Diagnosing Hydraulic Directional Valve Spool Stick Faults Enabled by Hybridized Intelligent Algorithms

Abstract

1. Introduction

- (1)

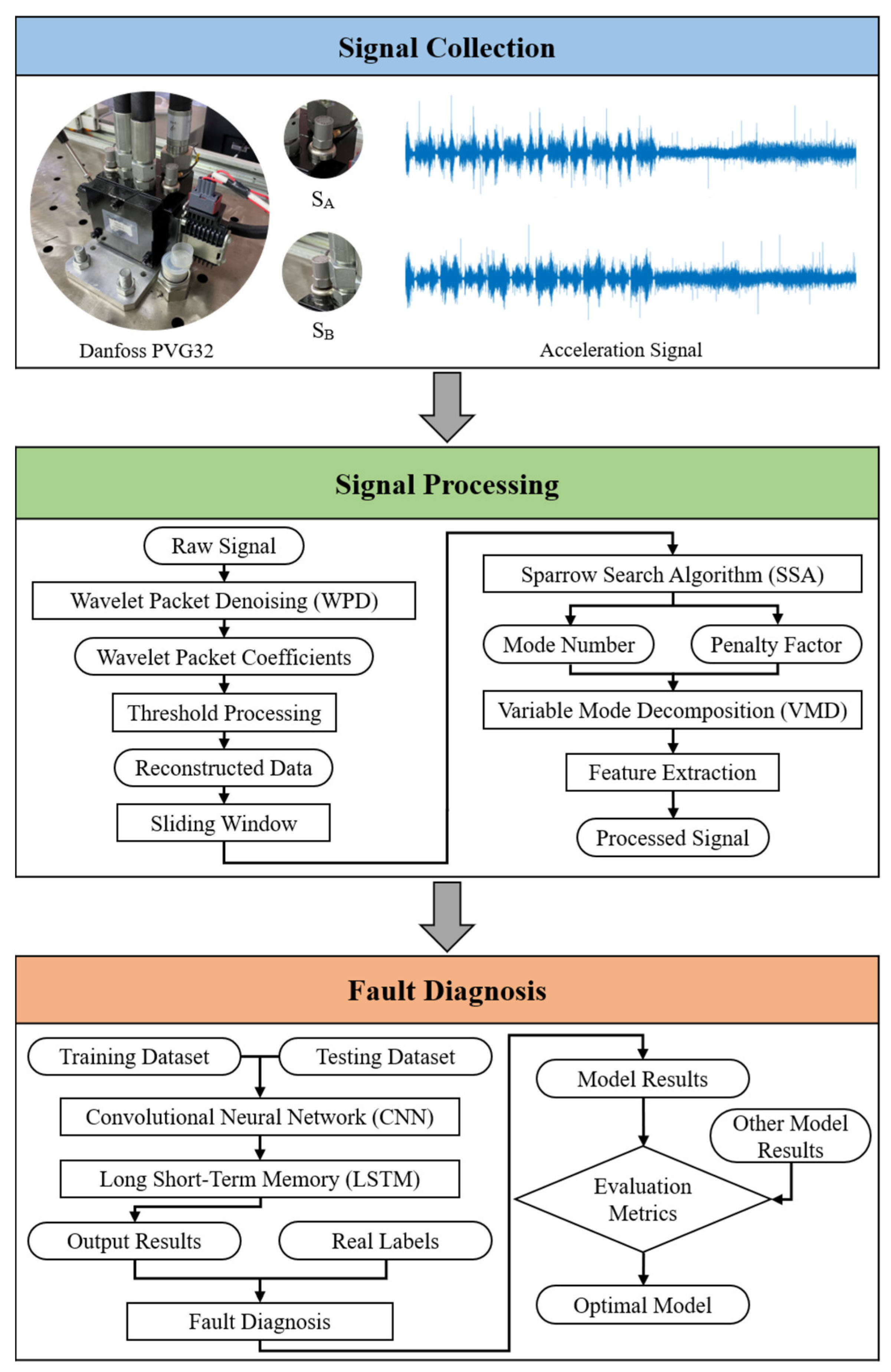

- A hybrid signal processing framework (WPD-SSA-VMD) is proposed to enhance signal quality and processing efficiency. The WPD is initially employed for the denoising of raw vibration signals, followed by SSA-optimized VMD for the purpose of adaptive signal decomposition. This combination significantly reduces processing time while preserving essential fault features.

- (2)

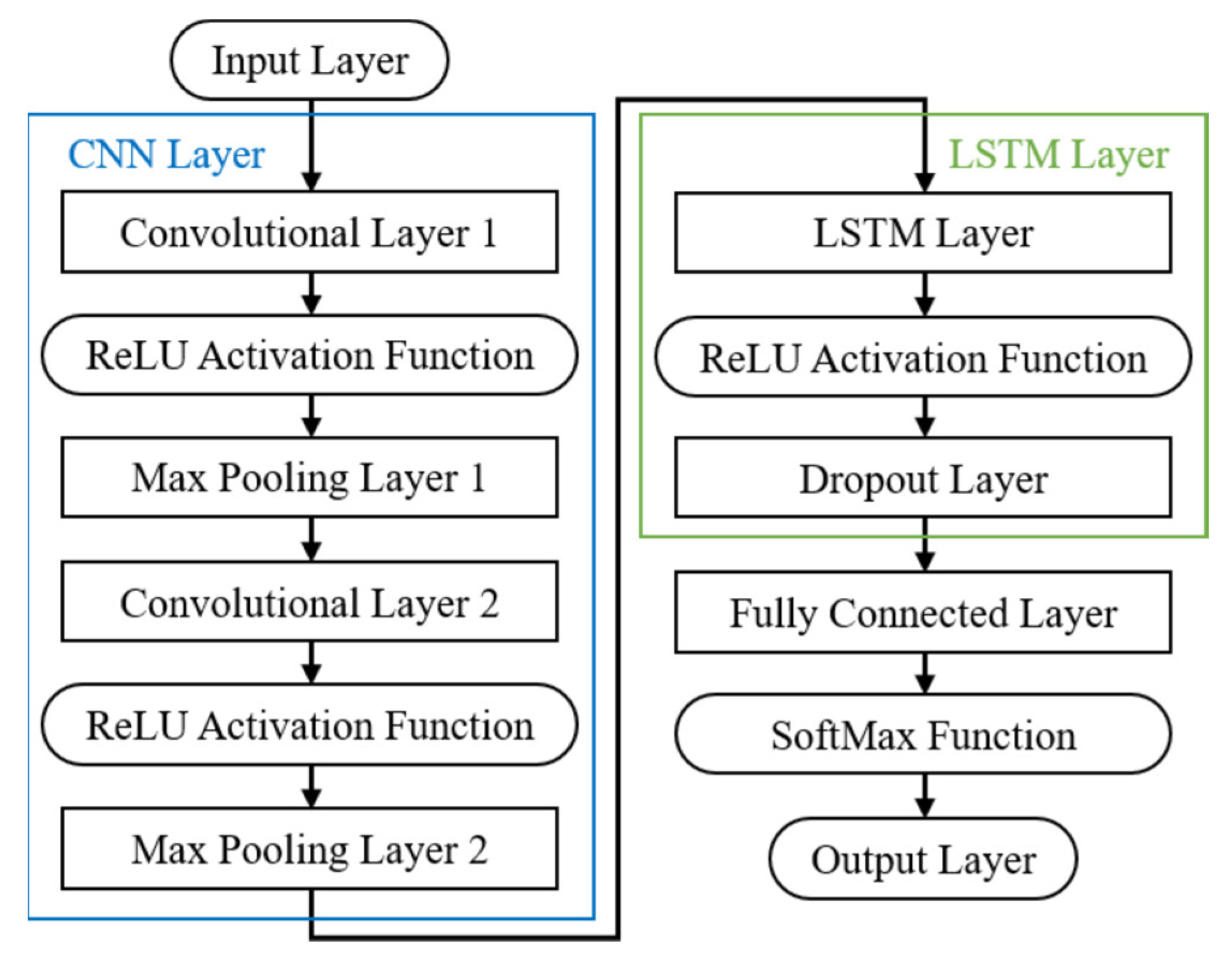

- An integrated CNN-LSTM deep learning model has been developed to diagnose spool stick faults. This model has been developed by leveraging the strengths of both architectures. The utilisation of CNN (Convolutional Neural Network) is employed for the purpose of spatial feature extraction, whilst LSTM (Long Short-Term Memory) is utilised for the purpose of capturing long-range temporal dependencies in sequential vibration data.

- (3)

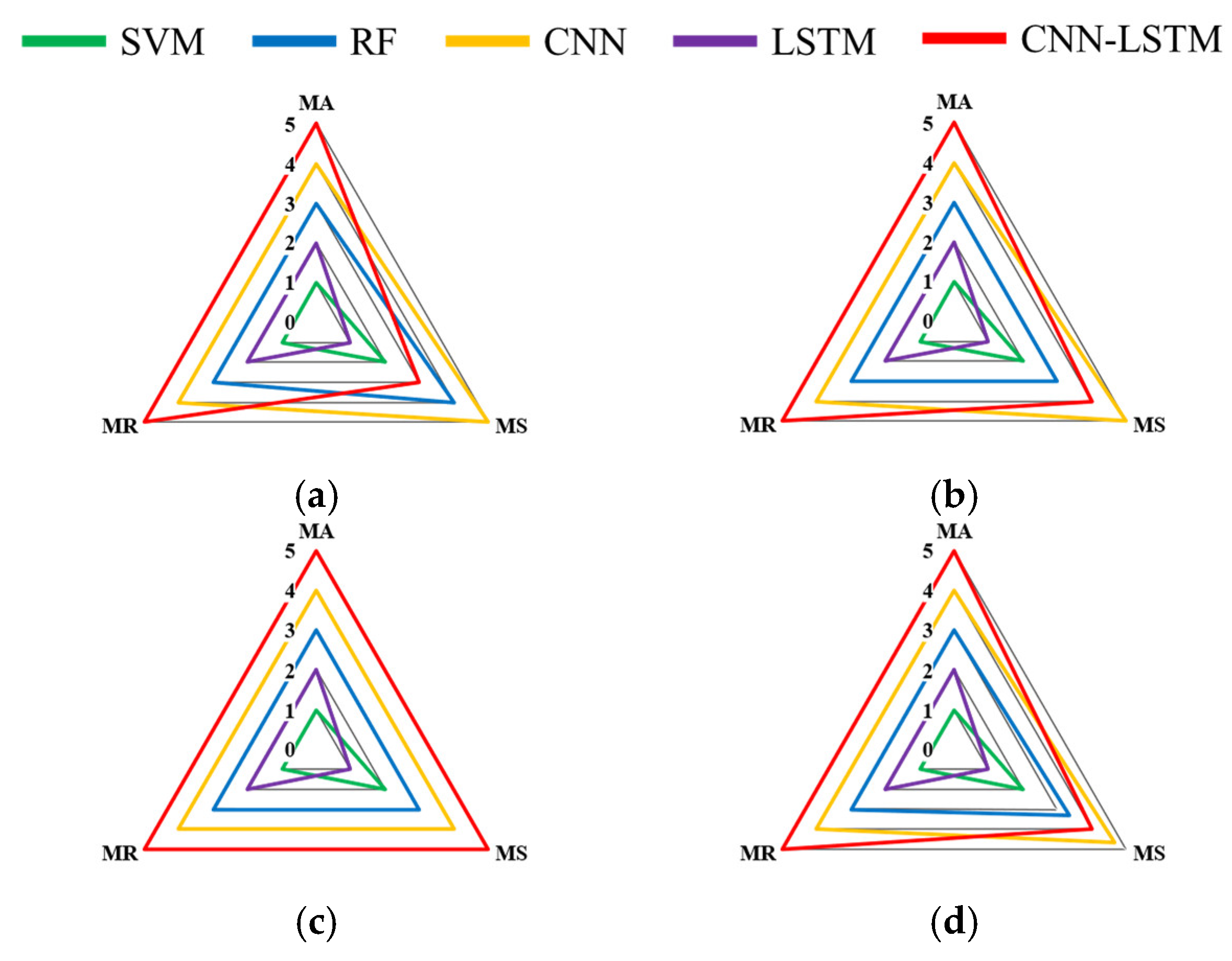

- A comprehensive evaluation system is established using three metrics: Model Accuracy (MA), Model Stability (MS), and Model Reliability (MR). A quantitative comparison and benchmarking against each other are conducted for these variables, utilising a 5-score ranking system. This enables a quantitative comparison and benchmarking of diagnostic performance across different models and sensor configurations.

2. Literature Survey

2.1. Signal Processing for Fault Diagnosis

2.2. Deep Learning-Enabled Fault Diagnosis

3. Materials and Methodologies

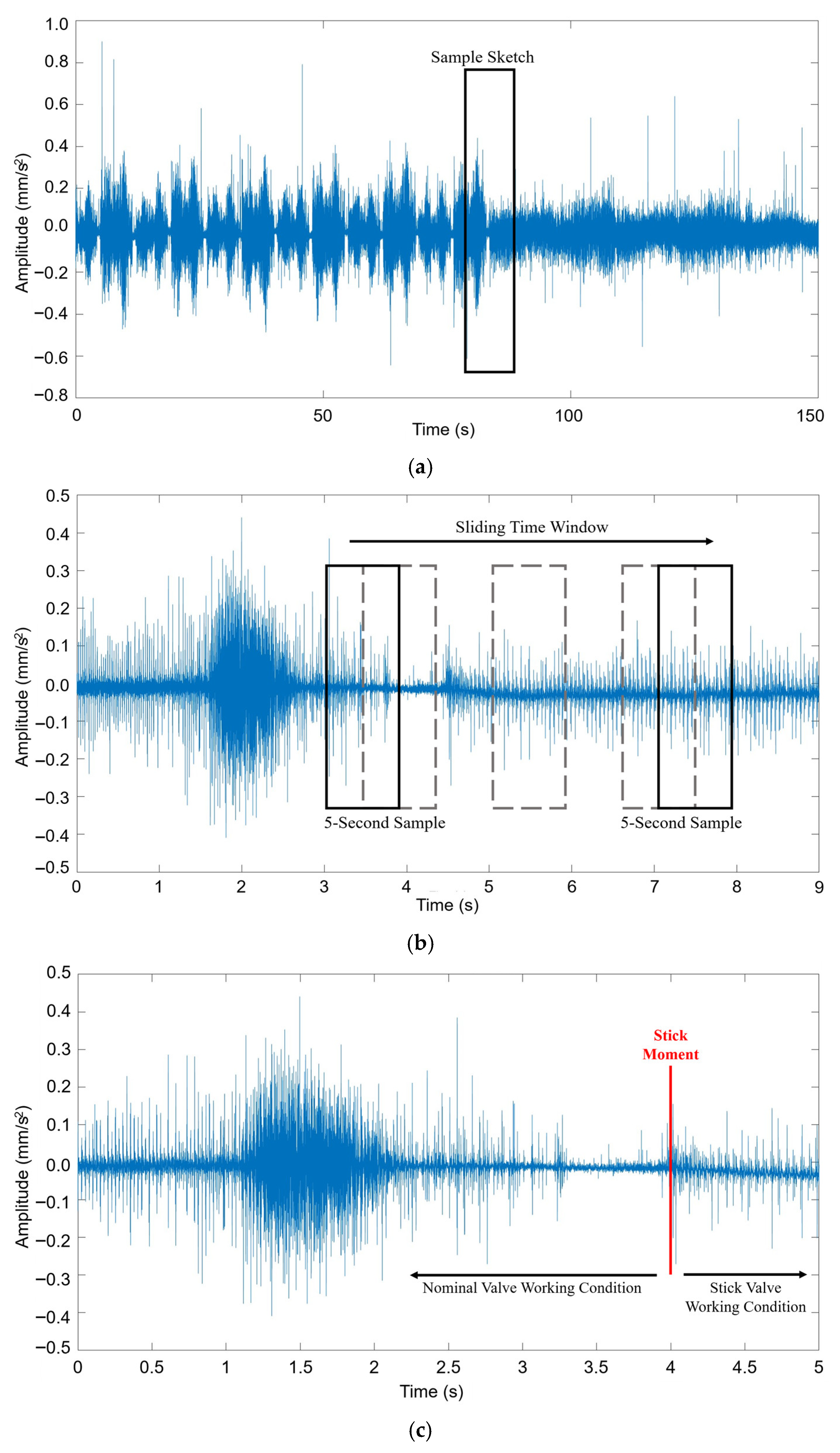

3.1. Signal Collection

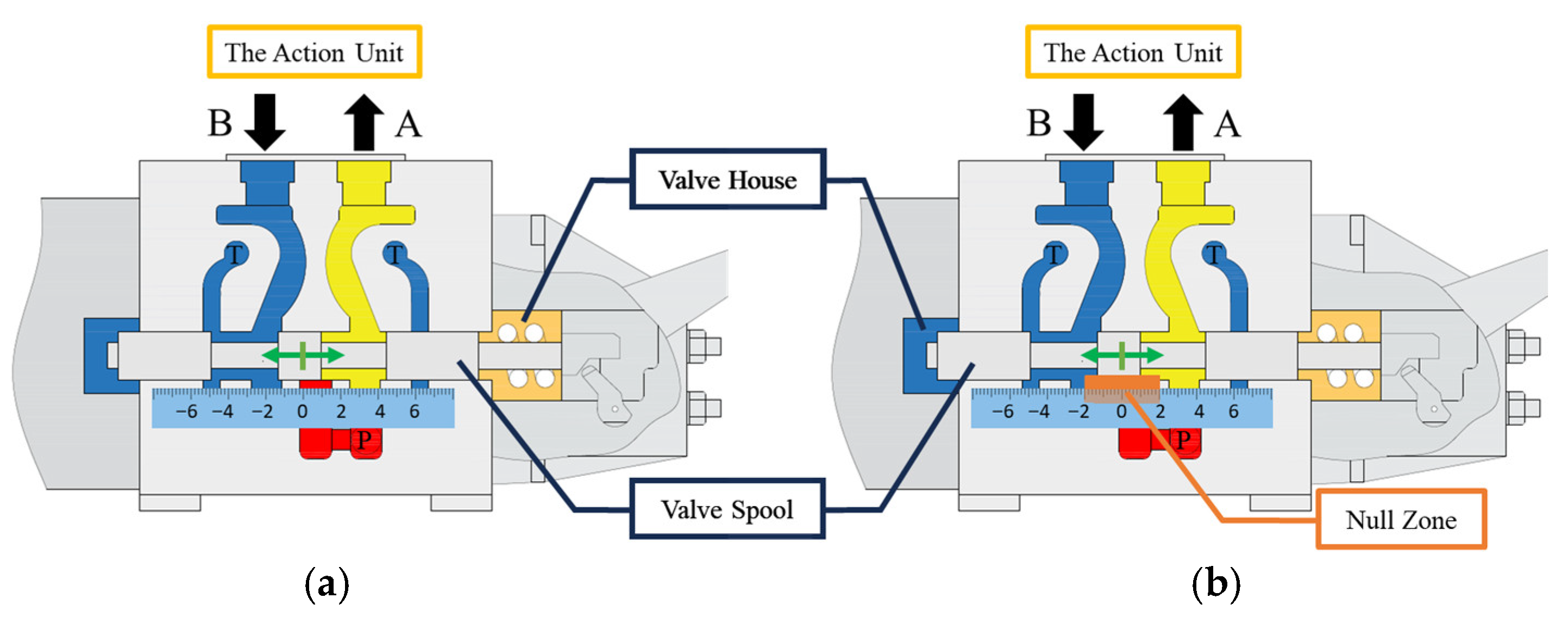

3.1.1. Experimental Setup and Apparatus

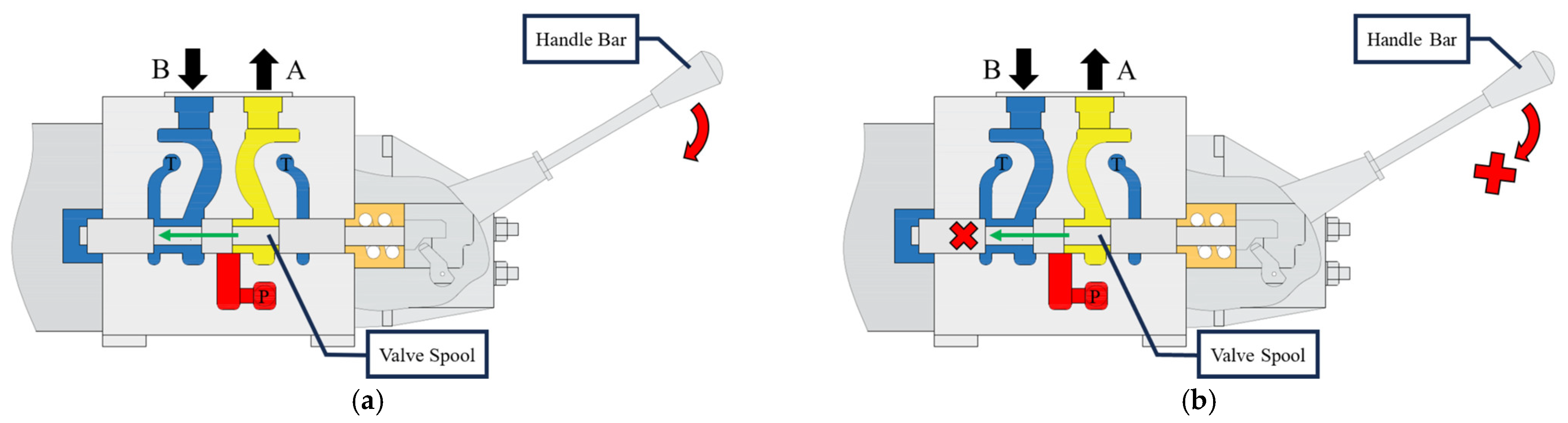

3.1.2. Fault Simulation Methodology

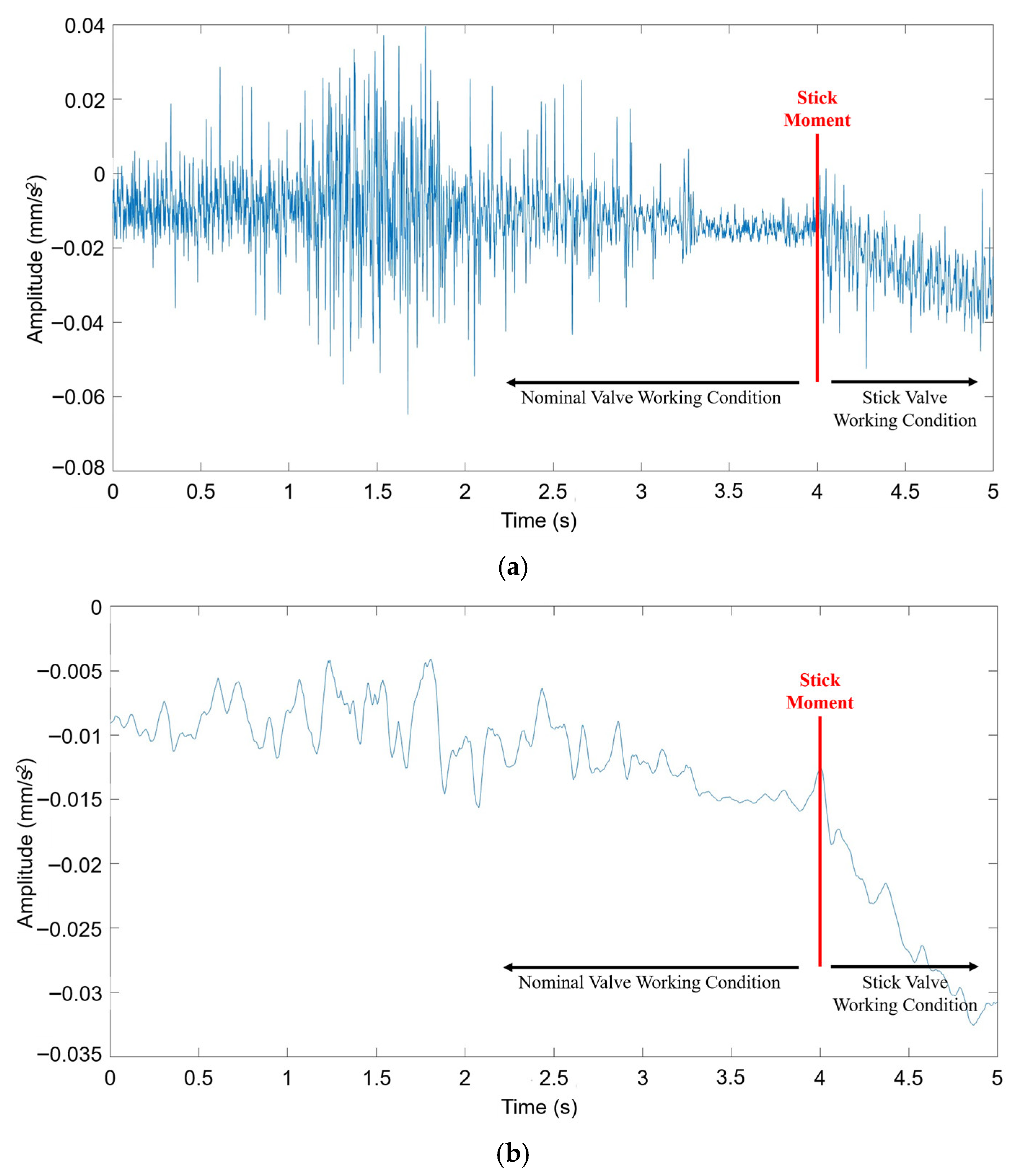

3.2. Signal Processing

3.2.1. Wavelet Packet Denoising

- (1)

- The signal decomposition:

- (2)

- The threshold processing:

- (3)

- The signal reconstruction:

3.2.2. Variational Mode Decomposition

- (1)

- The signal decomposition

- (2)

- Dealing the variational problem

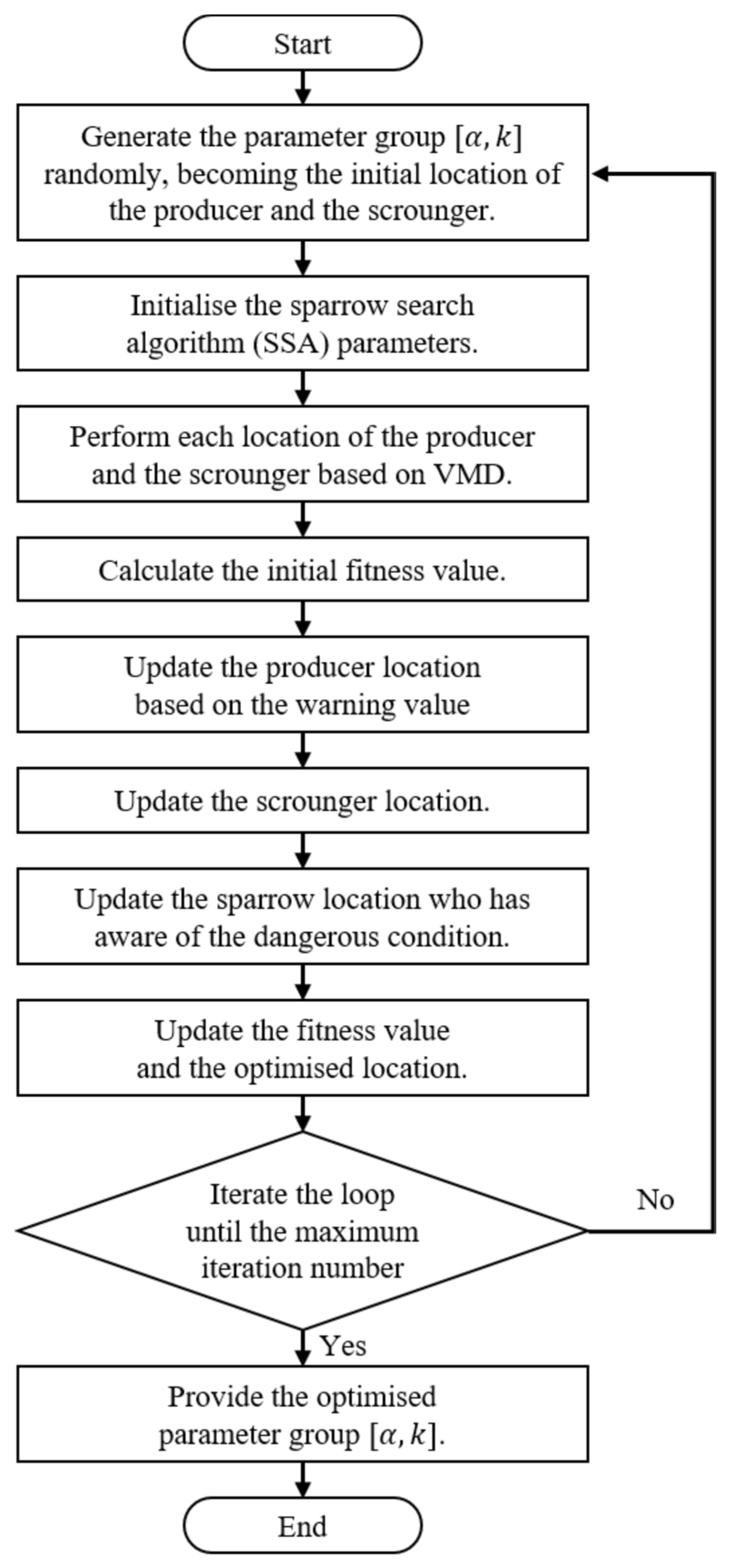

3.2.3. Sparrow Search Algorithm

- (a)

- Each sparrow has the potential to become a producer if it is able to find more suitable food sources. Meanwhile, the ratio of producers and scroungers remains constant throughout the entire population.

- (b)

- Producers tend to have high energy reserve levels, and forages or scroungers are being responsible for finding the rich food source.

- (c)

- Individuals start chirping as a warning alarm when the sparrow detects the predator. As soon as the value of this warning alarm exceeds a safe threshold, it will be necessary for the producers to lead all of scroungers to the other safe regions.

- (d)

- The higher-energy sparrows will become the producers, while some starving scroungers may fly to other districts in search of food rather than gain more energy in the current district.

- (e)

- Scroungers will always be followed by producers, who will find and supply the optimal food sources. However, numerous scroungers may persistently supervise these producers and even compete for their food, thereby increasing their predation rate on all sparrows.

- (f)

- Approximately 10% to 20% of the sparrow population at the periphery of the district are aware of the potential danger, so that they immediately move to a safer district in search of a more favourable environment.

3.2.4. VMD Parameter Optimization by SSA

- (1)

- Initialization: The SSA population (sparrows) is initialized with each individual representing a potential solution, i.e., a combination of the VMD parameters [, ].

- (2)

- Fitness Evaluation: For each individual in the population, the VMD algorithm is run with its specific [, ] values to decompose the signal. The fitness of the solution is calculated as the envelope entropy of the resulting Intrinsic Mode Functions (IMFs). Envelope entropy serves as an effective fitness function because a lower value indicates less noise and more pronounced fault features in the decomposed components, which is desirable for effective feature extraction.

- (3)

- SSA Population Update: Based on the fitness evaluation, the positions of the producers, scroungers, and scouts are updated according to the SSA rules (as defined in Section 3.2.3). This step aims to guide the population towards the parameter combination that minimizes the envelope entropy.

- (4)

- Termination Check: The algorithm checks if the maximum number of iterations has been reached or if the fitness value has converged. If not, the process returns to Step 2.

- (5)

- Output Optimal Parameters: Once the termination condition is met, the best parameter combination [, ] found by the SSA is output.

- (6)

- Final VMD: The denoised signal is finally decomposed using the VMD algorithm with the optimized parameters, yielding a set of high-quality IMFs for subsequent feature extraction.

3.2.5. Feature Extraction

3.3. Fault Diagnosis

3.3.1. Convolutional Neural Network

3.3.2. Long Short-Term Memory

3.3.3. Combination of CNN and LSTM

3.3.4. Evaluation Metrics

- (a)

- Model Accuracy (MA): The average accuracy of four model training ratios (50%, 60%, 70%, and 80%) is presented to demonstrate the overall diagnostic accuracy of the model.

- (b)

- Model Stability (MS): The standard deviation of the diagnostic accuracy at different training ratios is used to reflect the model stability under different conditions.

- (c)

- Model Reliability (MR): The logarithm of the MA is calculated using the log base of the MS. The overall model reliability with different training ratios can be obtained for the further analysis of the optimization of the approach.

4. Results and Analysis

4.1. Signal Processing Approach

4.2. Fault Diagnosis Model

5. Discussion

5.1. Parameter Selection

5.2. Potential Limitations

- (1)

- Computational Efficiency: Despite the incorporation of WPD leading to a significant reduction in signal processing time by 56.60%, the overall diagnostic process, particularly the SSA-optimized VMD and the CNN-LSTM model, remains computationally intensive. This may hinder the real-time application in industrial settings where computational resources are limited.

- (2)

- Generalization Ability: The model was subjected to training and validation procedures using a specific type of hydraulic directional valve (PVG32) within the confines of a controlled laboratory environment. However, the performance of the system under other valve types or under more varied and harsh real-world operating conditions (e.g., different fluid contaminants, temperature fluctuations, or pressure levels) remains unverified.

- (3)

- Sensor Dependency and Placement: The findings of this study demonstrated that the diagnostic accuracy was found to be sensitive to the sensor location. This was evidenced by a discrepancy in performance between the SA and SB sensor groups. This finding indicates that the model’s robustness may be influenced by the configuration of sensors in practical applications.

- (4)

- Feature Extraction Scope: The feature extraction process was predicated exclusively on time-domain features. While the inclusion of frequency-domain or time-frequency features was sufficient for the purposes of this study, the incorporation of such features could potentially capture more nuanced fault characteristics and further improve diagnostic robustness, especially with regard to incipient or compound faults.

5.3. Future Research

- (1)

- Multi-Sensor Information Fusion: Subsequent research endeavours will encompass the integration of supplementary sensor types, including pressure and temperature sensors. The objective of this integration is to develop a more comprehensive and robust array of fault features. It is hypothesised that this will enhance diagnostic accuracy and reliability to a greater extent than that achievable with vibration signals alone.

- (2)

- Model Lightweighting and Optimization: It is acknowledged that considerable effort will be expended on the development of lightweight versions of the diagnostic model. Such efforts may take the form of techniques such as model pruning, quantisation, or knowledge distillation. The objective of this approach is twofold: firstly, to reduce the computational burden, and secondly, to facilitate deployment in real-time embedded systems.

- (3)

- Transfer Learning and Generalizability: The present study will entail the execution of research, the objective of which is to apply transfer learning techniques. The implementation of these techniques will enable the pre-trained model to be adapted for the purpose of fault diagnosis in different types of hydraulic valves or systems with limited new data. It is hypothesised that the result of the adaptation process will be an enhancement in the generalisability of the model.

- (4)

- Enhanced Feature Extraction: The exploration of automated feature extraction, combining the time, frequency, and time-frequency domains using deep learning, will be pursued. Furthermore, the development of adaptive signal processing techniques capable of self-adjustment to varying noise levels and operational conditions is identified as a key objective.

6. Conclusions

- (1)

- The hybrid signal processing strategy (WPD-SSA-VMD) is of critical importance for achieving optimal diagnostic efficiency. In direct response to the challenge of computational cost, as discussed in Section 4.1, the integration of Wavelet Packet Denoising (WPD) as a pre-processing step was proven to be highly effective. The results presented in Table 2 offer quantitative evidence that this strategy led to a significant reduction in signal processing time per iteration by 56.60%, thereby decisively addressing the efficiency issue. This enhancement in processing speed was accompanied by a negligible yet valid trade-off in accuracy, with a reduction of approximately 1.29%, thereby validating the WPD-SSA-VMD as the optimal pre-processing pipeline for this specific application.

- (2)

- The CNN-LSTM model has been demonstrated to be the superior diagnostic architecture. The comprehensive model comparison in Section 4.2, evaluated using the MA, MS, and MR indices, conclusively demonstrated that the hybrid CNN-LSTM model outperformed all benchmark models (SVM, RF, CNN, LSTM). As outlined in Table 5 and Figure 9, the model demonstrated the highest Model Accuracy (MA) of 97.01% and 96.24% for individual sensors, and an impressive 99.55% for the fused sensor group. While its Model Stability (MS) was marginally lower than that of the CNN model in certain single-sensor scenarios, it exhibited the most consistent and reliable performance overall, as demonstrated by its superior Model Reliability (MR) scores. This finding serves to validate the design hypothesis that the combination of CNNs’ spatial feature extraction and LSTMs’ temporal modelling creates a more powerful diagnostic tool.

- (3)

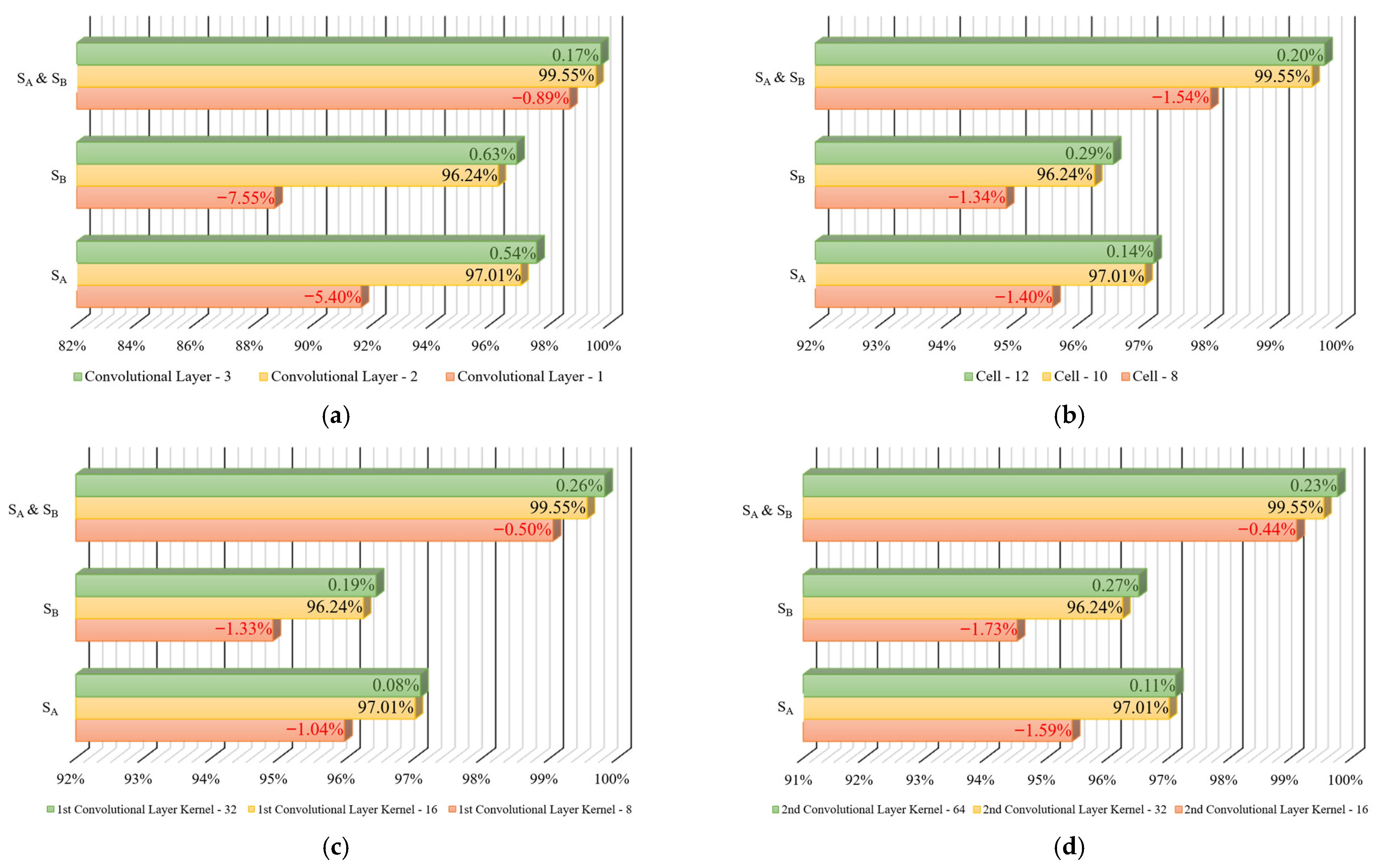

- The selection of model parameters is directly linked to achieving a balance between accuracy and speed. The detailed discussion in Section 5.1 on parameter selection provides a clear rationale for the final model configuration. The selected parameters, comprising two convolutional layers, 10 long short-term memory (LSTM) cells, and kernel sizes of 16 and 32, were not chosen randomly but were empirically determined to offer the optimal compromise. As outlined in Table 7, this configuration circumvents the substantial 4.61% accuracy decline associated with a reduced model and the 15.64% temporal augmentation observed in a more substantial model. Consequently, it ensures diagnostic efficacy without incurring substantial computational overheads.

- (4)

- The fusion of multiple sensors has been demonstrated to significantly enhance the robustness of diagnostic systems. The findings consistently highlighted the benefit of utilizing multiple sensors. As demonstrated in Table 4 and Table 5, the fused SA & SB sensor group consistently demonstrated the highest levels of accuracy and the lowest levels of standard deviation across all models. The final CNN-LSTM model demonstrated an accuracy of 99.55%, substantiating the hypothesis that data from multiple valve ports provides a more comprehensive and robust fault signature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADMM | Alternating Direction Multiplier Method |

| CNN | Convolutional Neural Network |

| EMD | Empirical Mode Decomposition |

| ERI | Electrical Resistivity Imaging |

| IMFs | Intrinsic Mode Functions |

| LSTM | Long Short-Term Memory |

| MA | Model Accuracy |

| MR | Model Reliability |

| MS | Model Stability |

| PVG32 | Proportional Valve Group 32 |

| RF | Random Forest |

| RNN | Recurrent Neural Network |

| SE | Shannon Entropy |

| SSA | Sparrow Search Algorithm |

| SVM | Support Vector Machine |

| VMD | Variational Mode Decomposition |

| WPD | Wavelet Packet Denoising |

References

- Wang, J.; Yang, Z.; Liu, S.; Zhang, Q.; Han, Y. A comprehensive overview of hybrid construction machinery. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef]

- Quan, Z.; Quan, L.; Zhang, J. Review of energy efficient direct pump controlled cylinder electro-hydraulic technology. Renew. Sustain. Energy Rev. 2014, 35, 336–346. [Google Scholar] [CrossRef]

- Kadar, F.; Hos, C.; Stepan, G. Delayed oscillator model of pressure relief valves with outlet piping. J. Sound Vib. 2022, 534, 117016. [Google Scholar] [CrossRef]

- Awad, H.; Parrondo, J. Hydrodynamic self-excited vibrations in leaking spherical valves with annular seal. Alex. Eng. J. 2020, 59, 1515–1524. [Google Scholar] [CrossRef]

- Simic, M.; Herakovic, N. Reduction of the flow forces in a small hydraulic seat valve as alternative approach to improve the valve characteristics. Energy Convers. Manag. 2015, 89, 708–718. [Google Scholar] [CrossRef]

- Licsko, G.; Champneys, A.; Hos, C. Nonlinear analysis of a single stage pressure relief valve. Int. J. Appl. Math. 2023, 39, 286–299. [Google Scholar] [CrossRef]

- Danfoss PVG 32 Proportional Valves. Available online: https://www.danfoss.com/en/products/dps/valves-and-actuators/valves/pvg-proportional-valves/pvg-32-proportional-valves (accessed on 10 September 2025).

- Danfoss PVG 32 Proportional Valve Group Technical Information. Available online: https://assets.danfoss.com/documents/197489/BC152886483664zh-001401.pdf (accessed on 10 September 2025).

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Abraham, A. Multi-fault diagnosis of industrial rotating machines using data-driven approach: A review of two decades of research. Eng. Appl. Artif. Intell. 2023, 123 Pt A, 106139. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.C.; Tung, C.C.; Liu, H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. A 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Lei, L.; Lin, J.; He, Z.; Zuo, M.J. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2012, 35, 108–126. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Jin, Z.; He, D.; Wei, Z. Intelligent fault diagnosis of train axle box bearing based on parameter optimization VMD and improved DBN. Eng. Appl. Artif. Intell. 2022, 110, 104713. [Google Scholar] [CrossRef]

- Li, J.; Luo, W.; Bai, M.; Song, M. Fault diagnosis of high-speed rolling bearing in the whole life cycle based on improved grey wolf optimizer-least squares support vector machines. Digit. Signal Process. 2024, 145, 104345. [Google Scholar] [CrossRef]

- Xue, J.; Shen, B. A novel swarm intelligence optimization approach: Sparrow search algorithm. Syst. Sci. Control Eng. 2019, 8, 22–34. [Google Scholar] [CrossRef]

- Xu, L.; Cai, D.; Shen, W.; Su, H. Denoising method for Fiber Optic Gyro measurement signal of face slab deflection of concrete face rockfill dam based on sparrow search algorithm and variational modal decomposition. Sens. Actuators A Phys. 2021, 331, 112913. [Google Scholar] [CrossRef]

- Liu, W.; Zhu, R.; Zhou, W.; Wang, J. Research on feature extraction method for different levels of cracks and pitting in spur gear based on dynamic characteristic templates. Measurement 2024, 228, 114335. [Google Scholar] [CrossRef]

- Jiang, F.; Dong, L.; Dai, Q.; Nobes, D.C. Using wavelet packet denoising and ANFIS networks based on COSFLA optimization for electrical resistivity imaging inversion. Fuzzy Sets Syst. 2018, 337, 93–112. [Google Scholar] [CrossRef]

- Beale, C.; Niezrecki, C.; Inalpolat, M. An adaptive wavelet packet denoising algorithm for enhanced active acoustic damage detection from wind turbine blades. Mech. Syst. Signal Process. 2020, 142, 106754. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Qin, X.; Sun, Y. A two-stage fault diagnosis methodology for rotating machinery combining optimized support vector data description and optimized support vector machine. Measurement 2022, 200, 111651. [Google Scholar] [CrossRef]

- Verikas, A.; Gelzinis, A.; Bacauskiene, M. Mining data with random forests: A survey and results of new tests. Pattern Recognit. 2011, 44, 330–349. [Google Scholar] [CrossRef]

- Cerrada, M.; Zurita, G.; Cabrera, D.; Sánchez, R.V.; Artés, M.; Li, C. Fault diagnosis in spur gears based on genetic algorithm and Random Forest. Mech. Syst. Signal Process. 2016, 70–71, 87–103. [Google Scholar] [CrossRef]

- Mansouri, M.; Fezai, R.; Trabelsi, M.; Mansour, H.; Nounou, H.; Nounou, M. Fault diagnosis of wind energy conversion systems using gaussian process regression-based multi-class random forest. IFAC-PapersOnLine 2022, 55, 127–132. [Google Scholar] [CrossRef]

- Marinković, D.; Dezső, G.; Milojević, S. Application of Machine Learning During Maintenance and Exploitation of Electric Vehicles. Adv. Eng. Lett. 2024, 3, 132–140. [Google Scholar] [CrossRef]

- Guo, Z.; Yang, M.; Huang, X. Bearing fault diagnosis based on speed signal and CNN model. Energy Rep. 2022, 8, 904–913. [Google Scholar] [CrossRef]

- Ruan, D.; Wang, J.; Yan, J.; Gühmann, C. CNN parameter design based on fault signal analysis and its application in bearing fault diagnosis. Adv. Eng. Inform. 2023, 55, 101877. [Google Scholar] [CrossRef]

- Zhao, K.; Xiao, J.; Li, C.; Xu, Z.; Yue, M. Fault diagnosis of rolling bearing using CNN and PCA fractal-based feature extraction. Measurement 2023, 223, 113754. [Google Scholar] [CrossRef]

- Ravikumar, K.N.; Yadav, A.; Kumar, H.; Gangadharan, K.V.; Narasimhadhan, A.V. Gearbox fault diagnosis based on multi-scale deep residual learning and stacked LSTM model. Measurement 2021, 186, 110099. [Google Scholar] [CrossRef]

- Qin, S.; Tao, J.; Zhao, Z. Fault diagnosis of wind turbine pitch system based on LSTM with multi-channel attention mechanism. Energy Rep. 2023, 10, 4087–4096. [Google Scholar] [CrossRef]

- Dao, F.; Zeng, Y.; Qian, J. Fault diagnosis of hydro-turbine via the incorporation of Bayesian algorithm optimized CNN-LSTM neural network. Energy 2024, 290, 130326. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, P.; Yang, X.; Hum, A. Fault detection of wind turbine based on SCADA data analysis using CNN and LSTM with attention mechanism. Measurement 2021, 175, 109094. [Google Scholar] [CrossRef]

- Guo, X.; Lu, K.; Cheng, Y.; Zhao, W.; Wu, H.; Li, D.; Li, J.; Yang, S.; Zhang, Y. Research on fault diagnosis method for hydraulic system of CFETR blanket transfer device based on CNN-LSTM. Fusion Eng. Des. 2022, 185, 113321. [Google Scholar] [CrossRef]

- CT10 Series–Current Sense Transformers. Available online: https://www.icecomponents.com/current-sense-transformers/ct10-series (accessed on 10 September 2025).

- Wang, T.; Zhang, Q.; Fang, J.; Lai, Z.; Feng, R.; Wei, J. Active fault-tolerant control for the dual-valve hydraulic system with unknown dead-zone. ISA Trans. 2024, 145, 399–411. [Google Scholar] [CrossRef] [PubMed]

- Lv, Z.; Wu, Y.; Zhuang, W.; Zhang, X.; Zhu, L. A multi-peak detection algorithm for FBG based on WPD-HT. Opt. Fiber Technol. 2022, 68, 102805. [Google Scholar] [CrossRef]

- Hao, Y.; Zhu, L.; Yan, B.; Qin, S.; Cui, D.; Lu, H. Milling chatter detection with WPD and power entropy for Ti-6Al-4V thin-walled parts based on multi-source Signals Fusion. Mech. Syst. Signal Process. 2022, 177, 109225. [Google Scholar] [CrossRef]

| Equipment | Software |

|---|---|

| Proportional Valve Group 32 (Danfoss, Nordborg, Denmark, Type PVG32) | Sign Collection: DAQami software (Version 3.0) |

| Acceleration Sensors (ICE Components, Marrieta, GA, USA, Type CT1010LC) | Signal Processing and Fault Diagnosis: MATLAB R2025a software (Version: v25.1.0.2943329) |

| Approach | SSA-VMD | WPD-SSA-VMD | ||||||

|---|---|---|---|---|---|---|---|---|

| Ratio | 50% | 60% | 70% | 80% | 50% | 60% | 70% | 80% |

| SA | 97.27% | 98.79% | 99.09% | 99.70% | 95.45% | 96.67% | 97.27% | 98.64% |

| SB | 97.27% | 97.88% | 98.18% | 99.09% | 95.15% | 96.18% | 96.36% | 97.27% |

| SA & SB | 99.64% | 99.77% | 100.00% | 100.00% | 99.09% | 99.39% | 99.70% | 100.00% |

| Approach | SSA-VMD | WPD-SSA-VMD | Difference |

|---|---|---|---|

| SA | 98.71% | 97.01% | 1.70% |

| SB | 98.11% | 96.24% | 1.86% |

| SA & SB | 99.85% | 99.55% | 0.31% |

| Time per Iteration | 17,345.45 s | 9818.18 s | 56.60% |

| Sensor Group | SA | SB | SA & SB | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Training Ratio | 50% | 60% | 70% | 80% | 50% | 60% | 70% | 80% | 50% | 60% | 70% | 80% |

| SVM | 69.82% | 70.68% | 72.12% | 73.18% | 69.45% | 70.91% | 72.12% | 73.64% | 86.91% | 87.05% | 88.48% | 89.55% |

| RF | 93.27% | 94.32% | 94.55% | 95.45% | 92.27% | 93.64% | 94.45% | 95.45% | 97.82% | 98.36% | 98.79% | 99.09% |

| CNN | 94.18% | 94.55% | 95.15% | 96.06% | 94.18% | 94.77% | 95.15% | 96.06% | 98.36% | 98.79% | 99.09% | 99.39% |

| LSTM | 78.76% | 79.64% | 82.36% | 83.64% | 78.64% | 79.27% | 82.36% | 83.18% | 94.27% | 95.59% | 96.59% | 97.64% |

| CNN-LSTM | 95.45% | 96.67% | 97.27% | 98.64% | 95.15% | 96.18% | 96.36% | 97.27% | 99.09% | 99.39% | 99.70% | 100.00% |

| Sensor Group | SA | SB | SA & SB | Rank | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Index | MA | MS | MR | MA | MS | MR | MA | MS | MR | MA | MS | MR |

| SVM | 71.45% | 0.0129 | 0.0773 | 71.53% | 0.0154 | 0.0803 | 88.00% | 0.0109 | 0.0283 | 1.00 | 2.00 | 1.00 |

| RF | 94.40% | 0.0078 | 0.0119 | 93.95% | 0.0117 | 0.0140 | 98.52% | 0.0048 | 0.0028 | 3.00 | 3.33 | 3.00 |

| CNN | 94.98% | 0.0071 | 0.0104 | 95.04% | 0.0068 | 0.0102 | 98.91% | 0.0038 | 0.0020 | 4.00 | 4.67 | 4.00 |

| LSTM | 81.10% | 0.0198 | 0.0534 | 80.86% | 0.0194 | 0.0539 | 96.02% | 0.0124 | 0.0092 | 2.00 | 1.00 | 2.00 |

| CNN-LSTM | 97.01% | 0.0115 | 0.0068 | 96.24% | 0.0075 | 0.0078 | 99.55% | 0.0034 | 0.0008 | 5.00 | 4.00 | 5.00 |

| Model Parameters | Average Time (s) | Model Parameters | Average Time (s) | ||

|---|---|---|---|---|---|

| CNN Convolutional Layer | 1 | 47.75 | Kernels in 1st CNN Convolutional Layer | 8 | 56.25 |

| 2 | 58.00 | 16 | 58.00 | ||

| 3 | 68.75 | 32 | 62.50 | ||

| Model Parameters | Average Time (s) | Model Parameters | Average Time (s) | ||

| LSTM Cell | 8 | 60.50 | Kernels in 2nd CNN Convolutional Layer | 16 | 56.00 |

| 10 | 58.00 | 32 | 58.00 | ||

| 12 | 59.25 | 64 | 62.75 | ||

| Model Parameters | Accuracy Ratio | Time Ratio | Model Parameters | Accuracy Ratio | Time Ratio | ||

|---|---|---|---|---|---|---|---|

| CNN Convolutional Layer | 1 | −4.61% | −17.67% | Kernels in 1st CNN Convolutional Layer | 8 | −0.95% | −3.02% |

| 2 | ― | ― | 16 | ― | ― | ||

| 3 | 0.45% | 15.64% | 32 | 0.18% | 7.20% | ||

| Model Parameters | Accuracy Ratio | Time Ratio | Model Parameters | Accuracy Ratio | Time Ratio | ||

| LSTM Cell | 8 | −1.43% | 4.13% | Kernels in 2nd CNN Convolutional Layer | 16 | −1.25% | −3.45% |

| 10 | ― | ― | 32 | ― | ― | ||

| 12 | 0.18% | 2.11% | 64 | 0.20% | 7.57% | ||

| Model Parameter | CNN Convolutional Layer | LSTM Cell | Kernels in 1st CNN Convolutional Layer | Kernels in 2nd CNN Convolutional Layer |

|---|---|---|---|---|

| Value | 2 | 10 | 16 | 32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Qiu, B.; Feng, C.; Li, W.; Lu, X. Diagnosing Hydraulic Directional Valve Spool Stick Faults Enabled by Hybridized Intelligent Algorithms. Appl. Sci. 2025, 15, 10937. https://doi.org/10.3390/app152010937

Wang Z, Qiu B, Feng C, Li W, Lu X. Diagnosing Hydraulic Directional Valve Spool Stick Faults Enabled by Hybridized Intelligent Algorithms. Applied Sciences. 2025; 15(20):10937. https://doi.org/10.3390/app152010937

Chicago/Turabian StyleWang, Zicheng, Binbin Qiu, Chunhua Feng, Weidong Li, and Xin Lu. 2025. "Diagnosing Hydraulic Directional Valve Spool Stick Faults Enabled by Hybridized Intelligent Algorithms" Applied Sciences 15, no. 20: 10937. https://doi.org/10.3390/app152010937

APA StyleWang, Z., Qiu, B., Feng, C., Li, W., & Lu, X. (2025). Diagnosing Hydraulic Directional Valve Spool Stick Faults Enabled by Hybridized Intelligent Algorithms. Applied Sciences, 15(20), 10937. https://doi.org/10.3390/app152010937