A Drilling Cutting Derived Material for High Performance Borehole Sealing

Abstract

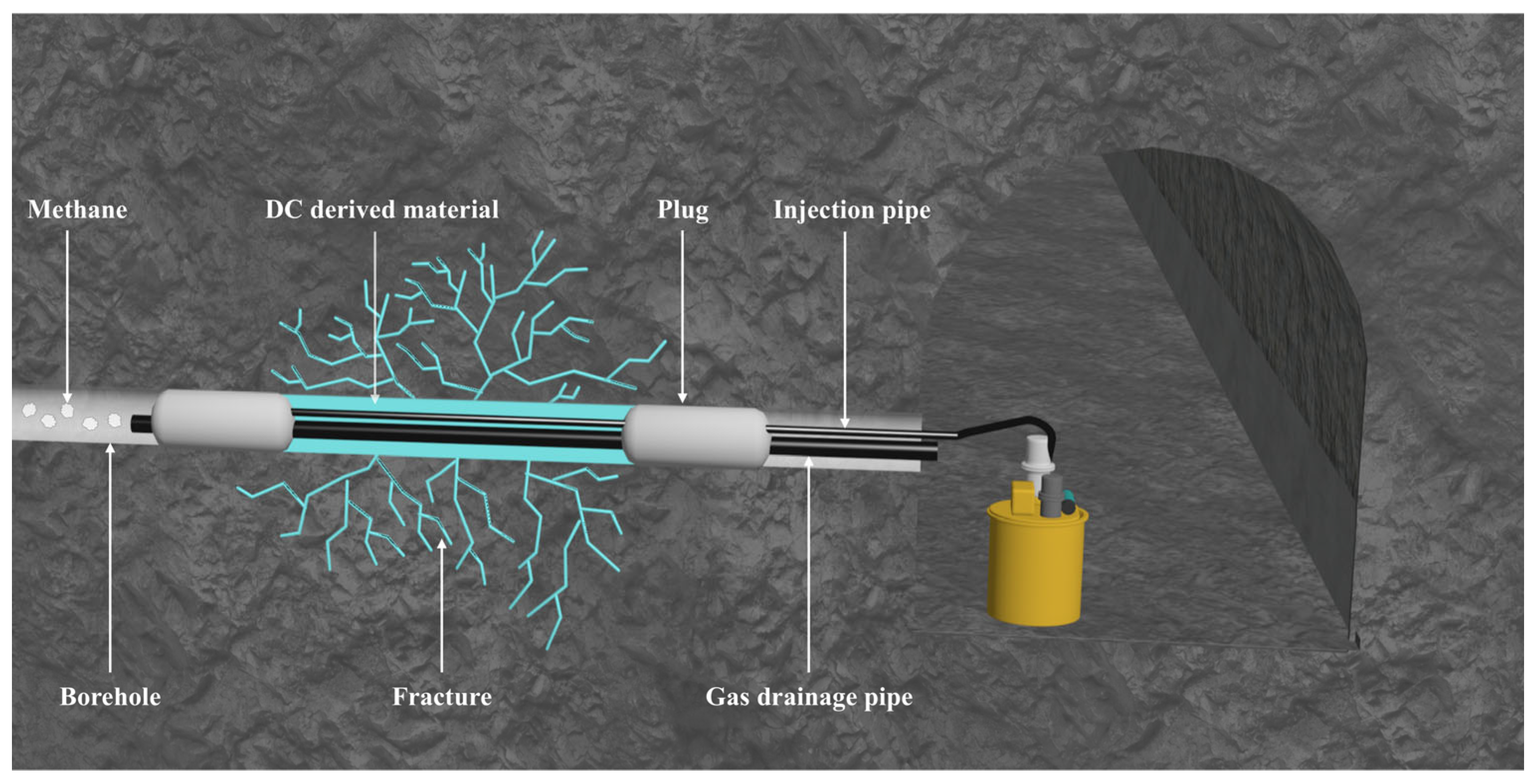

1. Introduction

2. Materials and Methods

3. Results and Discussion

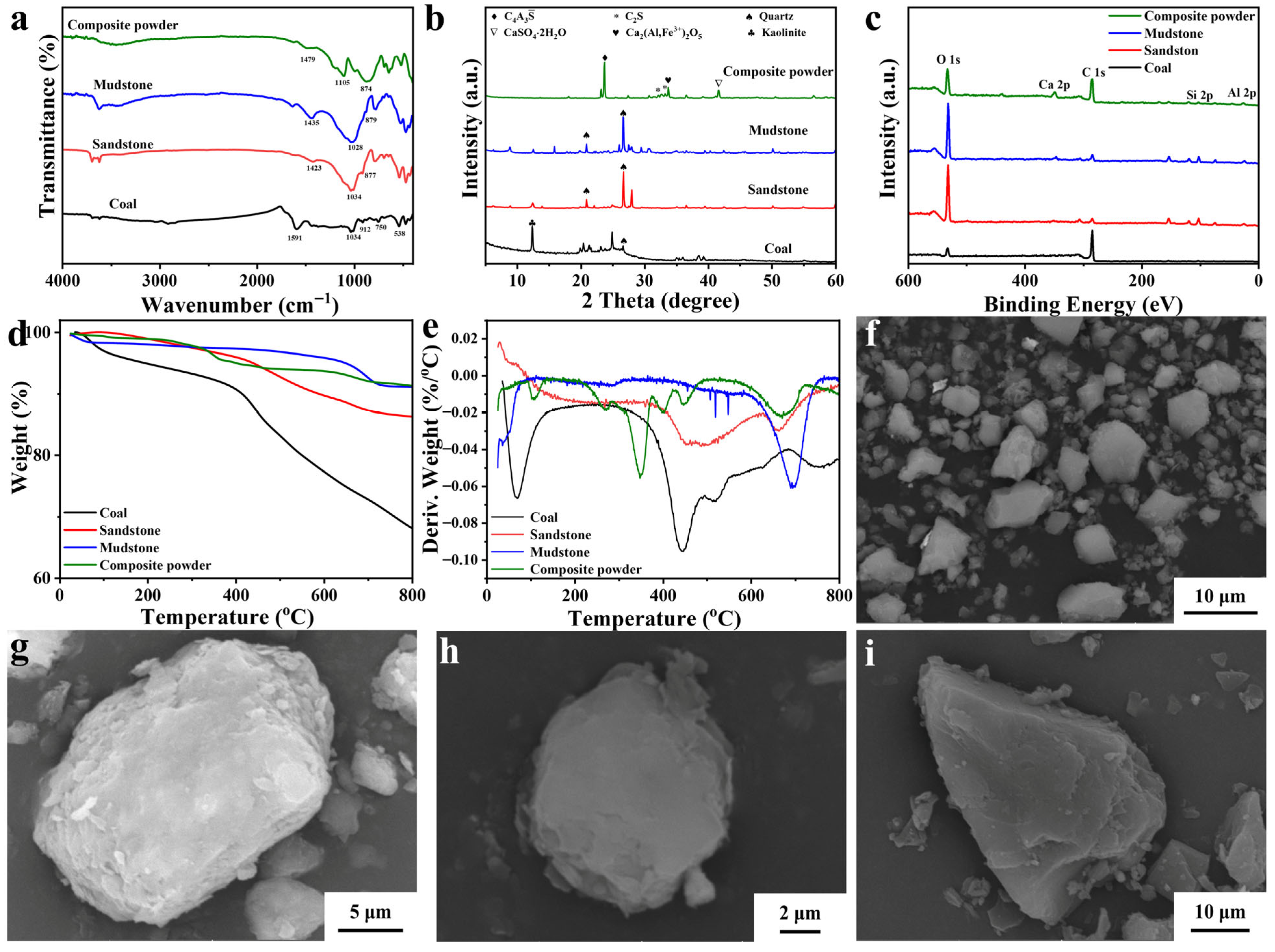

3.1. Characterization of the DC

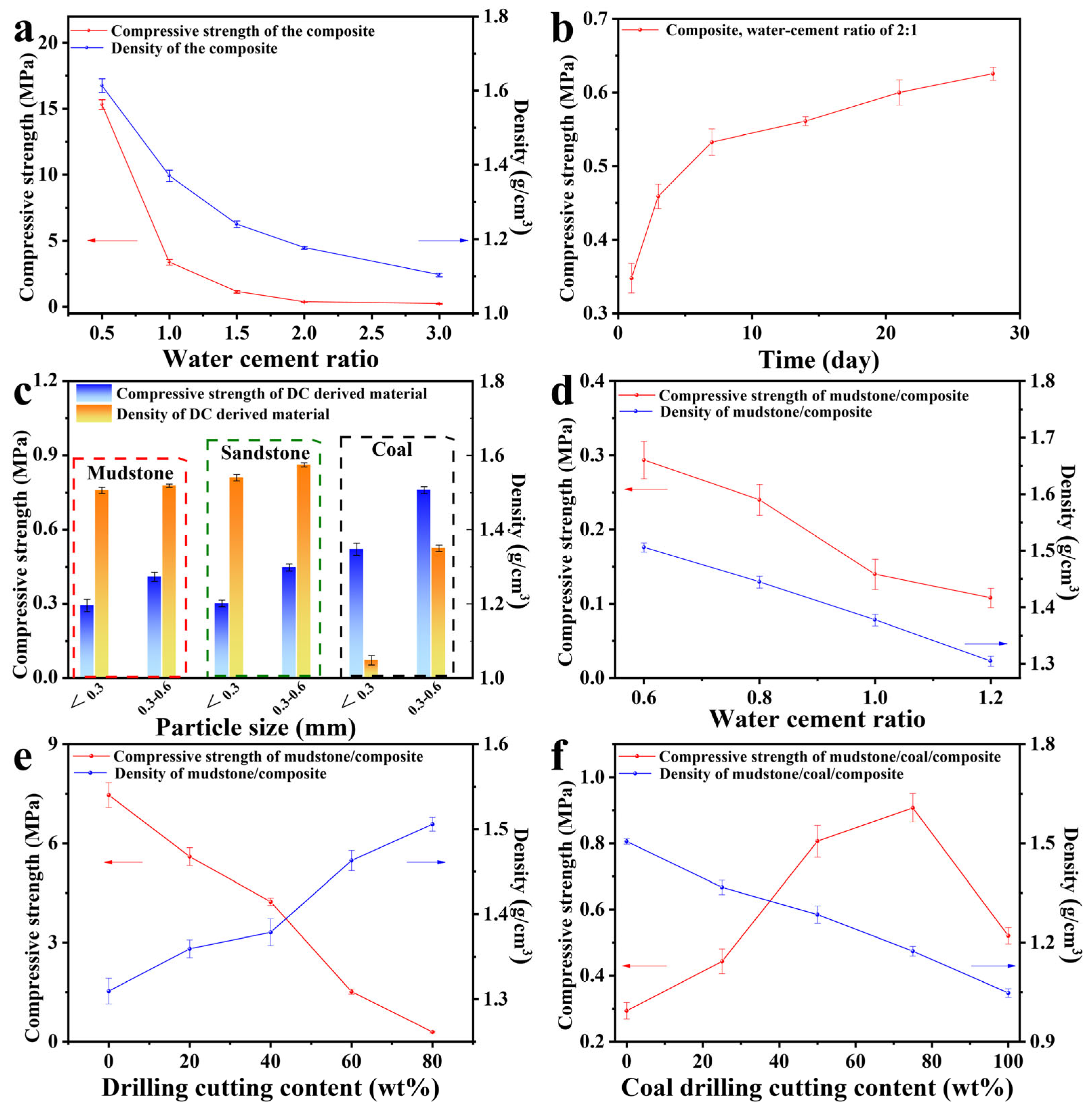

3.2. Mechanical Performance of the DC-Derived Material

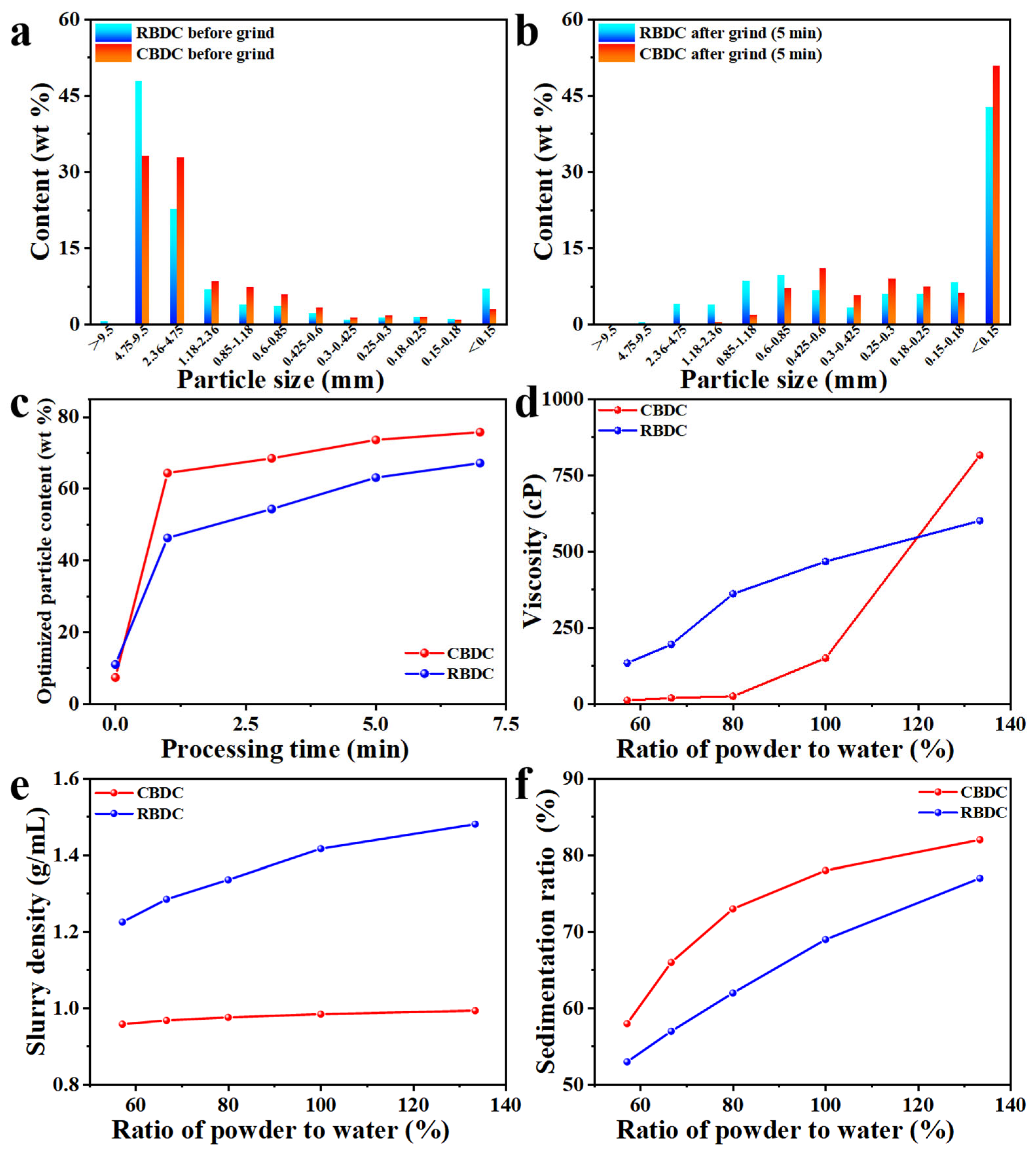

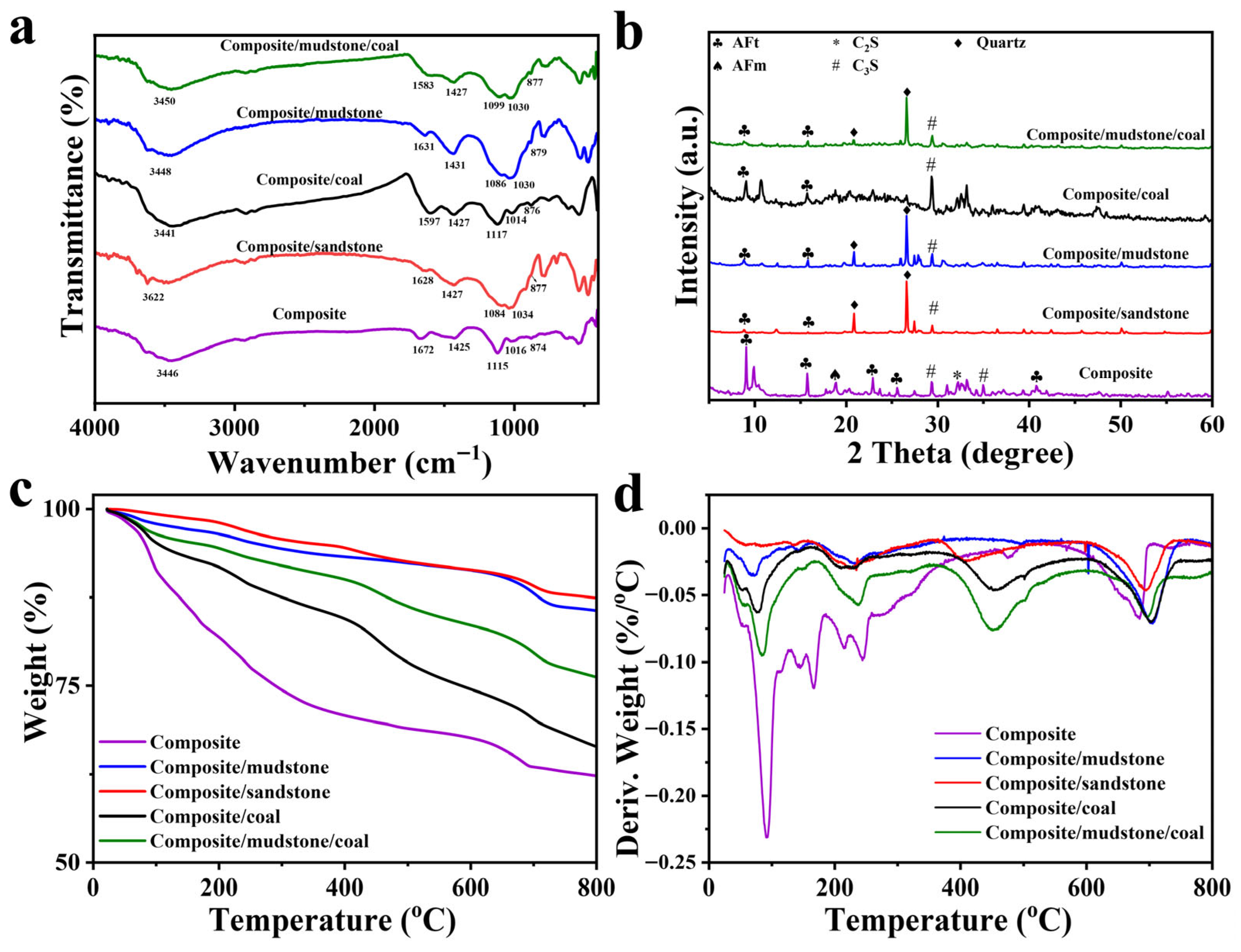

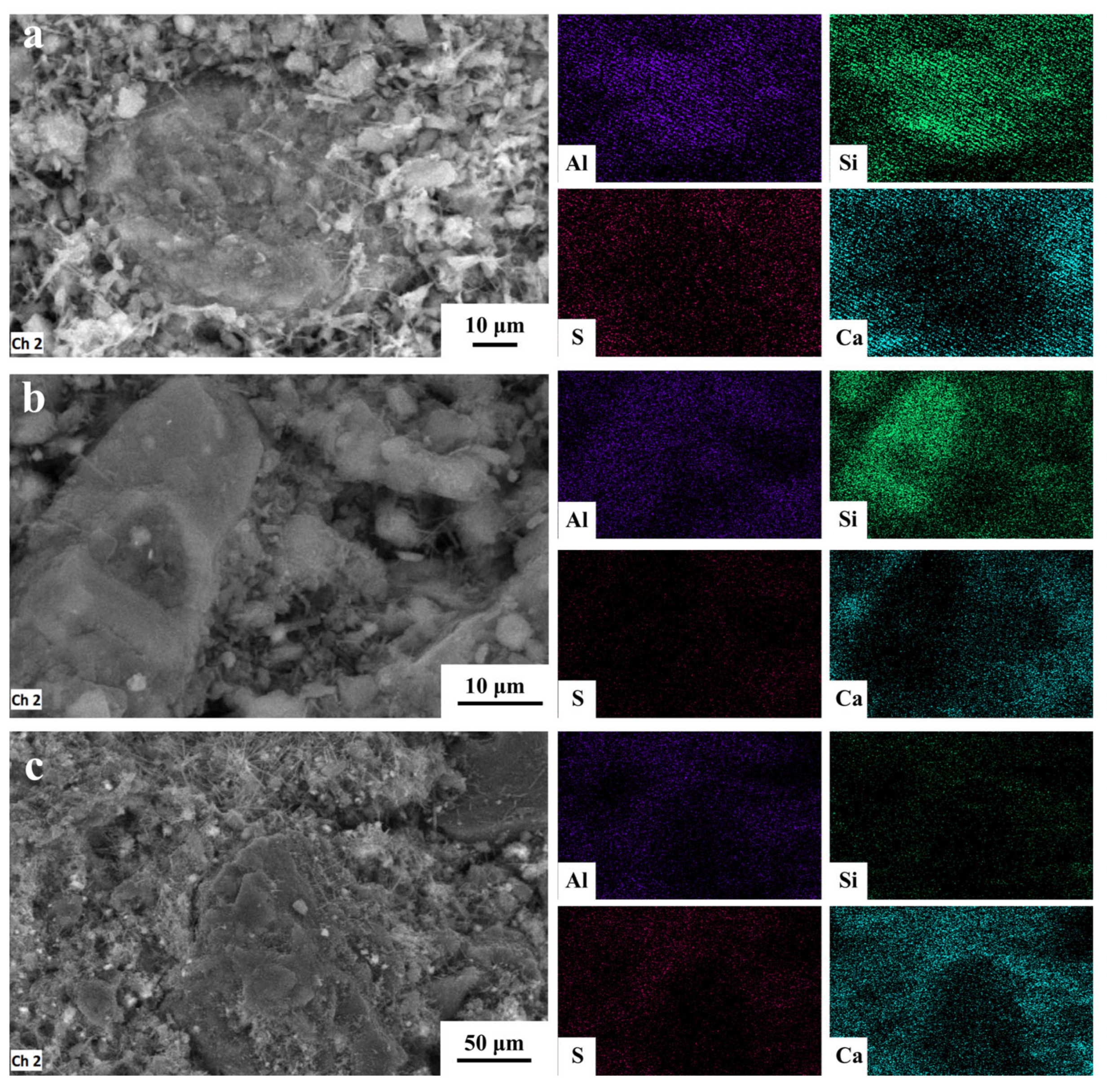

3.3. Physicochemical Properties of DC-Derived Material

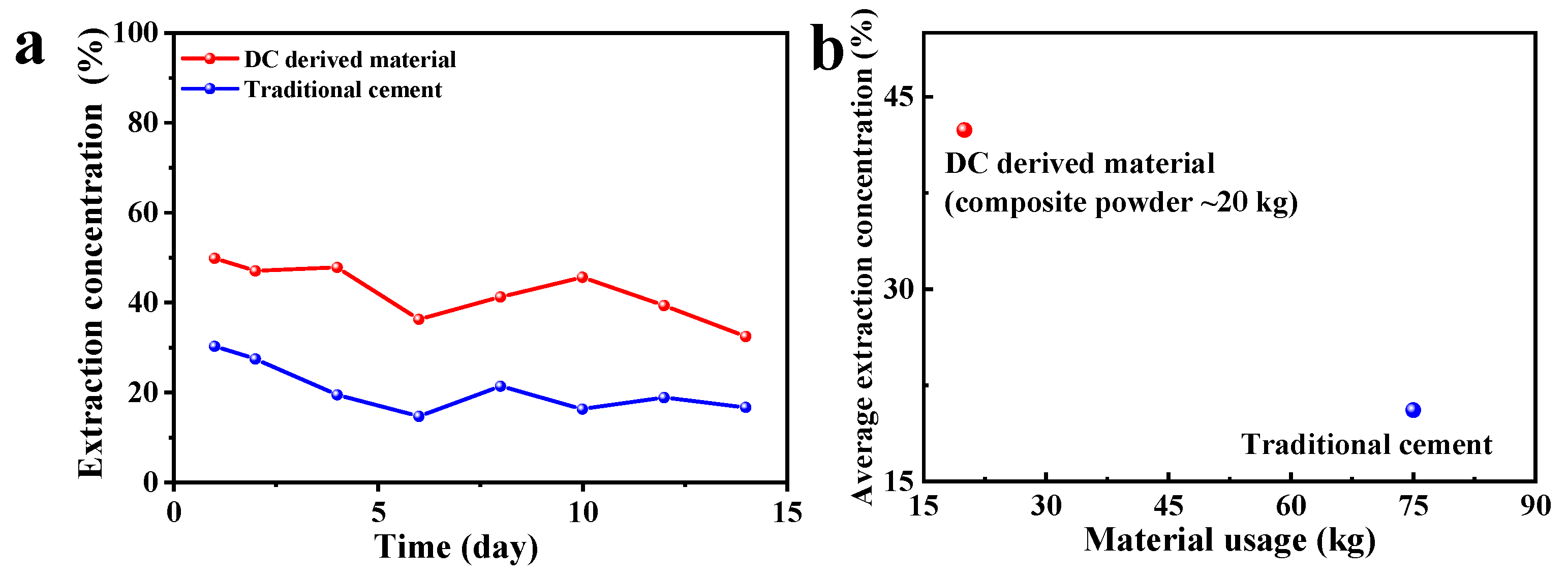

3.4. Sealing Performance of DC-Derived Material

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, J.; Chen, L.; Li, Z.; Huang, G. Study on Coal Fragmentation Induced by Instantaneously Depressurized Gas and Its Influence on Coal and Gas Outburst: A Case Study of Different Gas Types. Appl. Sci. 2025, 15, 9974. [Google Scholar] [CrossRef]

- Liu, C.; Yang, Z.; Qin, Y.; Yan, X.; Wang, Y.; Wang, Z. Excess Pore Pressure Behavior and Evolution in Deep Coalbed Methane Reservoirs. Int. J. Min. Sci. Technol. 2024, 34, 763–781. [Google Scholar] [CrossRef]

- Zhang, N.; Pan, Z.; Zhang, Z.; Zhang, W.; Zhang, L.; Baena-Moreno, F.M.; Lichtfouse, E. CO2 Capture from Coalbed Methane using Membranes: A Review. Environ. Chem. Lett. 2020, 18, 79–96. [Google Scholar] [CrossRef]

- Cheng, X.; Cheng, Y.; Wang, C.; Wang, J.; Hu, B. Methane as Probes for Characterizing Pore Volume in Coalbed Gas Reservoir: Expanding the Pore Analysis Method. Fuel 2025, 389, 134563. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Z.; Yue, J.; Zhou, A.; Liu, J.; Wang, L.; Wei, J.; Wang, K. A Novel Sealing-Free Technology for Coal Seam Gas Pressure Measurement: Based on Coal-Gas In-Situ Reservoir State Restoration. Fuel 2025, 399, 135628. [Google Scholar] [CrossRef]

- Nian, F.; Ju, F.; Zheng, C.; Wu, H.; Cheng, X. Effects of Coal Permeability Anisotropy on Gas Extraction Performance. Processes 2023, 11, 1408. [Google Scholar] [CrossRef]

- Shu, L. Study on Gas Extraction Technology for Goaf Using L-Shaped Borehole on the Ground. Appl. Sci. 2024, 14, 1594. [Google Scholar] [CrossRef]

- Xu, C.; Wang, K.; Li, X.; Yuan, L.; Zhao, C.; Guo, H. Collaborative Gas Drainage Technology of High and Low Level Roadways in Highly-Gassy Coal Seam Mining. Fuel 2022, 323, 124325. [Google Scholar] [CrossRef]

- Qin, R.R.; Zhang, C.; Jiang, B.; Liu, T.; Chang, J.; Fan, F. Preparation and performance of microencapsulated sealing material for coal mine gas drainage. ACS Omega 2022, 7, 47821–47831. [Google Scholar] [CrossRef]

- Liu, X.; Wei, S.; Yao, C.; Xu, S. Effect of Composite Fibers and Nanosilica on the Properties of Cement-Based Sealing Materials. ACS Omega 2025, 10, 6992–7003. [Google Scholar] [CrossRef]

- Hao, J.; Di, P.; Zhao, C.; Yang, W.; Li, X.; Shu, L. Environmental-Friendly, Long-Lastingly Moist Phase Change Gel with Tunable Cross-Linking Time for Effective Borehole Sealing. Langmuir 2024, 40, 16804–16812. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lao, J.; Zhou, Y.; Luo, X.; Du, S.; Song, H. In-Depth Review of Colloidal and Interfacial Fundamentals in Fracturing Development of Deep Coal Seam Methane. Adv. Colloid Interface Sci. 2025, 344, 103611. [Google Scholar] [CrossRef]

- Yuan, L.; Zhang, T.; Wang, Y.; Wang, X.; Wang, Y.; Hao, X. Scientific Problems and Key Technologies for Safe and Efficient Mining of Deep Coal Resources. J. China Coal Soc. 2025, 50, 1–12. [Google Scholar] [CrossRef]

- Liu, X.; Zhai, C.; Zheng, Y.; Wu, X.; Xu, J.; Tang, W.; Zhu, X.; Chen, A.; Xu, H.; Wang, Y. A Viscoelastic-Healing Suspension Sealing Material with a Double-Network Gel Structure for Improving Borehole-Sealing Performance. J. Appl. Polym. Sci. 2024, 141, e55963. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, K. A New Inorganic Sealing Material Used for Gas Extraction Borehole. Inorg. Chem. Commun. 2019, 102, 75–79. [Google Scholar] [CrossRef]

- Li, B.; Jian, W.; Zhang, J.; Wang, B.; Zhu, D.; Wang, N. Research Progress and Discussion on Modified Cement-Based Borehole Sealing Materials for Mining. ACS Omega 2023, 8, 13539–13550. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, Y.; Gao, X.; Wu, Q.; Zhang, Q.; Liu, C. Experimental Study on the Optimization of Polymer-Modified Cement-Based Composite Sealing Materials and Mechanical Properties and Permeability of Cemented Coal Bodies. Front. Mater. 2022, 9, 774887. [Google Scholar] [CrossRef]

- Li, H.; Guo, S.; Chen, H. Application of Coal-Powder Borehole-Sealing Material in Borehole-Sealing Engineering. Emerg. Mater. Res. 2019, 8, 290–296. [Google Scholar] [CrossRef]

- Chen, Y.; Zheng, Y.; Zhou, Y.; Zhang, W.; Li, W.; She, W.; Liu, J.; Miao, C. Multi-Layered Cement-Hydrogel Composite with High Toughness, Low Thermal Conductivity, and Self-Healing Capability. Nat. Commun. 2023, 14, 3438. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Hu, M.; Li, P.; Chang, Q.; Guo, J. An Alkali-Responsive Mineral Self-Healing Agent with Mechanical Property Enhancement for Cementitious Composites. Compos. Part B Eng. 2023, 266, 110986. [Google Scholar] [CrossRef]

- Feng, G.; Luo, S.; Luo, Q.; Long, W. Graphene Oxide-coated Sand for Enhancing Chloride Resistance of Cement-based Materials. J. Chin. Ceram. Soc. 2025, 03, 505–518. [Google Scholar] [CrossRef]

- Li, Y.; Chen, C.; Li, Z.; Li, Z. High-Throughput Atomistic Modeling of Nanocrystalline Structure and Mechanics of Calcium Aluminate Silicate Hydrate. Nat. Commun. 2025, 16, 5352. [Google Scholar] [CrossRef]

- Liu, M.; Hu, M.; Li, P.; Zhang, H.; Zhao, J.; Guo, J. A New Application of Fluid Loss Agent in Enhancing Autogenous Healing Ability and Improving Mechanical Properties of Oil Well Cement. Cem. Concr. Compos. 2022, 128, 104419. [Google Scholar] [CrossRef]

- Pan, X.; Wang, Y.; Kong, D.; Li, Y.; Cheng, Z.; Song, G.; Zuo, Y. Development, Optimisation and Performance Prediction of a Novel Cement-Based Materials for Borehole Sealing. Constr. Build. Mater. 2025, 478, 141404. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, H.; Lin, J.; Wang, F.; Liu, Z.; Wang, L.; Li, Z.; Li, Y.; Li, Y.; Lu, Z. Nature-Inspired Hierarchical Building Materials with Low CO2 Emission and Superior Performance. Nat. Commun. 2025, 16, 3018. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Song, W.; Sun, Y.; Zhai, X.; Wang, Z. Clogging Mechanical Model and Its Application in Gas Extraction Borehole. J. Chongqing Univ. 2014, 37, 119–127. [Google Scholar] [CrossRef]

- Li, B.; Zhang, J.; Wei, J.; Zhang, Q. Preparation and Sealing Performance of a New Coal Dust Polymer Composite Sealing Material. Adv. Mater. Sci. Eng. 2018, 2018, 8480913. [Google Scholar] [CrossRef]

- Li, X.; Han, G.; Wang, Y.; Xu, J.; Du, J.; Yang, B.; Zhang, M.; Li, T.; Li, B.; Zhang, J. Development and Performance Optimization of a New Composite Sealing Material Prepared by Drilling Cuttings. Front. Earth Sci. 2023, 11, 1283410. [Google Scholar] [CrossRef]

- Yang, K.; Zhao, X.; He, X.; Wei, Z. Basic Theory and Key Technology of Multi-Source Coal-Based Solid Waste for Green Backfilling. J. China Coal Soc. 2022, 47, 4201–4216. [Google Scholar] [CrossRef]

- Liu, Z.; Bi, Z.; Chen, Q.; Chen, Q. Leaching Characteristics and Solidification Mechanisms of Heavy Metals in Multi-Source Coal-Based Solid Waste Backfill Bodies. Coal Sci. Technol. 2025, 1–12. Available online: https://link.cnki.net/urlid/11.2402.td.20250804.1600.002 (accessed on 5 August 2025).

- Liu, Z.; Wu, W.; Bi, Z.; Fu, X.; Lang, Y.; Hou, Q.; Jia, X. Experimental Study on Preparation of Mine-Used Filling Cementitious Material from Multi-Source Coal-Based Solid Wastes. Saf. Coal Mines 2024, 55, 22–30. [Google Scholar] [CrossRef]

- Wang, C.; Xing, Y.; Xia, Y.; Zhang, R.; Wang, S.; Li, J.; Gui, X. Regulation Mechanism of Ionic Surfactants on the Wettability of Low-Rank Coal. J. China Coal Soc. 2022, 47, 3101–3107. [Google Scholar] [CrossRef]

- Ge, T.; Zhang, M.; Ma, X. XPS and FTIR Spectroscopy Characterization about the Structure of Coking Coal in Xinyang. Spectrosc. Spectr. Anal. 2017, 37, 2406–2411. [Google Scholar] [CrossRef]

- Zhou, T.; Liu, B.; Xue, S.; Jiang, X.; Zhang, X.; Sun, R. Multi-Method Characterization of Molecular Structure Changes and Mechanisms of Biodegradation of Coal with Different Degrees of Metamorphism. J. China Coal Soc. 2024, 1–13. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, Z.; Zhang, Y.; Zhang, S.; Li, Y.; Du, Z. Impact of Water Contents on the Chemical Composition and Structure of Coals under Supercritical CO2 (ScCO2). J. China Coal Soc. 2025, 1–13. [Google Scholar] [CrossRef]

- Tian, Q.; Wang, H.; Pan, Y. Associations of Gangue Minerals in Coal Flotation Tailing and Their Transportation Behaviors in the Flotation Process. ACS Omega 2022, 7, 27542–27549. [Google Scholar] [CrossRef]

- Li, B.; Zhang, W.; Xie, Z.; Chen, X.; Cui, Y. FTIR and XRD Microscopic Characterisation of Coal Samples with Different Degrees of Metamorphism. J. Mol. Struct. 2024, 1309, 138270. [Google Scholar] [CrossRef]

- Zong, Z.; Long, H.; Gui, Y.; Zhang, H.; Dong, W.; Zhou, X.; Ji, Y. Microstructure Characteristics of Nano Solid Waste High Sulfur Cement Based on XRD and FTIR. Spectrosc. Spectr. Anal. 2023, 43, 1974–1980. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, S.; Liao, G.; Mei, J.; Chen, Y. Effect of Sodium Gluconate on Hydration Process of Calcium Sulfoaluminate Cement. Mater. Rep. 2023, 37, 21100182. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, Y.; Zhao, G.; Cheng, X.; Ai, J.; Li, Y.; Meng, X. Study on Properties of Polypropylene Fiber-Modified Ultrafine Cement Composite Grouting Materials. Coal Sci. Technol. 2024, 52, 57–67. [Google Scholar] [CrossRef]

- Fu, M.; Wang, M.; Liu, Y.; Chen, L.; Lang, D.; Wang, Q.; Zhang, J.; Wang, M. Preparation and Performance Study of Red Mud-High-Grade Kaolin-Silica Fume-Cemen-Desulfurisation Gypsum Multi-Component Sealing Materials. J. China Coal Soc. 2025, 1–10. [Google Scholar] [CrossRef]

- Gao, F.; Lin, W.; Jia, Z.; Bai, Q.; Liu, J.; Wang, Y.; Li, W. Spectroscopic Study on the Evolution of Coal Molecular Structure During CO2 Storage. Spectrosc. Spectr. Anal. 2025, 45, 1791–1800. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, Z.; Zeng, R.; Liang, Q.; Liu, H. Insights into Pyrolysis Product Characteristics and Carbon Structure Evolution of Bituminous Coal under High-Temperature Thermal Shock. Fuel 2024, 371, 132096. [Google Scholar] [CrossRef]

- Wang, B.; Liu, W.; Xu, X.; Liu, W. Effect of Methyl Substituents on Flotation Performance of Cationic Collectors. Chin. J. Eng. 2023, 45, 1247–1253. [Google Scholar] [CrossRef]

- He, X.; Huang, W.; Tang, G.; Zhang, H. Mechanism Investigation of Cement-Based Permeable Crystalline Waterproof Material Based on Spectral Analysis. Spectrosc. Spectr. Anal. 2021, 41, 3909–3914. [Google Scholar] [CrossRef]

- Li, H.; Qi, D.; Zou, D.; Wang, J.; Wang, Z.; Hao, L.; Wang, Y.; Zhang, Y.; Liu, H. Comparative Study on Hydration Process of Ferroaluminate, Sulfoaluminate and Portland Cement. Bull. Chin. Ceram. Soc. 2024, 43, 2335–2345. [Google Scholar] [CrossRef]

- Geng, J.; Wang, S.; Sun, Q.; Hou, E.; Yang, Y.; Hu, X.; Xue, S. Pyrolysis Characteristics and Pore-Fracture Evolutionary Patterns of Tar-Rich Coals. Coal Geol. Explor. 2024, 52, 46–53. [Google Scholar] [CrossRef]

- Kuang, J.; Liu, P.; Luo, D.; Zhou, Y.; Huang, Z. Comparative Study on Kinetic Calculation Methods of Thermal Decomposition of Kaolinite. Mater. Rep. 2018, 32, 2376–2383. [Google Scholar] [CrossRef]

- Si, L.; Shi, W.; Wei, J.; Liu, Y.; Yao, B. Self-Healing Characteristics of Fracture in Sealing Materials Based on Self-Healing Effect. J. China Coal Soc. 2023, 48, 4097–4111. [Google Scholar] [CrossRef]

- Liu, S.; Yang, K.; Xu, L.; Duan, Z.; Xiao, J.; Yang, Z. Interaction of Carbonated Recycled Concrete Powder with Calcium Sulfoaluminate-Belite Cement: Early Hydration Kinetics and Microstructure Evolution. Constr. Build. Mater. 2025, 493, 143223. [Google Scholar] [CrossRef]

- Shi, J.; Qian, R.; Wang, D.; Liu, Z.; Zhang, Y. Experimental Study on Gas Permeability of Cement-Based Materials. Cem. Concr. Compos. 2022, 129, 104491. [Google Scholar] [CrossRef]

- Song, Y.; Dai, G.; Zhao, L.; Bian, Z.; Li, P.; Song, L. Permeability Prediction of Hydrated Cement Paste Based on Its 3D Image Analysis. Constr. Build. Mater. 2020, 247, 118527. [Google Scholar] [CrossRef]

- Tracz, T.; Zdeb, T. Effect of Hydration and Carbonation Progress on the Porosity and Permeability of Cement Pastes. Materials 2019, 12, 192. [Google Scholar] [CrossRef]

- Zhu, P.; Zhang, X.; Song, Y.; Sheng, Y.; Zhao, L.; Ge, P.; Wang, C. Gas Permeability of Partially Saturated Cement-Based Materials Considering Water Sensitivity. Constr. Build. Mater. 2024, 450, 138641. [Google Scholar] [CrossRef]

- Xiong, Q.X.; Tong, L.; Meftah, F.; Zhang, Y.; Liu, Q.F. Improved Predictions of Permeability Properties in Cement-Based Materials: A Comparative Study of Pore Size Distribution-Based Models. Constr. Build. Mater. 2024, 411, 133927. [Google Scholar] [CrossRef]

- Zhou, X.Z.; Ye, W.W.; Zhou, Y.Z.; Zheng, J.J.; Shao, H.X.; Rong, H. A Modified Effective Medium Approach for Water Permeability Coefficient of Cement Paste. Constr. Build. Mater. 2024, 442, 137607. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Shi, D.; Wang, Y.; Wang, H.; Liu, Z.; Yuan, K.; Li, X. Influence of Silicone Acrylic Emulsion on the Microstructure and Permeability Resistance of Cement Mortar. Constr. Build. Mater. 2025, 491, 142791. [Google Scholar] [CrossRef]

- Fan, J.; Li, G.; Deng, S.; Wang, Z. Mechanical Properties and Microstructure of Polyvinyl Alcohol (PVA) Modified Cement Mortar. Appl. Sci. 2019, 9, 2178. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of Theoretical Carbon Dioxide Emissions from Cement Production: Methodology and Application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Durastanti, C.; Moretti, L. Environmental Impacts of Cement Production: A Statistical Analysis. Appl. Sci. 2020, 10, 8212. [Google Scholar] [CrossRef]

| Sample | N/% | C/% | H/% | S/% | O/% |

|---|---|---|---|---|---|

| Coal-based DC | 0.87 | 70.26 | 3.94 | 0.46 | 11.33 |

| Sandstone-based DC | 0.07 | 4.18 | 0.88 | 0.19 | 5.33 |

| Mudstone-based DC | 0.05 | 1.4 | 0.54 | 0.07 | 6.98 |

| Sample | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 |

|---|---|---|---|---|---|

| Coal-based DC | 32.93 | 34.82 | 10.17 | 2.38 | 9.84 |

| Sandstone-based DC | 57.34 | 25.31 | 1.72 | 7.05 | 0.44 |

| Mudstone-based DC | 53.83 | 16.53 | 8.52 | 8.25 | 0.07 |

| Composite powder | 9.38 | 23.28 | 47.54 | 4.29 | 10.13 |

| Sample | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 |

|---|---|---|---|---|---|

| Composite | 9.02 | 21.93 | 48.36 | 4.74 | 10.31 |

| Composite/sandstone | 42.5 | 19.79 | 17.52 | 7.43 | 4.9 |

| Composite/mudstone | 37.2 | 17.67 | 21.95 | 7.96 | 4.8 |

| Composite/coal | 7.2 | 19.67 | 48.11 | 7.73 | 11.74 |

| Composite/mudstone/coal | 24.28 | 17.98 | 31.08 | 9.53 | 8.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di, P.; Hao, J.; Li, X.; Zhao, C.; Shu, L. A Drilling Cutting Derived Material for High Performance Borehole Sealing. Appl. Sci. 2025, 15, 10959. https://doi.org/10.3390/app152010959

Di P, Hao J, Li X, Zhao C, Shu L. A Drilling Cutting Derived Material for High Performance Borehole Sealing. Applied Sciences. 2025; 15(20):10959. https://doi.org/10.3390/app152010959

Chicago/Turabian StyleDi, Pengju, Jinwei Hao, Xin Li, Can Zhao, and Longyong Shu. 2025. "A Drilling Cutting Derived Material for High Performance Borehole Sealing" Applied Sciences 15, no. 20: 10959. https://doi.org/10.3390/app152010959

APA StyleDi, P., Hao, J., Li, X., Zhao, C., & Shu, L. (2025). A Drilling Cutting Derived Material for High Performance Borehole Sealing. Applied Sciences, 15(20), 10959. https://doi.org/10.3390/app152010959