patterns of Cavitation Clouds in Friction-Shear Cavitating Water Jets. Applied Sciences. 2025; 15(20):10992. https://doi.org/10.3390/app152010992

Chicago/Turabian StyleDong, Xing, Yun Jiang, Chenhao Guo, and Lu Chang. 2025. "Study on the Evolution Patterns of Cavitation Clouds in Friction-Shear Cavitating Water Jets" Applied Sciences 15, no. 20: 10992. https://doi.org/10.3390/app152010992

APA StyleDong, X., Jiang, Y., Guo, C., & Chang, L. (2025). Study on the Evolution Patterns of Cavitation Clouds in Friction-Shear Cavitating Water Jets. Applied Sciences, 15(20), 10992. https://doi.org/10.3390/app152010992