Integrated Fatigue Evaluation of As-Built WAAM Steel Through Experimental Testing and Finite Element Simulation

Abstract

1. Introduction

2. Experimental Procedure

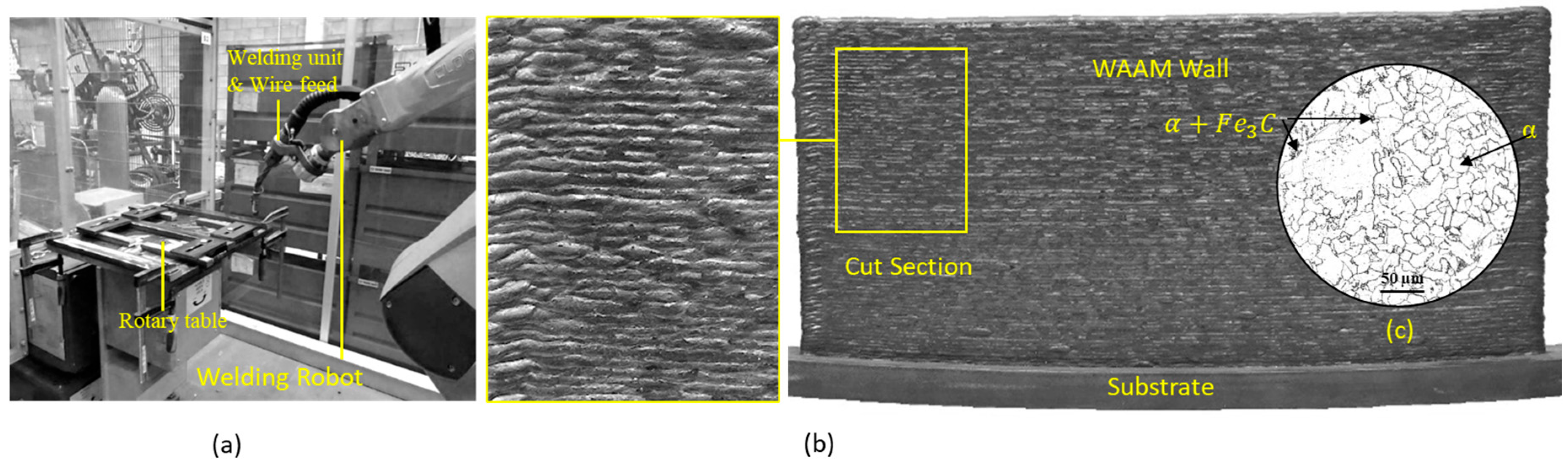

2.1. Material and Manufacturing WAAM Wall

2.2. Microstructural Characterization

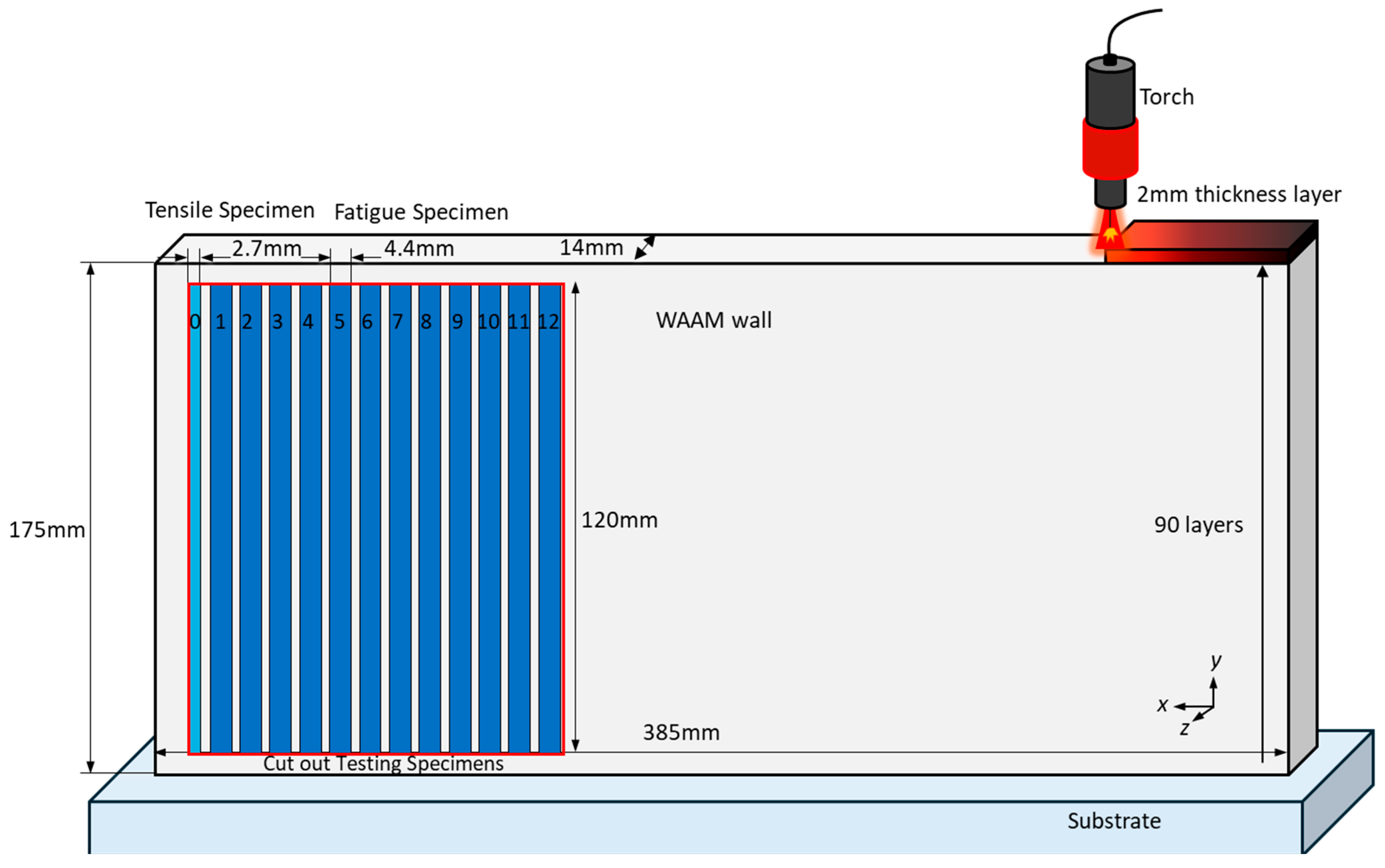

2.3. Specimen Extraction

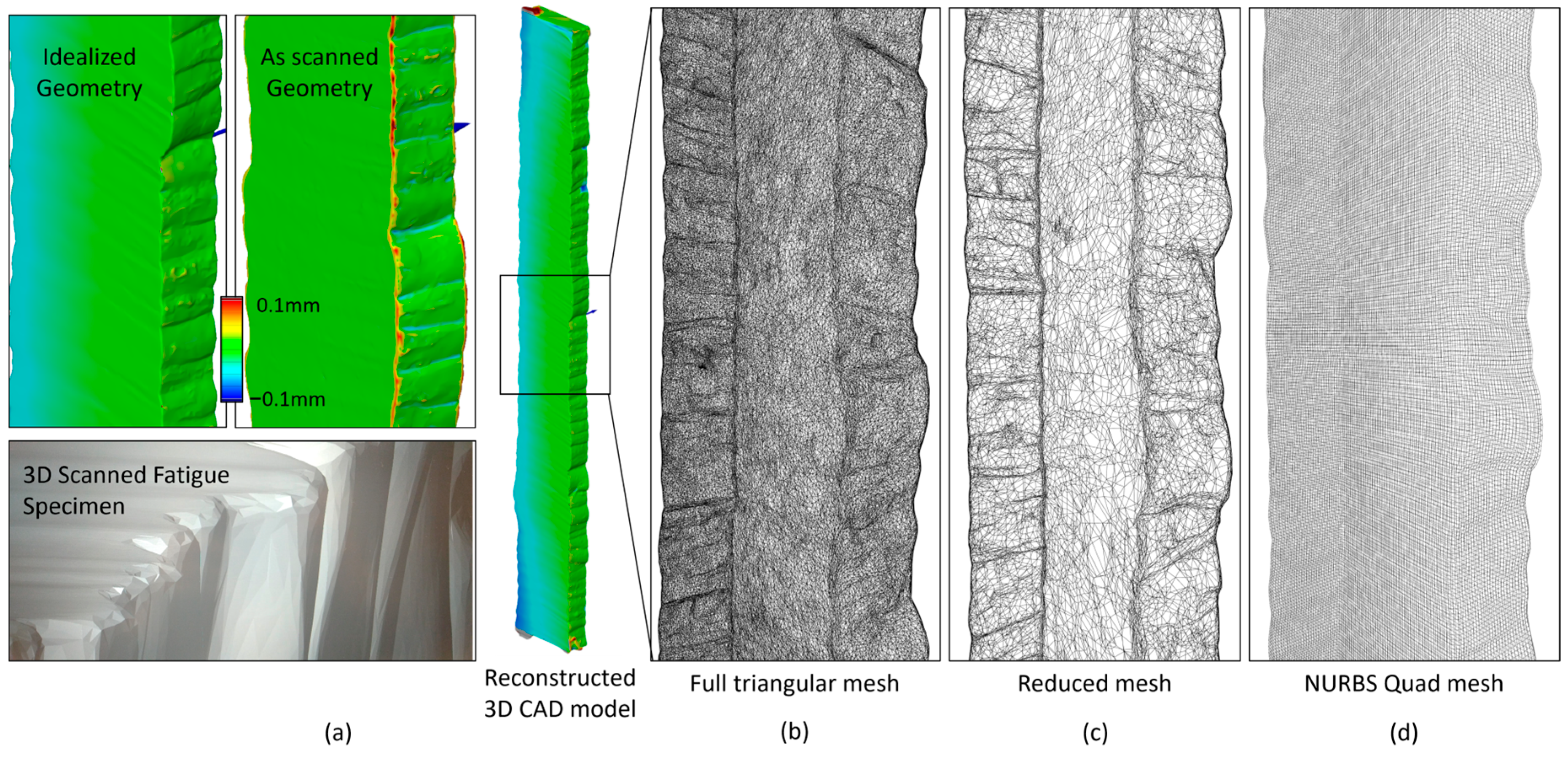

2.4. Surface Topography Reverse Engineering

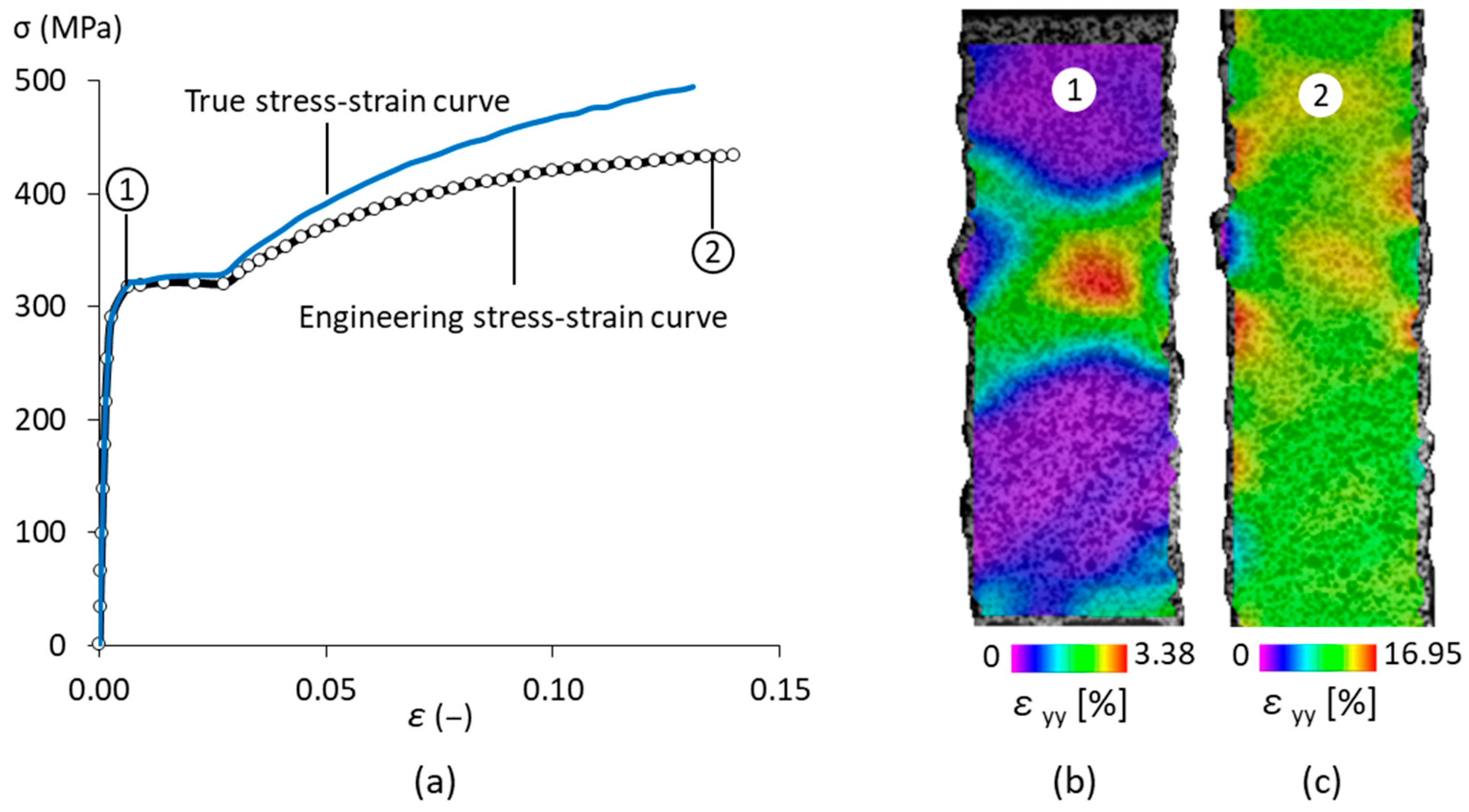

2.5. Uniaxial Tensile Test Using DIC Technique

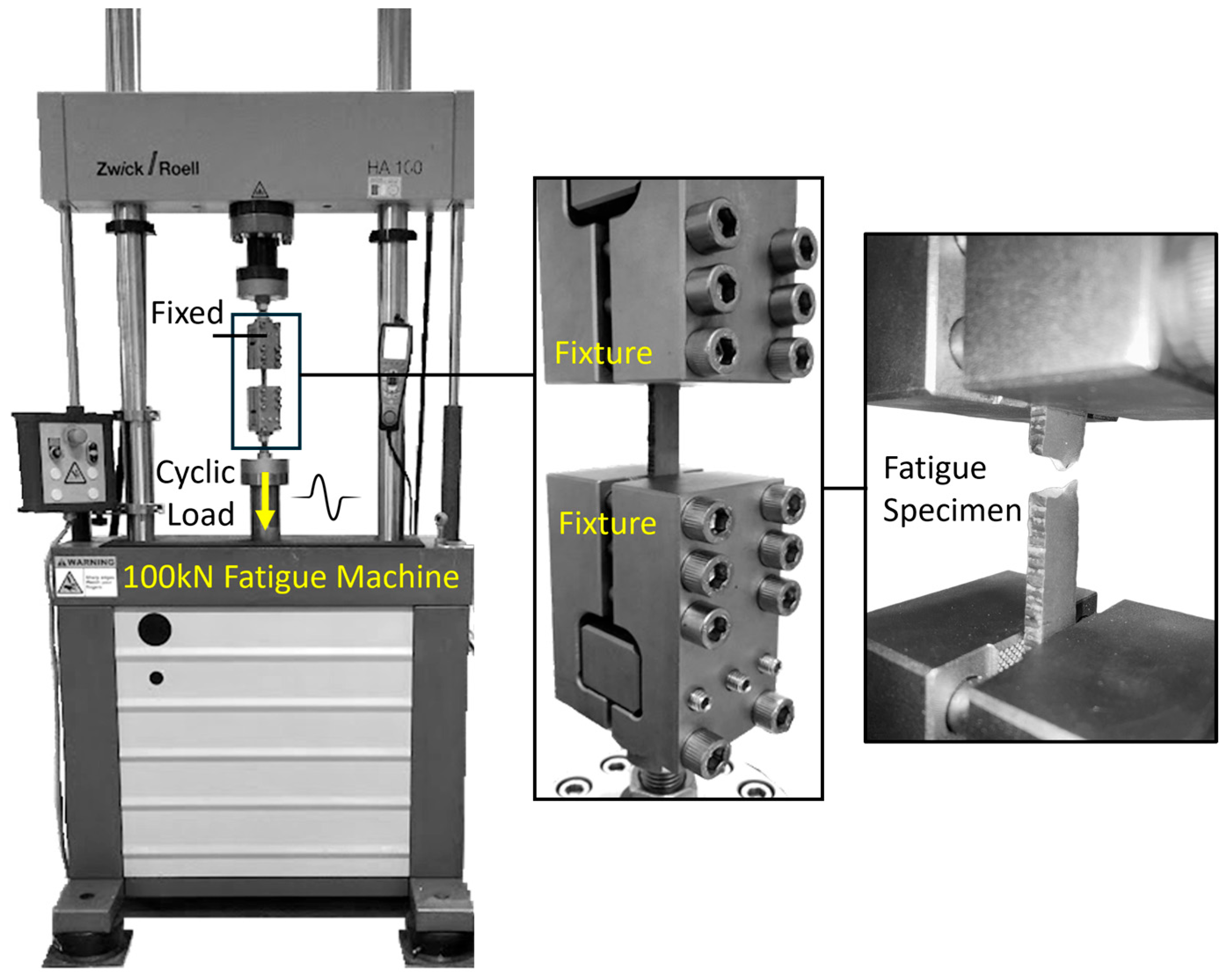

2.6. Fatigue Testing and Post Fracture Analysis

2.7. Fatigue Data Evaluation

3. Numerical Modelling

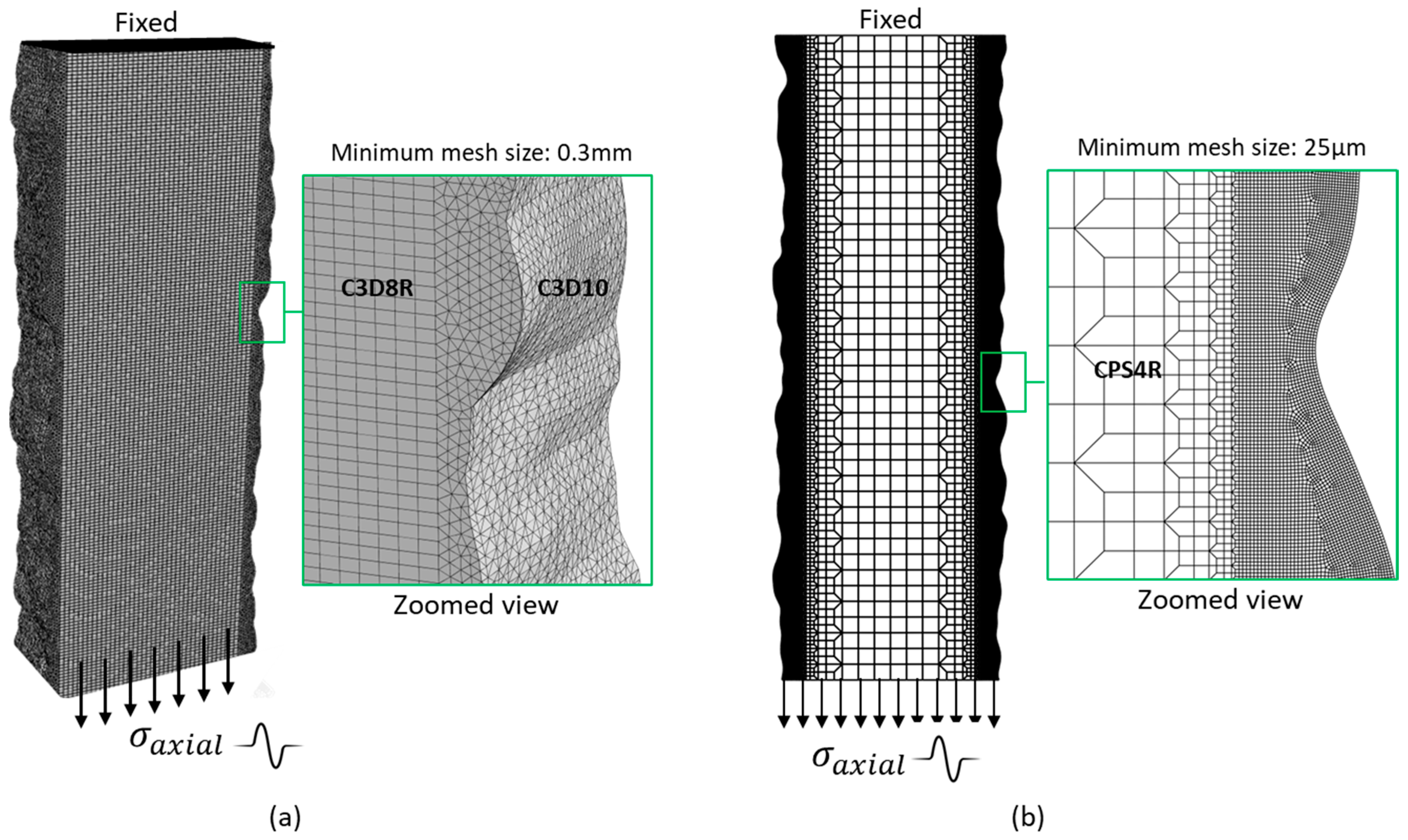

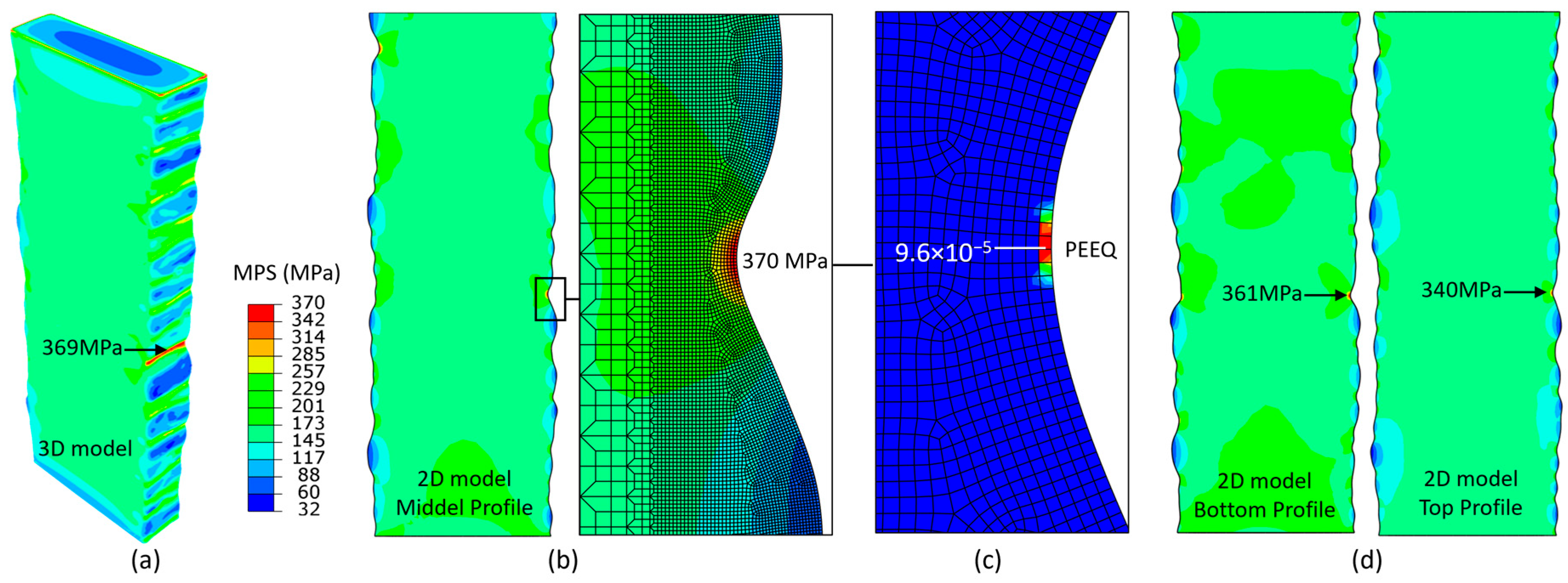

3.1. Developing 2D and 3D FE Models

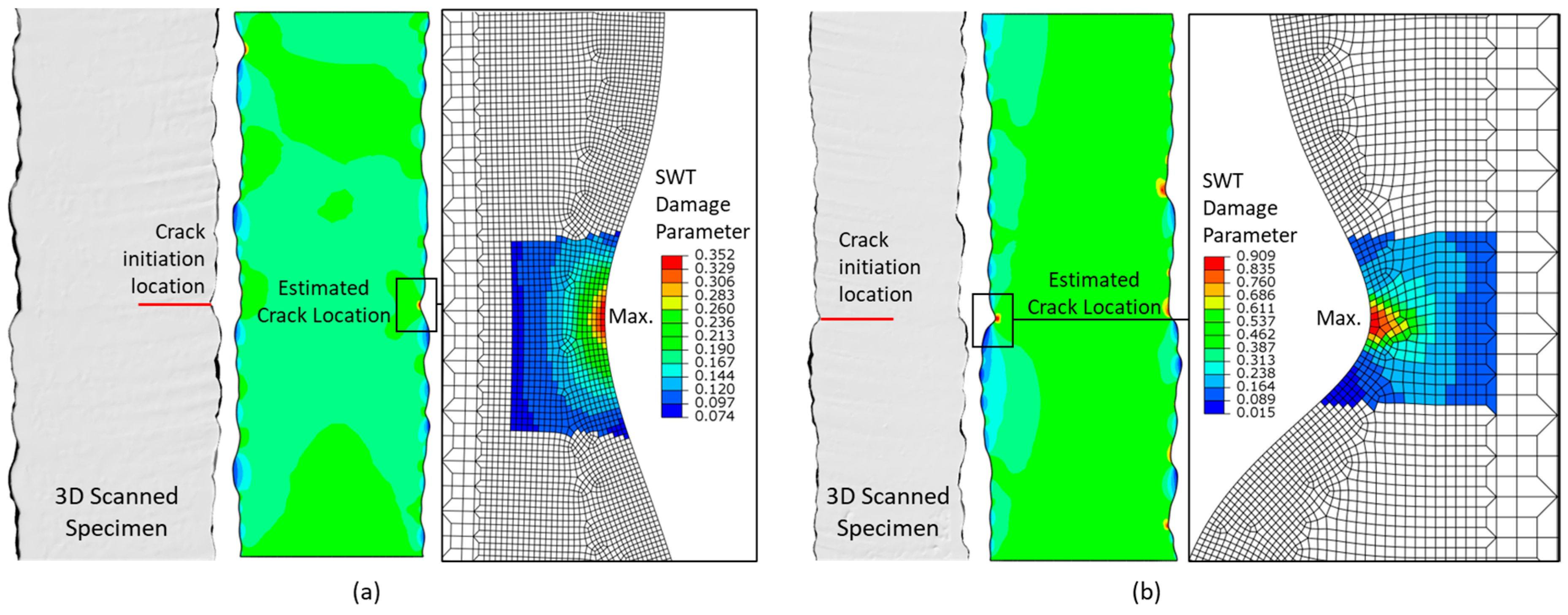

3.2. Multiaxial Fatigue Life Estimation Criterion

4. Results and Discussion

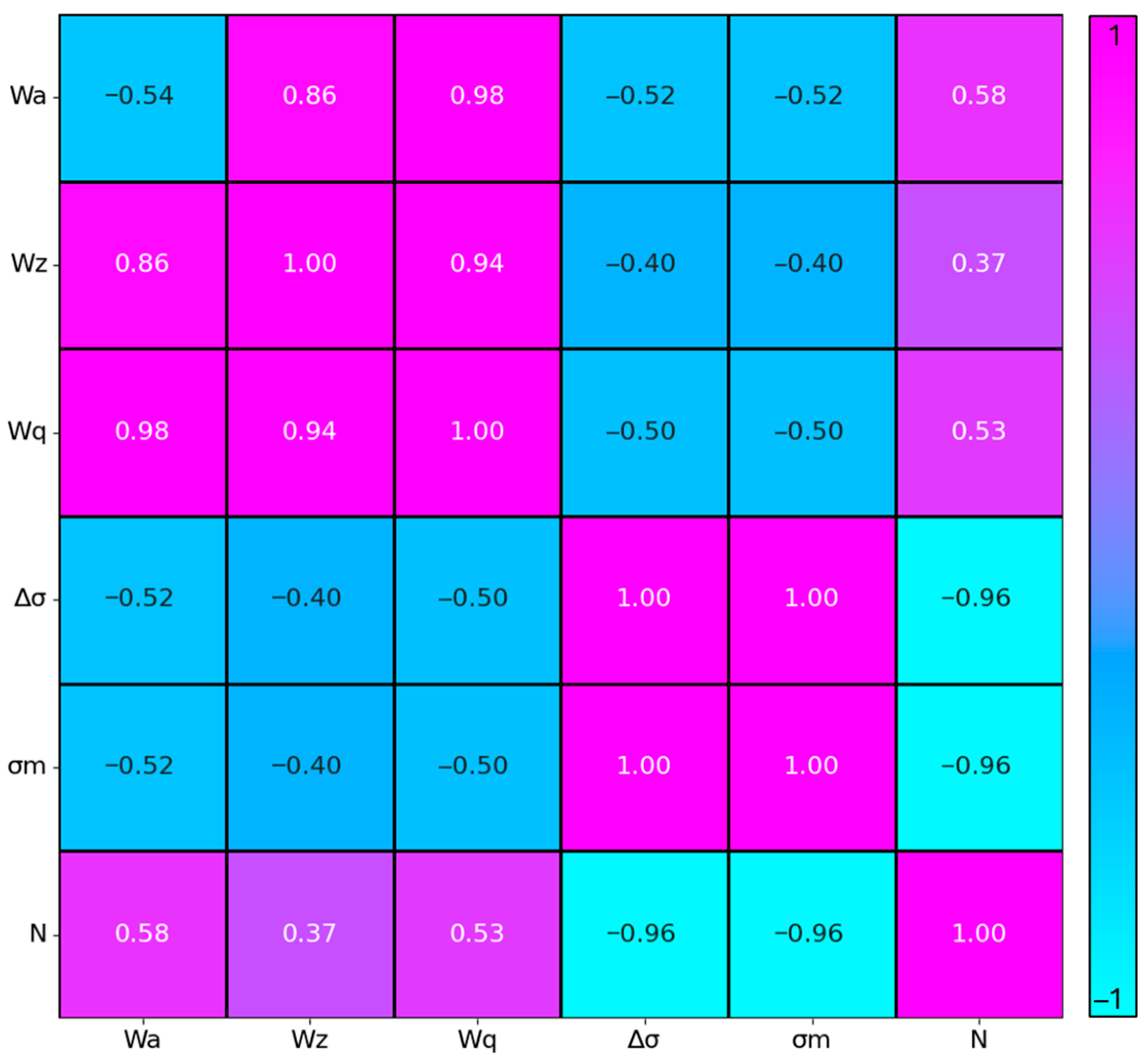

4.1. Reverse Engineering and Evaluation of As-Built Surface Topography

4.2. Tensile Properties

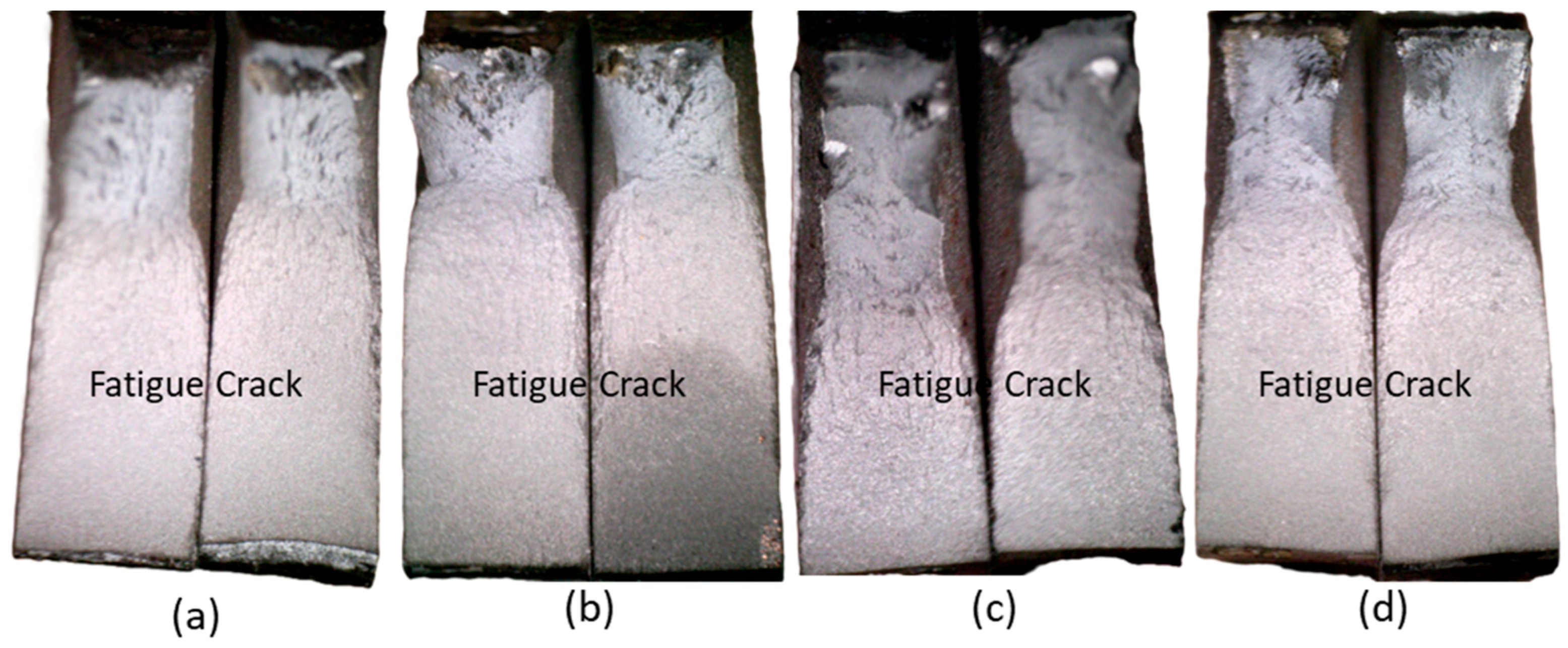

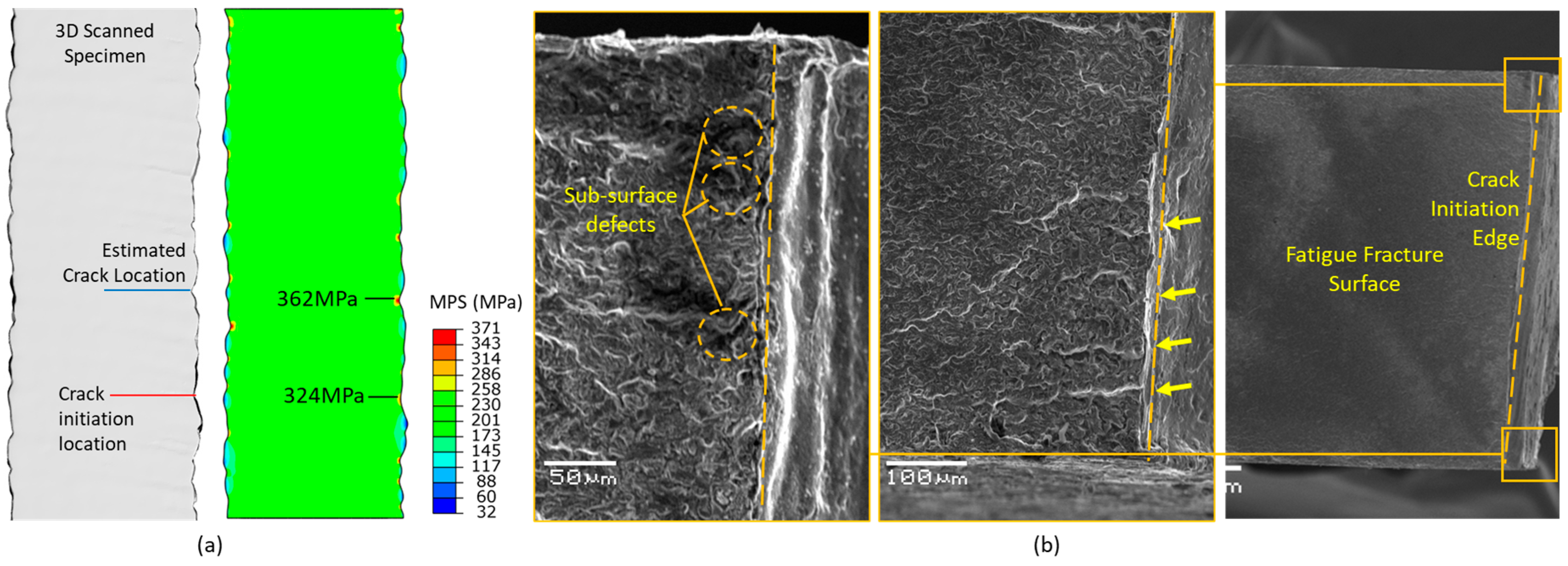

4.3. Fatigue Experiments and Fractography

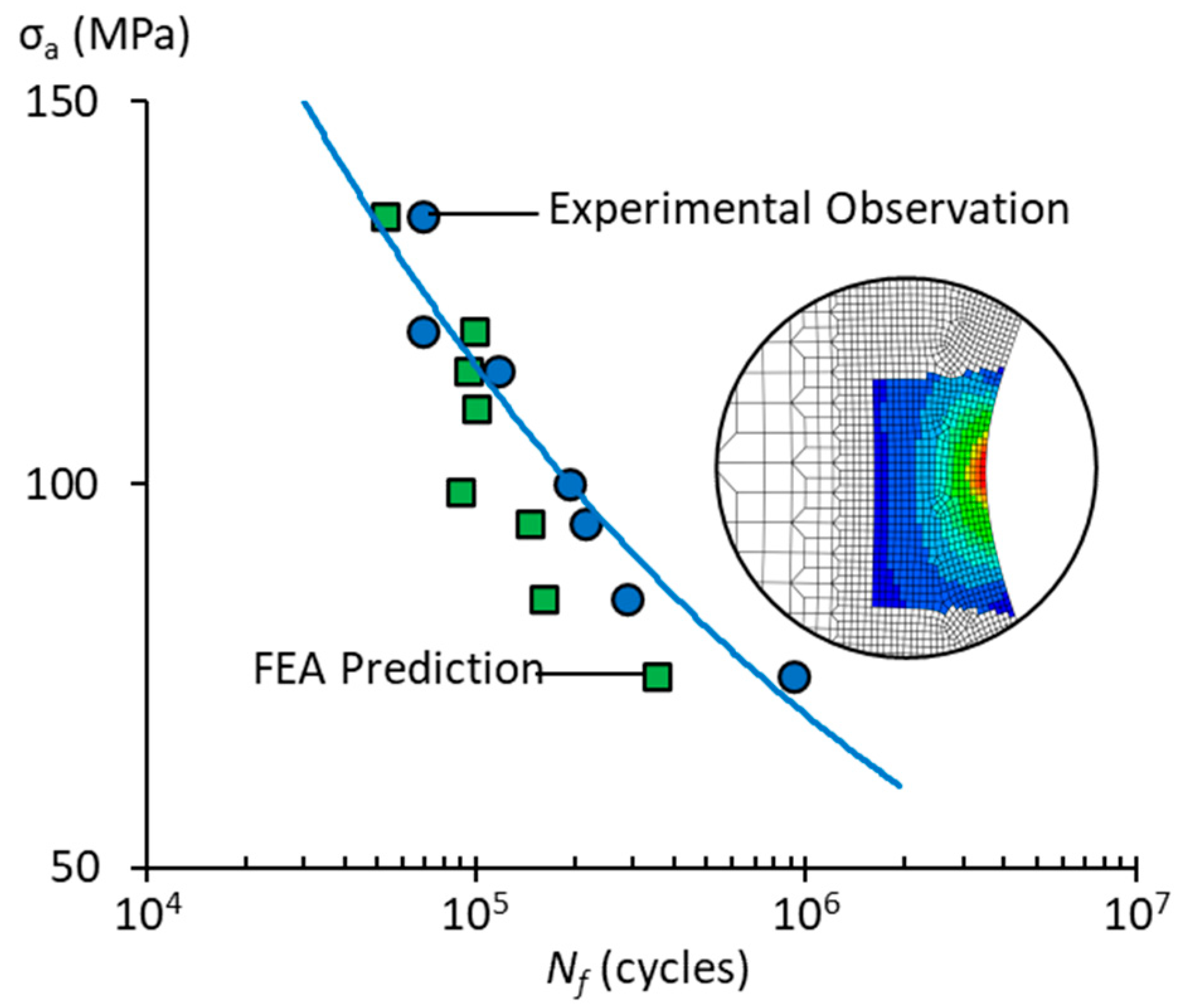

4.4. Stress Distribution and Fatigue Lifetime Estimation

5. Conclusions

- Surface waviness and subsurface porosities were confirmed as the primary drivers of fatigue crack initiation and early propagation, consistent with fractographic observations.

- 3D FE models generated from 3D-scanned geometries showed strong agreement with experimental results, validating their accuracy in predicting stress concentration factors and identifying failure-prone locations. Simplified 2D mid-contour models, while less detailed, proved to be an efficient alternative for preliminary fatigue evaluations.

- The integrated experimental–computational framework achieved a prediction accuracy with an average error of 36% when compared to measured fatigue lives. Although the FE models tended to underestimate life at lower stress levels, their conservative nature makes them suitable for engineering safety assessments.

- Statistical post-processing of fatigue data indicated a FAT class of 111 MPa with an inverse slope of 5, positioning the proposed approach as robust and comparable to, if not more representative than, state-of-the-art fatigue design methodologies for AM structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; Plessis, A.D. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Prakash, K.S.; Nancharaih, T.; Rao, V.V.S. Additive Manufacturing Techniques in Manufacturing—An Overview. Mater. Today Proc. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- Vasco, J.C. Additive manufacturing for the automotive industry. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 505–530. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Paul, S.K.; Sharma, A. Unraveling the failure mechanism of wire arc additive manufactured low carbon steel under tensile and high cycle fatigue loading. Eng. Fail. Anal. 2023, 150, 107347. [Google Scholar] [CrossRef]

- Evans, S.I.; Wang, J.; Qin, J.; He, Y.; Shepherd, P.; Ding, J. A review of WAAM for steel construction--manufacturing, material and geometric properties, design, and future directions. Structures 2022, 44, 1506–1522. [Google Scholar] [CrossRef]

- Smismans, T.; Chernovol, N.; Lauwers, B.; Van Rymenant, P.; Talemi, R. Influence of post-heat treatments on fatigue response of low-alloyed carbon-manganese steel material manufactured by Direct Energy Deposition-Arc technique. Mater. Lett. 2021, 302, 130465. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- EN ISO 14341; Welding Consumables–Wire Electrodes and Weld Deposits for Gas Shielded Metal Arc Welding of non Alloy and Fine Grain Steels-Classification. International Organization for Standardization: Geneva, Switzerland, 2020.

- Ozaner, O.C.; Talemi, R.; Tjahjowidodo, T.; Sharma, A. The influence of the wire and arc additive manufacturing parameters on the surface irregularities. J. Micromanuf. 2025, 8, 22–31. [Google Scholar] [CrossRef]

- Ozaner, O.C.; Klobčar, D.; Sharma, A. Machining strategy determination for single-and multi-material wire and arc additive manufactured thin-walled parts. Materials 2023, 16, 2055. [Google Scholar] [CrossRef] [PubMed]

- EN ISO 4288; Geometrical Product Specifications (GPS)-Surface Texture: Profile Method-Rules and Procedures for the Assessment of Surface Texture. ISO: Geneva, Switzerland, 1996; pp. 1–8.

- EN ISO 16610-21; Geometrical Product Specifications (GPS)—Filtration—Part 21: Linear Profile Filters: Gaussian Filters. ISO: Geneva, Switzerland, 2025.

- Al-Badrawi, M.H.; Liang, Y.; Seger, K.D.; Foster, C.M.; Kirsch, N.J. Caller ID for Risso’s and Pacific White-sided dolphins. Sci. Rep. 2022, 12, 4510. [Google Scholar] [CrossRef] [PubMed]

- Hobbacher, A.F. The new IIW recommendations for fatigue assessment of welded joints and components—A comprehensive code recently updated. Int. J. Fatigue 2009, 31, 50–58. [Google Scholar] [CrossRef]

- Raeymaekers, B. Design of Mechanical Elements: A Concise Introduction to Mechanical Design Considerations and Calculations; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Smith, K. A stress-strain function for the fatigue of metals. J. Mater. 1970, 5, 767–778. [Google Scholar]

- Gothivarekar, S.; Coppieters, S.; Talemi, R.; Debruyne, D. Effect of bending process on the fatigue behaviour of high strength steel. J. Constr. Steel Res. 2021, 182, 106662. [Google Scholar] [CrossRef]

- Mendez-Morales, M.; Branco, R.; Tankova, T.; Rebelo, C. Assessment of cyclic deformation behaviour of wire arc additively manufactured carbon steel. Int. J. Fatigue 2024, 184, 108307. [Google Scholar] [CrossRef]

- Huang, C.; Li, L.; Pichler, N.; Ghafoori, E.; Susmel, L.; Gardner, L. Fatigue testing and analysis of steel plates manufactured by wire-arc directed energy deposition. Addit. Manuf. 2023, 73, 103696. [Google Scholar] [CrossRef]

- Bartsch, H.; Kühne, R.; Citarelli, S.; Schaffrath, S.; Feldmann, M. Fatigue analysis of wire arc additive manufactured (3D printed) components with unmilled surface. Structures 2021, 31, 576–589. [Google Scholar] [CrossRef]

- Talemi, R. A numerical study on effects of randomly distributed subsurface hydrogen pores on fretting fatigue behaviour of aluminium AlSi10Mg. Tribol. Int. 2020, 142, 105997. [Google Scholar] [CrossRef]

- Hou, Y.; Kench, S.; Wauters, T.; Talemi, R. Numerical framework for predicting fatigue scatter in additively manufactured parts. Int. J. Mech. Sci. 2024, 281, 109562. [Google Scholar] [CrossRef]

- Hou, Y.; Hu, Z.; Wauters, T.; Talemi, R. Combined effect of random porosity and surface defect on fatigue lifetime of additively manufactured micro-sized Ti6Al4V components: An investigation based on numerical analysis and machine learning approach. Theor. Appl. Fract. Mech. 2024, 131, 104451. [Google Scholar] [CrossRef]

| Travel Speed [m/min] | Voltage [V] | Gas Flow [l/min] | Shielding Gas | CTWD [mm] |

|---|---|---|---|---|

| 0.34 | 19 | 15 | Argon | 15 |

| Materials | C | Si | Mn | P | S | Cu |

|---|---|---|---|---|---|---|

| Wire (G3Si1) | 0.088 | 0.900 | 1.510 | 0.012 | 0.012 | 0.190 |

| Substrate (S235) | 0.22 | 0.05 | 1.6 | 0.050 | 0.050 | - |

| Materials | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation [-] |

|---|---|---|---|

| Wire (G3Si1) | 420 | 500–640 | 0.20 |

| Substrate (S235) | 235 | 360 | - |

| Specimen No. | Wa [mm] | Wz [mm] | Wq [mm] |

|---|---|---|---|

| FTS-1 | 0.055 | 0.319 | 0.076 |

| FTS-2 | 0.077 | 0.377 | 0.095 |

| FTS-3 | 0.079 | 0.333 | 0.094 |

| FTS-4 | 0.128 | 0.525 | 0.147 |

| FTS-5 | 0.110 | 0.616 | 0.145 |

| FTS-6 | 0.086 | 0.567 | 0.118 |

| FTS-7 | 0.085 | 0.434 | 0.099 |

| FTS-8 | 0.064 | 0.312 | 0.082 |

| FTS-9 | 0.108 | 0.473 | 0.130 |

| FTS-10 | 0.126 | 0.554 | 0.148 |

| FTS-11 | 0.141 | 0.767 | 0.182 |

| Young’s Modulus [GPa] | Yield Strength [MPa] | Ultimate Strength [MPa] | Fracture Strain [-] |

|---|---|---|---|

| 183 | 323 | 434 | 0.13 |

| Specimen No. | Δσ [MPa] | σm [MPa] | [Cycles] |

|---|---|---|---|

| FTS-1 | 270 | 165.0 | 41,751 |

| FTS-2 | 200 | 122.2 | 191,018 |

| FTS-3 | 190 | 116.1 | 213,771 |

| FTS-4 | 230 | 140.6 | 116,035 |

| FTS-5 | 220 | 134.4 | 120,225 |

| FTS-6 | 250 | 152.8 | 48,746 |

| FTS-7 | 260 | 158.9 | 35,726 |

| FTS-8 | 240 | 146.7 | 69,075 |

| FTS-9 | 270 | 165.0 | 69,072 |

| FTS-10 | 150 | 91.7 | 921,175 |

| FTS-11 | 170 | 103.9 | 285,862 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gothivarekar, S.; Brains, S.; Raeymaekers, B.; Talemi, R. Integrated Fatigue Evaluation of As-Built WAAM Steel Through Experimental Testing and Finite Element Simulation. Appl. Sci. 2025, 15, 10936. https://doi.org/10.3390/app152010936

Gothivarekar S, Brains S, Raeymaekers B, Talemi R. Integrated Fatigue Evaluation of As-Built WAAM Steel Through Experimental Testing and Finite Element Simulation. Applied Sciences. 2025; 15(20):10936. https://doi.org/10.3390/app152010936

Chicago/Turabian StyleGothivarekar, Sanjay, Steven Brains, Bart Raeymaekers, and Reza Talemi. 2025. "Integrated Fatigue Evaluation of As-Built WAAM Steel Through Experimental Testing and Finite Element Simulation" Applied Sciences 15, no. 20: 10936. https://doi.org/10.3390/app152010936

APA StyleGothivarekar, S., Brains, S., Raeymaekers, B., & Talemi, R. (2025). Integrated Fatigue Evaluation of As-Built WAAM Steel Through Experimental Testing and Finite Element Simulation. Applied Sciences, 15(20), 10936. https://doi.org/10.3390/app152010936