Proposal for a Sustainable Model for Integrating Robotic Process Automation and Machine Learning in Failure Prediction and Operational Efficiency in Predictive Maintenance

Abstract

1. Introduction

2. State of the Art

3. Methodology

3.1. Method

- Articles directly addressing the implementation or evaluation of RPA and ML in predictive maintenance.

- Publications discussing the relationship between these technologies and sustainability in its various aspects (environmental, social, and economic).

- Studies conducted between 2010 and 2024.

- Articles published in peer-reviewed journals and available in full text.

- Articles that do not directly address the implementation of RPA and ML or that cover areas unrelated to predictive maintenance.

- Works that do not significantly discuss sustainability aspects.

- Publications that are not available in full text or are difficult to access.

- Studies that are not based on empirical methodologies or that do not provide clear quantitative and qualitative data on the impacts of the technologies.

3.2. Articles Synthesis and Analysis

3.3. Synthesis of the Results

- Prevalence of predictive maintenance: 59% of the articles focus on predictive maintenance, making it the most explored technology.

- Environmental focus: the majority of articles highlight the environmental pillar of sustainability, with an emphasis on reducing environmental impacts.

- Economic sustainability: the economic pillar is also widely addressed, particularly in studies on automation and process optimization.

- Less focus on social sustainability: social sustainability is mentioned less frequently, indicating limited focus on this pillar.

- Predominance of case studies and reviews: 33% of the articles are case studies and 45% are reviews, reflecting the consolidation of practical and theoretical knowledge.

- Models and practical applications: 16% of the article’s present models, reflecting the practical application of technologies for sustainability.

- Emerging technologies: automation and machine learning are linked to sustainability, focusing on efficiency and cost reduction.

4. Model (SIRPM)

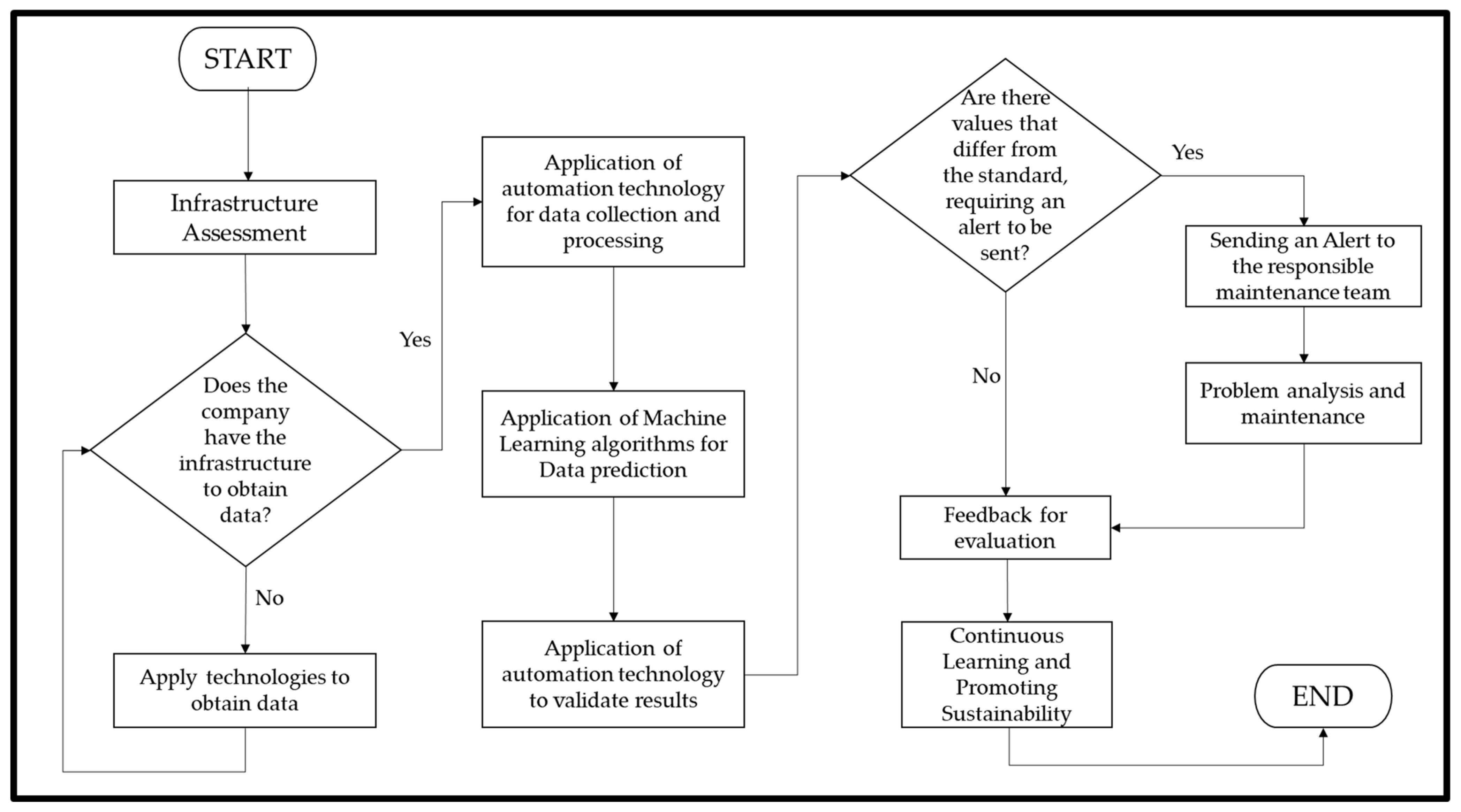

4.1. Proposal for a Model (SIRPM)

- Phase 1: Infrastructure Assessment: The organization’s technological readiness is evaluated to ensure the presence of smart sensors and reliable connectivity for data collection (Table 4). A company’s ability to obtain data from its machines depends on specific KPIs related to the infrastructure’s capacity and flexibility. Initially, the company must verify if it has the means to gather relevant data from the respective machines. If such capabilities are lacking, the installation of sensors or equipment capable of measuring key variables becomes necessary. These variables can include metrics such as the number of completed items, temperature, pressure, or other factors specific to the machine and study objective. The decision regarding whether the infrastructure is sufficient for data collection also considers KPIs such as the following:

- ○

- Frequency of data collection: the capability to capture and process data at the intervals required for meaningful analysis.

- ○

- Representativeness of data: the degree to which the captured data reflects the performance and conditions of the machine under study.

- ○

- Storage capacity: the available space in local devices (e.g., hard drives) or cloud solutions to accommodate the volume of collected data.

- ○

- Scalability: the flexibility of the infrastructure to adapt to variations in demand, including the potential need for future expansions.

- ○

- After assessing the adequacy of data collection and infrastructure, the organization must determine the appropriate storage solution—either local storage or cloud-based platforms. This decision is guided by the KPIs outlined above. Cloud storage is often preferred in scenarios requiring high integration and real-time data analysis, as it aligns with Industry 4.0 principles and enables enhanced connectivity and interoperability.

- Phase 2: Automation of Data Collection and Processing: data collection, preprocessing, and validation are automated using RPA to guarantee data accuracy and readiness for analysis (Table 5).

- Phase 3: Application of Machine Learning: Machine learning models are developed and applied to predict failures based on historical and real-time data (Table 6). Although machine learning algorithms play an essential role in the proposed model, their applicability depends directly on the specific characteristics of each case, namely the type of data collected in the previous phase. Factors such as the type of data (structured or unstructured), volume of data available, objective of the algorithm (classification, prediction, or clustering) and computational capacity are decisive for the selection of the appropriate method. Therefore, the model foresees a detailed prior assessment to ensure that the chosen algorithm is compatible with the conditions of the business environment and the objectives of the automation process.

- Phase 4: Integration of Results with RPA: Predictive results are integrated into operations through RPA bots, automating data analysis and anomaly detection (Table 7). The implementation of control automation processes in the proposed model requires the existence of an infrastructure that allows for automated interventions. These processes are more easily applicable in robust infrastructures, such as cloud-based solutions, which offer greater resilience and real-time responsiveness. For on-premise environments, the application of these processes may be limited due to resource constraints. However, when implemented, these mechanisms ensure the continuity of operations and the safe execution of machine learning algorithms, allowing the system to not only predict possible failures but also perform automatic corrections without compromising the integrity of business processes. In the specific case of this model, control automation processes can be applied given that there are platforms where automation intervention is required to collect data and subsequently organize structured data for the later application of machine learning algorithms.

- Phase 5: Action and Feedback: predictions are transformed into corrective actions by sending automated alerts, executing maintenance, and gathering feedback to improve the models (Table 8).

- Phase 6: Continuous Learning and Sustainability: continuous improvement is ensured through performance metrics, team training, and regular reviews, promoting sustainability and operational efficiency (Table 9).

- Data collection based on Industry 4.0 guidelines: Data collection in SIRPM is performed through smart sensors, aligned with I4 principles, such as connectivity and interoperability. These sensors generate data that can be stored locally, in the cloud or in hybrid infrastructures, depending on the organization’s technological maturity.

- Cloud-based storage and control: The model prioritizes cloud solutions to ensure resilience, scalability, and access to advanced machine learning (ML) tools. However, it is adaptable, allowing for initial control in on-premise infrastructures and a progressive evolution to cloud solutions as organizations advance in the process of technological modernization.

- Implementation of machine learning logic: The ML logic in SIRPM is designed to be implemented both in the cloud and on-premise, in a scalable and flexible way. In the context of I4, cloud technologies offer access to advanced ML libraries and robust computational capabilities, overcoming internal limitations that many companies still face.

- Mobility and accessibility in infrastructure: The hybrid architecture of the model ensures that even without a complete migration to the cloud, organizations can enjoy the benefits of connectivity and mobility, essential for I4. For example, the automation of data collection and processing by RPA can be achieved locally but with interfaces ready for future integration into cloud-based solutions, promoting a continuous flow of information between machines, systems, and people.

- Structured transition to cloud-based Industry 4.0: The model prepares the technological environment of organizations for a continuous and sustainable evolution towards the principles of I4. Each phase of SIRPM, from data collection to the analysis and integration of results, is designed to be fully compatible with cloud infrastructures, ensuring a harmonious and efficient transition.

4.2. Characteristics and Benefits of the Model (SIRPM)

- AI (artificial intelligence) encompasses various techniques to simulate human intelligence. Several articles mentioned in Table 12 utilize AI through diverse approaches, including machine learning algorithms, genetic algorithms, and dynamic programming.

- ML (machine learning), a subset of AI, focuses on systems that learn from data. Articles that explicitly use ML techniques, such as reinforcement learning algorithms, search algorithms, and Bayesian networks, aim to identify patterns and make predictions based on data.

- DL (deep learning) represents an advanced approach within ML, utilizing deep neural networks. The use of deep neural networks is more relevant in contexts involving large volumes of unstructured data, such as images or videos, which are not directly addressed in the studies in the table.

- [26] Deep learning in predictive maintenance, which is used to predict failures in industrial equipment, helping to optimize processes and reduce maintenance costs.

- [27] Deep learning in predictive maintenance employs deep learning models to analyze data and predict failures in industrial systems, increasing efficiency and sustainability.

- [28] RPA in business process optimization involves the automation of business processes to increase efficiency, reduce errors, and contribute to organizational sustainability.

- [29] RPA in digital transformation, which is used to improve business process efficiency, reducing manual errors and accelerating digital transformation.

- [30] Machine learning in predictive maintenance uses machine learning algorithms to predict failures in industrial systems, helping to reduce costs and increase operational efficiency.

- [31] Machine learning in predictive maintenance employs machine learning models for predictive maintenance strategies, increasing productivity and minimizing downtime.

- [32] Technologies for smart manufacturing and predictive maintenance integrates AI and machine learning technologies to predict failures and improve sustainability in manufacturing.

- [33] RPA in Industry 4.0: RPA implementation for the automation of industrial processes, promoting efficiency and sustainability in the sector.

- [34] Machine learning in predictive maintenance uses machine learning techniques to predict failures in industrial systems, reducing costs and increasing operational efficiency.

- [35] Machine learning in predictive maintenance applies machine learning algorithms to optimize manufacturing operations and reduce unexpected failures.

- [36] RPA and AI in Industry 4.0 combines RPA and AI for the intelligent automation of industrial processes, optimizing operations and promoting sustainability.

- [37] Deep learning for the predictive maintenance of industrial robots uses deep neural networks to predict failures and optimize the maintenance of industrial robots.

- [38] Data-driven algorithms for predictive maintenance applies machine learning algorithms to optimize predictive maintenance strategies and reduce costs.

- [39] Sustainable technologies in Industry 4.0 integrates technologies to improve maintenance and reduce environmental impacts in industrial processes.

- [40] Machine learning in predictive maintenance uses machine learning to improve efficiency and predict failures in industrial systems, promoting sustainability.

- [41] Predictive maintenance and sustainability: the application of predictive maintenance to reduce environmental impacts and improve sustainability in industrial systems.

- [42] AI and the IoT for predictive maintenance integrates AI and the IoT to optimize predictive maintenance, contributing to sustainability and operational efficiency.

- [43] Machine learning in predictive maintenance uses machine learning to predict failures and optimize maintenance, ensuring greater efficiency in the industrial environment.

- [44] Industrial AI and predictive maintenance applies AI to predict failures and optimize processes, promoting sustainability in manufacturing.

- [45] Predictive maintenance and AI uses AI to optimize predictive maintenance, improving production and promoting more sustainable industrial practices.

- [46] RPA and sustainability in Industry 4.0: RPA as a tool to improve sustainability and efficiency in industrial processes.

- [47] AI and predictive maintenance: the application of AI for predictive maintenance in industrial environments, improving the efficiency and sustainability of processes.

- [48] RPA in sustainability in supply chains: RPA for process automation in supply chains, aiming at sustainability and operational efficiency.

- [49] The IoT and machine learning for predictive maintenance integrates the IoT and machine learning to optimize the maintenance of industrial systems and reduce failures.

- [50] Smart predictive maintenance with AI and machine learning applies AI and machine learning to improve predictive maintenance in industrial environments.

- [51] Predictive maintenance and environmental impact uses predictive maintenance to reduce the environmental impact of industrial processes and promote sustainable practices.

- [52] Integration of AI and the IoT for predictive maintenance combines AI and the IoT to optimize maintenance and ensure sustainability in industrial systems.

- [53] Sustainable RPA: the implementation of sustainable RPA in industrial processes, promoting efficiency and reducing environmental impact.

- [54] Machine learning for predictive maintenance in Industry 4.0 uses machine learning to optimize maintenance and improve the efficiency of industrial systems.

- [55] Deep learning for predictive maintenance applies deep learning to optimize maintenance and predict failures in industrial systems.

- [56] The integration of AI and RPA proposes a sustainable model for integrating AI and RPA in industrial processes, optimizing operations and promoting sustainability.

- [57] RPA and energy efficiency: RPA used to optimize industrial processes, improving energy efficiency and reducing consumption.

- [58] Framework for RPA implementation: development of a framework for RPA project implementation and control, focusing on sustainability and operational efficiency.

- [59] Decision models for sustainable RPA implementation: review of decision models for the sustainable implementation of RPA, aiming for optimization and reduction in environmental impacts.

- [60] Sustainable RPA implementation in healthcare administrative services: analysis of RPA implementation in healthcare, focusing on sustainability and efficiency.

- [61] Universal model for sustainable RPA implementation: proposal of a universal model for sustainable RPA implementation, promoting efficiency and sustainability.

- [62] Sustainable RPA implementation: development of a mathematical model for the sustainable implementation of RPA across different industrial contexts.

- Advanced technology integration (RPA, machine learning): it offers a robust and comprehensive combination of technologies, providing greater effectiveness and a continuous flow of data between sensors, analysis platforms, and operational teams.

- Intelligent automation: it minimizes human intervention, reducing errors and making the process more efficient and secure.

- Continuous learning: the machine learning system continuously adapts based on operational feedback, enhancing the accuracy of predictions and decision-making over time.

- Flexibility and scalability: the model is modular and can be implemented gradually according to the specific needs of the company, allowing for expansion into other sectors or areas of the organization.

- Real-time monitoring: immediate anomaly detection and real-time alert generation facilitate a quick response to failures, reducing unplanned downtime.

- Energy efficiency and sustainability: the model promotes resource optimization and waste reduction, aligning with environmental goals and corporate sustainability regulations.

5. Case Study

5.1. Case Study Presentation

- Management (one person): The owner of the company is responsible for overall management and supervision. While actively involved in the factory operations, he makes strategic decisions and handles administrative matters.

- One financial manager oversees the company’s finances and cash flow, ensuring that production remains within a controlled budget.

- One production planning engineer is responsible for planning production schedules, ensuring orders are met on time and that machines operate within the designated hours.

- One marketing manager is focused on brand promotion and customer relations, ensuring client retention and the acquisition of new business.

- One production manager (production supervisor) oversees the production line, ensuring smooth operations during the work shift.

- Two machine operators operate the machines that produce the packaging, ensuring the production process follows technical specifications and that materials are available.

- One maintenance technician (responsible for basic maintenance) is responsible for performing minor repairs and adjustments to the machines when simple failures occur, such as part replacements or calibration adjustments. However, they did not perform systematic predictive or preventive maintenance.

- Two production support workers (packers and auxiliary operators) assist with packaging finished products and keeping the production process organized, moving boxes and materials.

- One driver/logistics manager is responsible for the distribution of packaging to customers and suppliers, as well as managing the flow of materials within the factory.

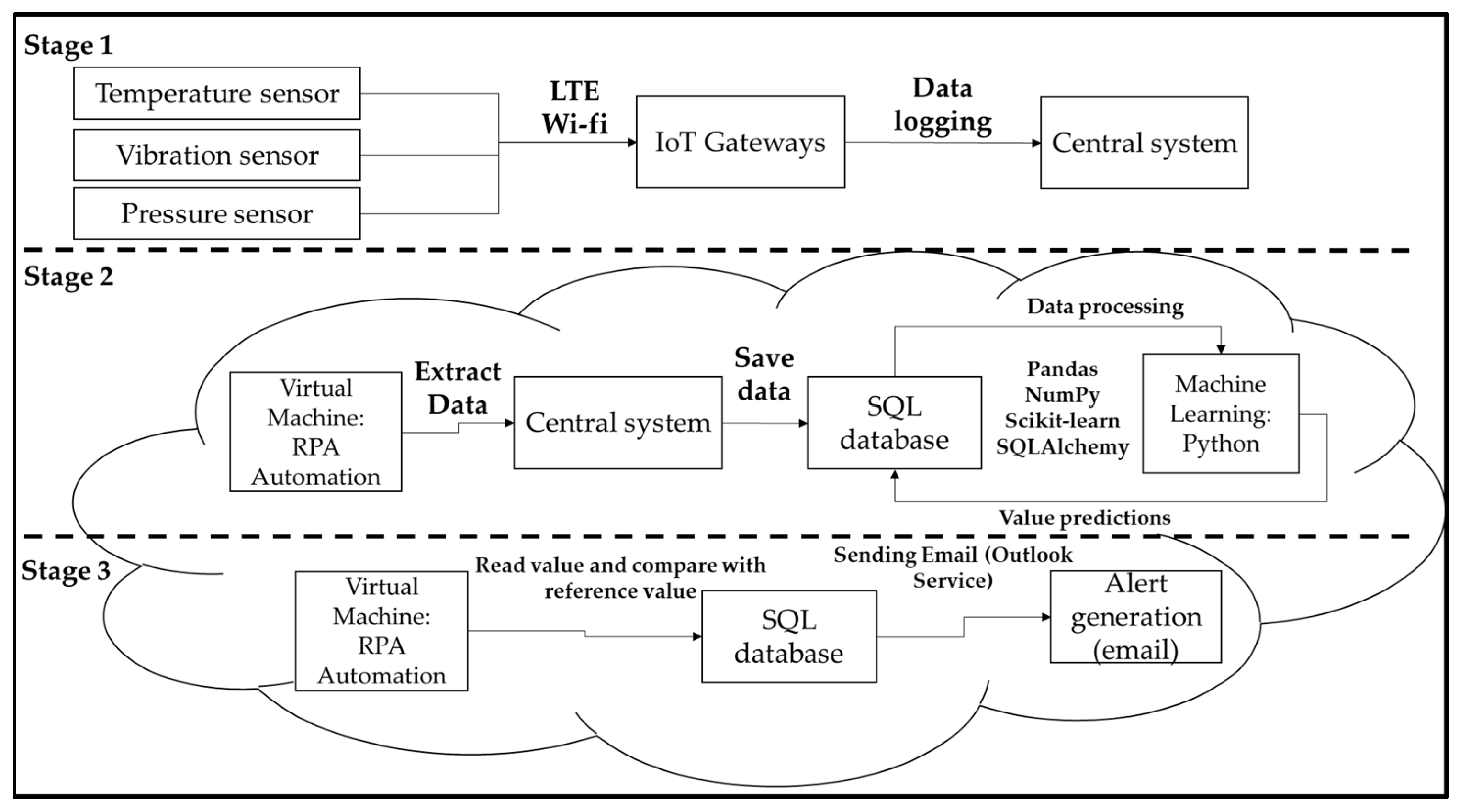

5.2. Application of the Model to the Case Study

- Phase 1: Infrastructure Assessment

- Smart sensors: install IoT-enabled sensors on critical machines to collect data on temperature, vibration, and pressure.

- Connectivity: ensure a robust connection between sensors and a central data platform using Wi-Fi or industrial connectors for reliable real-time data flow.

- Phase 2: Automation of Data Collection and Processing

- 3.

- Deploy RPA bots to collect data directly from the installed sensors and Alpha’s existing systems.

- 4.

- Automate preprocessing tasks like cleaning and normalizing data to make it analysis-ready. The preprocessing of the captured data was carried out in several steps to ensure its quality and usability. Initially, missing values were filled using linear interpolation to preserve data integrity. Then, outliers were identified and removed based on statistical metrics such as standard deviation. The data were then normalized, facilitating the predictive analysis and training of machine learning models. This transformation was essential to ensure comparability between different variables and reduce potential biases during analysis.

- 5.

- Validate data quality, ensuring only consistent and complete data are processed. Data quality validation is ensured through a rigorous pre-processing process, where automated actions are performed to ensure that the data collected from the sensors are consistent and complete. Initially, missing values are filled with linear interpolation, maintaining data integrity. Outliers are identified and removed based on statistical metrics, such as standard deviation, to avoid bias in the analyses. The data are then normalized to ensure comparability between different variables, facilitating the training of machine learning models. The final quality of the data is validated by automated checks, where it is compared with reference values and machine operating conditions. Inconsistent data or data outside the expected parameters are flagged or discarded, ensuring that only valid data ready for analysis are used, guaranteeing the effectiveness of predictive analysis and the accuracy of decisions based on these data. For data validation, the following steps were performed:

- ○

- Rigorous pre-processing: automated actions were implemented to ensure the consistency and completeness of sensor-collected data.

- ○

- Filling of missing values: linear interpolation was used to maintain data integrity.

- ○

- Outlier identification and removal: outliers were detected and eliminated based on statistical metrics, such as standard deviation, to avoid bias in the analyses.

- ○

- Data normalization: variables were normalized to ensure comparability, facilitating the training of machine learning models.

- ○

- Automated quality checks: data were compared against reference values and machine operating conditions to verify its validity.

- ○

- Flagging or discarding inconsistent data: data outside expected parameters were either flagged or discarded, ensuring only valid data were used for analysis.

- ○

- This process ensures effective predictive analysis and enhances the accuracy of decisions based on the validated data.

- Phase 3: Application of Machine Learning

- 6.

- Algorithm selection: use decision trees for initial predictions due to the small dataset and ease of interpretation.

- 7.

- Develop and train ML models.

- 8.

- Generate failure forecasts, identifying patterns indicative of imminent breakdowns.

- Phase 4: Integration of Results with RPA

- 9.

- Use RPA bots to extract ML predictions in real time.

- 10.

- Automate the cross-referencing of predictions with Alpha’s operational norms, identifying deviations.

- 11.

- Highlight anomalies, enabling the identification of potential failures before they disrupt production.

- Phase 5: Action and Feedback

- 12.

- Automatically send alerts to the responsible department through RPA upon detecting deviations or failures.

- 13.

- Execute maintenance, ensuring corrective actions are taken based on forecasts and alerts issued.

- 14.

- Collect feedback on the usefulness of the received alerts, assessing whether they were accurate, relevant, and helped prevent issues.

- 15.

- Record this evaluation for machine learning algorithm learning, updating the model with the feedback received, enabling continuous learning and improved accuracy.

- Phase 6: Continuous Learning and Sustainability

- 16.

- Operational efficiency and sustainability through the calculation of key metrics, such as mean time to repair (MTTR), mean time between failures (MTBF), and sustainability indicators, such as reduced energy consumption and emissions.

- 17.

- Training and adaptation of teams for the predictive maintenance system, ensuring all teams are trained to interpret results and interact with the system.

- 18.

- Periodic review of system performance, conducting regular assessments of RPA bots, the accuracy of machine learning models, and the overall impact on the production process.

- Integrated Computing Service:

- Connect to the SQL database through ODBC drivers, ensuring compatibility and security in data transmission.

- Execute pre-defined workflows that include the preprocessing, normalization, and application of machine learning algorithms.

- 2.

- Interfaces Used:

- Database interface: the service used structured queries to extract data from the SQL database, handling large volumes of records and applying filters for the most recent data (last 24 h).

- Results interface: after generating the forecasts, the predicted values were automatically inserted into a dedicated table within the same SQL database, allowing for tracking and integration with the alert system.

- 3.

- Controls and Automation:

- The service has been scheduled to automatically run tasks at regular (hourly) intervals using scheduling tools within the server operating system.

- Machine learning algorithms were implemented in a secure virtualized environment designed to ensure system integrity during data processing and analysis.

- 4.

- Interaction with the Alert System:

- After processing and predictive analysis, the service would forward the results to a second automated system (controlled by RPA). This system checked whether values were outside pre-defined limits and, if they were, triggered automatic notifications to the maintenance team.

- 5.

- Libraries Used:

- Pandas and NumPy: data manipulation, normalization, and mathematical operations.

- Scikit-learn: decision tree model training and inference (CART).

- SQLAlchemy: integrating and managing SQL database connections.

5.3. Detailed Description of the SIRPM Model

- Phase 1: Infrastructure Assessment

- ○

- Paper cutter—vibration sensor to monitor mechanical wear.

- ○

- Hydraulic press—pressure sensor to detect variations in hydraulic fluid.

- ○

- Flexographic printer—temperature sensor to predict overheating.

- Phase 2: Data Collection and Processing

- ○

- RPA: UiPath was employed to automate data collection from sensors connected to the machines. RPA (robotic process automation) was used to automate the collection of data from sensors connected to industrial machines. The tool chosen was UiPath, which was configured on a virtual machine in the hybrid cloud environment. In this environment, RPA robots were programmed to interact with the machines’ control systems and extract real-time data, such as vibration, pressure, and temperature values. UiPath was programmed to perform automatic logins to the machines’ monitoring systems, access the sensor data, and organize it in a structured way. After collection, the RPA sent the data to a SQL database, where it was stored for later analysis. The programming was performed using the UiPath Studio graphical interface, which allows you to create automated flows through specific activities for each task, such as logging in, extracting, and sending data.

- ○

- Python: Used for pre-processing and normalization, ensuring consistency and readiness for analysis. Python was used to access data from the SQL database using SQLAlchemy, clean missing values, and normalize variables for predictive analysis, with libraries like Pandas, NumPy, and Scikit-learn. Python was also used to feed a machine learning-based predictive model, which identified patterns and predicted possible machine failures. The Python scripts were executed on virtual machines within the same cloud environment, enabling integration with the data collected by the RPA, ensuring the continuity of the automated predictive maintenance process.

- Phase 3: Machine Learning Model Training

- ○

- Data cleaning: removal of inconsistencies and handling of missing values.

- ○

- Normalization: scaling data to ensure comparability and training accuracy.

- ○

- Data splitting: 80% of the data was used for training, with 20% reserved for model validation.

- Phase 4: Predictive Model Implementation with RPA Integration

- The RPA bot collected data and stored it in a SQL database.

- A Python script executed the machine learning algorithm, reading SQL table values, making predictions, and saving results in a new table.

- A secondary RPA script analyzed predicted values. If anomalies were detected, it generated automated email alerts to the maintenance team, specifying the affected machine and identified value.

- Data collection: sensors provided data stored in the SQL database.

- Data processing: the ML model analyzed patterns and made predictions.

- Alerts: anomalous values triggered automatic email notifications to the maintenance team.

- ○

- UiPath: for data collection and alert automation.

- ○

- Python (scikit-learn): for developing the machine learning model, leveraging libraries such as Pandas, NumPy, and matplotlib for data analysis and visualization.

- Vibration sensor (paper cutter): Excessive vibration is one of the first signs of mechanical wear or misalignment of machine parts. The ideal vibration range for the paper cutter was defined between 1.0 and 1.3 mm/s, considering normal machine operation. When vibration exceeded 1.5 mm/s, this indicated a possible imminent mechanical failure, such as a misalignment of parts or excessive wear, which could compromise machine operation. On the other hand, if the vibration fell below 1.0 mm/s, this could indicate that the machine’s moving components were having little interaction or contact, which could also cause operational problems. These values were used as a basis for triggering automatic alerts so that the maintenance team could investigate potential failures before they occurred.

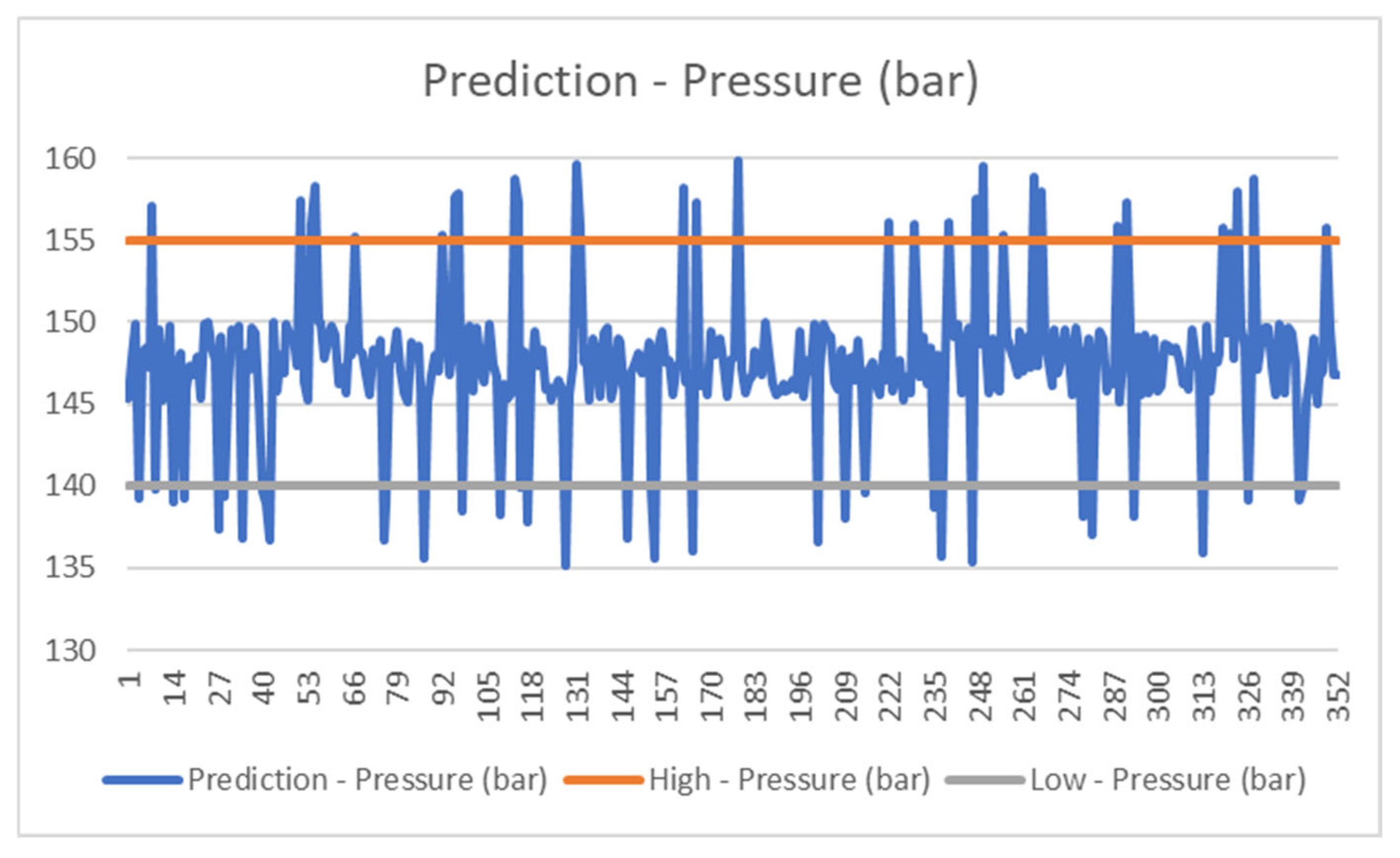

- Pressure sensor (hydraulic press): The pressure of the hydraulic fluid in the hydraulic press is essential to ensure that the pressing process occurs correctly and with quality. The ideal pressure range was established between 145 and 150 bar, with values outside this range indicating potential problems. If the pressure rose above 155 bar, this could signal failures in the pressure control system or even blockages in the hydraulic line, which would affect the quality of the packaging formation. On the other hand, pressures below 140 bar indicated that the hydraulic pressure was below what was necessary, which would impair the efficiency of the process and could cause failures in the pressing process. These alert values helped to anticipate the necessary maintenance, avoiding failures during operation.

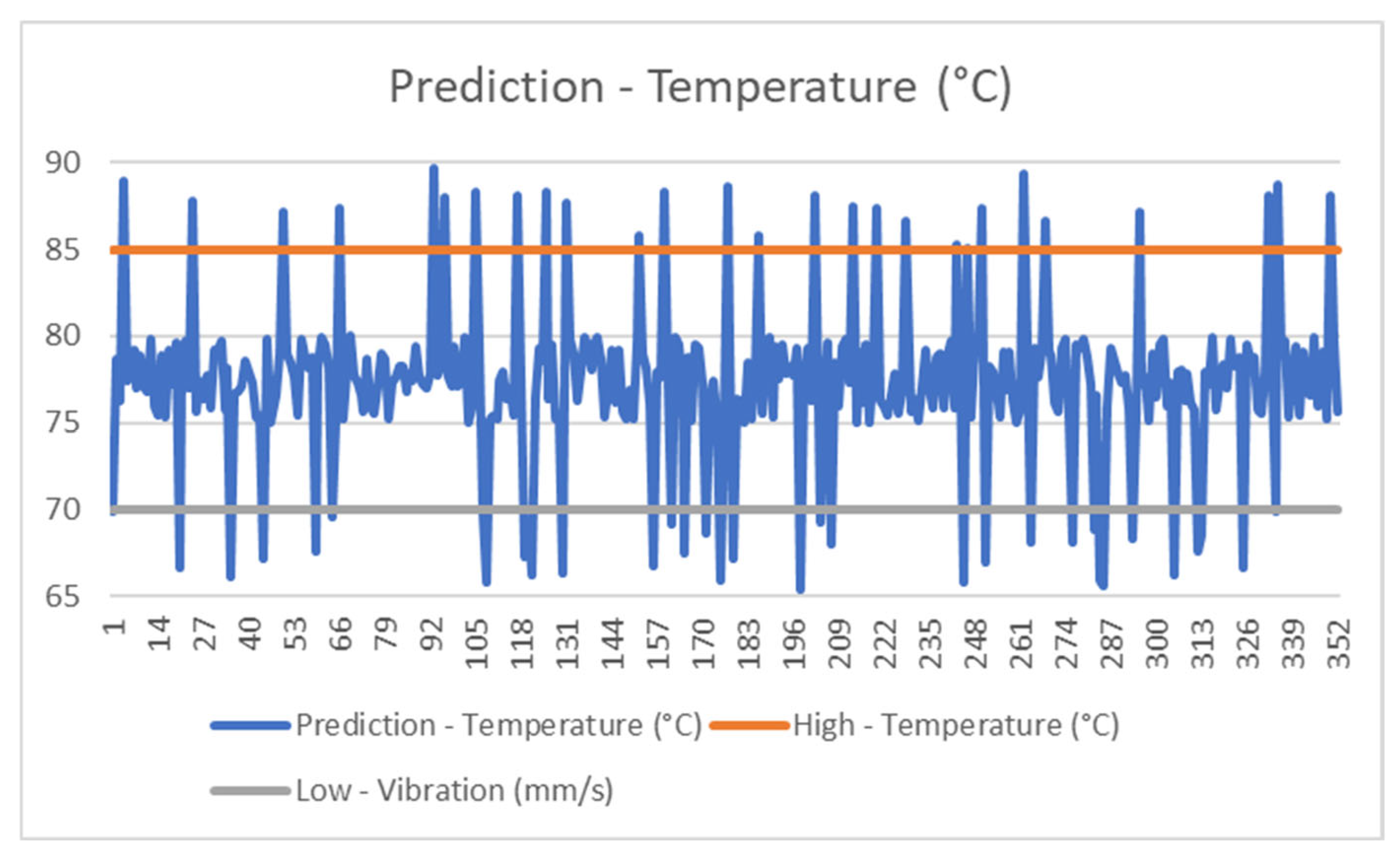

- Temperature sensor (flexographic printer): The temperature of the printheads is crucial to ensuring print quality and the efficiency of the flexographic printer’s operation. The ideal temperature range was defined as between 75 and 80 °C, with upper and lower limits to alert for failures in the cooling or heating system. If the temperature rose above 85 °C, this could indicate failures in the cooling system, which would result in overheating and possible damage to the printheads. Temperatures below 70 °C, on the other hand, indicated failures in the heating system, compromising print quality. These alerts were essential to avoid damage to the equipment and ensure the continuity of the production process.

- Phase 5: Proactive Action and Feedback

- ○

- Automated email alerts to the maintenance team.

- ○

- Execution of corrective maintenance and preventive adjustments.

- ○

- Feedback collection on alert effectiveness and prediction accuracy.

- Phase 6: Sustainability and Continuous Improvement

- ○

- The machine learning model’s performance was periodically reviewed.

- ○

- The RPA system was adjusted as needed for accuracy and efficient integration.

- ○

- Continuous staff training ensured adaptation to the new predictive maintenance methodology.

- Total Operating Time is the time during which the system or equipment is running without failures.

- Number of Failures is the number of failures that occur during the considered time period.

- Total Downtime is the total time during which the system or equipment was out of operation due to failures.

- Number of Failures is the number of failures that occur during the considered time period.

- The formula for calculating REDUCTION_Average Repair Costs is

- The formula for calculating REDUCTION_ Total Maintenance Costs is

- The formula for calculating REDUCTION_ Unplanned Downtime Costs is

- The formula for calculating REDUCTION_ Total Operational Costs is

6. Analysis of Results and Discussion

6.1. Analysis of Results

- ISO 50001 focuses on the continuous improvement of energy performance, with the main goal of reducing energy consumption. The standard suggests a reduction of 5% to 10% per year in companies that implement energy management systems [68]. The 25% reduction in energy consumption observed at Alpha significantly exceeds the standard’s objectives, demonstrating excellent performance in terms of energy efficiency.

6.2. Discussion

7. Conclusions

- A 100% increase in the mean time between failures (MTBF), from 23.47 h per event to 70.4 h per event.

- A 67% reduction in the mean time to repair (MTTR), from 12 h to 4 h.

- A 66.67% decrease in the number of unplanned downtime events, from fifteen to five events per month.

- A reduction in operational costs, with a 37.5% decrease in maintenance costs and a 71.4% reduction in costs related to unplanned downtime.

- Environmental gains, including a 25% reduction in energy consumption and a 40% decrease in CO2 emissions.

- Advanced technology integration: the combination of RPA and machine learning improves the system’s effectiveness, providing a continuous data flow between sensors, analysis platforms, and operational teams, enhancing failure predictions and response times.

- Intelligent automation: automation reduces human intervention, minimizing errors and increasing the efficiency and safety of processes.

- Continuous learning: the machine learning system adapts over time, improving predictions and decision-making.

- Flexibility and scalability: the model is modular and can be gradually implemented, allowing for expansion into other areas of the company.

- Real-time monitoring: the detection of anomalies and the generation of real-time alerts facilitate quick responses to failures, reducing unplanned downtime.

- Energy efficiency and sustainability: the model promotes resource optimization and waste reduction, aligning with environmental goals and corporate sustainability standards.

- Social: It promotes a better allocation of human resources by reducing repetitive and hazardous tasks while empowering teams with new digital skills. Additionally, it contributes to improved working conditions and enhanced operational safety.

- Environmental: the model contributes to waste reduction, decreased CO2 emissions, and lower energy consumption, aligning with global environmental preservation goals.

- Economic: the reduction in operational costs and increased productivity result in greater competitiveness for companies while ensuring long-term financial returns.

- H1: The combined application of RPA and ML significantly enhanced the ability to anticipate failures. This improvement was evident in the increase in the MTBF (+100%), the reduction in the MTTR (−67%), and the decrease in unplanned downtime events (−66.67%). These advances resulted in more efficient maintenance management and a 37.5% reduction in operational costs.

- H2: The research revealed positive impacts in all sustainability dimensions. Environmentally, there was a 25% reduction in energy consumption and a 40% decrease in CO2 emissions. Socially, the model promoted team empowerment, with greater safety and efficiency in operations. Economically, the benefits included increased productivity and significant reductions in costs associated with unplanned failures.

- Expanding the model with larger datasets.

- Integrating emerging technologies, such as big data and artificial intelligence, to increase prediction accuracy.

- Investigating the cultural adaptation and training of teams, which are crucial for the long-term acceptance and effective use of new technologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Esteban, A.; Zafra, A.; Ventura, S. Data mining in predictive maintenance systems: A taxonomy and systematic review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2022, 12, e1471. [Google Scholar] [CrossRef]

- Costa, D.; Mamede, H.; Silva, M. Robotic Process Automation (RPA) Adoption: A Systematic Literature Review. Eng. Manag. Prod. Serv. 2022, 14, 1–12. [Google Scholar] [CrossRef]

- Siderska, J.; Aunimo, L.; Süße, T.; Stamm, J.; Kedziora, D.; Aini, S. Towards Intelligent Automation (IA): Literature Review on the Evolution of Robotic Process Automation (RPA), its Challenges, and Future Trends. Eng. Manag. Prod. Serv. 2023, 15, 90–103. [Google Scholar] [CrossRef]

- Selçuk, Ş. Predictive maintenance, its implementation and latest trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1670–1679. [Google Scholar] [CrossRef]

- Yang, Z.; Djurdjanović, D.; Ni, J. Maintenance scheduling in manufacturing systems based on predicted machine degradation. J. Intell. Manuf. 2008, 19, 87–98. [Google Scholar] [CrossRef]

- Sue, P. Robotic Process Automation. Am. J. Intell. Syst. 2019, 9, 49–53. [Google Scholar] [CrossRef]

- Leukel, J.; González, J.; Riekert, M. Adoption of machine learning technology for failure prediction in industrial maintenance: A systematic review. J. Manuf. Syst. 2021, 61, 87–96. [Google Scholar] [CrossRef]

- Carvalho, T.; Soares, F.; Vita, R.; Francisco, R.; Basto, J.; Alcalá, S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Susto, G.; Schirru, A.; Pampuri, S.; McLoone, S.; Beghi, A. Machine Learning for Predictive Maintenance: A Multiple Classifier Approach. IEEE Trans. Ind. Inform. 2015, 11, 812–820. [Google Scholar] [CrossRef]

- Abdallah, M.; Joung, B.; Lee, W.; Mousoulis, C.; Sutherland, J.; Bagchi, S. Anomaly Detection and Inter-Sensor Transfer Learning on Smart Manufacturing Datasets. Sensors 2022, 23, 486. [Google Scholar] [CrossRef]

- Khorsheed, R.; Beyca, O. An integrated machine learning: Utility theory framework for real-time predictive maintenance in pumping systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 235, 887–901. [Google Scholar] [CrossRef]

- Janiesch, C.; Zschech, P.; Heinrich, K. Machine learning and deep learning. Electron. Mark. 2021, 31, 685–695. [Google Scholar] [CrossRef]

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2018, 14, 681–695. [Google Scholar] [CrossRef]

- Santos, P.; Neves, S.; Sant’Anna, D.; Oliveira, C.; Carvalho, H. The analytic hierarchy process supporting decision making for sustainable development: An overview of applications. J. Clean. Prod. 2019, 212, 119–138. [Google Scholar] [CrossRef]

- Jordan, M.; Mitchell, T. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Uskenbayeva, R.; Kalpeyeva, Z.; Satybaldiyeva, R.; Moldagulova, A.; Kassymova, A. Applying of RPA in Administrative Processes of Public Administration. In Proceedings of the 2019 IEEE 21st Conference on Business Informatics (CBI), Moscow, Russia, 15–17 July 2019; pp. 9–12. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, M.; Wang, D.; Song, C.; Liu, M.; Li, J.; Lou, L.; Liu, Z. Failure prediction using machine learning and time series in optical network. Opt. Express 2017, 25, 18553–18565. [Google Scholar] [CrossRef]

- Cook, D.; Guyatt, G.; McDonald, R.; McDonald, J.; Morris, A.; Munn, A.; Niven, D.; Sibbald, W.; Stevens, R.; Whelan, T. Central venous catheter replacement strategies: A systematic review of the literature. Crit. Care Med. 1997, 25, 1417–1424. [Google Scholar] [CrossRef]

- Eriksen, M.; Frandsen, T. The impact of patient, intervention, comparison, outcome (PICO) as a search strategy tool on literature search quality: A systematic review. J. Med. Libr. Assoc. 2018, 106, 420–431. [Google Scholar] [CrossRef]

- Nishikawa-Pacher, A. Research Questions with PICO: A Universal Mnemonic. Publications 2022, 10, 21. [Google Scholar] [CrossRef]

- Cumpston, M.; McKenzie, J.E.; Thomas, J.; Brennan, S.E. The Use of ’PICO for Synthesis’ and Methods for Synthesis Without Meta-Analysis: Protocol for a Survey of Current Practice in Systematic Reviews of Health Interventions. F1000Research 2021, 9, 678. [Google Scholar] [CrossRef]

- Brockmeier, A.; Ju, M.; Przybyla, P.; Ananiadou, S. Improving reference prioritisation with PICO recognition. BMC Med. Inform. Decis. Mak. 2019, 19, 256. [Google Scholar] [CrossRef] [PubMed]

- Ucar, A.; Karakose, M.; Kırımça, N. Artificial Intelligence for Predictive Maintenance Applications: Key Components, Trustworthiness, and Future Trends. Appl. Sci. 2024, 14, 20898. [Google Scholar] [CrossRef]

- Yiğit, E.; Bilgin, M.; Oner, A. Predictive Maintenance Studies Applied to an Industrial Press Machine Using Machine Learning. J. Intell. Syst. Appl. 2020, 12, 117. [Google Scholar] [CrossRef]

- Shi, J.; Sun, J.; Zhang, M.; Sun, J.; Zhao, Y.; Zhang, J. Research on Automatic Inspection System Based on Computer Artificial Intelligence RPA Technology. Int. J. Front. Eng. Technol. 2023, 5, 1108. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, T.; Wang, H. Predictive Maintenance of Industrial Equipment Based on Deep Learning Algorithms: A Comprehensive Survey. Procedia CIRP 2020, 93, 214–219. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, D.; Wang, H. Data-Driven Methods for Predictive Maintenance of Industrial Equipment: A Survey. IEEE Syst. J. 2019, 13, 2213–2227. [Google Scholar] [CrossRef]

- Vasiliadis, L.; Manitsaris, S.; Kapsalis, A. The Role of Robotic Process Automation in Business Process Optimization and Sustainability. Procedia Comput. Sci. 2021, 181, 1212–1219. [Google Scholar] [CrossRef]

- Lubis, L.; Sembiring, D. Driving Digital Transformation: Leveraging Robotic Process Automation (RPA) to Enhance Business Process Efficiency and Reducing Manual Errors. In Proceedings of the 2023 IEEE International Conference on Data and Software Engineering (ICoDSE), Toba, Indonesia, 7–8 September 2023; pp. 91–95. [Google Scholar] [CrossRef]

- Martínez-Gomez, J.; Martínez, P.; Ramos, F. Machine Learning for Predictive Maintenance: A Survey of Applications and Challenges. Eng. Appl. Artif. Intell. 2021, 99, 104165. [Google Scholar] [CrossRef]

- Singh, R.; Singh, A.; Pandey, P. A Review on Predictive Maintenance Strategies for Smart Manufacturing Systems. J. Manuf. Process. 2020, 56, 180–191. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory: Review. Sensors 2021, 21, 1470. [Google Scholar] [CrossRef]

- Santos, G.; Oliveira, J.; Silva, P. Robotic Process Automation: A New Frontier for Industry 4.0. Procedia CIRP 2021, 99, 365–370. [Google Scholar] [CrossRef]

- Chen, W.; Liu, Z.; Yang, F. Predictive Maintenance: A Survey on Machine Learning Approaches and Challenges. Mech. Syst. Signal Process. 2020, 137, 106554. [Google Scholar] [CrossRef]

- Anwar, A.; Mohd Ali, N.; Ali, I. Enhancing the Efficiency of Manufacturing Operations Through Predictive Maintenance and Machine Learning Algorithms. Sustain. Comput. Inform. Syst. 2020, 25, 100355. [Google Scholar] [CrossRef]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0—A Literature Review. Procedia Comput. Sci. 2020, 181, 51–58. [Google Scholar] [CrossRef]

- Kumar, P.; Khalid, S.; Kim, H.S. Prognostics and health management of rotating machinery of industrial robot with deep learning applications—A review. Mathematics 2023, 11, 3008. [Google Scholar] [CrossRef]

- Pisacane, O.; Potena, D.; Antomarioni, S.; Bevilacqua, M.; Ciarapica, F.; Diamantini, C. Data-Driven Predictive Maintenance Policy Based on Multi-Objective Optimization Approaches for the Component Repairing Problem. Eng. Optim. 2020, 53, 1752–1771. [Google Scholar] [CrossRef]

- Balaraman, K.; Palaniappan, S.; Zhuang, J. Sustainable Maintenance and Repair Technologies in the Industry 4.0 Era. J. Clean. Prod. 2021, 285, 124786. [Google Scholar] [CrossRef]

- Zonta, T.; Costa, C.; Righi, R.; Lima, M.; Da Trindade, E.; Li, G. Predictive Maintenance in the Industry 4.0: A Systematic Literature Review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Lee, J.; Davari, H.; Singh, J. Predictive Maintenance and Its Role in Sustainability: From Industrial Applications to Green Technologies. Sustainability 2021, 13, 6703. [Google Scholar] [CrossRef]

- Ribeiro, P.; Silva, F.; Rocha, A. Predictive Maintenance Using Artificial Intelligence and Internet of Things: An Industrial Sustainability Perspective. Sustainability 2021, 13, 5673. [Google Scholar] [CrossRef]

- Sharma, N.; Garg, H.; Arora, A. Machine Learning for Predictive Maintenance in Industrial Environments: A Case Study. Comput. Ind. Eng. 2021, 153, 107029. [Google Scholar] [CrossRef]

- Çınar, Z.; Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Abidi, M.; Mohammed, M.; Alkhalefah, H. Predictive Maintenance Planning for Industry 4.0 Using Machine Learning for Sustainable Manufacturing. Sustainability 2022, 14, 3387. [Google Scholar] [CrossRef]

- Sobczak, A.; Ziora, L. The Use of Robotic Process Automation (RPA) as an Element of Smart City Implementation: A Case Study of Electricity Billing Document Management at Bydgoszcz City Hall. Energies 2021, 14, 5191. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhou, J.; Zhao, Y. The Potential of Predictive Maintenance Using AI: An Industrial Perspective. J. Manuf. Sci. Eng. 2020, 142, 101206. [Google Scholar] [CrossRef]

- Alves, S.; Silva, J.; Lima, J. Robotic Process Automation for Sustainability in Supply Chains: A Case Study. Sustain. Prod. Consum. 2021, 26, 331–342. [Google Scholar] [CrossRef]

- Patil, A.; Nair, M.; Thomas, S. IoT and Machine Learning Integration for Predictive Maintenance in Manufacturing. J. Manuf. Process. 2021, 56, 150–165. [Google Scholar] [CrossRef]

- Teoh, Y.; Gill, S.; Parlikad, A. IoT and Fog-Computing-Based Predictive Maintenance Model for Effective Asset Management in Industry 4.0 Using Machine Learning. IEEE Internet Things J. 2021, 10, 2087–2094. [Google Scholar] [CrossRef]

- Meyer, D.; Redi, J.; Smith, T. The Role of Predictive Maintenance in Reducing Environmental Impact in Manufacturing. J. Clean. Prod. 2021, 287, 125500. [Google Scholar] [CrossRef]

- Kliestik, T.; Nica, E.; Durana, P.; Popescu, G. Artificial Intelligence-Based Predictive Maintenance, Time-Sensitive Networking, and Big Data-Driven Algorithmic Decision-Making in the Economics of Industrial Internet of Things. Oeconomia Copernic. 2023, 14, 33. [Google Scholar] [CrossRef]

- E-Fatima, K.; Khandan, R.; Hosseinian-Far, A.; Sarwar, D. The Adoption of Robotic Process Automation Considering Financial Aspects in Beef Supply Chains: An Approach towards Sustainability. Sustainability 2023, 15, 7236. [Google Scholar] [CrossRef]

- Ruiz-Sarmiento, J.; Monroy, J.; Moreno, F.; Galindo, C.; Bonelo, J.; Jiménez, J. A Predictive Model for the Maintenance of Industrial Machinery in the Context of Industry 4.0. Eng. Appl. Artif. Intell. 2020, 87, 103289. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Yang, D.; Xiang, Y. Deep-Learning-Enabled Predictive Maintenance in Industrial Internet of Things: Methods, Applications, and Challenges. IEEE Syst. J. 2023, 17, 2602–2615. [Google Scholar] [CrossRef]

- Patrício, L.; Varela, L.; Silveira, Z. Integration of Artificial Intelligence and Robotic Process Automation: Literature Review and Proposal for a Sustainable Model. Appl. Sci. 2024, 14, 9648. [Google Scholar] [CrossRef]

- Costa, C.R.S.; Patrício, L.; Ferreira, P.; Varela, L.R. The Contribution of Robotic Process Automation (RPA) in Improving Energy Efficiency: Case Study. In Proceedings of the Eighth International Congress on Information and Communication Technology, London, UK, 20–23 February 2023; Volume 3. [Google Scholar] [CrossRef]

- Patrício, L.; Costa, C.R.S.; Fernandes, L.P.; Varela, M.L.R. Structure for the Implementation and Control of Robotic Process Automation Projects. In Proceedings of the Advanced Network Technologies and Intelligent Computing (ANTIC 2022), Varanasi, India, 22–24 December 2022; pp. 261–274. [Google Scholar] [CrossRef]

- Patrício, L.; Avila, P.; Varela, L.; Cruz-Cunha, M.M.; Ferreira, L.P.; Bastos, J.; Castro, H.; Silva, J. Literature Review of Decision Models for the Sustainable Implementation of Robotic Process Automation. Procedia Comput. Sci. 2023, 219, 870–878. [Google Scholar] [CrossRef]

- Patrício, L.; Costa, C.R.S.; Varela, L.; Cruz-Cunha, M.M. Literature Review on the Sustainable Implementation of Robotic Process Automation (RPA) in Medical and Healthcare Administrative Services. Procedia Comput. Sci. 2024, 239, 166–176. [Google Scholar] [CrossRef]

- Daase, C.; Pandey, A.; Staegemann, D.; Turowski, K. Sustainability in Robotic Process Automation: Proposing a Universal Implementation Model. In Proceedings of the 20th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2023), Rome, Italy, 13–15 November 2023; pp. 770–779. [Google Scholar] [CrossRef]

- Patrício, L.; Costa, L.; Varela, L.; Ávila, P. Sustainable Implementation of Robotic Process Automation Based on a Multi-Objective Mathematical Model. Sustainability 2023, 15, 15045. [Google Scholar] [CrossRef]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. arXiv 2012, arXiv:1207.0203. [Google Scholar] [CrossRef]

- Cavalcante, E.; Pereira, J.; Alves, M.; Maia, P.; Moura, R.; Batista, T.; Delicato, F.; Pires, P. On the Interplay of Internet of Things and Cloud Computing: A Systematic Mapping Study. Comput. Commun. 2016, 89–90, 17–33. [Google Scholar] [CrossRef]

- Al-Fuqaha, A.; Guizani, M.; Mohammadi, M.; Aledhari, M.; Ayyash, M. Internet of Things: A Survey on Enabling Technologies, Protocols, and Applications. IEEE Commun. Surv. Tutor. 2015, 17, 2347–2376. [Google Scholar] [CrossRef]

- Xia, X.; Yu, J.; Cao, B. SCP-Trust Reasoning Strategy Based on Preference and Its Service Composition Process of Context-Aware Process. J. Comput. Chem. 2014, 2, 38–45. [Google Scholar] [CrossRef][Green Version]

- Marimon, F.; Casadesús, M. Reasons to Adopt ISO 50001 Energy Management System. Sustainability 2017, 9, 1740. [Google Scholar] [CrossRef]

- Mckane, A.; Therkelsen, P.; Scodel, A.; Rao, P.; Aghajanzadeh, A.; Hirzel, S.; Zhang, R.; Prem, R.; Fossà, A.; Lazarevska, A.; et al. Predicting the quantifiable impacts of ISO 50001 on climate change mitigation. Energy Policy 2017, 107, 278–288. [Google Scholar] [CrossRef]

| Group 1 | Group 2 | Group 3 | Group 4 |

|---|---|---|---|

| “RPA” OR “Robotic Process Automation” OR “Intelligent Process Automation” OR “Digital Process Automation” OR “Business Workflow Automation” | “Machine Learning” OR “ML Algorithms” OR “Supervised Learning” OR “Unsupervised Learning” OR “Reinforcement Learning” OR “Deep Learning” | “Predictive Maintenance” OR “Condition-Based Maintenance” OR “Maintenance Optimization” | “Sustainability” OR “Sustainable” OR “Social Sustainability” OR “Environment” OR “Environmental Sustainability” OR “Economic Sustainability” Or “Sustainable Development” |

| Set 1 | Set 2 | Set 3 | |

|---|---|---|---|

| Initial Result: | 436 | 825 | 2970 |

| 1—Restrict to Peer-Reviewed | 352 | 792 | 2318 |

| 2—From 2010 to 2024 | 351 | 780 | 2300 |

| 3—Language: English | 238 | 200 | 1667 |

| 4—Restrict to Full Text | 227 | 200 | 1530 |

| Themes of the Articles Articles (Author/Year/Ref.) | Predictive Maintenance | Robotic Process Automation | Machine Learning | Type of Contribution | Pillars of Sustainability Identified in the Articles |

|---|---|---|---|---|---|

| [26] Zhang, X.; Liu, T.; Wang, H. (2020) | x | x | Review | Environmental | |

| [27] Bai, X.; Li, J.; Zhang, Y. (2020) | x | x | Model | Environmental | |

| [28] Vasiliadis, L.; Manitsaris, S.; Kapsalis, A. (2021) | x | Case Study | Economic, Social | ||

| [29] Lubis, L.; Sembiring, D. (2023) | x | Case Study | Economic | ||

| [30] Martínez-Gomez, J.; Martínez, P.; Ramos, F. (2021) | x | x | Review | Environmental | |

| [31] Singh, R.; Singh, A.; Pandey, P. (2020) | x | Review | Environmental | ||

| [32] Xu, B.; Yu, D.; Hu, X. (2021) | x | Review | Environmental | ||

| [33] Santos, G.; Oliveira, J.; Silva, P. (2021) | x | Case Study | Economic | ||

| [34] Chen, W.; Liu, Z.; Yang, F. (2020) | x | x | Review | Environmental | |

| [35] Anwar, A.; Mohd Ali, N.; Ali, I. (2020) | x | x | Case Study | Environmental | |

| [36] Chen, J.; Zhang, H.; Ma, Q. (2020) | x | Case Study | Social, Economic | ||

| [37] Li, Y.; Ma, Y.; Liu, L. (2021) | x | x | Review | Environmental | |

| [38] Pisacane, O.; Potena, D.; Antomarioni, S.; Bevilacqua, M.; Ciarapica, F.; Diamantini, C. (2020) | x | Case Study | Environmental | ||

| [39] Balaraman, K.; Palaniappan, S.; Zhuang, J. (2021) | x | Review | Environmental | ||

| [40] García, F.; López, J.; Díaz, R. (2021) | x | Review | Environmental | ||

| [41] Lee, J.; Davari, H.; Singh, J. (2021) | x | Case Study | Environmental | ||

| [42] Ribeiro, P.; Silva, F.; Rocha, A. (2021) | x | Case Study | Environmental | ||

| [43] Sharma, N.; Garg, H.; Arora, A. (2021) | x | Case Study | Environmental | ||

| [44] Li, X.; Zuo, H.; Wang, J. (2020) | x | Review | Environmental | ||

| [45] Basu, R.; Kumbhar, D.; Acharya, R. (2021) | x | Review | Environmental | ||

| [46] Koumpis, M.; Jantunen, E.; Hildreth, P. (2021) | x | Case Study | Economic | ||

| [47] Cheng, Y.; Zhou, J.; Zhao, Y. (2020) | x | Case Study | Environmental | ||

| [48] Alves, S.; Silva, J.; Lima, J. (2021) | x | Case Study | Economic, Social | ||

| [49] Patil, A.; Nair, M.; Thomas, S. (2021) | x | x | Case Study | Environmental | |

| [50] Zhang, M.; Wang, Y.; Zhou, F. (2021) | x | x | Case Study | Environmental | |

| [51] Meyer, D.; Redi, J.; Smith, T. (2021) | x | Case Study | Environmental | ||

| [52] Wang, H.; Shi, X.; Xie, L. (2021) | x | Review | Environmental | ||

| [53] Jafari, M.; Rezaei, M.; Darvishi, M. (2020) | x | Review | Economic | ||

| [54] Pratap, P.; Soni, A.; Kumar, M. (2020) | x | x | Review | Environmental | |

| [55] Wang, H., Zhang, W., Yang, D.; Xiang, Y. (2023). | x | x | Review | Environmental | |

| [56] Patrício, L.; Varela, L.; Silveira, Z. (2024) | x | Model | Social, Environmental | ||

| [57] Costa, C.R.S.; Patrício, L.; Ferreira, P.; Varela, L.R. (2023) | x | Case Study | Environmental | ||

| [58] Patrício, L.; Costa, C.R.S.; Fernandes, L.P.; Varela, M.L.R. (2023) | x | Model | Economic | ||

| [59] Patrício, L.; Avila, P.; Varela, L.; Cruz-Cunha, M.M.; Ferreira, L.P.; Bastos, J.; Castro, H.; Silva, J. (2023) | x | Review | Economic, Social, Environmental | ||

| [60] Patrício, L.; Costa, C.R.S.; Varela, L.; Cruz-Cunha, M.M. (2024) | x | Review | Economic, Social, Environmental | ||

| [61] Daase, C., Pandey, A., Staegemann, D.; Turowski, K. (2023) | x | Model | Economic, Social, Environmental | ||

| [62] Patrício, L.; Costa, L.; Varela, L.; Ávila, P. (2023) | x | Model | Economic, Social, Environmental | ||

| % Themes p/articles | 59% | 27% | 30% |

| Phase 1: Infrastructure Assessment | |

|---|---|

| Assessment Criteria | Description |

|

|

|

|

| Phase 2: Automation of Data Collection and Processing | |

|---|---|

| Assessment Criteria | Description |

|

|

|

|

|

|

| Phase 3: Application of Machine Learning | |

|---|---|

| Assessment Criteria | Description |

|

|

|

|

|

|

| Phase 4: Integration of Results with RPA | |

|---|---|

| Assessment Criteria | Description |

|

|

|

|

|

|

| Phase 5: Action and Feedback | |

|---|---|

| Assessment Criteria | Description |

|

|

|

|

|

|

|

|

| Phase 6: Continuous Learning and Sustainability | |

|---|---|

| Assessment Criteria | Description |

|

|

|

|

|

|

| Model (SIRPM) Characteristics | |

|---|---|

| Characteristics | Description |

|

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

|

| Model (SIRPM) Benefits | |

|---|---|

| Benefits | Description |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

| Technology Integration (RPA, Machine Learning, IoT) | Method/ Algorithm | Intelligent Automation | Continuous Learning | Flexibility and Scalability | Real-Time Monitoring | Energy Efficiency and Sustainability | |

|---|---|---|---|---|---|---|---|

| [26] Zhang, X.; Liu, T.; Wang, H. (2020) | Deep Learning | Artificial Neural Networks (ANNs) | Moderate | ||||

| [27] Zhang, W.; Yang, D.; Wang, H. (2019) | Deep Learning | Artificial Neural Networks (ANNs) | Moderate | ||||

| [28] Vasiliadis, L.; Manitsaris, S.;Kapsalis, A. (2021) | RPA | Rule-Based Automation, UI Automation | x | High | |||

| [29] Lubis, L.; Sembiring, D. (2023) | RPA | Rule-Based Automation, UI Automation | x | High | |||

| [30] Martínez-Gomez, J.; Martínez, P.; Ramos, F. (2021) | Machine Learning | Random Forest, Decision Trees, SVM | x | Moderate | |||

| [31] Singh, R.; Singh, A.; Pandey, P. (2020) | Machine Learning | Random Forest, Decision Trees, SVM | x | Moderate | |||

| [32] Pech, M.; Vrchota, J.; Bednář, J. (2021) | Machine Learning, IoT | Random Forest, KNN, SVM | x | Moderate | Limited | ||

| [33] Santos, G.; Oliveira, J.; Silva, P. (2021) | RPA | Rule-Based Automation, UI Automation | High | ||||

| [34] Chen, W.; Liu, Z.; Yang, F. (2020) | Machine Learning | Random Forest, Decision Trees | x | Moderate | |||

| [35] Anwar, A.; Mohd Ali, N.; Ali, I. (2020) | Machine Learning | Random Forest, Decision Trees | x | Moderate | |||

| [36] Ribeiro, J., Lima, R., Eckhardt, T., & Paiva, S. (2020) | RPA, AI | Rule-Based Automation | x | x | Moderate | x | Moderate |

| [37] Kumar, P., Khalid, S., & Kim, H. (2023) | Machine Learning | ANN | x | Moderate | Moderate | ||

| [38] Kumar, R.; Nair, R. (2021) | Machine Learning | Random Forest, Decision Trees, SVM | x | Moderate | Limited | ||

| [39] Balaraman, K.; Palaniappan, S.; Zhuang, J. (2021) | Machine Learning | Random Forest, Decision Trees | Moderate | ||||

| [40] Zonta, T.; Costa, C.; Righi, R.; Lima, M.; Da Trindade, E.; Li, G. (2020) | AI, IoT | Genetic Algorithms | x | Moderate | x | ||

| [41] Lee, J.; Davari, H.; Singh, J. (2021) | AI | Reinforcement Learning Algorithms, Search Algorithms | x | High | x | x | |

| [42] Ribeiro, P.; Silva, F.; Rocha, A. (2021) | AI, IoT | Genetic Algorithms | x | Moderate | x | Moderate | |

| [43] Sharma, N.; Garg, H.; Arora, A. (2021) | Machine Learning | Random Forest, SVM | x | Moderate | |||

| [44] Çınar, Z.; Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. (2020) | AI | Bayesian Networks | x | Moderate | x | ||

| [45] Abidi, M.; Mohammed, M.; Alkhalefah, H. (2022) | Machine Learning | Random Forest, Decision Trees | x | Moderate | Limited | ||

| [46] Sobczak, A.; Ziora, L. (2021) | RPA | Rule-Based Automation | x | High | Moderate | ||

| [47] Cheng, Y.; Zhou, J.; Zhao, Y. (2020) | AI | Search Algorithms, Dynamic Programming | Moderate | x | |||

| [48] Alves, S.; Silva, J.; Lima, J. (2021) | RPA | Rule-Based Automation | High | ||||

| [49] Patil, A.; Nair, M.; Thomas, S. (2021) | IoT, Machine Learning | Random Forest, Decision Trees, KNN | x | Moderate | Moderate | ||

| [50] Teoh, Y.; Gill, S.; Parlikad, A. (2021) | Machine Learning | Random Forest, Decision Trees | x | Moderate | |||

| [51] Meyer, D.; Redi, J.; Smith, T. (2021) | AI | Reinforcement Learning Algorithms | Moderate | ||||

| [52] Kliestik, T.; Nica, E.; Durana, P.; Popescu, G. (2023) | AI, IoT | Reinforcement Learning Algorithms | x | Moderate | x | Moderate | |

| [53] E-Fatima, K.; Khandan, R.; Hosseinian-Far, A.; Sarwar, D. (2023) | RPA | Rule-Based Automation, UI Automation | High | ||||

| [54] Ruiz-Sarmiento, J.; Monroy, J.; Moreno, F.; Galindo, C.; Bonelo, J.; Jiménez, J. (2020) | Machine Learning | Random Forest, Decision Trees | x | Moderate | |||

| [55] Wang, H., Zhang, W., Yang, D.; Xiang, Y. (2023). | Deep Learning, IoT | Deep Neural Networks (DNNs) | x | x | High | x | x |

| [56] Patrício, L.; Varela, L.; Silveira, Z. (2024) | RPA, AI | Rule-Based Automation, UI Automation | x | High | x | Moderate | |

| [57] Costa, C.R.S.; Patrício, L.; Ferreira, P.; Varela, L.R. (2023) | RPA | Rule-Based Automation | x | High | x | Moderate | |

| [58] Patrício, L.; Costa, C.R.S.;Fernandes, L.P.; Varela, M.L.R. (2023) | RPA | Rule-Based Automation | x | High | x | Moderate | |

| [59] Patrício, L.; Avila, P.; Varela, L.; Cruz-Cunha, M.M.; Ferreira, L.P.;Bastos, J.; Castro, H.; Silva, J. (2023) | RPA | Rule-Based Automation | x | High | x | Moderate | |

| [60] Patrício, L.; Costa, C.R.S.; Varela, L.; Cruz-Cunha, M.M. (2024) | RPA | Rule-Based Automation | x | High | x | Moderate | |

| [61] Daase, C., Pandey, A., Staegemann, D.; Turowski, K. (2023) | RPA | Rule-Based Automation | x | High | x | Moderate | |

| [62] Patrício, L.; Costa, L.; Varela, L.; Ávila, P. (2023) | RPA | Rule-Based Automation | x | High | x | Moderate | |

| [This work] | RPA, Machine Learning | Rule-Based Automation, Decision Trees | x | x | High | x | High |

| Month | Average Vibration (Cutter) (mm/s) | Average Pressure (Press) (bar) | Average Temperature (Printer) (°C) |

|---|---|---|---|

| 1 | 1.2 | 150 | 75 |

| 2 | 1.3 | 145 | 78 |

| 3 | 1.4 | 140 | 80 |

| 4 | 1.5 | 138 | 82 |

| 5 | 1.3 | 142 | 77 |

| Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Mean Time Between Failures (MTBF) | 23.47 h/events | 70.4 h/events | +100% |

| Mean Time to Repair (MTTR) | 12 h | 4 h | −67% |

| Unplanned Downtime Events | 15 events/month | 5 events/month | −66.67% |

| Failure Prediction Accuracy | +60% | +90% | +50% |

| Cost Category | Before Implementation | After Implementation | Reduction |

|---|---|---|---|

| Average Repair Costs | EUR 2500 per incident | EUR 1200 per incident | −52% |

| Total Maintenance Costs | EUR 4000/month | EUR 2500/month | −37.5% |

| Unplanned Downtime Costs | EUR 3500/month | EUR 1000/month | −71.4% |

| Total Operational Costs | EUR 30,000/month | EUR 25,000/month | −16.67% |

| Environmental Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Energy Consumption | 10,000 kWh/month | 7500 kWh/month | −25% |

| CO2 Emissions | 5000 kg/month | 3000 kg/month | −40% |

| Waste Produced | 500 kg/month | 350 kg/month | −30% |

| Material Usage | 8000 kg/month | 6500 kg/month | −18.75% |

| Recycling Rate | 70% | 85% | +21.43% |

| Financial Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Profit Margin | 5% | 12% | +7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patrício, L.; Varela, L.; Silveira, Z. Proposal for a Sustainable Model for Integrating Robotic Process Automation and Machine Learning in Failure Prediction and Operational Efficiency in Predictive Maintenance. Appl. Sci. 2025, 15, 854. https://doi.org/10.3390/app15020854

Patrício L, Varela L, Silveira Z. Proposal for a Sustainable Model for Integrating Robotic Process Automation and Machine Learning in Failure Prediction and Operational Efficiency in Predictive Maintenance. Applied Sciences. 2025; 15(2):854. https://doi.org/10.3390/app15020854

Chicago/Turabian StylePatrício, Leonel, Leonilde Varela, and Zilda Silveira. 2025. "Proposal for a Sustainable Model for Integrating Robotic Process Automation and Machine Learning in Failure Prediction and Operational Efficiency in Predictive Maintenance" Applied Sciences 15, no. 2: 854. https://doi.org/10.3390/app15020854

APA StylePatrício, L., Varela, L., & Silveira, Z. (2025). Proposal for a Sustainable Model for Integrating Robotic Process Automation and Machine Learning in Failure Prediction and Operational Efficiency in Predictive Maintenance. Applied Sciences, 15(2), 854. https://doi.org/10.3390/app15020854