Abstract

The rising demand for sustainable agriculture and circular resource management has intensified interest in converting wastewater sludge into value-added products. This review explores the transformation of sewage sludge into slow- and controlled-release fertilizers (CRFs), with a focus on biochar production and encapsulation technologies. Sewage sludge is rich in essential macronutrients (N, P, K), micronutrients, and organic matter, making it a promising feedstock for agricultural applications. However, its use is constrained by challenges including compositional variability, presence of heavy metals, pathogens, and emerging contaminants such as microplastics and PFAS (Per- and Polyfluoroalkyl Substances). The manuscript discusses a range of stabilization and conversion techniques, such as composting, anaerobic digestion, pyrolysis, hydrothermal carbonization, and nutrient recovery from incinerated sludge ash. Special emphasis is placed on coating and encapsulation technologies that regulate nutrient release, improve fertilizer efficiency, and reduce environmental losses. The role of natural, synthetic, and biodegradable polymers in enhancing release mechanisms is analyzed in the context of agricultural performance and soil health. While these technologies offer environmental and agronomic benefits, large-scale adoption is hindered by technical, economic, and regulatory barriers. The review highlights key challenges and outlines future perspectives, including the need for advanced coating materials, improved contaminant mitigation strategies, harmonized regulations, and field-scale validation of CRFs. Overall, the valorisation of sewage sludge into CRFs presents a viable strategy for nutrient recovery, waste minimization, and sustainable food production. With continued innovation and policy support, sludge-based fertilizers can become a critical component of the green transition in agriculture.

1. Introduction

Wastewater sludge is one of the most abundant by-products of urban wastewater treatment, presenting both environmental liabilities and opportunities for resource recovery. Conventional disposal methods such as landfilling and incineration are increasingly criticized for their environmental footprint and failure to recover valuable nutrients. Recent research has shifted toward valorisation strategies, where sludge is converted into bioenergy, biochar, soil amendments, or fertilizers within the circular economy framework [1].

While several reviews have examined sludge management and nutrient recovery, most focus either on energy pathways or on general biosolid applications. This review provides a unique perspective by integrating sludge-conversion technologies with controlled-release fertilizer (CRF) design principles. Specifically, it highlights how biochar production and polymer encapsulation can be coupled to regulate nutrient release, mitigate contaminants, and align with sustainable agriculture goals. By linking conversion pathways with CRF performance, this review fills a gap in the literature where environmental safety, fertilizer efficiency, and agronomic applicability are rarely considered together.

Accordingly, the objectives of this review are to

- 1.

- Summarize the nutrient potential and environmental challenges of sewage sludge.

- 2.

- Critically evaluate thermochemical, biological, and stabilization processes in terms of their implications for CRF development.

- 3.

- Examine coating and encapsulation strategies that enable nutrient release.

- 4.

- Identify limitations, regulatory gaps, and research needs for scaling sludge-derived CRFs.

1.1. Global Challenges of Sludge Disposal

The disposal of sewage sludge continues to pose global challenges due to its large volumes, heterogeneous composition, and contaminant content. While traditional disposal routes such as landfilling and incineration remain common, they are increasingly criticized for their environmental impacts and inefficiencies in resource recovery [2]. A paradigm shift is required to transition from disposal-oriented approaches to valorisation strategies that align with sustainable development goals.

1.1.1. Wastewater Sludge Valorisation and Its Challenges in the Circular Economy

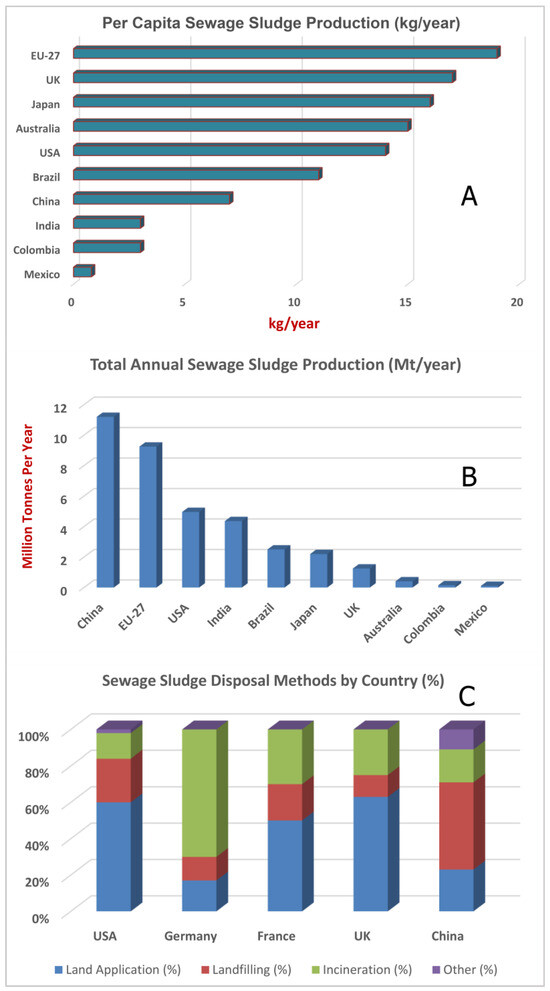

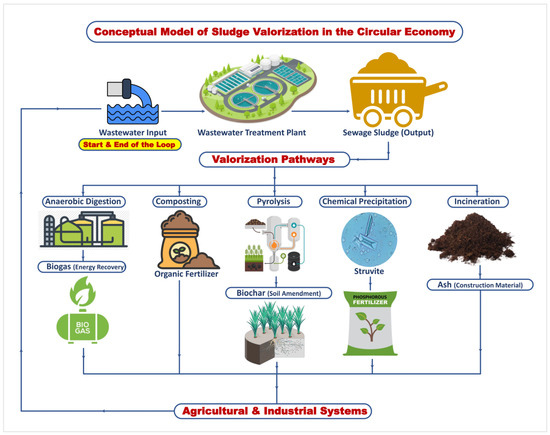

The transition from traditional wastewater sludge disposal to its valorisation is a critical component of advancing the circular economy (CE) in the wastewater sector. The CE framework promotes closing material loops and maximizing the recovery of resources from waste streams. Wastewater sludge, a byproduct rich in organic matter and nutrients, offers considerable potential for valorisation into products such as bioenergy, fertilizers, soil amendments, and construction materials [1,2]. Anaerobic digestion, composting, pyrolysis, hydrothermal carbonization, and nutrient recovery processes like struvite crystallization are among the leading valorisation pathways [3,4]. The increasing volume of sewage sludge generated globally, along with regional disparities in its disposal routes, underscores the urgency for sustainable valorisation strategies (Figure 1).

Valorisation not only contributes to resource recovery but also mitigates the significant environmental footprint of conventional disposal routes. For instance, sludge management activities may account for up to 40% of the total greenhouse gas emissions from wastewater treatment plants (WWTPs) [5]. Technologies like anaerobic digestion and thermal treatments can recover energy and reduce carbon intensity, aligning sludge management with sustainability goals. Moreover, the recovery of phosphorus and nitrogen from sludge-derived streams helps offset the depletion of finite mineral resources [6].

Despite these advantages, widespread implementation of sludge valorisation faces technical, economic, and institutional hurdles. A major challenge is the variability in sludge composition, which depends heavily on upstream wastewater characteristics and treatment processes [7]. This inconsistency affects process performance and product quality. Additionally, the presence of contaminants such as heavy metals, pathogens, microplastics, and emerging organic pollutants raises concerns about the environmental safety of recovered products [8,9].

From a regulatory perspective, the lack of harmonized standards for sludge-derived materials and ambiguity around “end-of-waste” criteria hinder market uptake. In many regions, legal frameworks still treat sludge as waste rather than a resource, discouraging investment in valorisation technologies [2]. Social acceptance also plays a role, as public skepticism regarding the reuse of sludge-based products in agriculture and land applications persists [10].

Figure 1.

Global sewage sludge production and disposal trends across selected countries. (A) Per capita sludge generation (kg/year); (B) total annual sludge production (million tons); (C) dominant disposal methods by country [11,12,13,14].

To realize the full potential of wastewater sludge within the circular economy, integrated strategies are needed. These include combining energy and nutrient recovery within WWTPs, establishing clear regulatory pathways, supporting market development for recovered products, and educating stakeholders on the benefits of sludge valorisation. As highlighted by Gherghel et al. [15], transforming WWTPs into urban biorefineries represents a forward-looking model for achieving both environmental protection and resource efficiency.

1.1.2. Turning Sewage Sludge into Value-Added Energy and Materials

Sewage sludge, historically managed through landfilling or land application, is increasingly viewed as a resource-rich feedstock for the recovery of energy and value-added materials. This paradigm shift aligns with global sustainability goals and the drive toward carbon neutrality. Owing to its high organic content and presence of nutrients, sewage sludge has significant potential for thermochemical valorisation through methods such as incineration, pyrolysis, gasification, and hydrothermal processing [16]. A variety of thermochemical and biological pathways are available to convert sewage sludge into value-added products, all of which align with circular economy principles (Figure 2). These techniques enable the transformation of sludge into thermal energy, bio-oils, syngas, biochar, and construction-grade ash-based materials, while also reducing volume and pathogen load [17,18].

Figure 2.

Conceptual model of sewage sludge valorisation within the circular economy.

Among these, pyrolysis and gasification have attracted increasing attention for their ability to convert sewage sludge into bio-oil, hydrogen-rich gas, and biochar under controlled conditions. For instance, pyrolysis can yield bio-oils rich in nitrogen-containing compounds, which may be refined for fuel use or chemical synthesis [19]. However, high moisture and ash content pose operational challenges, often requiring energy-intensive drying and pollutant control systems [20,21]. Similarly, gasification converts sludge into syngas, containing H2, CO, and CH4, via partial oxidation, but suffers from issues like tar formation, catalyst deactivation, and nitrogen oxide emissions [22,23].

The biochar produced through sludge pyrolysis exhibits promising potential for use in environmental remediation, soil amendment, and catalysis. Studies have shown that high-temperature pyrolysis improves the structural properties of biochar, such as BET surface area and mineral stability, enhancing its utility in adsorbing heavy metals and organic pollutants [24,25]. Functionalization strategies further expand the applications of biochar in CO2 capture, fuel cells, and heterogeneous catalysis [26,27].

Additionally, ash residues from incineration are being revalorised into construction materials. The mineral composition of sludge ash, rich in SiO2, Al2O3, and CaO, makes it suitable for incorporation into cement, concrete, and lightweight aggregates. This not only offsets the environmental impact of cement production but also reduces the need for natural raw materials [28,29]. Nevertheless, the presence of heavy metals and the variability in ash properties demand careful pre-treatment and leaching control.

Despite the technical promise of these routes, several challenges persist. Moisture content, operational costs, equipment corrosion, and stringent environmental regulations limit large-scale deployment. Furthermore, the development of low-cost, durable catalysts and efficient pollutant control technologies remains a bottleneck for clean energy recovery. As Hu et al. [16] emphasize, achieving environmental and economic sustainability in sludge valorisation depends on integrated strategies that couple energy and material recovery with pollutant control and downstream processing innovations.

1.2. Need for Sustainable Fertilizers

1.2.1. Potential Use of Sewage Sludge as Fertilizer in Organic Farming

The rising interest in sustainable agriculture has intensified the search for nutrient-rich alternatives to synthetic fertilizers, with sewage sludge emerging as a promising candidate. Generated as a byproduct of wastewater treatment, sewage sludge contains essential macronutrients such as nitrogen (N), phosphorus (P), and potassium (K), as well as critical micronutrients including iron (Fe), zinc (Zn), copper (Cu), and manganese (Mn), all of which contribute to soil fertility and plant health [30,31]. When properly treated, sludge can significantly improve soil structure, enhance water retention, stimulate microbial activity, and supply nutrients in a slow-release manner, traits well aligned with the principles of organic farming [32,33].

However, the use of sewage sludge in organic systems is not without limitations. Compared to conventional fertilizers, sludge generally contains lower concentrations of N, P, and K, which may require higher application rates to meet crop demands [34]. Additionally, the variability in sludge composition depending on treatment processes and influent sources introduces inconsistencies in nutrient availability and quality. Of particular concern is the risk of heavy metal accumulation, elements such as cadmium, mercury, and lead may persist in the sludge and potentially transfer into crops and soil ecosystems over time [35]. This highlights the need for rigorous monitoring and compliance with regulatory thresholds to ensure food safety and soil health.

Despite these risks, the organic matter content of sewage sludge remains highly beneficial. It promotes soil aggregation, supports beneficial microbial communities, and contributes to carbon sequestration, aligning with climate-smart agricultural goals [36]. Furthermore, sludge application has shown potential to reduce the environmental footprint of farming by lowering dependency on synthetic fertilizers and recycling nutrients otherwise lost during wastewater treatment [37,38].

Safe integration of sewage sludge into organic farming requires not only effective treatment technologies but also regulatory oversight and public awareness. Strategies such as composting, anaerobic digestion, and advanced thermal treatment help reduce pathogens and stabilize heavy metals, making sludge more suitable for agricultural use [39,40]. Additionally, strict adherence to biosolid quality standards and proper application methods can ensure that the benefits of sewage sludge outweigh its potential drawbacks in organic systems.

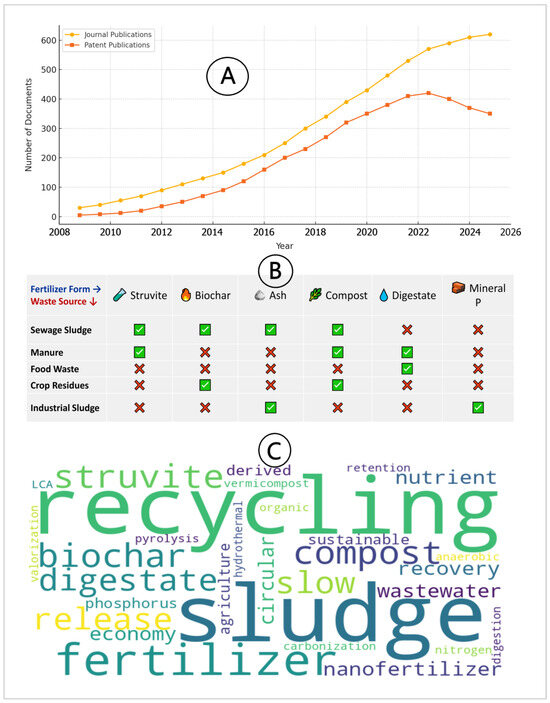

1.2.2. Sustainable Fertilizers: Publication Landscape on Wastes as Fertilizer Sources

In recent decades, the shift toward sustainable agricultural inputs has led to a significant rise in global interest in alternative fertilizer sources derived from wastes. A bibliometric analysis by Yilmazel et al. [41] offers a comprehensive review of academic and patent literature from 2001 to 2021, highlighting a dramatic increase in research output on sustainable fertilizers, particularly those utilizing recycled waste and wastewater. The study reveals a publication surge in journal articles, while patent filings, especially from China, peaked around 2017 before declining, indicating rapid innovation followed by stabilization in regulatory and technical landscapes [42,43].

Organic and inorganic waste, including sewage sludge, manure, food processing residues, and ashes, are extensively studied as nutrient sources. Processes such as composting, vermicomposting, anaerobic digestion, pyrolysis, and hydrothermal carbonization dominate this landscape, enabling the transformation of these wastes into nutrient-rich products like biochar, struvite, and ash-based amendments [44,45]. Biochar, in particular, has seen exponential publication growth since 2014, due to its versatility as a soil conditioner, nutrient carrier, and pollutant adsorbent. Its properties can be tailored through feedstock selection, pyrolysis conditions, and chemical modifications to enhance nutrient retention and controlled release [46,47].

The report also identifies struvite, a slow-release fertilizer crystallized from wastewater, as a key innovation. Combined with other phosphorus compounds such as hydroxyapatite and superphosphates, struvite has become a core component in intermediate-release formulations. These formulations reduce nutrient losses from leaching and volatilization, supporting both agronomic efficiency and environmental goals [44]. Additionally, nanomaterials and bioformulated fertilizers, such as nanoencapsulated microbes, are emerging as potent tools for precision nutrient delivery and soil health improvement [32].

Geographically, China leads both journal and patent publications in sustainable fertilizer research, followed by countries like Japan, the U.S., and Germany. This trend is aligned with national policies promoting green agriculture and circular economy initiatives [46]. However, discrepancies between sustainable claims and actual environmental performance remain a concern, underscoring the need for holistic assessments like life cycle analysis (LCA) [47].

Recent years have witnessed a notable increase in scientific and technological interest in transforming waste materials into sustainable fertilizers, as evidenced by rising publication trends, the diversity of valorization routes across waste streams, and the evolving research vocabulary in this domain (Figure 3).

Figure 3.

Research and innovation landscape of waste-derived sustainable fertilizers; (A) Global publication and patent trends (2008–2025), (B) Valorization routes linking waste sources to fertilizer types and (C) Keyword cloud highlighting key research themes.

This review is based on a comprehensive survey of the literature using databases such as Web of Science, Scopus, and Google Scholar. The search covered the period from 2010 to 2024, with emphasis on the most recent decade where research on sludge-derived CRFs has expanded significantly. In total, more than 160 peer-reviewed publications were consulted, including research articles, review papers, and technical reports. This approach ensures that the discussion reflects both established methods and the most recent advances in sludge valorization and CRF technologies.

The primary goal of this review is to critically examine the potential of sewage sludge as a resource for the development of controlled-release fertilizers. The specific objectives are to: (i) summarize conventional stabilization and advanced conversion technologies relevant to nutrient recovery and biosafety; (ii) evaluate sludge-derived materials such as biochar, hydrochar, and struvite as carriers or cores in CRF formulations; (iii) analyze encapsulation and coating strategies for enhancing nutrient-use efficiency and minimizing environmental risks; and (iv) identify current challenges, knowledge gaps, and future research directions necessary to advance the large-scale adoption of sludge-derived CRFs.

2. Composition and Nutrient Potential of Wastewater Sludge

2.1. Macronutrients and Micronutrients in Sludge

Sewage sludge is increasingly recognized as a valuable nutrient source for agriculture, owing to its content of essential macronutrients (N, P, K) and micronutrients (Fe, Zn, Cu, Mn), as well as its organic matter. When properly treated, sludge contributes to improved soil fertility and plant health in both conventional and organic systems [48,49].

2.1.1. Macronutrients N, P, K

Nitrogen (N) in treated sewage sludge typically ranges from 1.5 to 4.0% of dry matter [50,51], lower than synthetic urea (~46% N) but largely in organic forms that mineralize gradually [52,53]. This slow release reduces leaching risks and is advantageous in organic and no-till systems. Phosphorus (P) content (0.5–2.0%) [54,55,56,57] is also below that of commercial superphosphates (~20% P), but its gradual release improves nutrient use efficiency and root development [50,51]. Potassium (K) concentrations (0.5–2.5%) [58,59] are modest compared to muriate of potash (~60% K2O), yet contribute to stress resistance and osmotic regulation [50,51]. Although sludge-derived fertilizers require higher application rates than commercial fertilizers, they provide integrated nutrient supply with organic matter benefits, aligning with sustainable farming practices.

2.1.2. Micronutrients and Organic Matter

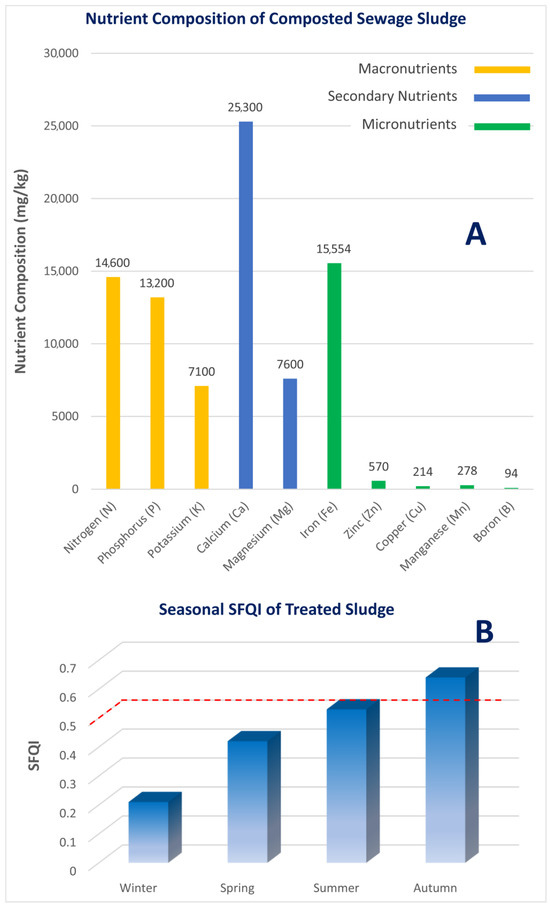

Micronutrients such as zinc (Zn), copper (Cu), iron (Fe), and manganese (Mn) are also present in appreciable concentrations in sewage sludge. For example, Zn and Cu contribute to photosynthetic enzymes and protein metabolism, while Fe is essential for chlorophyll synthesis and respiration [60,61]. These micronutrients are often deficient in intensively farmed soils, making biosolids a cost-effective supplement [55]. In addition, the organic matter in sewage sludge enhances soil structure, improves moisture retention, and supports microbial activity [62,63,64]. These benefits are essential for sustainable soil management, particularly in degraded or sandy soils. The nutrient composition and seasonal quality of treated sewage sludge are summarized in Figure 4, highlighting its agronomic potential.

Figure 4.

Nutrient potential of composted sewage sludge. (A) Average concentrations of macro-, secondary, and micronutrients in treated sludge. (B) Seasonal variation in the Sludge Fertilizer Quality Index (SFQI), with autumn showing the highest fertilizer value. The dotted red line indicates threshold value of SFQI. (Data adapted from [30,63,65]).

2.1.3. Variability in Nutrient Composition

The exact nutrient profile of sludge depends on several factors including the source of wastewater, treatment method (e.g., anaerobic digestion, composting), and post-treatment handling [48,56]. Composting, for instance, stabilizes organic matter and increases the carbon-to-nitrogen ratio, whereas anaerobic digestion may result in higher mineral N availability [51]. It is important to test sludge batches before application to align nutrient content with crop requirements and avoid over-fertilization or metal accumulation risks [57]. Table 1 represents various nutrients, their average concentrations in the sewage sludge and their plant functions [66].

Table 1.

Concentration of nutrients in sewage sludge and their plant functions [66].

2.2. Factors Affecting Nutrient Content

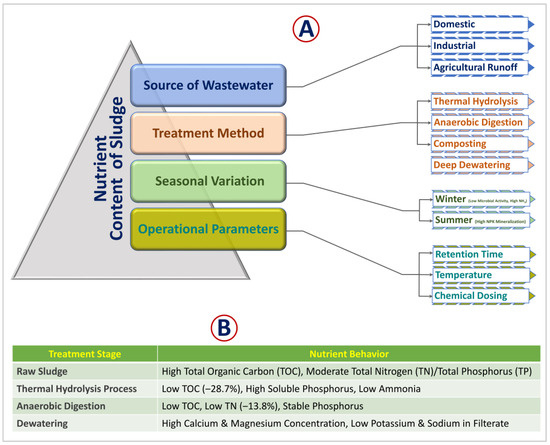

The nutrient content of sewage sludge is influenced by numerous factors including seasonal variation, the nature of incoming wastewater, treatment technologies, and sludge stabilization methods. Understanding these influences is crucial for maximizing nutrient recovery while ensuring environmental safety.

2.2.1. Seasonal Variations

Seasonal dynamics affect the accumulation of nutrients like nitrogen, phosphorus, and potassium in sewage sludge. Studies show that autumn sludge contains the highest levels of TOC, TN, and TP due to seasonal dietary shifts and microbial activity cycles. For example, one investigation recorded peak TN and TP levels at 44,470.70 mg/kg and 28,572.89 mg/kg, respectively, in autumn [65,67,68]. Indian studies further support that summer sludge shows higher average nitrogen and phosphorus due to reduced rainfall and better microbial stabilization. Conversely, the rainy season leads to nitrogen loss through leaching and denitrification [69,70]. Likewise, potassium, being highly soluble, is often washed away during heavy rainfall [71].

2.2.2. Treatment Technologies and Process Influence

Each sludge treatment step modifies nutrient concentration and availability: Thermal Hydrolysis (THP) improves solubilization of organic matter and phosphorus but can volatilize nitrogen as ammonia [67]. Anaerobic Digestion (AD) preserves macronutrients like nitrogen and potassium while reducing organic content [72,73,74]. Deep Dewatering increases concentrations of minerals such as Ca and Mg in the sludge cake, but some nutrients (e.g., K, Na) are lost into the supernatant due to their solubility [75]. Together, these processes affect the migration and transformation of nutrients such as K, Na, Ca, and Mg between reducible, oxidizable, and residual fractions [68].

2.2.3. Nutrient Speciation and Bioavailability

The bioavailability of nutrients depends on their chemical fractions. Studies report that thermal and anaerobic treatment increase the proportion of oxidizable and reducible nutrient fractions. For example, the oxidizable K fraction increased by over 100% following treatment, significantly enhancing bioavailability for plants [67].

2.2.4. Sludge Fertilizer Quality Index (SFQI)

The SFQI offers a consolidated measure of sludge agronomic quality. It increased from −0.33 (raw sludge) to 0.64 (post-AD and dewatering), especially in autumn, indicating enhanced nutrient retention and lower contaminant levels [75]. This metric helps rank sludge across seasons and processes in terms of safe application rates and fertilizing potential. The major influences on nutrient variability in sewage sludge are visualized in Figure 5, including both upstream factors and downstream transformation stages.

Figure 5.

Factors influencing nutrient variability in sewage sludge. (A) Conceptual map showing external influences. (B) Nutrient transformations across treatment stages. (Concept and data synthesized from [65,68,76]).

2.3. Key Challenges in Sludge Use as Fertilizer

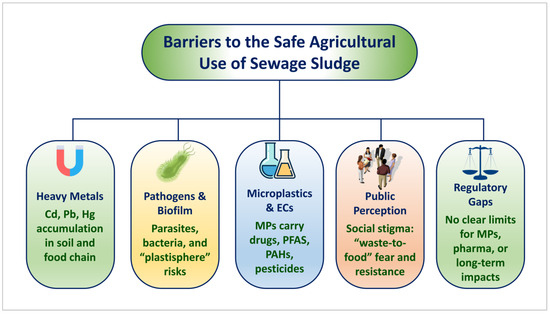

The valorisation of sewage sludge for fertilizer use offers nutrient recovery benefits, but it is also accompanied by a suite of environmental and health-related concerns. Among these, the presence of pathogens, heavy metals, emerging contaminants such as microplastics (MPs), and public acceptance barriers pose significant challenges to its safe and sustainable application.

2.3.1. Microplastics and Emerging Contaminants

Stabilized sludge contains 1700–2900 MP particles per 100 g dry matter, mostly polyethylene fragments [77]. MPs persist for decades and adsorb toxicants including heavy metals and pharmaceuticals [78]. Their presence not only raises environmental risks but also affects nutrient bioavailability: metals bound to MPs can reduce plant uptake efficiency, while adsorbed organics may alter mineralization rates of N and P. Thus, MPs and contaminants must be considered alongside nutrient content when evaluating sludge as a fertilizer resource. The adsorption of these toxicants to MPs amplifies the environmental risk associated with land application, especially considering the potential for bioaccumulation in crops and trophic transfer in food chains [79]. Despite their environmental impact, there are currently no regulatory standards governing the concentration of microplastics in fertilizers derived from sewage sludge [77].

2.3.2. Heavy Metal Accumulation

Stabilized sludge contains detectable levels of several heavy metals such as cadmium (0.7 ± 0.2 mg/kg), lead (20.6 ± 7.9 mg/kg), mercury (0.3 ± 0.1 mg/kg), and copper (321.2 ± 68.0 mg/kg), among others [77]. These metals can accumulate in soils upon repeated application and potentially enter the food chain. While some metals are essential micronutrients at low concentrations, elevated levels, particularly of Cd and Hg, can impair plant metabolism and pose serious health risks to humans and animals [80].

To place the nutrient content of sewage sludge in context, Table 2 compares its average composition with that of common commercial fertilizers, highlighting practical implications for agricultural use

Table 2.

Comparison of nutrient content in sewage sludge and conventional fertilizers, with implications for agricultural application.

2.3.3. Pathogenic Microorganisms and Biofilms

Although standard protocols like ISO 5667-13:2011 [81] are followed to minimize biological contamination, residual pathogens, including intestinal parasites and bacteria, can still be a risk, especially when sludge is not adequately treated [77]. Moreover, microplastics themselves can harbor and transport harmful microorganisms through the formation of biofilms, a microbial community known as the ‘plastisphere’, which enhances the survival of pathogens in soils [82].

In addition to heavy metals and organic contaminants, sewage sludge frequently contains pathogenic microorganisms that pose significant health risks. These include bacteria such as Salmonella spp. and Escherichia coli, viruses like enteroviruses and adenoviruses, protozoa such as Giardia and Cryptosporidium, and helminths including Ascaris lumbricoides, Trichuris trichiura, and hookworms. Helminth ova are particularly resistant and can remain viable in soil for extended periods, making them one of the most critical obstacles to the safe use of sludge as fertilizer. Effective stabilization and hygienization methods (e.g., composting, lime stabilization, pasteurization, or thermal drying) are therefore essential to reduce pathogen loads to acceptable levels before sludge can be utilized in CRF production

2.3.4. Public Perception and Regulatory Gaps

Even when treated to meet safety standards, the application of sludge-based fertilizers is often met with public skepticism due to the perceived “waste-to-food” route and concerns about long-term soil and food contamination. This perception is further exacerbated by the absence of comprehensive and enforceable regulatory frameworks in many countries, particularly for emerging contaminants like MPs and pharmaceuticals [83].

2.3.5. Regulatory and Legal Frameworks

The application of sewage sludge in agriculture is subject to regulatory oversight in many regions, primarily to ensure that concentrations of harmful substances remain below risk thresholds. For example, the U.S. EPA’s Part 503 Rule sets ceiling limits for heavy metals such as cadmium (Cd: 85 mg/kg), lead (Pb: 840 mg/kg), and mercury (Hg: 57 mg/kg) in biosolids intended for land application [84]. Similar frameworks exist in the EU under Directive 86/278/EEC, which also outlines permissible limits for pathogens and metal content in sludge-based fertilizers. However, these regulations are largely outdated and do not address the growing concern of emerging contaminants like microplastics, pharmaceuticals, flame retardants, or PFAS. The absence of standards for such pollutants presents a regulatory gap, leaving both farmers and consumers uncertain about the long-term safety of sludge-derived products [83]. Furthermore, differences in regulations across countries create inconsistencies in sludge management and fertilizer approvals. For instance, while some EU countries have banned land application of sludge altogether, others actively promote its reuse under strict monitoring programs [84]. A summary of the major technical, social, and regulatory barriers to sludge-based fertilizer adoption is presented in Figure 6.

Figure 6.

Barriers to the safe use of sewage sludge as fertilizer (Adapted from [77,83,85]).

2.4. Summary of the Key Studies on Sludge Valorization

A comprehensive overview of previous studies focusing on sludge valorisation, recovery mechanisms, and coating approaches is summarized in Table 3. The table highlights the diversity in feedstocks, technologies used, and nutrient recovery outcomes, thereby identifying the gaps that the present review addresses.

Table 3.

Summary of selected studies on the valorisation of sewage sludge into fertilizers.

3. Sludge Conversion into Fertilizer Products

The transformation of sewage sludge into controlled-release fertilizers (CRFs) requires not only nutrient recovery but also stabilization and conversion processes that ensure biosafety, environmental compliance, and agronomic functionality. A wide range of technologies have been developed, from conventional hygienization methods, such as composting and lime stabilization, to advanced thermochemical and nutrient-recovery routes like pyrolysis, hydrothermal carbonization (HTC), and incinerated sludge ash (ISSA) processing. These pathways vary in complexity, cost, and environmental performance but all contribute in distinct ways to the production of sludge-derived CRFs. Conventional stabilization techniques primarily prepare sludge for safe agricultural use by reducing pathogens, odor, and vector attraction, whereas advanced processes create engineered carbonaceous or mineral matrices that can serve as carriers or cores in CRF formulations.

3.1. Stabilization and Hygienization Techniques

Stabilization and hygienization are critical prerequisites for the safe reuse of sewage sludge. These processes aim to reduce pathogen content, control odors, and minimize vector attraction, thereby ensuring compliance with biosolids regulations such as U.S. EPA Part 503 and EU directives [99,100,101]. Among the most widely applied approaches, composting involves aerobic biodegradation under thermophilic conditions (≥55 °C), effectively reducing pathogens when maintained for sufficient time, though its long processing duration and land demand are limiting factors [102,103]. Pasteurization (≥70 °C for ≥30 min) achieves rapid pathogen destruction while preserving nutrient content, but resistant spores such as Clostridium may persist [104,105]. Thermal drying reduces sludge moisture below 10%, achieving pathogen inactivation and improved storage stability; dried pellets also offer better surfaces for subsequent polymer coatings [106,107]. Lime stabilization raises pH above 12 and generates heat through exothermic reactions, inactivating most pathogens and controlling odor, though high alkalinity and salinity limit direct fertilizer use unless neutralized or blended with other carriers [108,109].

Biological stabilization methods include aerobic digestion and anaerobic digestion (AD), which reduce volatile solids and pathogens, with AD additionally generating biogas for energy recovery [86,110]. Thermophilic AD offers faster pathogen reduction, whereas mesophilic AD is often combined with pasteurization to meet stringent Class A requirements. Stability is commonly assessed by volatile solids reduction (≥38%), specific oxygen uptake rate (SOUR < 1.5 mg O2/g TS/h), or final moisture content (<10%) [111,112]. Meeting these benchmarks not only minimizes odor and vector attraction but also produces a storage-stable sludge product suitable as a core for CRF manufacturing.

From a regulatory perspective, achieving Class A biosolids status is generally required for unrestricted land application and eventual marketability of sludge-derived fertilizers [113]. Overall, stabilization and hygienization methods play a foundational role in CRF development: they ensure biosafety, improve handling, and prepare consistent substrates that can be further engineered through encapsulation or combined with advanced carriers such as biochar and hydrochar.

3.2. Advanced Conversion Technologies

Beyond conventional stabilization, advanced thermochemical processes offer more sophisticated routes for sewage sludge valorization. These technologies not only reduce volume and stabilize contaminants but also generate engineered carbonaceous or mineral matrices that can be directly applied or further processed into CRFs (See Figure 7).

Figure 7.

Overview of thermochemical and nutrient recovery pathways from sewage sludge. (Adapted from: [23,47,64]).

Pyrolysis is one of the most widely studied methods, operating at 300–700 °C under oxygen-limited conditions to produce biochar, syngas, and bio-oil [114,115,116]. Sludge-derived biochar typically retains phosphorus in stable mineral forms while immobilizing heavy metals, thereby improving agronomic safety. Its high porosity and surface area make it a promising carrier for nutrient impregnation and polymer coatings, reducing nutrient leaching and enabling slow-release performance [117,118].

Gasification, conducted at higher temperatures (≈800–1000 °C), primarily yields syngas but also produces ash enriched with phosphorus and potassium [119]. When stabilized, this ash can be recovered as a mineral fertilizer input or incorporated into CRF formulations. However, the high energy demand and process cost limit its near-term scalability [120].

The HTC operates at 180–250 °C under autogenous pressure, making it particularly suitable for wet sludge without pre-drying [121]. The resulting hydrochar exhibits high cation exchange capacity and functionalized surfaces that support adsorption-controlled nutrient release and enhance compatibility with biodegradable coatings [122]. Nutrients dissolved in the process liquor can also be recovered, improving overall resource efficiency.

Torrefaction, a milder process at 200–300 °C, partially carbonizes sludge into solids with improved storage stability and moderate nutrient retention [123]. Though less explored, torrefied products may be blended with other carriers or coated to tailor nutrient-release profiles.

Together, these advanced conversion pathways expand the scope of sludge valorization from hygienized biosolids to engineered feedstocks tailored for CRF development. Nevertheless, challenges remain, including scaling reactor systems, managing energy and water balances, and validating long-term agronomic benefits under field conditions.

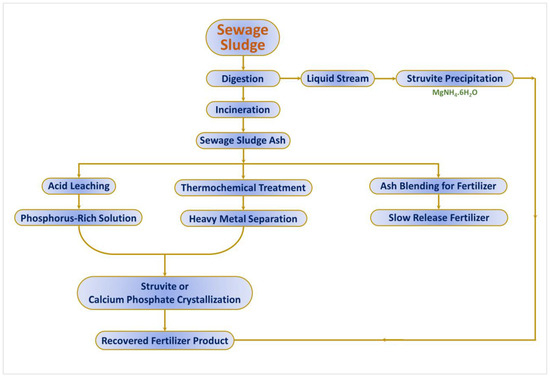

3.3. Nutrient Recovery from Incinerated Sludge Ash (ISA) and Other Residues

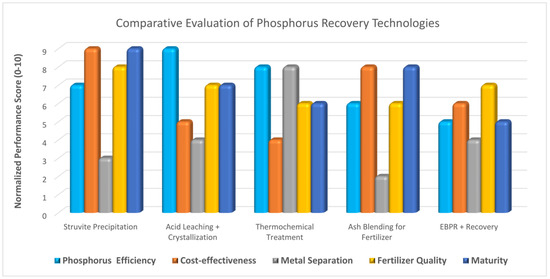

Incineration of sewage sludge produces ash containing up to 10% phosphorus by weight, often in mineral forms such as whitlockite or apatite [124]. Given the declining reserves of phosphate rock, ISA has attracted significant attention as a secondary phosphorus source. Recovery approaches include acid leaching, where strong or weak acids solubilize P alongside heavy metals; thermochemical treatments, which immobilize or volatilize contaminants while enhancing P bioavailability (see Figure 8); and precipitation as struvite (MgNH4PO4·6H2O) from dissolved ash extracts [87,125]. Biological and integrated methods, though less mature, are also being tested to improve selectivity and reduce chemical consumption [126].

Figure 8.

Comparative performance of phosphorus recovery technologies based on key evaluation criteria (Data compiled from: [12,54,105]).

From a CRF perspective, ISA-derived phosphorus offers multiple opportunities. Solubilized P can be recrystallized into struvite granules, which serve as slow-release fertilizer cores. Alternatively, ISA powders can be blended into biopolymer coatings, where they act as both nutrient contributors and filler materials. Several studies report that CRFs incorporating ISA-derived P exhibit delayed release patterns and reduced leaching losses compared to conventional phosphate fertilizers [88].

Despite these advantages, ISA recovery faces economic and technical barriers. Acid leaching generates large volumes of secondary waste, thermochemical processes require high energy input, and the presence of heavy metals raises regulatory hurdles [89]. Thus, while ISA recovery provides a sustainable route for phosphorus recycling, its integration into CRF production will depend on cost-effective processing and stricter quality control to ensure contaminant safety.

3.4. Biochar and Hydrochar as Fertilizer and Soil Amendment

Biochar and hydrochar derived from sludge have gained recognition as multifunctional soil amendments, offering benefits such as improved nutrient retention, enhanced soil structure, and immobilization of heavy metals [90,127]. Their porous architecture, high surface area, and abundance of functional groups enable strong interactions with both nutrients and contaminants, thereby improving agronomic safety and reducing leaching losses [128].

For CRF applications, these carbonaceous materials serve as engineered carriers or matrices. Biochar provides micro- and mesopores that can adsorb urea, ammonium, or phosphate, enabling gradual desorption into soil solutions [91]. Hydrochar, with its higher cation exchange capacity and hydrophilicity, is particularly suitable for adsorption-controlled nutrient release and shows good compatibility with biodegradable polymer coatings [129]. Both materials can also be impregnated with nutrients during production or coated with natural/synthetic polymers to produce hybrid CRFs.

Studies demonstrate that biochar- or hydrochar-based CRFs can extend nutrient release periods, reduce ammonia volatilization, and improve nitrogen-use efficiency by 15–30% compared to unmodified fertilizers [130]. In addition, their carbon-rich nature supports long-term carbon sequestration, linking CRF use with broader climate-mitigation goals.

However, performance varies depending on feedstock, pyrolysis/HTC conditions, and soil type [131]. Long-term field studies are limited, and uncertainties remain regarding interactions with soil microbiota, the stability of immobilized contaminants, and cost-effective scaling. Despite these challenges, sludge-derived biochar and hydrochar represent promising multifunctional carriers for CRF systems that combine nutrient management with environmental protection.

3.5. Encapsulation and Coating Techniques for Controlled-Release Fertilizers

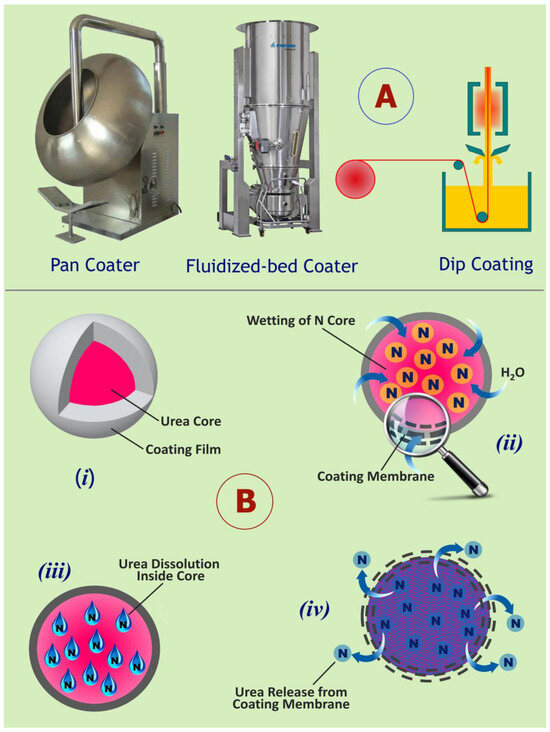

Encapsulation and coating methods are central to transforming sewage sludge into CRFs. These approaches regulate nutrient release through physical barriers, matrix embedding, or multilayer structures, thereby enhancing nutrient-use efficiency and minimizing nutrient losses [92,132]. They also offer opportunities to immobilize contaminants and improve biosafety when sludge-derived cores are used. Figure 9 illustrates different techniques used for coating and the mechanism of nutrient release.

Figure 9.

(A) Different coating equipment/techniques for fertilizer encapsulation, (B) Diffusion-controlled mechanism of nutrient release (N) from coated fertilizer.

3.5.1. Encapsulation Methods

Several techniques are employed to coat or encapsulate sludge-derived fertilizer cores. Spray and fluidized-bed coating (e.g., Wurster process) allow uniform application of polymers or composites onto stabilized granules, providing industrial scalability [133]. Immersion and layer-by-layer (LbL) deposition are simpler laboratory-scale methods that build multilayer coatings with tunable porosity and release profiles [134]. Matrix-based systems, in which nutrients are embedded within biodegradable polymers or nanocomposites, provide simultaneous nutrient delivery and soil amendment benefits [135].

Process parameters and scale-up. In fluidized-bed systems, inlet air temperature, atomization pressure, and spray rate govern film coalescence; improper settings cause defects that accelerate release. Binder viscosity, droplet size, and bed hydrodynamics co-determine coat uniformity, granule growth, and strength, which directly shape diffusion paths. Recent surface-modification strategies reduce coating mass without sacrificing control, improving process economics [136].

3.5.2. Types of Materials Used

Natural polymers such as starch, alginate, and chitosan are renewable, biodegradable, and inexpensive, though sometimes mechanically weak [137]. Synthetic polymers (e.g., polyurethane resins, polyolefins) offer durability and precise release control but raise concerns regarding persistence [138]. Biodegradable polyesters such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) combine strength with degradability, while nanocomposites (nano-clays, nano-cellulose) improve barrier properties at low loading levels [139].

Hybrid and nanostructured coatings. Practical CRFs often exploit bilayer films (e.g., a chitosan/alginate inner coat with a thin synthetic outer shell) to balance biodegradability and durability. Incorporating nanofillers enhances toughness, lowers effective diffusivity, and allows thinner coats to achieve long release spans [140]. Such strategies extend the material landscape by combining bio-based and synthetic attributes.

3.5.3. Nutrient Release Mechanisms

Nutrient release from coated fertilizers occurs via several mechanisms. Diffusion-controlled release involves molecular migration through micropores or imperfections in the coating; thicker or denser films reduce effective diffusivity [141]. Degradation-controlled release arises when the coating polymer undergoes hydrolysis or enzymatic breakdown, producing near zero-order or first-order kinetics depending on whether surface erosion or bulk degradation dominates [142]. Swelling-controlled release is typical of hydrogels, where polymer relaxation enlarges pores and enables nutrient efflux [143].

Short-time diffusion is often described by the Higuchi √t model, while long-time release can be modeled by Fickian film diffusion across a coating of thickness δ with effective diffusivity Deff. Degradation-driven systems may follow zero-order (surface erosion) or first-order (bulk erosion) kinetics. Swelling systems are commonly captured by the Korsmeyer–Peppas model, where the exponent indicates the balance between diffusion and relaxation [144].

Release behavior is influenced by coat thickness, coat mass fraction, polymer crosslink density, and filler loading (e.g., nanoclays) which reduce Deff. Soil factors such as pH, ionic strength, moisture, and temperature further modulate permeability and hydrolysis. Importantly, sludge-derived carriers such as biochar and hydrochar introduce tortuosity and adsorption sites, slowing nutrient migration and linking the carrier properties (Section 3.4) with coating performance [145].

Recent advances apply machine learning to predict nutrient release from biopolymer-coated CRFs using variables such as polymer type, thickness, and soil conditions, enabling faster optimization prior to pilot-scale coating trials [146].

3.5.4. Environmental and Agricultural Relevance

Encapsulation improves nutrient-use efficiency, typically reducing leaching and volatilization losses by 20–40% compared with uncoated fertilizers [147]. When sludge-derived carriers are paired with coatings, additional benefits include immobilization of heavy metals, buffering of soil pH, and reduction in contaminant mobility. Case studies with coated struvite granules, biochar-based CRFs, and Zn-fortified coated urea demonstrate yield improvements and more uniform release profiles under field conditions [148]. These outcomes highlight the potential for sludge-derived CRFs to achieve parity with commercial polymer-coated urea, provided challenges of coating adhesion, granule durability, and cost competitiveness of biodegradable polymers are addressed.

Despite these advances, several limitations and research gaps remain. Coating methods often face challenges in achieving uniform thickness, mechanical durability, and adhesion to sludge-derived cores, especially under field conditions. Biodegradable coatings, while environmentally favorable, are generally costlier and less predictable in performance compared to conventional synthetic polymers. Scale-up of fluidized-bed or LbL encapsulation systems requires optimization of process parameters to balance coating efficiency with economic feasibility. Moreover, long-term field trials assessing nutrient-use efficiency, contaminant immobilization, and soil ecological impacts are scarce. Addressing these gaps through pilot-scale demonstrations, cost–benefit analyses, and multi-season agronomic studies will be critical for translating sludge-derived CRFs into commercially viable and environmentally safe products.

To synthesize the diverse technologies discussed in this section, Table 4 compares conventional stabilization methods and advanced conversion pathways in terms of nutrient recovery, contaminant mitigation, cost and scalability, CRF relevance, and key limitations.

Table 4.

Comparison of sludge treatment technologies for CRF development.

While conventional stabilization techniques ensure biosafety and regulatory compliance, their contribution to CRF development remains limited. In contrast, advanced conversion routes such as pyrolysis, HTC, and ISA recovery not only enhance nutrient retention and contaminant control but also provide engineered carriers and cores suitable for encapsulation and coating. These insights set the stage for Section 4, which examines the specific development of sludge-derived CRFs and their performance compared to conventional fertilizers.

4. Performance Evaluation and Environmental Safety of Sludge-Derived Fertilizers

Building on the stabilization and conversion pathways described in Section 3, this section focuses on the development and performance of sludge-derived CRFs. While conventional processes prepare biosafe and stable cores, the emphasis here is on how these materials are engineered into CRFs through encapsulation, coating, and matrix embedding strategies, and how they perform relative to commercial counterparts.

4.1. Performance of Biochar-Based CRFs in Soil Systems

Biochar-based controlled-release fertilizers (CRFs) have demonstrated promising effects in improving soil properties, enhancing nutrient retention, and increasing crop productivity. One of the most notable benefits lies in their ability to improve the cation exchange capacity (CEC) of soil, which facilitates the retention of essential nutrients and reduces their leaching. This enhanced nutrient retention is crucial for minimizing environmental losses and improving nutrient use efficiency, especially in sandy or degraded soils [148]. Additionally, the porous structure and large surface area of biochar allow it to act as a slow-release matrix when combined with fertilizers, enabling a more controlled and prolonged nutrient supply to plants [93].

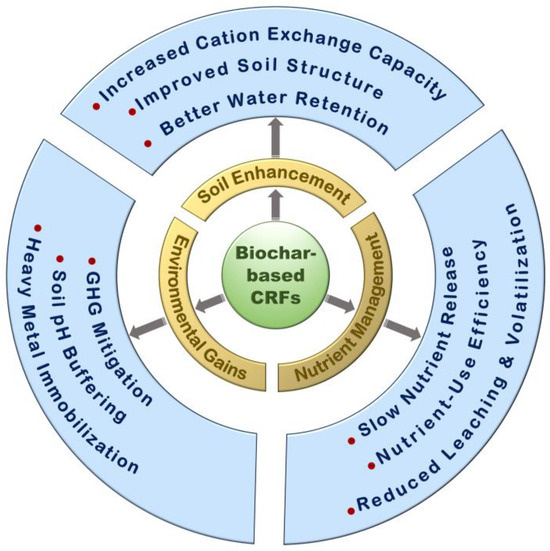

Field and greenhouse trials further demonstrate the positive impact of biochar-based CRFs on crop yield and quality. For example, the integration of biochar with nitrogen-based fertilizers has been shown to increase the yield of crops such as maize and wheat while simultaneously reducing nitrogen losses via leaching or volatilization [94]. Moreover, these formulations help stabilize soil pH, improve microbial activity, and enhance water-holding capacity, all of which contribute to better root development and nutrient uptake [95]. The multifaceted agronomic and environmental benefits of biochar-based CRFs are visually summarized in Figure 10.

Figure 10.

Integrated benefits of biochar-based controlled-release fertilizers (CRFs) in agricultural systems.

In acidic soils, biochar-amended CRFs have also been reported to neutralize soil pH and mitigate the toxicity of heavy metals such as aluminum, thereby improving root growth and nutrient availability [93]. In particular, biochar’s alkaline nature aids in correcting the pH of nutrient-depleted soils, contributing to long-term soil fertility and sustainability. The use of nutrient-enriched biochar also introduces additional macro- and micronutrients such as phosphorus, potassium, calcium, and magnesium into the soil system, further supporting plant growth [149].

Another critical advantage is the reduction in nutrient release rates compared to conventional fertilizers. This slow-release behavior ensures that nutrients are available in synchrony with plant demand, significantly reducing the risk of nutrient runoff and groundwater contamination [150]. The environmental benefits also extend to greenhouse gas mitigation, as biochar has been shown to reduce nitrous oxide (N2O) emissions from soils, especially when applied with urea-based fertilizers [151].

Despite these advantages, it is essential to consider that the performance of biochar-based CRFs can vary depending on biochar feedstock, production temperature, application rate, and soil type. Therefore, optimization based on local agro-climatic conditions is necessary to achieve the best results [149].

Recent studies indicate that sludge-derived CRFs can improve nitrogen-use efficiency by 20–35% compared with uncoated sludge or raw biosolids, and reduce nutrient leaching losses by up to 40% relative to conventional urea. Trials with biochar- or hydrochar-based CRFs further demonstrate reductions in ammonia volatilization and improved synchronization of nutrient release with crop demand. Such quantitative findings highlight their potential to achieve agronomic outcomes comparable to commercial CRFs, while providing additional environmental benefits.

Compared with conventional synthetic CRFs such as polymer-coated urea, sludge-derived CRFs offer distinct advantages and limitations. Their nutrient density is generally lower, but they provide multifunctional benefits such as enhanced soil organic matter, carbon sequestration, and contaminant immobilization. Synthetic CRFs typically ensure high nutrient concentration and well-calibrated release rates but rely on petrochemical-based coatings that raise environmental concerns. In contrast, sludge-based CRFs contribute to circular economy goals by recycling nutrients from waste streams and can improve soil biological health, though their agronomic performance still requires more validation

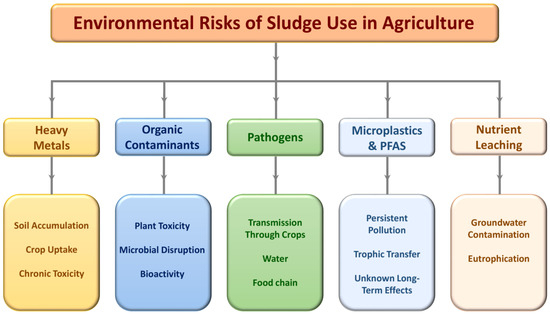

4.2. Environmental and Health Risks of Sewage Sludge Use in Agriculture

While sewage sludge offers potential benefits as a nutrient-rich amendment for agricultural soils, its application raises significant environmental and public health concerns. Chief among these are the persistent presence of heavy metals, organic contaminants, pathogens, and emerging pollutants, such as per- and polyfluoroalkyl substances.

4.2.1. Heavy Metal Accumulation

Sewage sludge often contains elevated levels of heavy metals such as cadmium (Cd), lead (Pb), mercury (Hg), and arsenic (As). Long-term application can result in their accumulation in soils and eventual uptake by crops, entering the food chain and posing chronic health hazards [150]. Although treatment processes like anaerobic digestion and composting can reduce pathogen loads, they do little to remove heavy metals [151].

4.2.2. Organic Contaminants and Pharmaceuticals

Modern sewage sludge is a sink for organic micropollutants, including pharmaceuticals, personal care products, hormones, and flame retardants. These compounds are often only partially removed during wastewater treatment and remain biologically active in the environment, with potential to disrupt soil microbial communities and affect plant health [152,153].

4.2.3. Pathogen Risks

Despite treatment, residual pathogens such as Escherichia coli, Salmonella, helminths, and viruses may still be present in treated sludge. Improper handling or insufficient treatment can lead to contamination of crops, particularly when sludge is surface-applied or incorporated shortly before planting [154].

4.2.4. Emerging Concerns: PFAS and Microplastics

Recent studies have raised alarms about PFAS, highly persistent chemicals used in industrial and consumer products, that accumulate in sewage sludge and may transfer to crops and groundwater when sludge is land-applied [85]. Similarly, microplastics present in sludge may alter soil structure and impact soil-dwelling organisms, while also potentially entering the food web [76,155].

4.2.5. Soil and Water Contamination

The leaching of contaminants from sludge-amended soils into water bodies poses a risk to aquatic ecosystems and human health through drinking water contamination. Nitrate leaching is another concern, particularly where high loading rates of sludge are used [96,156]. An overview of the major environmental and health-related risks associated with sewage sludge application in agriculture is presented in Figure 11.

Figure 11.

Environmental and health-related risks associated with the use of sewage sludge in agriculture.

Given these risks, stringent regulations, improved sludge treatment technologies, and long-term field studies are necessary to ensure safe and sustainable use of sludge in agriculture.

4.3. Hygienization and Pathogen Control in Sludge-Derived Fertilizers

One of the major safety challenges in the reuse of sewage sludge as fertilizer lies in its potential to harbor and transmit pathogens such as bacteria (e.g., Salmonella, E. coli), viruses (e.g., Norovirus), protozoa (e.g., Giardia, Cryptosporidium), and helminths (e.g., Ascaris). If inadequately treated, the application of such sludge to agricultural lands could result in the spread of infectious diseases through crops, groundwater contamination, and exposure risks to farmers and consumers [157].

To mitigate these risks, various hygienization strategies have been developed and regulated. Conventional stabilization techniques, such as anaerobic digestion and lime treatment, have been partially effective in reducing microbial load but often fail to eliminate resistant organisms such as helminth eggs [157]. Advanced thermal treatments like thermal drying and incineration offer higher reliability in pathogen reduction but are capital-intensive and energy-demanding [158]. Pasteurization, often applied before anaerobic digestion, is a middle-ground option that ensures sufficient microbial deactivation with moderate energy input [157].

Emerging techniques such as solar drying, microwave irradiation, ozonation, and the use of biochar as a stabilizing agent are gaining attention for their combined benefits in pathogen inactivation and environmental compatibility. Solar drying is particularly suitable for regions with high solar radiation, though its effectiveness can be weather-dependent. Microwave treatment, on the other hand, has demonstrated rapid pathogen destruction but is still limited to pilot-scale applications due to high operational costs [158].

Another dimension of pathogen control is regulatory enforcement. In Europe, the Sewage Sludge Directive (86/278/EEC) mandates specific limits for pathogens and vectors. Similarly, U.S. EPA regulations (40 CFR Part 503) define Class A and Class B biosolids based on microbial quality and intended use. However, inconsistencies across international standards often hinder harmonized implementation [159].

Continuous monitoring of microbial indicators like E. coli or fecal coliforms is essential to ensure that treated sludge meets safety benchmarks. However, these indicators may not always reflect the presence of more resistant or emerging pathogens. Hence, a shift toward more comprehensive pathogen detection systems, including molecular techniques (e.g., qPCR, metagenomics), is highly recommended for future sludge-derived fertilizer monitoring programs [159].

Robust hygienization is fundamental to the safe agricultural use of sewage sludge. Integrating advanced treatment technologies with regulatory oversight and continuous pathogen surveillance will not only protect public health but also build confidence in sludge-based fertilizer systems.

4.4. Techno-Economic Feasibility of Sewage Sludge Fertilizer Technologies

The large-scale adoption of sewage sludge-based fertilizers hinges significantly on their techno-economic viability. While environmental benefits and nutrient recovery potential make these technologies attractive, cost-effectiveness, infrastructure requirements, and market acceptance are critical parameters for real-world implementation.

One of the key technological routes explored for the conversion of sewage sludge into fertilizer is pyrolysis, which offers advantages in terms of energy recovery and the production of nutrient-rich biochar. However, the capital investment required for advanced pyrolysis units and the operational costs associated with maintaining optimal reaction conditions often challenge its widespread adoption [97]. To mitigate costs, hybrid approaches, such as integrating pyrolysis with anaerobic digestion, have been explored to maximize energy recovery and enhance process economics [160].

Another promising approach is the composting of sewage sludge, either alone or co-composted with other organic waste. This method is economically favorable due to its low capital and operational costs. However, challenges persist in ensuring consistent product quality and meeting regulatory standards, particularly concerning heavy metals and pathogens. Market acceptance is often hindered by negative perceptions regarding the safety and hygiene of composted sludge products [161].

Struvite precipitation, a method to recover phosphorus from sludge or sludge liquor, has gained traction in wastewater treatment plants due to its dual benefit of phosphorus recovery and scaling prevention. Despite its environmental and agronomic value, the cost of magnesium salts and the need for precise pH control make the process relatively expensive at full scale [97]. Economic assessments suggest that struvite recovery is more feasible when integrated into existing infrastructure, allowing shared use of equipment and energy resources [160].

A comprehensive techno-economic analysis must also account for hidden costs such as transportation, product marketing, certification, and end-user education. Recent studies emphasize the need to integrate life cycle cost assessment (LCCA) with traditional cost–benefit analysis to reflect the true feasibility of these technologies under diverse geographic and policy scenarios [161]. Furthermore, economic incentives like fertilizer subsidies, green credits, or carbon offsets could significantly improve the financial attractiveness of sludge-based fertilizers.

While the technological readiness of various sludge-to-fertilizer methods is advancing, their success depends equally on economic rationality, supportive policies, and stakeholder engagement. Regional differences in sludge characteristics, energy prices, and regulatory landscapes further underline the need for location-specific feasibility studies.

4.5. Comparative Analysis of Sludge Management Practices

The management of sewage sludge poses significant environmental and public health challenges, particularly concerning the safe disposal and potential resource recovery of the treated material. Globally, the three predominant pathways for sludge management include land application, incineration, and landfilling. Each method presents a unique set of benefits and limitations, and the selection often depends on national regulations, economic feasibility, environmental impact, and public perception.

4.5.1. Land Application

Land application is widely practiced for its potential to recycle nutrients and improve soil quality. This method involves the direct use of biosolids as soil amendments or fertilizers in agricultural lands, forests, and land reclamation areas. In the United States alone, approximately 2.39 million dry metric tons (dmt) of sewage sludge were land applied in 2023, including 1.24 million dmt on agricultural land [162]. The advantages of this practice include enhanced soil structure, increased organic content, and the provision of essential nutrients like nitrogen and phosphorus [163]. However, potential drawbacks include the risk of pathogen transfer, heavy metal accumulation, and the spread of emerging contaminants such as microplastics and PFAS [164]. Strict regulatory frameworks such as the U.S. EPA’s 40 CFR Part 503 standards are essential to minimize these risks [162].

4.5.2. Incineration

Incineration involves the thermal oxidation of sludge at high temperatures, significantly reducing sludge volume and destroying most organic pollutants and pathogens. In 2023, approximately 560,000 dmt of sewage sludge were incinerated in the U.S. [162]. This method is particularly advantageous for urban areas where land availability for application or disposal is limited. Moreover, energy recovery from incineration in the form of heat or electricity can contribute to the sustainability of treatment facilities [98]. However, incineration is capital-intensive and may generate air pollutants such as dioxins and heavy metals unless equipped with advanced air pollution control systems [165]. Additionally, the resulting ash requires further handling and disposal, often in landfills, though its potential for use in construction materials is under exploration [166].

4.5.3. Landfilling

Landfilling remains a common option for sludge disposal, particularly for small or under-resourced municipalities. In the U.S., nearly 955,000 dmt of sewage sludge were landfilled in 2023, including both municipal solid waste (MSW) landfills and monofills dedicated to sludge [162]. The primary advantage is its simplicity and relatively low cost of implementation. However, this method is increasingly scrutinized due to concerns over land use, methane emissions, and long-term leachate management [167]. Moreover, landfilling does not offer the same opportunities for nutrient or energy recovery as land application or incineration.

Table 5 presents a comparative summary of these three practices based on key evaluation criteria. While land application offers clear agronomic benefits and incineration supports energy recovery, both require stringent controls to mitigate environmental and health risks. Landfilling, while accessible, is gradually being phased out in several regions due to sustainability concerns.

Table 5.

Comparative Overview of Sludge Management Strategies.

Despite these promising results, most sludge-derived CRF studies remain at laboratory or pilot scale. Long-term, multi-season field trials are scarce, and evidence on their performance under diverse soil and climatic conditions is limited. Future research must therefore prioritize large-scale validation to fully establish the agronomic effectiveness, environmental safety, and commercial viability of sludge-based CRFs.

From an economic perspective, the treatment and conversion of sewage sludge into CRFs remain more expensive than bulk synthetic fertilizers, though costs vary with scale and technology. Typical stabilization and drying steps range between USD 30–50 per m3 of sludge, while advanced processes such as pyrolysis or hydrothermal carbonization can cost USD 70–120 per m3, depending on energy recovery integration. Encapsulation and coating add an additional USD 40–80 per m3. In comparison, the production of conventional polymer-coated urea is estimated at USD 200–300 per ton (equivalent to ~USD 15–20 per m3 at field application rates). Although sludge-derived CRFs may be costlier on a per-unit-nutrient basis, they offer co-benefits such as waste diversion, soil improvement, and reduced environmental externalities, which can offset costs in circular-economy frameworks.

5. Challenges and Future Perspectives

When sewage sludge is developed into CRFs, environmental risks extend beyond general biosolid concerns and must be evaluated in relation to product safety and field performance. Potential issues such as heavy metals, pathogens, and organic micropollutants directly affect the marketability and regulatory acceptance of sludge-derived CRFs, making risk assessment an integral step in their development

5.1. Technical and Environmental Challenges

Despite advancements in sludge valorisation technologies, several technical and environmental barriers continue to limit large-scale adoption. One of the most persistent issues is the heterogeneity of sewage sludge, which results in variable nutrient content, moisture levels, and contaminant loads. This variability affects the consistency and quality of sludge-derived fertilizers and complicates process optimization, particularly for thermal and encapsulation-based treatments [16,54].

Another critical concern is the presence of heavy metals, microplastics, and emerging contaminants such as pharmaceuticals and PFAS. While processes like composting, anaerobic digestion, and pyrolysis can reduce pathogen loads and stabilize organic matter, they are less effective at fully eliminating persistent pollutants [11,77]. The lack of efficient contaminant removal technologies presents a risk to environmental and human health when sludge products are applied to agricultural soils.

Moreover, nutrient loss during processing, especially nitrogen volatilization during thermal treatments and leaching during composting, remains a major challenge in maximizing agronomic value [20,54]. Encapsulation techniques promise more precise nutrient delivery, but are often hindered by coating imperfections, incomplete biodegradability, or high sensitivity to environmental conditions (e.g., soil pH, moisture, temperature).

The technical scalability remains limited. While several sludge conversion techniques have proven effective at the laboratory or pilot scale, their transition to industrial deployment is constrained by issues such as reactor design complexity, energy demand, and maintenance requirements, particularly in developing regions [97].

5.2. Socioeconomic and Policy Barriers

Beyond technical limitations, the socio-economic and regulatory landscape significantly influences the viability of sludge-based fertilizers. Public perception remains a major hurdle, particularly due to the “waste-to-food” stigma and concerns over the safety and cleanliness of sludge-derived products. This skepticism affects consumer acceptance and limits market penetration [83].

In parallel, regulatory inconsistencies and outdated standards hinder commercialization. For instance, while frameworks such as the U.S. EPA’s 40 CFR Part 503 and the EU’s Directive 86/278/EEC provide guidelines for heavy metals and pathogens, they lack provisions for emerging contaminants like microplastics and pharmaceutical residues [77,84]. The absence of global harmonization also means that technologies approved in one country may face legal barriers in another.

From an economic standpoint, the high capital and operational costs of advanced technologies like pyrolysis, gasification, or encapsulation systems discourage widespread adoption, especially in regions lacking subsidies or incentives [97]. Furthermore, logistics costs, certification hurdles, and limited access to markets for sludge-based products impose additional financial burdens.

There is also a gap in cross-sector collaboration among municipalities, researchers, industries, and farmers. Without integrated networks and supportive policies, such as green credits, circular economy mandates, or nutrient recycling targets, the long-term sustainability of sludge valorisation remains at risk [15].

5.3. Future Research Directions and Innovations

Future progress in this field will depend on multidisciplinary innovations targeting both technical and policy-related gaps. One key research direction involves the development of next-generation coating materials for CRFs, particularly biodegradable, stimuli-responsive, and nanostructured polymers that offer enhanced release control and environmental compatibility.

Another critical area is the advancement of contaminant mitigation strategies, such as selective sorbents, magnetic separation, and advanced oxidation processes, to reduce heavy metal mobility and remove micropollutants from sludge prior to use. Similarly, integrating life cycle assessment (LCA) and techno-economic analysis (TEA) into technology development pipelines can better inform feasibility decisions and support investor confidence.

Field-scale demonstrations and long-term agronomic trials are also urgently needed to evaluate the performance, safety, and environmental fate of sludge-derived fertilizers under diverse soil and climatic conditions. These studies should examine not only crop yield but also impacts on soil microbial communities, nutrient cycling, and pollutant residues.

Several mitigation strategies have been shown to reduce these risks in sludge-derived CRFs. Hygienization processes (e.g., lime stabilization, thermal drying, pasteurization) inactivate pathogens and reduce odor. Encapsulation and coating can create protective barriers that not only regulate nutrient release but also limit direct contact of contaminants with the soil environment. Carbonaceous carriers such as biochar and hydrochar further immobilize heavy metals through adsorption and pH buffering, lowering their bioavailability. Together, these approaches enhance both biosafety and environmental performance of CRFs produced from sludge

The future innovation must be accompanied by policy reform and public education campaigns. Establishing clear legal definitions for “recovered fertilizers,” updating contaminant thresholds, and creating economic incentives (e.g., carbon credits, waste-to-resource subsidies) will be vital for scaling up adoption. As research and policy converge, the vision of converting sewage sludge from an environmental liability into a sustainable agricultural asset can be fully realized.

Nevertheless, long-term monitoring of contaminant dynamics in soils amended with sludge-derived CRFs remains limited, and future studies must evaluate their fate under diverse field conditions to fully establish safety and sustainability

6. Conclusions

This review has highlighted the potential of sewage sludge as a feedstock for the development of controlled-release fertilizers through a combination of stabilization, advanced conversion, and encapsulation strategies. Conventional treatments provide biosafe substrates, while advanced processes such as pyrolysis, hydrothermal carbonization, and ISSA recovery generate engineered carriers or nutrient sources suitable for CRF design. The integration of biochar, hydrochar, and encapsulated struvite demonstrates promising nutrient-use efficiency gains and reduced environmental losses compared to uncoated fertilizers.

Despite these advances, important challenges remain. The nutrient density of sludge-based CRFs is often lower than that of commercial fertilizers, large-scale encapsulation faces cost and durability barriers, and the long-term impacts of biochar and other sludge-derived amendments on soil ecosystems require further study. Regulatory compliance, especially with heavy metal thresholds, is another critical issue that must be addressed to enable wider adoption. In addition, most current studies are limited to laboratory or pilot scale, and there is a need for multi-season field trials to validate agronomic performance and environmental safety under diverse conditions.

Future research should focus on optimizing cost-effective processing pathways, developing biodegradable yet durable coatings, integrating nutrient recovery with CRF production at scale, and evaluating circular-economy benefits in real agricultural systems. With these advances, sludge-derived CRFs could transition from experimental formulations to commercially viable products, supporting sustainable agriculture and waste valorization simultaneously.

Funding

This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (grant number IMSIU-DDRSP2502).

Acknowledgments

During the preparation of this work, the author(s) used ChatGPT 5.0 in order to improve the clarity, grammar, and structure of the manuscript, as well as to enhance the presentation of results and technical descriptions. After using this tool/service, the author(s) reviewed and edited the content as needed and take(s) full responsibility for the content of the publication.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods, A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Gao, N.; Kamran, K.; Quan, C.; Williams, P.T. Thermochemical conversion of sewage sludge: A critical review. Prog. Energy Combust. Sci. 2020, 79, 100843. [Google Scholar] [CrossRef]

- Dutta, N.; Giduthuri, A.T.; Khan, M.U.; Garrison, R.; Ahring, B.K. Improved valorization of sewage sludge in the circular economy by anaerobic digestion: Impact of an innovative pretreatment technology. Waste Manag. 2022, 154, 105–112. [Google Scholar] [CrossRef]

- Cebi, D.; Celiktas, M.S.; Sarptas, H. A review on sewage sludge valorization via hydrothermal carbonization and applications for circular economy. Circ. Econ. Sustain. 2022, 2, 1345–1367. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, J.; Lee, D.J.; Chang, Y.; Lee, Y.J. Sludge treatment: Current research trends. Bioresour. Technol. 2017, 243, 1159–1172. [Google Scholar] [CrossRef]

- Yetilmezsoy, K.; Karakaya, K.; Bahramian, M.; Abdul-Wahab, S.A.; Goncaloğlu, B.İ. Black-, gray-, and white-box modeling of biogas production rate from a real-scale anaerobic sludge digestion system in a biological and advanced biological treatment plant. Neural Comput. Appl. 2021, 33, 11043–11066. [Google Scholar] [CrossRef]

- Huang, D.; Gao, Y.; Zhang, L.; Zhang, R.; Wu, Y.; Guan, H.; Luo, D. Enhancing waste management and nutrient recovery: Preparation of N slow-release fertilizer using sewage sludge and its release behavior, effects on ryegrass (Lolium perenne L.) growth. Biochem. Eng. J. 2025, 216, 109664. [Google Scholar] [CrossRef]

- Guo, X.; Liang, S.; Zou, Z.; Xu, X.; Yang, F.; Quan, J.; Li, X.; Duan, H.; Yu, W.; Yang, J. Enhanced phosphorus bioavailability of biochar derived from sewage sludge co-pyrolyzed with K, Ca-rich biomass ash. Water Res. 2025, 271, 122901. [Google Scholar] [CrossRef]

- Wang, L.; Chang, Y.; Li, A. Hydrothermal carbonization for energy-efficient processing of sewage sludge: A review. Renew. Sustain. Energy Rev. 2019, 108, 423–440. [Google Scholar] [CrossRef]

- Kelessidis, A.; Stasinakis, A.S. Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Manag. 2012, 32, 1186–1195. [Google Scholar] [CrossRef] [PubMed]

- Edelstein, M.; Ben-Hur, M. Heavy metals and metalloids: Sources, risks and strategies to reduce their accumulation in horticultural crops. Sci. Hortic. 2018, 234, 431–444. [Google Scholar] [CrossRef]

- Yang, G.; Zhang, G.; Wang, H. Current state of sludge production, management, treatment and disposal in China. Water Res. 2015, 78, 60–73. [Google Scholar] [CrossRef] [PubMed]

- Eurostat. Sewage Sludge Production and Disposal Statistics. 2022. Available online: https://ec.europa.eu/eurostat/ (accessed on 12 June 2025).

- United States Environmental Protection Agency. Biosolids Annual Report 2022–2023. 2023. Available online: https://www.epa.gov/biosolids (accessed on 15 June 2025).

- Gherghel, A.; Teodosiu, C.; De Gisi, S. A review on wastewater sludge valorisation and its challenges in the context of circular economy. J. Clean. Prod. 2019, 228, 244–263. [Google Scholar] [CrossRef]

- Hu, M.; Hu, H.; Ye, Z.; Tan, S.; Yin, K.; Chen, Z.; Guo, D.; Rong, H.; Wang, J.; Pan, Z.; et al. A review on turning sewage sludge to value-added energy and materials via thermochemical conversion towards carbon neutrality. J. Clean. Prod. 2022, 379, 134657. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Towards sewage sludge based biofuels via thermochemical conversion—A review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Olsson, G. Energy issues in sustainable urban wastewater management: Use, demand reduction and recovery in the urban water cycle. Sustainability 2019, 12, 266. [Google Scholar] [CrossRef]

- Fonts, I.; Gea, G.; Azuara, M.; Ábrego, J.; Arauzo, J. Sewage sludge pyrolysis for liquid production: A review. Renew. Sustain. Energy Rev. 2012, 16, 2781–2805. [Google Scholar] [CrossRef]

- Pelagalli, V.; Langone, M.; Matassa, S.; Race, M.; Tuffi, R.; Papirio, S.; Lens, P.N.L.; Lazzazzara, M.; Frugis, A.; Petta, L.; et al. Pyrolysis of municipal sewage sludge: Challenges, opportunities and new valorization routes for biochar, bio-oil, and pyrolysis gas. Environ. Sci. Water Res. Technol. 2024, 10, 2282–2312. [Google Scholar] [CrossRef]