Abstract

State Departments of Transportation (DOTs) face challenges with traditional bridge inspections that are time-consuming, inconsistent, and paper-based. This study focused on an existing research gap regarding automated methods that streamline the bridge inspection process, prioritize maintenance effectively, and allocate resources efficiently. Thus, this paper introduces a digitalized bridge inspection framework by integrating Building Information Modeling (BIM) and Business Intelligence (BI) to enable near-real-time monitoring and digital documentation. This study adopts a Design Science Research (DSR) methodology, a recognized paradigm for developing and evaluating the innovative SmartBridge to address pressing bridge inspection problems. The method involved designing an Autodesk Revit-based plugin for data synchronization, element-specific comments, and interactive dashboards, demonstrated through an illustrative 3D bridge model. An illustrative example of the digitalized bridge inspection with the proposed framework is provided. The results show that SmartBridge streamlines data collection, reduces manual documentation, and enhances decision-making compared to conventional methods. This paper contributes to this body of knowledge by combining BIM and BI for digital visualization and predictive analytics in bridge inspections. The proposed framework has high potential for hybridizing digital technologies into bridge infrastructure engineering and management to assist transportation agencies in establishing a safer and efficient bridge inspection approach.

1. Introduction

The Architecture, Engineering, and Construction (AEC) industry is at a pivotal point where the growing complexity of projects demands a parallel advancement in technological capabilities [1] and digital transformation [2]. This shift is driven by the need for integrated data environments, near-real-time collaboration, and predictive analytics to enhance efficiency, accuracy, and sustainability across the project lifecycle [2]. Although technology is essential throughout the entire project lifecycle, the most significant advancements of digital technologies have emerged during the design phase [2]. This growing reliance on digital innovation in the early project stages underscores the urgent need to extend similar advancements to downstream activities such as bridge inspection and maintenance [3], where efficiency and safety are equally critical. Ensuring the quality of bridge inspection and maintenance practices in the United States is critical to maintaining functionality and accessibility [3]. According to the US DOT database, the US has built 68,624 bridges since 2010, with 91% classified as being in good condition [4]. This is compared to the older generation of 463,520 bridges built from 1950 to 2010, with 43% classified as being in good condition [4]. These statistics show evidence of urgent action to identify both minor and major deficiencies through the procedural steps outlined in the Code of Federal Regulations [5]. Applying the Code of Federal Regulations can ensure timely maintenance interventions and reduce the risk of structural failures while enhancing public safety [3].

Traditional bridge inspection methods, which rely on manual assessments and paper-based reporting, are not up-to-date anymore; they are inefficient, unproductive, unsafe, time-consuming, and prone to human error [3]. The absence of digital technologies presents significant challenges for transportation agencies in streamlining bridge inspections, effectively prioritizing maintenance, and efficiently allocating resources [4]. Additionally, fixed inspection schedules, rather than near-real-time structural health monitoring, lead to delayed interventions, increasing safety risks for the public [6]. This study identified a gap in the research of the field of automated bridge inspection methods, specifically in the digitalization of inspection workflows, enhancement of data accuracy, and optimization of resource allocation. BIM, a digital process that enables the development and management of data-rich 3D models [7], has been widely used in the vertical construction sector [8], whereas its use in horizontal infrastructure, especially for bridge inspection and maintenance, is still in its initial phase [9]. The vertical construction sector typically refers to buildings and structures that rise vertically, such as residential, commercial, and industrial buildings [4]. In contrast, horizontal infrastructure encompasses transportation-related structures, including roads, bridges, tunnels, and railways, which extend horizontally across landscapes [4]. This distinction is important for understanding the application of digital technologies, e.g., BIM, which are more mature in vertical construction but still emerging in horizontal infrastructure domains such as bridge inspection [6]. On the other hand, BI, a technology-driven process for analyzing data and presenting actionable information, enables transportation agencies to make informed decisions by leveraging near-real-time analytics, predictive insights, and interactive visualizations [10]. This study’s findings demonstrate that integrating BIM and BI equips transportation agencies with data-driven tools to improve decision-making, automate inspection workflows, and enhance structural health monitoring.

The objective of this paper is to develop SmartBridge, an automated BIM-based framework with integrated BI designed to significantly increase the efficiency of bridge inspection workflows, facilitate data visualization, and improve the quality and safety of infrastructure assessments through predictive analytics. This framework addresses key limitations of traditional bridge inspection methods, such as manual data collection, inefficiencies, and fragmented documentation, by enabling automated data extraction, centralized digital visualization, and information sharing across inspection teams. With the SmartBridge concept, this study presents a practical solution for modernizing bridge inspections and maintenance practices. BI also plays a role in transforming raw data into actionable insights, fostering data-driven maintenance and informed decision-making. By responding to key challenges such as interoperability, implementation costs, and on-site application limitations, this paper’s proposed concept advances safer and more efficient infrastructure management. This study focuses on the development, design, and technical demonstration of the SmartBridge framework. While an illustrative example is provided to showcase its functionality, the empirical validation of its impact on inspection efficiency and accuracy through controlled field studies is identified as a critical next phase of this research and is detailed in the conclusion. The uniqueness of this study lies in its focus on horizontal infrastructure, where BIM adoption is still emerging, and its emphasis is on field-to-office integration. By allowing inspectors to input observations directly into the BIM model and instantly reflect them in BI dashboards, the developed SmartBridge framework transforms static inspection records into dynamic, actionable datasets. This approach not only streamlines inspection workflows but also enhances decision-making through predictive analytics and historical data tracking.

2. Background

2.1. Current Methods for Bridge Inspection Practices

State DOTs currently implement various bridge inspection practices incorporating both conventional and advanced methods to ensure the safety and integrity of bridge infrastructure [11,12]. Alabama, for instance, employs a comprehensive, data-driven approach to address structural deficiencies, utilizing a mix of conventional methods like visual inspections and new technologies such as drones and acoustic and thermal inspections [11]. Inspectors gather detailed information, including load ratings, environmental conditions, and structural deficiencies, ensuring regular monitoring and timely maintenance. Similarly, Alaska integrates traditional and modern techniques, using tools like sounding tests, cathodic protection systems, and advanced diagnostics like acoustic imaging to assess bridge conditions in challenging geographies [13]. In Arizona, bridge inspections follow the National Bridge Inspection Standards (NBIS), with routine visual inspections complemented by advanced non-destructive evaluation methods such as ultrasonic testing and magnetic particle testing to detect internal defects [14]. Arkansas follows a mix of conventional methods, such as visual inspections and innovative technologies, including ground-penetrating radar (GPR) and 3D laser scanning, which enhance inspection accuracy and reduce the need for manual inspections [15]. California incorporates drones and unmanned aerial systems (UAS) for high-definition imagery and 3D modeling in bridge inspections, reducing the need for lane closures and improving efficiency [16].

Conventional bridge inspections predominantly depend on visual evaluations conducted by certified inspectors who possess specialized training, field experience, and accreditation in structural evaluation [11]. In the United States, for example, the Federal Highway Administration (FHWA) mandates a routine visual inspection of public bridges at least once every two years [17]. Inspectors assess visible components for signs of cracks, corrosion, and deformation, and record their observations, recommendations and timeline to mitigate in standardized reports or databases [18]. In addition to visual inspections, inspectors typically rely on manual documentation tools like written notes, checklists, and sketches, often accompanied by photographs, to record any defects [19]. To address these limitations, recent studies have explored the incorporation of nondestructive evaluation (NDE) techniques and deterioration models to improve inspection planning and execution [3]. A bridge inspection system that facilitates monitoring and documenting the progression of damage in bridge elements using information from UAS and machine learning techniques was proposed [20]. Overall, NDE methods and hybrid inspection systems have improved over the years and continue to advance due to developments in artificial intelligence (AI) and visualization methods, such as photogrammetry [8].

Recently, state DOTs started to adopt and implement advanced bridge inspection data collection approaches, including Unmanned Aerial Vehicles (UAVs), computer vision (CV), lean engineering, and BIM [21,22,23,24]. The implementation of UAVs has emerged as a transformative approach to bridge inspections [23,25,26]. UAVs facilitate the collection of high-resolution images and videos, enabling detailed assessments of structural conditions without necessitating direct human access to potentially hazardous areas [27]. A novel methodology utilizing UAVs for bridge inspections demonstrated the capability to efficiently capture comprehensive data (images, videos, point clouds), which can be processed to identify structural defects, thereby enhancing the accuracy of inspections [21,27]. Advancements in CV have further revolutionized bridge monitoring by enabling automated detection of surface defects, vibration measurements, and vehicle parameter identification [21,28]. CV-based methods offer non-contact, cost-effective solutions for continuous structural health monitoring. The efficacy of CV techniques in identifying cracks, spalling, and corrosion, as well as in measuring displacements and modal parameters, was highlighted by underscoring their potential to augment traditional inspection methods and provide more objective assessments [28].

2.2. Digital Technologies for Bridge Inspection

The integration of BIM into bridge inspection practices in the United States has advanced through initiatives, including the Transportation Pooled Fund (TPF)-5(372) project, which is encouraged by the American Association of State Highway and Transportation Officials (AASHTO). This project aims to establish national standards for the use of semantic and geometric data in bridge design, construction, and maintenance [29,30]. These efforts build on earlier international standards and provide a foundation for states to tailor BIM implementation at local levels [30]. By leveraging BIM technology, bridge inspections have become more efficient, precise, and data-driven, allowing for better management of bridge infrastructures. The use of digital models integrated with physical bridge assessments enhances data exchange and monitoring throughout the entire lifecycle of a bridge, which is a crucial step forward in modernizing the U.S. infrastructure maintenance practices [30].

Despite the potential of BIM and its integration with advanced digital technologies in the AEC industry, several challenges hinder its seamless adoption and implementation [31]. The application of digital twins is understood in principle [32]. A virtual model is created to simulate the entire life cycle of the bridge. Implementing this BIM integration in practice remains challenging due to the absence of standardized protocols and the limited availability of supporting technologies [33]. A limited data framework has been published, resulting in varying procedural applications [33]. While current BIM models are effective for visualizing bridge structures, they often lack the detailed quantitative data and domain-specific insights required to generate accurate digital twin point clouds [31,34]. They are often developed from 3D laser scans to retrieve as much data as possible, but when transferred to the DT model, the information oversimplifies critical information [31,35,36]. BI has been extensively adopted in the manufacturing sector to enhance decision-making and operational efficiency. Refs [37,38,39] found that BI tools facilitate the analysis of large datasets from various sources, allowing manufacturers to identify inefficiencies and improve supply chain management. Additionally, BI applications in manufacturing significantly strengthen quality control by proactively detecting anomalies in production processes, thereby ensuring superior product quality and driving higher levels of customer satisfaction [40]. The reviewed literature collectively presents the pivotal role of BI in transforming raw data into actionable insights, driving innovation, and maintaining competitiveness in the manufacturing industry [41,42].

Existing BIM and BI-integrated frameworks often focus on generalized applications in the building sector, such as cost estimation and clash detection [10]. For instance, a BIM-to-BI workflow was demonstrated for automating data extraction and visualization for tasks such as cost analysis and change detection in building projects [10]. However, the application of such integrated frameworks to practices in the horizontal construction sector, such as bridge inspection, with its unique requirements for element-level condition tracking, up-to-date field data integration, and long-term maintenance history, remains underdeveloped. This study fills that gap by proposing a purpose-built framework, SmartBridge, designed explicitly for the bridge inspection workflow, incorporating bidirectional data flow and inspector-in-the-loop functionality.

2.3. Research Motivation

The current literature shows that approximately 221,000 bridges in the United States need major repair or replacement, with 42,000 rated in poor condition and classified as structurally deficient in 2023, according to the American Road and Bridge Transportation Builders Association. State DOTs must implement effective inspection strategies to prevent failures and costly emergency repairs [43]. As the US DOT manual outlines the current procedure for bridge inspections, an on-site human inspector is currently required for documentation [5]. This requires the transportation and mobilization of employees who need access and visibility to the critical points on the bridge [44]. However, limited as-built information is accessible, making the opinion of the inspector critical to identifying deficiencies [45]. Since the advent of computer modeling software and BIM in the AEC industry, the need for the implementation of these technologies and modeling information into inspection procedures has become critical [46]. As more inspection data becomes available in various types, there is a need for a digitalization platform to efficiently streamline and effectively visualize the inspection workflow for inspectors [47]. A research gap exists regarding methods to advance the integration of BIM-enabled digital platforms and BI-powered data visualization tools to facilitate near-real-time data workflow, automated reporting, and integration with asset management systems, improving maintenance planning and resource allocation. The motivation for this study is to automate data analytics and enhance decision-making in bridge inspection processes by proposing a BIM-centered platform for storing, analyzing, and transforming the data into actionable insights, enabling data-driven maintenance and smarter resource management.

3. Methodology

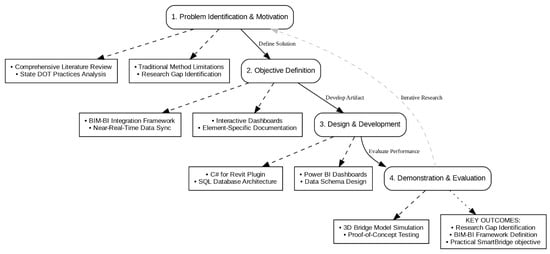

This study adopts the Design Science Research (DSR) methodology, a recognized paradigm for developing and evaluating innovative IT artifacts to address pressing organizational problems. As shown in Figure 1, the research process comprised key DSR stages: (1) Problem Identification through a comprehensive literature review, which established the need for digitalized bridge inspections and defined the scope and significance. This process also included a review and analysis of current state DOT practices, which revealed that traditional methods still rely heavily on manual assessments and paperwork; (2) Objective Definition, based on the identified gap, to create a solution framework integrating BIM and BI to enable near-real-time data synchronization, provide interactive dashboards, and facilitate element-specific digital documentation; (3) Design and Development of the SmartBridge framework, including its Revit plugin, database, and dashboards, using C# for the Revit plugin, SQL for database architecture, and Power BI for dashboard creation. This stage also involved designing the data schema and developing the user interface; and (4) Demonstration and Evaluation through an illustrative example, which served as a proof of concept to assess the framework’s feasibility, utility, and potential impact by comparing its capabilities against traditional inspection methods. The illustrative example used a sample 3D bridge model in Revit to simulate the inspection workflow and demonstrate data extraction, commenting, and visualization. The outcome provided evidence of the framework’s technical viability and a compelling argument for its potential to improve inspection accuracy, efficiency, and collaborative decision-making, as documented in the Results and Discussion section.

Figure 1.

Design science research methodology.

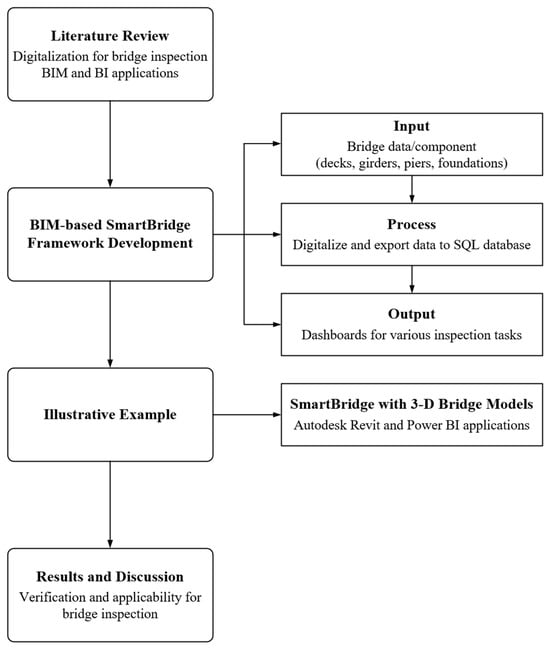

The methodology is organized into four phases to ensure both theoretical grounding and practical validation: (1) conducting a literature review to establish the theoretical foundation; (2) designing the BIM-based SmartBridge framework; (3) presenting an illustrative case to demonstrate its application, and (4) analyzing and discussing the results to assess its potential impact on bridge inspection practices, as outlined in Figure 2.

Figure 2.

Research methodology.

First, a comprehensive literature review of bridge inspection methods and BIM-enabled BI applications in the AEC industry within the past decade was performed. Journal articles published in English with the title, abstract, and keywords consisting of “bridge inspection”, “digitalization”, “Building Information Modeling”, “Business Intelligence”, “data visualization for bridge inspection”, “bridge engineering data workflow”, were included in the literature review. All duplicated and unrelated papers were ignored and removed from the resulting list. To ascertain the relevance and contextual pertinence of identified sources, particular emphasis was accorded to exploring emerging technologies in concert with BIM software, thereby furnishing a nuanced understanding of the symbiotic relationship between technologies and construction techniques. Various search engines, chief among them being Google Scholar, American Society of Civil Engineers (ASCE), and Science Direct, in the continual pursuit of pertinent and applicable scholarly contributions, thereby facilitating the individualization of this study. The existing literature shows that there is a general upward trend in the adoption and discussion of BIM and digital technologies for bridge engineering, operation, inspection, and maintenance from 2021 to 2024. This trend suggests a progressive integration of advanced technologies within the construction sector, particularly for bridge infrastructure.

Second, a BIM-based SmartBridge framework was developed to address challenges in automating and digitalizing bridge inspection processes. The framework was designed to integrate BIM with advanced digital technologies, enabling near-real-time data synchronization, element-specific comments, and interactive dashboards for bridge inspection. The SmartBridge framework enables near-real-time data synchronization between field inspectors and project managers. Inspectors can attach element-specific comments directly within the BIM model, linking observations to bridge components such as piers, girders, and decks. These comments are instantaneously reflected in the Power BI dashboard, allowing for dynamic inspection tracking. To enhance usability, the framework was designed with a user-friendly interface, featuring automated data extraction buttons and an interactive dashboard. The interface allows users to select specific bridge components, extract detailed attributes, and visualize quantities, materials, and near-real-time updates. This approach streamlines the traditional inspection process by reducing manual data entry and improving information accessibility.

Finally, to showcase the capabilities of the framework, an illustrative example was conducted using a sample 3D bridge model in Autodesk Revit 2025. This demonstration was designed to highlight the framework’s functionality rather than serve as a real-world case study. The goal was to simulate how the framework could enhance bridge inspection workflows by automating data extraction, enabling near-real-time visualization, and enhancing digital documentation. The outcomes of the illustrative example can present the feasibility and potential benefits of the SmartBridge framework in modernizing digital bridge inspection practices. Finally, the performance of the SmartBridge framework was thoroughly assessed to evaluate its impact on construction workflows. Key metrics, such as workflow efficiency, resource management, and decision-making capabilities, were analyzed to determine the effectiveness of the framework.

4. BIM-Based SmartBridge Development

A key feature of the SmartBridge framework is its ability to support near-real-time data synchronization. This feature ensures that any changes made during on-site inspections are immediately reflected in the BIM model and database. The framework was also integrated with Power BI, a BI tool, to create interactive dashboards for visualizing inspection data. These dashboards provide a user-friendly interface for displaying critical metrics such as material quantities, structural dimensions, and near-real-time updates. Additionally, the framework allows inspectors to add element-specific comments directly within the BIM model, enhancing the accuracy and comprehensiveness of inspection reports.

4.1. Development of Revit Plugin Integrated with BI

The initial conceptual design of the SmartBridge plugin was grounded in feedback from site engineers and bridge inspectors who were actively involved in infrastructure projects. Their insights shaped the core functionalities, focusing on ease of data input, near-real-time access to structural data, and the ability to attach inspection comments directly to specific bridge components. The user interface was designed to be intuitive, allowing inspectors to navigate 3D bridge models and input their findings with minimal training. This user-centered approach ensured that the plugin would cater to the actual needs of end users, reducing the learning curve and improving overall adoption. The development process of the framework involved close integration with BIM platforms, particularly Autodesk Revit 2025, ensuring that it could extract, process, and manage comprehensive data about the structural elements of bridges. This integration allows the plugin to extract detailed information on materials, dimensions, and locations of key elements such as piers, decks, beams, and reinforcement structures. Additionally, the plugin was designed to automate the extraction of these attributes and export them to SQL Server databases, ensuring secure and structured storage of inspection data, as shown in Table 1.

Table 1.

Pseudo code for creating database tables for bridge girders.

A key aspect of the plugin’s development was its ability to support near-real-time data synchronization between the site and the back-office teams. Bridge data is extracted from the BIM model through a Revit plugin to enrich the database and the inspector with the attributes shown in Table 2. The data flow architecture was developed with high efficiency, ensuring that changes made in the field are reflected immediately in the database, allowing project managers and engineers to make data-driven decisions without delays. Furthermore, the plugin was built to allow easy scalability, enabling it to be extended to other infrastructure projects or to include additional inspection features in the future.

Table 2.

Bridge element attributes aligned with AASHTO and ISO standards.

The data format of the SmartBridge framework has been designed to align with key industry standards, ensuring practical adoption and seamless integration with state DOT systems. The new national bridge information modeling standards are mapped to the design attributes, while UniFormat II and OmniClass codes are applied to categorize each bridge component, ensuring consistent identification across various agency systems. To enable smooth data exchange with asset management platforms such as AASHTOW and BrM, the condition assessment attributes are structured to comply with the AASHTO Bridge Element Guide. Additionally, to meet national reporting requirements, the framework incorporates NBI condition ratings (0–9) from previous inspections. Furthermore, ISO 19650 guidelines for information management throughout the asset lifecycle are followed in the metadata structure. Each inspection data package is treated as an “information container” with standardized metadata, including project identification, version control, status (e.g., draft, approved, archived), and classification (e.g., as-inspected, as-maintained). This approach ensures proper information governance and facilitates integration with broader digital twin ecosystems.

The dashboards of the framework and reporting features were also an essential part of the development process. These features were designed to offer a clear and concise overview of inspection data, allowing engineers to visualize the condition of various bridge elements. The development team focused on creating customizable reporting options, enabling users to generate automated reports tailored to specific project needs. This reduces the time spent on paperwork and manual data consolidation, allowing inspectors to focus more on on-site activities.

4.2. Enhancement of the Framework

This section highlights the evolution of SmartBridge from a basic BIM data extraction tool to an integrated inspection platform. The enhancements were driven by the need to overcome limitations of static data workflows and improve collaboration between field and office teams. The first key improvement is to provide near-real-time feedback, which can help inspectors attach element-specific comments directly within the BIM model, transforming static geometry into actionable inspection data. The second improvement is to establish interactive dashboards demonstrating the visualization of structural attributes, material quantities, and inspection notes, supporting data-driven decision-making. The third improvement is to promote field-to-office synchronization so that updates made during inspections are reflected instantly in the database, reducing delays and enabling timely maintenance planning.

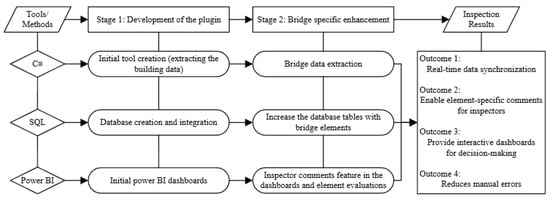

Figure 3 shows the flow of the enhancement and development of the framework. The development of the SmartBridge plugin followed a structured, phased approach to address the growing need for efficient data extraction and management in large-scale infrastructure projects, particularly for bridges. The first phase involved creating a foundational tool capable of extracting data from Revit models, focusing on key structural, electrical, plumbing, HVAC, and architectural components. Initially, the plugin automated the extraction of critical attributes such as dimensions, material types, levels, quantities, and other key specifications, which were then exported to an SQL Server database for seamless integration with project management systems.

Figure 3.

Programming and development stages of SmartBridge.

The latest enhancement to the SmartBridge framework further bridges the gap between digital models and field inspections by introducing the ability for inspectors to add near-real-time comments on specific bridge elements, such as piers. This feature transforms the static nature of the BIM data into a dynamic, interactive platform where inspectors can document their observations, concerns, and recommendations directly within the digital model. By allowing for comments on structural components like piers, inspectors can now capture critical, element-specific information during the inspection process, creating a more integrated and comprehensive dataset. To enhance functionality, the framework was integrated with dashboards that allowed users to visualize the extracted data in near-real-time. For example, the dashboard displays detailed information on quantities of concrete, steel, and other materials, along with associated costs and timeframes for formwork. Additionally, this phase of development included the implementation of an interactive feature enabling inspectors to add near-real-time comments on specific elements, such as piers or girders, directly within the digital model. These comments were synced with the extracted data, allowing project teams to incorporate both physical assessments from site inspections and digital model data in one cohesive platform. This integration of field data and BIM was a crucial step in making bridge inspection processes more dynamic, enabling near-real-time updates and better decision-making across teams. This enhancement is particularly valuable in the context of bridge infrastructure, where on-site inspections often yield nuanced observations that may not be fully captured by digital sensors or automated data extraction. A direct note can be entered into the program via a tablet during inspection, allowing all experts involved to access the information anytime and from any location. This real-time synchronization facilitates remote work from home offices and ensures transparency in communication across the team. These comments are stored alongside the BIM data, providing engineers and project managers with a richer, more detailed understanding of the bridge’s condition.

Beyond its core functionality of near-real-time data synchronization, the SmartBridge framework incorporates foundational security measures to ensure data integrity and controlled access. The system currently uses role-based authentication, requiring username and password verification to regulate database access and export permissions within the Revit environment. This approach ensures that inspectors, engineers, and project managers can only access and modify data appropriate to their designated roles. For future production deployment, additional security layers, such as data encryption during transmission and comprehensive audit trails, are planned to further enhance privacy protection and meet the stringent security standards required for managing critical infrastructure data. While the framework enables dynamic data synchronization between field inspections and digital models, it is important to clarify the boundaries of automation. The current implementation achieves near-real-time data updates through inspector-initiated synchronization following manual observation entry, rather than fully automated sensor-based monitoring. This represents a significant advancement over traditional paper-based methods, where data consolidation could take days or weeks, but it falls short of continuous automated monitoring systems. The term “near-real-time” more accurately reflects the workflow, in which data becomes available to stakeholders within minutes of inspector documentation, enabling timely decision-making while preserving the crucial role of human expert assessment in bridge inspection.

5. Introducing SmartBridge Practical Application

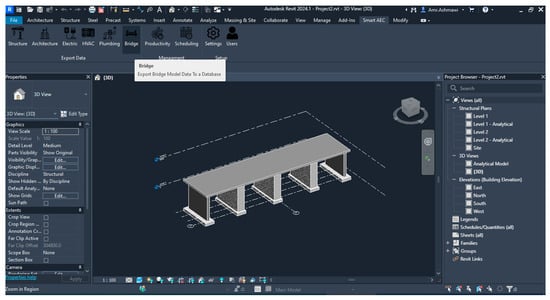

The integration between BIM and BI through the Revit plugin can enhance construction field engineering by reducing the paper and 2D drawings and replacing them with Power BI interactive dashboards, which have all the federated model information the field engineer may need. This approach was developed and equipped to work with inspection and monitoring bridges. The process began by loading a pre-existing 3D BIM model of a bridge into Autodesk Revit 2025. The model included essential structural elements such as piers, girders, decks, and abutments, representing a typical bridge configuration. Once the model was prepared, the SmartBridge framework was activated to extract detailed information about these elements. The framework automatically retrieved geometric properties, material specifications, reinforcement details, and element locations. This data was then structured and stored in an SQL Server database, ensuring seamless retrieval for further analysis. After data extraction, the next step involved visualizing the extracted information in an interactive format. The SmartBridge framework was integrated with Power BI, where the bridge data was displayed through interactive dashboards. These dashboards allowed users to filter specific bridge elements, inspect near-real-time updates, and review structural attributes in a user-friendly format. A key feature demonstrated in this example was the ability to attach element-specific comments directly within the BIM model. Inspectors could input observations, deficiencies, or maintenance notes related to individual components, such as cracks in piers or corrosion in girders. These comments were then automatically synchronized with the Power BI dashboard, ensuring that stakeholders had instant access to the latest inspection findings. As shown in Figure 4, the panel has a new bridge button. That was used to extract bridge data from the Revit 3D bridge model. The bridge data can be extracted by this button, such as the materials, dimensions, levels, elevations, etc.

Figure 4.

User interface and the 3D bridge model.

As shown in Figure 4, a Bridge button was introduced into the plugin’s interface, designed to automate the extraction of key bridge components, specifically targeting decks, girders, piers, and foundations. This button streamlined the process of isolating and extracting data for these critical bridge elements, providing comprehensive material take-offs, dimensions, and reinforcement details directly from the Revit model. This enhancement was especially critical for improving workflow efficiency, as it reduced the manual effort required to capture and process data on these key components. By combining inspector feedback with BIM data, the plugin enhances decision-making capabilities. Maintenance teams can prioritize repairs based on near-real-time data provided by inspectors, improving the overall efficiency of bridge management. Additionally, project dashboards have been upgraded to display these inspector comments in a user-friendly format, allowing project managers to quickly identify critical issues and schedule necessary interventions.

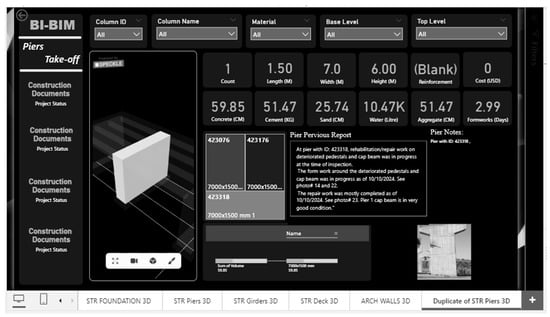

In addition to the improvements made to the SmartBridge framework, an upgrade has been introduced in the form of an interactive dashboard, as shown in Figure 5. This dashboard integrates near-real-time BIM data with inspector feedback, providing a user-friendly interface where bridge elements such as piers are displayed in 3D. It also features detailed metrics on materials used (such as concrete, sand, and aggregate), dimensions, and associated formwork days, making it easier for engineers and project managers to assess the current state of the structure. These dashboards reduce the amount of paperwork that is used in the bridge inspection or reports and the lack of the previous inspection data and the bridge material and dimension data that the inspector has.

Figure 5.

SmartBridge dashboard for bridge pier inspection.

6. Results and Discussion

6.1. Applicability of BIM and BI for Bridge Inspection Activities

The illustrative example demonstrated how the SmartBridge framework could improve bridge inspection workflows. By automating data extraction and visualization, the framework reduces reliance on manual documentation and traditional paper-based methods. Additionally, by allowing near- real-time collaboration between inspectors and engineers, it enhances the efficiency and accuracy of bridge assessments. The results demonstrated that the integration of BIM data with SQL Server and Power BI improved project efficiency, enhanced collaboration among stakeholders, and reduced manual processes. The use of mobile-friendly dashboards further allows near-real-time data sharing, minimizing delays and errors in communication. These findings validated the potential of SmartBridge to address existing gaps in the integration of BIM with digital technologies, setting a precedent for future advancements in construction project management and bridge inspections. This systematic methodology not only highlights the feasibility and advantages of the proposed solution but also provides a pathway for future research and development in the field. By addressing both technical and operational challenges, the SmartBridge framework establishes a strong foundation for improving efficiency, accuracy, and collaboration in infrastructure projects.

BIM applications integrated with BI are pivotal in streamlining and enhancing bridge inspection and maintenance processes by providing detailed, data-rich digital representations of bridge structures. The developed BIM-based SmartBridge framework enables inspectors to visualize structures, detect anomalies, and make data-driven decisions more efficiently. For instance, using the SmartBridge framework to overlay the designed bridge model on the existing physical structure allows inspectors to assess structural conditions with greater precision. This visual alignment minimizes subjective errors, allowing for an evidence-based assessment that reduces inspection time and increases accuracy. The constructive collaboration between BIM and other digital tools extends beyond structural inspections. The SmartBridge framework, for instance, can process and analyze large datasets generated by 3D BIM models and embedded in bridge components, allowing data-driven maintenance and risk assessment. Additionally, the developed SmartBridge framework facilitates near-real-time monitoring by creating virtual models that mimic near-real-time bridge behavior under various load conditions. This capability enhances long-term decision-making for infrastructure maintenance and improves safety protocols, making digital twins indispensable in predicting and mitigating bridge failures before they occur.

6.2. Enhancing Bridge Inspection Using BI-Integrated BIM Framework

The integration of BI with BIM through the SmartBridge framework presents a transformative approach to bridge inspections. Traditional inspection methods often rely on manual data collection, fragmented documentation, and subjective assessments, leading to inefficiencies and inconsistencies in decision-making. By leveraging BIM-integrated BI tools, the SmartBridge framework enhances inspection workflows by automating data extraction, enabling near-real-time collaboration, and providing interactive dashboards for improved data visualization. This section discusses the results of this study to validate the effectiveness of this approach and demonstrate its impact on bridge inspection efficiency, data accuracy, and collaborative decision-making.

The framework streamlines the retrieval of structural and material properties, reducing the need for manual documentation. By integrating SQL Server databases, extracted data is securely stored and readily accessible, eliminating issues associated with lost or inconsistent paper records. The results demonstrated that automated data retrieval reduced the time required for inspectors to collect and process information, leading to an increase in efficiency compared to traditional methods. This improvement is crucial for bridge maintenance agencies, where timely and accurate inspections are essential for ensuring infrastructure safety and longevity. Key attributes such as bridge component conditions, material specifications, and inspection comments are presented in a structured and easily accessible format, allowing stakeholders to quickly identify areas requiring maintenance or further evaluation. This capability minimizes the risk of oversight and enhances data-driven decision-making, ensuring that critical structural deficiencies are addressed before they escalate into major safety concerns. The transition from traditional inspection methods to digital, BIM-integrated approaches is transforming the way bridges are inspected and maintained. A comparison between traditional methods and the SmartBridge framework highlights the substantial advancements that digital technologies bring to bridge inspection, as shown in Table 3.

Table 3.

Comparison between traditional bridge inspection and the developed BIM-driven framework.

The integration of BI with BIM in bridge inspection systems, particularly through tools like the SmartBridge framework, plays a vital role in advancing data analysis and decision-making processes. BI enables engineers and project managers to visualize complex data in an accessible format through interactive dashboards. Using platforms like Power BI, inspectors can create customized views of bridge conditions, material statuses, and inspection notes, which helps managers quickly identify trends and anomalies. For instance, key metrics such as bridge component wear, material usage, and repair schedules can be displayed graphically, allowing teams to track maintenance requirements in near-real-time. With BI, the data extracted and updated through SmartBridge can be continuously monitored, providing a dynamic and up-to-date overview of the bridge’s condition. Predictive analytics in BI tools can analyze historical data to forecast maintenance needs and identify components at risk of failure before issues arise.

Traditional inspection processes require extensive documentation, with manual records that can be difficult to consolidate and analyze. BI simplifies this by automating report generation based on near-real-time data. The SmartBridge plugin collects input directly from inspectors, which is then structured within BI systems to create comprehensive reports on bridge conditions, inspection frequency, and maintenance requirements. This streamlined reporting process not only saves time but also improves data accuracy and accessibility. BI’s data aggregation capabilities allow project managers to access historical inspection data quickly, facilitating long-term planning. By identifying wear patterns and recurring issues across multiple inspections, BI aids in setting data-driven maintenance schedules and optimizing repair budgets. Additionally, by analyzing data trends, agencies can make more informed decisions on resource allocation, ensuring that high-risk bridges receive timely attention and resources. With BI tools integrated into SmartBridge, data collected from inspections is shared in near-real-time with all stakeholders, creating a collaborative environment. Engineers, inspectors, and project managers can access unified data, reducing the communication lag between field and office teams. This seamless data flow enables quicker decision-making and fosters a coordinated approach to bridge management. The combination of BIM-based tools like SmartBridge with BI capabilities marks a step forward in bridge inspection and maintenance. By transitioning from traditional methods to digital inspection systems, teams can harness BI’s power for more informed, data-driven decisions that improve safety, efficiency, and sustainability in bridge management. Integrating BI into bridge inspection not only simplifies the data management process but also transforms raw data into predictive insights, setting a new standard for proactive infrastructure maintenance.

6.3. Recommendations for BIM-Enabled SmartBridge Framework for Bridge Inspection

The developed BIM-enabled SmartBridge framework complements the existing adoption of BIM-based processes and digital technologies for bridge inspection. Initiatives such as the TPF-5(372) project by AASHTO offer a promising foundation by advocating for national standards that encourage BIM integration across various phases of bridge lifecycle management. Developing these standards further to include practical field applications would bolster technology adoption and ensure consistency in bridge inspection practices. The developed SmartBridge framework can be further invested in transportation pilot programs and research initiatives, which can yield valuable insights into best practices and technological requirements. Future case studies implementing the SmartBridge framework can provide practical applications and successful outcomes of BIM integration.

To maximize the potential of the developed BIM-enabled SmartBridge framework for bridge inspection, appropriate training programs are required to guide bridge inspectors and engineers on the effective use of the tool. Training should emphasize practical skills and demonstrate how these technologies can streamline workflows and improve data accuracy. Furthermore, collaboration among technology developers, industry professionals, and academic researchers would facilitate innovation and ensure that emerging solutions are aligned with field needs. Creating comprehensive data management frameworks is critical to mitigate security risks associated with near-real-time data integration. These frameworks should outline data storage, sharing, and protection protocols that safeguard sensitive information without compromising the accessibility and utility of BIM-integrated digital tools. Such frameworks would provide a structured approach to data handling, ensuring that bridge inspection data is both secure and actionable.

7. Conclusions

This study aimed to develop a framework that integrates BI technology with BIM to enhance data accuracy, reduce paperwork, digitalize the inspection processes, and improve near-real-time data for bridge inspection without any missing data or previous inspection comments. However, implementing the framework still involves several challenges, including technical issues such as system integration and data interoperability, operational constraints related to initial setup costs and resource allocation, and human–technology interaction gaps, where inspectors require specialized training to effectively use BIM-BI tools in field conditions. These areas represent critical gaps that future studies should address. Integrating the framework with Power BI tools will enhance the decision-making process and give a constant rating of the component regardless of the inspector’s experience. The added value is shown in its ability to reduce inspection time, improve data accuracy, and enable transparent collaboration across teams, positioning SmartBridge as a potential lighthouse project for digital transformation in infrastructure management. By aligning with AASHTO and ISO standards, SmartBridge serves as a role model for state DOTs seeking interoperability and compliance while modernizing inspection practices. Its success rate is projected to be high in pilot implementations, given its scalability, intuitive interface, and compatibility with existing asset management systems. Beyond efficiency gains, SmartBridge fosters predictive maintenance and proactive decision-making, setting a benchmark for future digital inspection frameworks in the U.S. and globally.

The integration of BIM and digital technologies has the potential to revolutionize the AEC industry, particularly in the realm of bridge inspection and maintenance. By improving the accuracy and efficiency of inspections, these technologies can enhance public safety and extend the lifespan of critical infrastructure. Furthermore, the adoption of data-driven maintenance practices enabled by BIM and digital twins can lead to significant cost savings and more sustainable infrastructure management. This research underscores the importance of continued innovation and collaboration to fully realize the benefits of these technologies.

While this study provides valuable insights into the integration of BIM and digital technologies in bridge inspection, it is not without limitations. The research primarily relies on theoretical frameworks and a limited number of case studies, which may not fully capture the complexities of real-world applications. Future research should focus on collecting more empirical data through pilot programs and real-world implementations to validate the findings of this study. Additionally, this study highlights the need for further technological advancements to address issues related to data processing and interoperability, which remain significant barriers to widespread adoption. The SmartBridge framework establishes a foundational digital platform enabling a BIM-BI reporting inspection process for bridge construction projects. Future work will directly build upon this foundation by integrating automated defect detection algorithms using computer vision. The element-specific, historically tracked data generated by SmartBridge provides the essential labeled dataset required to train and deploy such models, a capability that generalized BIM-BI frameworks do not provide. Controlled pilot studies with state DOTs are essential for the empirical validation of the developed SmartBridge framework. A case study paper will be developed to conduct pilot implementations with one to three state DOTs, focusing on comparing SmartBridge against traditional paper-based methods in terms of inspection time, defect detection accuracy, and cost. Statistical sampling and interrater reliability tests will be used to ensure robust evaluation. Although the current SmartBridge implementation uses a direct Revit–SQL integration for efficiency, future work will focus on adopting openBIM standards to enhance interoperability. Specifically, we plan to implement IFC 4.3-compliant data exchange as the canonical format for bridge models, ensuring compatibility with heterogeneous platforms such as Bentley OpenBridge and Esri ArcGIS. This will involve developing an IFC-based export/import pipeline, validating information requirements through building SMART IDS, and conducting cross-platform testing to confirm data fidelity and semantic consistency. These enhancements will allow SmartBridge to integrate seamlessly into broader digital ecosystems and support long-term asset management strategies.

This study developed and demonstrated the technical viability of the BIM-based SmartBridge framework for digitalizing bridge inspection. However, the primary limitation of this work is its reliance on an illustrative academic model without field validation. To address this, the immediate and critical next step is to execute a controlled pilot study as part of future work. The outcomes of this future work will directly address key metrics such as inspection efficiency, data accuracy, and cost-effectiveness. Furthermore, future research will also focus on integrating automated defect detection algorithms using computer vision and machine learning to enable data-driven maintenance planning [48], as well as developing standardized data protocols to ensure interoperability between the SmartBridge framework and existing DOT asset management systems, such as AASHTOWare Bridge Management software [7]. The successful implementation of the proposed pilot study will provide the necessary empirical evidence to transition the SmartBridge framework from a promising prototype to a validated tool ready for industry adoption. The immediate next step involves integrating drone-captured imagery and point clouds, which can be directly linked to the BIM model using the existing element-specific commenting system to provide rich, geolocated visual data. This represents a logical and methodologically sound evolution of the current work. Broader exploration into fully automated AI image processing for defect recognition is acknowledged as a distinct, longer-term research trajectory that would require a separate, rigorous validation framework beyond the scope of this study.

As the AEC industry continues to evolve, the integration of BIM and digital technologies will play a pivotal role in shaping the future of bridge construction, inspection, and maintenance. The findings of this research highlight the transformative potential of these technologies and underscore the need for continued innovation, collaboration, and investment to overcome existing challenges. By embracing these advancements, the industry can move towards a safer, more efficient, and sustainable future for infrastructure management.

Author Contributions

Conceptualization, L.N. and P.H.D.N.; methodology, L.N. and P.H.D.N.; software, A.A.; validation, P.H.D.N.; formal analysis, L.N., P.H.D.N. and A.A.; investigation, L.N. and A.A.; resources, P.H.D.N.; data curation, A.A.; writing—original draft preparation, L.N. and P.H.D.N.; writing—review and editing, P.H.D.N. and A.A.; visualization, A.A.; supervision, P.H.D.N.; project administration, P.H.D.N.; funding acquisition, P.H.D.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Future Innovators of America (FIA) Fellowship for Undergraduate Research from the Jerome J. Lohr College of Engineering at South Dakota State University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request. The data are not publicly available due to size and technical limitation. The dataset exceeds available repository storage limits.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tang, X.; Wang, M.; Li, H. Understanding the effects of service innovation capability on firm performance in AEC industry: Mediating role of business model. Eng. Constr. Arch. Manag. 2023, 32, 893–911. [Google Scholar] [CrossRef]

- Abrishami, S.; Goulding, J.; Rahimian, F.P.; Ganah, A. Integration of BIM and Generative Design to Exploit AEC Conceptual Design Innovation. Inf. Technol. Constr. 2014, 19, 350–359. [Google Scholar]

- Abdallah, A.M.; Atadero, R.A.; Ozbek, M.E. A State-of-the-Art Review of Bridge Inspection Planning: Current Situation and Future Needs. J. Bridge Eng. 2022, 27, 03121001. [Google Scholar] [CrossRef]

- FHWA. Tech Brief Hybrid Approach to BIM in Iowa BIM as Part of the Construction Contract Background; Federal Highway Administration: Washington, DC, USA, 2018. [Google Scholar]

- CFRs. Code of Federal Regulations (CFRs)–Tile 23: Highways–Chapter I: Federal Highway Administration, Department of Transportation-Subchapter G: Engineering and Traffic Operations–Part 650: Bridges, Structures, and Hydraulics–Subpart C: National Bridge. 2022. Available online: https://www.ecfr.gov/current/title-23/chapter-I/subchapter-G/part-650?toc=1 (accessed on 19 January 2025).

- Hesse, A.A.; Atadero, R.A.; Ozbek, M.E. Uncertainty in Common NDE Techniques for Use in Risk-Based Bridge Inspection Planning: Existing Data. J. Bridge Eng. 2015, 20, 4015004. [Google Scholar] [CrossRef]

- Mohamed, A.G.; Khaled, A.; Abotaleb, I.S. A Bridge Information Modeling (BrIM) Framework for Inspection and Maintenance Intervention in Reinforced Concrete Bridges. Buildings 2023, 13, 2798. [Google Scholar] [CrossRef]

- Nguyen, D.-C.; Nguyen, T.-Q.; Jin, R.; Jeon, C.-H.; Shim, C.-S. BIM-based mixed-reality application for bridge inspection and maintenance. Constr. Innov. 2022, 22, 487–503. [Google Scholar] [CrossRef]

- Xu, G.; Cao, Z.; Wang, J.; Xue, S.; Tang, M. A novel machine learning-based framework for predicting impact force in ship-bridge pier collisions. Ocean Eng. 2023, 285, 115347. [Google Scholar] [CrossRef]

- Kadcha, Y.; Legmouz, D.; Hajji, R. An Integrated Bim-Power Bi Approach for Data Extraction and Visualization. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci.-ISPRS Arch. 2022, 48, 67–73. [Google Scholar] [CrossRef]

- Alabama DOT. Alabama Manual for Bridge Inspection. 2021. Available online: https://www.dot.state.al.us/publications/Maintenance/pdf/Bridge/BridgeInspectionManual.pdf (accessed on 25 January 2025).

- FHWA. Bridge Inspector’s Reference Manual (BIRM). 2022. Available online: https://www.fhwa.dot.gov/bridge/nbis/pubs/nhi23024.pdf (accessed on 4 February 2025).

- Alaska DOT. Alaska Bridges and Structures Manual; Alaska Department of Transportation and Public Facilities: Juneau, Alaska, 2023.

- Arizona DOT. Bridge Inspection Guidelines. 2018. Available online: https://azdot.gov/sites/default/files/2019/09/1803BridgeInspectionGuidelines.pdf (accessed on 4 January 2025).

- Arkansas DOT. Bridge Inspection Manual. 2022. Available online: https://www.ardot.gov/wp-content/uploads/2022/05/ARDOT_BIM_20220507.pdf (accessed on 5 January 2025).

- California DOT. Caltrans Bridge Element Inspection Manual. 2017. Available online: https://dot.ca.gov/-/media/dot-media/programs/maintenance/documents/f0009170-elem-man-a11y.pdf (accessed on 8 January 2025).

- Zhang, X.; Wogen, B.E.; Liu, X.; Iturburu, L.; Salmeron, M.; Dyke, S.J.; Poston, R.; Ramirez, J.A. Machine-Aided Bridge Deck Crack Condition State Assessment Using Artificial Intelligence. Sensors 2023, 23, 4192. [Google Scholar] [CrossRef]

- Congress, S.S.C.; Puppala, A.J.; Khan, A.; Biswas, N.; Kumar, P. Application of Unmanned Aerial Technologies for Inspecting Pavement and Bridge Infrastructure Assets Conditions. Transp. Res. Rec. 2022, 2679, 036119812211052. [Google Scholar] [CrossRef]

- Zhang, X.; Wogen, B.E.; Chu, Z.; Dyke, S.J.; Poston, R.; Hacker, T.; Ramirez, J.; Liu, X.; Iturburu, L.; Baah, P.; et al. Machine-Supported Bridge Inspection Image Documentation Using Artificial Intelligence. Transp. Res. Rec. 2023, 2677, 720–736. [Google Scholar] [CrossRef]

- Perry, B.J.; Guo, Y.; Atadero, R.; van de Lindt, J.W. Streamlined bridge inspection system utilizing unmanned aerial vehicles (UAVs) and machine learning. Measurement 2020, 164, 108048. [Google Scholar] [CrossRef]

- Rakoczy, A.M.; Ribeiro, D.; Hoskere, V.; Narazaki, Y.; Olaszek, P.; Karwowski, W.; Cabral, R.; Guo, Y.; Futai, M.M.; Milillo, P.; et al. Technologies and Platforms for Remote and Autonomous Bridge Inspection–Review. Struct. Eng. Int. 2024, 35, 354–376. [Google Scholar] [CrossRef]

- Miao, P.; Xing, G.; Ma, S.; Srimahachota, T. Deep Learning–Based Inspection Data Mining and Derived Information Fusion for Enhanced Bridge Deterioration Assessment. J. Bridge Eng. 2023, 28, 04023048. [Google Scholar] [CrossRef]

- Chen, S.; Laefer, D.F.; Mangina, E.; Zolanvari, S.M.I.; Byrne, J. UAV Bridge Inspection through Evaluated 3D Reconstructions. J. Bridge Eng. 2019, 24, 05019001. [Google Scholar] [CrossRef]

- McGuire, B.; Atadero, R.; Clevenger, C.; Ozbek, M. Bridge Information Modeling for Inspection and Evaluation. J. Bridge Eng. 2016, 21, 04015076. [Google Scholar] [CrossRef]

- Bono, A.; D’alfonso, L.; Fedele, G.; Filice, A.; Natalizio, E. Path Planning and Control of a UAV Fleet in Bridge Management Systems. Remote Sens. 2022, 14, 1858. [Google Scholar] [CrossRef]

- Congress, S.S.C.; Escamilla, J.; Chimauriya, H.; Puppala, A.J. Eye in the Sky: 360° Inspection of Bridge Infrastructure Using Uncrewed Aerial Vehicles (UAVs). Transp. Res. Rec. 2024, 2678, 482–504. [Google Scholar] [CrossRef]

- Cano, M.; Pastor, J.L.; Tom, R.; Riquelme, A.; Asensio, J.L. A New Methodology for Bridge Inspections in Linear Infrastructures from Optical Images and HD Videos Obtained by UAV. Remote Sens. 2022, 14, 1244. [Google Scholar] [CrossRef]

- Luo, K.; Kong, X.; Zhang, J.; Hu, J.; Li, J.; Tang, H. Computer Vision-Based Bridge Inspection and Monitoring: A Review. Sensors 2023, 23, 7863. [Google Scholar] [CrossRef]

- Iowa DOT. BIM for Bridges & Structures. Available online: https://rosap.ntl.bts.gov/view/dot/79794/dot_79794_DS1.pdf (accessed on 19 January 2025).

- Mitchell, A.; Rivera, J. TPF-5(372) BIM for Bridges and Structures: Information Delivery Manual. 2021. Available online: https://www.buildingsmart.org/wp-content/uploads/2022/10/394-PROFESSIONAL-TPF-5372-BIM-for-Bridges-and-Structures-Transportation-Pooled-Fund.pdf (accessed on 15 January 2025).

- Biagini, C.; Bongini, A. BIM and Data Integration: A Workflow for the Implementation of Digital Twins BT-Beyond Digital Representation: Advanced Experiences in AR and AI for Cultural Heritage and Innovative Design; Giordano, A., Russo, M., Spallone, R., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 821–835. [Google Scholar] [CrossRef]

- Honghong, S.; Gang, Y.; Haijiang, L.; Tian, Z.; Annan, J. Digital twin enhanced BIM to shape full life cycle digital transformation for bridge engineering. Autom. Constr. 2023, 147, 104736. [Google Scholar] [CrossRef]

- Farsangi, E.N.; Shehata, A.O.; Rashidi, M.; Ghassempour, N.; Mirjalili, S. Transitioning from BIM to Digital Twin to Metaverse. Front. Built Environ. 2024, 10, 1486423. [Google Scholar] [CrossRef]

- Badenko, V.; Bolshakov, N.; Celani, A.; Puglisi, V. Principles for Sustainable Integration of BIM and Digital Twin Technologies in Industrial Infrastructure. Sustainability 2024, 16, 9885. [Google Scholar] [CrossRef]

- Achuthan, K.; Hay, N.; Aliyari, M.; Ayele, Y.Z. A digital information model framework for uas-enabled bridge inspection. Energies 2021, 14, 6017. [Google Scholar] [CrossRef]

- Haupt, T.C.; Akinlolu, M.; Raliile, M.T. Applications of digital technologies for health and safety management in construction. In Proceedings of the 8th World Construction Symposium, Colombo, Sri Lanka, 8–10 November 2019; pp. 88–97. [Google Scholar] [CrossRef]

- Bordeleau, F.-E.; Mosconi, E.; de Santa-Eulalia, L.A. Business intelligence and analytics value creation in Industry 4.0: A multiple case study in manufacturing medium enterprises. Prod. Plan. Control. 2020, 31, 173–185. [Google Scholar] [CrossRef]

- Abdullah, O.; Yousuf, M. Data Analysis and Visualization of Road Accident Using Power BI. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 689–695. [Google Scholar] [CrossRef]

- Seppe, F.R.; Cisneros, E.A.G.C.G.; Torné, I.G.; Sobrinho, A.F.G.d.A.; Printes, A.L.; Cardoso, F.D.S. The Power Business Intelligence (PBI) tool in research and development project management. Concilium 2023, 23, 199–211. [Google Scholar] [CrossRef]

- Bordeleau, F.-E.; Mosconi, E.; Santa-Eulalia, L. Business Intelligence in Industry 4.0. In Proceedings of the 51st Hawaii International Conference on System Sciences, Waikoloa Village, HI, USA, 3–6 January 2018; pp. 3944–3953. Available online: https://scholarspace.manoa.hawaii.edu/handle/10125/50383 (accessed on 19 January 2025).

- Solanki, V.V. Evolution of Business Intelligence Tools. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 1149–1151. [Google Scholar] [CrossRef]

- Foster, K.; Smith, G.; Ariyachandra, T.; Frolick, M.N. Business Intelligence Competency Center: Improving Data and Decisions. Inf. Syst. Manag. 2015, 32, 229–233. [Google Scholar] [CrossRef]

- ARTBA. Bridge Report. Available online: https://artbabridgereport.org/ (accessed on 15 January 2025).

- Abdelmaksoud, A.M.; Balomenos, G.P.; Becker, T.C. Parameterized Logistic Models for Bridge Inspection and Maintenance Scheduling. J. Bridge Eng. 2021, 26, 04021072. [Google Scholar] [CrossRef]

- Iacovino, C.; Turksezer, Z.I.; Giordano, P.F.; Limongelli, M.P. Comparison of Bridge Inspection Policies in terms of Data Quality. J. Bridge Eng. 2022, 27, 04021115. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Chang, J.-X.; Su, Y.-C. Developing construction defect management system using BIM technology in quality inspection. J. Civ. Eng. Manag. 2016, 22, 903–914. [Google Scholar] [CrossRef]

- Schiavi, B.; Havard, V.; Beddiar, K.; Baudry, D. BIM data flow architecture with AR/VR technologies: Use cases in architecture, engineering and construction. Autom. Constr. 2022, 134, 104054. [Google Scholar] [CrossRef]

- Ashmawi, A.; Nguyen, P.; Jawdhari, A. State-of-the-art review of machine learning applications for bridge inspections. Adv. Struct. Eng. 2025, 13694332251381220. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).